Optical In-Process Measurement: Concepts for Precise, Fast and Robust Optical Metrology for Complex Measurement Situations

Abstract

1. Introduction

- In situ surface metrology: Measurement of the workpiece surface is carried out on the same work floor and in the same manufacturing environment, without isolating the workpiece from the manufacturing environment.

- In-line/On-line surface metrology: Measurement of the workpiece surface is carried out on a production line without moving the workpiece outside the production line.

- On-machine surface metrology: Measurement of the workpiece surface is carried out on a manufacturing machine where the workpiece is manufactured.

- In-process surface metrology: The on-machine measurement of the workpiece surface is carried out while the manufacturing process is taking place.

- Post-process measurement: The measurement occurs after the finished workpiece is removed from the machine. A typical scenario is a measurement using a coordinate measuring machine to inspect the finished workpiece. Post-process measurements usually can afford time-consuming procedures and dedicated inspection areas, e.g., with vibration isolation, constant temperature or the like and is thus often used for high precision metrology that is not applicable in a production environment.

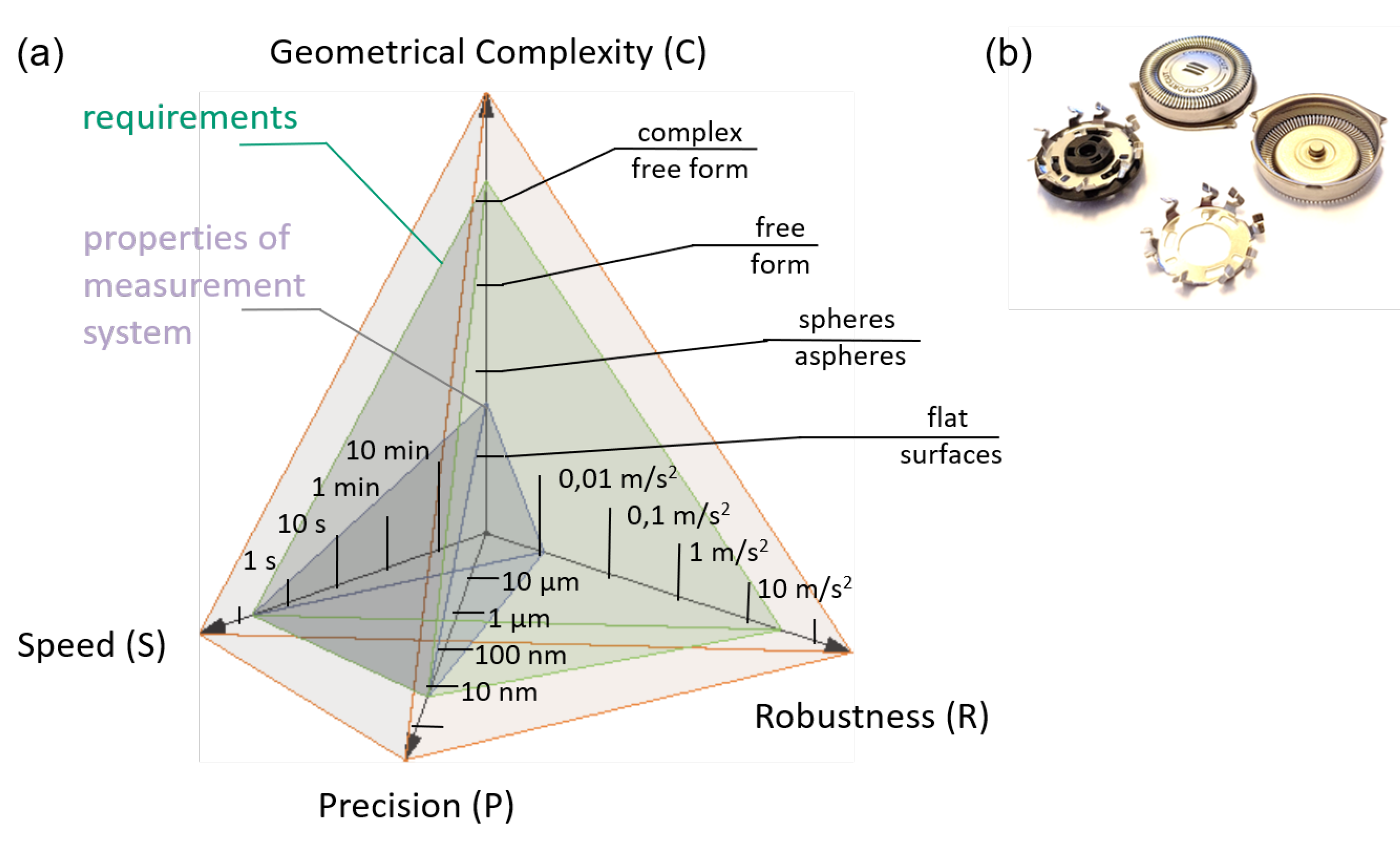

2. Methods and Scope of Approaches for In-Process Optical Metrology

3. Selected Results of Optical Metrology Techniques

3.1. Techniques Based on Interferometry

3.1.1. Rapid Holographic Shape Measurement of Micro Parts

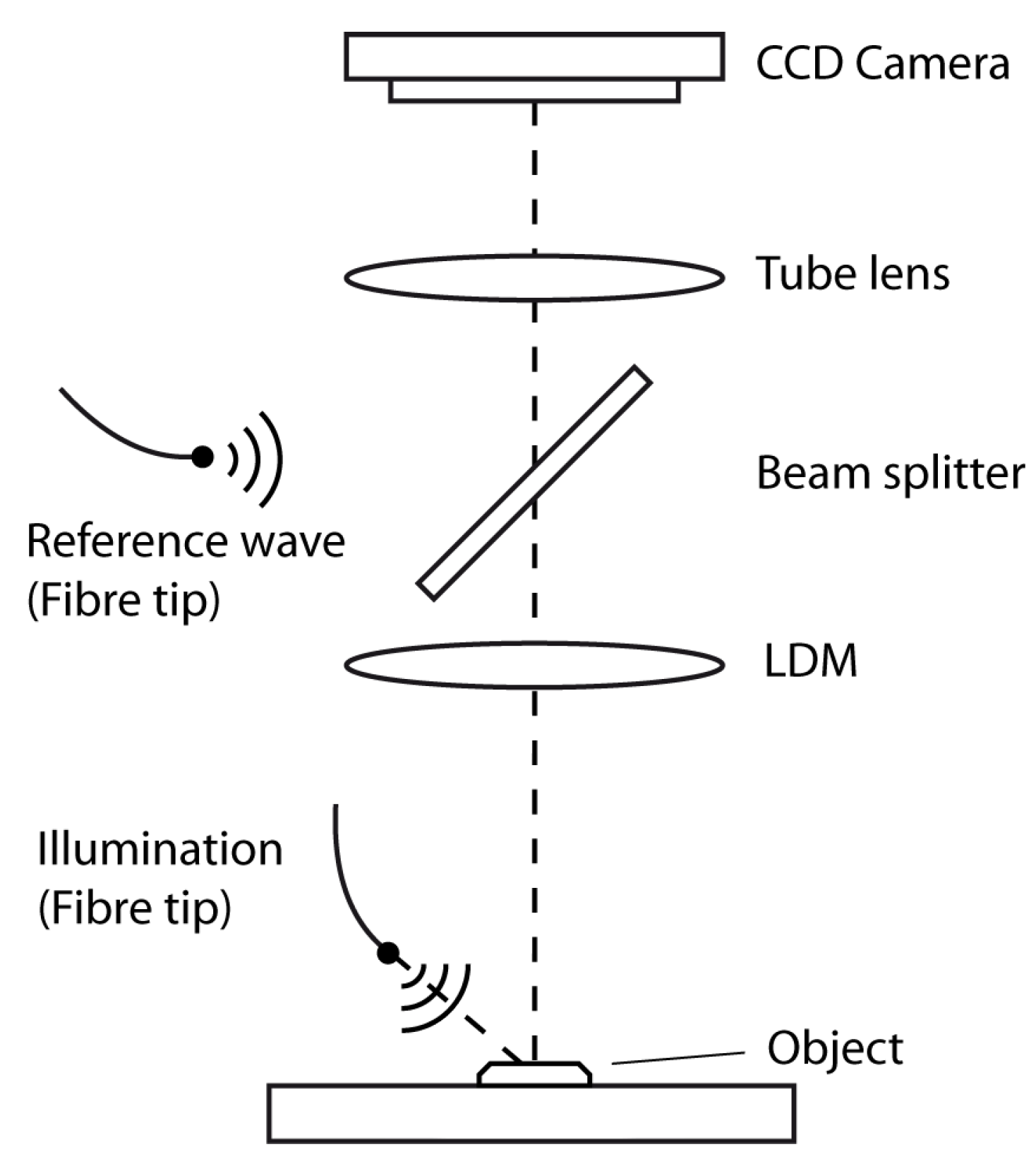

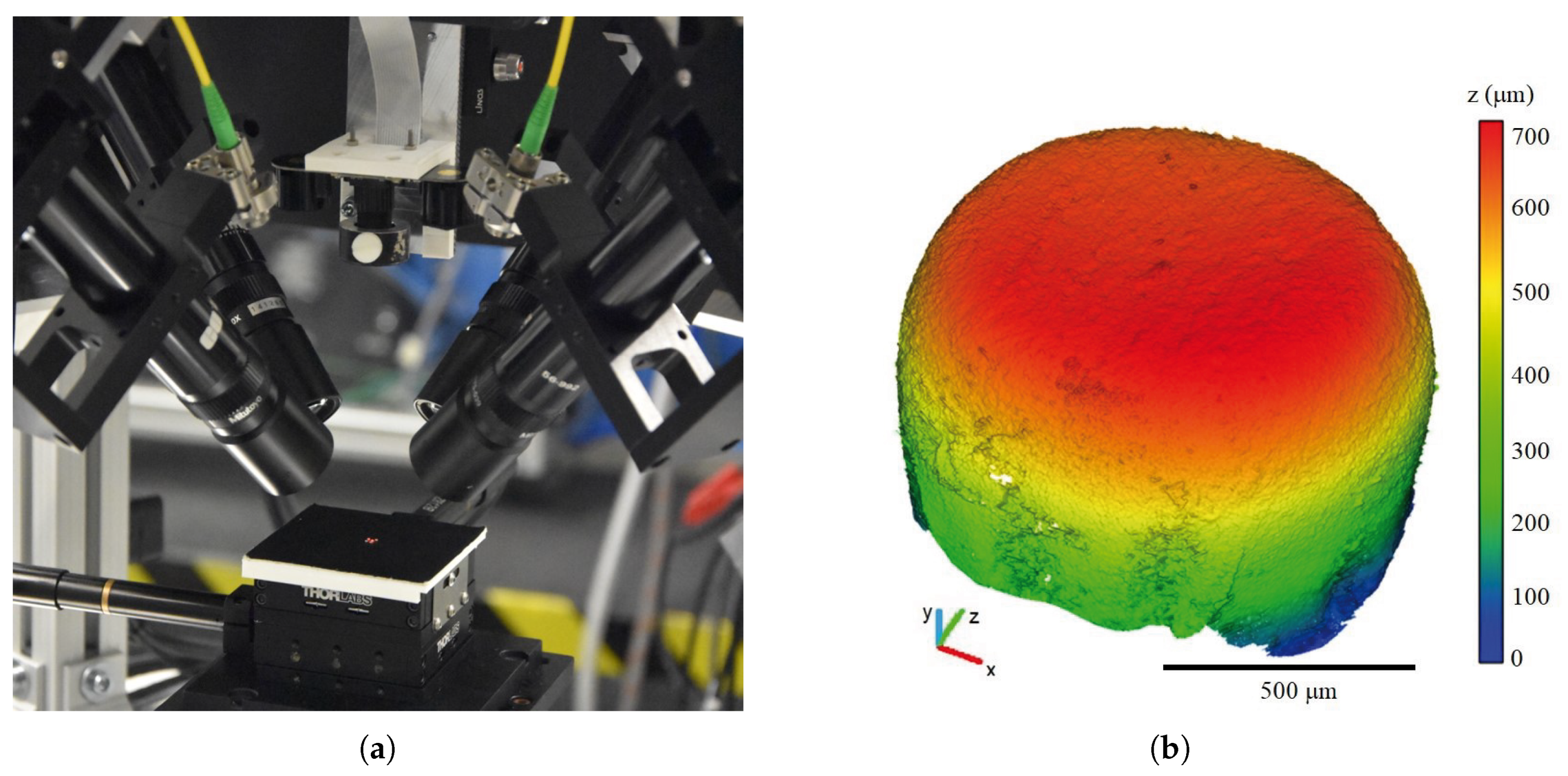

Multiple Simultaneous Viewing Directions Using Four Digital Holographic Microscopes (MuVie)

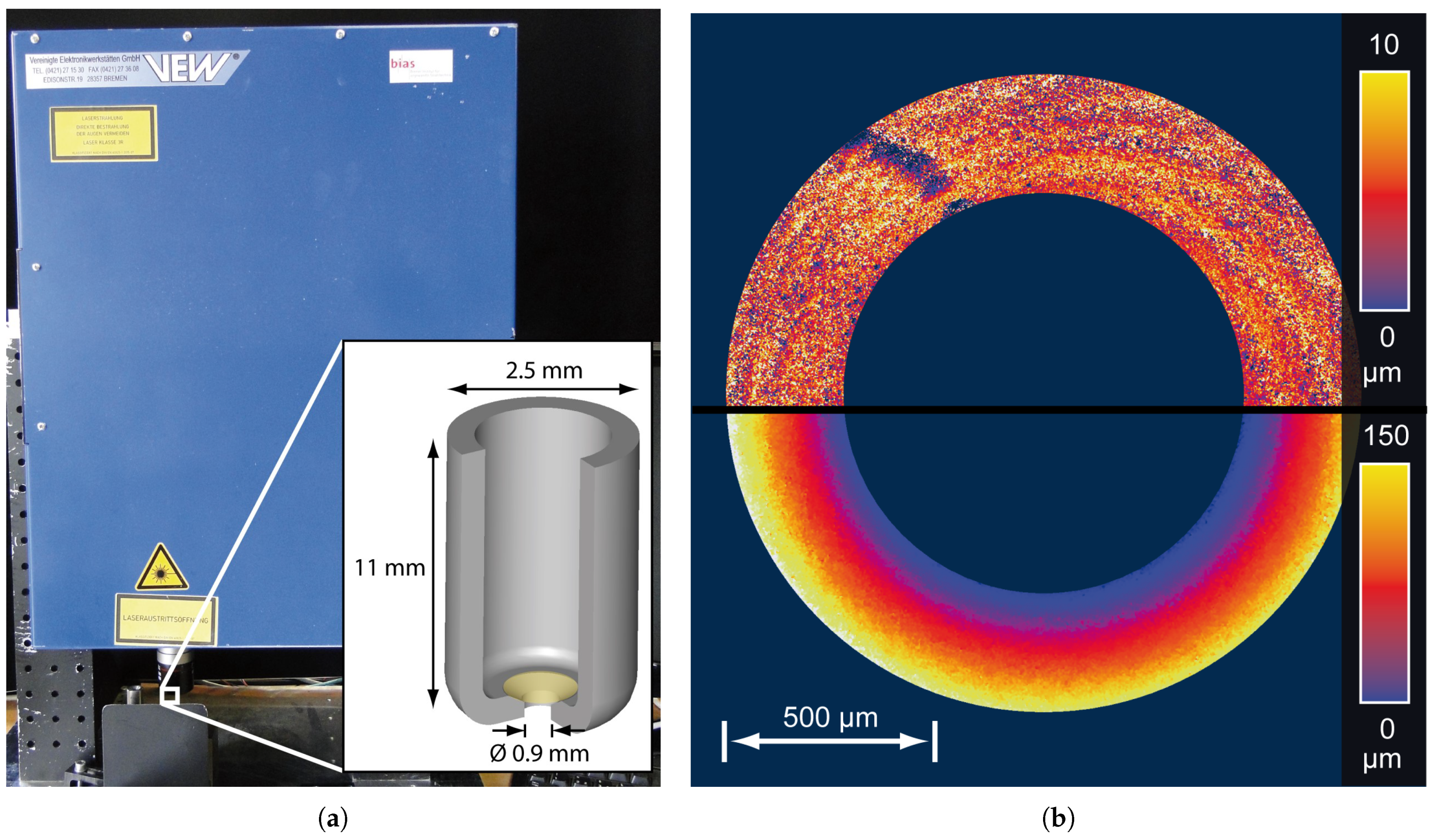

Investigation of Functional Surfaces within the Cavity of a Micro Component

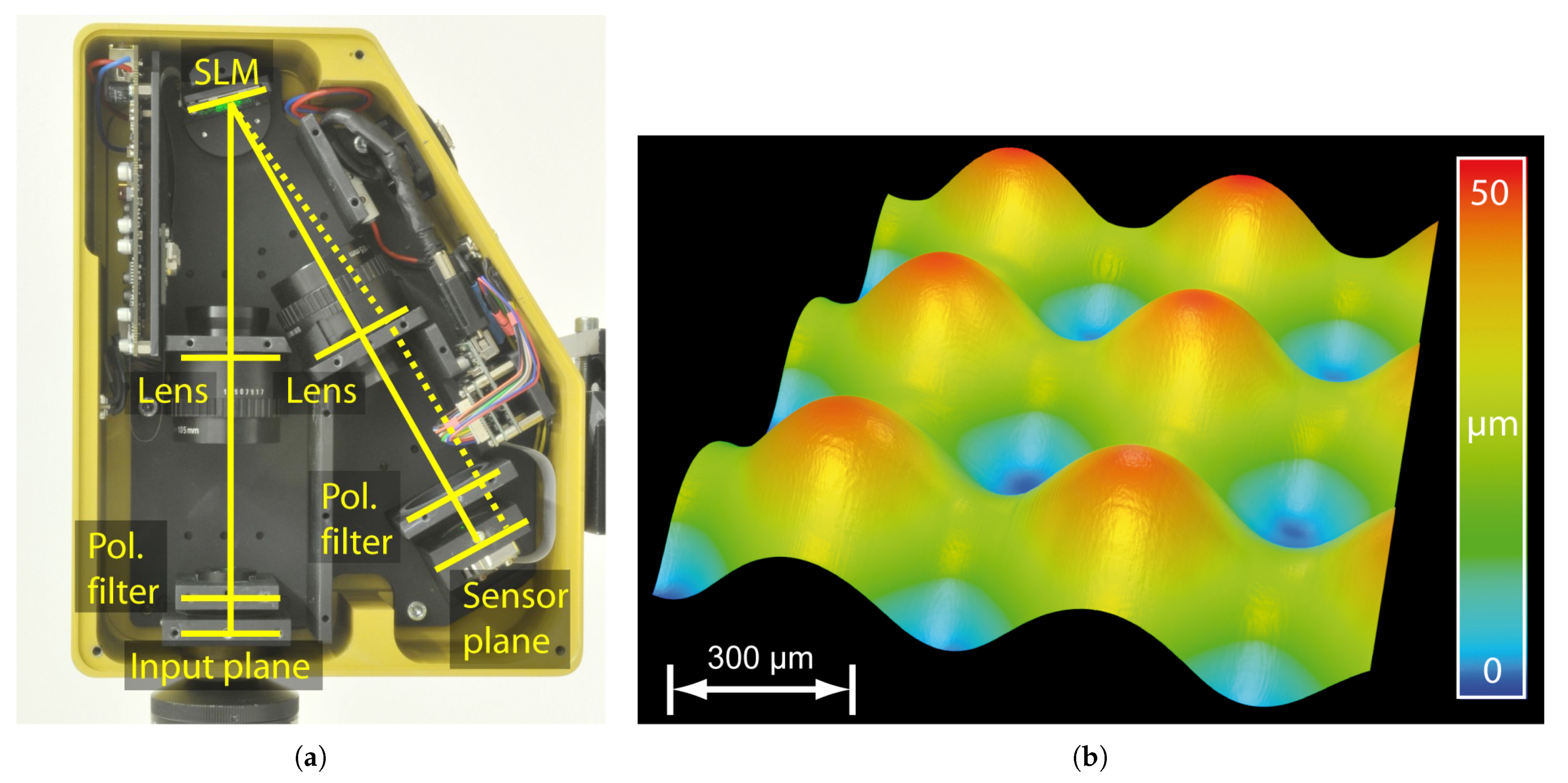

3.1.2. Robust Interferometric Inspection Using Computational Shear Interferometry (COSI)

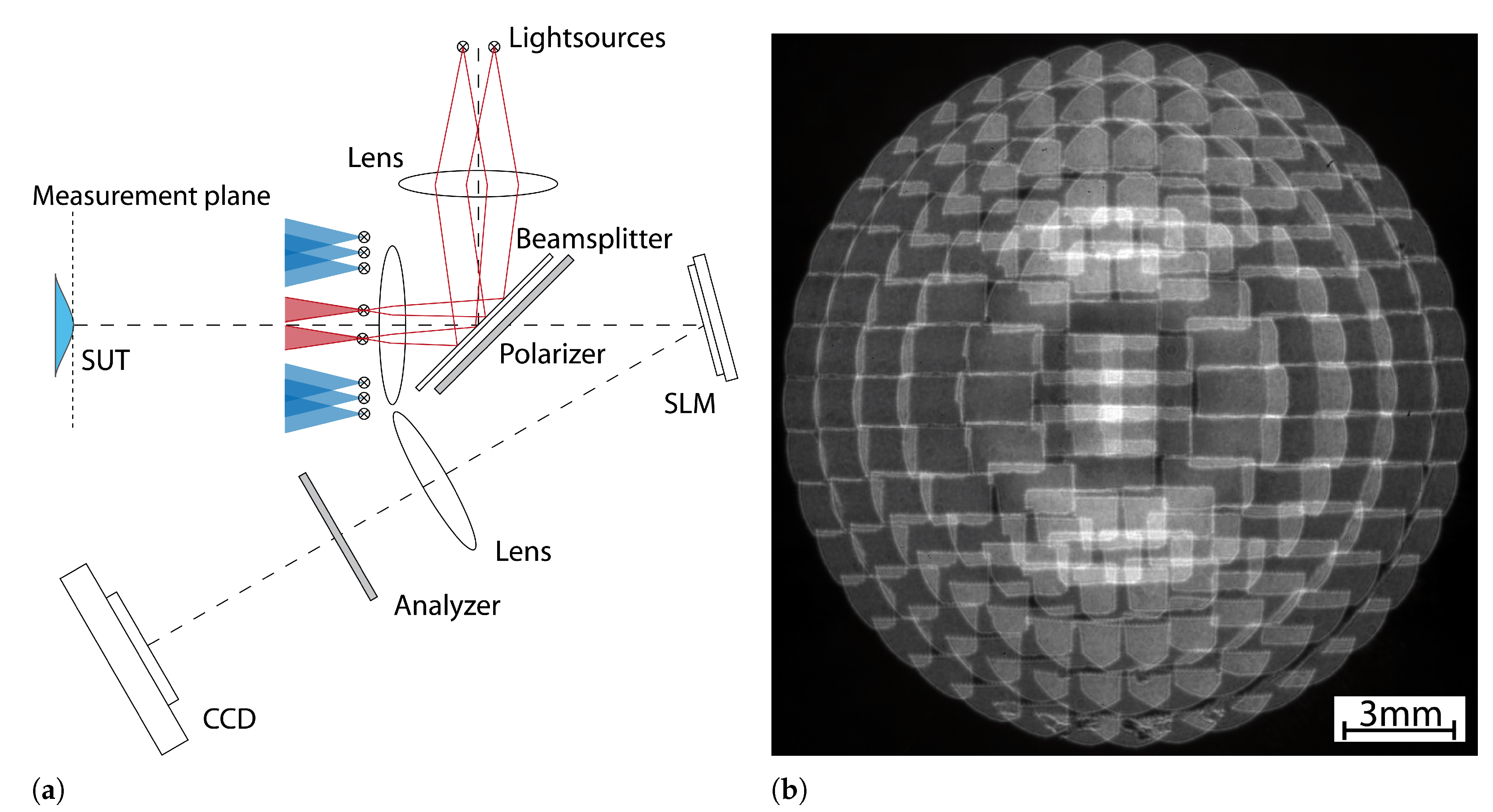

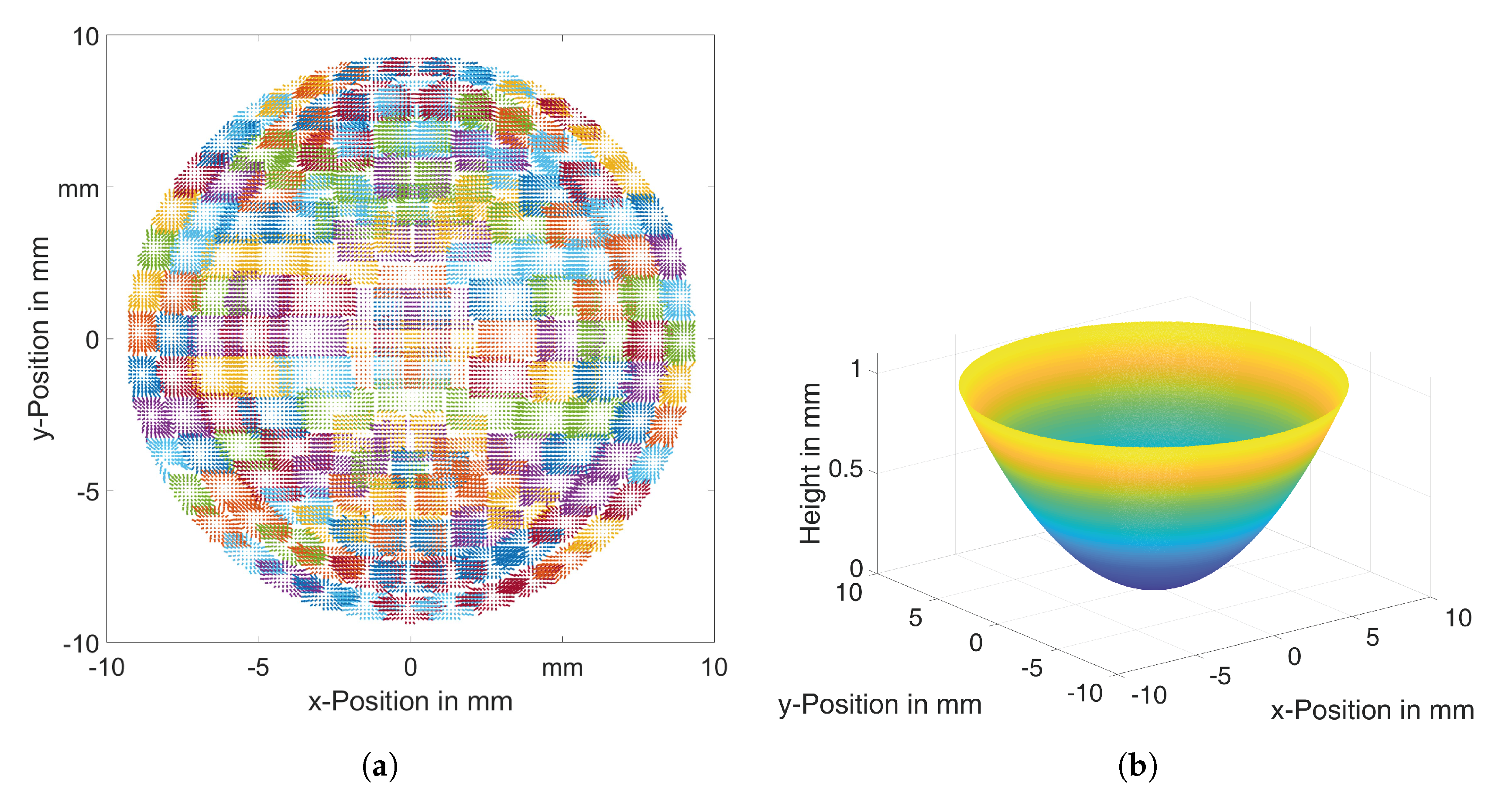

3.1.3. Multiple Aperture Shear Interferometry (MArS)

3.2. Techniques Based on Geometrical Optics Suitable for In-Process and In Situ Applications

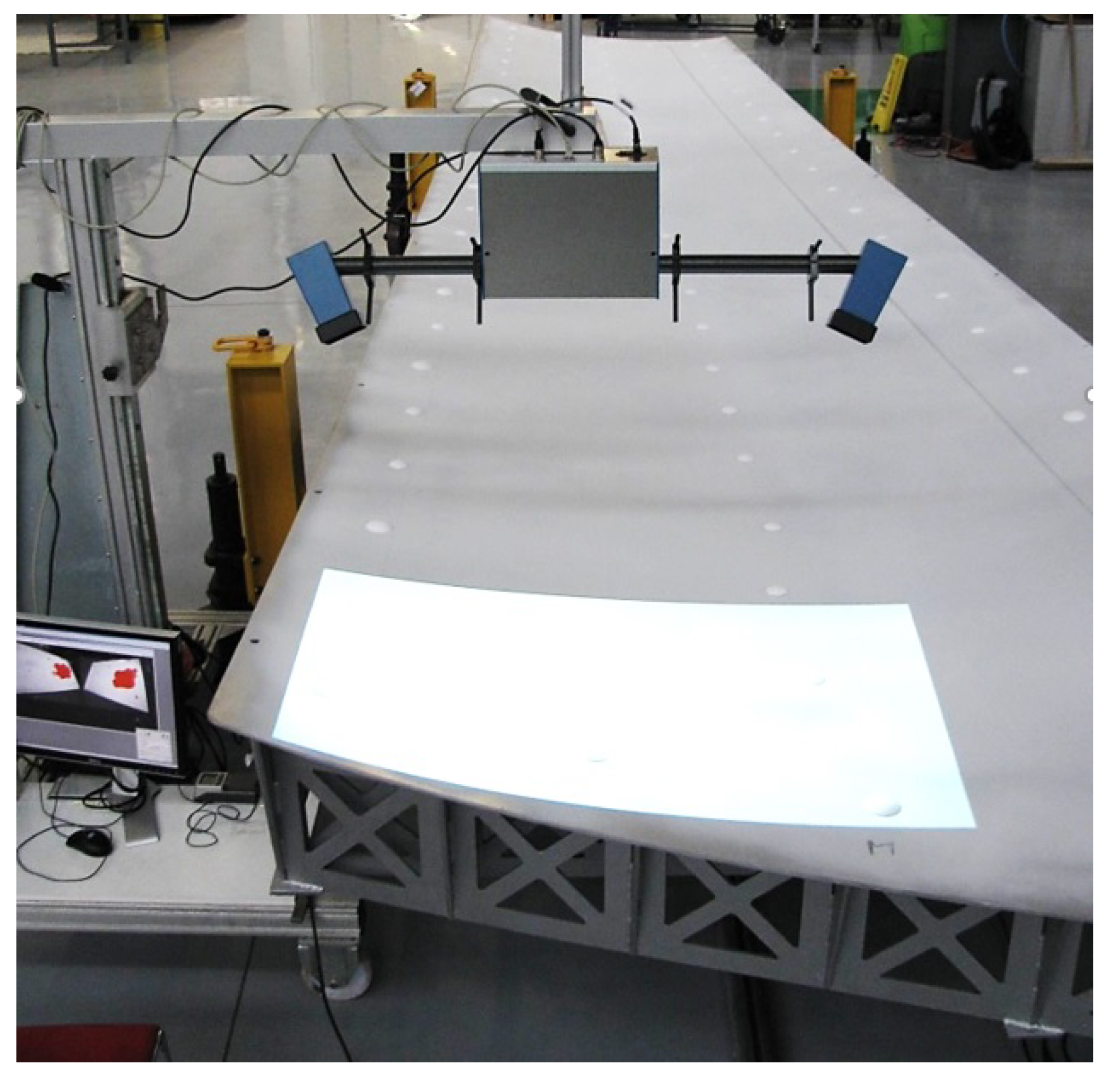

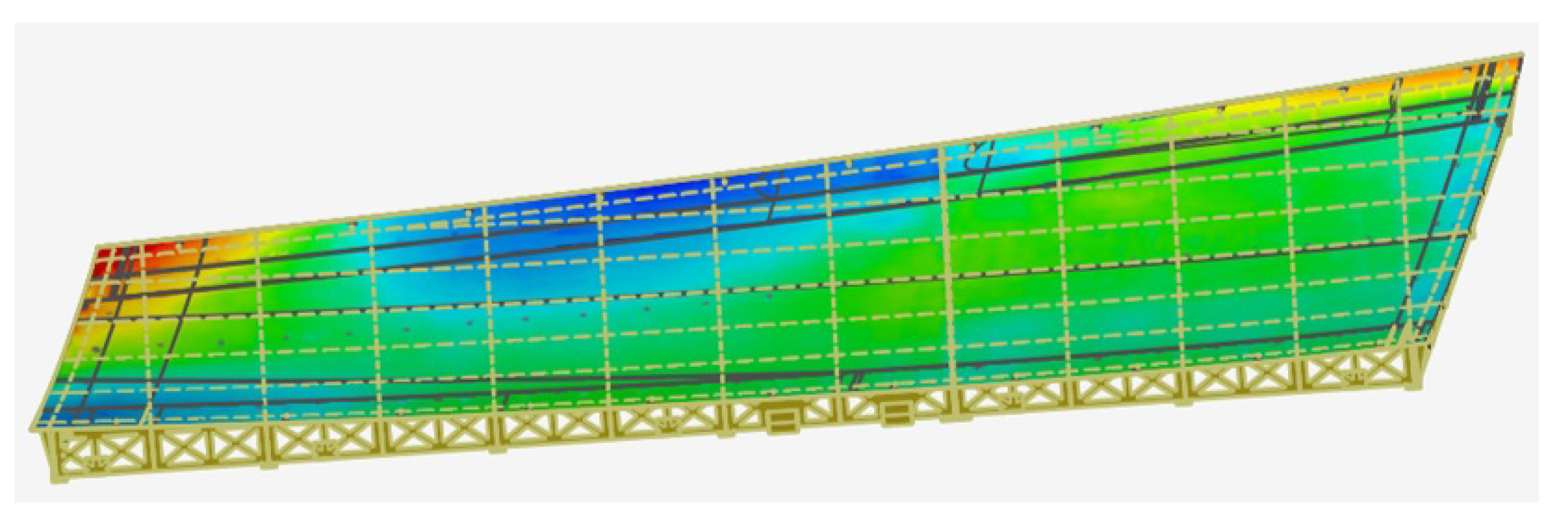

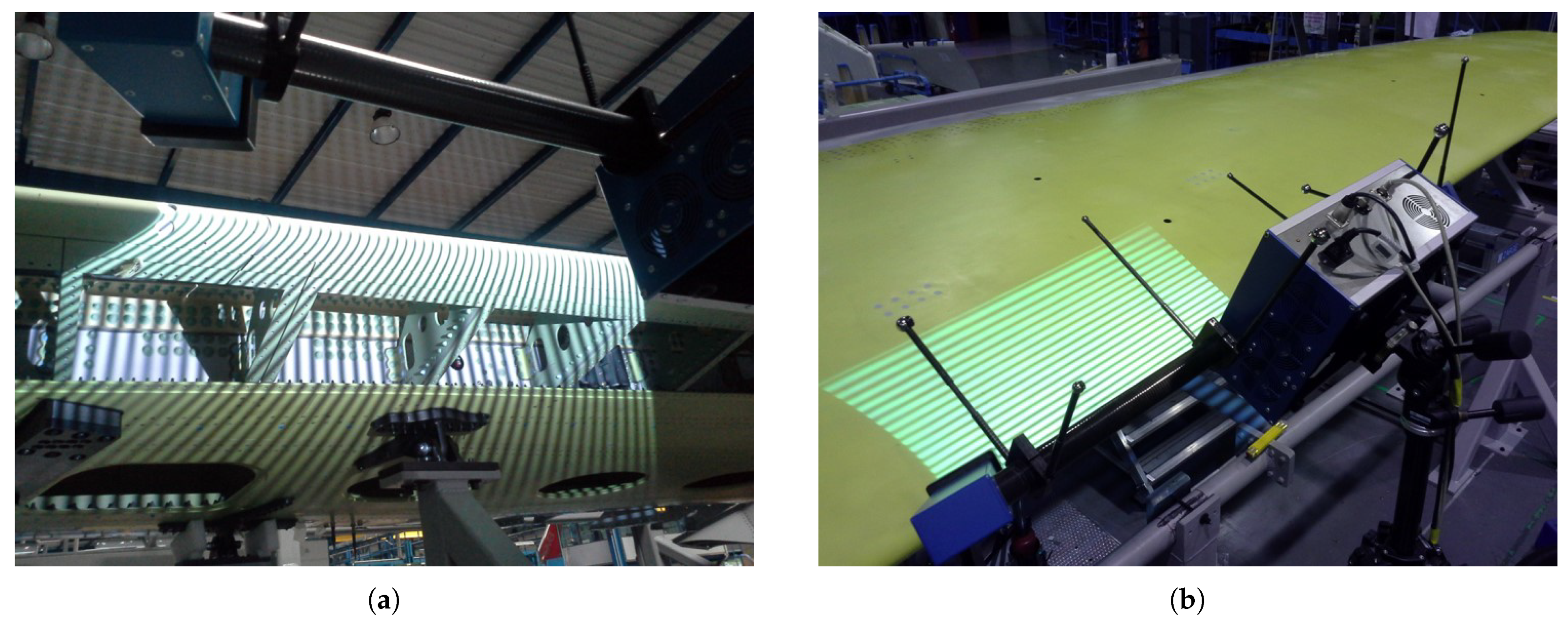

3.2.1. Measurement of Wing Shapes Using Fringe Projection

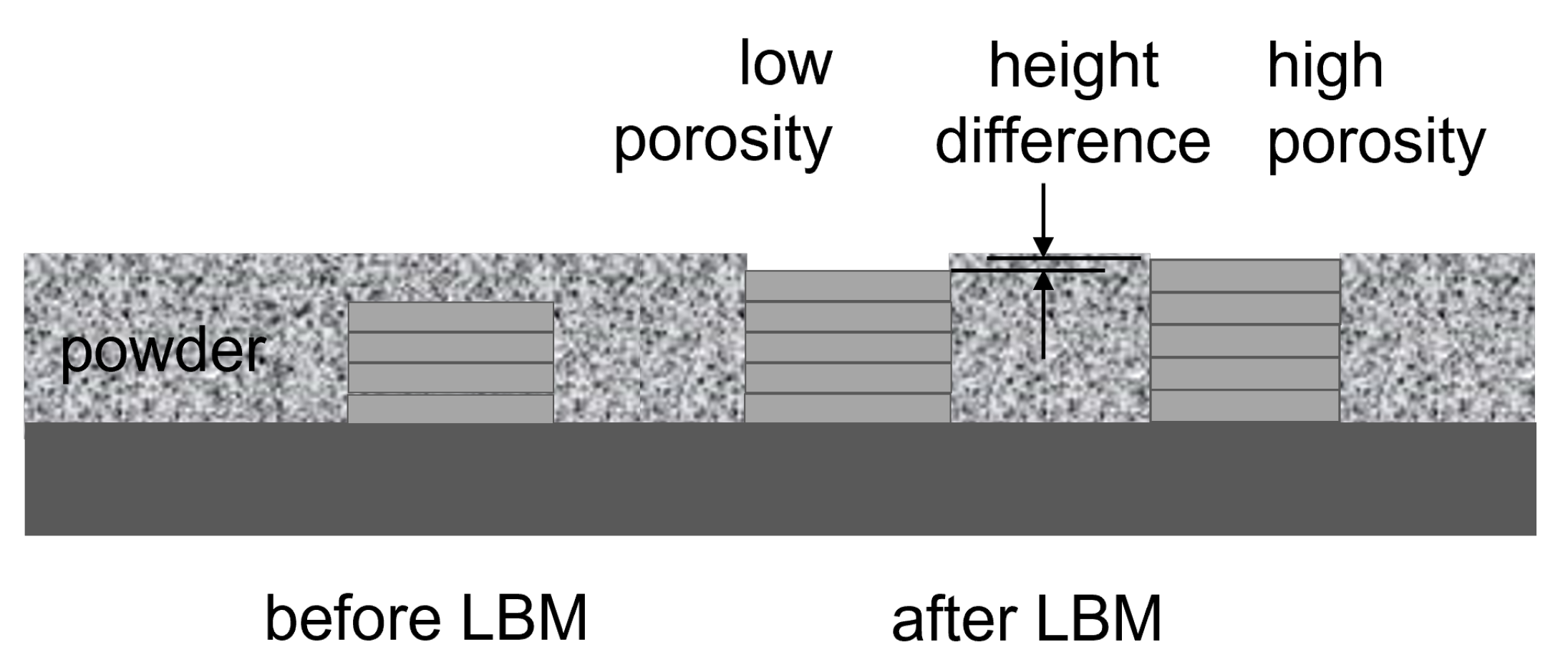

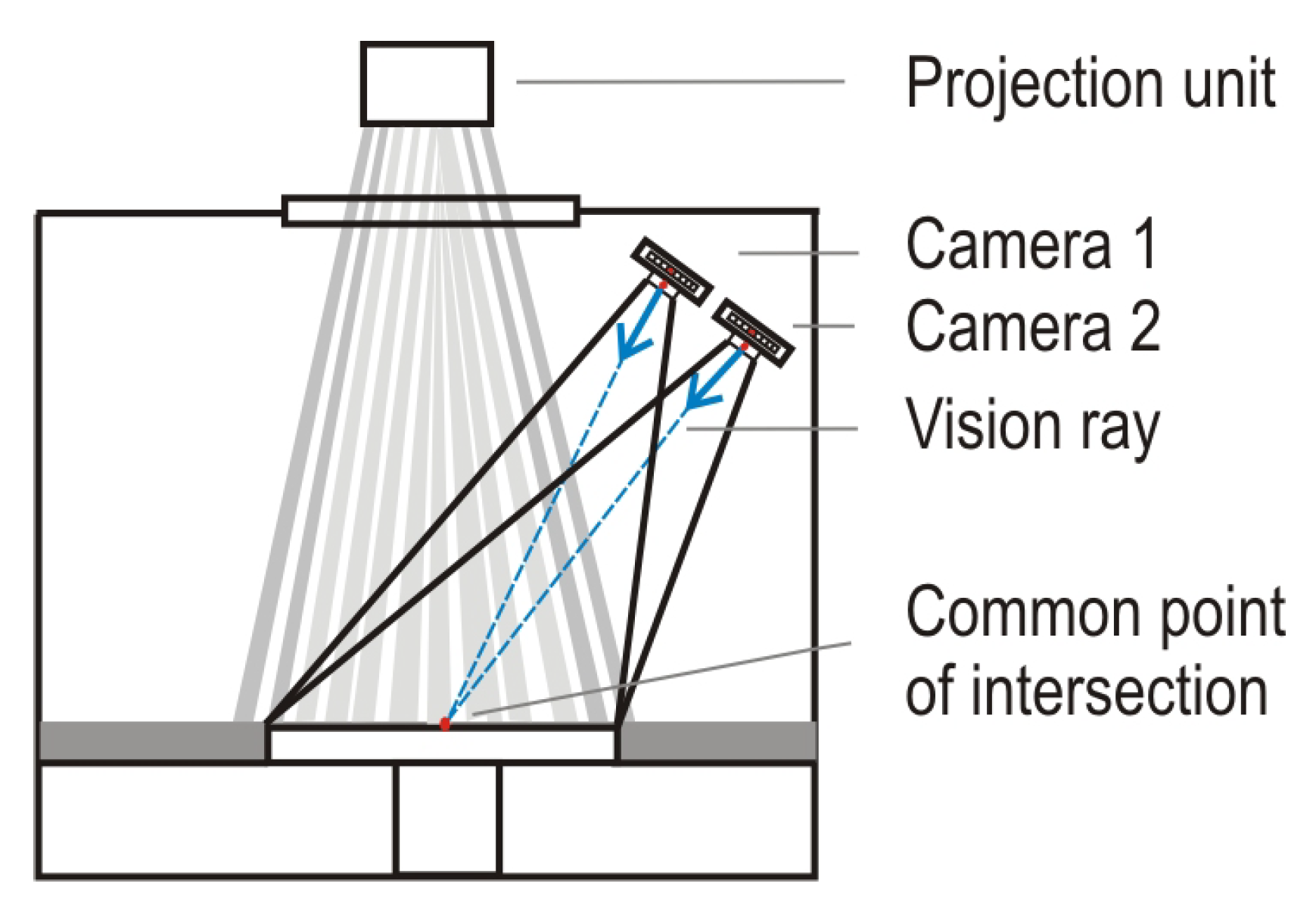

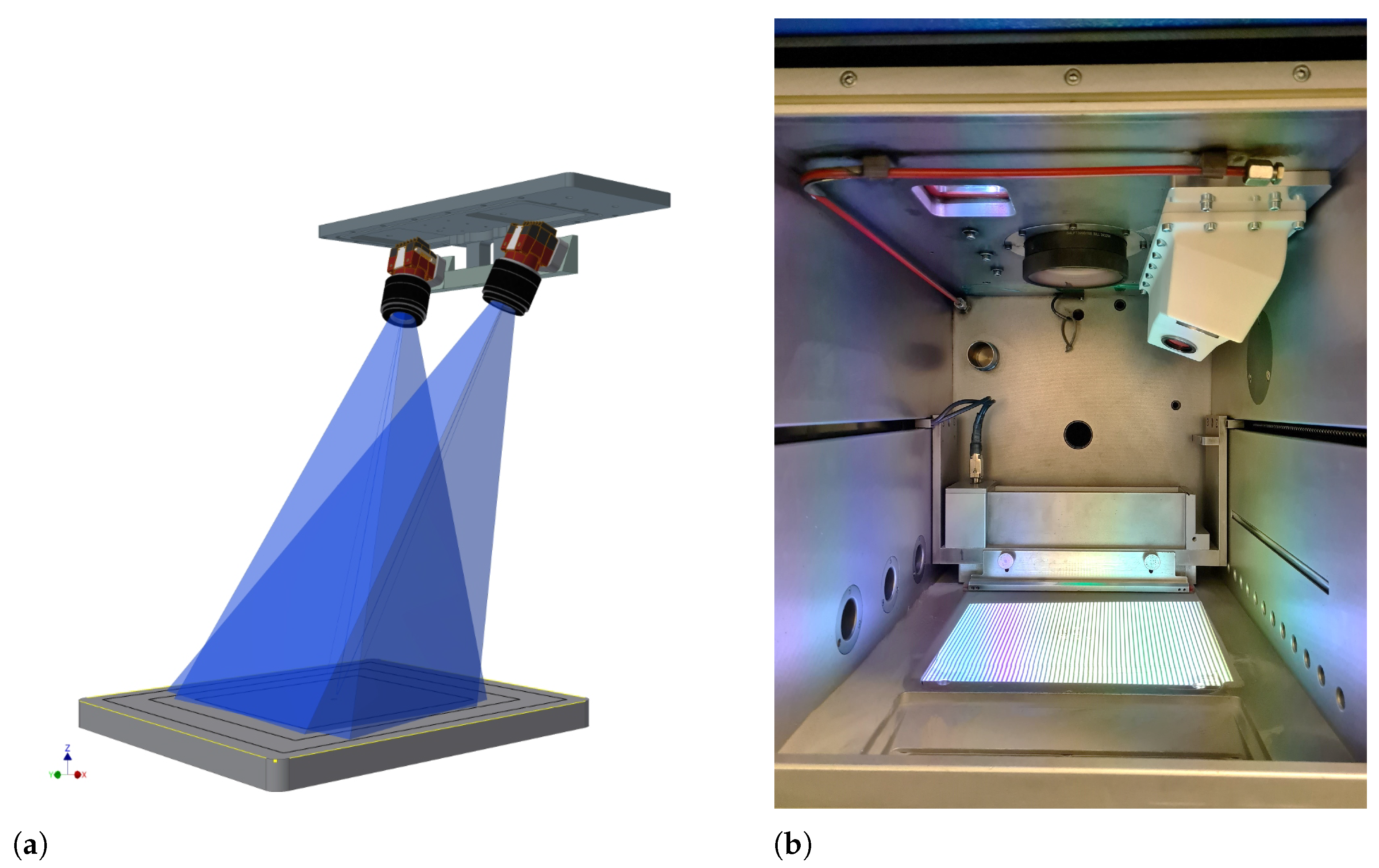

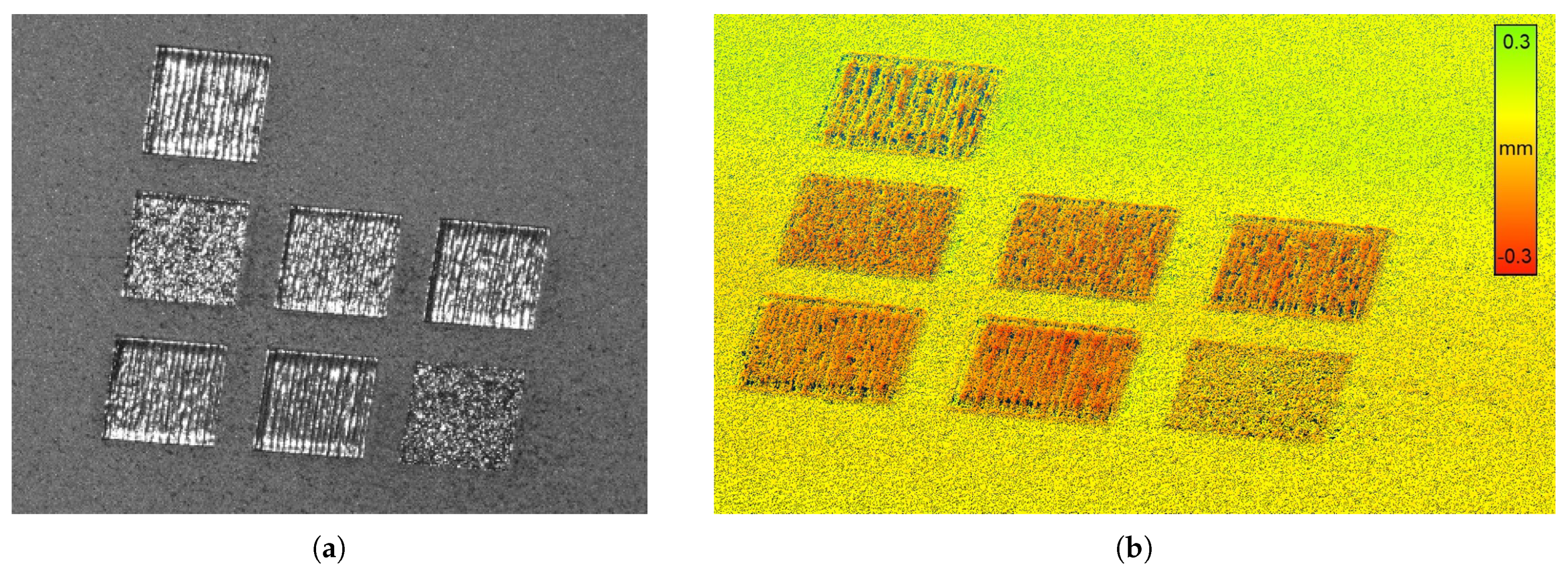

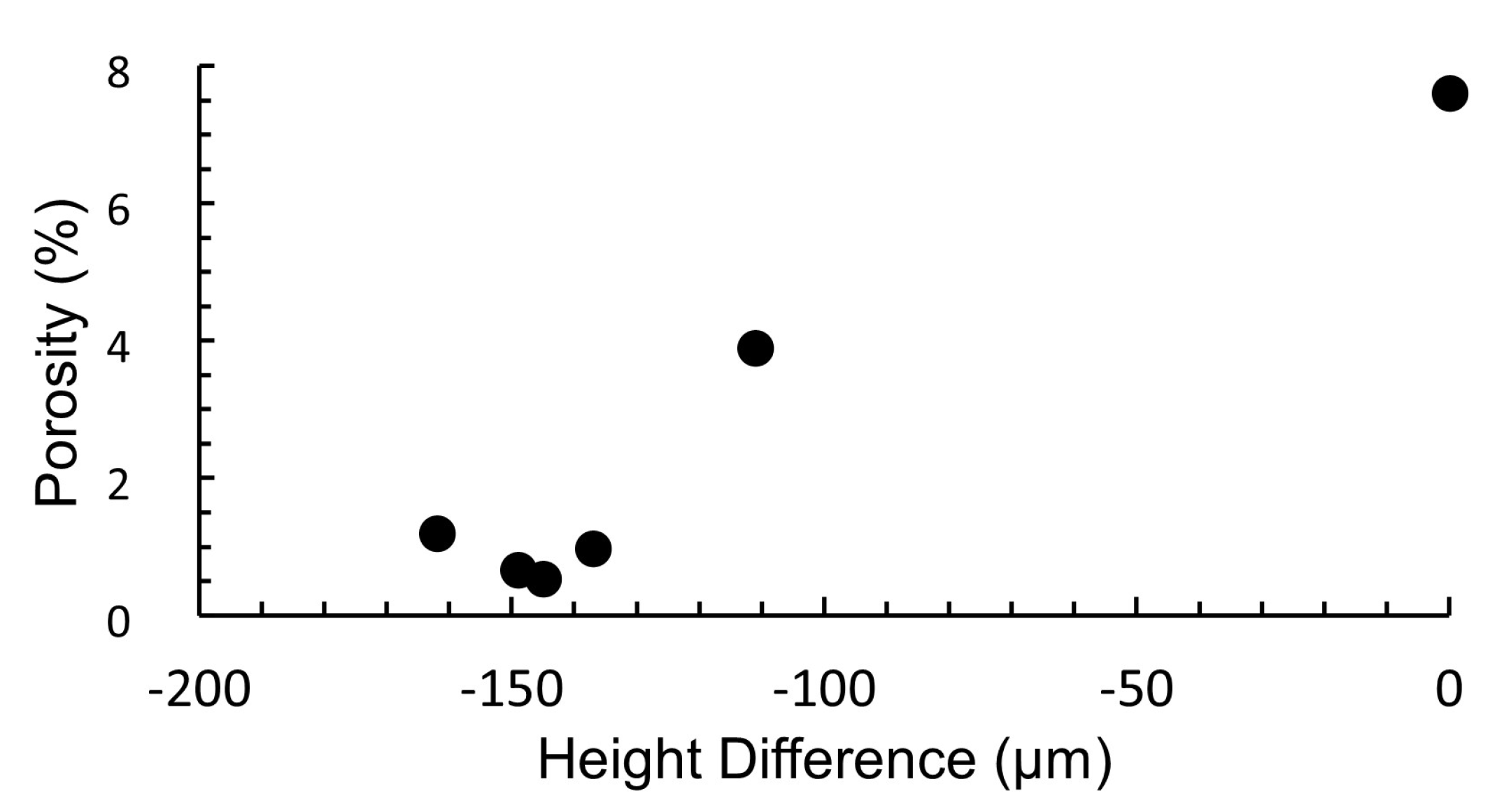

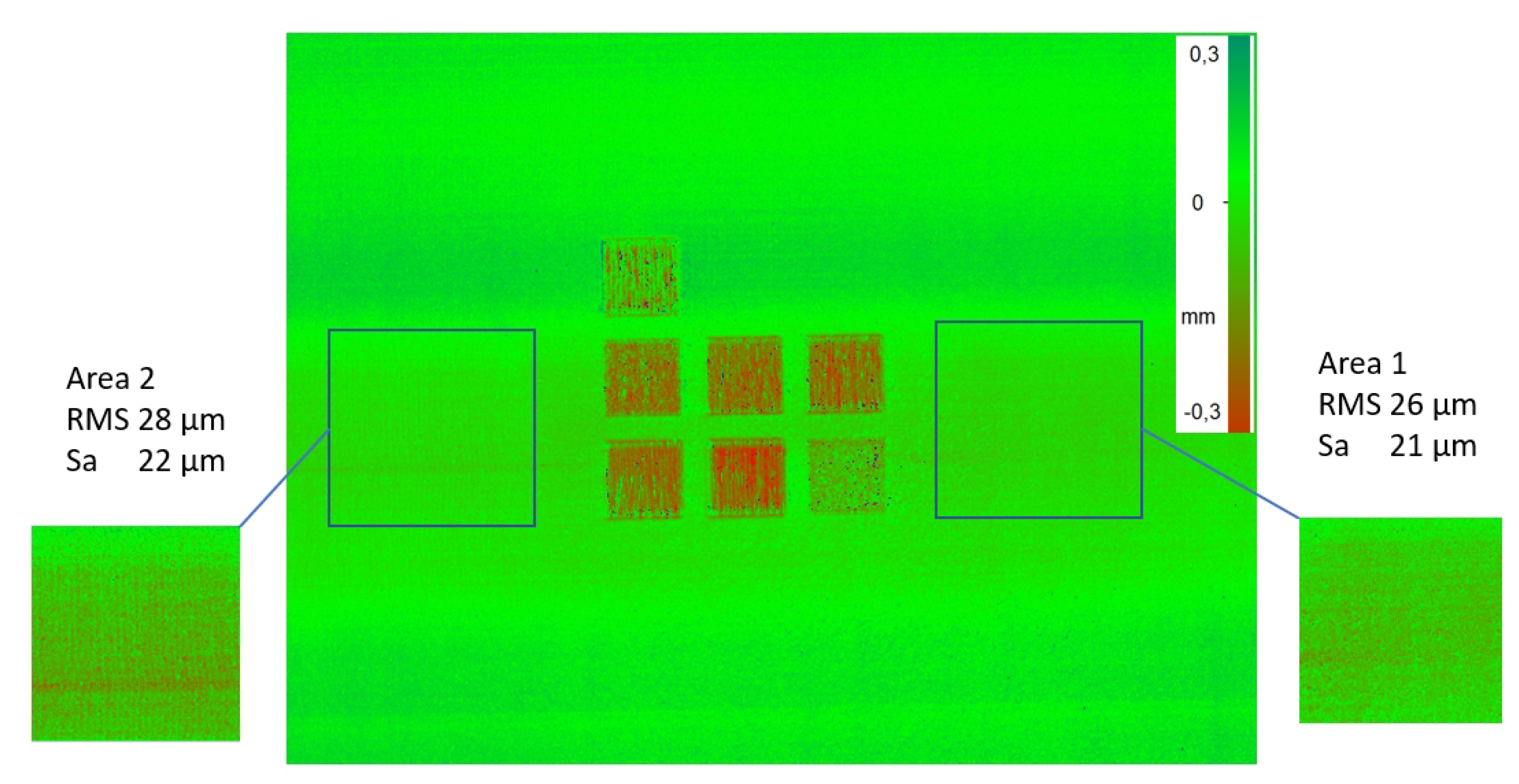

3.2.2. In-Process Measurement and Evaluation of Laser Added Manufacturing Processes for Metals

4. Discussion

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| CoSi | Computational Shear Interferometry |

| DH | Digital Holography |

| FP | Fringe Projection |

| MArS | Multiple Aperture Shear Interferometry |

| MuVie | Multiple Viewing Direction Digital Holographic Microscopy |

| NA | Numerical Aperture |

| PBF-LB/M | Laser-based Powder Bed Fusion of Metals |

| SF | Structure Function |

| SLM | Spatial Light Modulator |

| SUT | Surface Under Test |

| X-CT | X-Ray Computed Tomography |

Appendix A

| Sample Location | ||||||

|---|---|---|---|---|---|---|

| Row | Middle | Lower | ||||

| Position in Row | Left | Center | Right | Left | Center | Right |

| laser power (W) | 110 | 140 | 170 | 170 | 200 | 80 |

| scanning speed (mm/s) | 500 | 500 | 500 | 400 | 400 | 500 |

| mean height (m) | −111 | −145 | −149 | −137 | −162 | 0 |

| degree of porosity (%) | 3.9 | 0.53 | 0.66 | 0.97 | 1.2 | 7.6 |

References

- Gao, W.; Haitjema, H.; Fang, F.Z.; Leach, R.K.; Cheung, C.F.; Savio, E.; Linares, J.M. On-machine and in-process surface metrology for precision manufacturing. CIRP Ann. Manuf. Technol. 2019, 68, 843–866. [Google Scholar] [CrossRef]

- Shimizu, Y.; Chen, L.C.; Kim, D.W.; Chen, X.; Li, X.; Matsukuma, H. An insight into optical metrology in manufacturing. Meas. Sci. Technol. 2021, 32, 042003. [Google Scholar] [CrossRef]

- Vacharanukul, K.; Mekid, S. In-process dimensional inspection sensors. Measurement 2005, 38, 204–218. [Google Scholar] [CrossRef]

- Takaya, Y. In-Process and On-Machine Measurement of Machining Accuracy for Process and Product Quality Management: A Review. Int. J. Automat. Technol. 2014, 8, 566–590. [Google Scholar] [CrossRef]

- Bergmann, R.B. Computational Optical Metrology. In Proceedings of the International Conference on Optical and Photonic Engineering (icOPEN 2016), Chengdu, China, 26–30 September 2016; p. 13. [Google Scholar]

- de Groot, P. Principles of interference microscopy for the measurement of surface topography. Adv. Opt. Photon. 2015, 7, 1–65. [Google Scholar] [CrossRef]

- de Groot, P. Vibration in phase-shifting interferometry. J. Opt. Soc. Am. A 1995, 12, 354–365. [Google Scholar] [CrossRef]

- Albertazzi, A. Interferometry in harsh environments. In Optical Imaging and Metrology; Osten, W., Reingand, N., Eds.; Wiley-VCH: Weinheim, Germany, 2012; pp. 369–391. [Google Scholar]

- Häusler, G.; Leuchs, G. Physikalische Grenzen der optischen Formerfassung mit Licht. Physikalische Blätter 1997, 53, 417–422. [Google Scholar] [CrossRef]

- Pavliček, P.; Häusler, G. Methods for Optical Shape Measurement and their Measurement Uncertainty. Optomechatronics 2014, 8, 292–303. [Google Scholar] [CrossRef]

- Schnars, U.; Falldorf, C.; Watson, J.; Jüptner, W. Digital Holography and Wavefront Sensing; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Fischer, A. Fisher information and Cramér-Rao bound for unknown systematic errors. Measurement 2018, 113, 131–136. [Google Scholar] [CrossRef]

- Yoshizawa, T. Handbook of Optical Metrology; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Bergmann, R.B.; Bothe, T.; Falldorf, C.; Huke, P.; Kalms, M.; von Kopylow, C. Optical Metrology and Optical Non-Destructive Testing from the Perspective of Object Characteristics. In Proceedings of the SPIE 7791, Interferometry XV: Applications, San Diego, CA, USA, 4–5 August 2010; p. 779102. [Google Scholar]

- Bergmann, R.B.; Huke, P. Advanced methods for optical non-destructive testing. In Optical Imaging and Metrology–Advanced Technologies; Osten, W., Reingand, N., Eds.; Wiley-VCH: Weinheim, Germany, 2012; pp. 393–412. [Google Scholar]

- Schuth, M.; Buerakov, W. (Eds.) Handbuch Optische Messtechnik–Praktische Anwendungen für Entwicklung, Versuch, Fertigung und Qualitätssicherung; Hanser: Munich, Germany, 2017. [Google Scholar]

- Harding, K. (Ed.) Handbook of Optical Dimensional Metrology; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Elandaloussi, F.; Mueller, B.; Osten, W. Determination of technological parameters in strip mining by time-of-flight and image processing. In Proceedings of the Optical Measurement Systems for Industrial Inspection, Munich, Germany, 16–17 June 1999; pp. 346–352. [Google Scholar] [CrossRef]

- Sirohi, R.S. Introduction to Optical Metrology; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Bergmann, R.B.; Burke, J.; Falldorf, C. Precision optical metrology without lasers. In Proceedings of the International Conference on Optical and Photonic Engineering (icOPEN 2015), Singapore, 14–16 April 2015; Volume 9524, p. 952403. [Google Scholar]

- Agour, M.; von Freyberg, A.; Staar, B.; Falldorf, C.; Fischer, A.; Lütjen, M.; Freitag, M.; Goch, G.; Bergmann, R.B. Quality inspection and logistic quality assurance of micro technical manufacturing processes. In Cold Micro Metal Forming; Vollertsen, F., Kuhfuß, B., Thomy, C., Friedrich, S., Maaß, P., Zoch, H.W., Eds.; Springer Nature: Cham, Switzerland, 2020; pp. 256–274. [Google Scholar]

- Agour, M.; Falldorf, C.; Bergmann, R. Spatial multiplexing and autofocus in holographic contouring for inspection of micro-parts. Opt. Express 2018, 26, 28576–28588. [Google Scholar] [CrossRef]

- Simic, A.; Falldorf, C.; Bergmann, R. Internal Inspection of Micro Deep Drawing Parts Using Digital Holography. In Proceedings of the Imaging and Applied Optics 2016, Heidelberg, Germany, 25–28 July 2016; Optical Society of America: Washington, DC, USA, 2016; p. DW1H.3. [Google Scholar]

- Falldorf, C.; Huferath-von Luepke, S.; von Kopylow, C.; Bergmann, R.B. Reduction of speckle noise in multiwavelength contouring. App. Opt. 2012, 51, 8211–8215. [Google Scholar] [CrossRef] [PubMed]

- Agour, M.; Falldorf, C.; Staar, B.; von Freyberg, A.; Fischer, A.; Lütjen, M.; Bergmann, R.B. Fast Quality Inspection of Micro Cold Formed Parts using Telecentric Digital Holographic Microscopy. In Proceedings of the MATEC Web of Conferences, Auckland, New Zealand, 4–8 February 2018; EDP Sciences: Les Ulis, France, 2018; Volume 190, p. 15008. [Google Scholar]

- De Groot, P.; Kishner, S. Synthetic wavelength stabilization for two-color laser-diode interferometry. Appl. Opt. 1991, 30, 4026–4033. [Google Scholar] [CrossRef]

- Goodman, J.W. Introduction to Fourier Optics, 3rd ed.; Roberts and Company: Englewood, CO, USA, 2005. [Google Scholar]

- Falldorf, C.; von Kopylow, C.; Bergmann, R.B. Wave field sensing by means of computational shear interferometry. J. Opt. Soc. Am. A 2013, 30, 1905–1912. [Google Scholar] [CrossRef] [PubMed]

- Falldorf, C.; Agour, M.; Bergmann, R.B. Digital holography and quantitative phase contrast imaging using computational shear interferometry. Opt. Eng. 2015, 54, 024110. [Google Scholar] [CrossRef]

- Falldorf, C.; Kopylow, C.; Juptner, W. Compact lateral shearing interferometer to determine continuous wave fronts. In Proceedings of the 2007 3DTV Conference, Kos, Greece, 7–9 May 2007; pp. 1–4. [Google Scholar]

- Falldorf, C.; Osten, S.; Kopylow, C.V.; Jüptner, W. Shearing interferometer based on the birefringent properties of a spatial light modulator. Opt. Lett. 2009, 34, 2727–2729. [Google Scholar] [CrossRef]

- Hariharan, P.; Oreb, B.F.; Eiju, T. Digital phase-shifting interferometry: A simple error-compensating phase calculation algorithm. Appl. Opt. 1987, 26, 2504–2506. [Google Scholar] [CrossRef]

- Burge, J.H. Applications of computer-generated holograms for interferometric measurement of large aspheric optics. In Proceedings of the International Conference on Optical Fabrication and Testing, Tokyo, Japan, 2 August 1995; International Society for Optics and Photonics: Bellingham, WA, USA, 1995; Volume 2576, pp. 258–269. [Google Scholar]

- Falldorf, C. Taking the next step: The advantage of spatial covariance in optical metrology. In Proceedings of the Imaging and Applied Optics 2016, Heidelberg, Germany, 25–28 July 2016; Optical Society of America: Washington, DC, USA, 2016; p. DW3E.1. [Google Scholar]

- Müller, A.F.; Falldorf, C.; Lotzgeselle, M.; Ehret, G.; Bergmann, R.B. Multiple Aperture Shear-Interferometry (MArS): A solution to the aperture problem for the form measurement of aspheric surfaces. Opt. Express 2020, 28, 34677–34691. [Google Scholar] [CrossRef]

- Falldorf, C.; Hagemann, J.H.; Ehret, G.; Bergmann, R.B. Sparse light fields in coherent optical metrology. Appl. Opt. 2017, 56, F14–F19. [Google Scholar] [CrossRef]

- Hagemann, J.H.; Falldorf, C.; Ehret, G.; Bergmann, R.B. Form determination of optical surfaces by measuring the spatial coherence function using shearing interferometry. Opt. Express 2018, 26, 27991–28001. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- Burke, J.; Li, W.; Heimsath, A.; von Kopylow, C.; Bergmann, R.B. Qualifying parabolic mirrors with deflectometry. J. Eur. Opt. Soc. Rap. Public 2013, 8, 13014. [Google Scholar] [CrossRef]

- Schachtschneider, R.; Fortmeier, I.; Stavridis, M.; Asfour, J.; Berger, G.; Bergmann, R.B.; Beutler, A.; Blümel, T.; Klawitter, H.; Kubo, K.; et al. Interlaboratory comparison measurements of aspheres. Mess. Sci. Technol. 2018, 29, 055010. [Google Scholar] [CrossRef]

- Bartsch, J.; Sperling, Y.; Bergmann, R.B. Efficient vision ray calibration of multi-camera systems. Opt. Express 2021, 29, 17125–17139. [Google Scholar] [CrossRef] [PubMed]

- Reh, T.; Li, W.; Gesierich, A.; Bergmann, R.B. Vision Ray Camera Calibration for Small Field of View. In Proceedings of the Deutsche Gesellschaft für Angewandte Optik (DGAO), Brunswick, Germany, 21–25 May 2013; p. A019-9. Available online: http://www.dgao-proceedings.de (accessed on 29 October 2021).

- Kalms, M. WIMO (Outer Wing Metrology)—Novel Strategies to Better Measure the Quality of Wing Surfaces—Final Report Summary; European Commission: Brussels, Belgium, 2017; Available online: https://cordis.europa.eu/article/id/147160-novel-strategies-to-better-measure-the-quality-of-wing-surfaces (accessed on 29 October 2021).

- Kalms, M. WiMo (286745) & WIMCAM (641489) Outer Wing Metrology & Measurement Campaigns, Final Report Summary; European Commission: Brussels, Belgium, 2017; Available online: https://cordis.europa.eu/docs/results/286/286745/final1-wimo-wimcam-publishable-summary.pdf (accessed on 29 October 2021).

- Burke, J.; Gesierich, A.; Li, W.; Bergmann, R.B. Measurement of Mould Tool for Laminar-flow Carbon-fibre Composite Airplane Wing Cover. In Photogrammetrie—Laserscanning—Optische 3D-Messtechnik: Beiträge der Oldenburger 3D-Tage; Wichmann Verlag: Berlin, Germany, 2014; pp. 116–125. [Google Scholar]

- ISO/ASTM. Additive Manufacturing—Design—Part 1: Laser-Based Powder Bed Fusion of Metals; ISO/STN; Iteh Standards: Newark, NJ, USA, 2019; Volume 52911-1:2019. [Google Scholar]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 1–25. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Pavlov, M.; Grigoriev, S.; Tikhonova, E.; Smurov, I. Comprehensive optical monitoring of selective laser melting. J. Laser Micro/Nanoeng. 2012, 7, 236–243. [Google Scholar] [CrossRef]

- Tyralla, D.; Seefeld, T. Thermal based process monitoring for laser powder bed fusion (LPBF). Adv. Mater. Res. 2021, 1161, 123–130. Available online: https://www.scientific.net/AMR.1161.123 (accessed on 29 October 2021). [CrossRef]

- Neef, A.; Seyda, V.; Herzog, D.; Emmelmann, C.; Schoenleber, M.; Kogel-Hollacher, M. Low coherence interferometry in selective laser melting. Phys. Procedia 2014, 56, 82–89. [Google Scholar] [CrossRef]

- Gardner, M.R.; Lewis, A.; Park, J.; McElroy, A.B.; Estrada, A.D.; Fish, S.; Beaman, J.J.; Milner, T.E. In situ process monitoring in selective laser sintering using optical coherence tomography. Opt. Eng. 2018, 57, 041407. [Google Scholar] [CrossRef]

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Meas. Sci. Technol. 2017, 28, 044005. [Google Scholar] [CrossRef]

- Kalms, M.; Narita, R.; Thomy, C.; Vollertsen, F.; Bergmann, R.B. New approach to evaluate 3D laser printed parts in powder bed fusion-based additive manufacturing in-line within closed space. Addit. Manuf. 2019, 26, 161–165. [Google Scholar] [CrossRef]

- Geng, J. Structured-light 3D surface imaging: A tutorial. Adv. Opt. Photonics 2011, 3, 128–160. [Google Scholar] [CrossRef]

- DIN EN ISO. Geometrical Product Specification (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters; DIN; Beuth-Verlag: Berlin, Germany, 2012; Volume 25178-2:2012-09. [Google Scholar]

- Kolmogorov, A.N. The local structure of turbulence in incompressible viscous fluids at very large Reynolds numbers. Dokl. Akad. Nauk SSSR 1941, 30, 299–303. (In Russian) [Google Scholar]

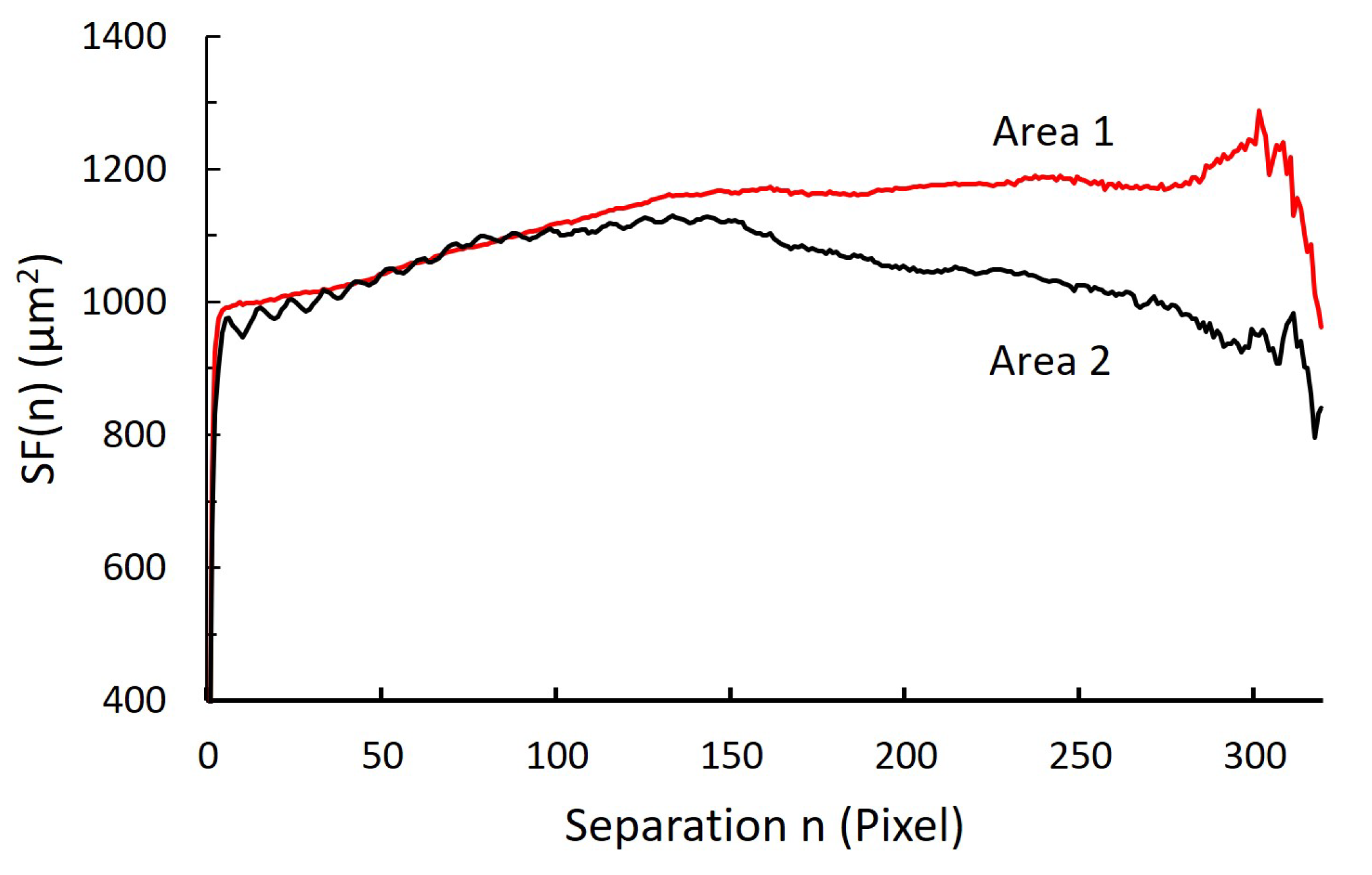

- Kalms, M.; Bergmann, R.B. Structure function analysis of powder beds in additive manufacturing by laser beam melting. Addit. Manuf. 2020, 36, 101396. [Google Scholar] [CrossRef]

- Kalms, M.; Bergmann, R.B. In-line quality control using dimensional metrology of 3D metal parts printed by laser beam melting. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure and Transportation XIII, Denver, CO, USA, 3–7 March 2019; p. 109710N. [Google Scholar] [CrossRef]

- Kreis, T.; Burke, J.; Bergmann, R.B. Surface characterization by structure function analysis. J. Eur. Opt. Soc. Rap. Public 2014, 9, 14032. [Google Scholar] [CrossRef]

- Kalms, M.; Kreis, T.; Bergmann, R.B. Characterization of technical surfaces by structure function analysis. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XII, Denver, CO, USA, 4–8 March 2018; p. 1059924. [Google Scholar] [CrossRef]

- Wiersma, J.T.; Wyant, J.C. Vibration insensitive extended range interference microscopy. Appl. Opt. 2013, 52, 5957–5961. [Google Scholar] [CrossRef][Green Version]

- Li, Y.; Kästner, M.; Reithmeier, E. Vibration-insensitive low coherence interferometer (LCI) for the measurement of technical surfaces. Measurement 2017, 104, 36–42. [Google Scholar] [CrossRef]

- Bartsch, J.; Kalms, M.; Bergmann, R.B. Improving the calibration of phase measuring deflectometry by a polynomial representation of the display shape. J. Europ. Opt. Soc.—Rap. Publ. 2019, 15, 1–7. [Google Scholar] [CrossRef]

- Bartsch, J.; Sperling, Y.; Bergmann, R.B. Qualification of holistic and generic camera-system calibration by fringe projection. In Proceedings of the Automated Visual Inspection and Machine Vision IV, Online, 20 June 2021; p. 117870G. [Google Scholar] [CrossRef]

- Szeliski, R. (Ed.) Computer Vision—Algorithms and Applications; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Eldar, Y.; Kutyniok, G. (Eds.) Compressed Sensing—Theory and Application; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Bishop, C.H. (Ed.) Pattern Recognition and Machine Learning; Information Science and Statistics; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

| Requirement | Method | Principle Feature | Benefits |

|---|---|---|---|

| Robustness (R) | Computational Shear Interferometry (CoSi) | measures finite phase differences (defined by shear) | (i) enables interferometry using low coherent light, (ii) intrinsically robust against vibration |

| Deflectometry | differential measurement | intrinsically robust against vibration | |

| Fringe Projection | triangulation | robust against ambient conditions | |

| Complexity (C) | Multiple Viewing Directions for digital holography (MuVie) | multiple illumination and observation directions | enables -view |

| Computational Shear Interferometry (CoSI) | measures coherence function | (i) measures extended curvature due to variable shear, (ii) enables use of MArS | |

| Multiple Aperture Shear Interferometry (MArS) | simultaneous use of multiple light sources | (i) enables measurement of aspheres, (ii) solves aperture problem | |

| Fringe Projection | triangulation | suitable for complex sample geometry |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bergmann, R.B.; Kalms, M.; Falldorf, C. Optical In-Process Measurement: Concepts for Precise, Fast and Robust Optical Metrology for Complex Measurement Situations. Appl. Sci. 2021, 11, 10533. https://doi.org/10.3390/app112210533

Bergmann RB, Kalms M, Falldorf C. Optical In-Process Measurement: Concepts for Precise, Fast and Robust Optical Metrology for Complex Measurement Situations. Applied Sciences. 2021; 11(22):10533. https://doi.org/10.3390/app112210533

Chicago/Turabian StyleBergmann, Ralf B., Michael Kalms, and Claas Falldorf. 2021. "Optical In-Process Measurement: Concepts for Precise, Fast and Robust Optical Metrology for Complex Measurement Situations" Applied Sciences 11, no. 22: 10533. https://doi.org/10.3390/app112210533

APA StyleBergmann, R. B., Kalms, M., & Falldorf, C. (2021). Optical In-Process Measurement: Concepts for Precise, Fast and Robust Optical Metrology for Complex Measurement Situations. Applied Sciences, 11(22), 10533. https://doi.org/10.3390/app112210533