Control of an Omnidirectional UAV for Transportation and Manipulation Tasks

Abstract

:1. Introduction

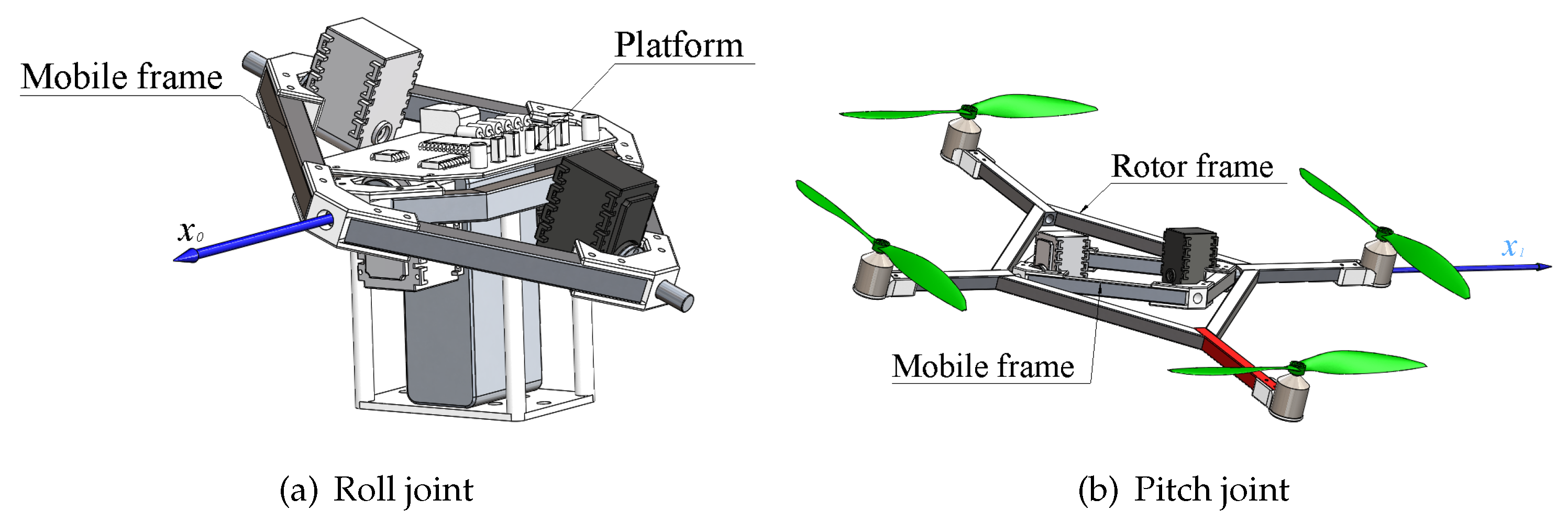

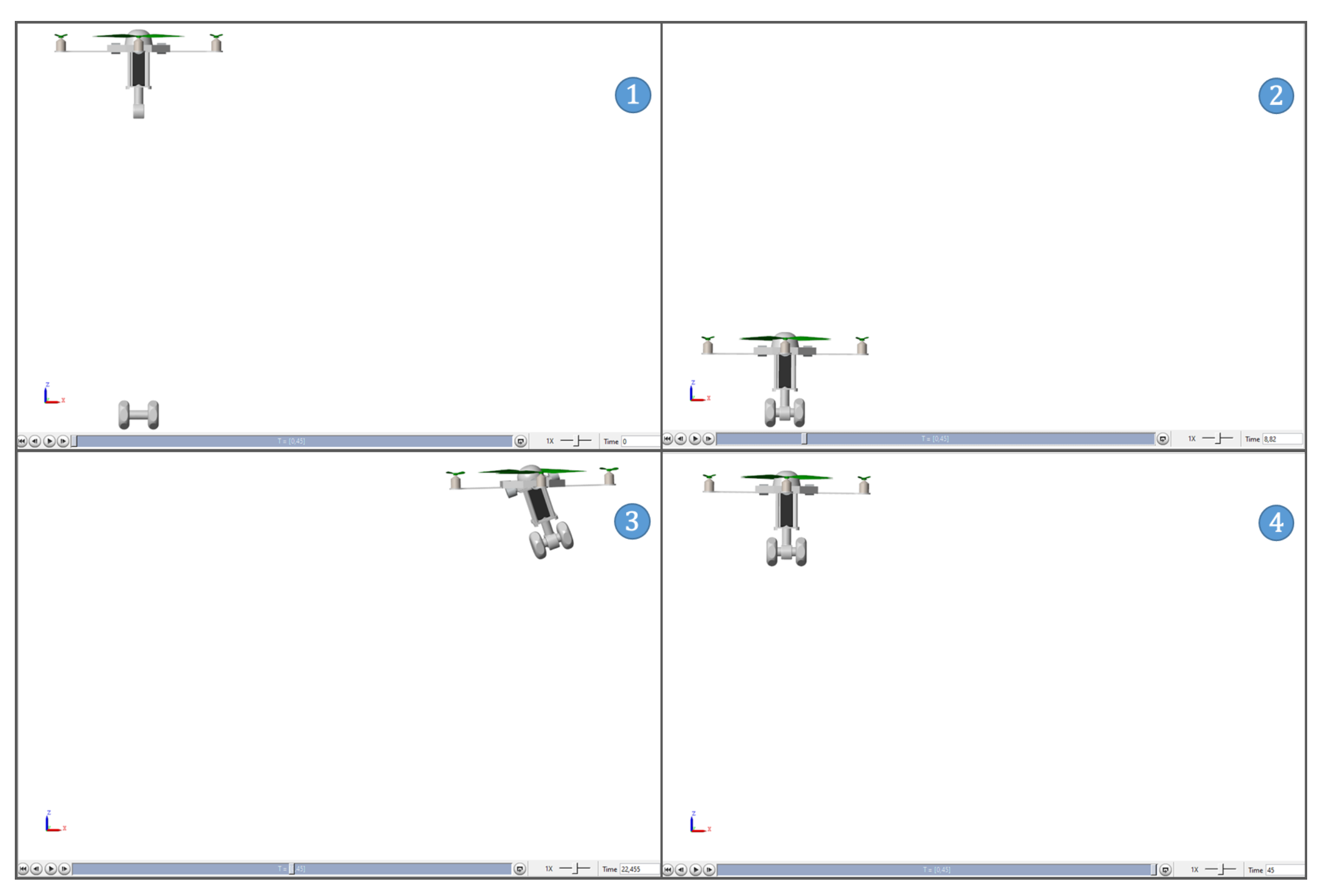

2. ODQuad: A Novel Omnidirectional Quadrotor

- A platform, hosting computing hardware, electronics, batteries, and sensors;

- A rotor frame that supports the propellers;

- A mobile frame that connects the platform and the rotor frames with the roll and pitch rotational joints.

- The inertial coordinate frame,

- The coordinate frame , attached to the platform in such a way that the axis coincides with the axis of the roll joint

- The coordinate frame , attached to the mobile frame in such a way that the axis coincides with the axis of the pitch joint

- The coordinate frame , attached to the rotor frame in such a way that the axis coincides with .

3. Modeling

3.1. Kinematics

3.2. Dynamics

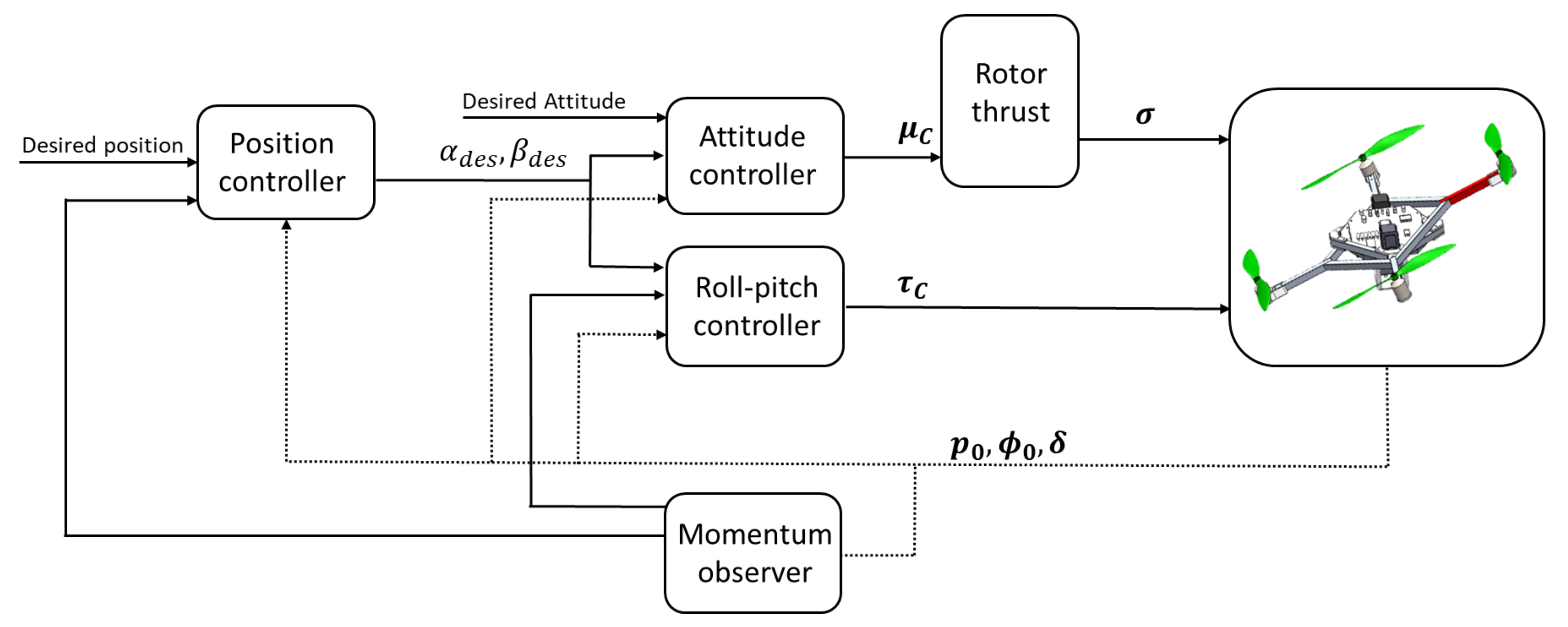

4. Motion Control

4.1. Outer Loop: Position Controller

- vanishes: it can happen only if, namely in the presence of a null total thrust;

- deg ordeg. It cannot happen since both α and β are mechanically limited to [] deg.

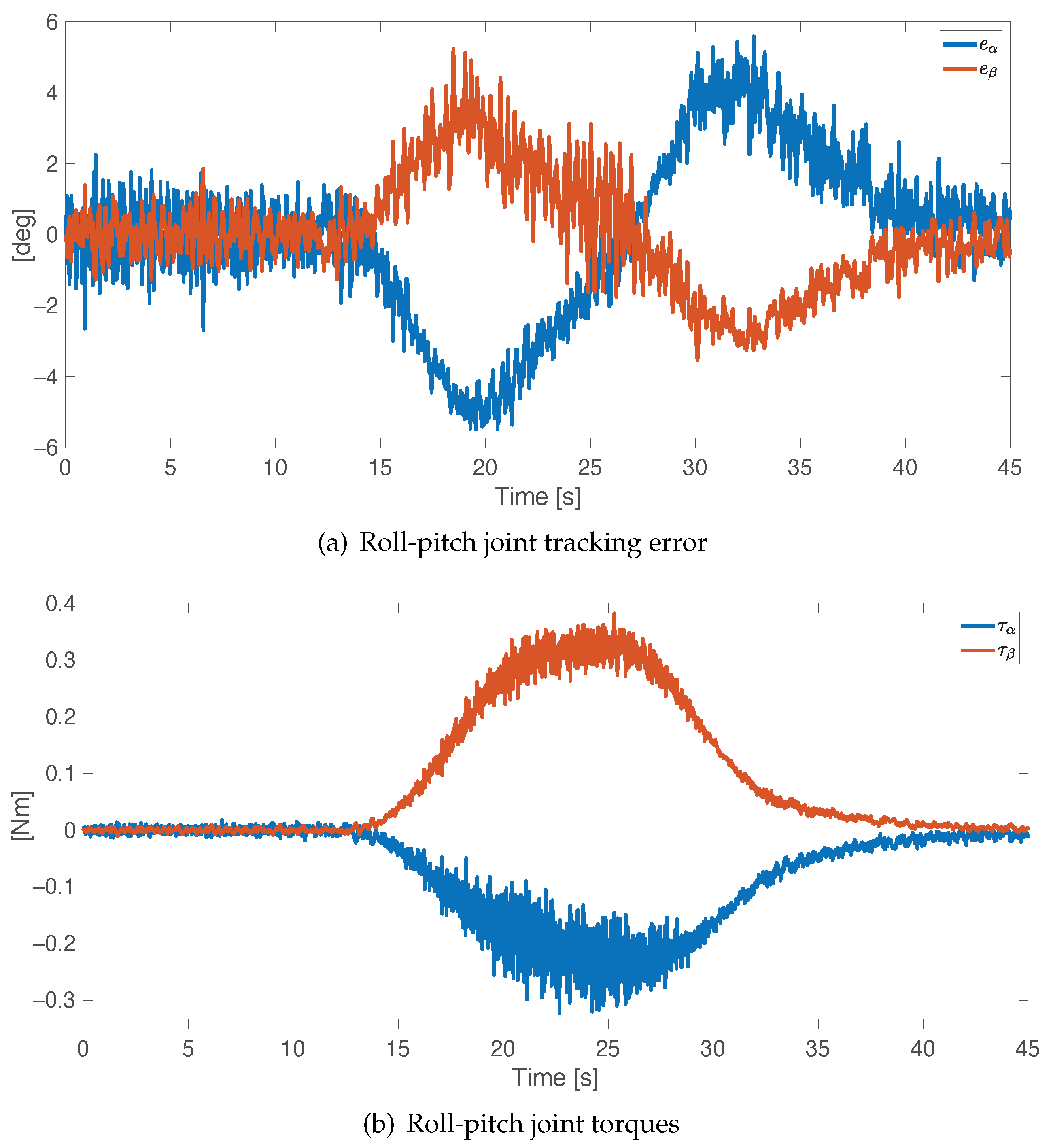

4.2. Inner Loop: Attitude and Roll-Pitch Controller

5. Stability Analysis

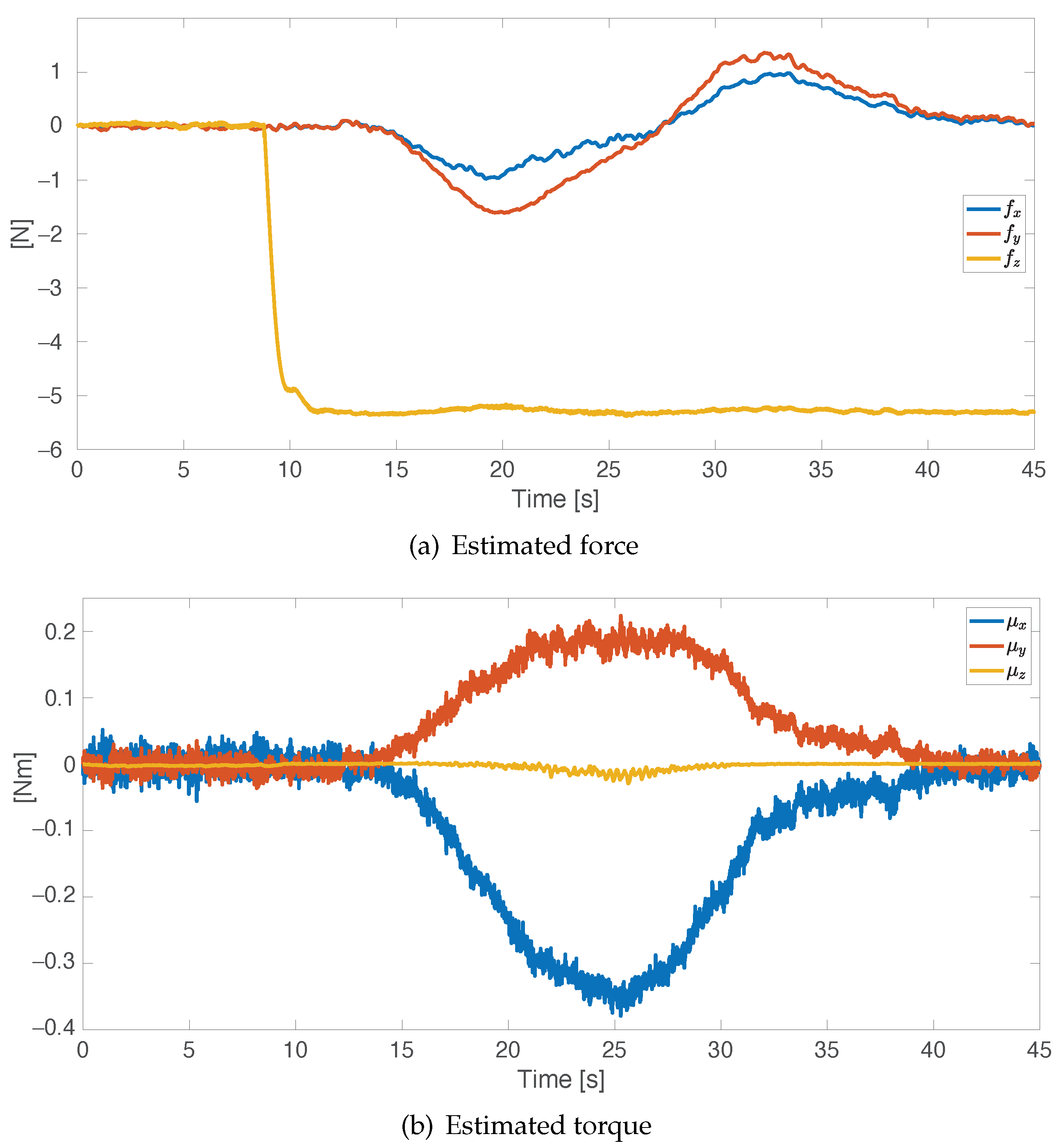

6. Interaction Wrench Compensation

Wrench Estimation

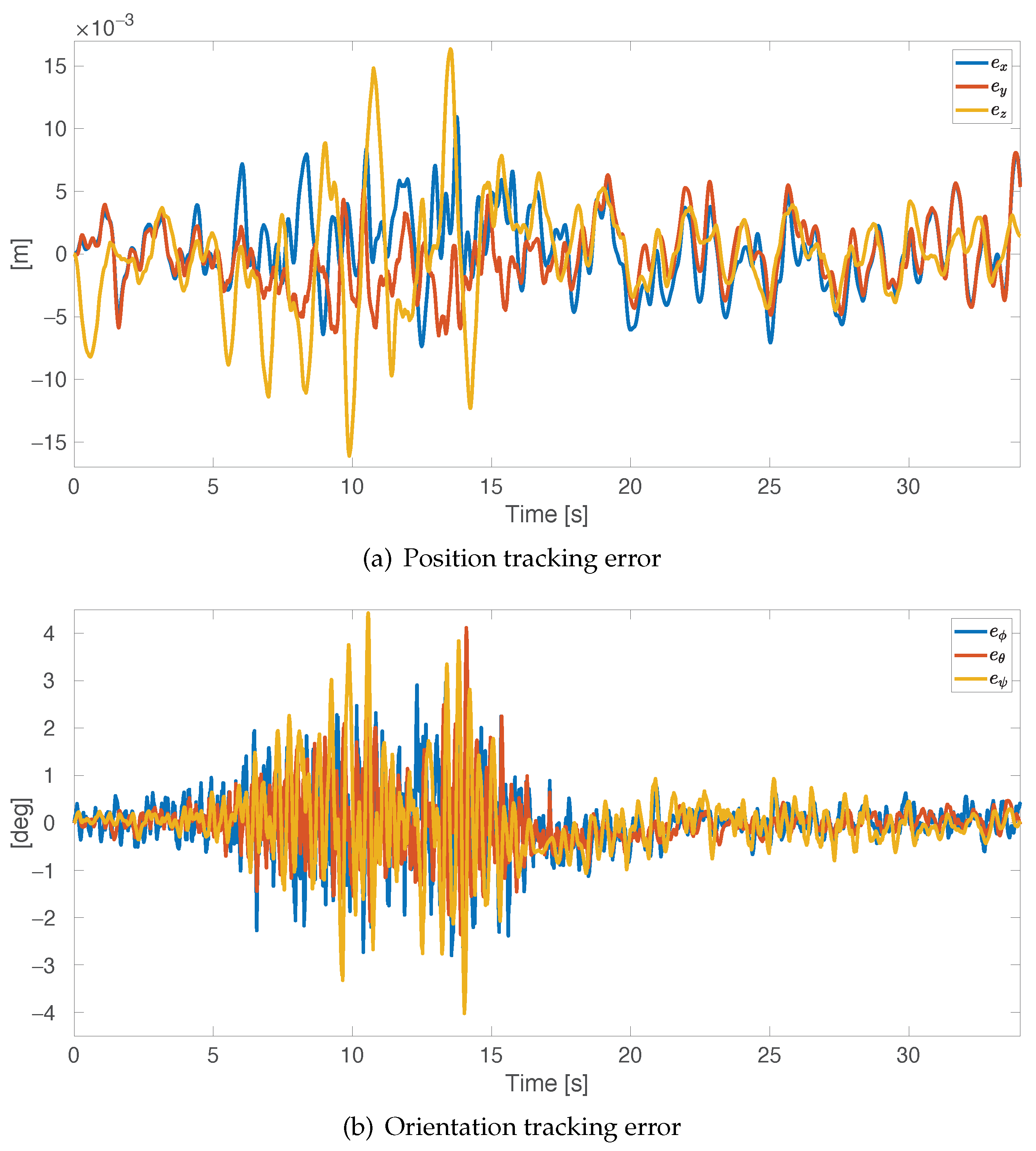

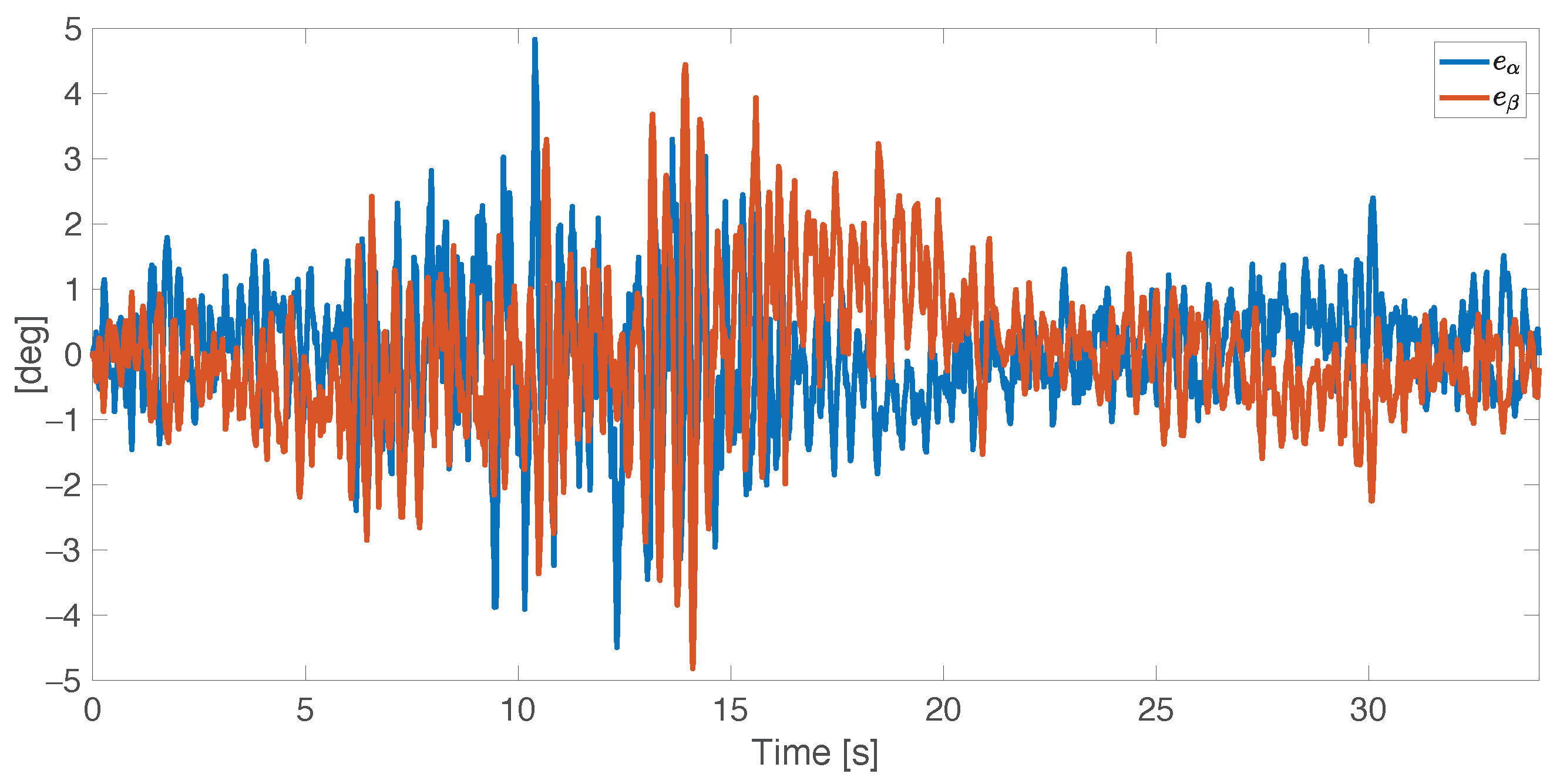

7. Simulation Results

- reliable, but noisy, measurements of the platform position and orientation are available, e.g., provided by a motion capture system and an IMU;

- white noise has been added to measures of the platform position (with standard deviation m) and orientation (with standard deviation rad);

- the angular positions of the roll and pitch joints are available via sensors usually integrated into the servomotors, while the angular velocities are obtained via numerical filtering. Thus, the orientation of the rotor frame relative to the platform frame can be computed via (1);

- viscous friction has been included in the simulation model but not considered in the control design.

8. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| CoM | Center of Mass |

| DOF | Degree of Freedom |

| ODQuad | OmniDirectional Quadrotor |

| UAV | Unmanned Aerial Vehicles |

References

- Jordan, S.; Moore, J.; Hovet, S.; Box, J.; Perry, J.; Kirsche, K.; Lewis, D.; Tse, Z.T.H. State-of-the-art technologies for UAV inspections. IET Radar Sonar Navig. 2017, 12, 151–164. [Google Scholar] [CrossRef]

- Alejo, D.; Cobano, J.A.; Heredia, G.; Martínez-de Dios, J.R.; Ollero, A. Cooperative Robots and Sensor Networks 2015; Springer International Publishing: Cham, Switzerland, 2015; pp. 53–75. [Google Scholar]

- Tokekar, P.; Vander Hook, J.; Mulla, D.; Isler, V. Sensor planning for a symbiotic UAV and UGV system for precision agriculture. IEEE Trans. Robot. 2016, 32, 1498–1511. [Google Scholar] [CrossRef]

- Augugliaro, F.; Lupashin, S.; Hamer, M.; Male, C.; Hehn, M.; Mueller, M.W.; Willmann, J.S.; Gramazio, F.; Kohler, M.; D’Andrea, R. The Flight Assembled Architecture installation: Cooperative construction with flying machines. IEEE Control. Syst. Mag. 2014, 34, 46–64. [Google Scholar]

- Caccavale, F.; Giglio, G.; Muscio, G.; Pierri, F. Cooperative impedance control for multiple UAVs with a robotic arm. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–3 October 2015; pp. 2366–2371. [Google Scholar]

- Pierri, F.; Nigro, M.; Muscio, G.; Caccavale, F. Cooperative manipulation of an unknown object via omnidirectional unmanned aerial vehicles. J. Intell. Robot. Syst. 2020, 100, 1635–1649. [Google Scholar] [CrossRef]

- Nonami, K.; Kendoul, F.; Suzuki, S.; Wang, W. Atonomous Flying Robots, Unmanned Aerial Vehicles and Micro Aerial Vehicles; Springer: London, UK, 2010. [Google Scholar]

- Ryll, M.; Muscio, G.; Pierri, F.; Cataldi, E.; Antonelli, G.; Caccavale, F.; Bicego, D.; Franchi, A. 6D interaction control with aerial robots: The flying end-effector paradigm. Int. J. Robot. Res. 2019, 38, 1045–1062. [Google Scholar] [CrossRef] [Green Version]

- Ryll, M.; Bülthoff, H.H.; Giordano, P.R. A novel overactuated quadrotor unmanned aerial vehicle: Modeling, control, and experimental validation. IEEE Trans. Control. Syst. Technol. 2015, 23, 540–556. [Google Scholar] [CrossRef] [Green Version]

- Segui-Gasco, P.; Al-Rihani, Y.; Shin, H.S.; Savvaris, A. A novel actuation concept for a multi rotor UAV. J. Intell. Robot. Syst. 2014, 74, 173–191. [Google Scholar] [CrossRef]

- Rajappa, S.; Ryll, M.; Bülthoff, H.H.; Franchi, A. Modeling, control and design optimization for a fully-actuated hexarotor aerial vehicle with tilted propellers. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 4006–4013. [Google Scholar]

- Ryll, M.; Bicego, D.; Franchi, A. Modeling and control of FAST-Hex: A fully-actuated by synchronized-tilting hexarotor. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016. [Google Scholar]

- Kamel, M.S.; Verling, S.; Elkhatib, O.; Sprecher, C.; Wulkop, P.; Jeremy Taylor, Z.; Siegwart, R.; Gilitschenski, I. The Voliro Omnidirectional Hexacopter: An Agile and Maneuverable Tiltable-Rotor Aerial Vehicle. IEEE Robot. Autom. Mag. 2018, 25, 34–44. [Google Scholar] [CrossRef] [Green Version]

- Tognon, M.; Franchi, A. Omnidirectional aerial vehicles with unidirectional thrusters: Theory, optimal design, and control. IEEE Robot. Autom. Lett. 2018, 3, 2277–2282. [Google Scholar] [CrossRef] [Green Version]

- Hamandi, M.; Sawant, K.; Tognon, M.; Franchi, A. Omni-Plus-Seven (O7+): An Omnidirectional Aerial Prototype with a Minimal Number of Unidirectional Thrusters. In Proceedings of the 2020 International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 1–4 September 2020; pp. 754–761. [Google Scholar]

- Odelga, M.; Stegagno, P.; Bülthoff, H.H. A fully actuated quadrotor UAV with a propeller tilting mechanism: Modeling and control. In Proceedings of the 2016 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Banff, AB, Canada, 12–15 July 2016; pp. 306–311. [Google Scholar]

- Nigro, M.; Pierri, F.; Caccavale, F. Preliminary design, modeling and control of a fully actuated quadrotor uav. In Proceedings of the 2019 International Conference on Unmanned Aircraft Systems (ICUAS), Atlanta, GA, USA, 11–14 June 2019; pp. 1108–1116. [Google Scholar]

- Hoffmann, G.; Huang, H.; Waslander, S.; Tomlin, C. Quadrotor helicopter flight dynamics and control: Theory and experiment. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit, Keystone, CO, USA, 21–24 August 2007. [Google Scholar]

- Araar, O.; Aouf, N. Full linear control of a quadrotor UAV, LQ vs. ∞. In Proceedings of the 2014 UKACC International Conference on Control (CONTROL), Loughborough, UK, 9–11 July 2014; pp. 133–138. [Google Scholar]

- Bangura, M.; Mahony, R. Real-time model predictive control for quadrotors. Ifac Proc. Vol. 2014, 47, 11773–11780. [Google Scholar] [CrossRef]

- Antonio-Toledo, M.E.; Sanchez, E.N.; Alanis, A.Y.; Flórez, J.; Perez-Cisneros, M.A. Real-time integral backstepping with sliding mode control for a quadrotor UAV. IFAC-PapersOnLine 2018, 51, 549–554. [Google Scholar] [CrossRef]

- Nadda, S.; Swarup, A. Development of backstepping based sliding mode control for a quadrotor. In Proceedings of the 2014 IEEE 10th International Colloquium on Signal Processing and Its Applications, Kuala Lumpur, Malaysia, 7–9 March 2014; pp. 10–13. [Google Scholar]

- Palunko, I.; Cruz, P.; Fierro, R. Agile load transportation. Safe and efficient load manipulation with aerial robots. IEEE Robot. Autom. Mag. 2012, 19, 69–79. [Google Scholar] [CrossRef]

- Ruggiero, F.; Cacace, J.; Sadeghian, H.; Lippiello, V. Passivity-based control of VToL UAVs with a momentum-based estimator of external wrench and unmodeled dynamics. Robot. Auton. Syst. 2015, 72, 139–151. [Google Scholar] [CrossRef]

- Forte, F.; Naldi, R.; Macchelli, A.; Marconi, L. Impedance control of an aerial manipulator. In Proceedings of the American Control Conference (ACC), 2012, Montreal, QC, Canada, 27–29 June 2012; pp. 3839–3844. [Google Scholar]

- Watterson, M.; Zahra, A.; Kumar, V. Geometric Control and Trajectory Optimization for Bidirectional Thrust Quadrotors. In Proceedings of the International Symposium on Experimental Robotics, Buenos Aires, Argentina, 5–8 November 2018; pp. 165–176. [Google Scholar]

- Meraglia, S.; Lovera, M. Smoother-Based Iterative Learning Control for UAV Trajectory Tracking. IEEE Control. Syst. Lett. 2021, 6, 1501–1506. [Google Scholar] [CrossRef]

- Park, S.; Her, J.; Kim, J.; Lee, D. Design, modeling and control of omni-directional aerial robot. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 1570–1575. [Google Scholar]

- Ducard, G.; Hua, M.D. Discussion and practical aspects on control allocation for a multi-rotor helicopter. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2011, 38, 95–100. [Google Scholar] [CrossRef] [Green Version]

- Convens, B.; Merckaert, K.; Nicotra, M.M.; Naldi, R.; Garone, E. Control of fully actuated unmanned aerial vehicles with actuator saturation. IFAC-PapersOnLine 2017, 50, 12715–12720. [Google Scholar] [CrossRef]

- Nicotra, M.M.; Naldi, R.; Garone, E. A robust explicit reference governor for constrained control of unmanned aerial vehicles. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016; pp. 6284–6289. [Google Scholar]

- Franchi, A.; Carli, R.; Bicego, D.; Ryll, M. Full-pose tracking control for aerial robotic systems with laterally bounded input force. IEEE Trans. Robot. 2018, 34, 534–541. [Google Scholar] [CrossRef] [Green Version]

- Hamandi, M.; Usai, F.; Sablé, Q.; Staub, N.; Tognon, M.; Franchi, A. Design of multirotor aerial vehicles: A taxonomy based on input allocation. Int. J. Robot. Res. 2021, 40, 1015–1044. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics—Modelling, Planning and Control; Springer: London, UK, 2009. [Google Scholar]

- Pierri, F.; Muscio, G.; Caccavale, F. An adaptive hierarchical control for aerial manipulators. Robotica 2018, 36, 1527–1550. [Google Scholar] [CrossRef] [Green Version]

- Reger, J.; Ramírez, H.S.; Fliess, M. On non-asymptotic observation of nonlinear systems. In Proceedings of the IEEE Conference on Decision and Control and European Control Conference CDC-ECC’05, Seville, Spain, 12–15 December 2005; pp. 4219–4224. [Google Scholar]

- Pereira, F.M. Block matrices and stability theory. Tatra Mt. Math. Publ. 2007, 38, 147–162. [Google Scholar]

- Siciliano, B.; Villani, L. An adaptive force/position regulator for robot manipulators. Int. J. Adapt. Control. Signal Process. 1993, 7, 389–403. [Google Scholar] [CrossRef]

- Khalil, H. Nonlinear Systems, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Cataldi, E.; Muscio, G.; Trujillo, M.A.; Rodríguez, Y.; Pierri, F.; Antonelli, G.; Caccavale, F.; Viguria, A.; Chiaverini, S.; Ollero, A. Impedance control of an aerial-manipulator: Preliminary results. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 3848–3853. [Google Scholar]

- De Luca, A.; Mattone, R. Sensorless robot collision detection and hybrid force/motion control. In Proceedings of the 2005 IEEE International Conferenc on Robotics and Automation, Barcelona, Spain, 18–22 April 2005; pp. 999–1004. [Google Scholar]

| Gain | Value |

|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nigro, M.; Pierri, F.; Caccavale, F. Control of an Omnidirectional UAV for Transportation and Manipulation Tasks. Appl. Sci. 2021, 11, 10991. https://doi.org/10.3390/app112210991

Nigro M, Pierri F, Caccavale F. Control of an Omnidirectional UAV for Transportation and Manipulation Tasks. Applied Sciences. 2021; 11(22):10991. https://doi.org/10.3390/app112210991

Chicago/Turabian StyleNigro, Michelangelo, Francesco Pierri, and Fabrizio Caccavale. 2021. "Control of an Omnidirectional UAV for Transportation and Manipulation Tasks" Applied Sciences 11, no. 22: 10991. https://doi.org/10.3390/app112210991

APA StyleNigro, M., Pierri, F., & Caccavale, F. (2021). Control of an Omnidirectional UAV for Transportation and Manipulation Tasks. Applied Sciences, 11(22), 10991. https://doi.org/10.3390/app112210991