Neural Identification of a Temperature Field in the Storing Phase of Thermal Energy in Rock Bed Thermal Storage

Abstract

1. Introduction

- α—Darcy’s constant [m−2];

- μ—dynamic viscosity [kg·(m·s)−1];

- ψ—porosity;

- ρf—fluid density [kg·m−3];

- ρfo—fluid density at the reference temperature [kg·m−3];

- b—Forchheimer’s constant [m−1];

- pT—dynamic pressure [Pa];

- β—volumetric temperature expansion coefficient [K−1];

- Tf—air temperature [K];

- To—reference temperature [K];

- g—acceleration due to gravity [m·s−2];

- k—vertical unit vector.

- Asf—interface surface [m2];

- cfp—fluid specific heat [J·(kg·K)−1];

- kf—effective thermal conductivity of fluid [W·(m·K)−1];

- h—convective heat transfer coefficient [W·(m2·K)−1];

- Ts—deposit temperature [K];

- t—time [s];

- ∀—volume deposit [m3].

- csp—rock-bed-specific heat [J·(kg·K)−1];

- ks—effective thermal conductivity of rock bed [W·(m·K)−1];

- ρs—rock bed density [kg·m−3].

2. Materials and Methods

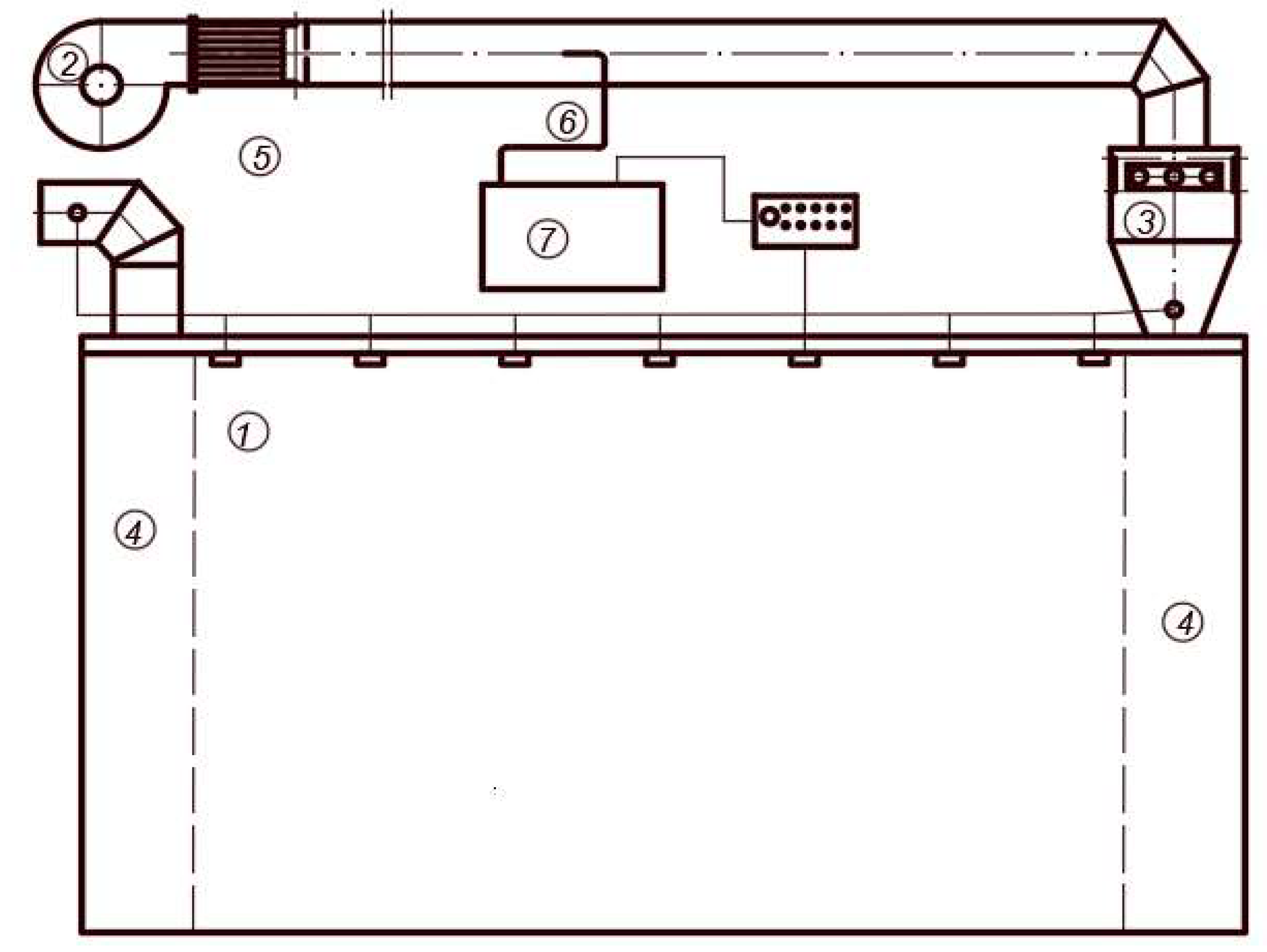

2.1. Storage Phase of the Rock Bed Thermal Storage

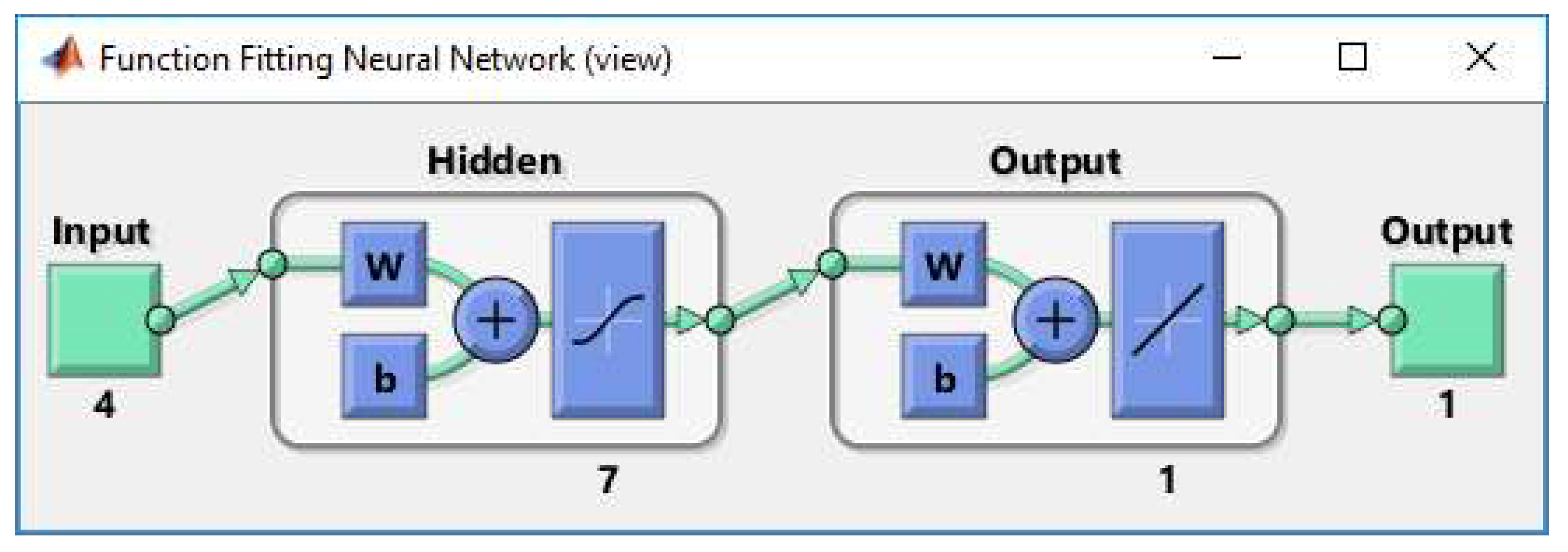

2.2. Neural Models of Temperature Distribution

- Maximum training epochs (epochs parameter): 1500;

- Maximum subsequent epochs, in which the error function value may deteriorate for the validation file (max_fail parameter): 100;

- Minimum error function gradient (min_grad parameter): 1 × 10−7.

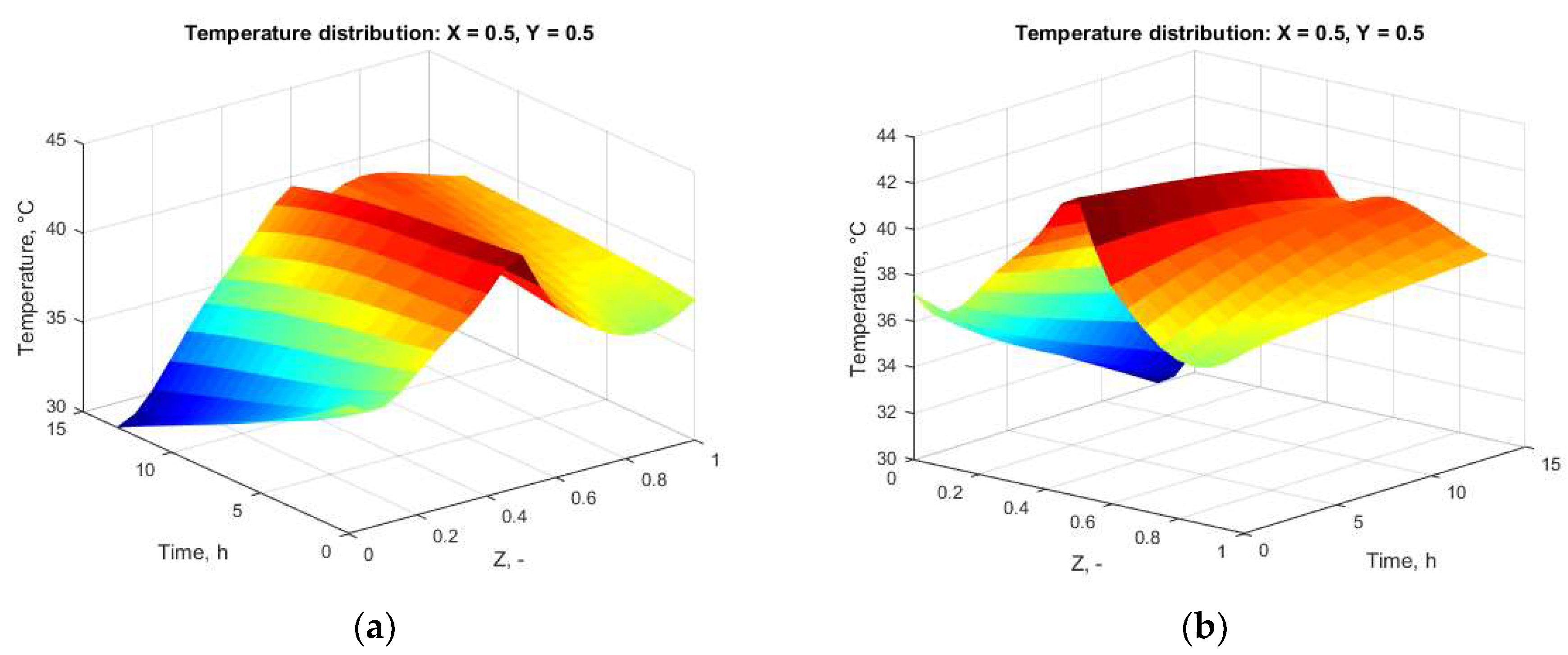

3. Results

- n—number of cases;

- Tmi—measured values of temperature;

- Tpi—values of temperature predicted with the use of the neural model.

- 0.4324 for the training file;

- 0.4462 for the validation file;

- 0.4554 for the test file.

- 0.2604 for the training file;

- 0.2780 for the validation file;

- 0.2809 for the test file.

- 0.1437 for the training file;

- 0.1626 for the validation file;

- 0.1578 for the test file.

- Data Mean—the mean value of the output variable calculated based on the required values of this variable, collected in the training, validation or testing files, as appropriate. The regression statistics were determined independently for the training, validation and testing files.

- Data S.D.—the standard deviation calculated for the required (as above) values of the output variable.

- Error Mean—mean error (the modulus of difference between the required value and the obtained output value) for the output variable.

- Error S.D.—standard deviation of errors for an output variable.

- Abs Mean—mean absolute error (difference between the required value and the obtained output value) for the output variable.

- S.D. Ratio—the ratio of standard deviations for the errors and for the data. This was the main quality coefficient of the regression model generated by the network.

- Correlation—the standard Pearson R correlation coefficient for the values required and obtained at the output.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramadan, M.R.I.; El-Sebaii, A.A.; Aboul-Enein, S.; El-Bialy, E. Thermal performance of a packed bed double-pass solar air heater. Energy 2007, 32, 1524–1535. [Google Scholar] [CrossRef]

- Baghban, A.; Kahani, M.; Nazari, M.A.; Ahmadi, M.H.; Yan, W.H. Sensitivity analysis and application of machine learning methods to predict the heat transfer performance of CNT/water nanofluid flows through coils. Int. J. Heat Mass Transf. 2019, 128, 825–835. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Nazari, M.A.; Ghasempour, R.; Madah, H.; Shafii, M.B.; Ahmadi, M.A. Thermal conductivity ratio prediction of Al2O3/water nanofluid by applying connectionist methods. Colloids Surf. Physicochem. Eng. Asp. 2018, 541, 154–164. [Google Scholar] [CrossRef]

- Hänchen, M.; Brückner, S.; Steinfeld, A. High-temperature thermal storage using a packed bed of rocks—Heat transfer analysis and experimental validation. Appl. Therm. Eng. 2011, 31, 1798–1806. [Google Scholar] [CrossRef]

- Bindra, H.; Bueno, P.; Morris, J.F.; Shinnar, R. Thermal analysis and exergy evaluation of packed bed thermal storage systems. Appl. Therm. Eng. 2013, 52, 255–263. [Google Scholar] [CrossRef]

- N G Barton, “Simulations of air-blown thermal storage in a rock bed. Appl. Therm. Eng. 2013, 55, 43–50. [CrossRef]

- Sadeghzadeh, M.; Ahmadi, M.H.; Kahani, M.; Sakhaeinia, H.; Chaji, H.; Chen, L. Smart modeling by using artificial intelligent techniques on thermal performance of flat-plate solar collector using nanofluid. Energy Sci. Eng. 2019, 7, 1649–1658. [Google Scholar] [CrossRef]

- Stamps, D.W.; Clark, J.A. Thermal destratification in a cylindrical packed bed. Int. J. Heat Mass Transf. 1992, 35, 727–737. [Google Scholar] [CrossRef][Green Version]

- Ahmadi, M.H.; Mohseni-Gharyehsafa, B.; Ghazvini, M.; Goodarzi, M.; Jilte, R.D.; Kumar, R. Comparing various machine learning approaches in modeling the dynamic viscosity of CuO/water nanofluid. J. Therm. Anal. Calorim. 2020, 139, 2585–2599. [Google Scholar] [CrossRef]

- Pintaldi, S.; Perfumo, C.; Sethuvenkatraman, S.; White, S.; Rosengarten, G. A review of thermal energy storage technologies and control approaches for solar cooling. Renew. Sustain. Energy Rev. 2015, 41, 975–995. [Google Scholar] [CrossRef]

- Stamps, D.W.; Arpaci, V.S.; Clark, J.A. Unsteady three-dimensional natural convection in a fluid-saturated porous medium. J. Fluid Mech. 1990, 213, 377. [Google Scholar] [CrossRef]

- Maddah, H.; Ghazvini, M.; Ahmadi, M.H. Predicting the efficiency of CuO/water nanofluid in heat pipe heat exchanger using neural network. Int. Commun. Heat Mass Transf. 2019, 104, 33–40. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Sadeghzadeh, M.; Raffiee, A.H.; Chau, K. Applying GMDH neural network to estimate the thermal resistance and thermal conductivity of pulsating heat pipes. Eng. Appl. Comput. Fluid Mech. 2019, 13, 327–336. [Google Scholar] [CrossRef]

- Koszela, K.; Łukomski, M.; Mueller, W.; Górna, K.; Okoń, P.; Boniecki, P.; Zaborowicz, M.; Wojcieszak, D. Classification of dried vegetables using computer image analysis and artificial neural networks. In Proceedings of the Ninth International Conference on Digital Image Processing (ICDIP 2017), Hong Kong, China, 19–22 May 2017; Volume 10420, p. 1042031. [Google Scholar]

- Kujawa, S.; Dach, J.; Kozłowski, R.; Przybył, K.; Niedbała, G.; Mueller, W.; Tomczak, R.; Zaborowicz, M.; Koszela, K. Maturity classification for sewage sludge composted with rapeseed straw using neural image analysis. In Proceedings of the SPIE—The International Society for Optical Engineering, Chengu, China, 20–22 May 2016; Volume 10033, p. 100332H. [Google Scholar]

- Vrbka, J.; Nica, E.; Podhorská, I. The application of Kohonen networks for identification of leaders in the trade sector in Czechia. Equilibrium 2019, 14, 739–761. [Google Scholar] [CrossRef]

- Przybył, K.; Gawałek, J.; Koszela, K.; Wawrzyniak, J.; Gierz, L. Artificial neural networks and electron microscopy to evaluate the quality of fruit and vegetable spray-dried powders. Case study: Strawberry powder. Comput. Electron. Agric. 2018, 155, 314–323. [Google Scholar] [CrossRef]

- Zaborowicz, M.; Włodarek, J.; Przybylak, A.; Przybył, K.; Wojcieszak, D.; Czekała, W.; Ludwiczak, A.; Boniecki, P.; Koszela, K.; Przybył, J.; et al. Image acquisitions, processing and analysis in the process of obtaining characteristics of horse navicular bone. In Proceedings of the SPIE—The International Society for Optical Engineering, Los Angeles, CA, USA, 9–10 April 2015; Volume 9631, p. 963111. [Google Scholar]

- Maknickiene, N.; Lapinskaite, I.; Maknickas, A. Application of ensemble of recurrent neural networks for forecasting of stock market sentiments. Equilibrium 2018, 13, 7–27. [Google Scholar] [CrossRef]

- Ashhab, M.S.; Al-Salaymeh, A. Optimization of hot-wire thermal flow sensor based on a neural net model. Appl. Therm. Eng. 2006, 26, 948–955. [Google Scholar] [CrossRef]

- Sözen, A.; Arcaklioğlu, E. Exergy analysis of an ejector-absorption heat transformer using artificial neural network approach. Appl. Therm. Eng. 2007, 27, 481–491. [Google Scholar] [CrossRef]

- Sun, M.T.; Chang, C.H.; Lin, B.F. Using ANNs in calibrating the measurements of a simplified hot-plate method. Appl. Therm. Eng. 2009, 29, 1818–1824. [Google Scholar] [CrossRef]

- Xie, G.N.; Wang, Q.W.; Zeng, M.; Luo, L.Q. Heat transfer analysis for shell-and-tube heat exchangers with experimental data by artificial neural networks approach. Appl. Therm. Eng. 2007, 27, 1096–1104. [Google Scholar] [CrossRef]

- Hakeem, M.A.; Kamil, M.; Arman, I. Prediction of temperature profiles using artificial neural networks in a vertical thermosiphon reboiler. Appl. Therm. Eng. 2008, 28, 1572–1579. [Google Scholar] [CrossRef]

- António, C.C.; Afonso, C.F. Air temperature fields inside refrigeration cabins: A comparison of results from CFD and ANN modelling. Appl. Therm. Eng. 2011, 31, 1244–1251. [Google Scholar] [CrossRef]

- Palomba, V.; Frazzica, A. A fast-reduced model for an innovative latent thermal energy storage for direct integration in heat pumps. Appl. Sci. 2021, 11, 8972. [Google Scholar] [CrossRef]

- Le, T.-H.; Tang, M.; Jang, J.H.; Jang, H.; Shin, S. Integration of Functional Link Neural Networks into a Parameter Estimation Methodology. Appl. Sci. 2021, 11, 9178. [Google Scholar] [CrossRef]

- Raba, B.; Nowakowski, K.; Lewicki, A.; Przybył, K.; Zaborowicz, M.; Koszela, K.; Boniecki, P.; Mueller, W. The Non-touching Method of the Malting Barley Quality Evaluation. In Proceedings of the 6th International Conference on Digital Image Processing (ICDIP 2014), Athens, Greece, 5–6 April 2014; Volume 9159. [Google Scholar]

- Przybył, K.; Gawałek, J.; Koszela, K.; Przybył, J.; Rudzińska, M.; Gierz, Ł.; Domian, E. Neural image analysis and electron microscopy to detect and describe selected quality factors of fruit and vegetable spray-dried powders—Case study: Chokeberry powder. Sensors 2019, 19, 4413. [Google Scholar] [CrossRef] [PubMed]

- Przybył, K.; Duda, A.; Koszela, K.; Stangierski, J.; Polarczyk, M.; Gierz, Ł. Classification of dried strawberry by the analysis of the acoustic sound with artificial neural networks. Sensors 2020, 20, 499. [Google Scholar] [CrossRef]

| Name | Designation | Unit | |

|---|---|---|---|

| Input signals (4 variables) | |||

| 1 | x coordinates of the location | X | Non dimensional |

| 2 | y coordinates of the location | Y | Non dimensional |

| 3 | z coordinates of the location | Z | Non dimensional |

| 4 | Time | t | [h] |

| Output signal (1 variable) | |||

| 5 | Temperature | T | [°C] |

| No. | X | Y | Z | t [h] | T [°C] |

|---|---|---|---|---|---|

| 331 | 0.6511 | 0.5 | 0.5 | 7.133 | 42.55 |

| 332 | 0.6511 | 0.5 | 0.5 | 7.300 | 42.53 |

| 333 | 0.6511 | 0.5 | 0.5 | 7.466 | 42.50 |

| 334 | 0.6511 | 0.5 | 0.5 | 7.633 | 42.48 |

| 335 | 0.6511 | 0.5 | 0.5 | 7.800 | 42.46 |

| 336 | 0.6511 | 0.5 | 0.5 | 7.966 | 42.46 |

| 337 | 0.6511 | 0.5 | 0.5 | 8.150 | 42.43 |

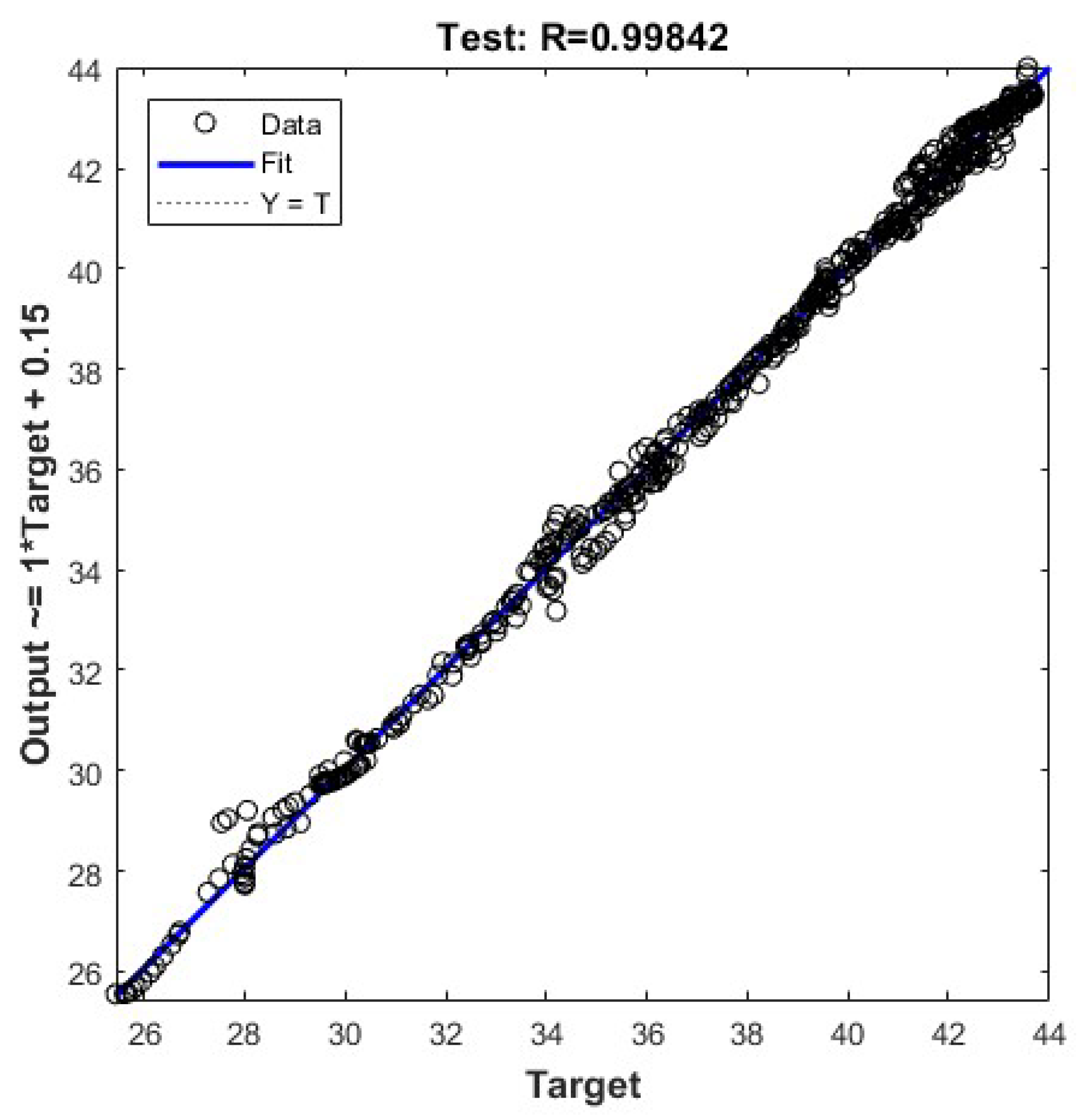

| MLP 4-7-1 | |||

| Regression Statistics | T for Training File | T for Validation File | T for Testing File |

| Data Mean | 37.8574 | 37.9499 | 37.4636 |

| Data S.D. | 4.8059 | 5.0527 | 4.9947 |

| Error Mean | −0.0002 | −0.0120 | −0.0181 |

| Error S.D. | 0.2605 | 0.2780 | 0.2806 |

| Abs Mean | 0.1923 | 0.2107 | 0.2082 |

| S.D. Ratio | 0.0542 | 0.0550 | 0.0562 |

| Correlation | 0.9985 | 0.9985 | 0.9984 |

| MLP 4-10-1. | |||

| Regression Statistics | T for Training File | T for Validation File | T for Testing File |

| Data Mean | 37.6776 | 38.0241 | 37.7491 |

| Data S.D. | 5.0388 | 4.7779 | 4.8083 |

| Error Mean | 0 | 0.0040 | −0.0058 |

| Error S.D. | 0.1438 | 0.1627 | 0.1579 |

| Abs Mean | 0.1046 | 0.1079 | 0.1073 |

| S.D. Ratio | 0.0285 | 0.0341 | 0.0328 |

| Correlation | 0.9996 | 0.9994 | 0.9995 |

| MLP 4-5-1. | |||

| Regression Statistics | T for Training File | T For Validation File | T for Testing File |

| Data Mean | 37.9323 | 37.7615 | 37.5023 |

| Data S.D. | 4.8752 | 4.6902 | 5.2108 |

| Error Mean | 0 | 0.098 | 0.0197 |

| Error S.D. | 0.4326 | 0.4466 | 0.4554 |

| Abs Mean | 0.3445 | 0.3454 | 0.3557 |

| S.D. Ratio | 0.0887 | 0.0952 | 0.0874 |

| Correlation | 0.9961 | 0.9955 | 0.9962 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mueller, W.; Koszela, K.; Kujawa, S. Neural Identification of a Temperature Field in the Storing Phase of Thermal Energy in Rock Bed Thermal Storage. Appl. Sci. 2021, 11, 10711. https://doi.org/10.3390/app112210711

Mueller W, Koszela K, Kujawa S. Neural Identification of a Temperature Field in the Storing Phase of Thermal Energy in Rock Bed Thermal Storage. Applied Sciences. 2021; 11(22):10711. https://doi.org/10.3390/app112210711

Chicago/Turabian StyleMueller, Wojciech, Krzysztof Koszela, and Sebastian Kujawa. 2021. "Neural Identification of a Temperature Field in the Storing Phase of Thermal Energy in Rock Bed Thermal Storage" Applied Sciences 11, no. 22: 10711. https://doi.org/10.3390/app112210711

APA StyleMueller, W., Koszela, K., & Kujawa, S. (2021). Neural Identification of a Temperature Field in the Storing Phase of Thermal Energy in Rock Bed Thermal Storage. Applied Sciences, 11(22), 10711. https://doi.org/10.3390/app112210711