Using the Instrumented Indentation Technique to Determine Damage in Sintered Metal Matrix Composites after High-Temperature Deformation

Abstract

:1. Introduction

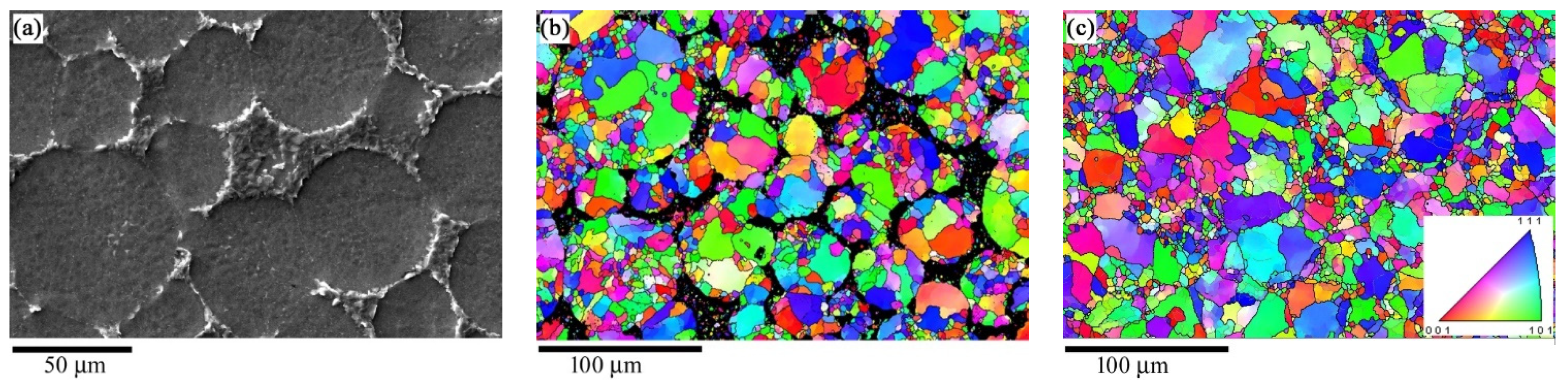

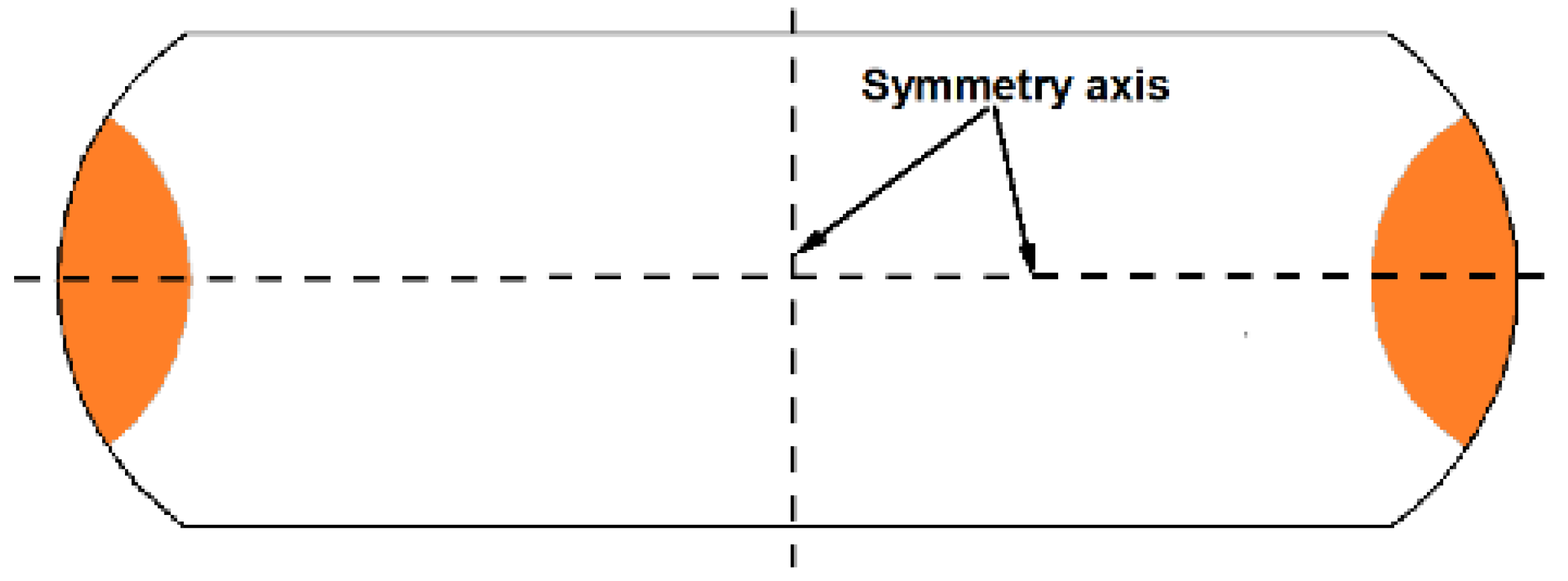

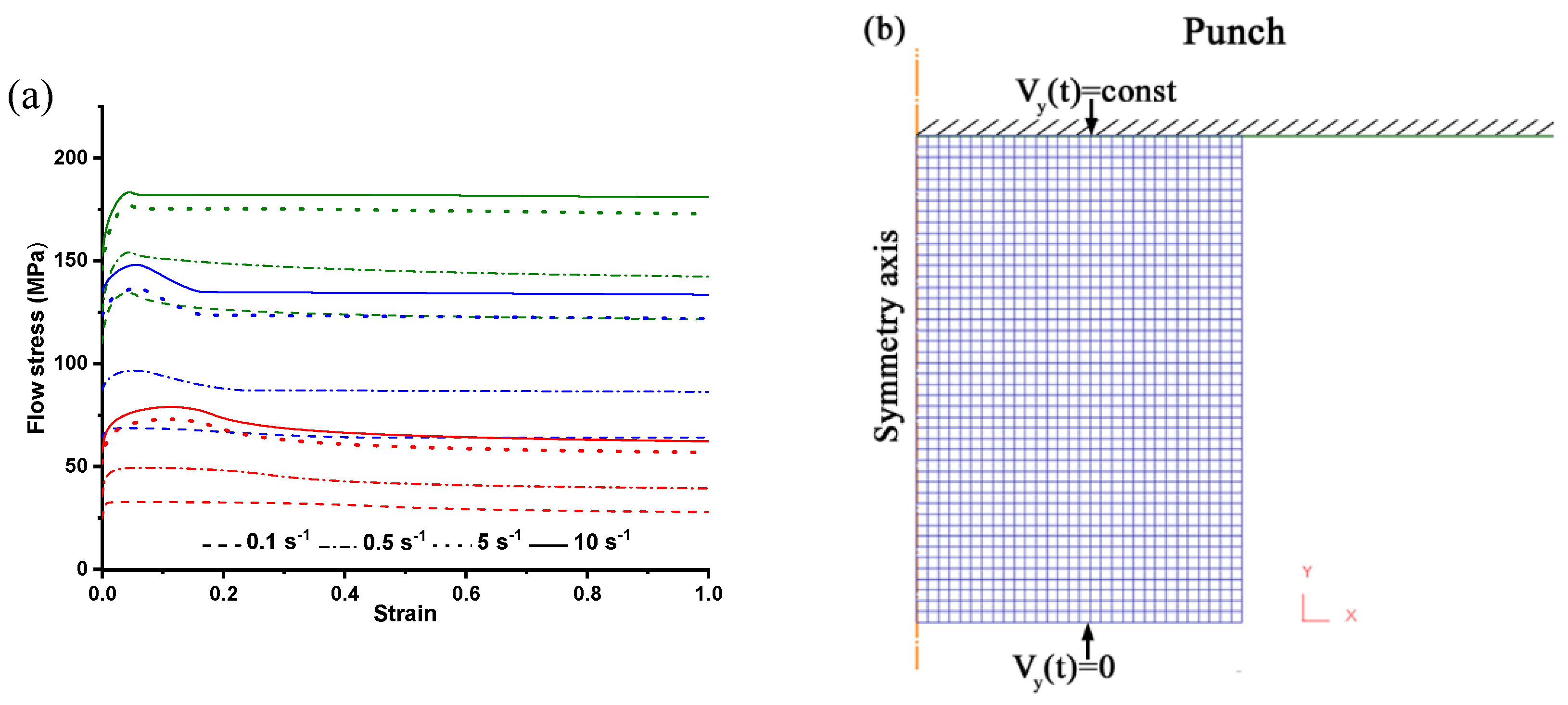

2. Material and Research Methods

3. Methodology for Measuring Damage in a Metal Matrix Composite and Discussion of Results

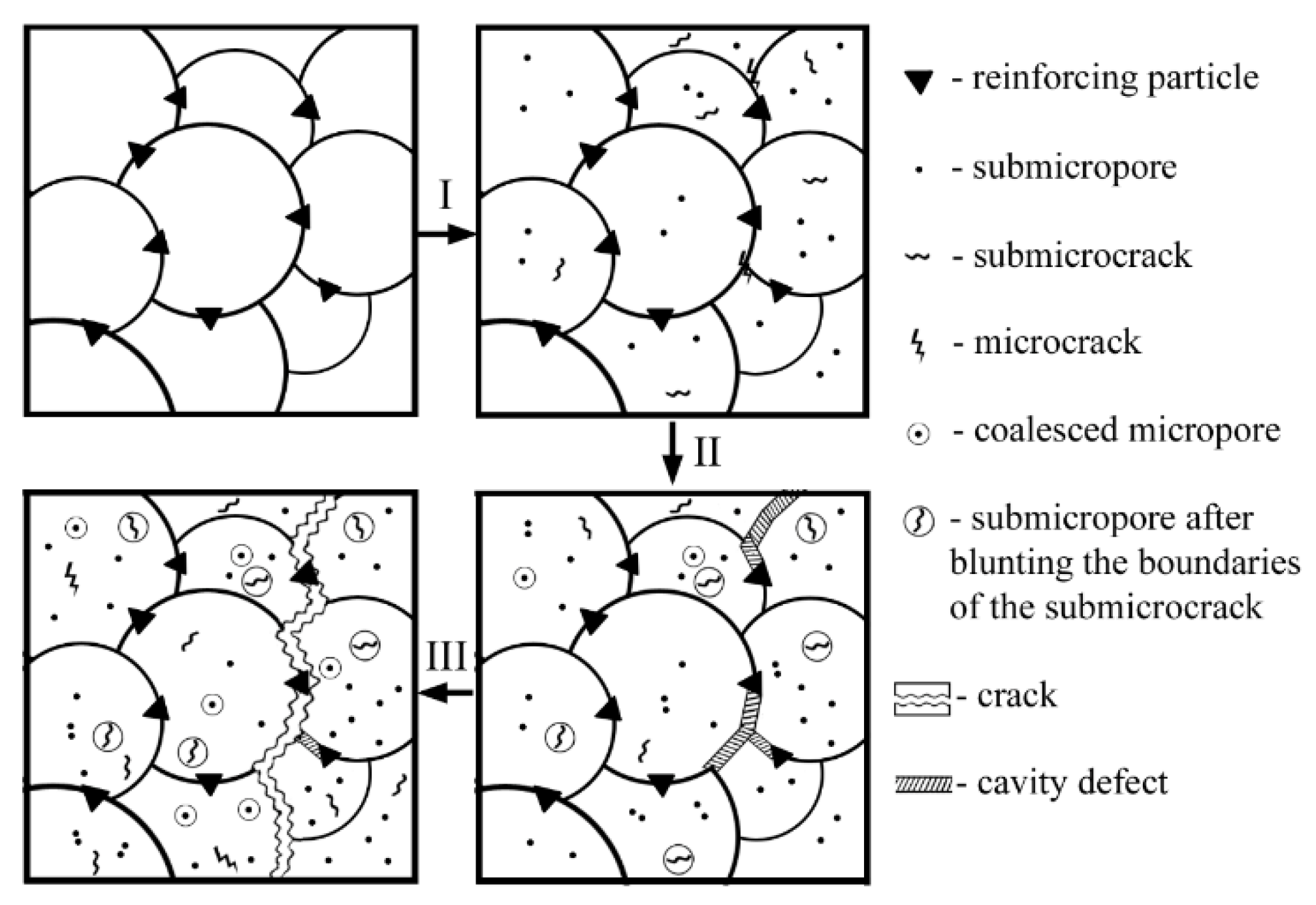

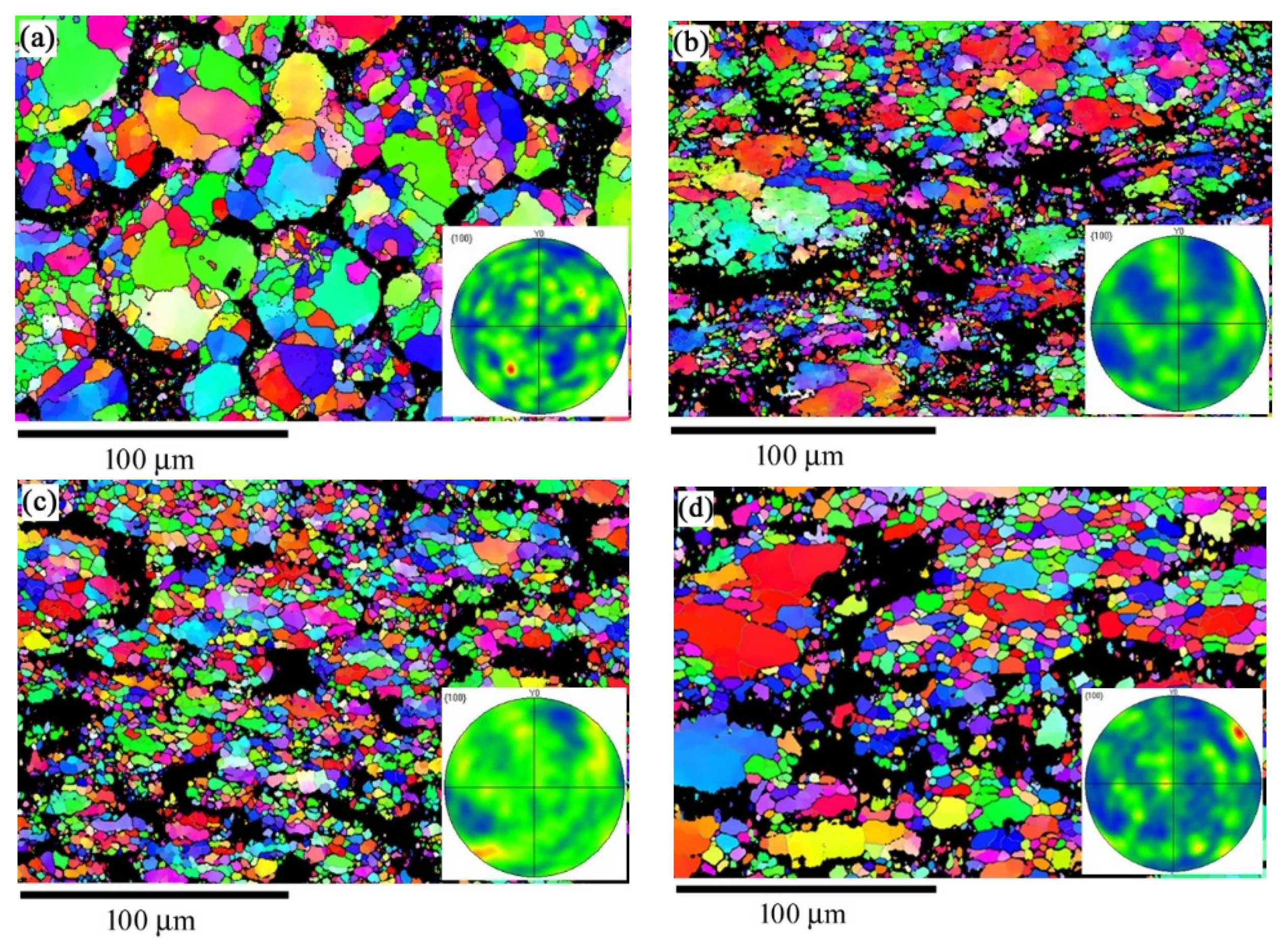

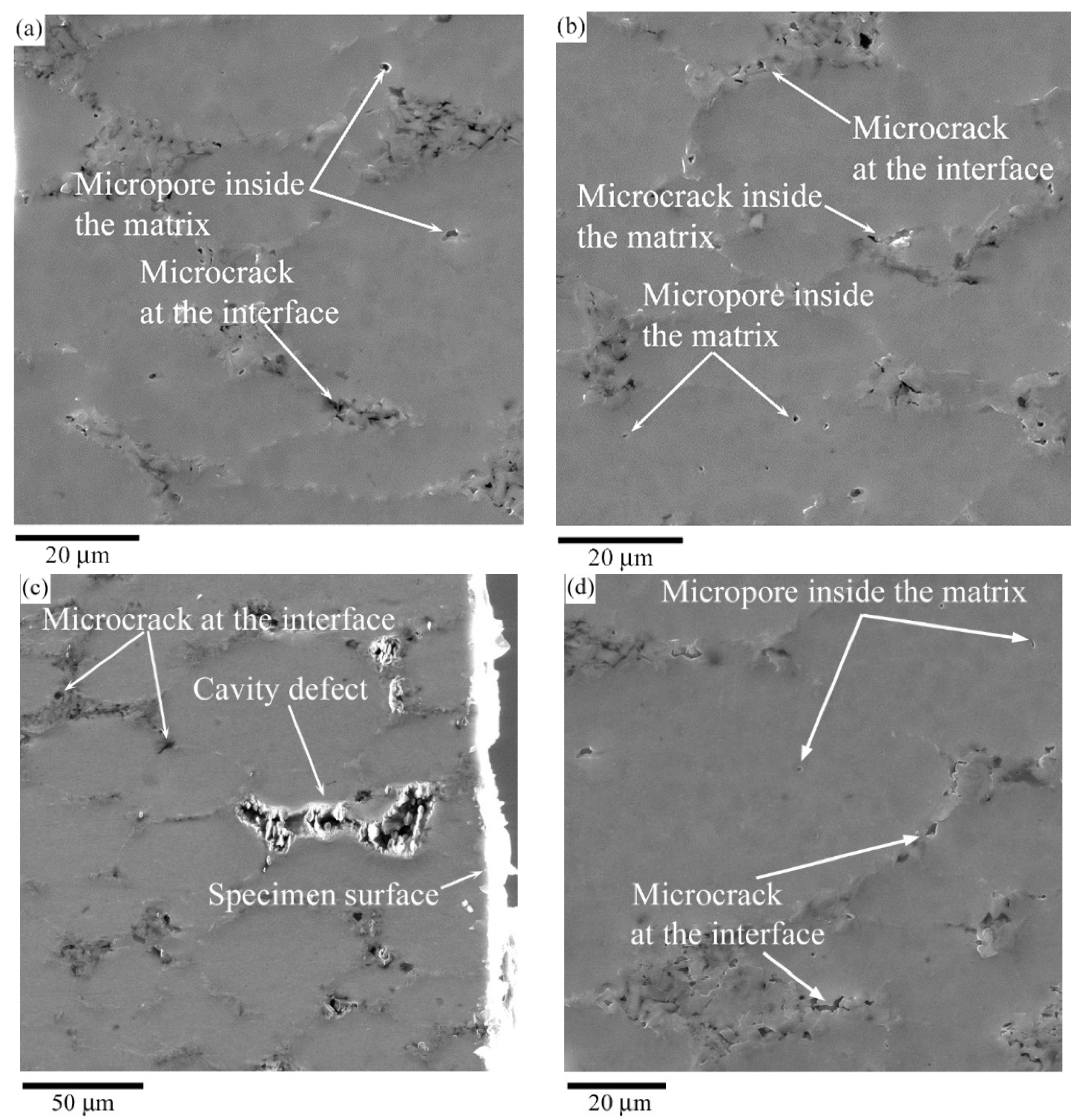

3.1. The Mechanism of Fracture in the Sintered V95\10% SiC Metal Matrix Composite

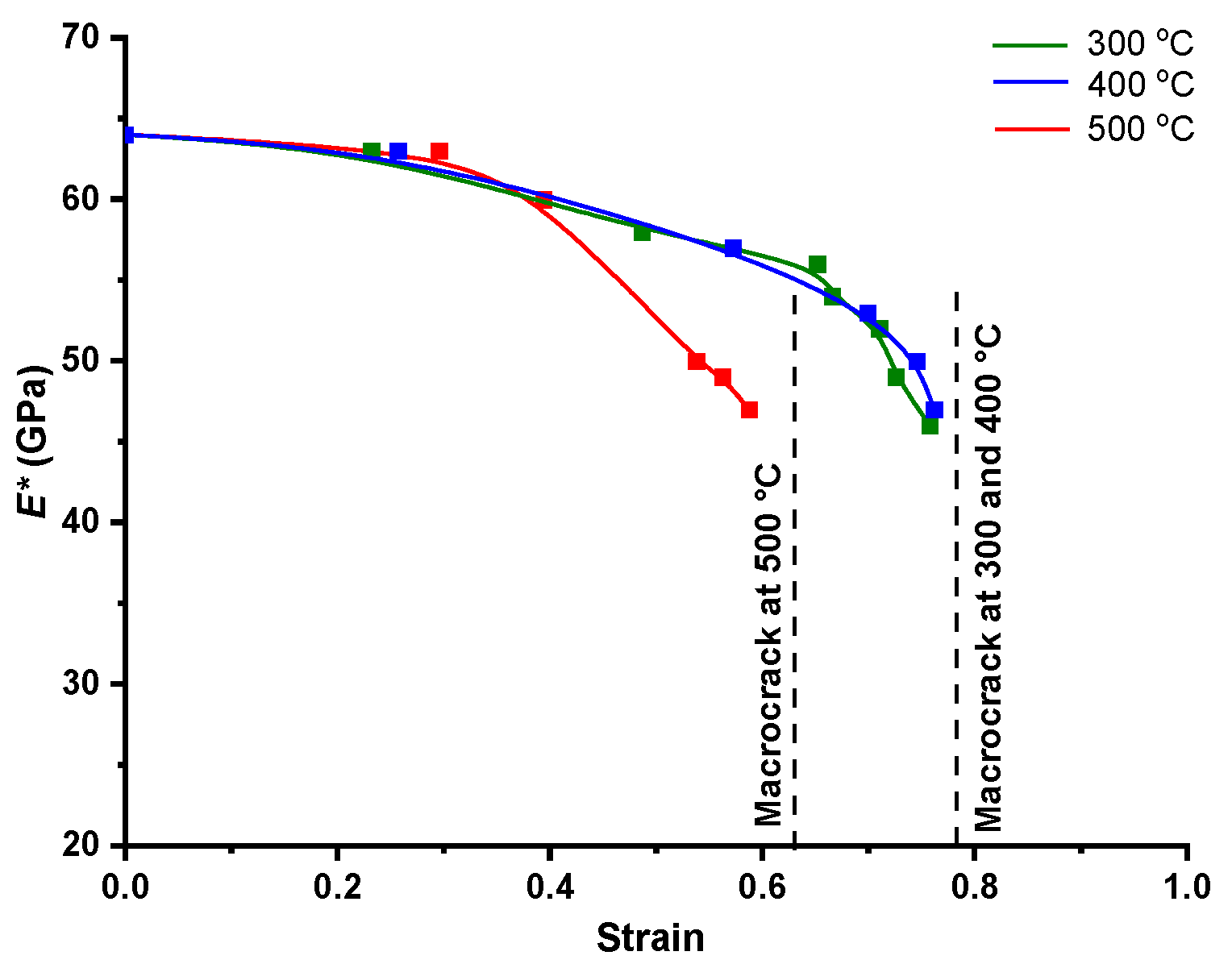

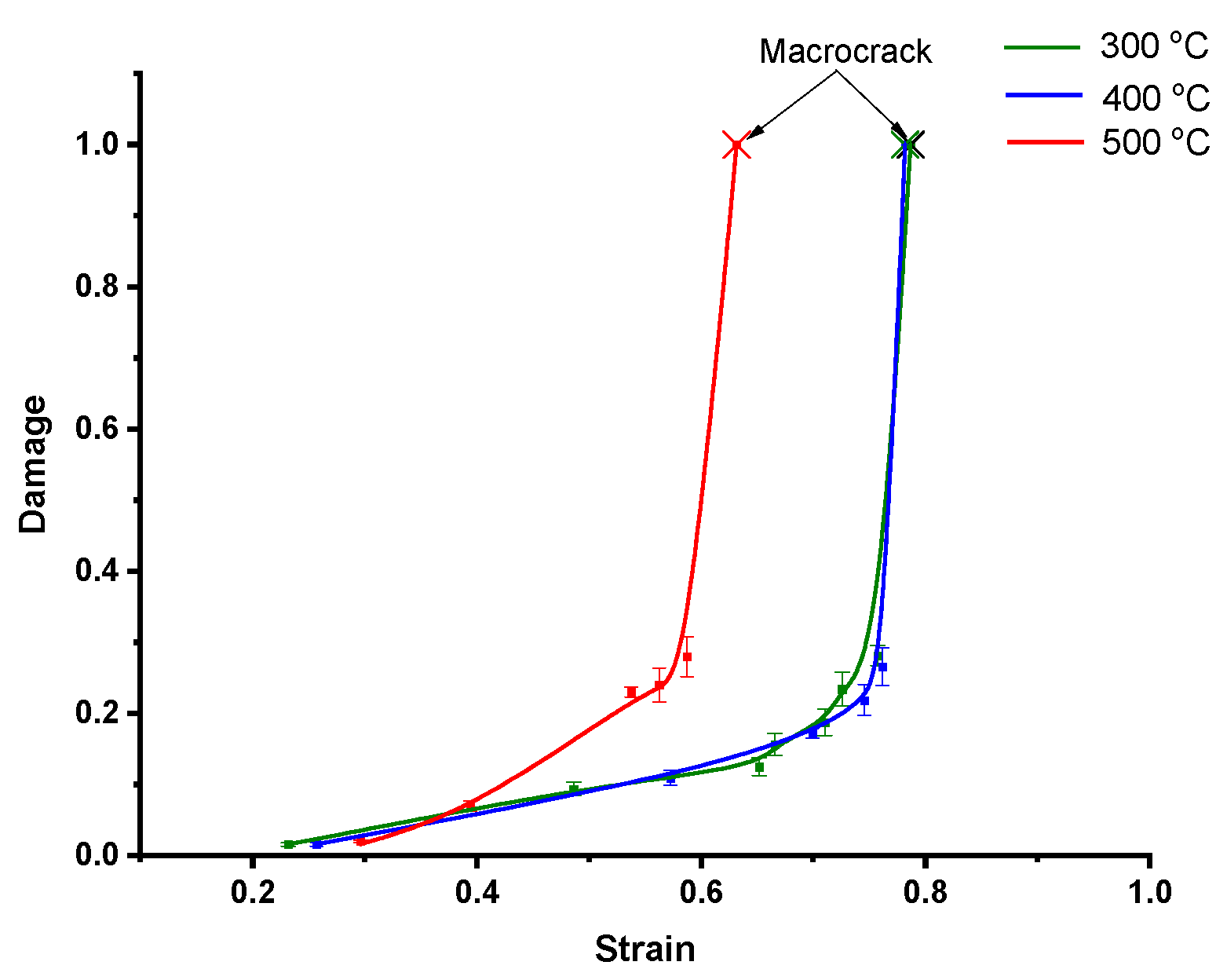

3.2. Damage Measurement Technique

4. Conclusions

- 1.

- A mechanism of damage accumulation in a sintered V95\10% SiC metal matrix composite has been proposed. The mechanism consists of a three-stage accumulation of defects on the interphase boundaries and inside the composite matrix.

- 2.

- The applicability of data on elastic modulus evolution obtained from instrumented microindentation in order to determine damage in sintered metal matrix composites after high-temperature deformation has been exemplified by the V95\10% SiC metal matrix composite. The correctness of using the technique for determining damage by indentation requires that the possible effect of residual stresses and texture be taken into account and that the volume of the deformed material under the indenter exceed the minimum material volume (the representative volume) containing a sufficient number of carriers of the structural phase state for a statistical description of the material state.

- 3.

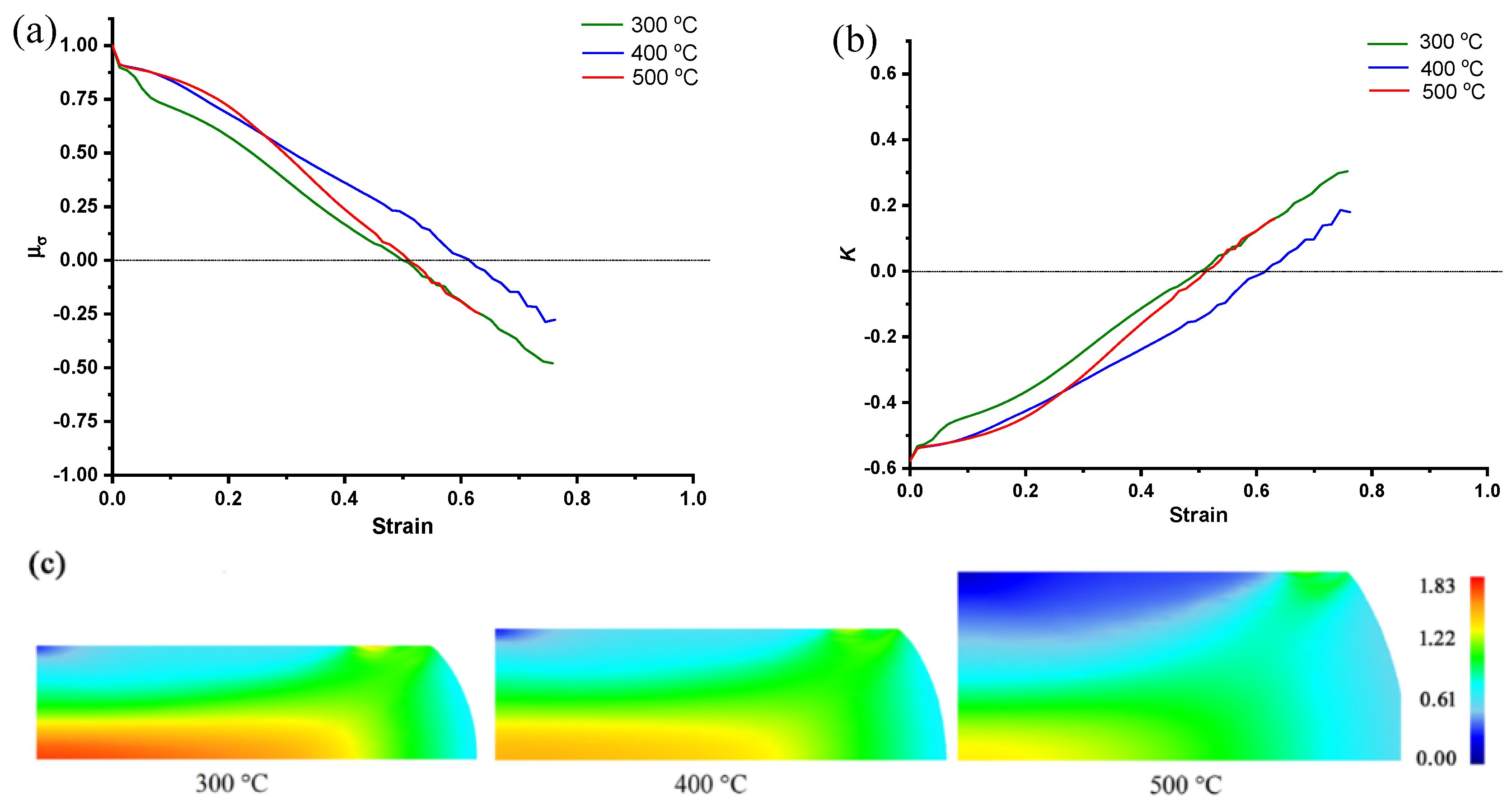

- The strain dependences of damage for temperatures ranging from 300 to 500 °C have been obtained for the V95\10% SiC MMC. It has been shown that the best plasticity of the composite under compression conditions at the macro-level is observed at a temperature of 300 °C. At a deformation temperature of 500 °C, the plastic properties significantly decrease from those at 300 and 400 °C.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tang, B.; Wu, F.; Guo, N.; Liu, J.; Ge, H.; Bruschi, S.; Li, X. Numerical modeling of ductile fracture of hot stamped 22MnB5 boron steel parts in three-point bending. Int. J. Mech. Sci. 2020, 188, 105951. [Google Scholar] [CrossRef]

- Modanloo, V.; Alimirzaloo, V.; Elyasi, M. Optimal Design of Stamping Process for Fabrication of Titanium Bipolar Plates Using the Integration of Finite Element and Response Surface Methods. Arab. J. Sci. Eng. 2020, 45, 1097–1107. [Google Scholar] [CrossRef]

- Imran, M.; Afzal, M.J.; Buhl, J.; Bambach, M.; Dunlap, A.; Schwedt, A.; Aretz, A.; Wang, S.; Lohmar, J.; Hirt, G. Evaluation of process-induced damage based on dynamic recrystallization during hot caliber rolling. Prod. Eng. 2020, 14, 5–16. [Google Scholar] [CrossRef]

- Zhang, K.; Badreddine, H.; Hfaiedh, N.; Saanouni, K.; Liu, J. Enhanced CDM model accounting of stress triaxiality and Lode angle for ductile damage prediction in metal forming. Int. J. Damage Mech. 2021, 30, 260–282. [Google Scholar] [CrossRef]

- Smirnov, S.; Vichuzhanin, D.; Nesterenko, A.; Smirnov, A.; Pugacheva, N.; Konovalov, A. A fracture locus for a 50 volume-percent Al/SiC metal matrix composite at high temperature. Int. J. Mater. Form. 2017, 10, 831–843. [Google Scholar] [CrossRef]

- Meya, R.; Kusche, C.F.; Löbbe, C.; Al-Samman, T.; Kerzel, S.K.; Tekkaya, A.E. Global and high-resolution damage quantification in dual-phase steel bending samples with varying stress states. Metals 2019, 9, 319. [Google Scholar] [CrossRef] [Green Version]

- Schmitt, J.H.; Jalinier, J.M.; Baudelet, B. Analysis of damage and its influence on the plastic properties of copper. J. Mater. Sci. 1981, 16, 95–101. [Google Scholar] [CrossRef]

- Lemaitre, J.; Dufailly, J. Damage measurements. Eng. Fract. Mech. 1987, 28, 643–661. [Google Scholar] [CrossRef]

- Smirnov, S.V. Accumulation and healing of damage during plastic metal forming: Simulation and experiment. Key Eng. Mater. 2013, 528, 61–69. [Google Scholar] [CrossRef]

- Alves, M. Measurement of ductile material damage. Mech. Struct. Mach. 2001, 29, 451–476. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.P.M.; Geers, M.G.D. A brittle-fracture methodology for three-dimensional visualization of ductile deformation micromechanisms. Scr. Mater. 2009, 61, 20–23. [Google Scholar] [CrossRef]

- Hild, F.; Bouterf, A.; Roux, S. Damage measurements via DIC. Int. J. Fract. 2015, 191, 77–105. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.P.M.; Geers, M.G.D. A critical assessment of indentation-based ductile damage quantification. Acta Mater. 2009, 57, 4957–4966. [Google Scholar] [CrossRef]

- Mkaddem, A.; Gassara, F.; Hambli, R. A new procedure using the microhardness technique for sheet material damage characterisation. J. Mater. Process. Technol. 2006, 178, 111–118. [Google Scholar] [CrossRef]

- Saijun, Z.; Chi, Z.; Qinxiang, X.; Songmao, C. Measurement of full-field ductile damage based on resistance Method. Procedia Eng. 2014, 81, 1055–1060. [Google Scholar] [CrossRef] [Green Version]

- Harizi, W.; Anjoul, J.; Acosta Santamaría, V.A.; Aboura, Z.; Briand, V. Mechanical behavior of carbon-reinforced thermoplastic sandwich composites with several core types during three-point bending tests. Compos. Struct. 2021, 262, 113590. [Google Scholar] [CrossRef]

- Kumar, J.; Sundara Raman, S.G.; Kumar, V. Analysis and Modeling of Thermal Signatures for Fatigue Damage Characterization in Ti–6Al–4V Titanium Alloy. J. Nondestruct. Eval. 2016, 35, 1–10. [Google Scholar] [CrossRef]

- Sharkeev, Y.P.; Vavilov, V.P.; Skripnyak, V.A.; Klimenov, V.A.; Belyavskaya, O.A.; Nesteruk, D.A.; Kozulin, A.A.; Tolmachev, A.I. Evolution of the temperature field during deformation and fracture of specimens of coarse-grained and ultrafine-grained titanium. Russ. J. Nondestruct. Test. 2011, 47, 701–706. [Google Scholar] [CrossRef]

- Fedorova, A.Y.; Bannikov, M.V.; Plekhov, O.A. A study of the stored energy in titanium under deformation and failure using infrared data. Frat. ed Integrita Strutt. 2013, 24, 81–88. [Google Scholar] [CrossRef] [Green Version]

- Tasan, C.C.; Hoefnagels, J.P.M.; Geers, M.G.D. Identification of the continuum damage parameter: An experimental challenge in modeling damage evolution. Acta Mater. 2012, 60, 3581–3589. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.H.; Li, X. Effect of sample tilt on nanoindentation behaviour of materials. Philos. Mag. 2007, 87, 2299–2312. [Google Scholar] [CrossRef]

- Kim, H.S.; Bush, M.B. Effects of grain size and porosity on the elastic modulus of nanocrystalline materials. Nanostruct. Mater. 1999, 11, 361–367. [Google Scholar] [CrossRef]

- Shen, T.D.; Koch, C.C.; Tsui, T.Y.; Pharr, G.M. On the elastic moduli of nanocrystalline Fe, Cu, Ni, and Cu-Ni alloys prepared by mechanical milling/alloying. J. Mater. Res. 1995, 10, 2892–2896. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.P.M.; Geers, M.G.D. Indentation-based damage quantification revisited. Scr. Mater. 2010, 63, 316–319. [Google Scholar] [CrossRef]

- Zapara, M.A.; Tutyshkin, N.D.; Müller, W.H.; Wille, R. Experimental study and modeling of damage of Al alloys using tensor theory. Contin. Mech. Thermodyn. 2010, 22, 99–120. [Google Scholar] [CrossRef]

- Degtyarev, M.V.; Chashchukhina, T.I.; Voronova, L.M. Grain growth in dynamically recrystallized copper during annealing above and below the temperature of thermally activated nucleation. Diagn. Resour. Mech. Mater. Struct. 2016, 5, 15–29. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Sarkar, A.; Kapoor, R.; Chakravartty, J.K.; Ray, R.K.; Suwas, S. Understanding the Mechanism of Dynamic Recrystallization During High-Temperature Deformation in Nb-1Zr-0.1C Alloy. J. Mater. Eng. Perform. 2019, 28, 448–462. [Google Scholar] [CrossRef]

- Gourdet, S.; Montheillet, F. An experimental study of the recrystallization mechanism during hot deformation of aluminium. Mater. Sci. Eng. A 2000, 283, 274–288. [Google Scholar] [CrossRef]

- Rollett, A.D.; Rohrer, G.S.; Humphreys, F.J. Recrystallization and Related Annealing Phenomena; Elsevier: Oxford, UK, 2004; ISBN 9780080982359. [Google Scholar]

- Zamani, M.; Seifeddine, S.; Jarfors, A.E.W. High temperature tensile deformation behavior and failure mechanisms of an Al-Si-Cu-Mg cast alloy—The microstructural scale effect. Mater. Des. 2015, 86, 361–370. [Google Scholar] [CrossRef] [Green Version]

- Bannikov, M.; Bilalov, D.; Oborin, V.; Naimark, O. Damage evolution in the AlMg6 alloy during high and very high cycle fatigue. Frat. Integrita Strut. 2019, 13, 383–395. [Google Scholar] [CrossRef]

- Zhang, K.; Badreddine, H.; Yue, Z.; Hfaiedh, N.; Saanouni, K.; Liu, J. Failure prediction of magnesium alloys based on improved CDM model. Int. J. Solids Struct. 2021, 217–218, 155–177. [Google Scholar] [CrossRef]

- Saanouni, K.; Devalan, P. Damage Mechanics in Metal Forming: Advanced Modeling and Numerical Simulation; John Wiley & Sons Inc.: London, UK, 2012; ISBN 9781118562192. [Google Scholar]

- Karamyshev, A.P.; Nekrasov, I.I.; Nesterenko, A.V.; Parshin, V.S.; Smirnov, S.V.; Fedulov, A.A.; Shveikin, V.P. Studying the damage of ingots under plastic deformation on a lever-type radial forging machine. AIP Conf. Proc. 2016, 1785, 030010. [Google Scholar]

- Versteylen, C.D.; Sluiter, M.H.F.; van Dijk, N.H. Modelling the formation and self-healing of creep damage in iron-based alloys. J. Mater. Sci. 2018, 53, 14758–14773. [Google Scholar] [CrossRef] [Green Version]

- Junaedi, H.; Ibrahim, M.F.; Ammar, H.R.; Samuel, A.M.; Soliman, M.S.; Almajid, A.A.; Samuel, F.H. Effect of testing temperature on the strength and fracture behavior of Al-B4C composites. J. Compos. Mater. 2016, 50, 2871–2880. [Google Scholar] [CrossRef]

- Kurşun, A.; Bayraktar, E.; Enginsoy, H.M. Experimental and numerical study of alumina reinforced aluminum matrix composites: Processing, microstructural aspects and properties. Compos. Part B Eng. 2016, 90, 302–314. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Cui, Z.; Chen, Z.; Chen, D.; Wang, H. Investigation on the high-temperature ductility and fracture mechanisms of an in-situ particle reinforced Al matrix composite 7075Al/TiB2. Mater. Sci. Eng. A 2019, 764, 138263. [Google Scholar] [CrossRef]

- Weck, A.; Wilkinson, D.S.; Maire, E. Observation of void nucleation, growth and coalescence in a model metal matrix composite using X-ray tomography. Mater. Sci. Eng. A 2008, 488, 435–445. [Google Scholar] [CrossRef]

- Tekkaya, A.E.; Bouchard, P.O.; Bruschi, S.; Tasan, C.C. Damage in metal forming. CIRP Ann. 2020, 69, 600–623. [Google Scholar] [CrossRef]

- Smirnov, A.S.; Shveikin, V.P.; Smirnova, E.O.; Belozerov, G.A.; Konovalov, A.V.; Vichuzhanin, D.I.; Muizemnek, O.Y. Effect of silicon carbide particles on the mechanical and plastic properties of the AlMg6/10% SiC metal matrix composite. J. Compos. Mater. 2018, 52, 3351–3363. [Google Scholar] [CrossRef]

- Konovalov, D.A.; Veretennikova, I.A.; Bykova, T.M.; Michurov, N.S. Development of an Approach to Determining the Representative Volume Element of the Al/SiC Metal Matrix Composite Material Fabricated by Squeeze Casting. Russ. Metall. 2020, 2020, 738–745. [Google Scholar] [CrossRef]

| Material | Density, g/cm3 | Porosity, % | |

|---|---|---|---|

| Experimental | Calculated | ||

| V95\10% SiC | 2.85 | 2.86 | 0.30 |

| V95\0% SiC | 2.81 | - | 0.12 |

| V95 alloy | 2.82 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smirnov, A.; Smirnova, E.; Konovalov, A.; Kanakin, V. Using the Instrumented Indentation Technique to Determine Damage in Sintered Metal Matrix Composites after High-Temperature Deformation. Appl. Sci. 2021, 11, 10590. https://doi.org/10.3390/app112210590

Smirnov A, Smirnova E, Konovalov A, Kanakin V. Using the Instrumented Indentation Technique to Determine Damage in Sintered Metal Matrix Composites after High-Temperature Deformation. Applied Sciences. 2021; 11(22):10590. https://doi.org/10.3390/app112210590

Chicago/Turabian StyleSmirnov, Alexander, Evgeniya Smirnova, Anatoly Konovalov, and Vladislav Kanakin. 2021. "Using the Instrumented Indentation Technique to Determine Damage in Sintered Metal Matrix Composites after High-Temperature Deformation" Applied Sciences 11, no. 22: 10590. https://doi.org/10.3390/app112210590

APA StyleSmirnov, A., Smirnova, E., Konovalov, A., & Kanakin, V. (2021). Using the Instrumented Indentation Technique to Determine Damage in Sintered Metal Matrix Composites after High-Temperature Deformation. Applied Sciences, 11(22), 10590. https://doi.org/10.3390/app112210590