Advanced Tribological Characterization of DLC Coatings Produced by Ne-HiPIMS for the Application on the Piston Rings of Internal Combustion Engines

Abstract

:Featured Application

Abstract

1. Introduction

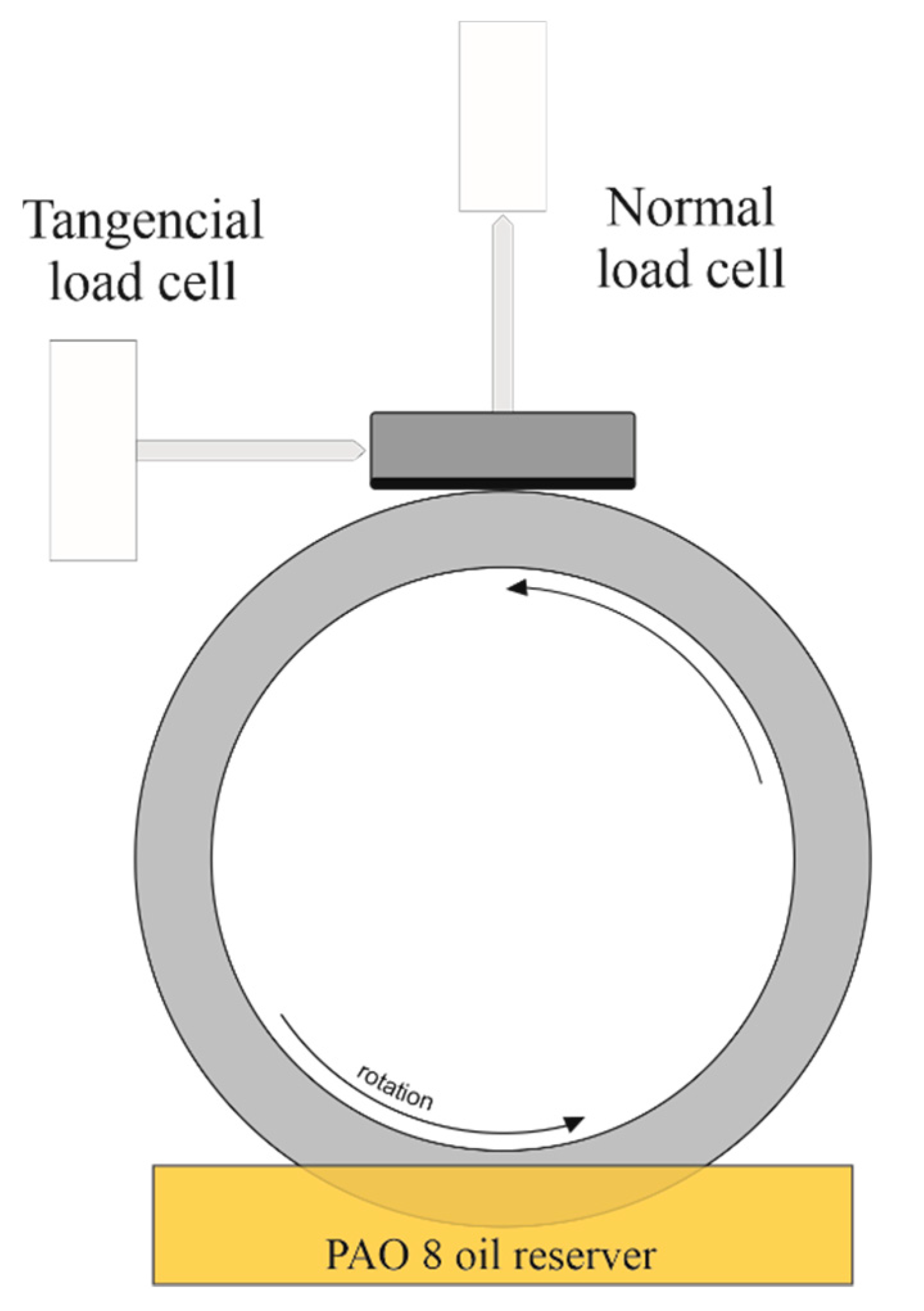

2. Materials and Methods

3. Results and Discussion

3.1. Counter Body Characterization

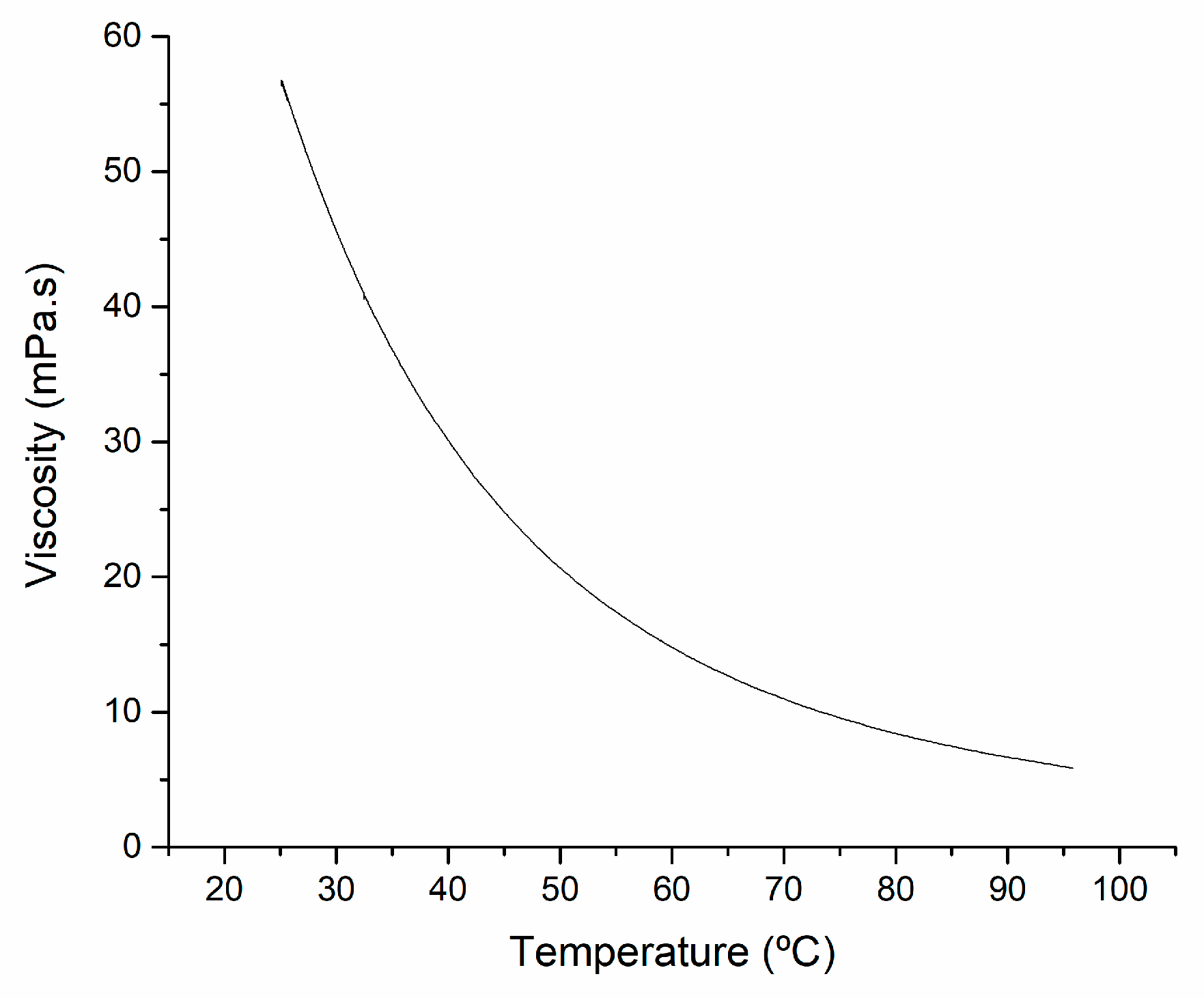

3.2. Lubricant Viscosity

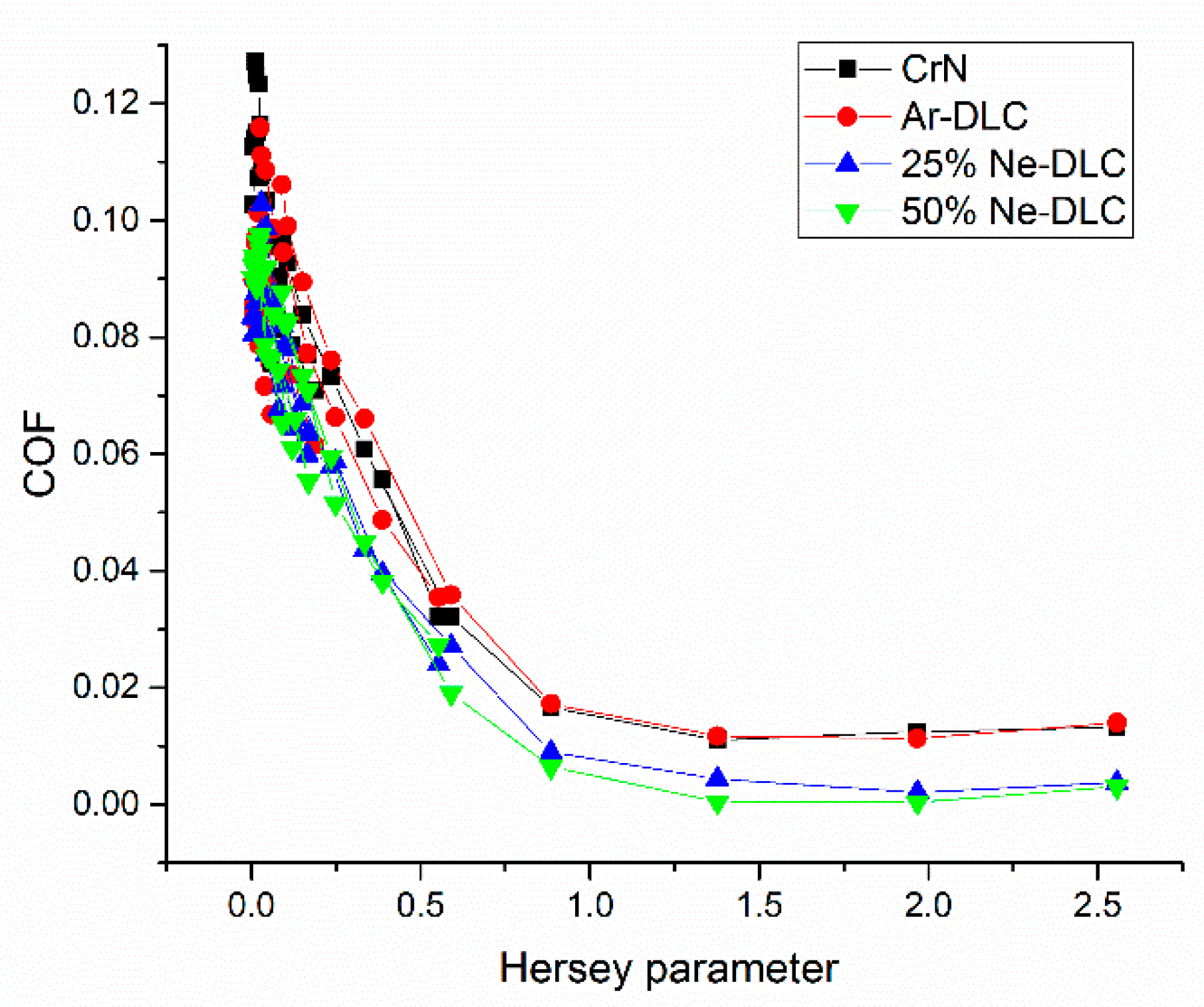

3.3. Stribeck Curves

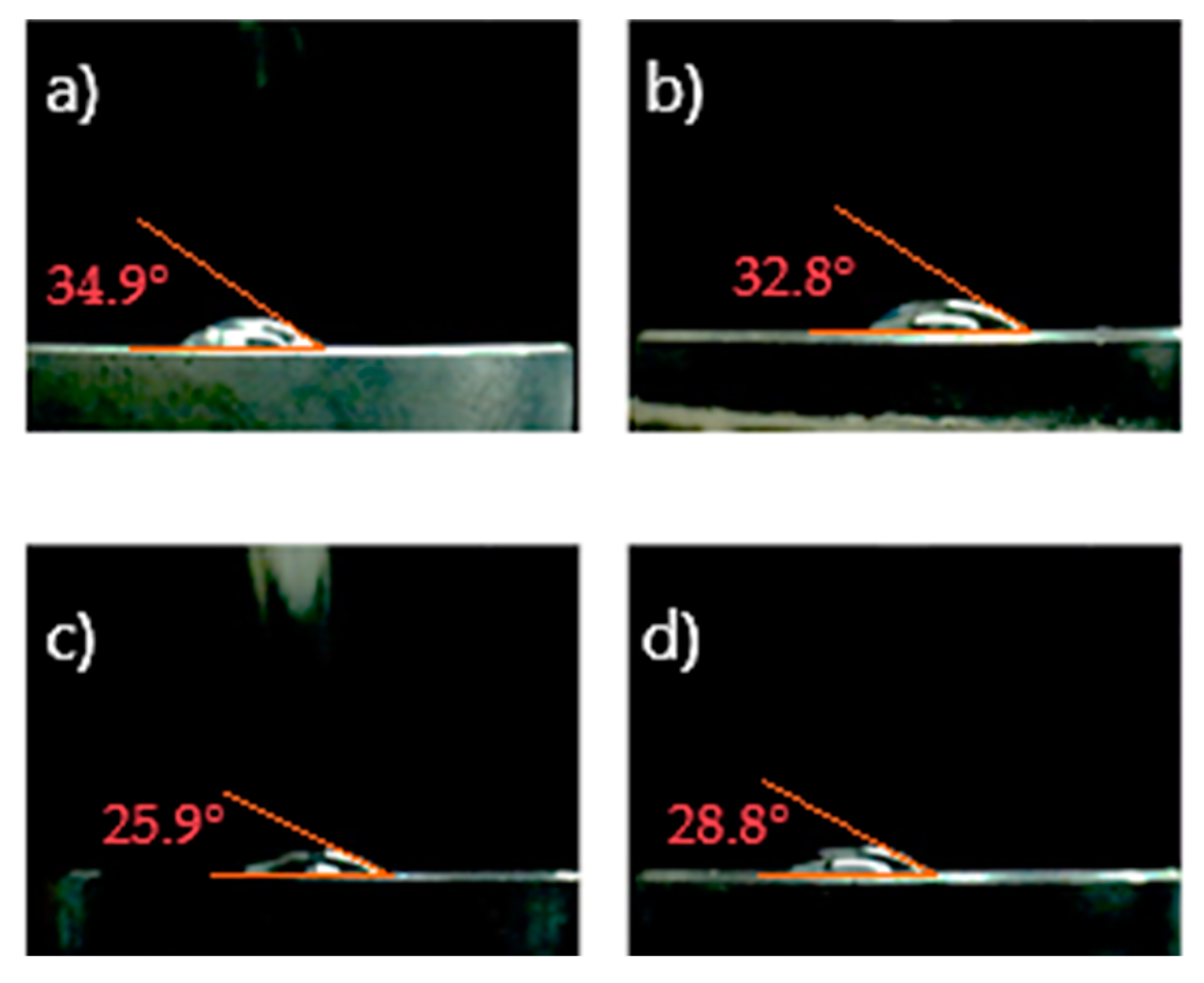

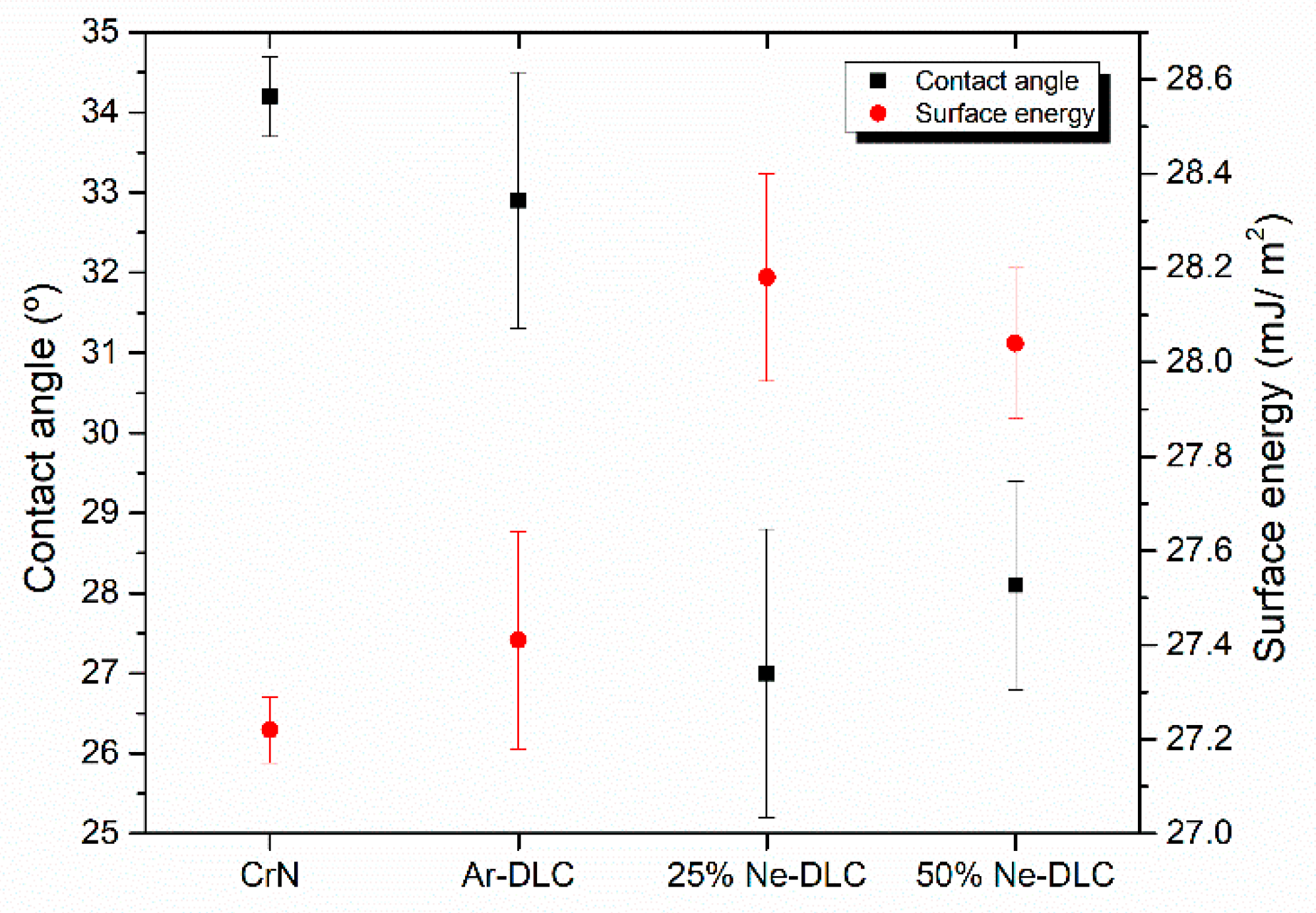

3.4. Wettability and Surface Free Energy

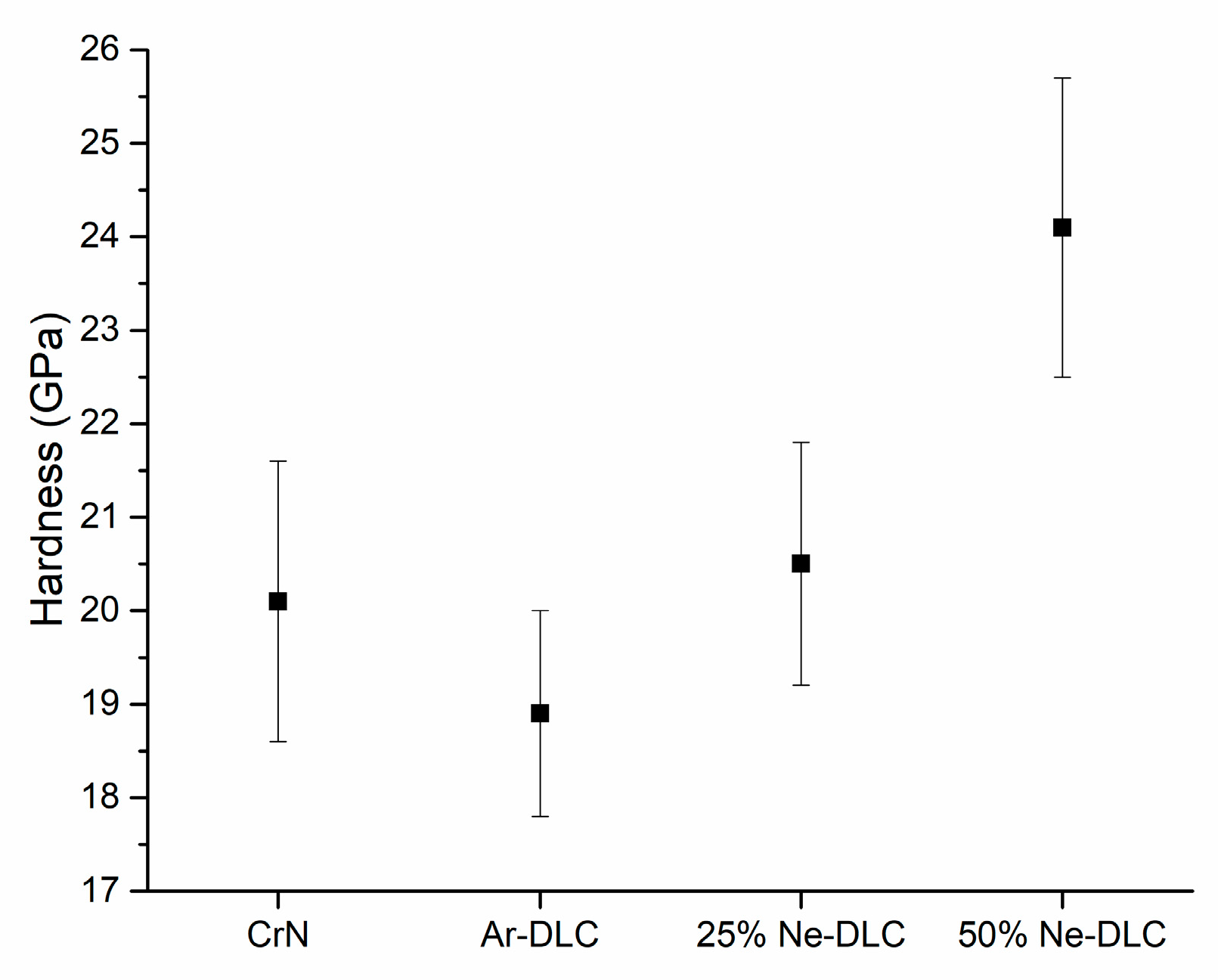

3.5. Hardness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tung, S.C.; Tseregounis, S.I. An investigation of tribological characteristics of energy-conserving engine oils using a reciprocating bench test. No. 2000-01-1781. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Smedley, G. Piston Ring Design for Reduced Friction in Modern Internal Combustion Engines. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2004. [Google Scholar]

- Haque, T.; Morina, A.; Neville, A. Influence of friction modifier and antiwear additives on the tribological performance of a non-hydrogenated DLC coating. Surf. Coat. Technol. 2010, 204, 4001–4011. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Sproul, W.D.; Mishra, B.; Wu, Z.; Wang, J. The structure and properties of chromium nitride coatings deposited using dc, pulsed dc and modulated pulse power magnetron sputtering. Surf. Coat. Technol. 2010, 204, 2230–2239. [Google Scholar] [CrossRef]

- Ferreira, R.; Carvalho, Ó.; Sobral, L.; Carvalho, S.; Silva, F. Influence of morphology and microstructure on the tribological behavior of arc deposited CrN coatings for the automotive industry. Surf. Coat. Technol. 2020, 397, 126047. [Google Scholar] [CrossRef]

- Fontaine, J.; Donnet, C.; Erdemir, A. Fundamentals of the Tribology of DLC Coatings. In Tribology of Diamond-Like Carbon Films; Springer: Boston, MA, USA, 2008; pp. 139–154. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Kleinsorge, B.; Morrison, N.A.; Hart, A.; Stolojan, V.; Robertson, J. Stress reduction and bond stability during thermal annealing of tetrahedral amorphous carbon. J. Appl. Phys. 1999, 85, 7191–7197. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like carbon: State of the art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- Santiago, J.A.; Fernández-Martínez, I.; Kozák, T.; Capek, J.; Wennberg, A.; Molina-Aldareguia, J.M.; Bellido-González, V.; González-Arrabal, R.; Monclús, M.A. Fundamentals of the Tribology of DLC Coatings. Surf. Coat. Technol. 2019, 358, 43–49. [Google Scholar] [CrossRef]

- Helmersson, U.; Lattemann, M.; Bohlmark, J.; Ehiasarian, A.P.; Gudmundsson, J.T. Ionized physical vapor deposition (IPVD): A review of technology and applications. Thin Solid Film. 2006, 513, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Samuelsson, M.; Lundin, D.; Jensen, J.; Raadu, M.A.; Gudmundsson, J.T.; Helmersson, U. On the film density using high power impulse magnetron sputtering. Surf. Coat. Technol. 2010, 205, 591–596. [Google Scholar] [CrossRef] [Green Version]

- Sarakinos, K.; Braun, A.; Zilkens, C.; Mráz, S.; Schneider, J.; Zoubos, H.; Patsalas, P. Exploring the potential of high power impulse magnetron sputtering for growth of diamond-like carbon films. Surf. Coat. Technol. 2012, 206, 2706–2710. [Google Scholar] [CrossRef] [Green Version]

- Aijaz, A.; Sarakinos, K.; Lundin, D.; Brenning, N.; Helmersson, U. A strategy for increased carbon ionization in magnetron sputtering discharges. Diam. Relat. Mater. 2012, 23, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Aijaz, A.; Ferreira, F.; Oliveira, J.; Kubart, T. Mechanical Properties of Hydrogen Free Diamond-Like Carbon Thin Films Deposited by High Power Impulse Magnetron Sputtering with Ne. Coatings 2018, 8, 385. [Google Scholar] [CrossRef] [Green Version]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Engels, M. Synthesis of a-C coatings by HPPMS using Ar, Ne and He as process gases. Surf. Coat. Technol. 2016, 308, 80–89. [Google Scholar] [CrossRef]

- Cardoso, F.; Ferreira, F.; Cavaleiro, A.; Ramalho, A. Performance of diamond-like carbon coatings (produced by the innovative Ne-HiPIMS technology) under different lubrication regimes. Wear 2021, 477, 203775. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Ramalho, A.; Cavaleiro, A. Grooved surface texturing by electrical discharge machining (EDM) under different lubrication regimes. Lubr. Sci. 2017, 29, 493–501. [Google Scholar] [CrossRef]

- Mansori, M.E.; Goeldel, B.; Sabri, L. Performance impact of honing dynamics on surface finish of precoated cylinder bores. Surf. Coat. Technol. 2013, 215, 334–339. [Google Scholar] [CrossRef] [Green Version]

- Pusterhofer, M.; Summer, F.; Wuketich, D.; Grün, F. Development of a Model Test System for a Piston Ring/Cylinder Liner-Contact with Focus on Near-to-Application Seizure Behaviour. Lubricants 2019, 7, 104. [Google Scholar] [CrossRef] [Green Version]

- Bolander, N.W.; Steenwyk, B.D.; Sadeghi, F.; Gerber, G.R. Lubrication regime transitions at the piston ring-cylinder liner interface. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2005, 219, 19–31. [Google Scholar] [CrossRef]

- ExxonMobil Spectrasyn™ 2 Polyalphaolefin (PAO) Fluid Datasheet. Available online: http://www.lookpolymers.com/pdf/ExxonMobil-SpectraSyn-2-Polyalphaolefin-PAO-Fluid.pdf (accessed on 29 October 2021).

- Arai, K.; Yamada, M.; Asano, S.; Yoshizawa, S.; Ohira, H.; Hoshino, K.; Ueda, F.; Akiyama, K. Lubricant Technology to Enhance the Durability of Low Friction Performance of Gasoline Engine Oils. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 1995; pp. 1964–1972. [Google Scholar] [CrossRef]

- Kwok, D.Y.; Neumann, A.W. Contact angle interpretation in terms of solid surface tension. Colloids Surf. A Physicochem. Eng. Asp. 2000, 161, 31–48. [Google Scholar] [CrossRef]

- Bahari, A.; Lewis, R.; Slatter, T. Hardness characterisation of grey cast iron and its tribological performance in a contact lubricated with soybean oil. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 232, 190–203. [Google Scholar] [CrossRef] [Green Version]

- Evans, R. Selection and testing of metalworking fluids. In Metalworking Fluids (MWFs) for Cutting and Grinding; Woodhead Publishing: Cambridge, UK, 2012; pp. 23–78. [Google Scholar] [CrossRef]

- Gundlach, R.; Meyer, M.; Winardi, L. Influence of Mn and S on the Properties of Cast Iron Part III—Testing and Analysis. Int. J. Met. 2015, 9, 69–82. [Google Scholar] [CrossRef]

- Mu, L.; Wu, J.; Matsakas, L.; Chen, M.; Vahidi, A.; Grahn, M.; Rova, U.; Christakopoulos, P.; Zhu, J.; Shi, Y. Lignin from Hardwood and Softwood Biomass as a Lubricating Additive to Ethylene Glycol. Molecules 2018, 23, 537. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferreira, F.; Serra, R.; Cavaleiro, A.; Oliveira, J. Diamond-like carbon coatings deposited by deep oscillation magnetron sputtering in Ar-ne discharges. Diam. Relat. Mater. 2019, 98, 107521. [Google Scholar] [CrossRef]

| Pressure | Ne | Vp | Ip | Pp | Fi |

|---|---|---|---|---|---|

| (Pa) | (%) | (V) | (A) | (KW) | (Hz) |

| 0 | 1384 | 76.1 | 105 | 247 | |

| 0.8 | 25 | 1365 | 90 | 123 | 261 |

| 50 | 1349 | 96 | 130 | 266 |

| rpm | 4.6 | 5.4 | 7.7 | 12 | 17 | 30 | 45 | 70 | 100 | 130 |

| m/s | 0.028 | 0.033 | 0.047 | 0.073 | 0.103 | 0.182 | 0.273 | 0.425 | 0.607 | 0.7790 |

| Element | C | Si | Mn | S | P | Others | Fe |

| Typical | 2.95–3.45 | 2.1–2.9 | 0.55–0.75 | 0.04–0.07 | 0.1–0.2 | Residual | Balance |

| Temp. | (°C) | 25 | 60 | 80 | 100 |

| Viscosity | (mPa.s) | 56.063 | 15.579 | 7.632 | 3.695 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vahidi, A.; Fonseca, D.; Oliveira, J.; Cavaleiro, A.; Ramalho, A.; Ferreira, F. Advanced Tribological Characterization of DLC Coatings Produced by Ne-HiPIMS for the Application on the Piston Rings of Internal Combustion Engines. Appl. Sci. 2021, 11, 10498. https://doi.org/10.3390/app112110498

Vahidi A, Fonseca D, Oliveira J, Cavaleiro A, Ramalho A, Ferreira F. Advanced Tribological Characterization of DLC Coatings Produced by Ne-HiPIMS for the Application on the Piston Rings of Internal Combustion Engines. Applied Sciences. 2021; 11(21):10498. https://doi.org/10.3390/app112110498

Chicago/Turabian StyleVahidi, Alireza, Diogo Fonseca, João Oliveira, Albano Cavaleiro, Amílcar Ramalho, and Fábio Ferreira. 2021. "Advanced Tribological Characterization of DLC Coatings Produced by Ne-HiPIMS for the Application on the Piston Rings of Internal Combustion Engines" Applied Sciences 11, no. 21: 10498. https://doi.org/10.3390/app112110498

APA StyleVahidi, A., Fonseca, D., Oliveira, J., Cavaleiro, A., Ramalho, A., & Ferreira, F. (2021). Advanced Tribological Characterization of DLC Coatings Produced by Ne-HiPIMS for the Application on the Piston Rings of Internal Combustion Engines. Applied Sciences, 11(21), 10498. https://doi.org/10.3390/app112110498