1. Introduction

Climate change has a significant impact on the overall productivity of food. Differences are mainly represented by a lack of water. Nearly 70% of the world’s water is already used for agriculture [

1]. Water is vital for plant growth, development, and productivity. Water stress causes limitations for plant growth and performance of cultivated crops more than any other environmental factor [

2]. The water absorption of seeds is crucial for the initiation of swelling and germination. At the same time, water intake plays a decisive role in seed emergence [

3]. Greater water intake is crucial in stressful conditions, such as drought or high temperature [

4]. Stressful situations require some support for plant growth through proper treatment, such as chemical, biological, or physical treatment. Recent physical procedures involve the use of low-temperature plasma discharge. This technology has recently found application in plant biology and agriculture [

5].

Plasma discharges are now widely used in many industries in processes such as surface sterilisation [

6,

7], biomedical applications [

8], object decontamination in closed containers [

9], inactivation of bacteria [

10] and removal of contaminants from water [

11,

12]. Plasma can change the surface properties of the seed in terms of surface tension and nutrient [

13] and water permeability through its layers into the interior. Water absorption is related to changes in seed surface and structure. These changes can be indicated by determining the surface’s wettability by measuring the contact angle [

14]. A more wettable surface in the sense of reducing contact angle and higher surface tension has a beneficial effect on water intake and more effective adhesion of possible biological treatment.

There have been several previously published articles in which the effect of plasma treatment on the surface changes is presented, for example in [

15,

16,

17,

18,

19,

20]. Guimarães et al. used DBD plasma discharge as a pre-germination treatment for

Leucaena seeds to improve wettability and germination [

15]. Junior et al. observed the effect of DBD-type discharge on

Erythrina velutina seeds in which the contact angle was reduced [

16]. Da Silva et al. used the same type of discharge to reduce the contact angle in seeds of

Mimosa Caesalpiniafolia [

17]. Sadhu et al. improved the wetting angle in mung bean seeds with the help of RF type discharge [

18]. Velichko et al. used a similar type of discharge and observed a lower contact angle in wheat seeds [

19]. Medvecká et al. discovered a positive effect of diffuse coplanar discharge on the wettability of maize, barley, and wheat seeds [

20]. Unfortunately, their results are complicated to compare because of the vast complexity of plasma systems with many different process parameters and the diverse seed type used.

As reported in [

21], conventional seed treatment methods can lead to a number of negative effects, including significant reductions in germination, dry shoot biomass and reduced plant vigour. For this reason, the present study investigates the use of low temperature plasma as an alternative ecological method for seed treatment, with the ambition of eliminating the above mentioned disadvantages of conventional methods. Hence, this paper aims to compare two different plasma discharges concerning the various seed wettability. Since each plasma system is unique and complex, the processing parameters of the devices were considered. Low-pressure microwave discharge (LPMD) and atmospheric pressure discharge (APD), respectively, were used for experiments concerning three representatives of diverse seed types such as cereal, oilseed, and legume.

2. Materials and Methods

2.1. Materials and Preparing

The seeds of spring wheat (Triticum aestivum L.), of the variety Tercia from the Selgen breeding company, were used as the representatives of cereals. The legume seeds were represented by winter pea (Pisum sativum L.), of the variety Aviron, also from the Selgen breeding company (Sibřina, Czech Republic). The sunflower seeds (Helianthus annuus L.), of the variety Bella, provided by Oseva Agro, Ltd. (Brno, Czech Republic), were selected as the representatives of oilseeds.

Several treatment variants were prepared for all crops. Each process variant for both discharges used was designed in the same way independently. Several seeds were placed on the adhesive tape inside the Petri dish to avoid seed turning or other movements during treatment. The Petri dish was placed on the holder under the plasma jet of the atmospheric plasma system. When low-pressure plasma discharge was used, the Petri dish was placed at the bottom of the vacuum chamber. Subsequently, the plasma treatment of prepared samples was performed under the preset process conditions.

2.2. Plasma Treatment

Two utterly different plasma discharges were used in our experiments. Firstly, the Gliding Arc type plasma discharge burning at atmospheric pressure in open space (APD), and secondly, the microwave plasma discharge generated at low pressure in a vacuum chamber (LPMD).

The APD system consists of a high voltage source with working gas control, an air compressor, and a plasma jet. The plasma jet was powered by a high-voltage power supply GVN1k 2011 supplied by Radan Ltd. (Barchov, Czech Republic) with a power input of 1.3 kW operating at a frequency of 50 Hz. The ignited discharge was blown out by working gas flow from the area between divergent stainless steel electrodes toward the treated sample. Compressed air was used as the carrier gas. The minimal overpressure of the compressed gas at the inlet into the plasma system was maintained at values of 600 kPa by the air compressor PKS 9-2/100 supplied by Orlík-Kompresory (Česká Třebová, Czech Republic). The gas flow was controlled by the FL-2008 flow meter provided by Omega Engineering Inc. (Norwalk, CT, USA). It can change the gas flow in the range from 10 to 100 SCFH (gas flow 1 Nm

3·h

−1 corresponds to 35.3 SCFH). The electric field distribution in the vicinity of electrodes was described in detail in [

22,

23].

Only two different process parameters used in APD treatment, particularly carrier gas flow and treatment duration, were considered to vary. The working gas flow of 30 and 50 SCFH was used. The treated seeds were exposed to plasma discharge for 10, 30 and 60 s, respectively. The distance between the edge of the plasma jet and the seed surface was 8 cm for all the prepared samples. Hereafter, the APD treated variants are signed TxxFyy, where xx indicates the treatment time and yy denotes the working gas flow used.

The LPMD consists of a stainless steel vacuum chamber, a microwave power generator, and vacuum pumps. The MNG 1K-08 power supply supplied by Radan Ltd. (Barchov, Czech Republic) generates pulsed microwave plasma with output power in the range of 100 to 850 W. The working pressure in the vacuum chamber was maintained at the value of 50 Pa using two rotary oil pumps connected in series, RV100/1 supplied by Lavat Plc. (Radim u Kolína, Czech Republic) and Adixen 2015SD provided by Pfeiffer Vacuum Components & Solutions Ltd. (Aßlar, Germany). Simultaneously, a small flow of dry air as working gas is added into the recipient via the FV 201–CV valve system and mass flow meters supplied by Bronkhorst High-TechH B.V. (Ruurlo, The Netherlands). The experimental set-up of LPMD is described in more detail in [

24,

25].

The parameters of the LPMD processes varied in microwave power and duration time. The treatment process used pulsed microwave power at values of 500 and 800 W. The treated seeds were exposed to plasma discharge for 10, 30 and 60 s. The working pressure in the vacuum chamber was maintained at 50 Pa for all treatment processes. Hereafter, the LPMD treated variants are signed TxxPyyy, where xx indicates the treatment time and yyy denotes the power used.

2.3. Surface Wettability Analysis

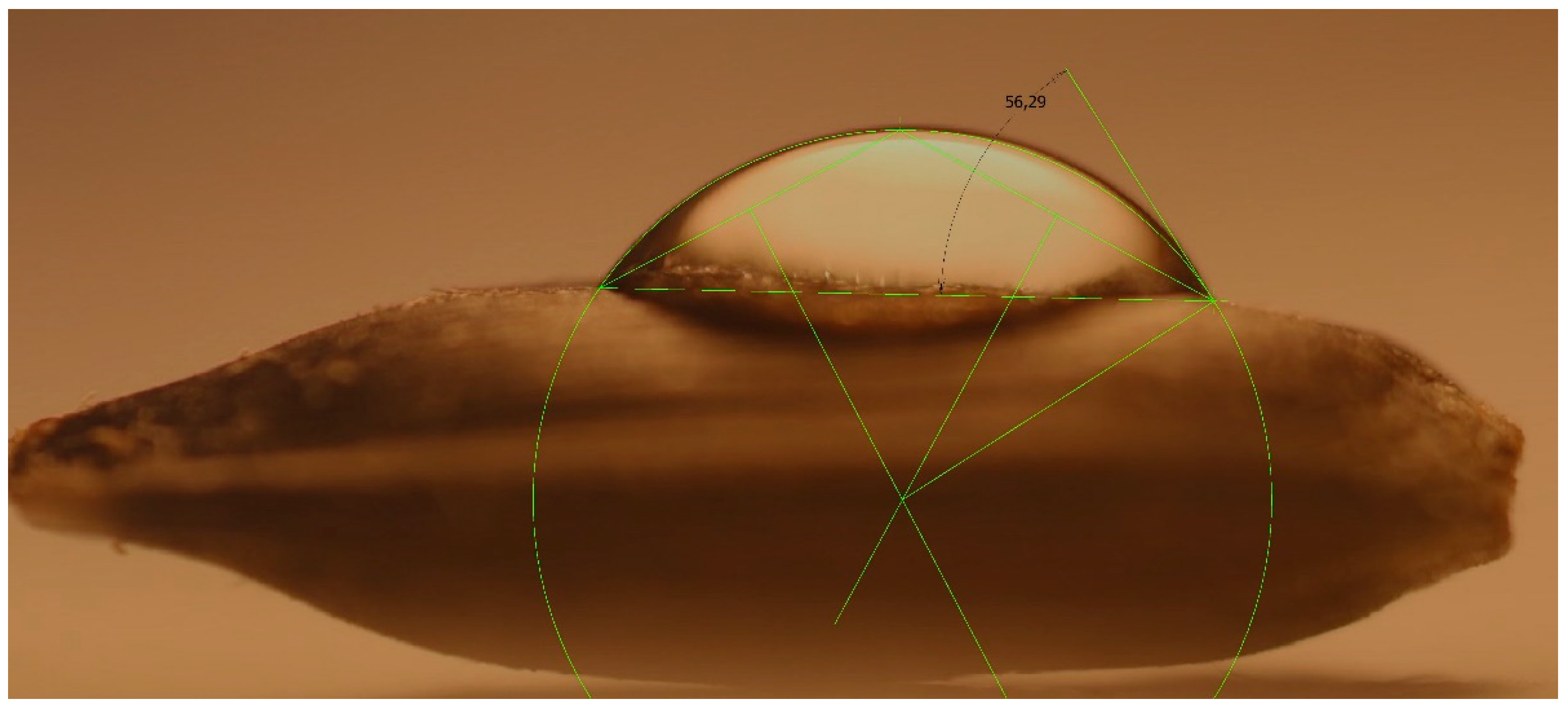

Changes in surface wettability are reflected in the contact angle between the seed and the droplet of liquid variations. The seed surface is not planar, and therefore only apparent contact angles can be determined [

26]. For this purpose, a 2.3 µL distilled water droplet was applied to the seed surface with Eppendorf

® 3123000012 pipette (Eppendorf, Germany). The air was the surrounding phase around the drop and the seed (ambient temperature was maintained at 22 °C with relative humidity of 55%). Snapshots of the droplets on the surface were taken with the EOS 70D digital camera equipped with a MP-E 65mm f/2.8 1–5x Macro Photo lens supplied by Canon Inc. (Tokyo, Japan). The camera was set in manual mode with the following parameters: exposure time 1/20 s; aperture f/16; sensitivity ISO-1600; camera flash off, illumination only with diffuse natural light. Snapshot evaluation was carried out with Autodesk Inventor 2018 software. The water droplet shape was approximated with the circle by choosing three non-collinear points on the droplet surface. Two of them correspond to the intersections of the droplet and seed surfaces, and the third point is selected arbitrarily from the droplet edge. Subsequently, the apparent contact angle was determined as the angle between the line passing through the intersections and the tangent of the circle in the point.

The contact angles of all variants (including untreated control variants) were measured for five different seeds, to which drops of distilled water were applied. At the same time, five repetitions of the contact angle evaluation were performed from each snapshot. The data obtained were statistically processed. The average apparent contact angles were determined for each variant and compared with the others using p-values obtained by Tukey’s HSD test at the significance level of 0.05.

3. Results

The representative snapshot of the water droplet on the sunflower seed surface can be seen in

Figure 1. The results of the measurements are presented in

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6 and

Figure 7. The effects of plasma treatment on the apparent water contact angle on the pea seed surface are demonstrated in

Figure 2 (APD treatment) and

Figure 3 (LPMD treatment), on the wheat seed surface in

Figure 4 (APD treatment) and

Figure 5 (LPMD treatment), and on the sunflower seed surface in

Figure 6 (APD treatment), and

Figure 7 (LPMD treatment), respectively.

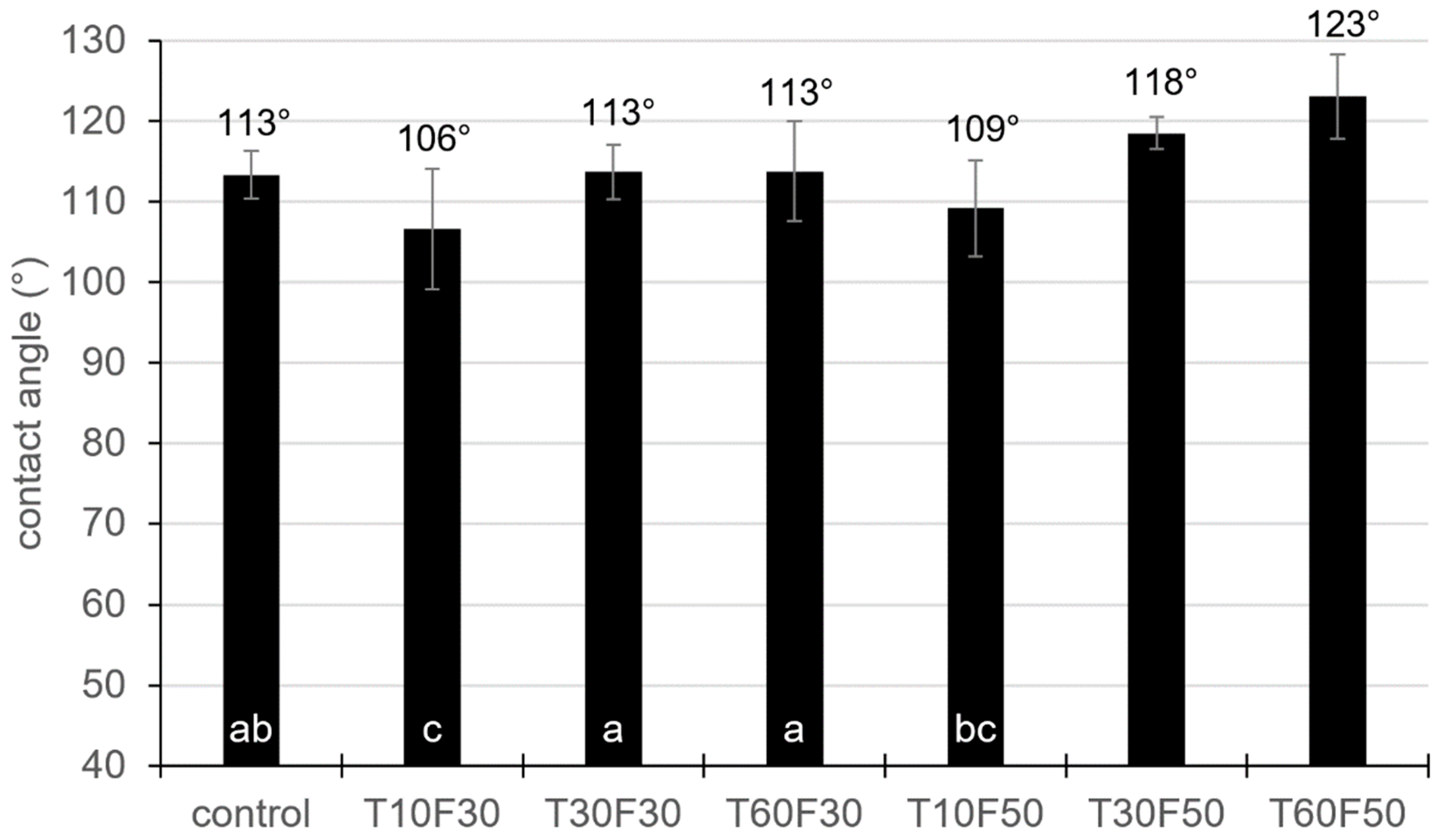

As shown in

Figure 2, the untreated control variant of the pea seeds had a hydrophobic surface with an apparent contact angle of 113°. It is also evident that the APD treatment had a relatively small influence on the apparent water contact angle. The angle decrease was observed only in the case of 10 s treatment for both gas flows, but it is statistically significant only for the flow of 30 SCFH (

p = 0.001, 4% decrease). The other variants show either minor (nonsignificant) contact angle changes or even slight, statistically significant increases (

p = 0.008, 5% increase for 30 s treatment duration;

p = 0.000, 9% increase for 60 s treatment duration).

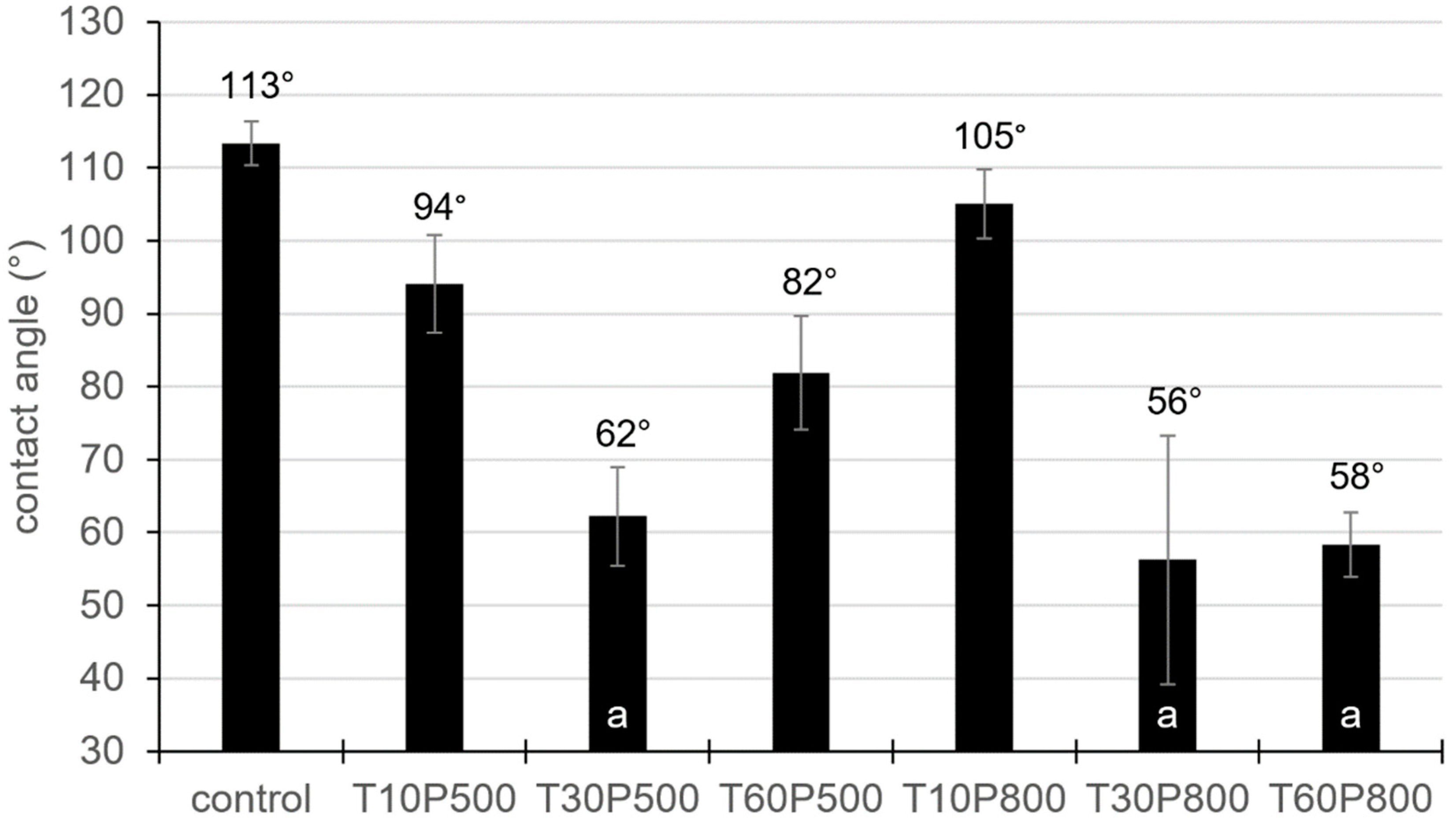

Completely different results were obtained with LPMD treatment (see

Figure 3). All treated variants showed significant changes in apparent water contact angle compared to the untreated variant (

p < 0.020 for all). At a power of 500 W, the contact angle gradually decreased with increasing treatment duration, but the longest time (60 s) is the exception. The continuing decreasing trend was not found there. The lowest contact angle was 45% lower than for the control sample (

p = 0.000) at a treatment time of 30 s. A similar trend was found at the power of 800 W. At the treatment duration of 30 s, approximately 50% lower contact angle was found compared to the control (

p = 0.000). A slight nonsignificant increase was observed when the treatment time was extended from 30 s to 60 s (

p = 0.970).

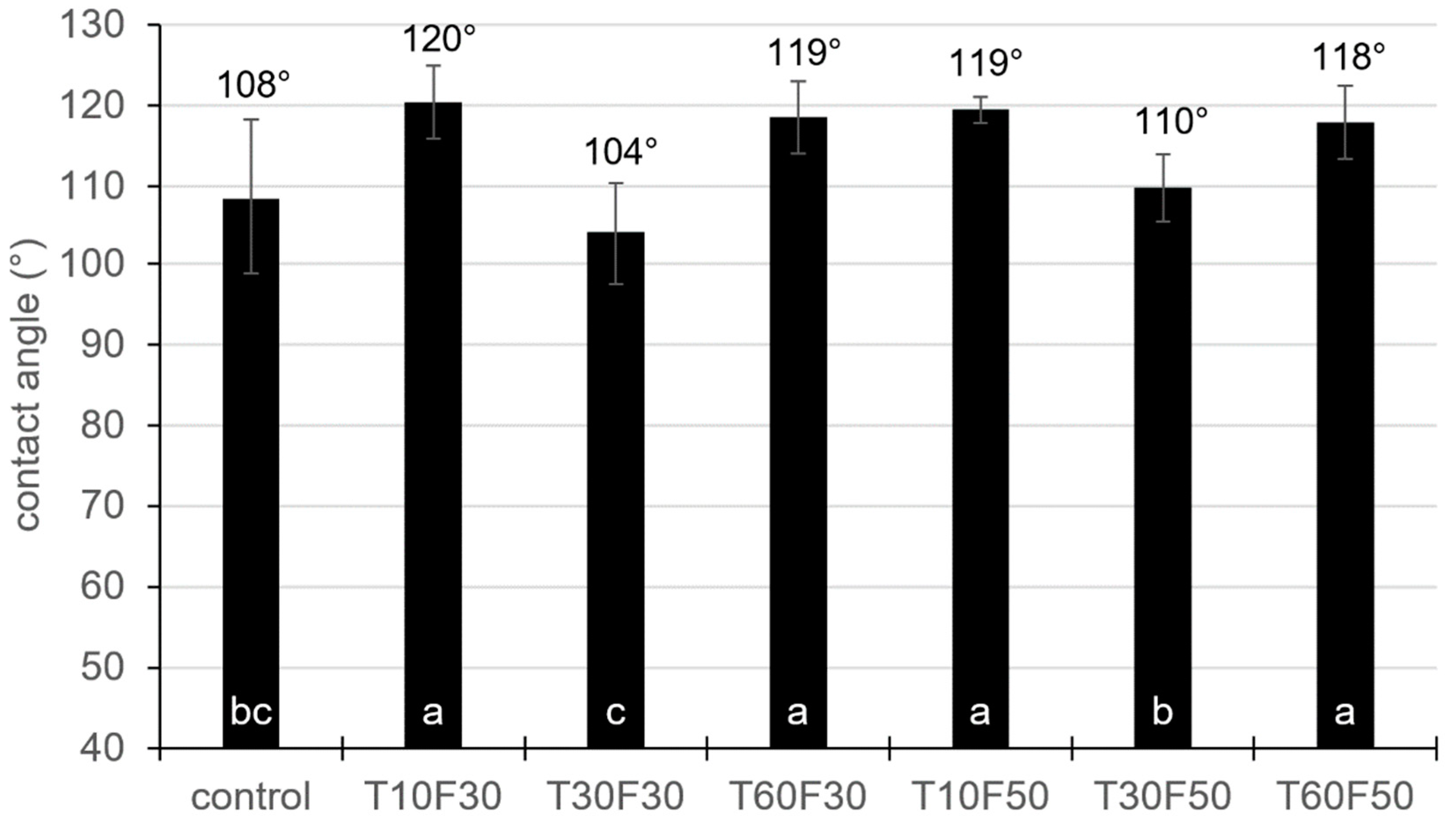

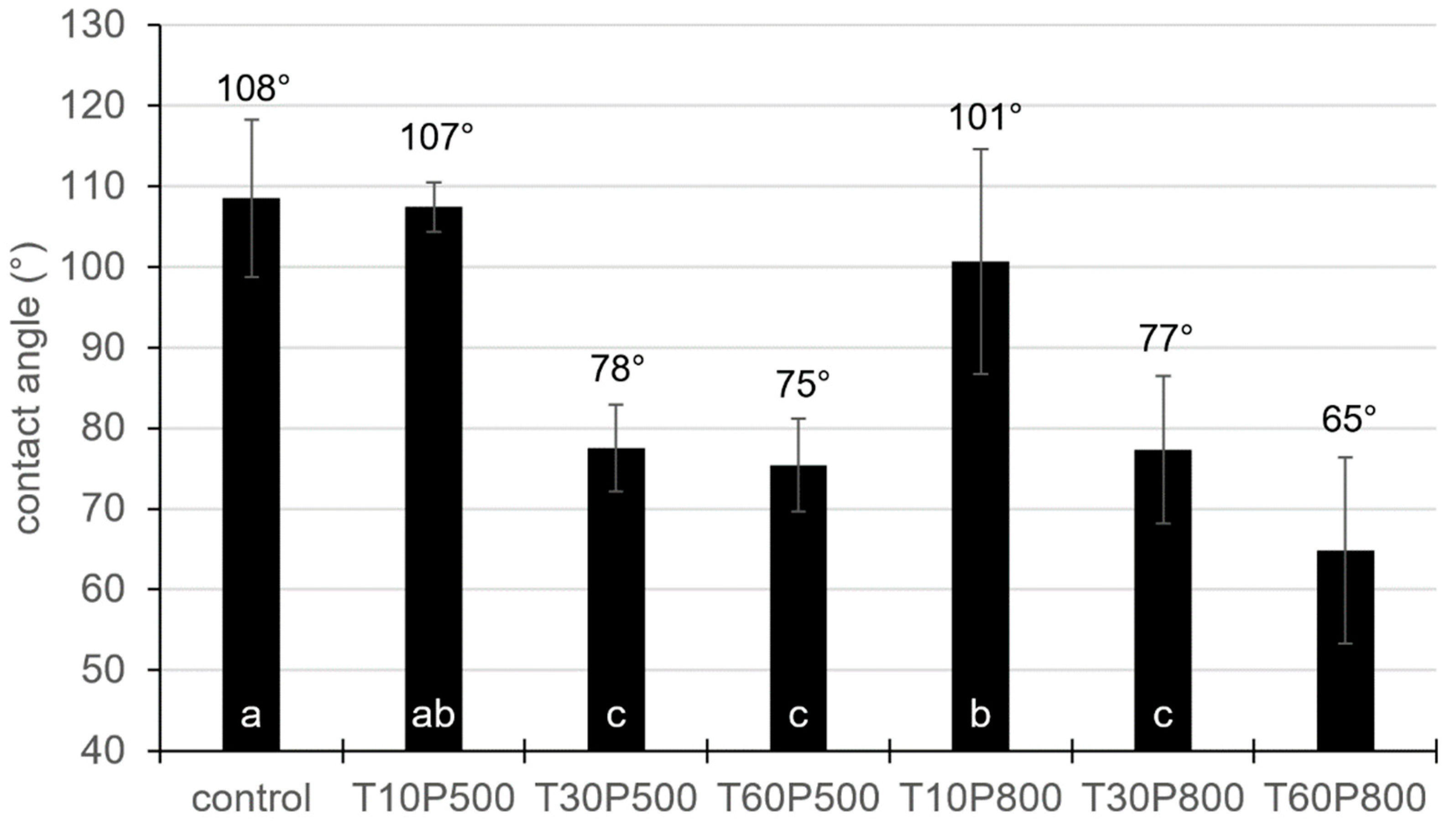

The results of APD treatment on apparent water contact angle on the wheat seed surface are fully inconclusive (see

Figure 4). The only decrease, of approximately 4%, compared to the untreated sample (hydrophobic surface with the contact angle of 108°), was observed for 30 s treatment duration at 30 SCFH airflow. However, it was still statistically nonsignificant (

p = 0.063). On the contrary, all other variants had a higher contact angle of up to 11% for 10 s treatment duration at 30 SCFH flow. In contrast, only variant T30F50 resulted in a nonsignificant increase in contact angle compared to the untreated one. Hence, it seems that there is no causation between the APD process parameters and the apparent water contact angle.

The results of the LPMD treatment of wheat seed in

Figure 5 are much more promising. Though 10 s treatment had a weak influence on the contact angle for both used power, a more extended treatment more substantially reduced the contact angle. At a power of 500 W, the treatment duration of 30 s caused a significant drop in the contact angle (approximately 78°,

p = 0.000), but a more prolonged treatment had no significant additional effect. On the contrary, at a power of 800 W, the apparent water contact angle was continuously significantly decreased for further treatment. The maximum impact (reduction to 65°) was achieved for the variant treated at 800 W for 60 s (

p = 0.000), whereby the contact angle was about 40% lower than for the untreated one.

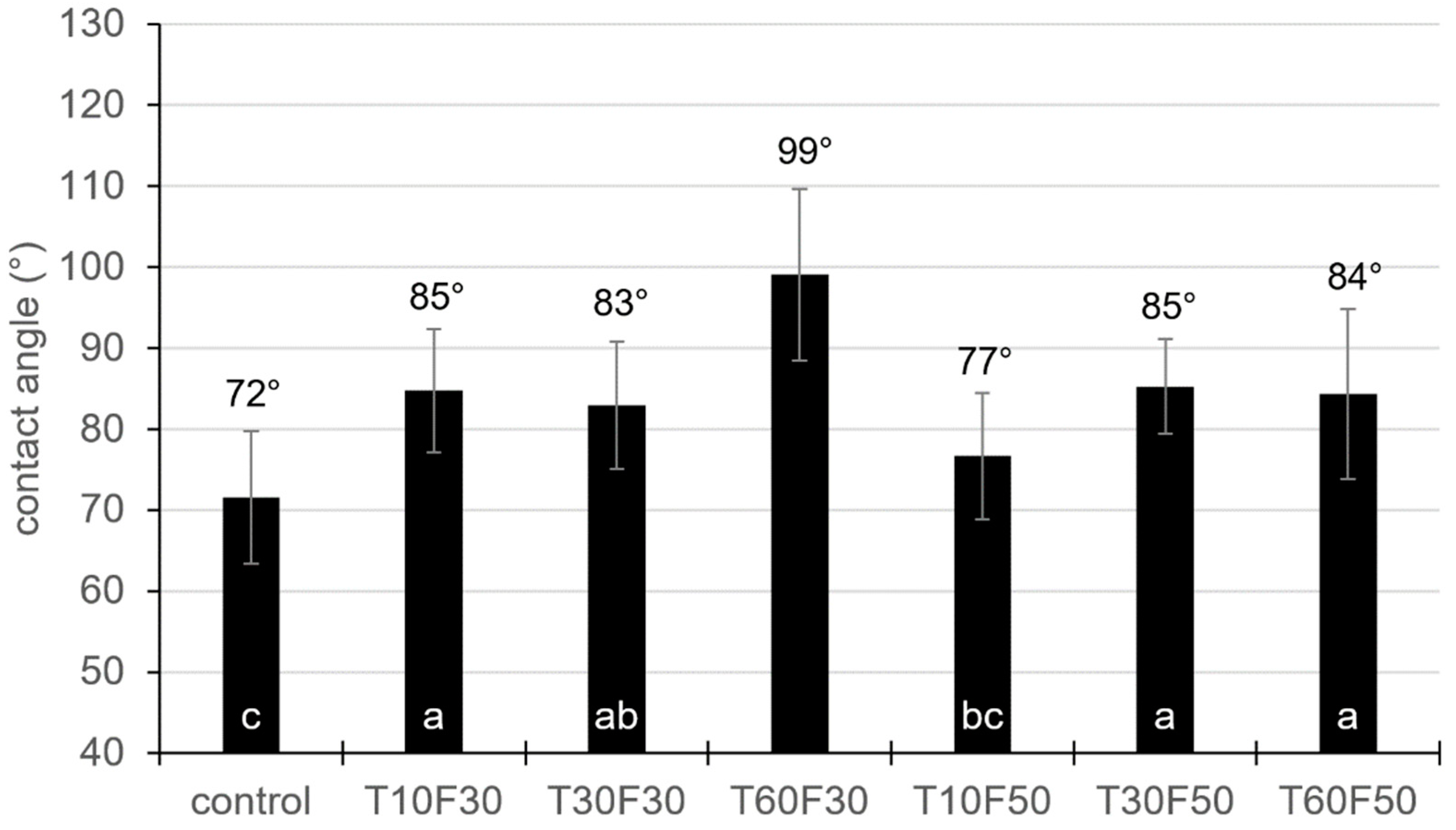

It can be seen in

Figure 6 that the untreated sunflower seeds were not so hydrophobic compared to other reported types. Their apparent water contact angle is lower and only achieved 72°. However, it is also clear that the APD treatment of the sunflower seeds had only a negative effect on their wettability. Compared to the untreated sample, the apparent contact angle values were significantly higher for all sets of process parameters, except for the variant T10F50, where the increase was the lowest and statistically nonsignificant (

p = 0.338). The most harmful effect was observed for the 60 s treatment at the airflow of 30 SCFH, where the contact angle increased by 38% (approximately 99°,

p = 0.000).

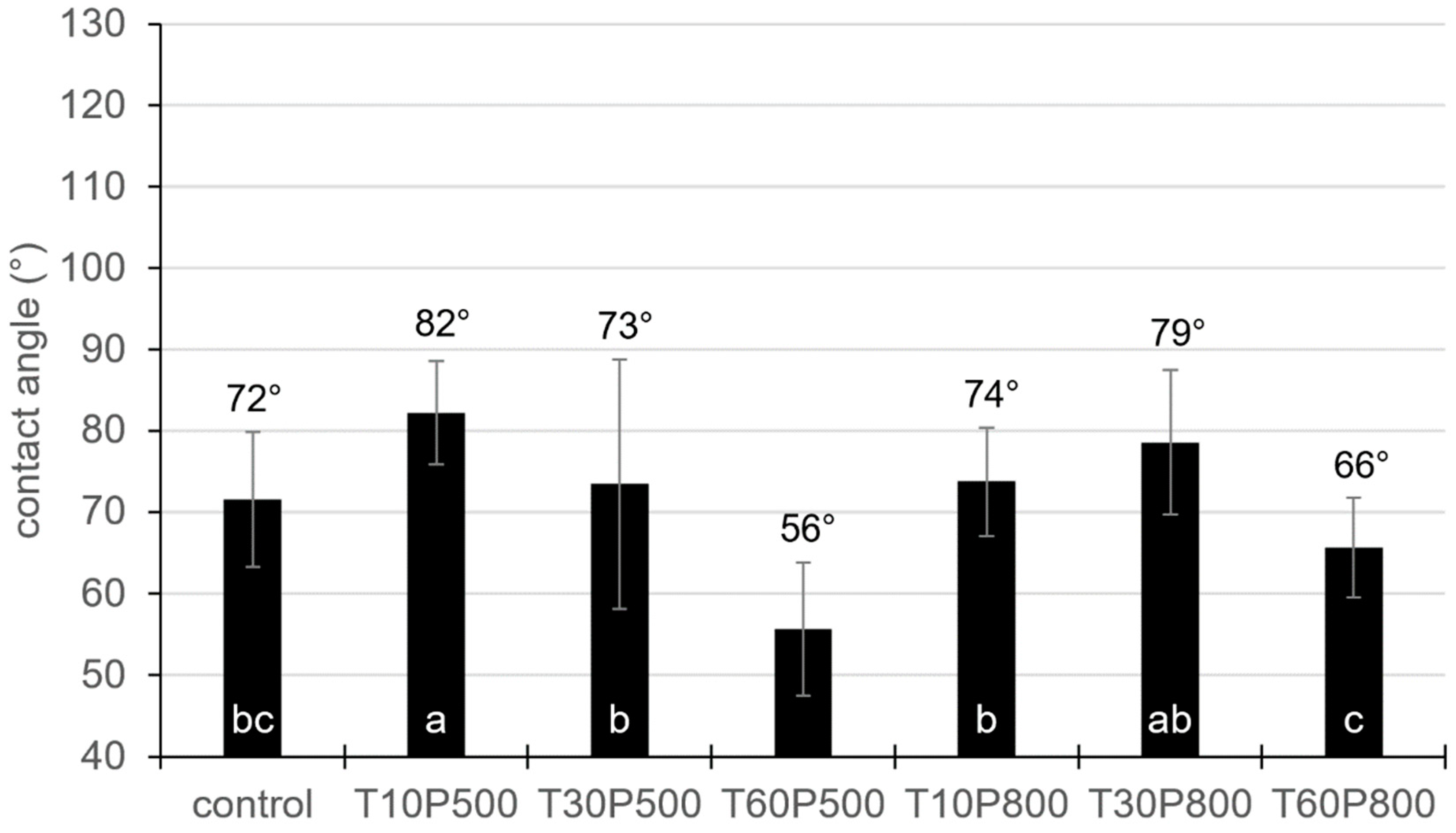

The contradictory results of the LPMD treatment of sunflower seeds are presented in

Figure 7. However, it is possible to find some similar trends for both microwave powers. The apparent contact angle of the treated variants was higher than that of the untreated one for treatment durations of up to 30 s and lower for the 60 s treatment. The most prolonged treatment significantly reduced the contact angle compared to a shorter duration. However, concerning the untreated sample, there was a statistically significant difference only at 500 W (

p = 0.000), while it was nonsignificant for the power of 800 W (

p = 0.246). The best effect (decrease to approximately 56°) was observed for the T60P500 variant, and its contact angle achieved 78% of the untreated variant value.

4. Discussion

Based on the results above, some crucial outcomes for APD treatment could be highlighted. It has a small and rather negative effect on all seeds. It seems inappropriate because the seed surface is hydrophobized, and the contact angle is increased—by up to 9% for peas, 11% for wheat, and 38% for sunflower. A short treatment of peas for 10 s at a flow rate of 30 SCFH is the only exception, where a statistically significant decrease of 6% in the value of the contact angle was achieved. However, more prolonged treatment has negligible or even negative effects. This negative effect is more pronounced for higher airflow. Furthermore, it seems that there is no causation between the APD process parameters and the apparent water contact angle of the wheat and sunflower seed surfaces. Therefore, it could be stated that concerning the relatively high carrier gas temperature [

22] used in the treatment, the APD treatment is utterly unsuitable for seed surface wettability improvement in general.

LPMD treatment seems much more effective in this area, but it depends on the type of seed. It positively affects the wettability of the pea and wheat seed surfaces at various process parameters. It could be concluded that the power of 800 W seems to be ideal for improving the wettability of these seeds. The contact angle can decrease by up to 50% for the pea seed or by 40% for the wheat seed. Completely different outcomes were achieved for sunflower seeds. A short treatment of sunflower seeds increases the water contact angle by up to 15%, and only the more prolonged treatment to 60 s leads to an improvement in wettability. LPMD treatment does not even have to positively affect the seeds, which could be due to the relatively good wettability of the untreated variant. This plasma treatment probably has no significant effect on changes in the apparent water contact angle. It can even worsen the seed wettability of sunflower (as a representative of oilseed). The observed adverse effect could be related to the composition of the seed, where the fat content of the sunflower seed is significantly (minimum of 20 times) higher than that of the wheat or pea seed. Due to the high fat content, sunflower seeds could also be more sensitive to the higher temperature of the working gas [

27]. This can cause undesirable changes on the seeds’ surface or even damage them.

In order to maintain the Gliding Arc discharge, it is necessary to supply a large amount of energy, which is manifested by the higher temperature of the carrier gas. The temperature decreases with increasing distance from the active area of the discharge [

22]. Therefore, it is crucial to place the substrate at a greater distance from the electrodes than is usual for other atmospheric discharges to avoid unwanted thermal damage. In addition, the mean free path of the particles under atmospheric pressure is very low compared to low pressure processes. For this reason, the probability of impact of active particles generated by APD is significantly lower than that of LPMD, leading to the low wettability of the seeds.

Some authors previously reported similar results of their experiments. Sadhu et al. used RF plasma to treat mung bean seeds and observed a 57% lower contact angle of the water droplet on the seed surface exposed to the plasma [

18]. Velichko et al. used the same plasma type and observed a decrease in the contact angle from 113° to 74° for wheat seeds [

19]. This phenomenon was the result of exposure of the seeds to plasma discharge for 300 s. The DBD type atmospheric plasma discharge in terms of the wettability change was used in [

15,

16,

17]. The discharges differed only in excitation frequency. Guimarães et al. was able to improve the wettability of wild

Mimosa with this type of discharge. Junior et al. treated

Erythrina velutina seeds and observed an increase in water absorption and, at the same time, a lower contact angle of the water droplet on the seed surface (48%) [

15]. Silva et al. also observed the positive effects of plasma treatment on the wettability of

Mimosa Caesalpiniafolia seed. The treated seeds showed a contact angle of 43% lower than that of the untreated ones [

17]. Medvecká et al., using diffuse coplanar discharge, changed the wettability of the corn, barley, and wheat surfaces. The contact angles of the water droplet were reduced from 100° to 20°. According to the authors, changes in contact angles are probably due to oxidation of the seed surface by reactive particles from the plasma [

20].

Plasma discharges containing nitrogen (such as those that burn in the air) can result in a more hydrophilic seed surface, manifesting in lowering the contact angle between the water droplet and seed surface. The decrease in contact angles of various seeds with plasma treatments is related to the chemical mechanisms of seed surface modification, making it more hydrophilic. The surface changes are caused by the adsorption of highly reactive radicals such as hydroxyl free radicals (•OH), ionized molecules of N

2, ozone (O

3), electrons, and UV radiation. When these species interact with organic surfaces, such as seeds, they promote partial breakage of the polymeric chains that constitute the surface structure, including creating functional groups containing oxygen and nitrogen [

28,

29]. Additionally, Yan et al. reported a similar plasma etching effect on inorganic compounds that produce surface defects which can cause certain changes in wettability [

30].

It is known that an alteration may occur on the surface of the seed as a result of the incorporation of new functional groups of hydrophilic character or due to an increasing level of surface porosity [

31,

32]. Therefore, the functional groups may have modified the seed surface by promoting the appearance of pores or cavities in the seed integument, thus facilitating the entry of water into the seed. Seed pretreatment with plasma may improve the seed surface and water interaction, consequently providing better wettability. Plasma can oxidize the fibers on the surface of the seeds, and it can also produce covalent cross-links of inter fibers. All these things help the seeds to reduce their hydrophobic nature and improve their wettability. Similar mechanisms were also previously suggested in [

4].

5. Conclusions

The novelty of this study is based on the comparison of the effect of two types of plasma discharges on seeds and demonstrates their necessity to optimize the process parameters for each type of seed separately.

Plasma treatment can affect the wettability of the surface of various seeds, but it is strongly dependent on the type of plasma discharge and the selected process parameters. LPMD has a significantly more positive effect on reducing the value of the apparent water contact angle on the seed surface. Generally, higher microwave power together with prolonged duration has a more significant effect. However, it is necessary to set up the process parameters in such a manner as to avoid thermal seed damage. APD reduces the water contact angle value only minimally, and instead, there is a negative effect on the wettability.