Analysis of Storage Effects in the Recirculation Zone Based on the Junction Angle of Channel Confluence

Abstract

:1. Introduction

2. Methods and Background

2.1. Flow and Mixing Characteristics at a Confluence

2.1.1. Separation and Recirculation Zone Downstream of a Confluence

2.1.2. Transverse Mixing at a Confluence

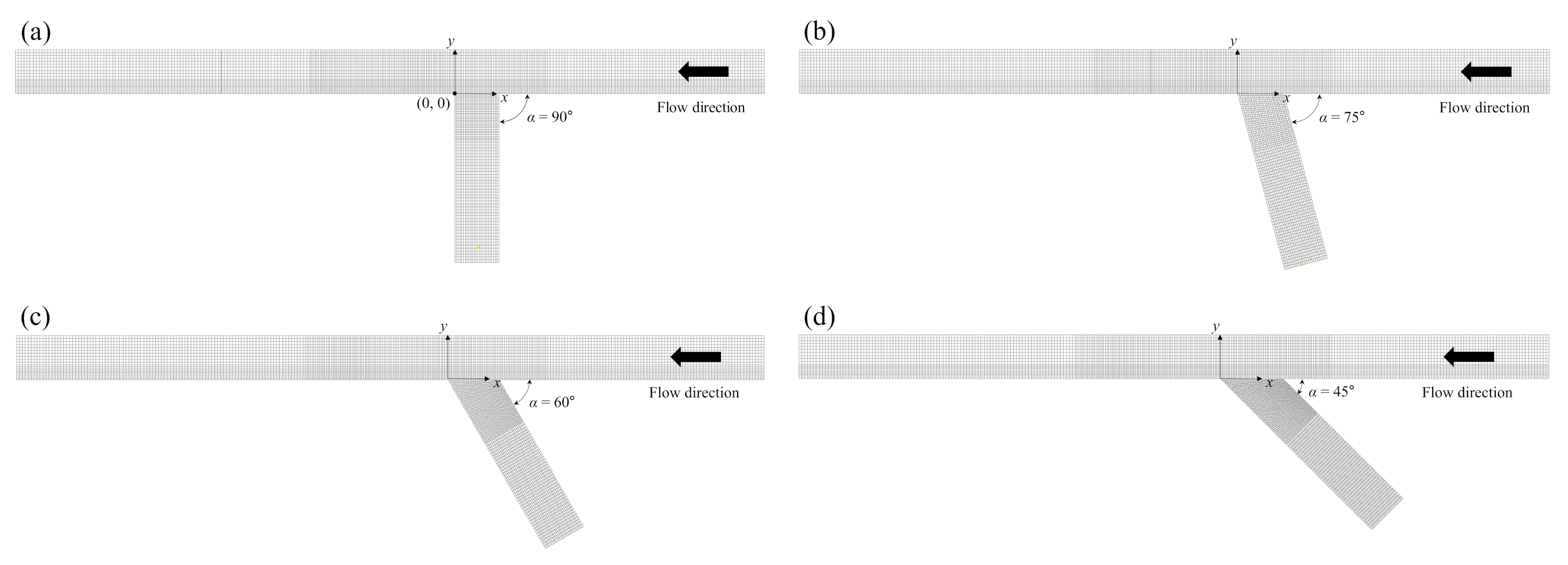

2.2. Model Descriptions and Grid Sensitivity Analysis

2.2.1. Descriptions of EFDC

2.2.2. Grid Sensitivity Analysis Results

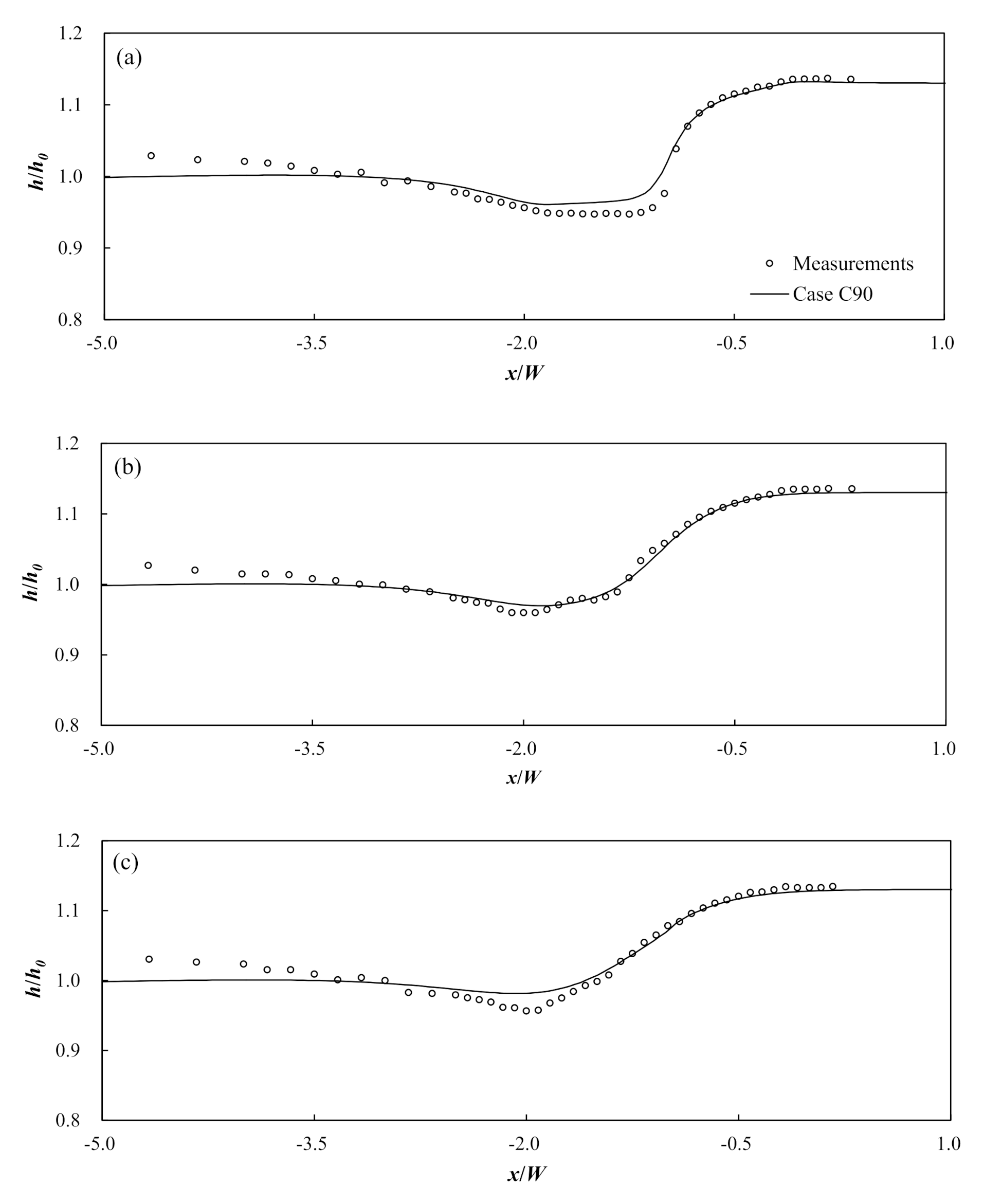

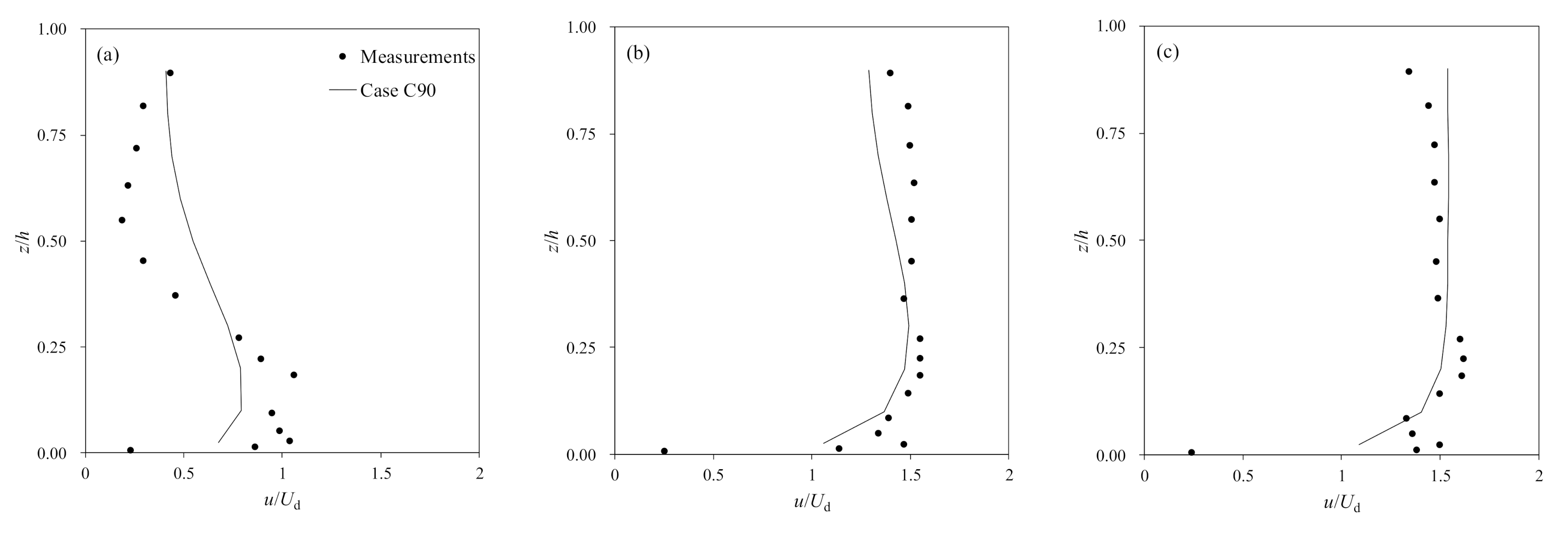

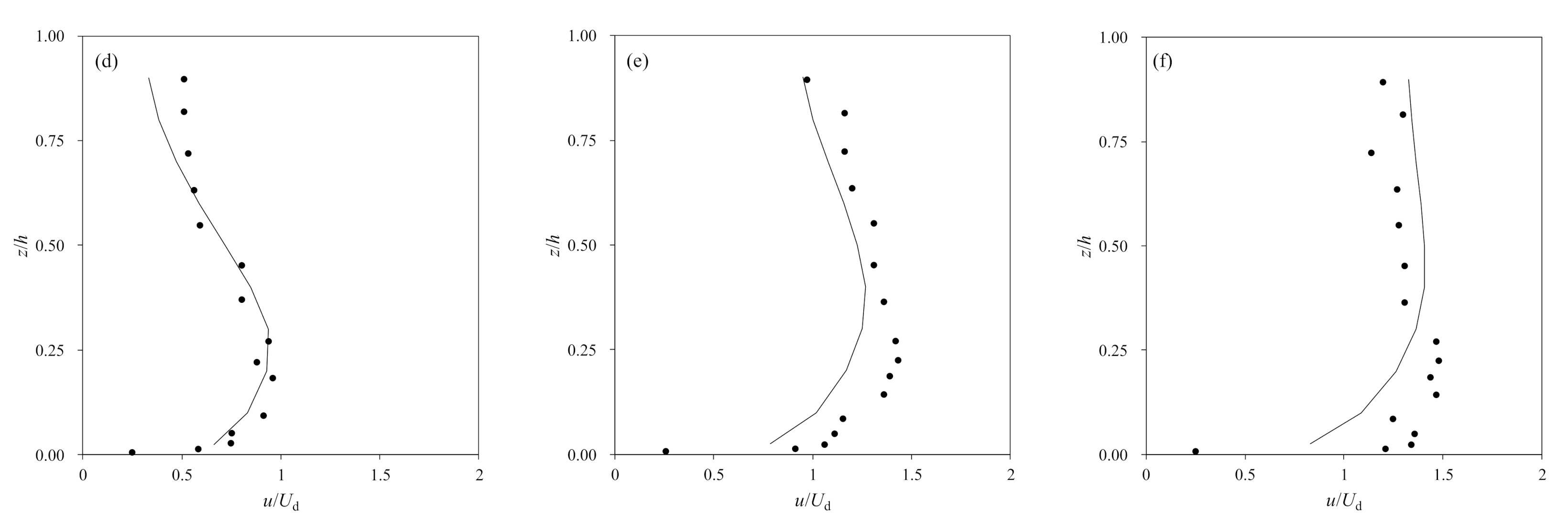

2.3. Model Settings and Validations

3. Results

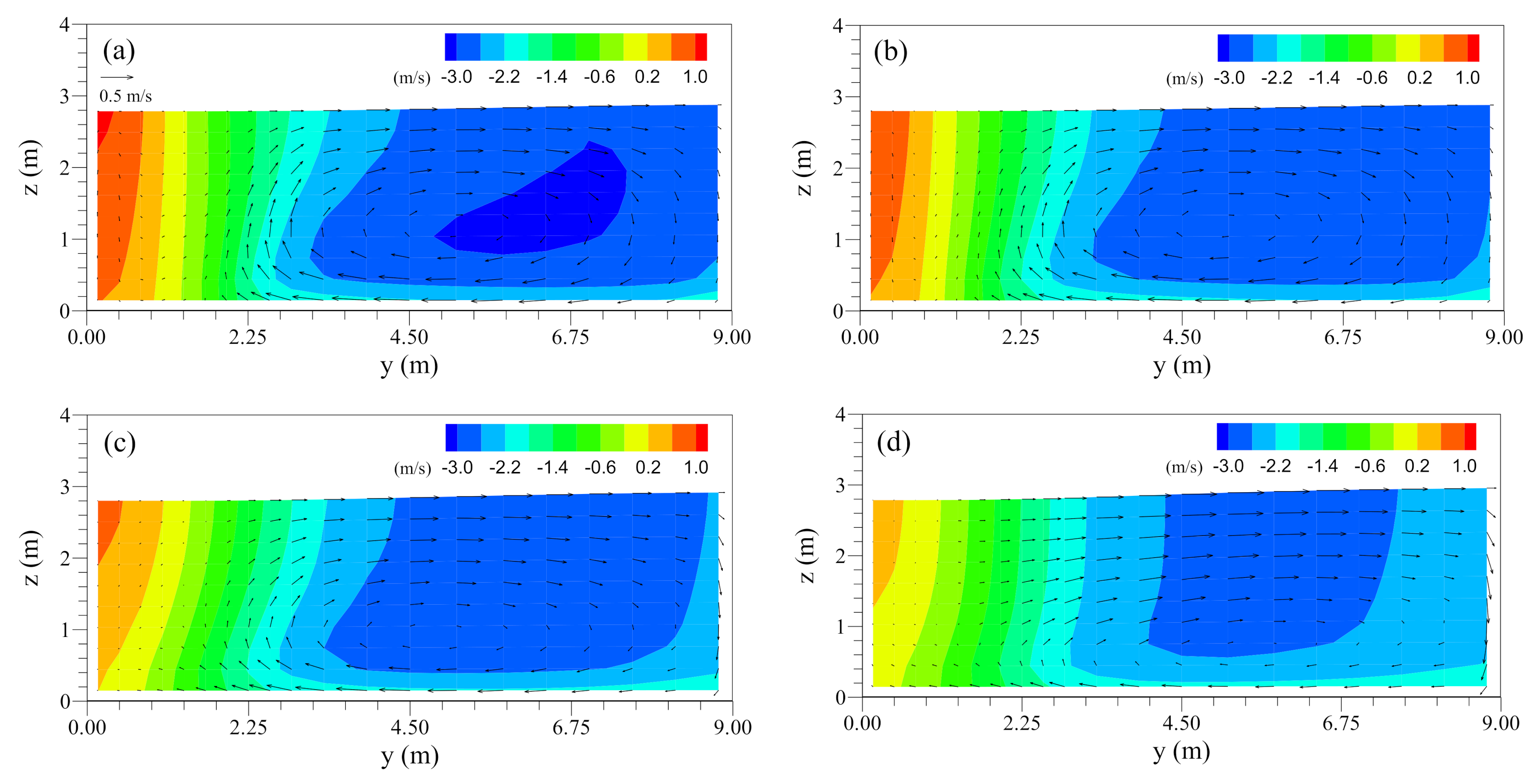

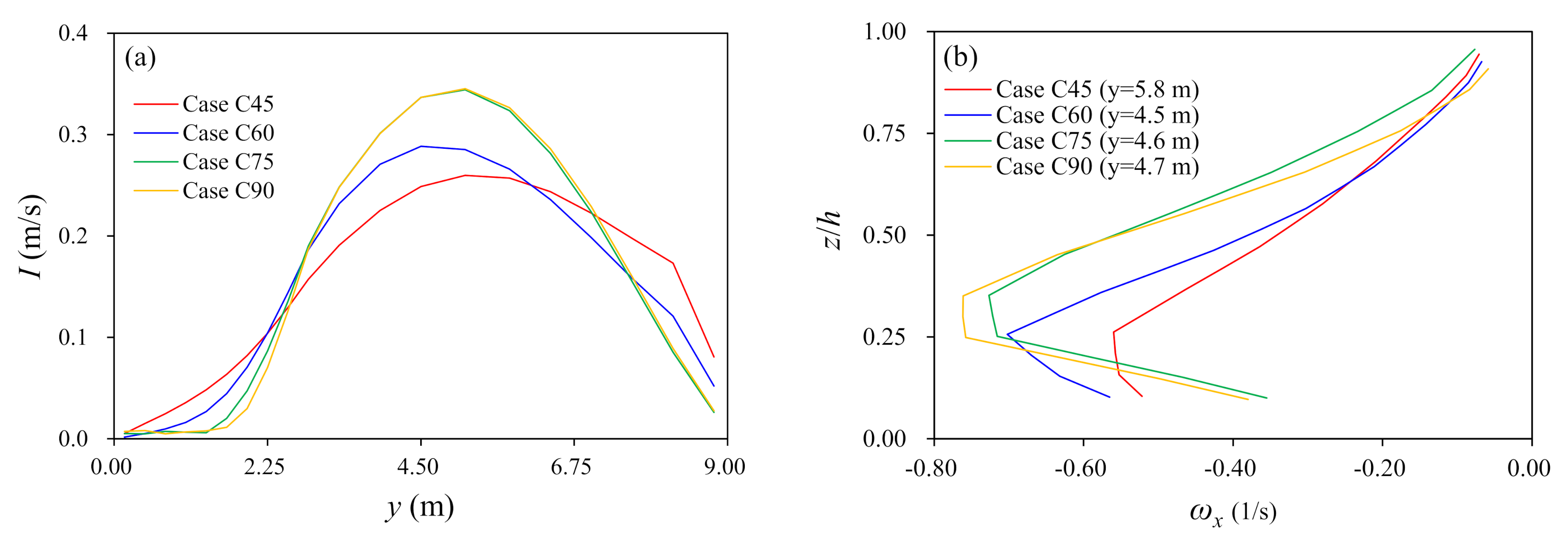

3.1. Effects of Junction Angle on Flow Characteristics

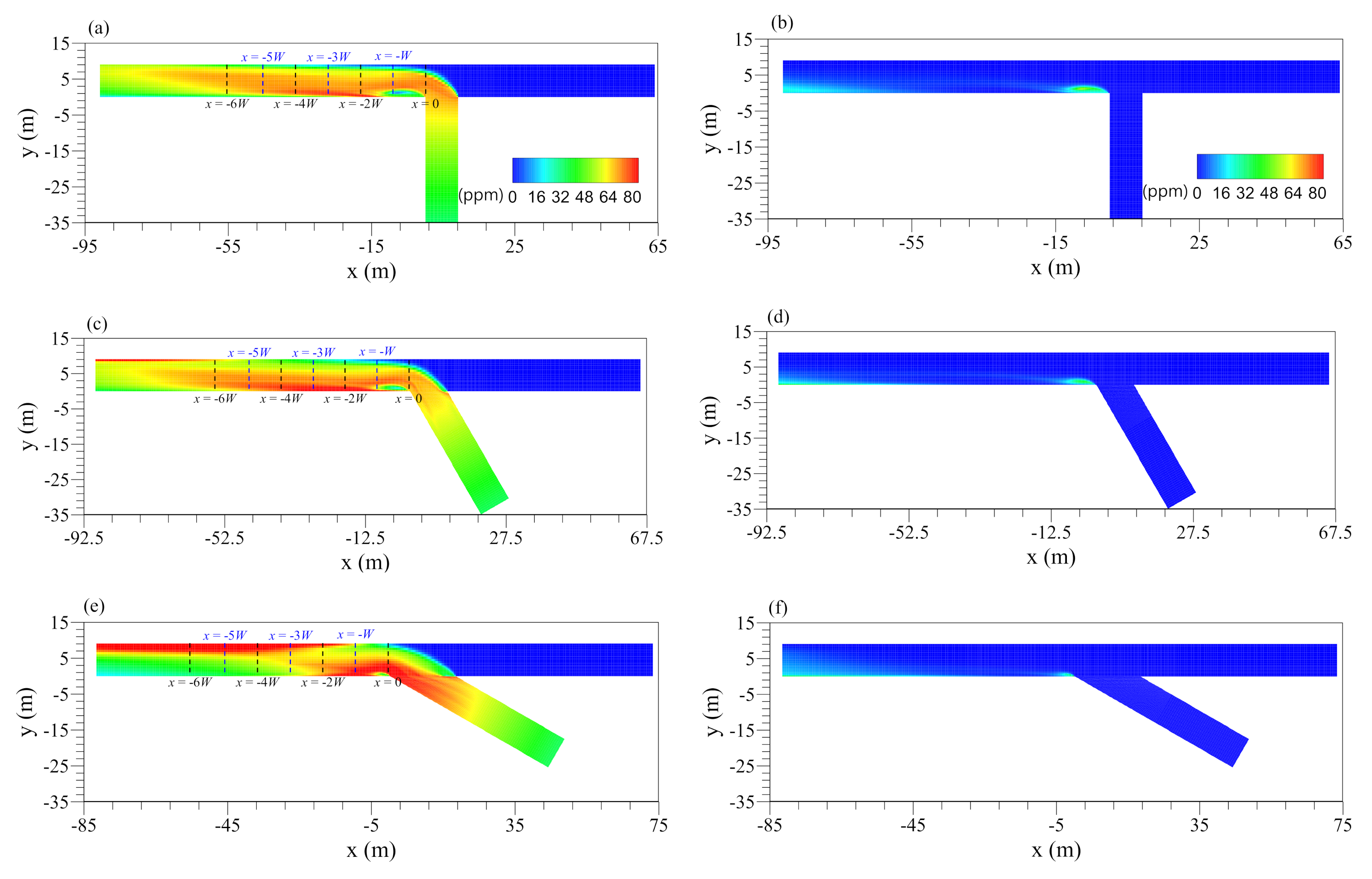

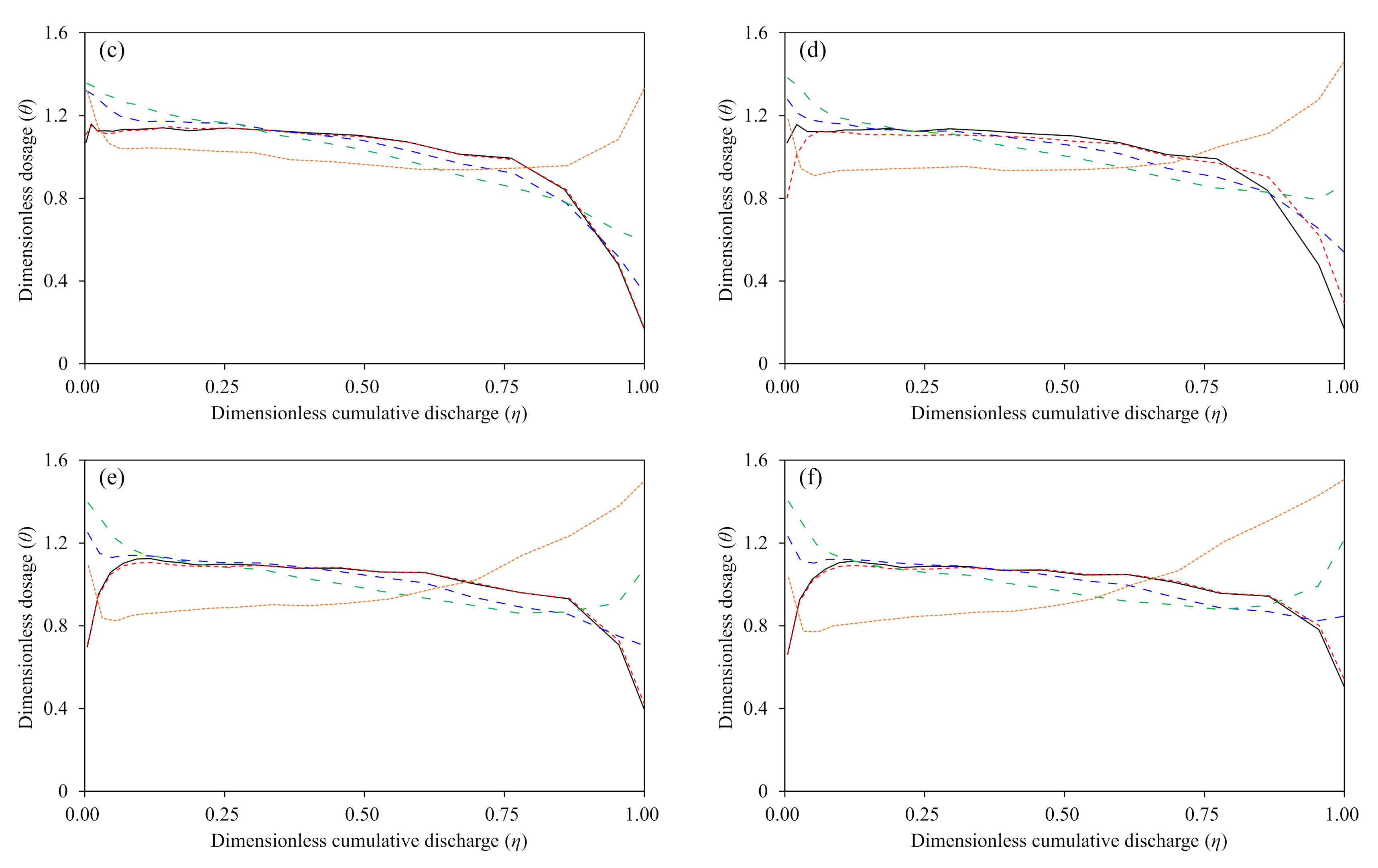

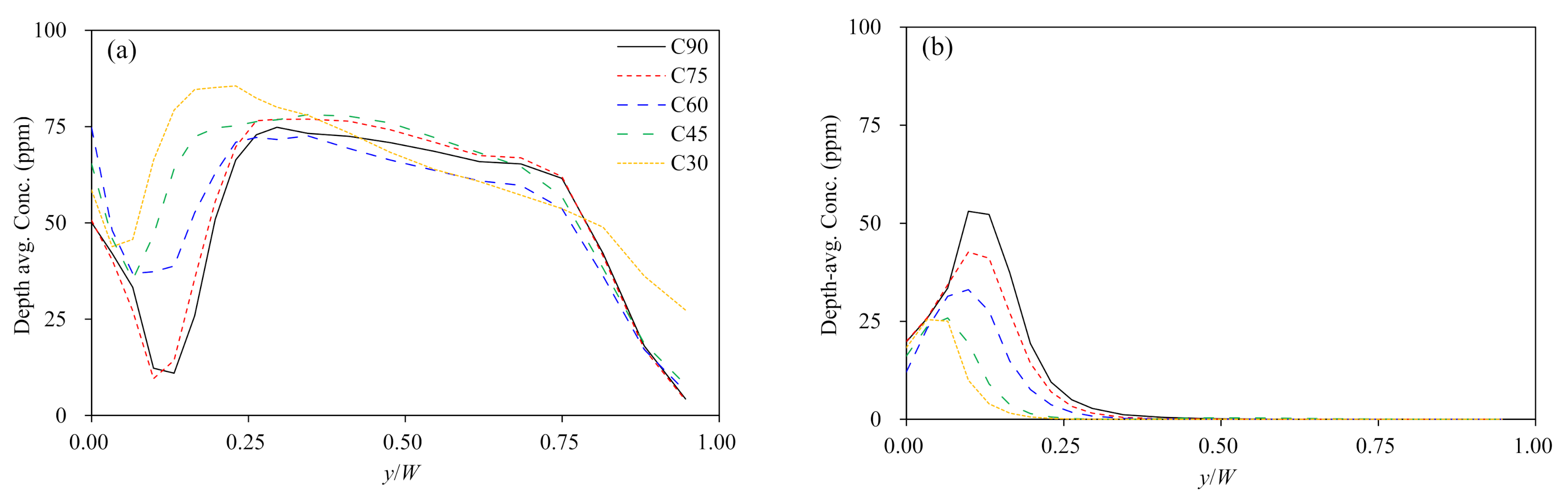

3.2. Solute Transport Results

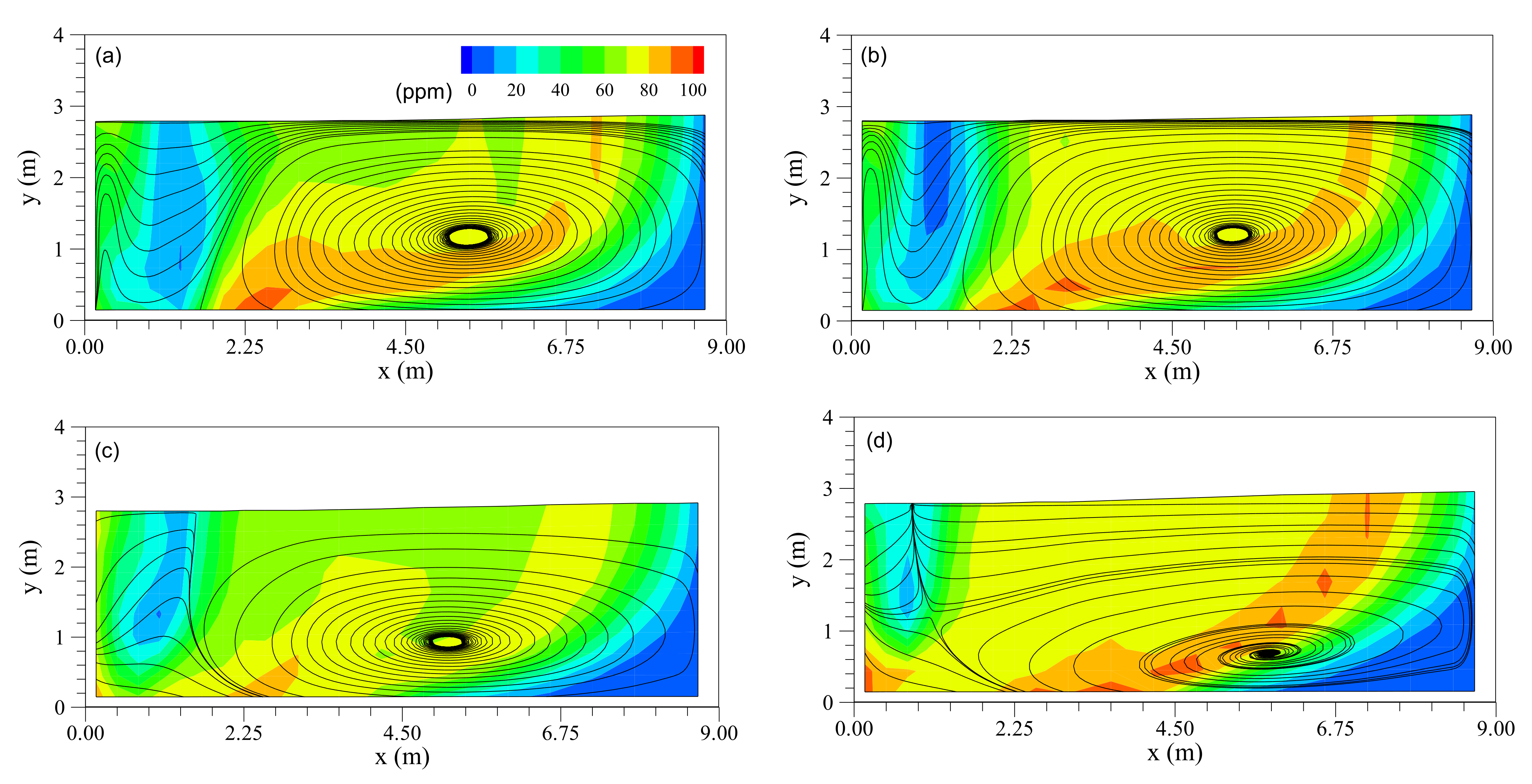

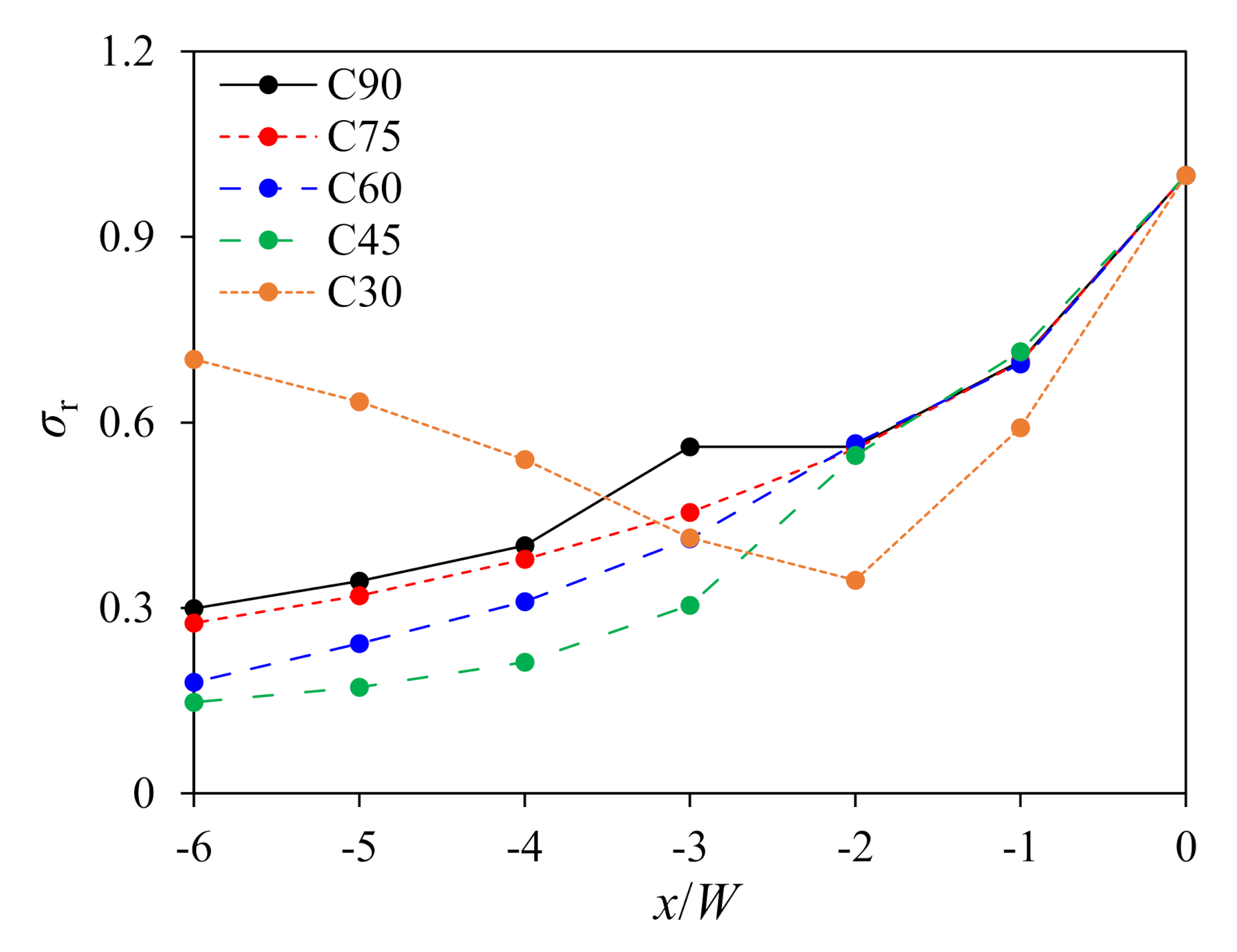

3.3. Storage Effects in the Recirculation Zone

4. Discussion

4.1. Solute Mixing Downstream of Junction

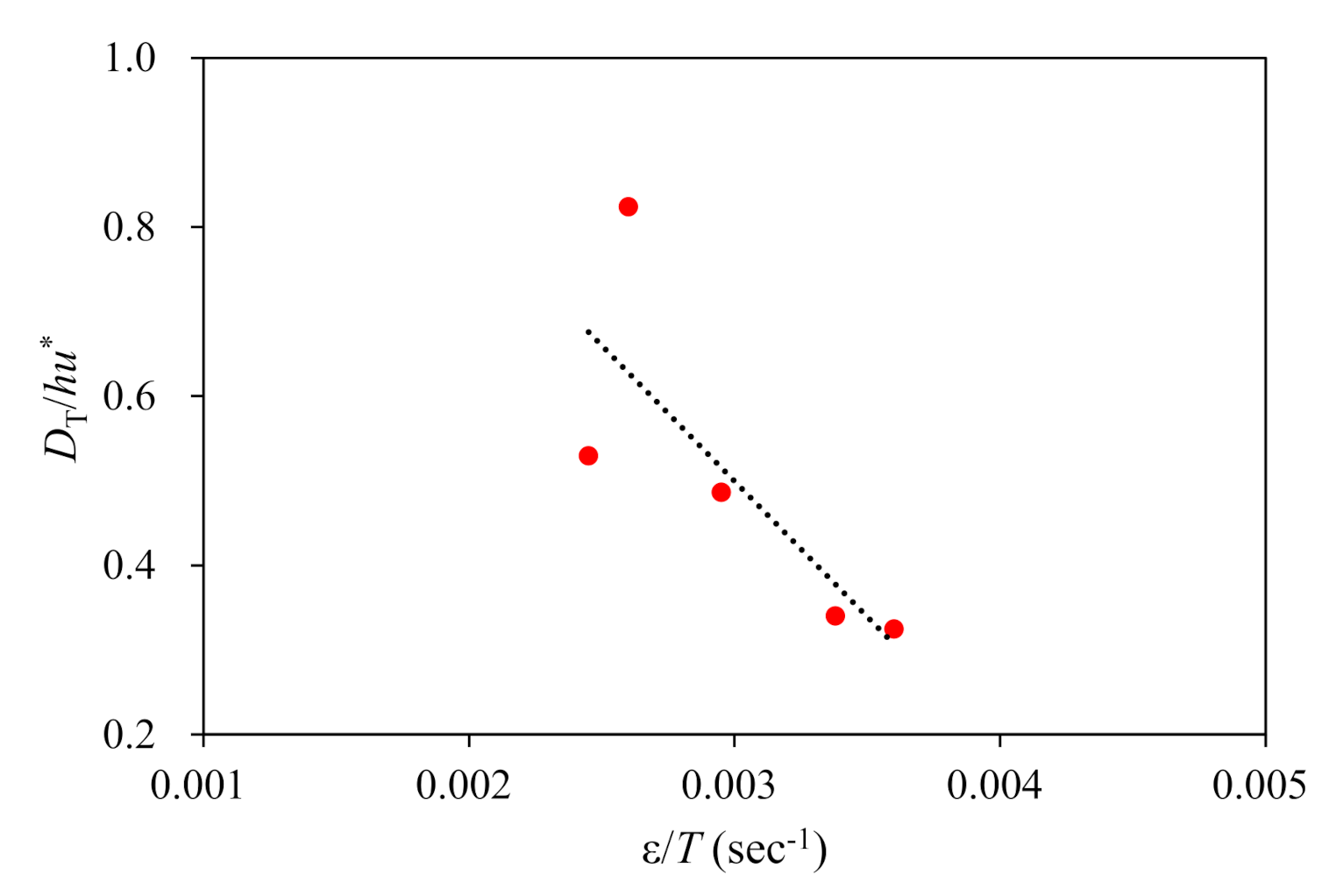

4.2. Storage Zone Effects on Transverse Mixing

5. Conclusions

- As the junction angle increases, the strength of helical motion and vorticity magnitude increase, leading to an increase in the vertical gradient of the mixing layer and mixing metric of the dosage curves.

- The recirculation zone creates a boundary layer that interrupts the inflow of solute and simultaneously accumulates solute. These storage effects of the recirculation zone generate long-tailed concentration curves, where the skewness significantly increases at junction angles of 30° to 60°.

- The interaction between the helical motion and recirculation zone affects transverse mixing, where the transverse dispersion coefficient exhibits a positive correlation with the helical motion intensity and negative correlation with the recirculation zone size.

- The transverse dispersion coefficient has an inverse relationship with the mass exchange rate of the storage zone. Based on these results, it can be inferred that transverse dispersion is replaced by mixing due to strongly developed storage zones.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taylor, G.I. The dispersion of matter in turbulent flow through a pipe. Proc. R. Soc. Lond. Math. Phys. Eng. Sci. 1954, 223, 446–468. [Google Scholar]

- Rana, S.M.M.; Scott, D.T.; Hester, E.T. Effects of in-stream structures and channel flow rate variation on transient storage. J. Hydrol. 2017, 548, 157–169. [Google Scholar] [CrossRef] [Green Version]

- Jackson, T.R.; Haggerty, R.; Apte, S.V. A fluid-mechanics based classification scheme for surface transient storage in riverine environments: Quantitatively separating surface from hyporheic transient storage. Hydrol. Earth Syst. Sci. 2013, 17, 2747–2779. [Google Scholar] [CrossRef] [Green Version]

- Bencala, K.E.; Walters, R.A. Simulation of solute transport in a mountain pool-and riffle stream: A transient storage model. Water Resour. Res. 1983, 19, 718–724. [Google Scholar] [CrossRef]

- Runkel, R.L. One-Dimensional Transport with Inflow and Storage (OTIS): A Solute Transport Model for Streams and Rivers; US Department of the Interior, US Geological Survey: Washington, DC, USA, 1998; Volume 98.

- Seo, I.W.; Cheong, T.S. Moment-Based calculation of parameters for the storage zone model for river dispersion. J. Hydraul. Eng. 2001, 127, 453–465. [Google Scholar] [CrossRef]

- Kelleher, C.; Wagener, T.; McGlynn, B.; Ward, A.S.; Gooseff, M.N.; Payn, R.A. Identifiability of transient storage model parameters along a mountain stream. Water Resour. Res. 2013, 49, 5290–5306. [Google Scholar] [CrossRef]

- Rodrigues, P.P.G.W.; Gonzalez, Y.M.; de Sousa, E.P.; Neto, F.D.M. Evaluation of dispersion parameters for River Sao Pedro, Brazil, by the simulated annealing method. Inverse Probl. Sci. Eng. 2013, 21, 34–51. [Google Scholar] [CrossRef]

- Femeena, P.V.; Chaubey, I.; Aubeneau, A.; McMillan, S.; Wagner, P.D.; Fohrer, N. Simple regression models can act as calibration-substitute to approximate transient storage parameters in streams. Adv. Water Resour. 2019, 123, 201–209. [Google Scholar] [CrossRef]

- Noh, H.; Kwon, S.; Seo, I.W.; Baek, D.; Jung, S.H. Multi-gene genetic programming regression model for prediction of transient storage model parameters in natural rivers. Water 2021, 13, 76. [Google Scholar] [CrossRef]

- Jung, S.H.; Seo, I.W.; Kim, Y.D.; Park, I. Feasibility of velocity-based method for transverse mixing coefficients in river mixing analysis. J. Hydraul. Eng. 2019, 145, 04019040. [Google Scholar] [CrossRef]

- Best, J.L.; Reid, I. Separation zone at open-channel junctions. J. Hydraul. Eng. 1984, 110, 1588–1594. [Google Scholar] [CrossRef]

- Rhoads, B.L.; Riley, J.D.; Mayer, D.R. Response of bed morphology and bed material texture to hydrological conditions at an asymmetrical stream confluence. Geomorphology 2009, 190, 161–173. [Google Scholar] [CrossRef]

- Ramón, C.L.; Hoyer, A.B.; Armengol, J.; Dolz, J.; Rueda, F.J. Mixing and circulation at the confluence of two rivers entering a meandering reservoir. Water Resour. Res. 2013, 49, 1429–1445. [Google Scholar] [CrossRef]

- Horna-Munoz, D.; Constantinescu, G.; Rhoads, B.; Lewis, Q.; Sukhodolov, A. Density effects at a concordant bed natural river confluence. Water Resour. Res. 2020, 58, e2019WR026217. [Google Scholar] [CrossRef]

- Lewis, Q.; Rhoads, B.; Sukhodolov, A.; Constantinescu, G. Advective lateral transport of streamwise momentum governs mixing at small river confluence. Water Resour. Res. 2020, 56, e2019WR026817. [Google Scholar] [CrossRef]

- Schindfessel, L.; Creelle, S.; Mulder, T.D. Flow patterns in an open channel confluence with increasingly dominant tributary inflow. Water 2015, 7, 4724–4751. [Google Scholar] [CrossRef] [Green Version]

- Yuan, S.; Tang, H.; Xiao, Y.; Qiu, X.; Zhang, H.; Yu, D. Turbulent flow structure at a 90-degree open channel confluence: Accounting for the distortion of the shear layer. J. Hydro-Environ. Res. 2016, 12, 130–147. [Google Scholar] [CrossRef] [Green Version]

- Gualtieri, C.; Filizola, N.; de Oliveira, M.; Santos, A.M.; Ianniruberto, M. A field study of the confluence between Negro and Solimões Rivers. Part 1: Hydrodynamics and sediment transport. C. R. Geosci. 2018, 350, 31–42. [Google Scholar] [CrossRef]

- Yuan, S.; Tang, H.; Li, K.; Xu, L.; Xiao, Y.; Gualtieri, C.; Rennie, C.; Melville, B. Hydrodynamics, sediment transport and morphological features at the confluence between the Yangtze River and the Poyang Lake. Water Resour. Res. 2020, 57, e2020WR028284. [Google Scholar] [CrossRef]

- Huang, J.; Weber, L.J.; Lai, Y.G. Three-dimensional numerical study of flows in open-channel junctions. J. Hydraul. Eng. 2002, 128, 268–280. [Google Scholar] [CrossRef]

- Biron, P.M.; Ramamurthy, A.S.; Han, S. Three-dimensional numerical modeling of mixing at river confluences. J. Hydraul. Eng. 2004, 130, 243–253. [Google Scholar] [CrossRef]

- Shakibainia, A.; Tabatabai, M.R.M.; Zarrati, A.R. Three-dimensional numerical study of flow structure in channel confluences. Can. J. Civ. Eng. 2010, 37, 772–781. [Google Scholar] [CrossRef]

- Rooniyan, F. The effect of confluence angle on the flow pattern at a rectangular open-channel. Eng. Technol. Appl. Sci. Res. 2014, 4, 576–580. [Google Scholar] [CrossRef]

- Lyubimova, T.P.; Lepikhin, A.P.; Parshakova, Y.N.; Kolchanov, V.Y.; Gualtieri, C.; Roux, B.; Lane, S.N. A numerical study of the influence of channel-scale secondary circulation on mixing processes downstream of river junctions. Water 2020, 12, 2969. [Google Scholar] [CrossRef]

- Constantinescu, G.S.; Miyawaki, S.; Rhoads, B.; Sukhodolov, A.; Kirkil, G. Structure of turbulent flow at a river confluence with momentum and velocity ratio close to 1: Insights from an eddy-resolving numerical simulation. Water Resour. Res. 2011, 47, W05507. [Google Scholar] [CrossRef]

- Constantinescu, G.; Miyawaki, S.; Rhoads, B.; Sukhodolov, A. Numerical analysis of the effect of momentum ratio on the dynamics and sediment-entrainment capacity of coherent flow structures at a stream confluence. J. Geophys. Res. 2012, 117, 1–21. [Google Scholar] [CrossRef]

- Constantinescu, G.; Miyawaki, S.; Rhoads, B.; Sukhololov, A. Influence of planform geometry and momentum ratio on thermal mixing at a stream confluence with a concordant bed. Environ. Fluid Mech. 2016, 16, 845–873. [Google Scholar] [CrossRef]

- Cheng, Z.; Constantinescu, G. Shallow mixing layers between non-parallel streams in a flat-bed wide channel. J. Fluid Mech. 2021, 916, 1–37. [Google Scholar] [CrossRef]

- Pouchoulin, S.; Coz, J.L.; Mignot, E.; Gond, L.; Riviere, N. Predicting transverse mixing efficiency downstream of a river confluence. Water Resour. Res. 2019, 56, e2019WR026367. [Google Scholar] [CrossRef]

- Lane, S.N.; Parsons, D.R.; Best, J.L.; Orfeo, O.; Kostaschuk, R.A.; Hardy, R.J. Causes of rapid mixing at a junction of two large rivers: Rio Parana and Rio Paraguay, Argentina. J. Geophys. Res. Earth Surf. 2008, 113, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Ramón, C.L.; Armengol, J.; Dolz, J.; Prats, J.; Rueda, F.J. Mixing dynamics at the confluence of two large rivers undergoing weak density variations. J. Geophys. Res. Oceans 2014, 119, 2386–2402. [Google Scholar] [CrossRef]

- Gualtieri, C.; Ianniruberto, M.; Filizola, N. On the mixing of rivers with a difference in density: The study case of the Negro/Solimões confluence, Brazil. J. Hydrol. 2019, 578, 124029. [Google Scholar] [CrossRef]

- Kim, K.; Park, M.; Min, J.H.; Ryu, I.; Kang, M.R.; Park, L.J. Simulation of algal bloom dynamics in a river with the ensemble Kalman filter. J. Hydrol. 2014, 519, 2810–2821. [Google Scholar] [CrossRef]

- Zhu, Z.; Oberg, N.; Morales, V.M.; Quijano, J.C.; Landry, B.J.; Garcia, M.H. Integrated urban hydrologic and hydraulic modelling in Chicago, Illinois. Environ. Model. Softw. 2016, 77, 63–70. [Google Scholar] [CrossRef]

- Weiskerger, C.J.; Phanikumar, M.S. Numerical modeling of microbial fate and transport in natural waters: Review and implications for normal and extreme storm events. Water 2020, 12, 1876. [Google Scholar] [CrossRef]

- Tinh, N.X.; Tanaka, H.; Abe, G.; Okamoto, Y.; Pakoksung, K. Mechanisms of flood-induced levee breaching in Marumori town during the 2019 Hagibis typhoon. Water 2021, 13, 244. [Google Scholar] [CrossRef]

- Gurram, S.K.; Karki, K.S.; Hager, W.H. Subcritical junction flow. J. Hydraul. Eng. 1997, 123, 447–455. [Google Scholar] [CrossRef]

- Gualtieri, C. RANS-based simulation of transverse turbulent mixing in a 2D geometry. Environ. Fluid Mech. 2010, 10, 137–156. [Google Scholar] [CrossRef]

- Fischer, H.B.; List, J.E.; Koh, R.C.Y.; Imberger, J.; Brooks, N.H. Mixing in Inland and Coastal Waters, 2nd ed.; Academic Press: San Diego, CA, USA, 1979. [Google Scholar]

- Lewis, Q.W.; Rhoads, B.L. Rates and patterns of thermal mixing at a small stream confluence under variable incoming flow conditions. Hydrol. Process. 2015, 29, 4442–4456. [Google Scholar] [CrossRef]

- Beltaos, S. Evaluation of transverse mixing coefficients from slug tests. J. Hydraul. Res. 1975, 13, 351–360. [Google Scholar] [CrossRef]

- Kim, J.S.; Baek, D.; Park, I. Evaluating the impact of turbulence closure models on solute transport simulations in meandering open channels. Appl. Sci. 2020, 10, 2769. [Google Scholar] [CrossRef]

- Nordin, C.F.; Troutman, B.M. Longitudinal dispersion in rivers: The persistence of skewness in observed data. Water Resour. Res. 1980, 16, 123–128. [Google Scholar] [CrossRef]

- Hamrick, J.M. A three-dimensional environmental fluid dynamics computer code: Theoretical and computational aspects. In Special Report in Applied Marine Science and Ocean Engineering, 317; Virginia Institute of Marine Science: Gloucester Point, VA, USA, 1992; pp. 7–9. [Google Scholar]

- Smagorinsky, J. General circulation experiments with the primitive equations. Mon. Weather Rev. 1963, 91, 99–164. [Google Scholar] [CrossRef]

- Mellor, G.L.; Yamada, T. Development of a turbulence closure model for geophysical fluid problems. Rev. Geophys. Space Phys. 1982, 20, 851–875. [Google Scholar] [CrossRef] [Green Version]

- Constantinescu, G. Le of shallow mixing interfaces: A review. Environ. Fluid Mech. 2014, 14, 971–996. [Google Scholar] [CrossRef]

- Cheng, Z.; Constantinescu, G. Stratification effects on flow hydrodynamics and mixing at a confluence with a highly discordant bed and a relatively low velocity ratio. Water Resour. Res. 2018, 54, 4537–4562. [Google Scholar] [CrossRef]

- Gualtieri, C.; Angeloudis, A.; Bombardelli, F.; Jha, S.; Stosser, T. On the values for the turbulent Schmidt number in environmental flows. Fluids 2020, 2, 17. [Google Scholar] [CrossRef] [Green Version]

- Shumate, E.D. Experimental Description of Flow at an Open-Channel Junction. Master’s Thesis, University of Iowa, Iowa City, IA, USA, 1 December 1998. [Google Scholar]

- Song, C.G.; Seo, I.W.; Kim, Y.D. Analysis of secondary current effect in the modeling of shallow flow in open channels. Adv. Water Resour. 2012, 41, 29–48. [Google Scholar] [CrossRef]

- Penna, N.; Marchis, M.D.; Canelas, O.B.; Napoli, E.; Cardoso, A.; Gaudio, R. Effect of the junction angle on turbulent flow at a hydraulic confluence. Water 2018, 10, 469. [Google Scholar] [CrossRef] [Green Version]

- Rhoads, B.L.; Kenworthy, S.T. Flow structure at an asymmetrical stream confluence. Geomorphology 1995, 11, 273–293. [Google Scholar] [CrossRef]

- Park, I.; Seo, I.W. Modeling non-Fickian pollutant mixing in open channel flows using two-dimensional particle dispersion model. Adv. Water Resour. 2018, 111, 105–120. [Google Scholar] [CrossRef]

- Choi, S.Y.; Seo, I.W.; Kim, Y.O. Parameter uncertainty estimation of transient storage model using Bayesian inference with formal likelihood based on breakthrough curve segmentation. Environ. Model. Softw. 2020, 123, 104558. [Google Scholar] [CrossRef]

| W/dx | MAPE (%) | |||||

|---|---|---|---|---|---|---|

| Recirculation Zone | Water Depth | |||||

| Ls | bs | y/W = 0.17 | y/W = 0.50 | y/W = 0.82 | ||

| 0.25 | 10 | 100.0 | 100.0 | 6.4 | 5.5 | 5.6 |

| 15 | 28.5 | 32.3 | 3.7 | 2.8 | 3.2 | |

| 20 | 6.6 | 15.8 | 2.6 | 1.8 | 2.0 | |

| 25 | 4.9 | 5.3 | 2.6 | 1.8 | 2.0 | |

| Case | α (°) | (m3/s) | (m3/s) | (m) | (m) | (ppm) | dt (s) | n, Manning’s Roughness Coefficient | ||

|---|---|---|---|---|---|---|---|---|---|---|

| C90 | 90 | 13.6 | 40.2 | 9.14 | 2.96 | 100 | 0.005 | 0.013 | 1.62 | 0.37 |

| C75 | 75 | |||||||||

| C60 | 60 | |||||||||

| C45 | 45 | |||||||||

| C30 | 30 |

| (°) | 90 | 75 | 60 | 45 | 30 |

| (s) | 77.52 | 76.34 | 73.53 | 71.94 | 50.76 |

| (m2) | 29.76 | 26.04 | 16.56 | 6.72 | 3.60 |

| 0.24 | 0.22 | 0.18 | 0.14 | 0.11 | |

| (s−1) | 3.10 10−3 | 2.88 10−3 | 2.45 10−3 | 1.95 10−3 | 2.17 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.; Lee, S.; Park, I. Analysis of Storage Effects in the Recirculation Zone Based on the Junction Angle of Channel Confluence. Appl. Sci. 2021, 11, 11607. https://doi.org/10.3390/app112411607

Shin J, Lee S, Park I. Analysis of Storage Effects in the Recirculation Zone Based on the Junction Angle of Channel Confluence. Applied Sciences. 2021; 11(24):11607. https://doi.org/10.3390/app112411607

Chicago/Turabian StyleShin, Jaehyun, Sunmi Lee, and Inhwan Park. 2021. "Analysis of Storage Effects in the Recirculation Zone Based on the Junction Angle of Channel Confluence" Applied Sciences 11, no. 24: 11607. https://doi.org/10.3390/app112411607

APA StyleShin, J., Lee, S., & Park, I. (2021). Analysis of Storage Effects in the Recirculation Zone Based on the Junction Angle of Channel Confluence. Applied Sciences, 11(24), 11607. https://doi.org/10.3390/app112411607