Influences of Brass Surface Morphology on Leidenfrost Effect during Liquid Nitrogen Cooling

Abstract

:1. Introduction

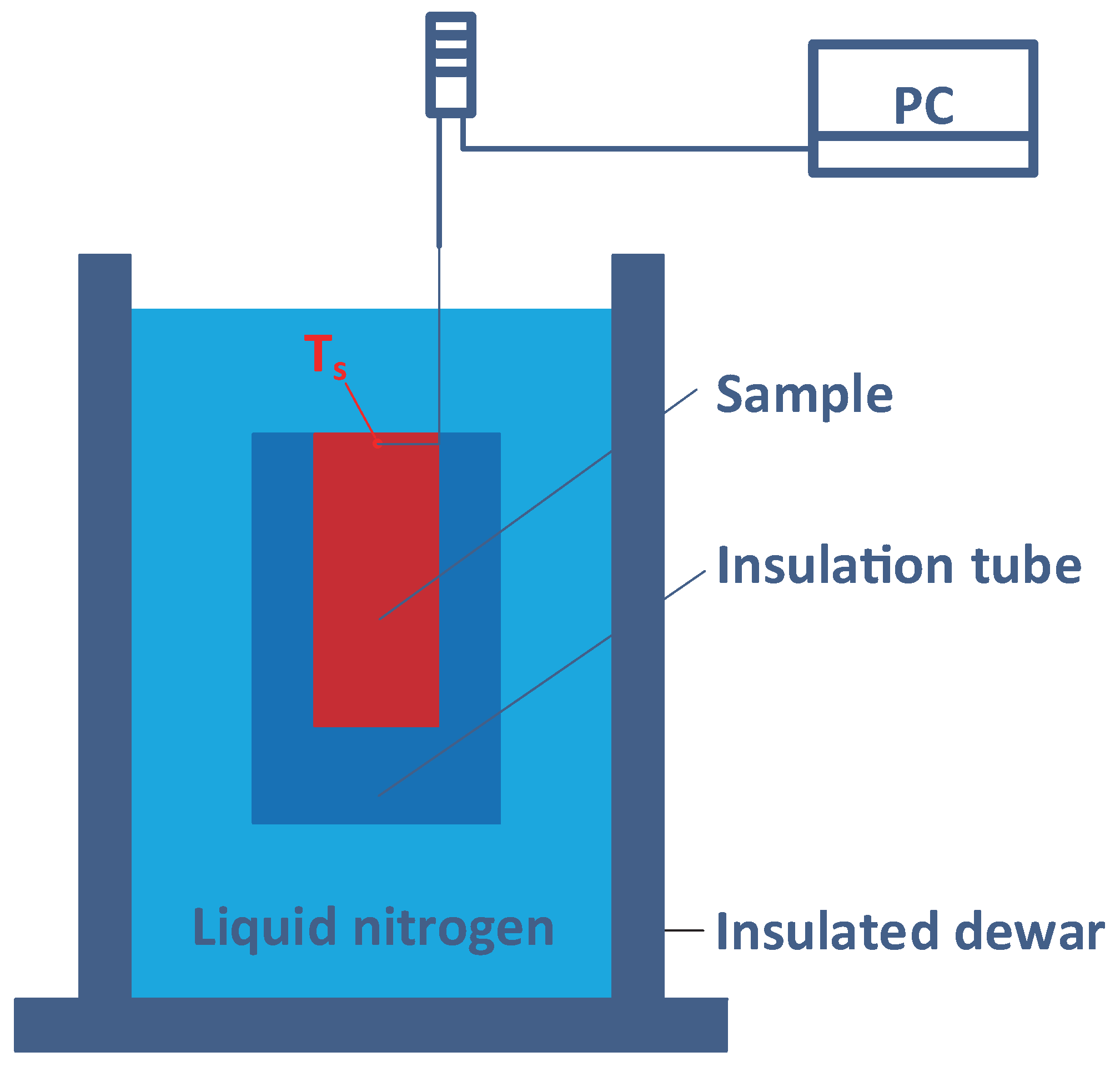

2. Experimental Details

2.1. Apparatus and Samples

2.2. Calculation Methods

2.3. Uncertainty Analysis

3. Results

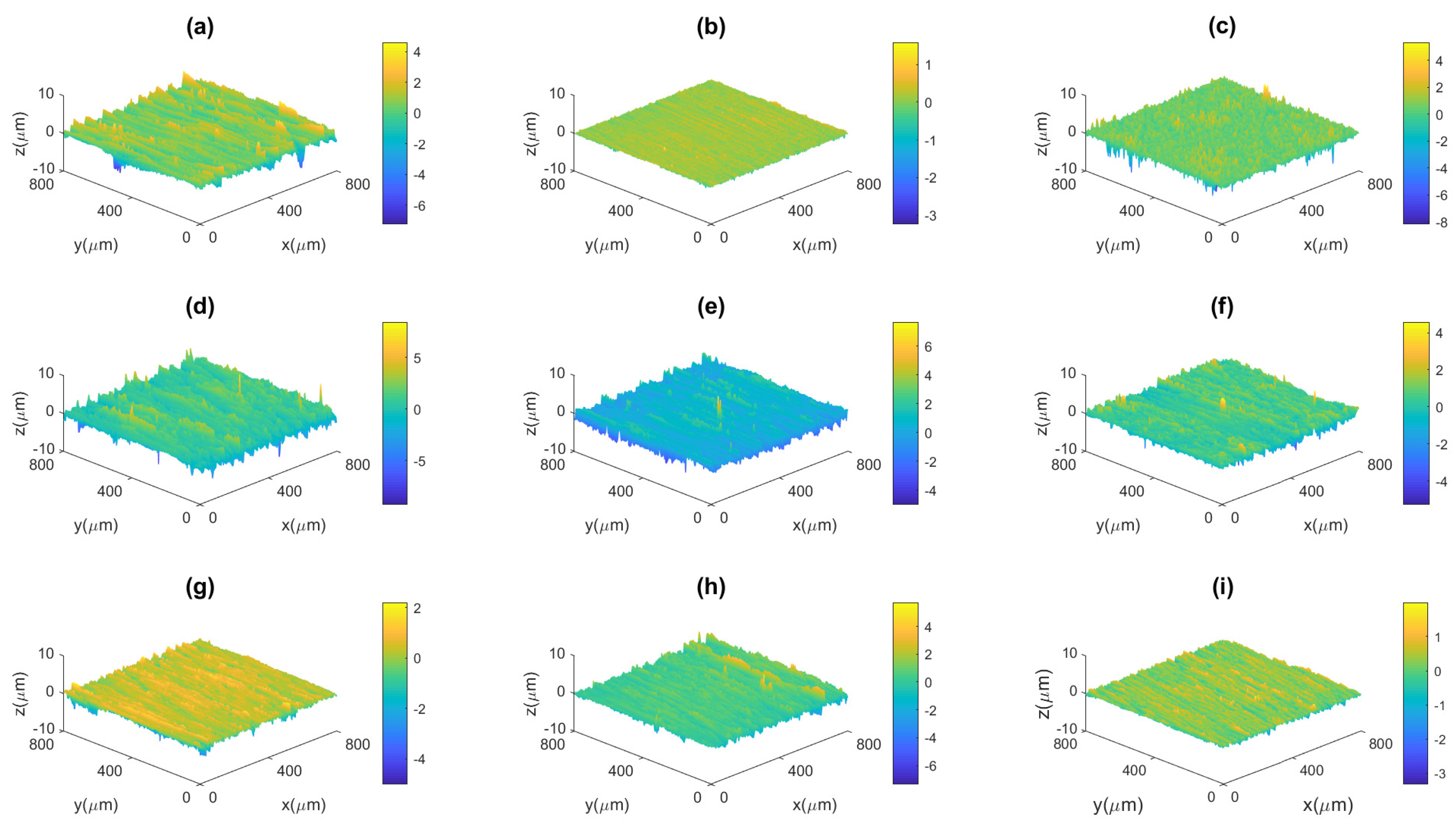

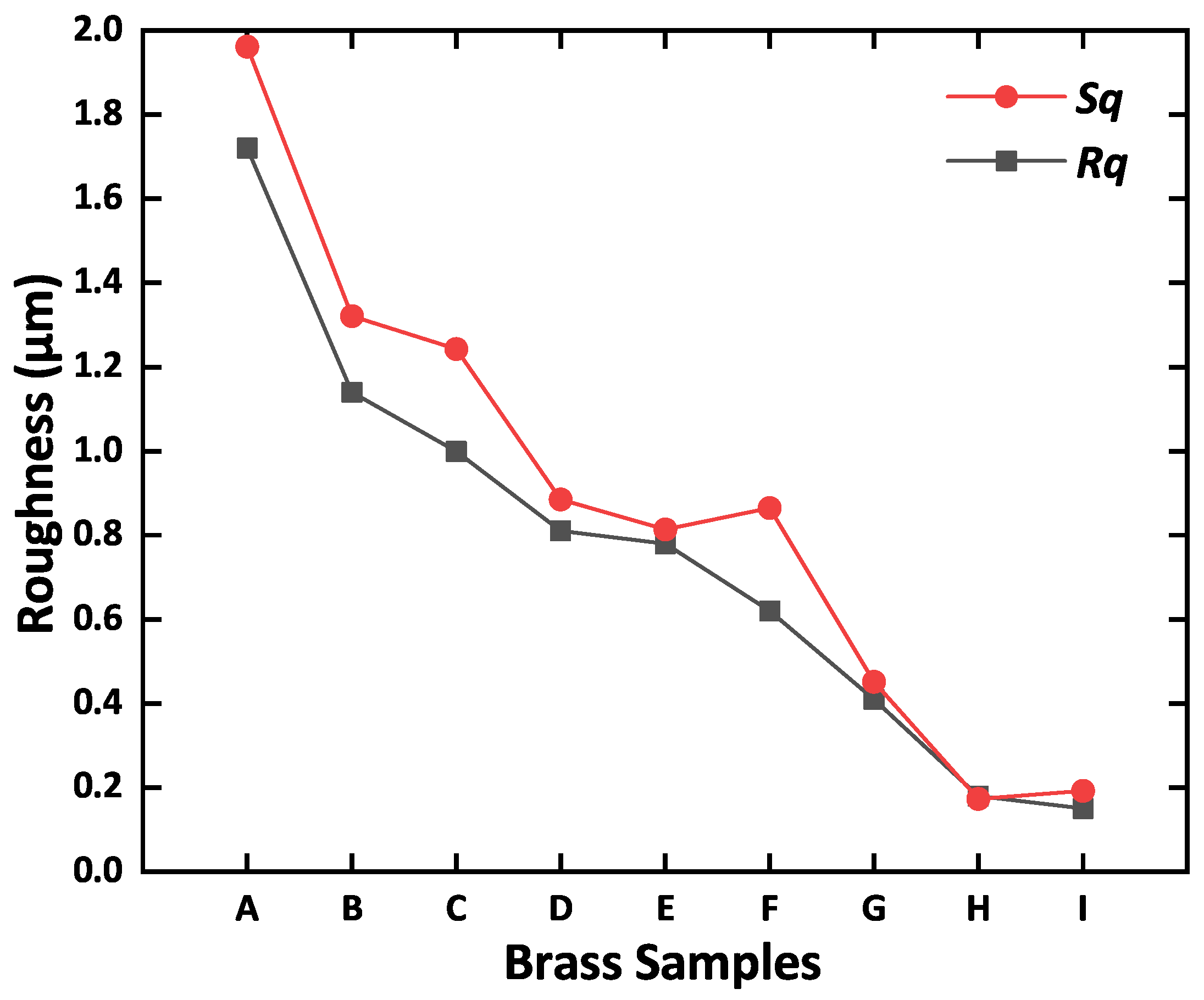

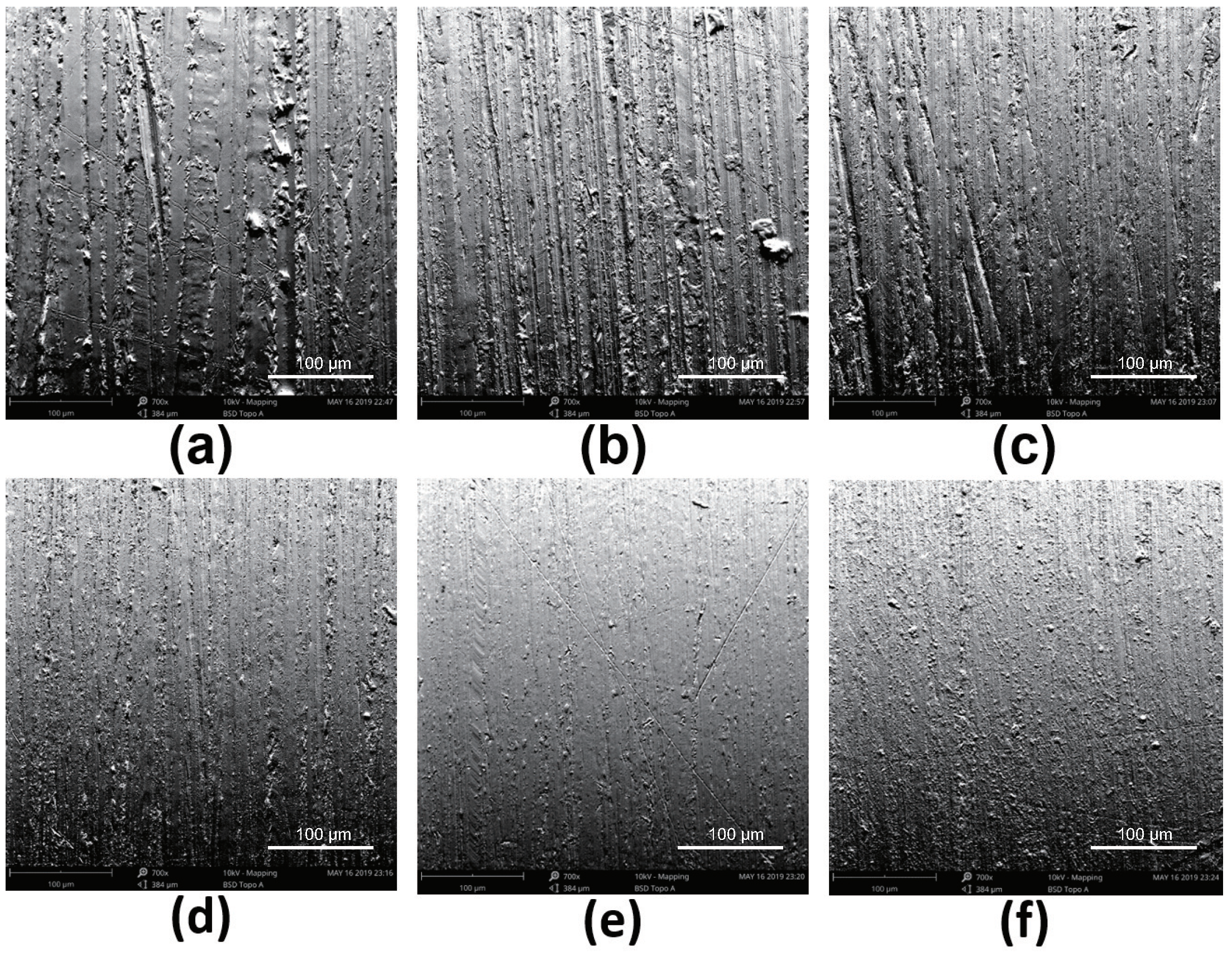

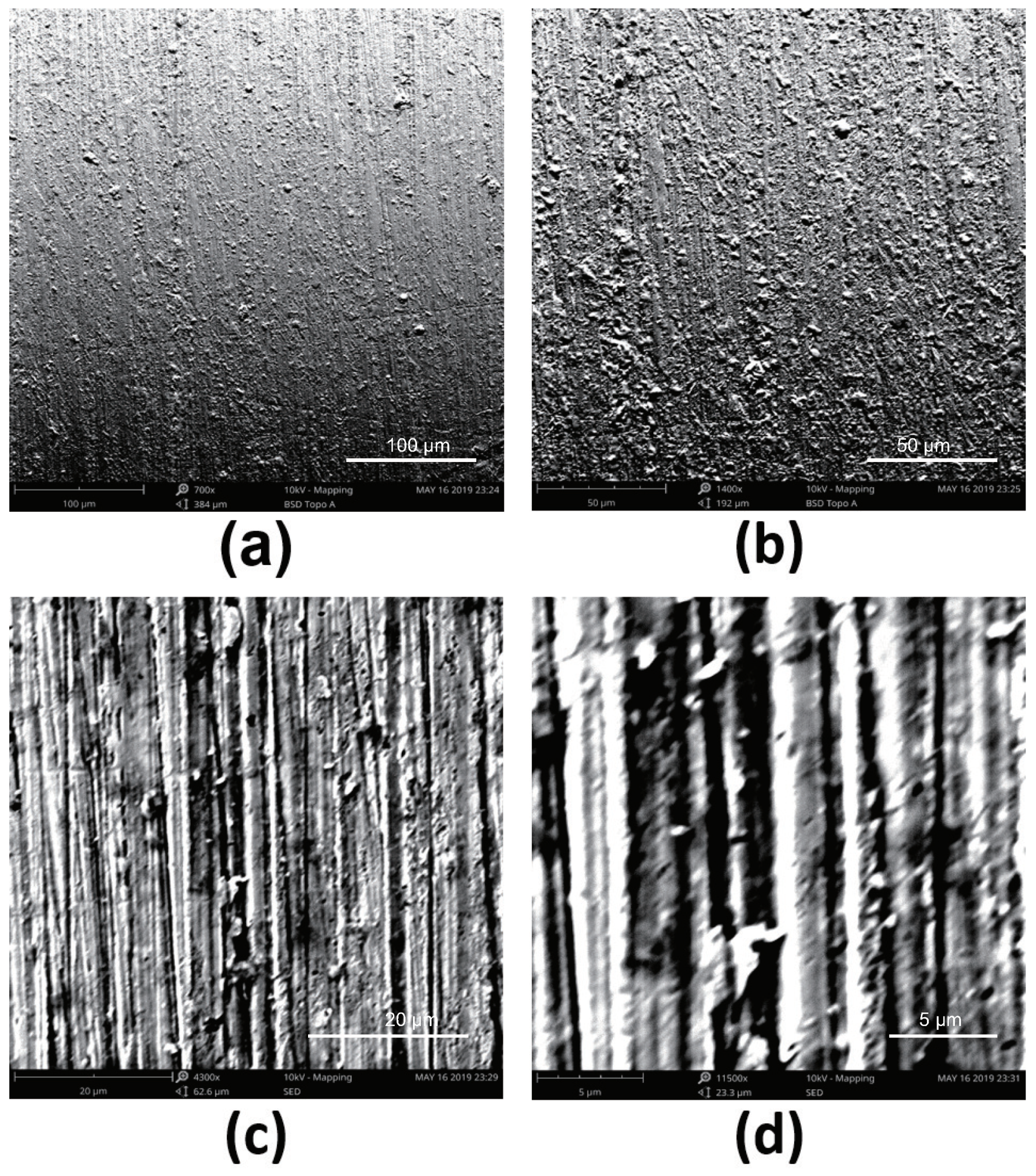

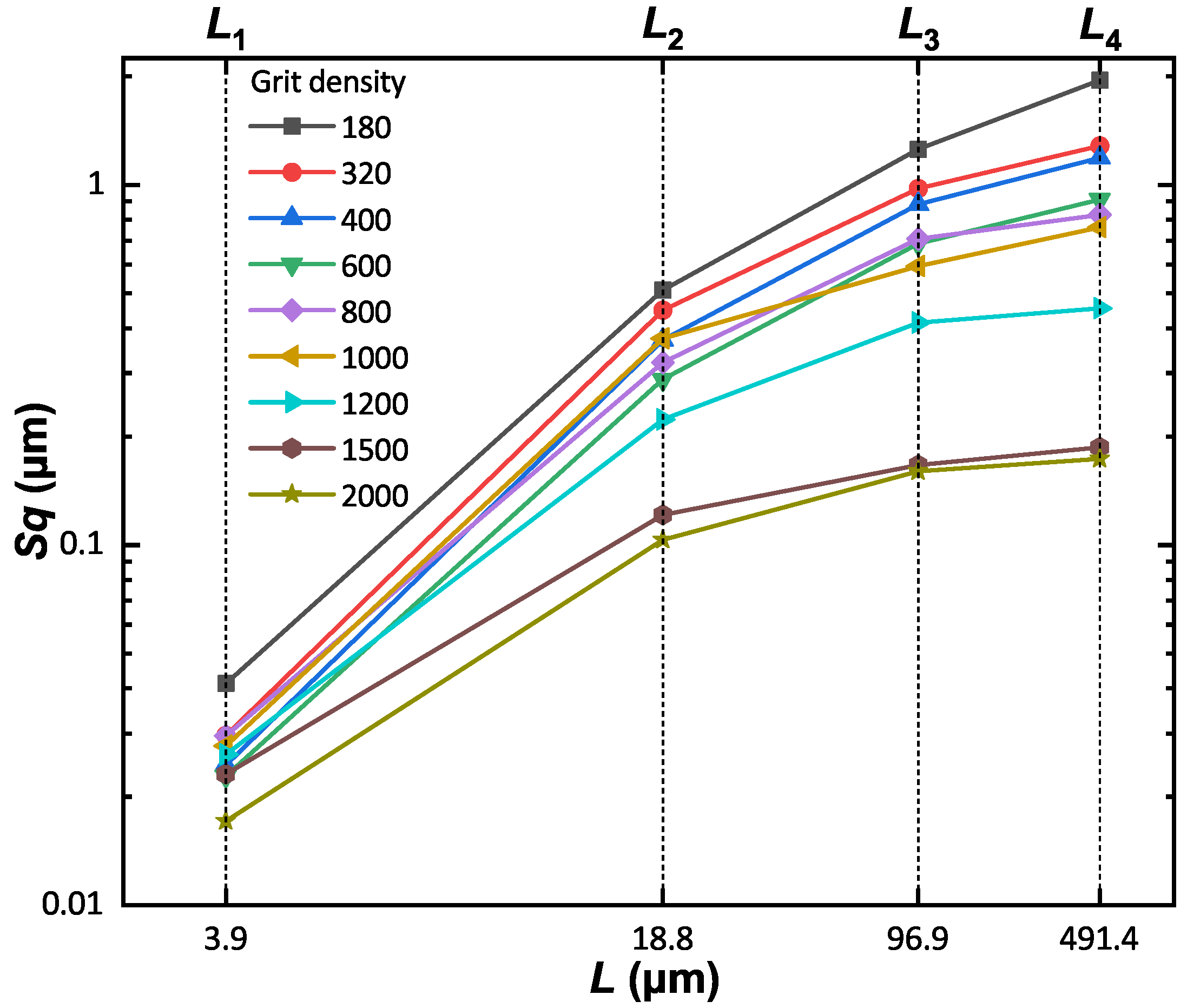

3.1. Surface Morphology

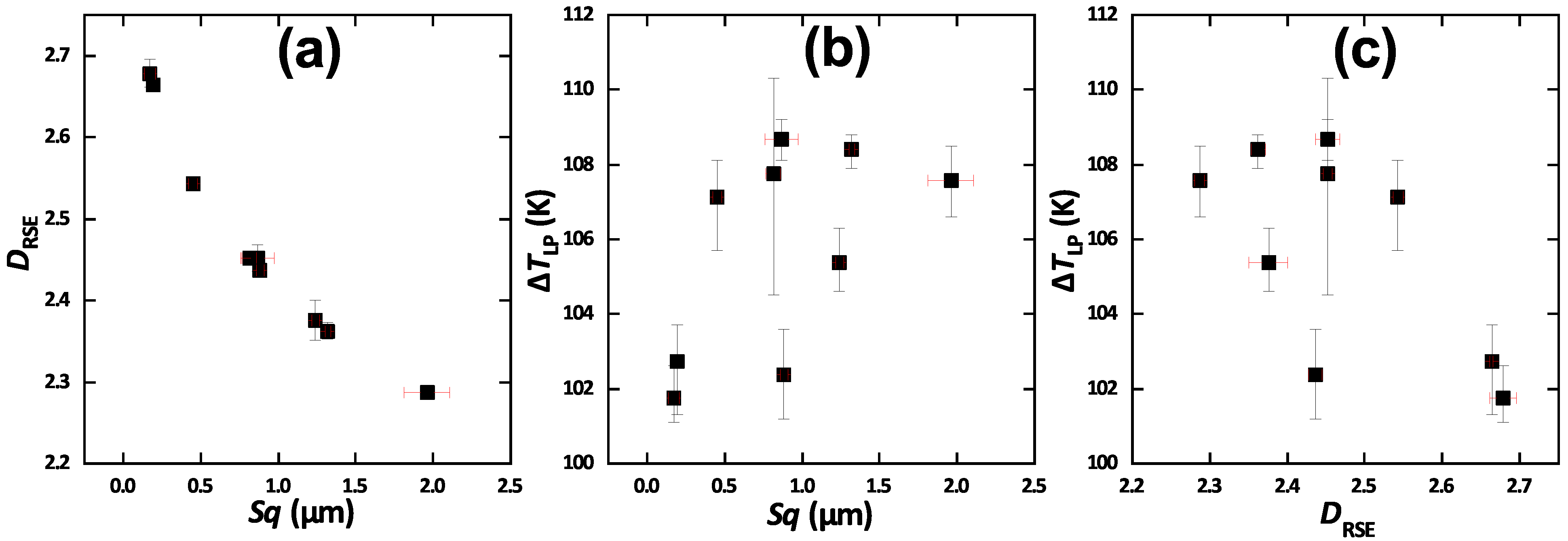

3.2. Leidenfrost Indexes

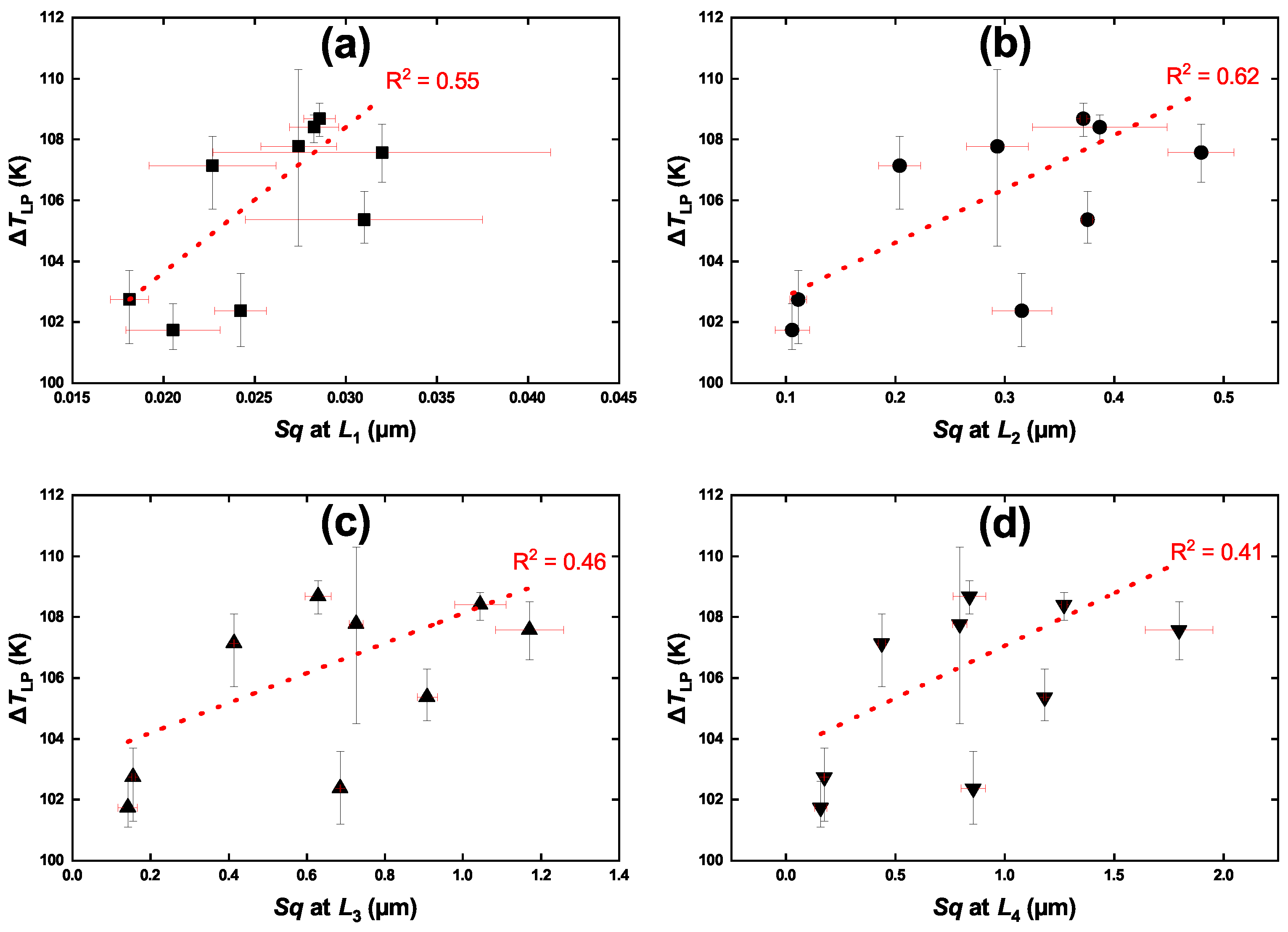

3.3. Multi-Scaled Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| The wall superheat at Leidenfrost point | |

| The wall superheat at critical heat flux | |

| HTS | High-temperature superconducting |

| WLI | White light interferometer |

| SEM | Scanning electron microscope |

| RSE | Roughness scaling extraction |

| Root mean square deviation roughness of profile | |

| Root mean square deviation roughness of surface | |

| L | Scale |

| D | Fractal dimension |

| Fractal dimension calculated by RSE algorithm | |

| q | Heat flux |

| Heat flow | |

| A | Area |

| c | Specific heat |

| m | Mass |

| T | Temperature |

| t | Time |

| Coefficient of determination |

References

- Gottfried, B.S.; Lee, C.J.; Bell, K.J. The leidenfrost phenomenon: Film boiling of liquid droplets on a flat plate. Int. J. Heat Mass Transf. 1966, 9, 1167–1188. [Google Scholar] [CrossRef]

- Tran, T.; Staat, H.J.J.; Prosperetti, A.; Sun, C.; Lohse, D. Drop Impact on Superheated Surfaces. Phys. Rev. Lett. 2012, 108, 036101. [Google Scholar] [CrossRef] [Green Version]

- Bouillant, A.; Mouterde, T.; Bourrianne, P.; Lagarde, A.; Clanet, C.; Quéré, D. Leidenfrost wheels. Nat. Phys. 2018, 14, 1188–1192. [Google Scholar] [CrossRef]

- Galicia, E.S.; Otomo, Y.; Saiwai, T.; Takita, K.; Orito, K.; Enoki, K. Subcooled Flow Boiling Heat Flux Enhancement Using High Porosity Sintered Fiber. Appl. Sci. 2021, 11, 5883. [Google Scholar] [CrossRef]

- Shiro, N. The maximum and minimum values of the heat Q transmitted from metal to boiling water under atmospheric pressure. Int. J. Heat Mass Transf. 1966, 9, 1419–1433. [Google Scholar] [CrossRef]

- Shiro, N. Memories of my research on boiling. Int. J. Heat Mass Transf. 1984, 27, 955–957. [Google Scholar] [CrossRef]

- Linke, H.; Aleman, B.J.; Melling, L.D.; Taormina, M.J.; Francis, M.J.; Dow-Hygelund, C.C.; Narayanan, V.; Taylor, R.P.; Stout, A. Self-propelled Leidenfrost droplets. Phys. Rev. Lett. 2006, 96, 154502. [Google Scholar] [CrossRef] [Green Version]

- Ivan, U.V.; Neelesh, A.P.; Jeremy, O.M.; Derek, Y.C.C.; Sigurdur, T.T. Stabilization of Leidenfrost vapour layer by textured superhydrophobic surfaces. Nature 2012, 489, 274–277. [Google Scholar]

- Otomo, Y.; Santiago, G.E.; Enoki, K. Enhancement of Subcooled Flow Boiling Heat Transfer with High Porosity Sintered Fiber Metal. Appl. Sci. 2021, 11, 1237. [Google Scholar] [CrossRef]

- Kim, H.; Truong, B.H.; Buongiorno, J.; Hu, L.W. On the effect of surface roughness height, wettability, and nanoporosity on Leidenfrost phenomena. Appl. Phys. Lett. 2011, 98, 083121. [Google Scholar] [CrossRef]

- Kwon, H.M.; Bird, J.C.; Varanasi, K.K. Increasing Leidenfrost point using micro-nano hierarchical surface structures. Appl. Phys. Lett. 2013, 103, 365–689. [Google Scholar] [CrossRef] [Green Version]

- Liang, G.T.; Mudawar, I. Review of drop impact on heated walls. Int. J. Heat Mass Transf. 2017, 106, 103–126. [Google Scholar] [CrossRef]

- Bernardin, J.D.; Mudawar, I.J. The Leidenfrost Point: Experimental Study and Assessment of Existing Models. J. Heat Transf. 1999, 121, 894–903. [Google Scholar] [CrossRef]

- Bernardin, J.D.; Stebbins, C.J.; Mudawar, I. Effects of surface roughness on water droplet impact history and heat transfer regimes. Int. J. Heat Mass Transf. 1996, 40, 73–88. [Google Scholar] [CrossRef]

- Avedisian, C.T.; Koplik, J. Leidenfrost boiling of methanol droplets on hot porous/ceramic surfaces. Int. J. Heat Mass Transf. 1987, 30, 379–393. [Google Scholar] [CrossRef]

- Bradfield, W.S. Liquid-Solid Contact in Stable Film Boiling. Ind. Eng. Chem. Fundam. 1966, 5, 200–204. [Google Scholar] [CrossRef]

- Baumeister, K.J.; Simon, F.F. Leidenfrost Temperature—Its Correlation for Liquid Metals, Cryogens, Hydrocarbons, and Water. J. Heat Transf. 1973, 95, 166–173. [Google Scholar] [CrossRef]

- Vachon, R.I.; Tanger, G.E.; Davis, D.L.; Nix, G.H. Pool Boiling on Polished and Chemically Etched Stainless-Steel Surfaces. J. Heat Transf. 1968, 90, 231–238. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C.; Shi, M.; Peterson, G.P. Optimal surface fractal dimension for heat and fluid flow in microchannels. Appl. Phys. Lett. 2010, 97, 084101. [Google Scholar] [CrossRef]

- Langroudi, A.A.; Jefferson, I.; O’Hara-Dhand, K.; Smalley, I. Micromechanics of quartz sand breakage in a fractal context. Geomorphology 2014, 211, 1–10. [Google Scholar] [CrossRef]

- Gou, X.F.; Justin, S. Fractal analysis of the role of the rough interface between Bi2Sr2CaCu2Ox filaments and the Ag matrix in the mechanical behavior of composite round wires. Supercond. Sci. Technol. 2013, 26, 055016. [Google Scholar] [CrossRef]

- Matos, R.S.; Ţălu, Ş.; Mota, G.V.S.; Pinto, E.P.; Pires, M.A.; Abraçado, L.G.; Ferreira, N.S. Correlating Structure and Morphology of Andiroba Leaf (Carapa guianensis Aubl.) by Microscopy and Fractal Theory Analyses. Appl. Sci. 2021, 11, 5848. [Google Scholar] [CrossRef]

- Feng, F.; Huang, J.L.; Li, X.H.; Qu, T.M.; Liu, B.B.; Zhou, W.M.; Qian, X.; Feng, P.F. Influences of planarization modification and morphological filtering by AFM probe-tip on the evaluation accuracy of fractal dimension. Surf. Coat. Tech. 2019, 363, 436–441. [Google Scholar] [CrossRef]

- Li, Z.W.; Qian, X.; Feng, F.; Qu, T.M.; Xia, Y.S.; Zhou, W.M. A continuous variation of roughness scaling characteristics across fractal and non-fractal profiles. Fractals 2021, 29, 2150109. [Google Scholar] [CrossRef]

- Malozemoff, A.P. Second-Generation High-Temperature Superconductor Wires for the Electric Power Grid. Ann. Rev. Mater. Res. 2012, 42, 373–397. [Google Scholar] [CrossRef]

- Xin, Y.; Gong, W.Z.; Hong, H.; Gao, Y.Q.; Niu, X.Y.; Zhang, J.Y.; Sun, Y.W.; Ren, A.L.; Wang, H.Z.; Zhang, L.F.; et al. Development of a 220 kV/300 MVA superconductive fault current limiter. Supercond. Sci. Technol. 2012, 25, 105011. [Google Scholar] [CrossRef]

- Snitchler, G.; Gamble, B.; King, C.; Winn, P. 10 MW Class Superconductor Wind Turbine Generators. IEEE Trans. Appl. Supercond. 2011, 21, 1089–1092. [Google Scholar] [CrossRef]

- Hahn, S.; Kim, K.; Kim, K.; Hu, X.B.; Painter, T.; Dixon, I.; Kim, S.; Bhattarai, K.; Noguchi, J.; Jaroszynski, J.; et al. 45.5-tesla direct-current magnetic field generated with a high-temperature superconducting magnet. Nature 2019, 570, 496–499. [Google Scholar] [CrossRef]

- Yanagisawa, Y.; Okuyama, E.; Nakagome, H.; Takematsu, T.; Takao, T.; Hamada, M.; Matsumoto, S.; Kiyoshi, T.; Takizawa, A.; Takahashi, M.; et al. The mechanism of thermal runaway due to continuous local disturbances in the YBCO-coated conductor coil winding. Supercond. Sci. Tech. 2012, 25, 075014. [Google Scholar] [CrossRef]

- Wang, X.; Trociewitz, U.P.; Schwartz, J. Near-adiabatic quench experiments on short YBa2Cu3O7 coated conductors. J. Appl. Phys. 2007, 101, 053904. [Google Scholar] [CrossRef]

- Song, H.H.; Kevin, G.; Justin, S. Quench behavior of conduction-cooled YBa2Cu3O7 coated conductor pancake coils stabilized with brass or copper. Supercond. Sci. Technol. 2010, 23, 065021. [Google Scholar] [CrossRef]

- Shin, H.; Bautista, Z.; Gorospe, A.; Lee, J.; Lee, H.; Moon, S. Electro-Mechanical Properties of Single-Side Brass Foil Laminated Coated Conductor Tapes at 77 K Under Self-Field. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Westwater, J.W.; Hwalek, J.J.; Irving, M.E. Suggested standard method for obtaining boiling curves by quenching. Ind. Eng. Chem. Fundam. 1986, 25, 685–692. [Google Scholar] [CrossRef]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill: New York, NY, USA, 2010; pp. 141–143. [Google Scholar]

- Li, J.Q. On the Microscale Mechanisms of the Effects of Surface Properties on the Cooling Rate and Boiling Heat Transfer during Quenching; Zhejiang University: Hangzhou, China, 2019. (In Chinese) [Google Scholar]

- Bernardin, J.D.; Mudawar, I. A cavity activation and bubble growth model of the leidenfrost point. J. Heat Transf. 2002, 124, 864–874. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yu, D.; Cui, J.; Feng, P.; Feng, F. Influences of Brass Surface Morphology on Leidenfrost Effect during Liquid Nitrogen Cooling. Appl. Sci. 2021, 11, 10323. https://doi.org/10.3390/app112110323

Li Z, Yu D, Cui J, Feng P, Feng F. Influences of Brass Surface Morphology on Leidenfrost Effect during Liquid Nitrogen Cooling. Applied Sciences. 2021; 11(21):10323. https://doi.org/10.3390/app112110323

Chicago/Turabian StyleLi, Zhiwei, Dingwen Yu, Jie Cui, Pingfa Feng, and Feng Feng. 2021. "Influences of Brass Surface Morphology on Leidenfrost Effect during Liquid Nitrogen Cooling" Applied Sciences 11, no. 21: 10323. https://doi.org/10.3390/app112110323

APA StyleLi, Z., Yu, D., Cui, J., Feng, P., & Feng, F. (2021). Influences of Brass Surface Morphology on Leidenfrost Effect during Liquid Nitrogen Cooling. Applied Sciences, 11(21), 10323. https://doi.org/10.3390/app112110323