Mechanical Behavior of Weathered Granite Exposed to Water

Abstract

:1. Introduction

2. Materials and Methods

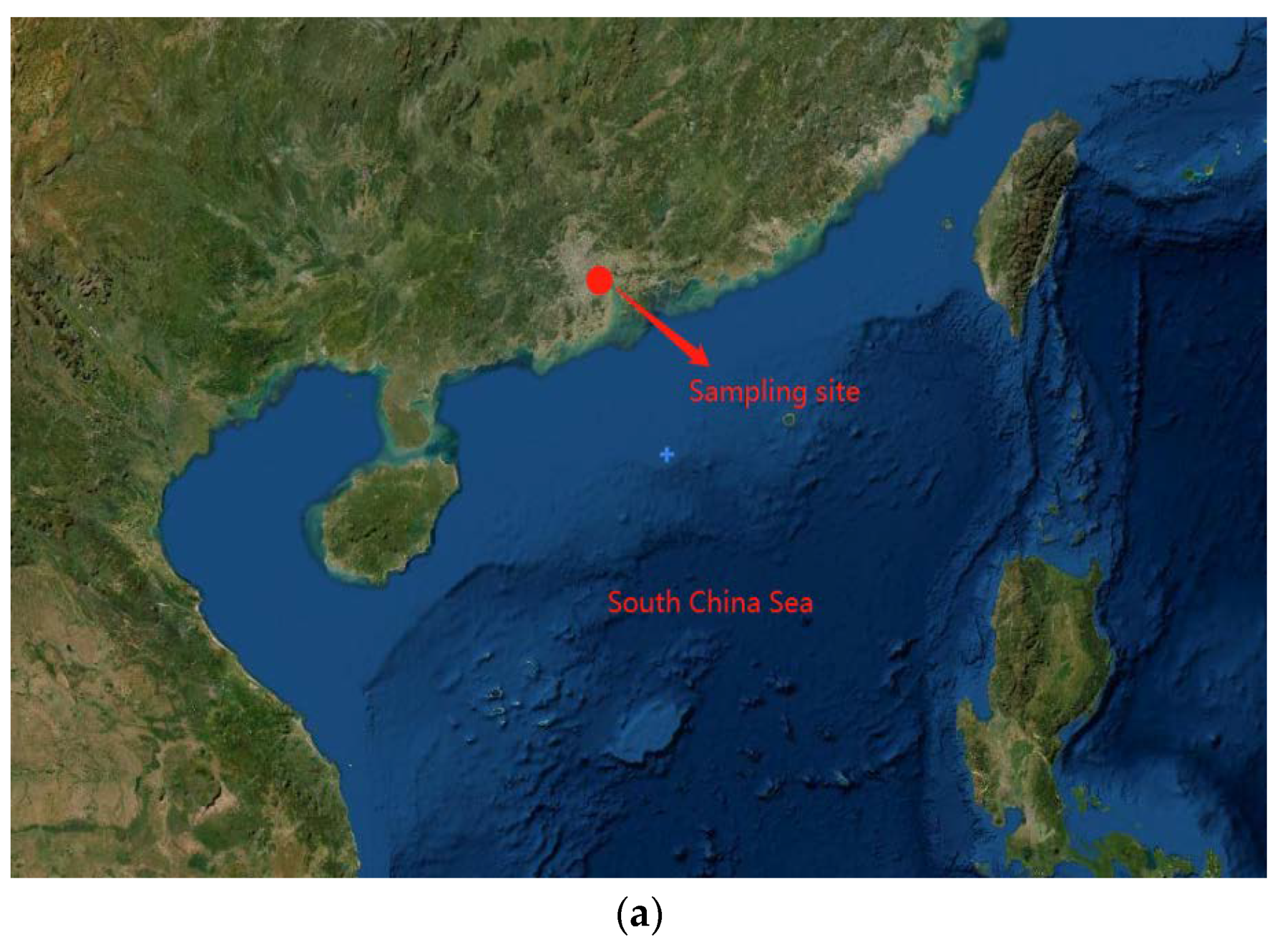

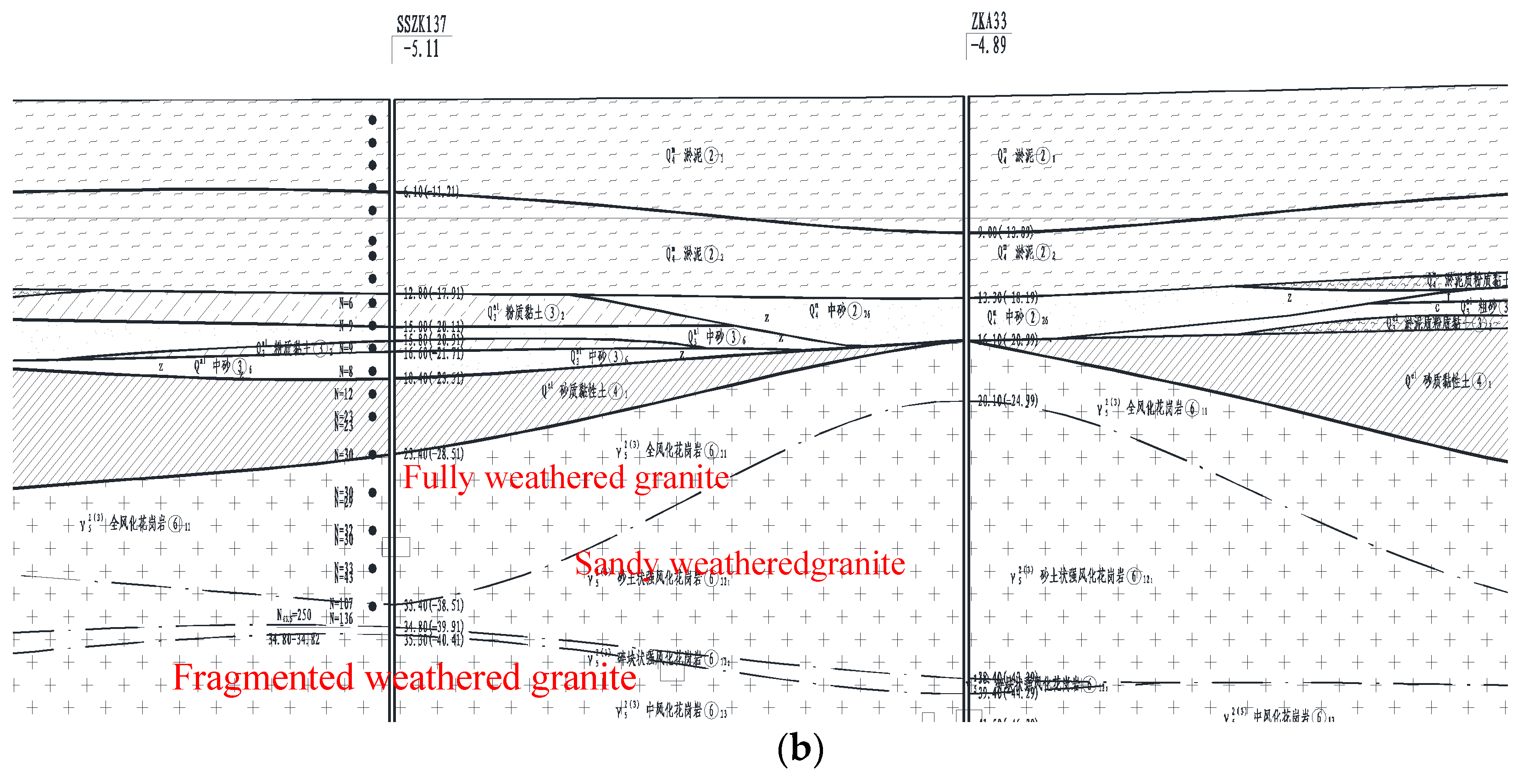

2.1. Testing Materials

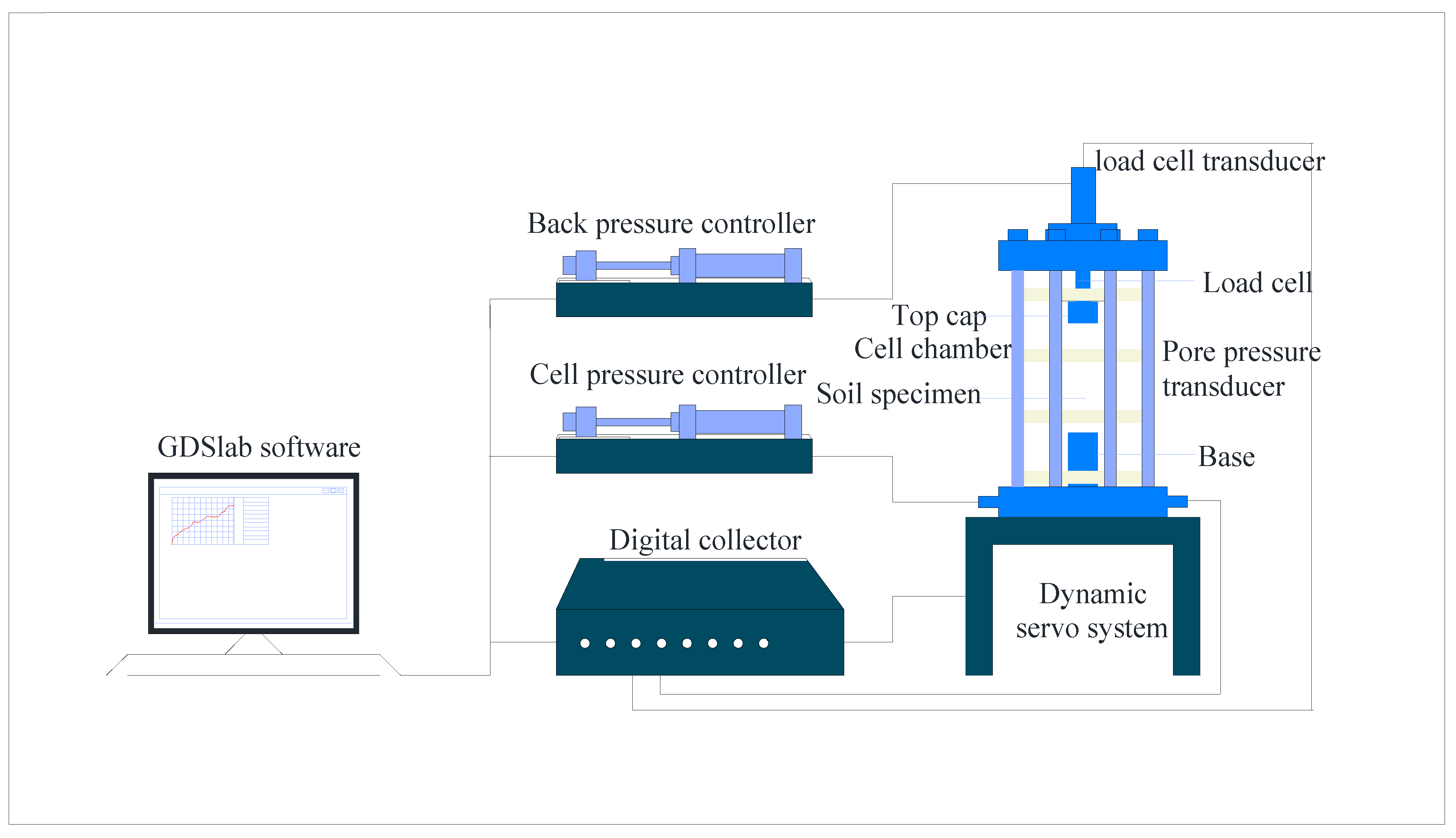

2.2. Testing Equipment and Specimen Preparation

2.3. Experimental Procedures

3. Test Results

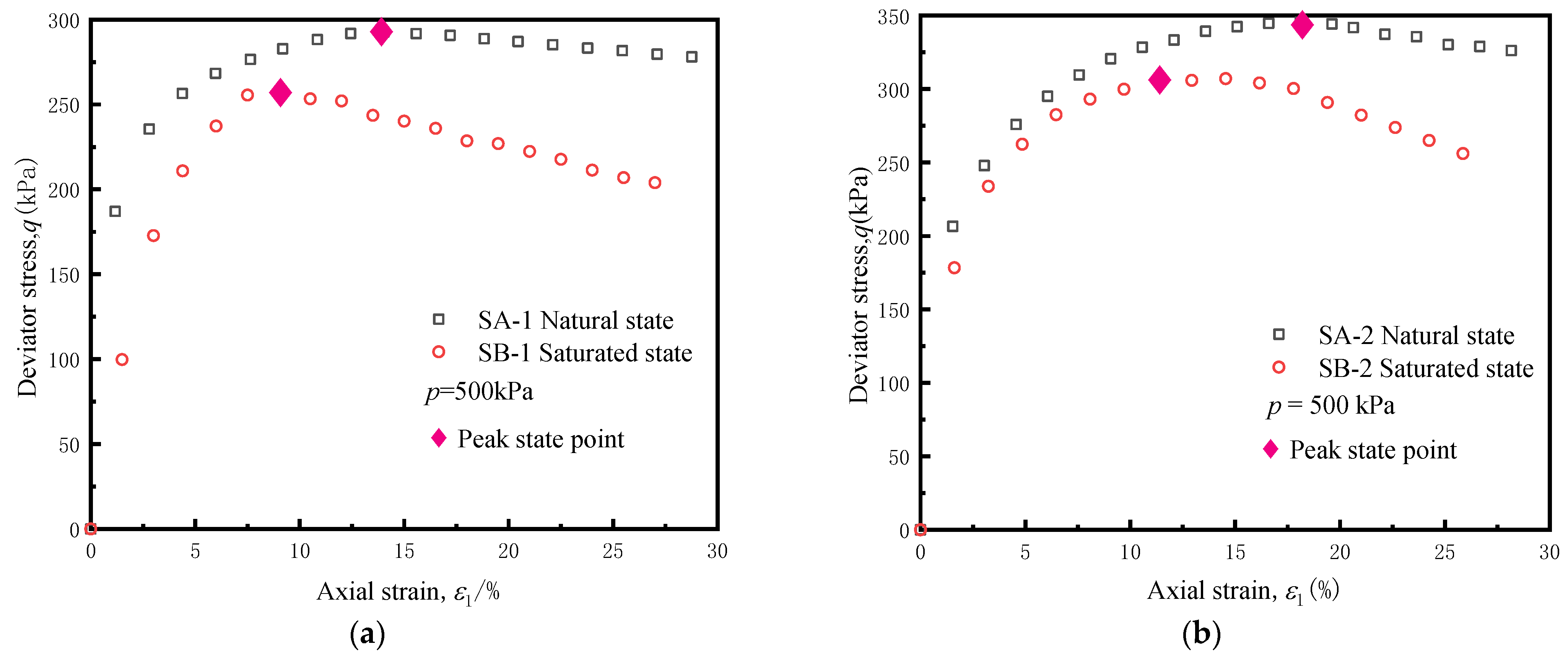

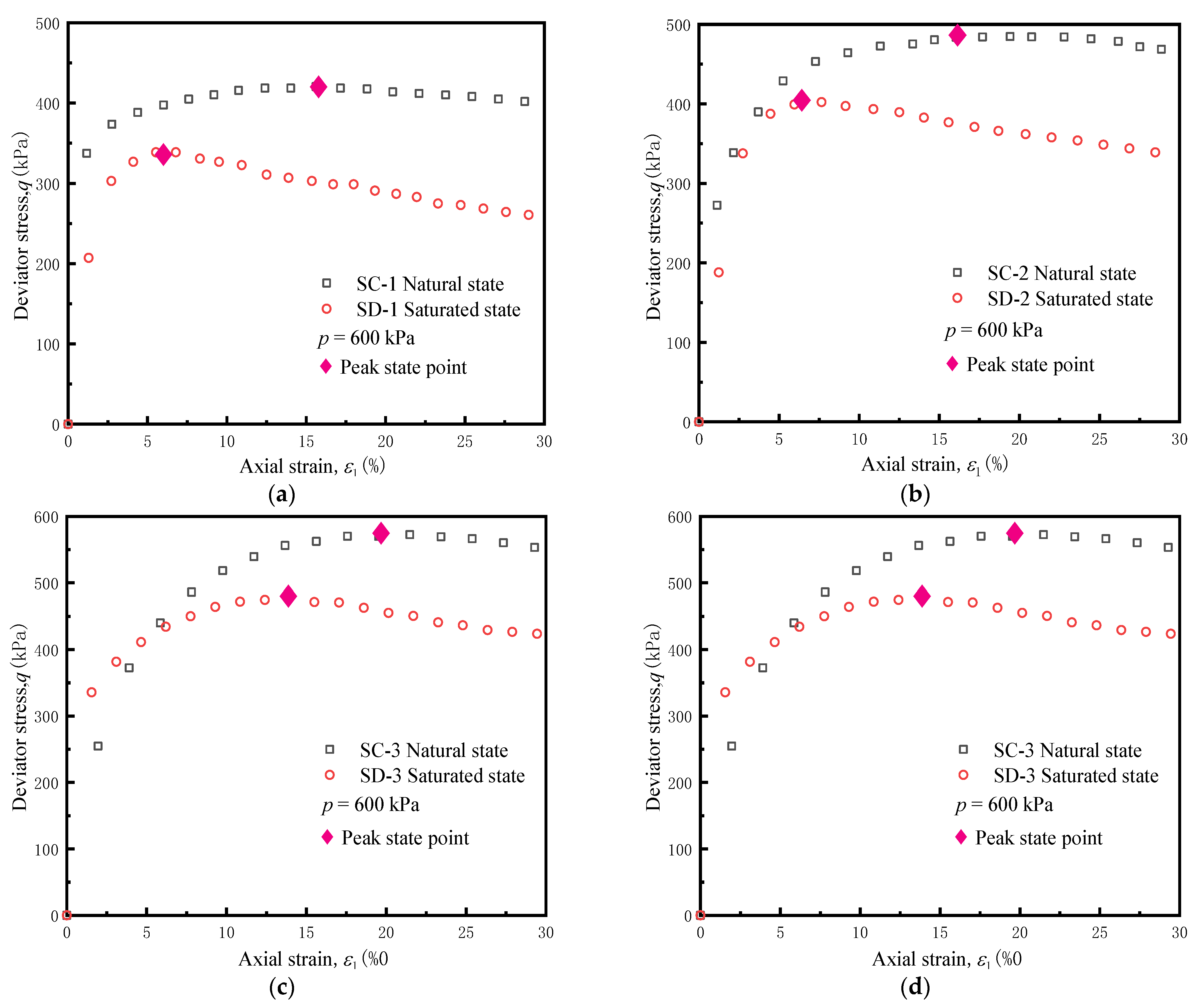

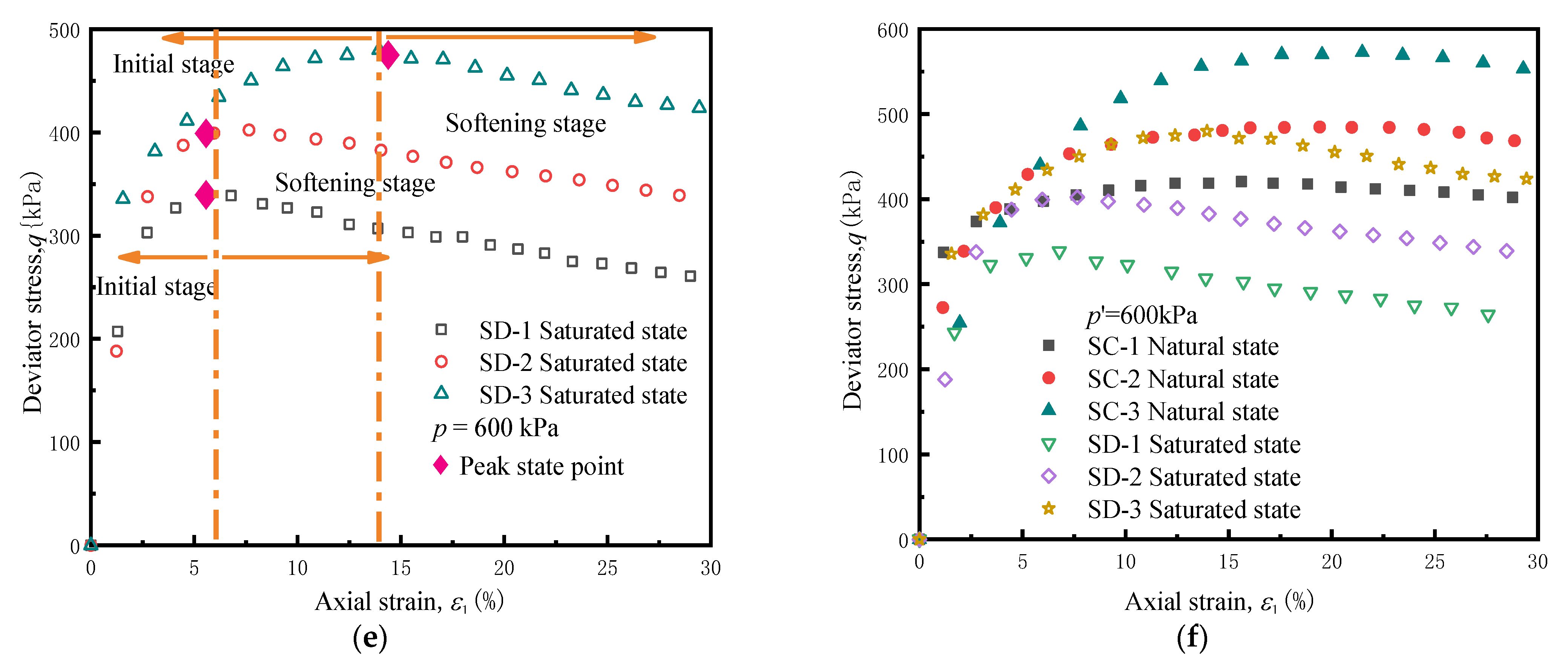

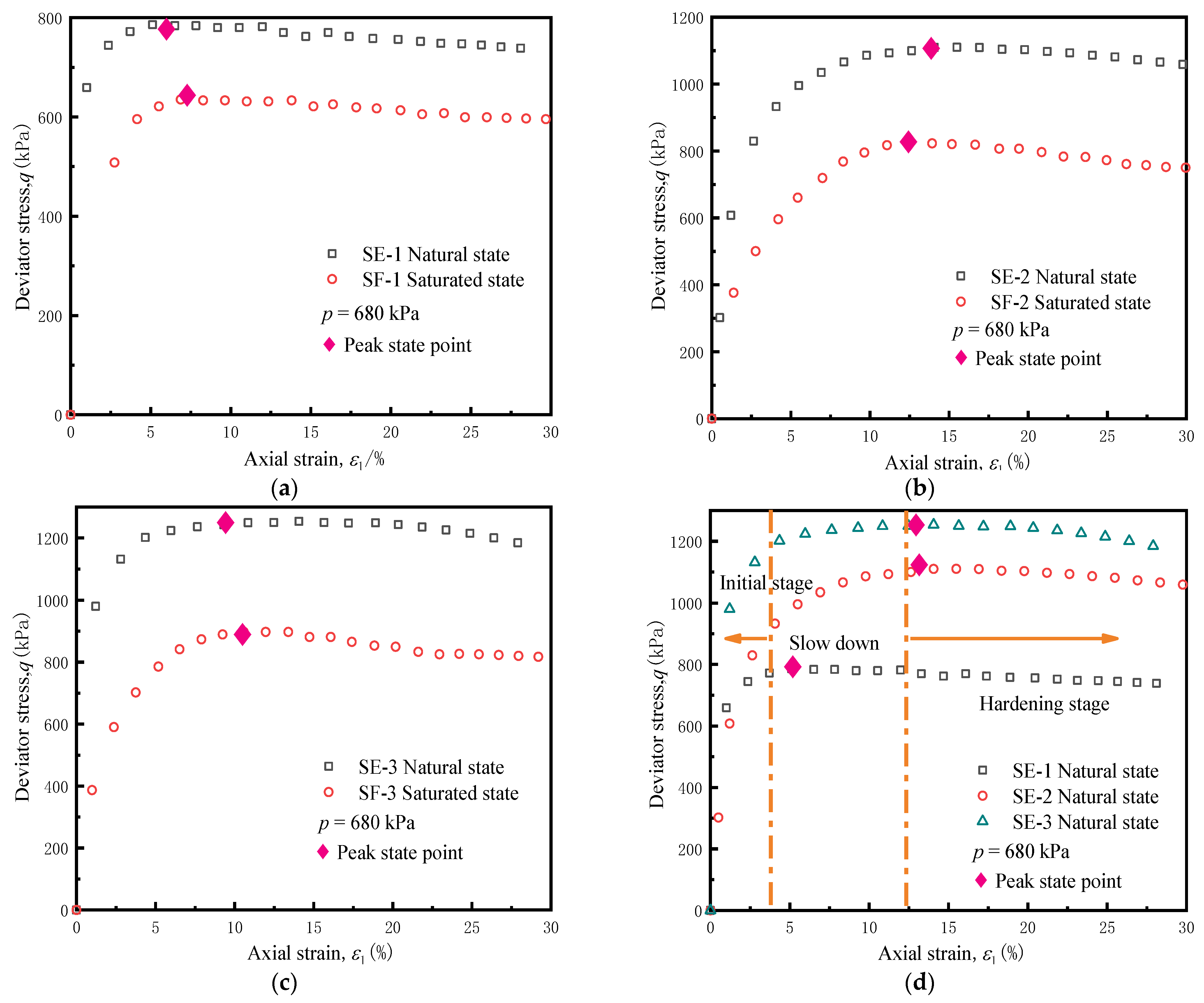

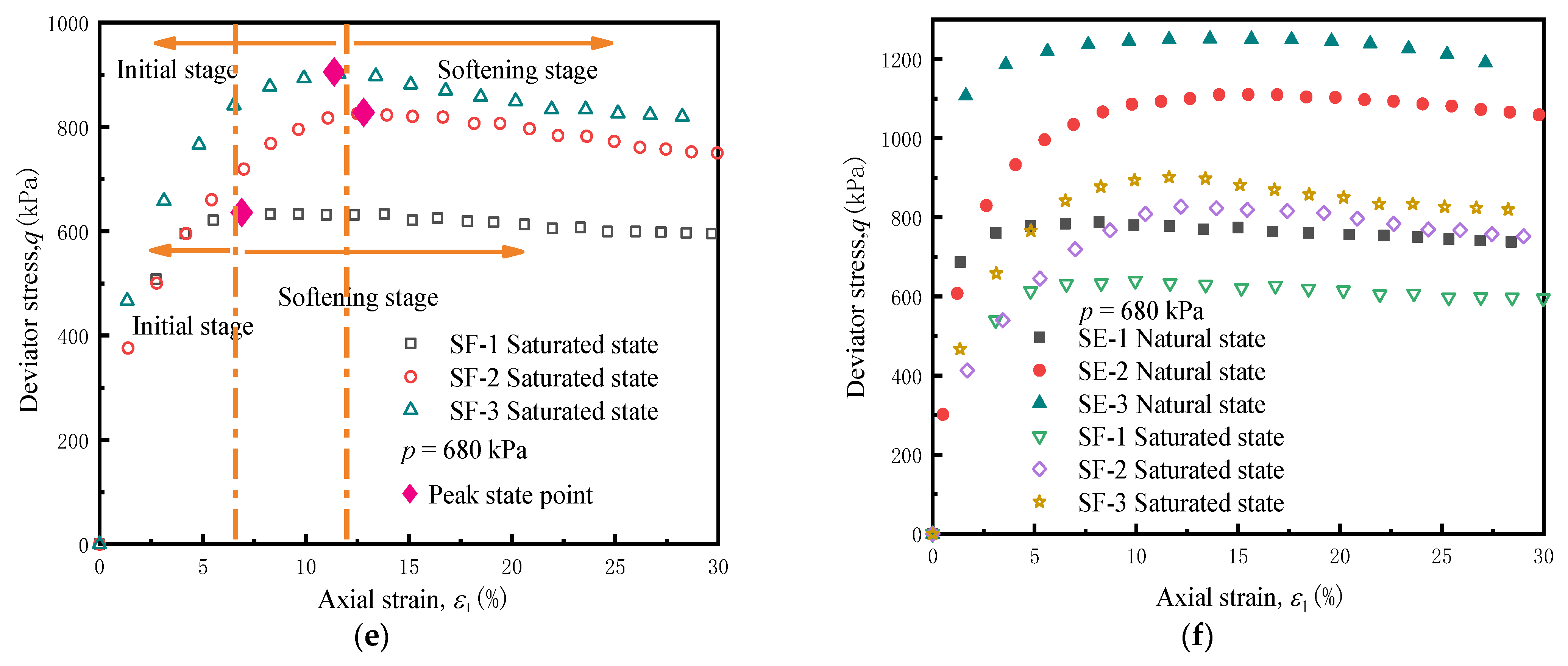

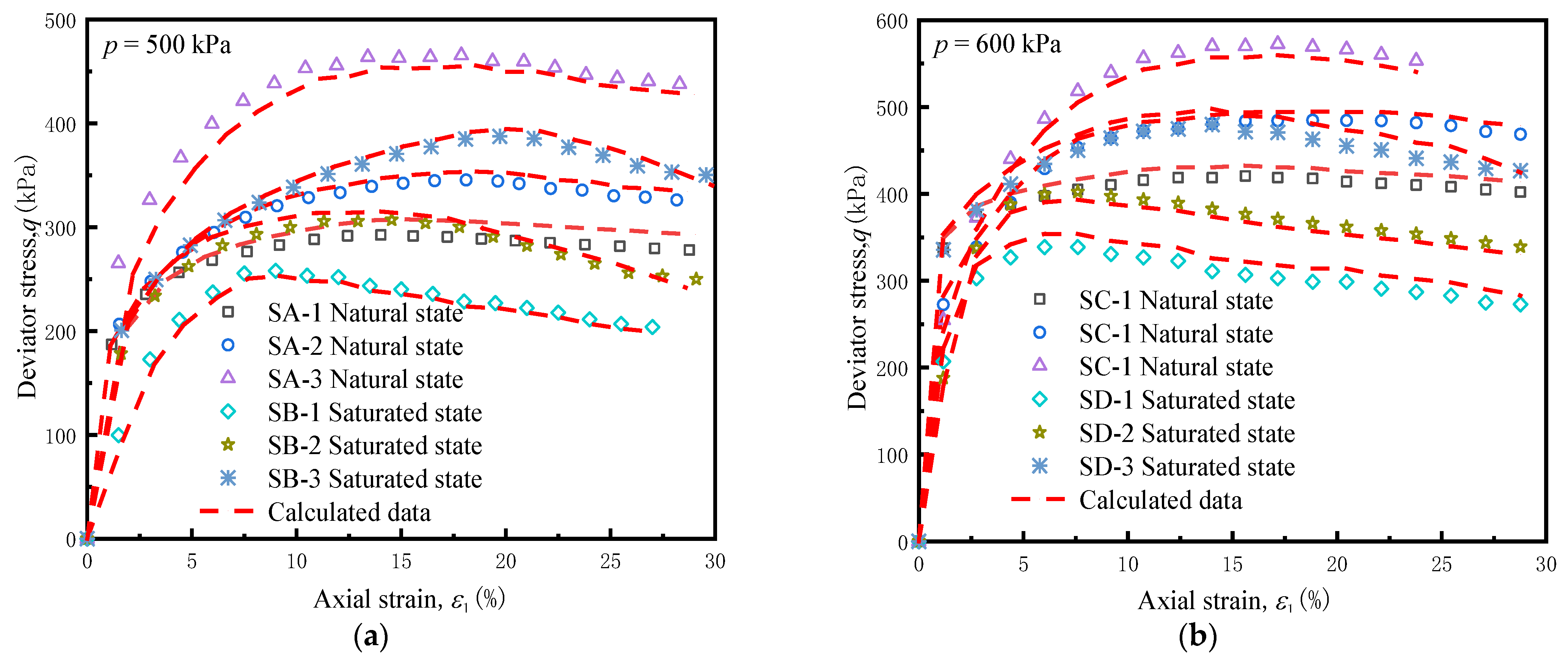

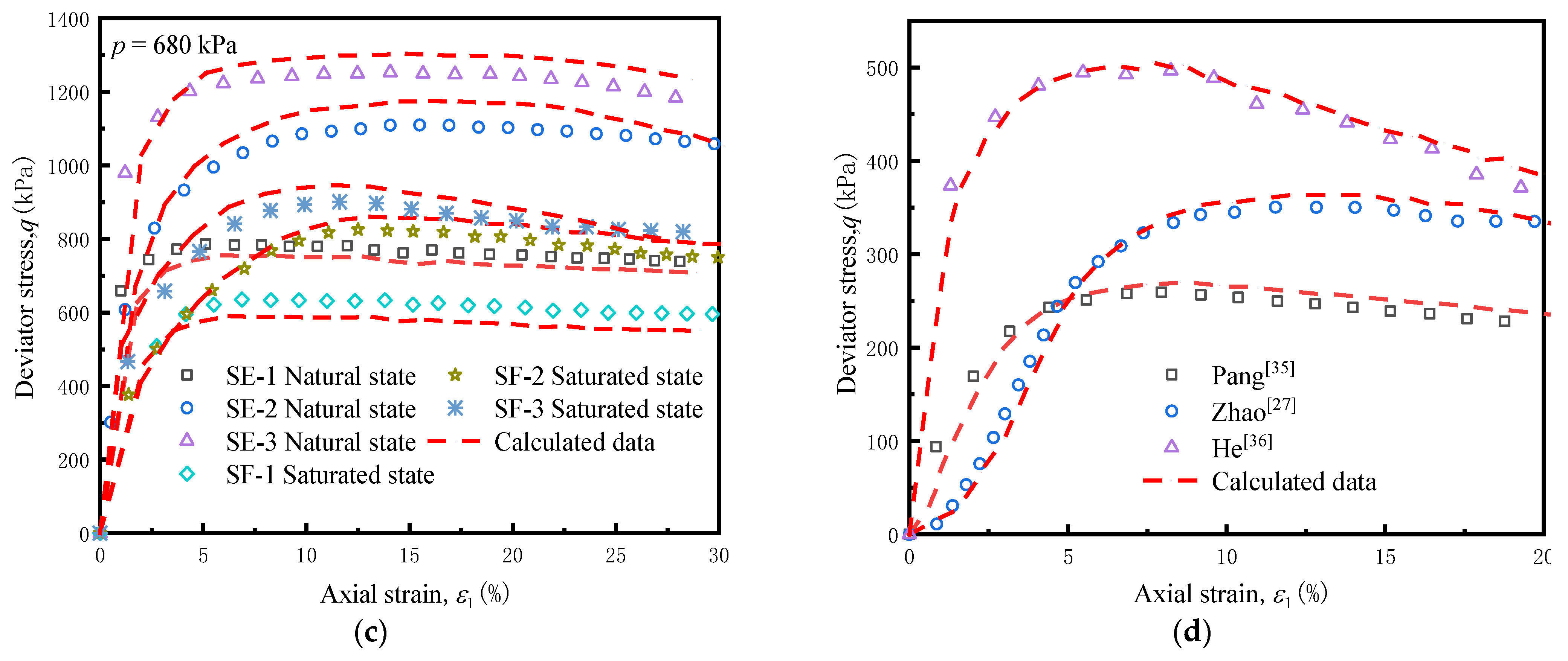

3.1. Stress and Axial Strain

3.2. Pore Pressure and Axial Strain

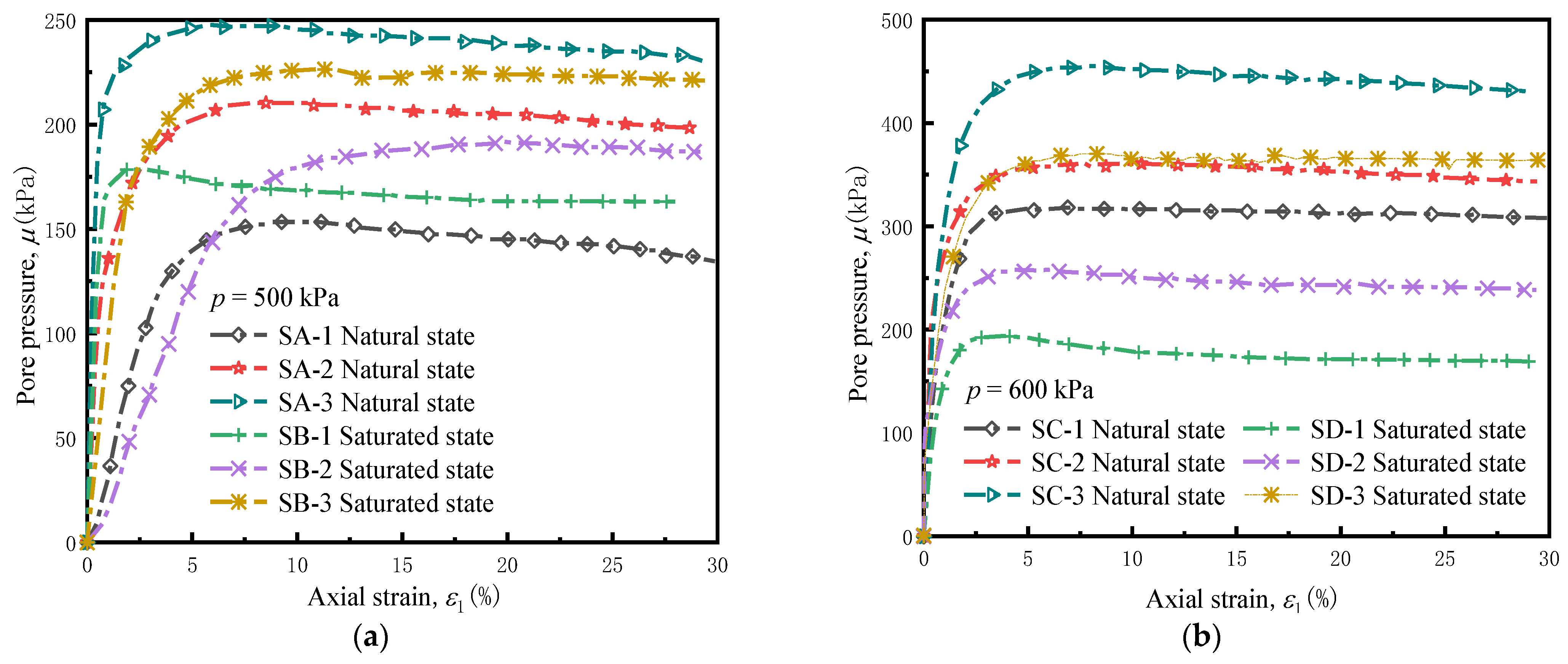

3.3. Strength Degradation Index

4. Modeling

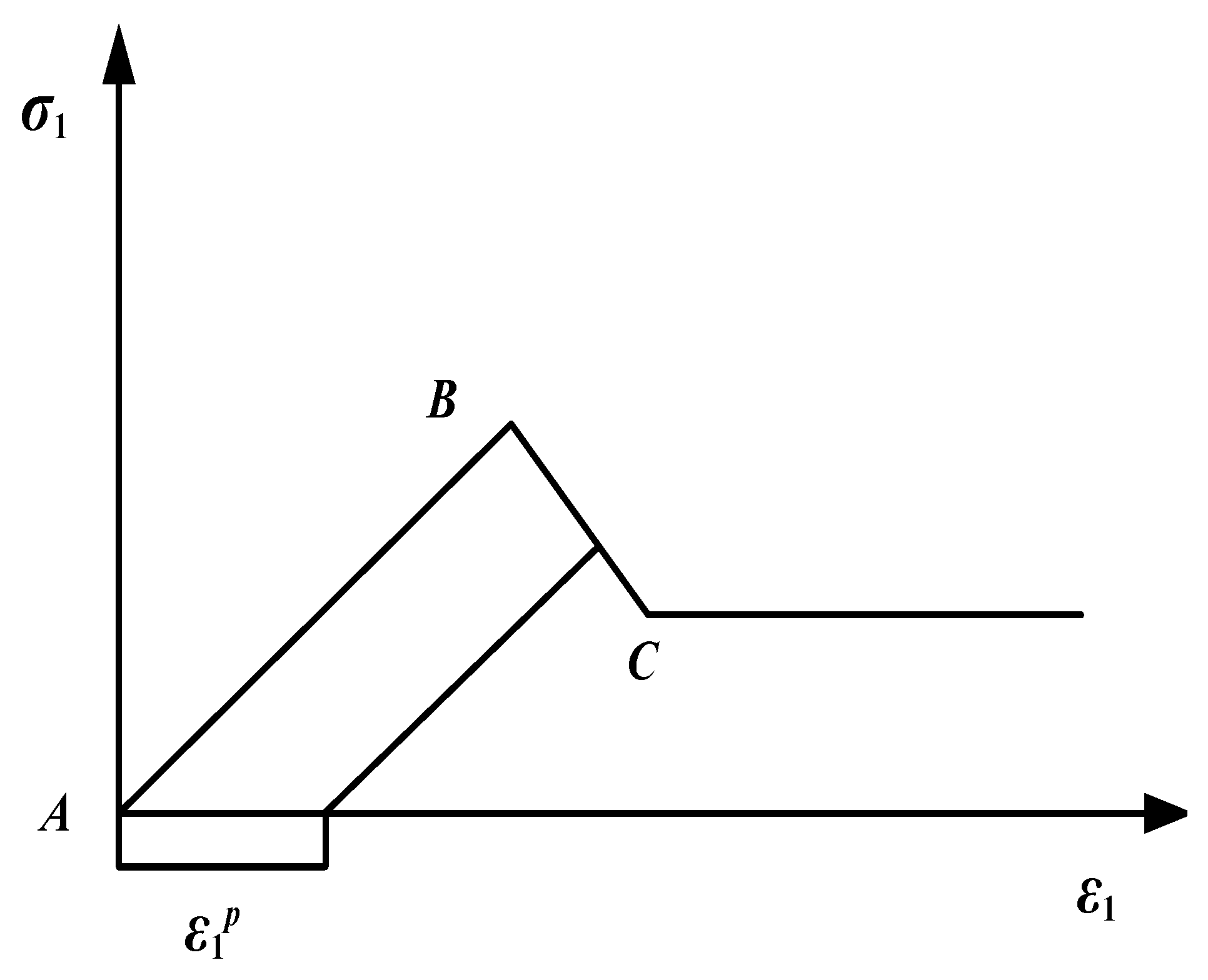

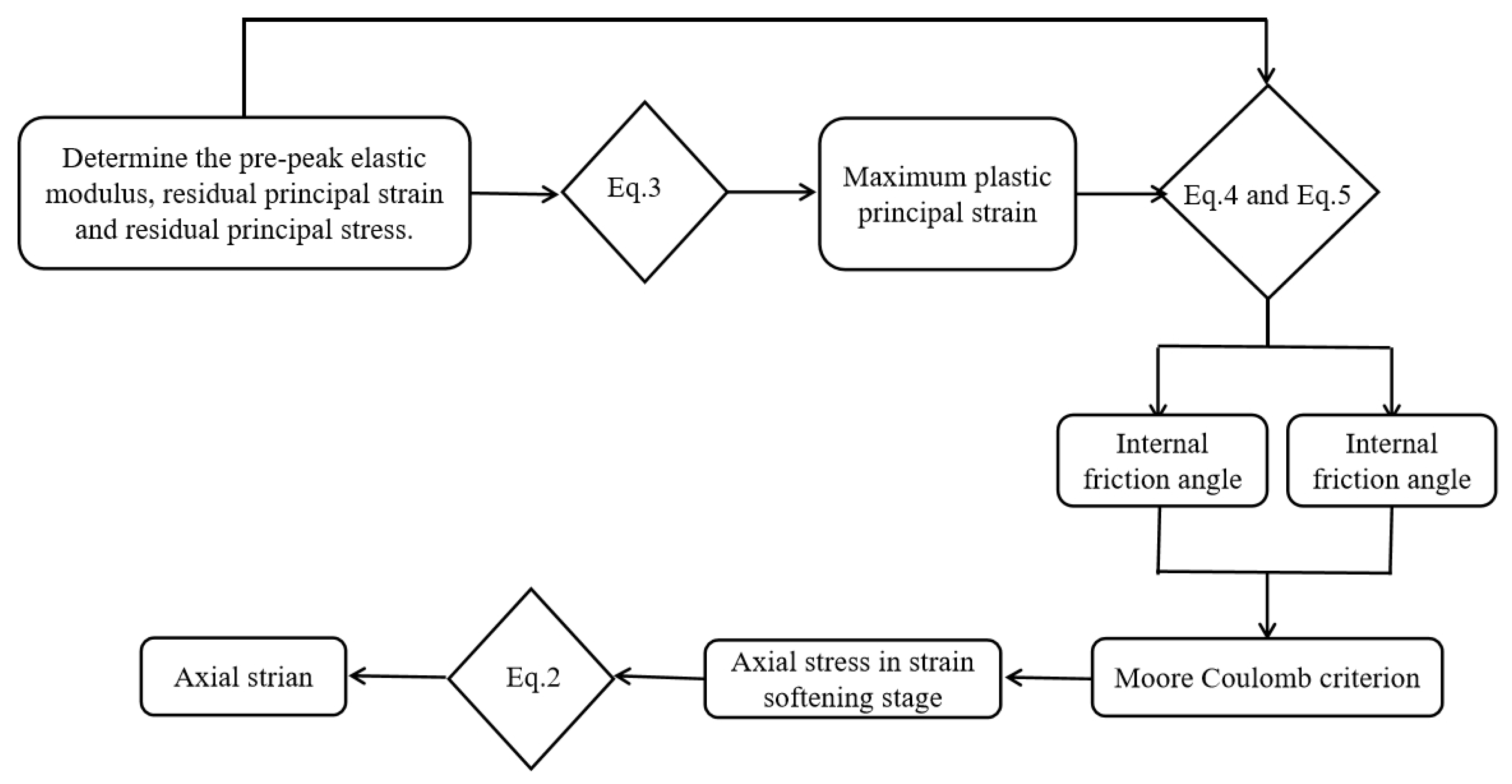

4.1. Model for Predicting Strain Softening

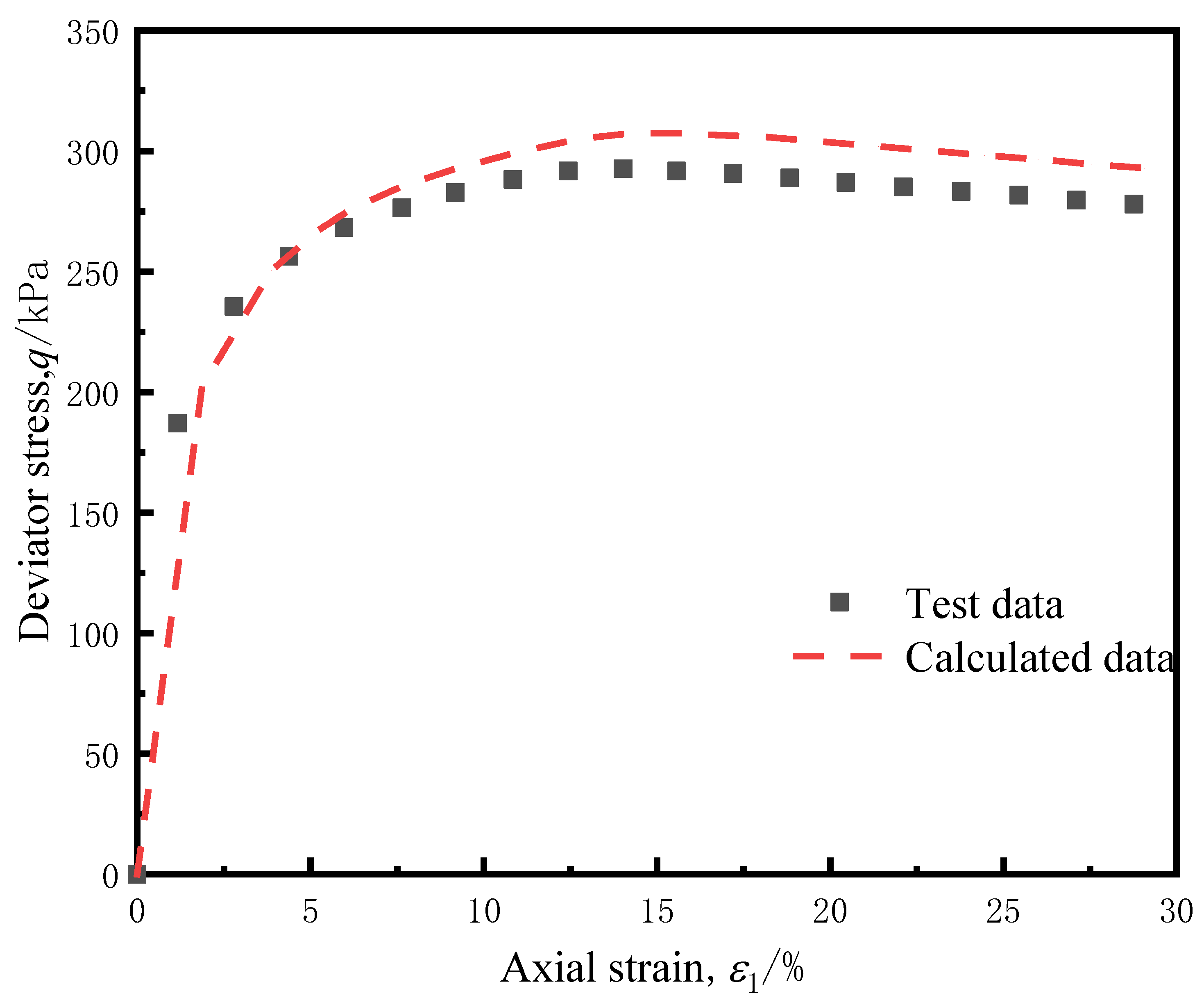

4.2. Validation of Model

5. Conclusions

- The stress–strain curve of the weathered granite in its natural state can be roughly divided into three stages. In the initial stage, which happens at an axial strain of lower than 10%, 8%, and 5% for the fully weathered granite, the sandy weathered granite, and the fragmented weathered granite, respectively, the shear stress on the specimen soars with the axial strain; however, the slope of the stress–strain curve and thus the growth rate of the shear stress decline as the axial strain enlarges. After the sample reaches the peak stress, which happens at an axial strain of higher than 16%, 17%, and 12% for the fully weathered granite, the sandy weathered granite, and the fragmented weathered granite, respectively, the shear stress on the rock decreases with the axial strain, implying a particular strain-softening trend.

- The stress–strain curve of the weathered granite in the saturated state is divided into two stages. Before the rock reaches its peak strength, the shear stress soars approximately linearly with the axial strain. When the weathered granite reaches its peak strength, it undergoes noticeable strain softening; in other words, the shear stress plummets with the axial strain.

- Comparing the test results obtained in the natural and saturated states of the weathered granite reveals that the peak strength of the weathered granite decreases dramatically after exposure to water, and its corresponding peak strain is affected.

- In actual engineering, weathered rock masses are often under deviator stress consolidation rather than isotropic consolidation. Therefore, studying the mechanical behavior of the weathered rocks under deviator stress consolidation is of more practical significance and theoretical value. The softening degree of the weathered granite varies as the consolidation mode changes and decreases to a certain extent as the shear stress applied by the deviator stress consolidation enlarges.

- In the initial stages of the loading, shear shrinkage occurs since the pore water pressure increases; later, as the axial strain continues to increase, the rock shows a trend of shear dilatation until it reaches a critical state. The axial strain required for the shear stress to reach the peak value is always greater than that required for the dilatancy to occur.

- We also established an empirical model describing the strain softening of weathered granite by utilizing the internal cohesion and the internal friction angle; the model suits weathered granite in natural and saturated states.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Q.; Hu, Q.; Larsen, C.; Zhao, C.; Sun, M.; Zhang, Y.; Zhang, T. Microfracture-pore structure characterization and water-rock interaction in three lithofacies of the Lower Eagle Ford Formation. Eng. Geol. 2021, 292, 106276. [Google Scholar] [CrossRef]

- Song, K.-I.; Cho, G.-C.; Lee, S.-W. Effects of spatially variable weathered rock properties on tunnel behavior. Probabilistic Eng. Mech. 2011, 26, 413–426. [Google Scholar] [CrossRef]

- Xiaoqing, L.; Qingping, J. Compacting Deformation Engineering Characteristics of Weathered Soft Rock Mixture in Subgrade. J. China Univ. Geosci. 2008, 19, 298–306. [Google Scholar] [CrossRef]

- Zhang, K.C.; Zhu, J.B.; Cheng, M. The shear strength research on rock-soil mixture material of weathered granite blocks and residual soil after dynamic compaction. Geotech. Eng. Technol. 2016, 30, 20–23+45. [Google Scholar]

- Zhou, S.H.; Wang, Y.H.; Qing, Q.X.; He, Q. Experimental study of appropriateness improved granitic residual soil for high -speed railway subgrade. Chin. J. Rock Mech. Eng. 2011, 30, 625–634. [Google Scholar]

- Nian, H.F.; Zhang, C.H. Study of micro-softening mechanism and strength model of saturated slate in reservoir area of wudongde hydropower station. J. China Three Gorges Univ. Nat. Sci. 2018, 40, 6–10. [Google Scholar]

- Zhang, Q.Y.; Deng, H. Research on strength softening when Wet of rotten rock based on triaxial compression tests of a hydropower station. Pearl River 2019, 40, 101–110. [Google Scholar]

- Song, Z.P.; Yang, T.T.; Jiang, A.N. Experimental investigation and numerical simulation of surrounding rock creep for deep mining tunnels. J. S. Afr. Inst. Min. Metall. 2016, 116, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Ling, S.X.; Wu, X.Y.; Sun, C.W. Experimental study of chemical damage and mechanical deterioration of black shale due to water-rock chemical action. J. Exp. Mech. 2016, 31, 511–524. [Google Scholar]

- Xiao, Y.X.; Wang, Y.J.; Lu, S.Z. Assessment of hydromechanically equivalent continuum model for fractured rock masses. Chin. J. Rock Mech. Eng. 1999, 18, 76–81. (In Chinese) [Google Scholar]

- An, W.B.; Wang, L.G.; Chen, H. Mechanical Properties of Weathered Feldspar Sandstone after Experiencing Dry-Wet Cycles. Adv. Mater. Sci. Eng. 2020, 2020, 6268945. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.H.; Jiang, Q.H.; Zhou, C.B. Strength and failure characteristics of Jurassic red-bed sandstone under cyclic wetting-drying conditions. Geophys. J. Int. 2014, 196, 1034–1044. [Google Scholar] [CrossRef]

- Auvray, C.; Homand, F.; Sorgi, C. The aging of gypsum in underground mines. Eng. Geol. 2004, 74, 183–196. [Google Scholar] [CrossRef]

- Hoxha, D.; Homand, F.; Auvray, C. Deformation of natural gypsum rock: Mechanisms and questions. Eng. Geol. 2006, 86, 1–17. [Google Scholar] [CrossRef]

- Yilmaz, I. Influence of water content on the strength and deformability of gypsum. Int. J. Rock Mech. Min. Sci. 2010, 47, 342–347. [Google Scholar] [CrossRef]

- Eliek, J.M. Rockslide in Sunbury, Pennsylvania. Pa. Geol. 2002, 32, 2–7. [Google Scholar]

- Hawkins, A.B.; Mcconnell, B.J. Sensitivity of sandstone strength and deformability to changes in moisture content. Q. J. Eng. Geol. 1992, 25, 115–130. [Google Scholar] [CrossRef]

- Zheng, X.Q.; Liu, J.; Bian, K.; Liu, S.G.; Liu, Z.P.; Ai, F. Softening micro-mechanism and mechanical properties of water-saturated shale in Northwestern Hubei. Rock Soil Mech. 2017, 38, 2022–2028. [Google Scholar]

- Gurson, A.L. Continuum theory of ductile rupture by void nucleation and growth. Part I. Yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 1975, 99, 297–300. [Google Scholar]

- Krajcinovic, D.; Silva, M.A.G. Statistical aspects of the continuous damage theory. Int. J. Solids Struct. 1982, 18, 551–562. [Google Scholar] [CrossRef]

- Krajcinovic, D. Continuous damage mechanics. Appl. Mech. Rev. 1984, 37, 1–5. [Google Scholar]

- Darabi, M.K.; Al-rub, R.K.A.; Little, D.N. A continuum damage mechanics framework for modeling micro-damage healing. Int. J. Solids Struct. 2012, 49, 492–513. [Google Scholar] [CrossRef] [Green Version]

- He, S.H.; Zhi, D.; Xia, T.D.; Zhou, W.H.; Gan, X.L.; Chen, Y.Z.; Xia, F. Long-term behavior and degradation of calcareous sand under cyclic loading. Eng. Geol. 2020, 278, 122740. [Google Scholar]

- He, S.H.; Shan, H.F.; Xia, T.D.; Liu, Z.J.; Ding, Z.; Xia, F. The effect of temperature on the drained shear behavior of calcareous sand. Acta Geotech. 2021, 16, 613–633. [Google Scholar] [CrossRef]

- Yu, J.G.; Sun, M.M.; He, S.H.; Huang, X.; Liu, L.Y. Accumulative Deformation Characteristics and Microstructure of Saturated Soft Clay under Cross-River Subway Loading. Materials 2021, 14, 537. [Google Scholar] [CrossRef]

- Sun, M.M.; Yu, J.G.; Ding, Z.; He, S.H. Numerical Model about the Influence of Cyclic Load on the Hydraulic Conductivity of Soft Clay. KSCE J. Civ. Eng. 2021, 1–14. [Google Scholar] [CrossRef]

- Zhao, J.J.; Wang, S.J.; Shang, Y.J.; Yue, S.Q. Dilatation in direct shear tests of Hong Kong completely decomposed granite (CDG). J. Eng. Geol. 2005, 13, 44–48. (In Chinese) [Google Scholar]

- Niu, X.R.; Gao, J.P.; Zhang, E.S. An experimental study of the physical and mechanical properties of compacted weathered granite soil. Rock Soil Mech. 2016, 37, 701–710. (In Chinese) [Google Scholar]

- Zhao, J.J.; Wang, S.J.; Shang, Y.J.; Yue, Z.Q. Control factors on shear strength of completely decomposed granite. Rock Soil Mech. 2005, 26, 624–628. (In Chinese) [Google Scholar]

- Liu, P. Experimental Study and Constitutive Model of Completely Decomposed Granite; South China University of Technology: Guangzhou, China, 2016. [Google Scholar]

- Yan, M. Experimental Study and Constitutive Modeling of Re-Compacted Compacted Completely Decomposed Granite. Ph.D. Thesis, Department of Civil Engineering, Hong Kong University of Science and Technology, Hongkong, China, January 2003. [Google Scholar]

- Li, X.S.; Dafalias, Y.F. Dilatancy of cohesionless soils. Geotechnique 2000, 50, 449–460. [Google Scholar] [CrossRef]

- Chiu, C.F. Behavior of Unsaturated Loosely Compacted Weathered Materials. Ph.D. Thesis, Hong Kong University of Science and Technology, Hongkong, China, March 2003. [Google Scholar]

- To, C.Y. A Unified Elastoplastic Model for Saturated Loosely Compacted Completely Decomposed Granite. Master’s Thesis, The University of Hong Kong, Hongkong, China, June 2008. [Google Scholar]

- Pang, X.C. Experimental Study and Constitutive Modeling of Shenzhen Natural Completed Decomposed Granite; China Academy of Railway Sciences: Beijing, China, October 2011. [Google Scholar]

- He, Y.B. Experiment Study of Shear Properties of Completed Decomposed Granite; South China University of Technology: Guangzhou, China, 2015. [Google Scholar]

| Property | Fully Weathered Granite | Sandy Weathered Granite | Fragmented Weathered Granite |

|---|---|---|---|

| Natural water content (w) | 25.78% | 17.30% | 18.80% |

| Specific gravity (Gs) | 2.7 | 2.68 | 2.65 |

| Void ratio (e) | 0.79 | 0.62 | 0.54 |

| Liquid limit (WL) | 31.59% | 29.56% | 26.78% |

| Plastic limit (WP) | 14.52% | 12.77% | 11.45% |

| Test ID | State Before Test | Specimen Type | Consolidation Method | p (kPa) |

|---|---|---|---|---|

| SA-1 | Natural | Fully weathered granite | Isotropic consolidation | 500 |

| SA-2 | (σ1 − σ3)1 | |||

| SA-3 | (σ1 − σ3)2 | |||

| SB-1 | Saturated | Isotropic consolidation | ||

| SB-2 | (σ1 − σ3)1 | |||

| SB-3 | (σ1 − σ3)2 | |||

| SC-1 | Natural | Sandy weathered granite | Isotropic consolidation | 600 |

| SC-2 | (σ1 − σ3)1 | |||

| SC-3 | (σ1 − σ3)2 | |||

| SD-1 | Saturated | Isotropic consolidation | ||

| SD-2 | (σ1 − σ3)1 | |||

| SD-3 | (σ1 − σ3)2 | |||

| SE-1 | Natural | Fragmented weathered granite | Isotropic consolidation | 680 |

| SE-2 | (σ1 − σ3)1 | |||

| SE-3 | (σ1 − σ3)2 | |||

| SF-1 | Saturated | Isotropic consolidation | ||

| SF-2 | (σ1 − σ3)1 | |||

| SF-3 | (σ1 − σ3)2 |

| Specimen Type | Consolidation Method | |||

|---|---|---|---|---|

| Fully weathered granite | 0 | 292.63 | 267.03 | 0.91 |

| 0.3 | 343.77 | 305.89 | 0.89 | |

| 0.6 | 460.75 | 375.81 | 0.82 | |

| Sandy weathered granite | 0 | 400.46 | 338.74 | 0.85 |

| 0.3 | 484.22 | 402.20 | 0.83 | |

| 0.6 | 575.96 | 469.73 | 0.81 | |

| Fragmented weathered granite | 0 | 783.96 | 633.31 | 0.81 |

| 0.3 | 1109.74 | 827.09 | 0.75 | |

| 0.6 | 1249.13 | 901.40 | 0.72 |

| p (kPa) | φ (°) | c (kPa) | σ1 (kPa) | ||

|---|---|---|---|---|---|

| 500 | 0 | 18.6 | 39.08 | 202.04 | 1.87 |

| 1.55 | 19.5 | 38.05 | 250.48 | 3.87 | |

| 3.1 | 20.4 | 36.98 | 271.46 | 5.61 | |

| 4.65 | 21.3 | 35.98 | 283.29 | 7.27 | |

| 6.2 | 22.2 | 34.94 | 291.45 | 8.90 | |

| 7.75 | 23.1 | 33.93 | 297.78 | 10.51 | |

| 9.3 | 24 | 33.01 | 303.20 | 12.11 | |

| 10.85 | 24.9 | 32.02 | 306.79 | 13.69 | |

| 12.4 | 25.8 | 31.21 | 307.63 | 15.25 | |

| 13.95 | 26.7 | 30.20 | 306.64 | 16.79 | |

| 15.5 | 27.6 | 29.38 | 305.65 | 18.33 | |

| 17.05 | 28.5 | 28.59 | 303.75 | 19.86 | |

| 18.6 | 29.4 | 27.99 | 302.00 | 21.40 | |

| 20.15 | 30.3 | 27.40 | 300.12 | 22.93 | |

| 21.7 | 31.2 | 26.91 | 298.22 | 24.46 | |

| 23.25 | 32.1 | 26.52 | 296.63 | 26.00 | |

| 24.8 | 33 | 26.48 | 294.56 | 27.53 | |

| 26.35 | 33.9 | 25.03 | 293.00 | 29.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Yu, J.; Wu, X.; Ding, Y.; Fu, T.; Yang, Y.; Jiang, J. Mechanical Behavior of Weathered Granite Exposed to Water. Appl. Sci. 2021, 11, 10356. https://doi.org/10.3390/app112110356

Sun M, Yu J, Wu X, Ding Y, Fu T, Yang Y, Jiang J. Mechanical Behavior of Weathered Granite Exposed to Water. Applied Sciences. 2021; 11(21):10356. https://doi.org/10.3390/app112110356

Chicago/Turabian StyleSun, Miaomiao, Jiangang Yu, Xi Wu, Yuqin Ding, Tengfei Fu, Yingwu Yang, and Jiqing Jiang. 2021. "Mechanical Behavior of Weathered Granite Exposed to Water" Applied Sciences 11, no. 21: 10356. https://doi.org/10.3390/app112110356

APA StyleSun, M., Yu, J., Wu, X., Ding, Y., Fu, T., Yang, Y., & Jiang, J. (2021). Mechanical Behavior of Weathered Granite Exposed to Water. Applied Sciences, 11(21), 10356. https://doi.org/10.3390/app112110356