Abstract

The occurrence of musculoskeletal diseases (MSDs) among oil palm harvesters has been studied extensively, but there is a lack of published studies on the evaluation of the range of harvesting movements. This information is important to design the ergonomic tools needed in the manual harvesting of oil palm. We examined the upper limb motion of oil palm harvesters to determine the effects of age and initial shoulder postures on their range of harvesting movements. Twenty male harvesters performed a manual push-pull-cutting technique (≥3 m fresh fruit branches (FFBs) height). The study was conducted by capturing the 1-D push-pull cutting technique harvesting movement via the Quintic system at the sagittal plane. The active range of harvesting movements during the harvesting phases and the range of the harvesting movement of the initial and maximum postures of their upper arms were calculated based on the kinematic data generated with the Quintic Biomechanics system (Version 29). Participants were divided into three groups based on their age, and two groups based on their initial support shoulder position, and dominant shoulder position. Data were analysed using the ANOVA and t-test. The joint movement angle pattern of the harvesters was classified into three phases: preparation, execution, and ending. The age-related variances for the initial and maximum support shoulder postures were determined. The range of harvesting movements and the active range of harvesting movements during the preparation phase at the support shoulder and wrist region were also observed. The initial support shoulder posture displayed a statistical variance in the maximum support and dominant range of harvesting movements of the shoulder. It was also linked to a reduced active range of harvesting movements for the support shoulder flexion and dominant wrist ulnar deviation at the preparation phase. Furthermore, the initial dominant shoulder exhibited a statistically significant difference for the dominant arm and a reduced active range of harvesting movements in the dominant wrist ulnar deviation at the preparation phase. This study produced important evidence about factors to be considered for the ergonomic design of harvesting tools and workplaces, especially within the oil palm industry.

1. Introduction

The oil palm industry is significant in Malaysia as it has a great potential to boost the country’s economy. Several reports highlighted oil palm as one of the major agricultural commodity sectors that contributed to 37% of the Malaysian gross domestic product in 2012 [1]. Apart from fulfilling the increasing global food and energy consumption demand [2], the oil palm industry also provides job opportunities [3]. Malaysia is one of the world’s largest producers and exporters of oil palm [3], thus making oil palm an important crop in Malaysia.

Given the significance of oil palm in the economic development and growth of Malaysia, it is vital to look into ways to facilitate and improve the harvesting process of oil palm. Several characteristics of oil palm trees such as the crown-canopy arrangement of the fronds, the configuration of the fresh fruit bunches (FFBs) stalk attachments to the tree trunk, the height of the trees, and the weight of the FFBs may require the harvesters to work in unfavourable awkward postures. They also need to handle heavy loads and perform repetitive work with high force exertion [4]. These factors, if poorly handled, may affect the productivity and yield of the oil palm industry, resulting in a negative impact on the economy. Another factor to consider is the gradual cutbacks in labour availability [5]. Although an increasing number of automation techniques have been proposed and used in manufacturing industries [6], the majority of the oil palm harvesting process is being performed manually with human strength and skill. In addition, there is a lack of ergonomic designs for many oil palm manual handling activities and tasks, thus predisposing the workers to inappropriate postures and physical fatigue. As a result, there is a high prevalence of musculoskeletal disorders (MSDs) among the oil palm FFB manual workers [1,3,7,8]. Their subsequent absence from work may be burdensome to the industry [9].

In the past two decades, MSDs have been investigated and studied among different professions such as farmers [10,11,12,13,14], manufacturing industry workers [15], and computer users [16]. Recently, there is increasing research of MSDs among oil palm harvesting workers. However, most of the studies were observational research or questionnaire-based surveys. Common questionnaires included the modified Nordic questionnaire, Ovako working posture assessment system [1,3,4], rapid entire body assessment [3], rapid upper limb assessment (RULA) [17], and simple ergonomics risk assessment [18]. These paper-based observational techniques can provide useful information about the occurrence of MSD among occupational workers. However, to design ergonomic equipment and an ergonomic workplace for the workers, findings from the observational techniques need to be complemented with a biomechanical analysis such as human motion simulation. The Human motion simulation software and the digital human model have been utilised by many researchers in predicting human motion. However, the researchers need to understand the motor tasks involved in daily life or work in order to provide the essential data for the simulation of realistic human motion. The examples of human tasks include reaching overhead, crouching, lifting objects, bathing, shaking hands, or eating [19]. These human tasks have been studied in previous research. For example, a mathematical model was constructed for the control of the human arm in performing the reaching movement [20]. Another published review focused on the methods of modelling human motion and methods for studying and modelling human reaches [21]. Ref. [21] also highlighted the types of information of interest to designers to develop the digital human models, such as anthropometric data, and population demographic subgroups. These data enabled the designers to simulate realistic motion and postures with minimum task input descriptions. Additionally, it was also established that human motor tasks or performances can be affected by age [19,22].

According to [22], increasing age can lead to a decline in the human motor task performance. Other factors that can affect human tasks such as reach movement included the reach locations or targets, seat configurations, and tool weights [23]. To date, there is a lack of research on the human motor tasks related to oil palm harvesting movement. In a previous study, [24] studied the oil palm harvesting movement in terms of the range of motion (ROM) at three different tree heights [24]. Ref. [24] performed the work-motions analyses based on the recorded data of the actual harvesting tasks. The maximum range of joints angle were determined within a cutting cycle by [24] to represent the ROM of the harvester. In the study by [24], after considering the natural ROM suggested by [25] and the four zones of ROM referred from [26], 30° of neck extension, 90° of shoulder flexion, 31° of shoulder extension, 45° of back flexion, 20° of back extension, 120° of elbow flexion, 90° of hip flexion, 90° of knee flexion, and 20° of ankle flexion were predetermined as the extreme limits of the body motions accordingly. Based on these predetermined extreme limits, [24] concluded that the harvesters were frequently in an extremely awkward position and potentially vulnerable to MSD risk. However, [24] did not elaborate on the factors that affected the harvesting movement [24].

In short, there is a lack of available data on harvesting movement data and factors affecting the upper arm harvesting movement of oil palm harvesters using the push-pull-cutting technique. Furthermore, in attempting to develop a biomechanical model and provide harvesting movement data that can reflect a realistic simulation of their harvesting posture and movement, the objectives of this study were two-fold: to describe the upper limb movement which consisted of shoulder, elbow and wrist joints of oil palm harvesters, and to investigate the effects of age and initial shoulder posture on the harvesters’ range of harvesting motion.

2. Methods

2.1. Participants and Study Design

This study was conducted in two mini oil palm estates at Parit Haji Karim in Pontian Johor and UKM Bangi in Selangor, Malaysia. Twenty male harvesters who performed manual handling tasks at the two estates were randomly selected to participate in the study. In this study, harvesters refers to the employees at the mini oil palm estates who performed the push-pull-cutting technique. Institutional approval of the study protocol was granted by UKM (PPI/111/8/JEP-2016-558).

2.2. Experimental Procedure

The motion studied included the harvesting movements of the bilateral upper arm joints, namely the shoulder, elbow, and wrist joints. In total, the movements of the six joints were evaluated from the initial posture of the oil palm harvesters. Two high-speed cameras of 120 frames per second (SJCAM SJ5000X and YI action camera) were used as part of the Quintic Biomechanics system to capture the 1-D movements involved in harvesting FBBs at the sagittal plane.

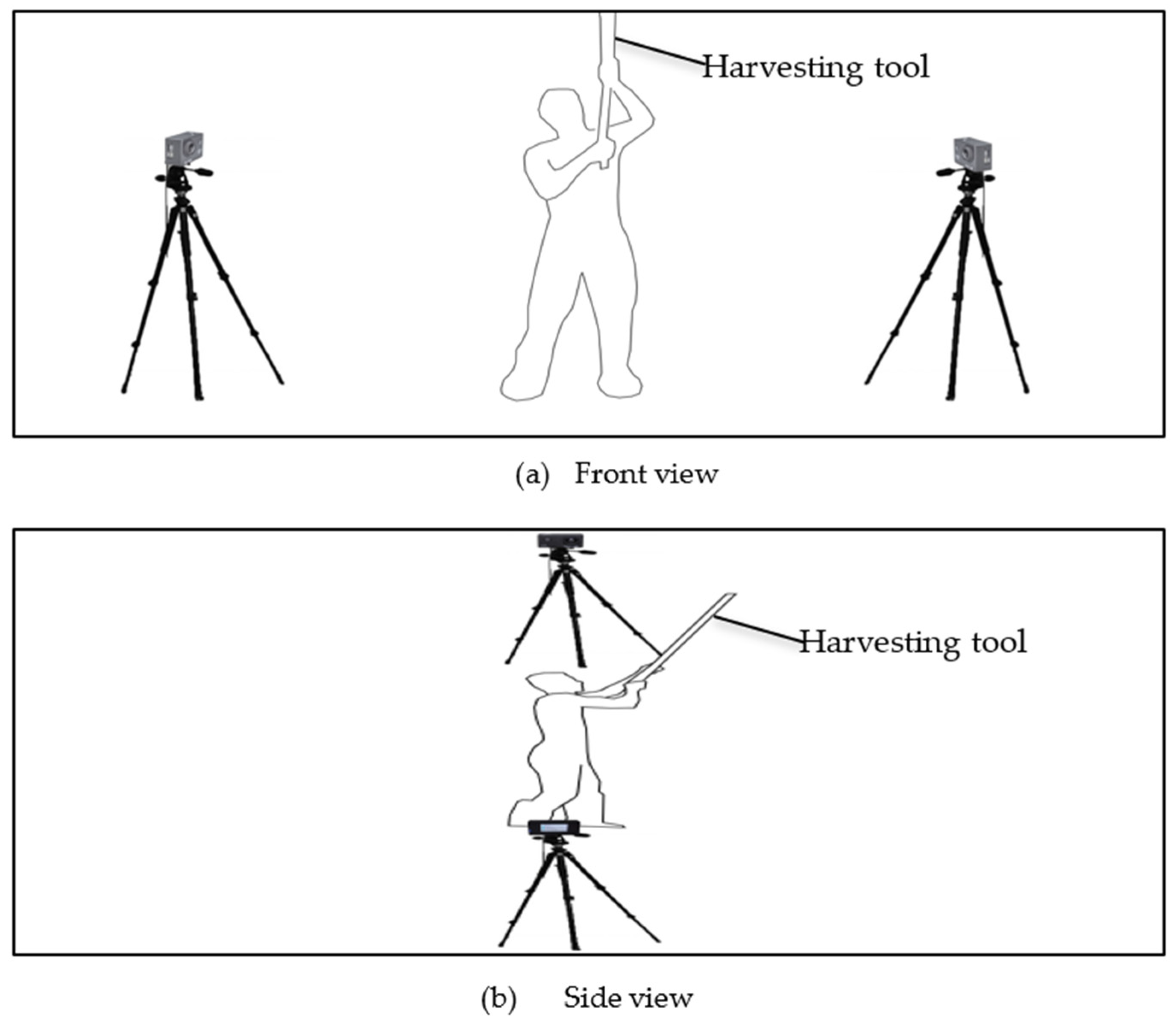

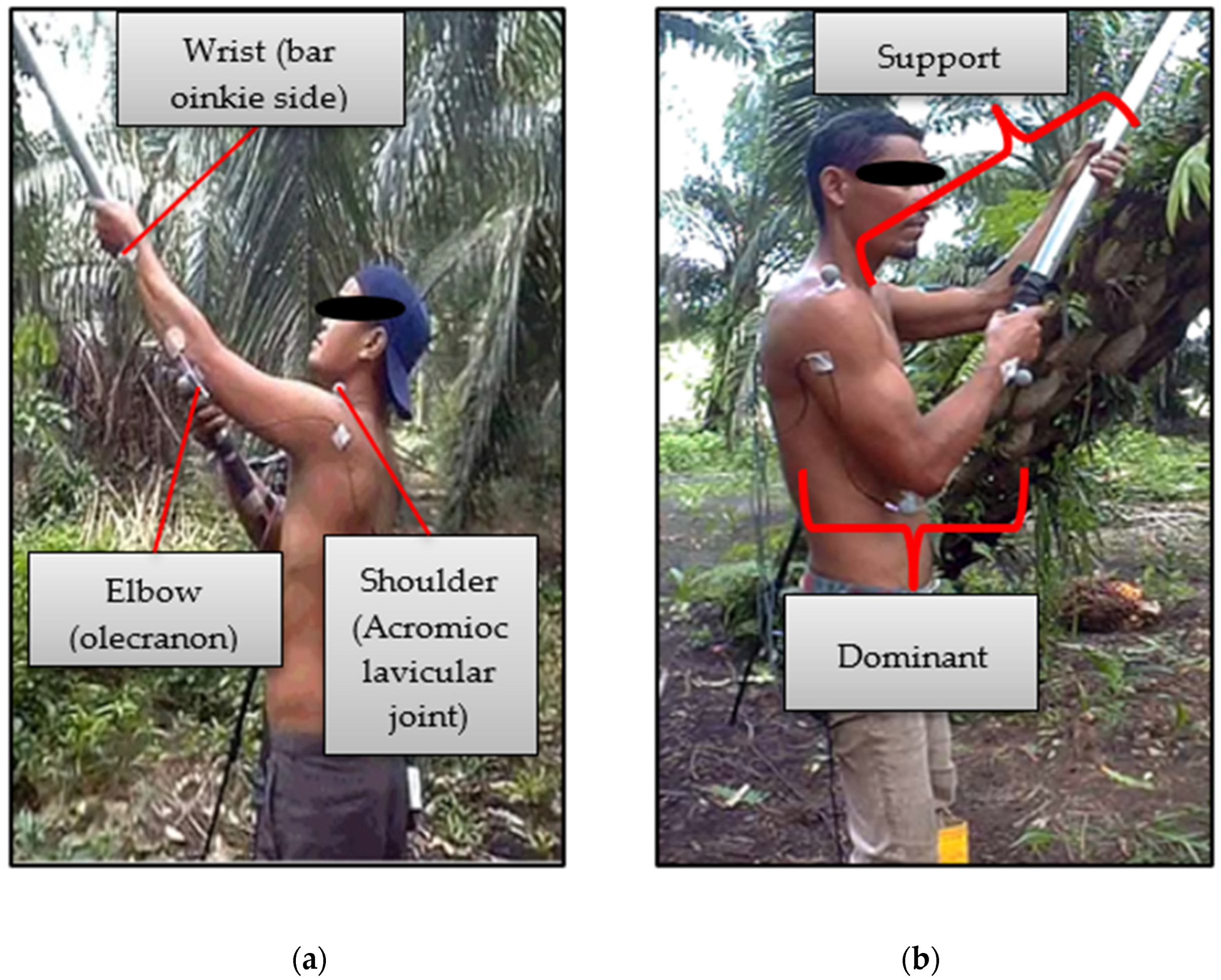

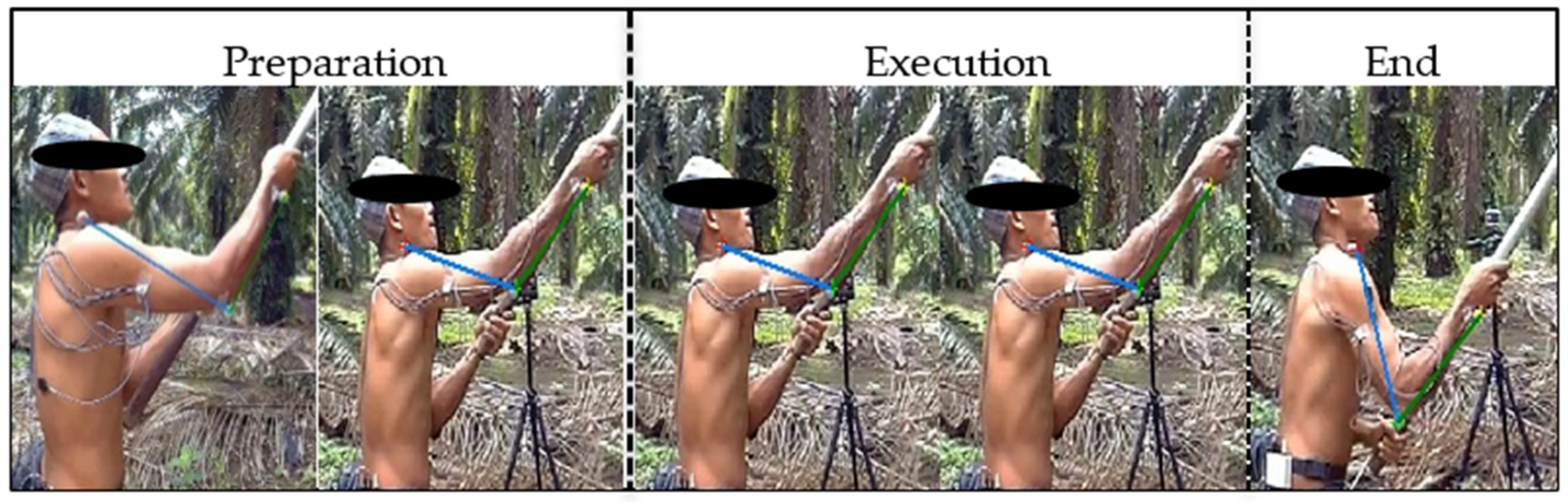

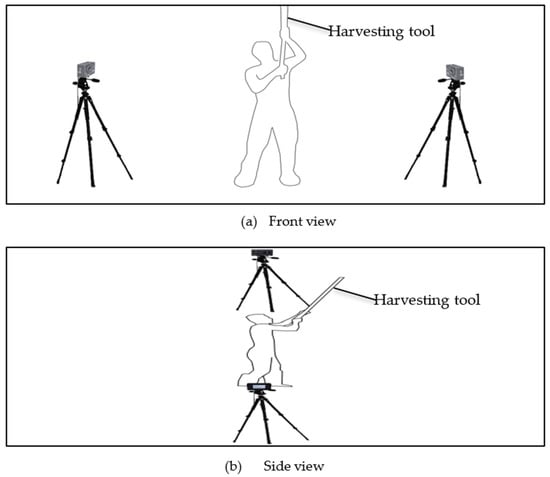

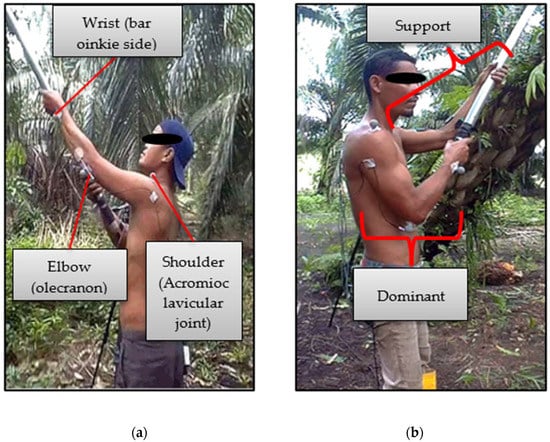

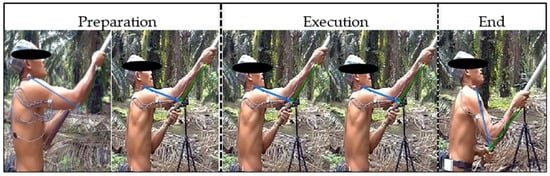

These cameras were placed perpendicular to the plane of movements, as portrayed in Figure 1. Hence, all the movements of push-pull-cutting (≥3 m FFB height) that took place at the sagittal plane could be captured. The push-pull-cutting was performed with a commonly-used tool called an egrek, a sickle-shaped tool [24]. Figure 1a,b shows the front and side view of the camera positions to capture the harvesting of FFBs movement at the sagittal plane, respectively. The participants were informed about the motion-recording process. After obtaining informed consent, spherical markers were placed on the three anatomical landmarks on the participants’ right and left arms: the shoulder (acromioclavicular), elbow (olecranon), and wrist (bar pinkie side) joints. The three anatomical landmarks were selected so that they would not impede harvester movement and would be easy to identify during the digitization process. Next, Figure 2a illustrates the Quintic Biomechanics system anatomical landmarks at the sagittal plane. As displayed in Figure 2b, the participants’ arms were divided into two categories, namely the dominant arm or support arm for analysis purpose. The support arm was the arm placed above the dominant arm on the tool while the dominant arm served as the main arm that drove the pulling action during the harvesting movements. Each participant was asked to perform his normal push-pull-cutting routine for the FFB harvesting activity up to five trials (n = 100). Next, Figure 3 shows one cycle of push-pull-cutting movement of an oil palm harvester. In each cycle of push-pull-cutting, the participant began in a posture corresponding to the placement of the harvesting tool on the targeted FFB. This was followed by the pushing movement, the pulling movement, and lastly returning to the original resting position.

Figure 1.

(a) Front and (b) side view of the camera positions to capture the harvesting of FFBs movement at the sagittal plane.

Figure 2.

(a) The dominant and support arms. (b) The anatomical landmarks placed on the participants at their initial posture from the sagittal plane view.

Figure 3.

One cycle of push-pull-cutting movement.

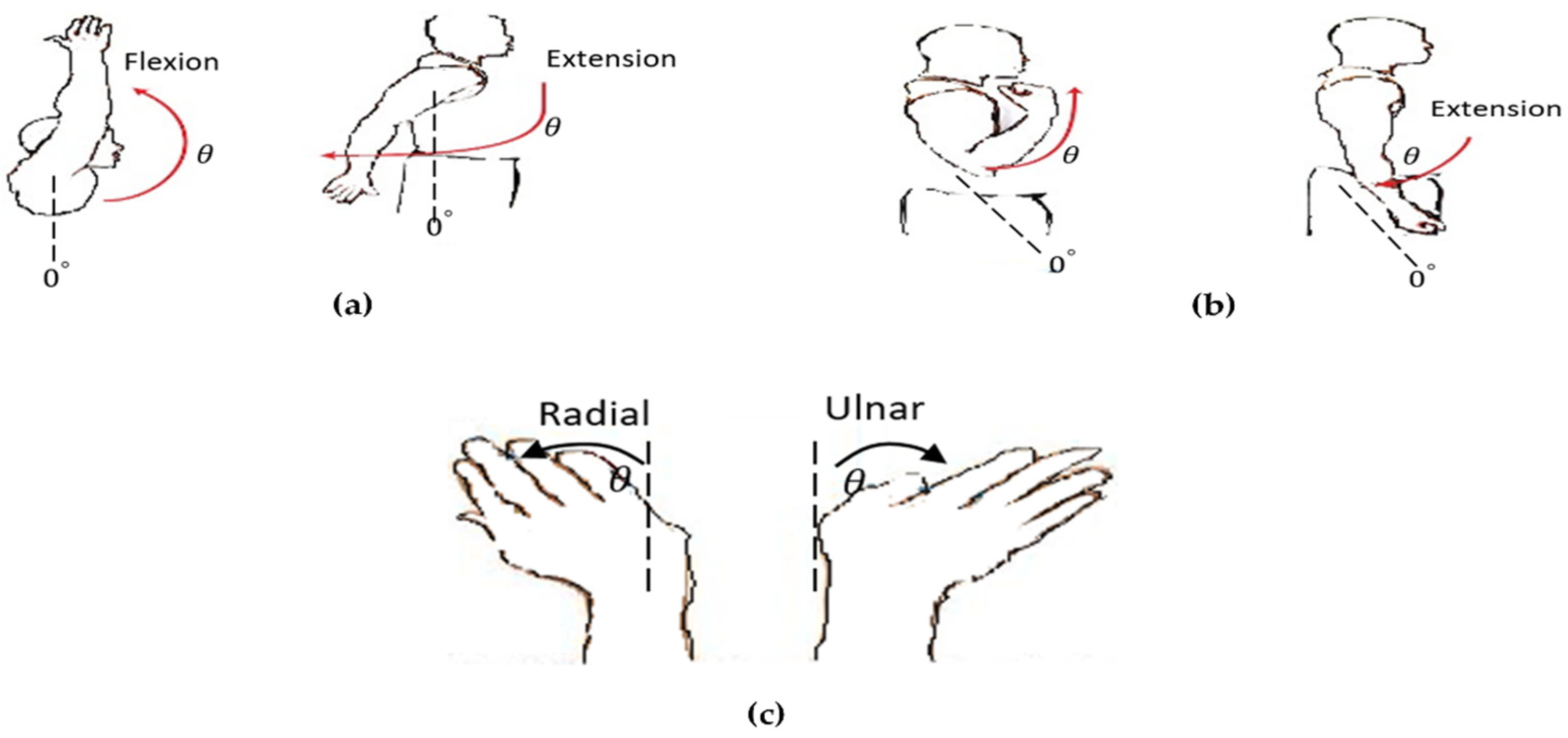

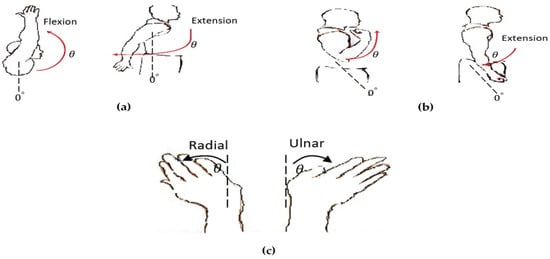

Next, Figure 4 exhibits the 1-D movements that were studied: flexion and extension of the shoulder and elbow joints, and radial-ulnar deviation of the wrist joint. The 1-D movements from Figure 4 were used to facilitate the determination of angular displacements of each joint in the Quintic Biomechanics system. The angular displacements were determined from the determination of the angle between two segments in the Quintic Biomechanics system. The angular displacement of the shoulder joint was determined from the determination of the angle between the vertical axis and the upper arm segment; while the angular displacement of the elbow joint was determined from the determination of the angle between the upper arm and lower arm segment. Last, the angular displacement of the wrist joint was determined from the determination of the angle between the lower arm segment and the horizontal axis. The horizontal axis was chosen because the lower arm and hand were parallel to the horizontal axis when holding the pole at 90° of the elbow joint. Next, Equation (1) was used as part of the determination of the angular displacement for both shoulder and wrist joints.

Figure 4.

Flexion and extension of the (a) shoulder joint and (b) elbow joint, and (c) radial-ulnar deviation of the wrist joint. Source: Clark et al. (2010).

3. Data Analysis

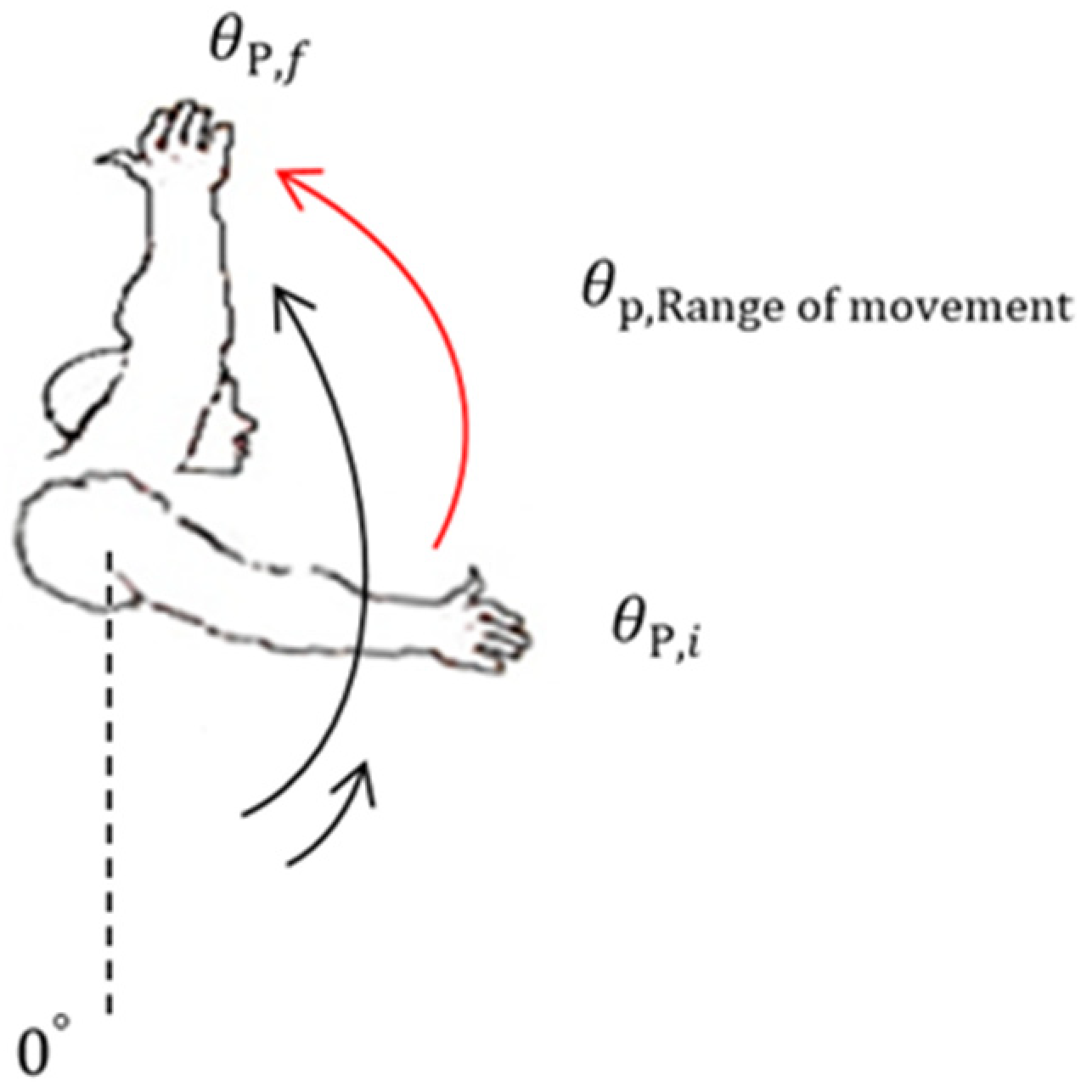

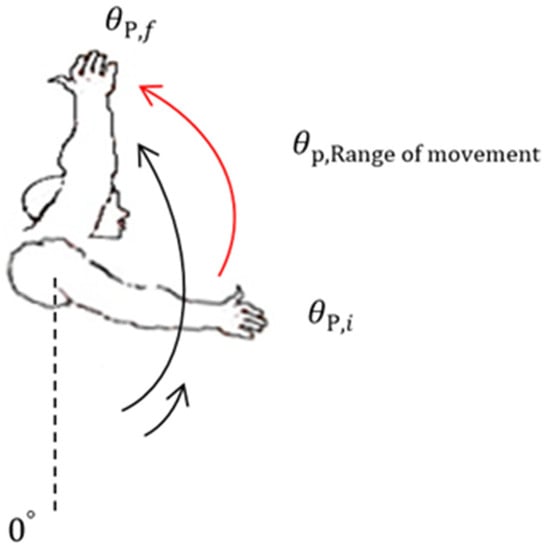

The data on the angular displacements generated from the Quintic Biomechanics system were used to determine the range of harvesting movement of the respective joints. It was defined as the motion of the joint to achieve a certain movement goal, such as the placement of the harvesting tool on the targeted FFB and push-and-pull harvesting movement in this study as illustrated in Figure 5. The range of the harvesting movement was calculated by using a simple mathematical equation as shown in Equation (2). The active range of the harvesting movement of flexion and extension movements of the shoulder and elbow joints, as well as the active range of harvesting movement for the ulnar and radial movements of the wrist joint, were calculated for every participant. In this study, the active range of harvesting movement was referred to as the range of harvesting movements after the placement of the harvesting tool on the targeted FFB. The range of the harvesting movements of the initial shoulder posture (the angular displacement between the standing position to the posture corresponding to the placement of the harvesting tool on the targeted FFB) and the maximum posture range of harvesting movements (the angular displacement between the standing position to the maximum angular displacement) were also measured.

where P is the phase (preparation, execution, and end), i is the initial, and f is the finish.

Figure 5.

The range of movement of the shoulder joint.

For each of the studied joint motions, descriptive statistics such as means and standard deviations were computed to summarise the range of harvesting movements data of the twenty harvesters. To identify any age effects, participants were divided into three groups by age: 20–29 years of age, 30–39 years of age, and 40–49 years of age. Next, to examine the effect of the FFB target locations on the initial shoulder posture angle, the participants were divided into two posture angle groups according to their RULA scores. The RULA categorises the upper body postures using the positions 20°, 45°, 90° and above [27].

Most of the range of the harvesting movements of the shoulder, elbow, and wrist joints obtained in this study followed a normal distribution according to the Shapiro–Wilk test. A two-step approach was applied to transform the continuous variables with non-normal distributions to normal distributions [28]. Firstly, the variables were transformed towards a statistical uniformity by calculating the percentile rank. Next, the inverse-normal transformation was performed on the results of the first step to establish normally distributed data for the variables. ANOVA and t-test analyses were performed to determine the effects of age, initial shoulder support, and dominant shoulder posture on the active range of harvesting movement of the joints at the three phases.

4. Results

4.1. Characteristics of the Participants

Table 1 and Table 2 show the characteristics of the participants by age and initial shoulder posture respectively. From Table 1, 40% of the participants were from group of 30–39 years of age; whereas, both of the groups of 20–29 and 40–49 years of age had equal percentages of participants which were 30%. The average ± STD of weight and height for the group of 20–29 years of age were 62.0 ± 7.0 kg and 166.0 ± 8.0 cm, respectively. Next, the average and standard deviation of weight and height for the group of 30–39 years of age were 64.0 ± 9.0 kg and 162.0 ± 5.0 cm, respectively. While the average and standard deviation of weight and height for the group of 40–349 years of age were 60.0 ± 6.0 kg and 160.0 ± 5.0 cm, respectively. Although the average of weight and height were different between the three groups, they were not statistically significant. Generally, the range for average lengths of the upper arm, lower arm and hand between the three groups were 32 to 34 cm, 26 to 27 cm, and 9 to 10 cm, respectively.

Table 1.

Characteristics of the participants by age (values given as average ± STD; S: supporting arm; D: dominant arm; Wt: weight; Ht: height).

Table 2.

Characteristics of the participants by initial shoulder posture (values given as average ± STD; S: supporting arm; D: dominant arm; Wt: weight; Ht: height).

From Table 2 for the initial support shoulder effect, 40% of the participants were from the group of initial support shoulder of θ > 90° with the average ± STD of weight and height were 62.6 ± 5.5 kg and 163.4 ± 5.5 cm, respectively. While 60% of the participants were from the group of initial support shoulder of 90° ≥ θ ≥ 45° with the average ± STD of weight and height were 61.6 ± 8.6 kg and 161.6 ± 6.4 cm, respectively. Next for the initial dominant shoulder effect, 40% of the participants were from the group of initial dominant shoulder of 90° ≥ θ 45° with the average ± STD of weight and height were 61.1 ± 7.0 kg and 161.6 ± 6.3 cm, respectively; Whereas, 60% of the participants were from the group of initial dominant shoulder of 45° ≥ θ ≥ 0 with the average ± STD of weight and height were 62.6 ± 7.8 kg and 162.8 ± 5.9 cm, respectively. Although the average of weight and height were slightly different between the groups for the initial support shoulder and initial dominant shoulder effect, they were not statistically significant. Table 1 and Table 2 showed that the range for the average length of upper arm, lower arm and hand when categorized based on the initial shoulder effect were 32 to 34 cm, 26 to 27 cm and 9 to 10 cm, respectively.

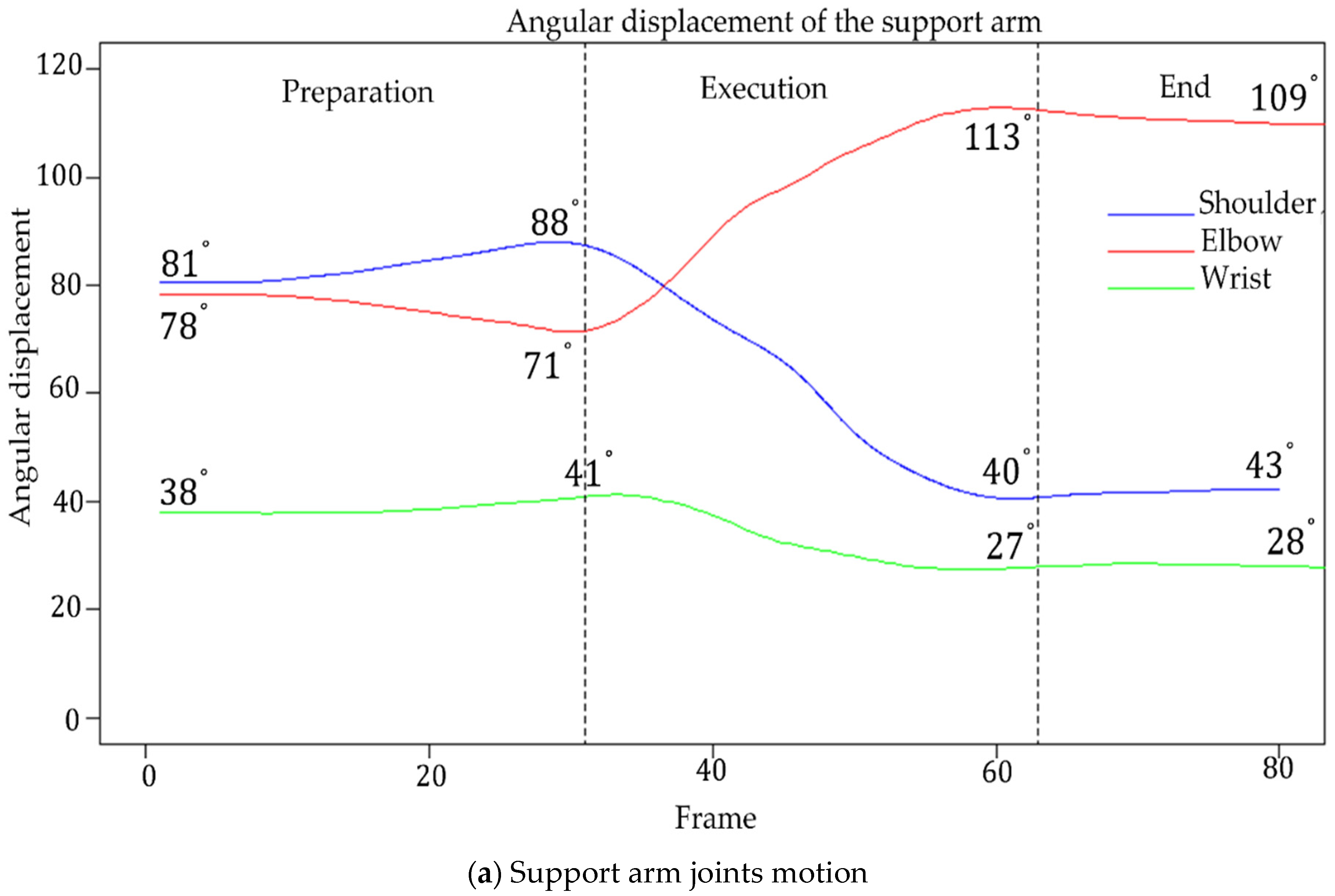

4.2. Harvesting Phases

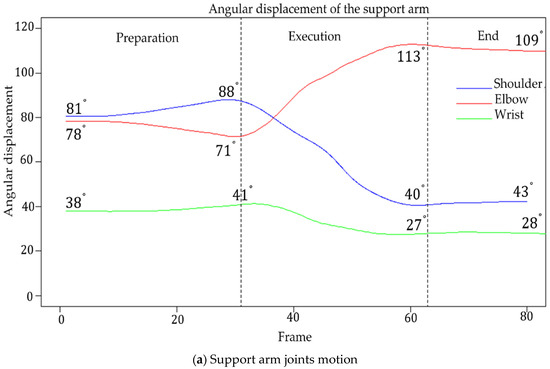

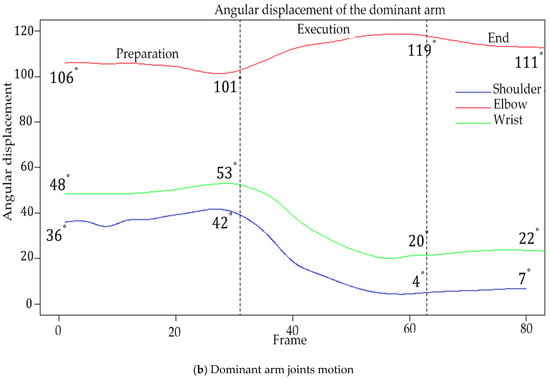

Figure 6 shows the angular displacement patterns generated from the average values of the twenty subjects. During the preparation phase, the initial angular displacement at the support shoulder joint was greater at an angle of 81° compared with the dominant shoulder joint. However, both the dominant elbow and the wrist joints displayed a greater initial angular displacement compared with the support joints at the preparation phase, at with angular values of 106° and 48°, respectively. At the end of preparation phase, both the support and dominant shoulders exhibited upward flexion movements with a slight increase in the flexion angle by 8.6% and 17.0%, respectively. This was similar to the wrist joint that exerted a slight increment in the ulnar deviation angle in both the support and dominant wrist angular movements by 8% and 10% respectively. In contrast, both the support and dominant elbows showed a slight decrease in the flexion angle in the extension direction at the end of the preparation phase by 9% and 5%, respectively.

Figure 6.

The average value of angular displacement patterns of twenty subjects for (a) the support arm and (b) the dominant arm during the three phases.

Next, at the execution phase, both the support and dominant shoulders showed downward flexion or extension movements. Thus, at the end of the execution phase, there was a decrease in the flexion angle by 55% and 90%, respectively. A similar scenario was noted for the support and dominant wrist joints, in which there was a decline in the ulnar deviation angle at the end of the execution phase by 34% and 62%, respectively. Meanwhile, the support and dominant elbow patterns showed an increase in the flexion angles by 59% and 18% at the end of the execution phase, respectively.

At the end phase, both the support and the dominant shoulders reached the flexion angles of 43° and 7°, respectively. The same patterns were observed for the support and dominant wrist joints whereby slight increments were recorded for the ulnar deviation angles by 4% and 9%, respectively. Nevertheless, a slight decrease was found in the flexion angles for both the support and dominant elbows by 4% and 7%, respectively.

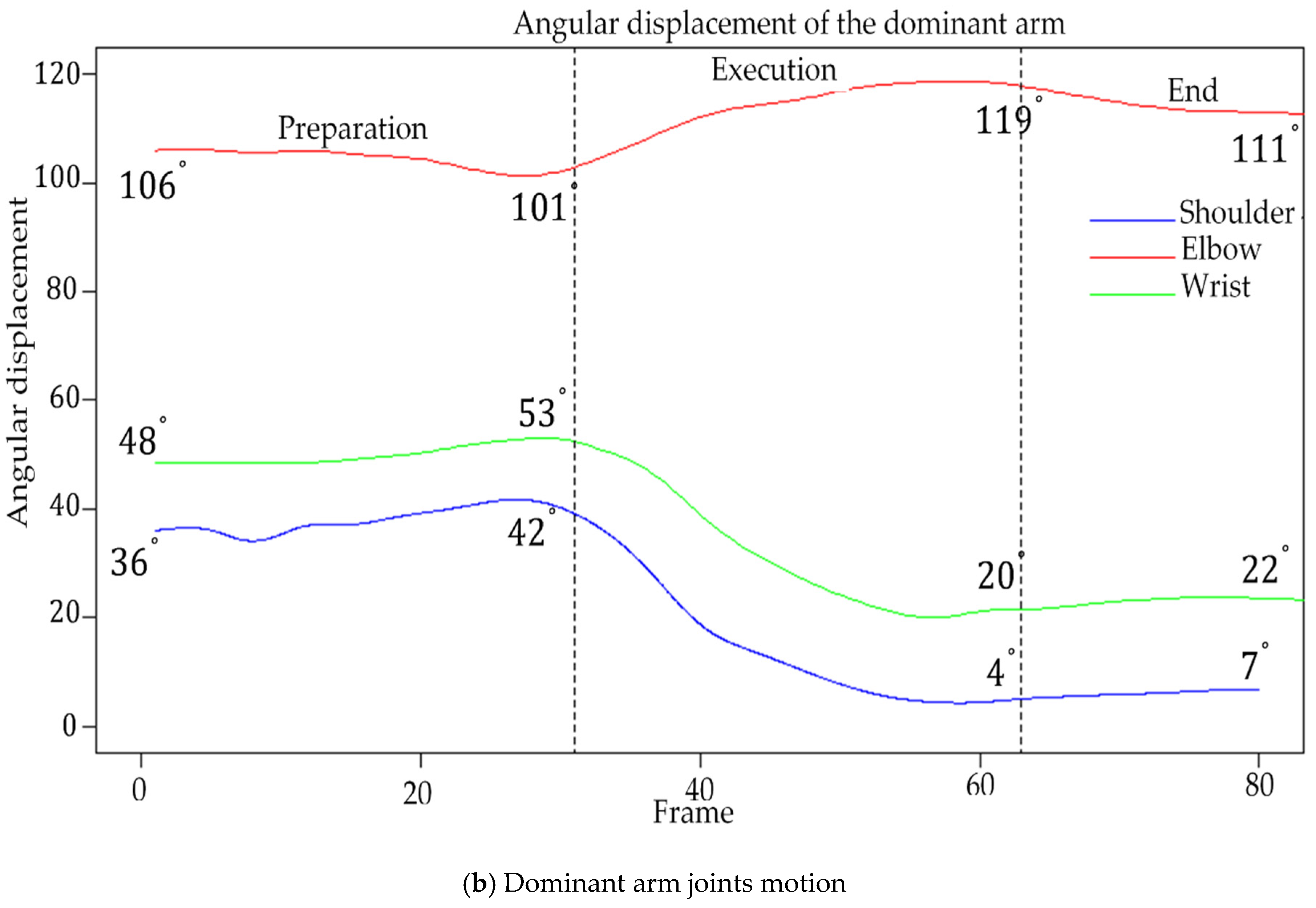

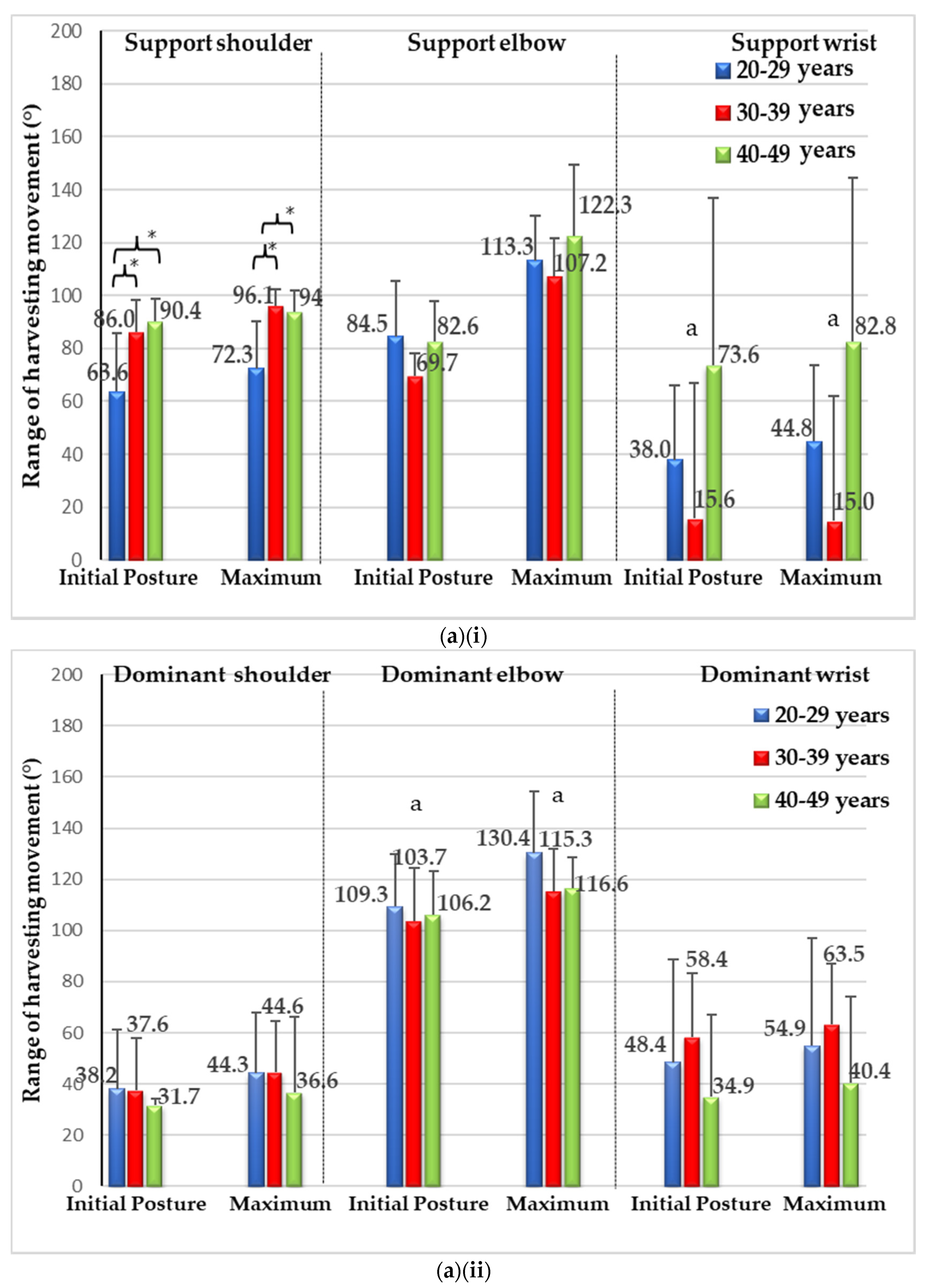

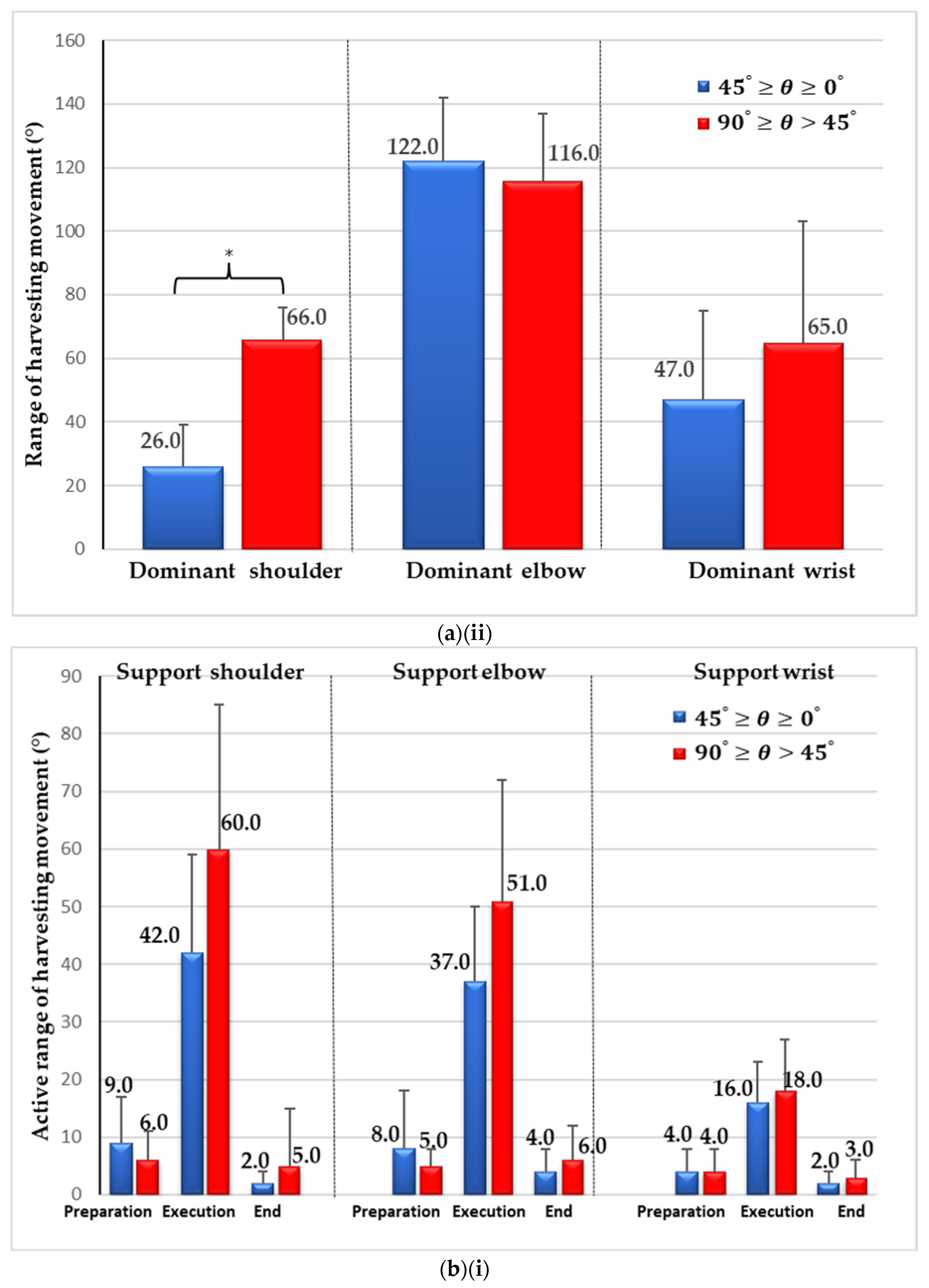

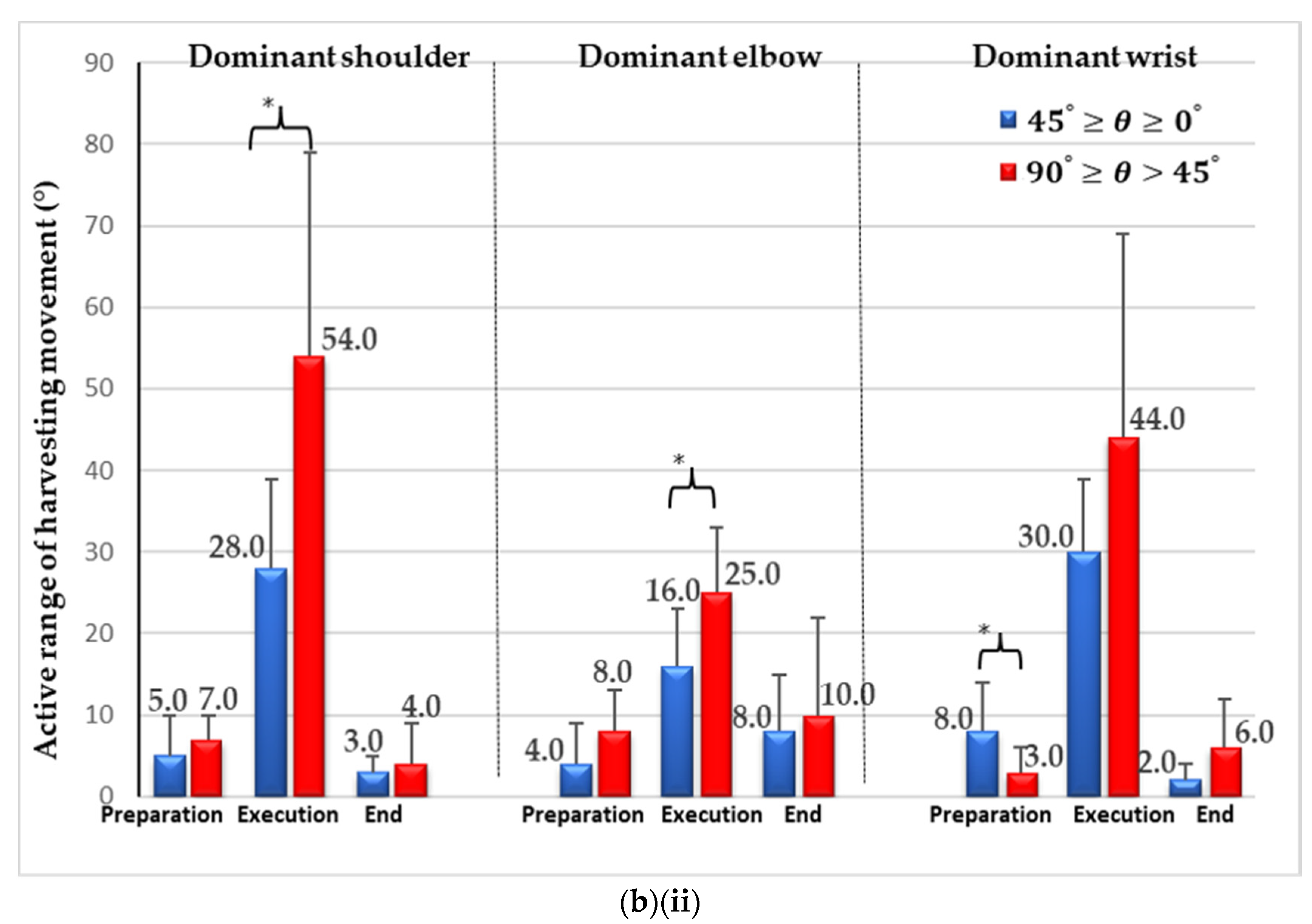

4.3. Range of Harvesting Movement

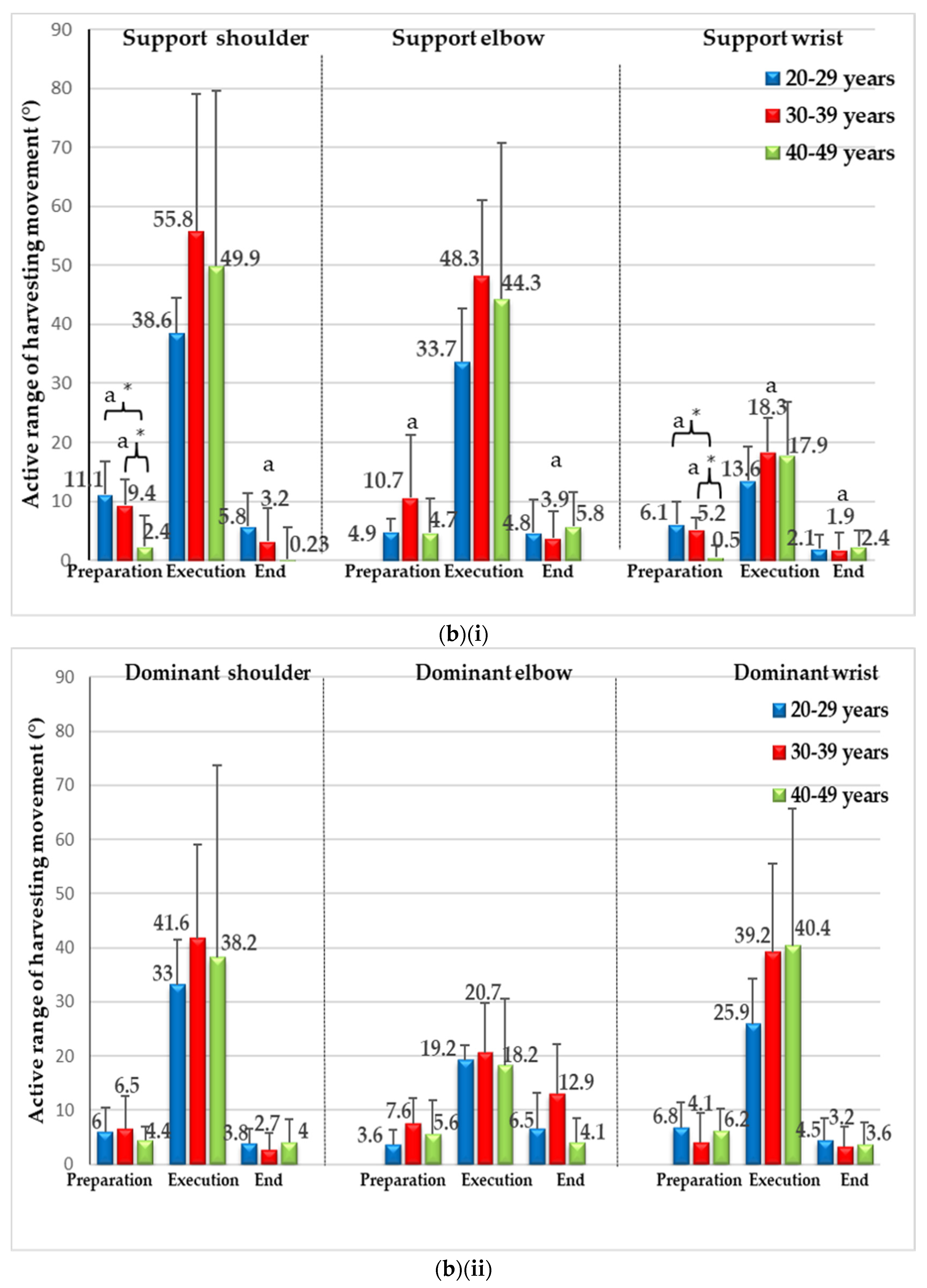

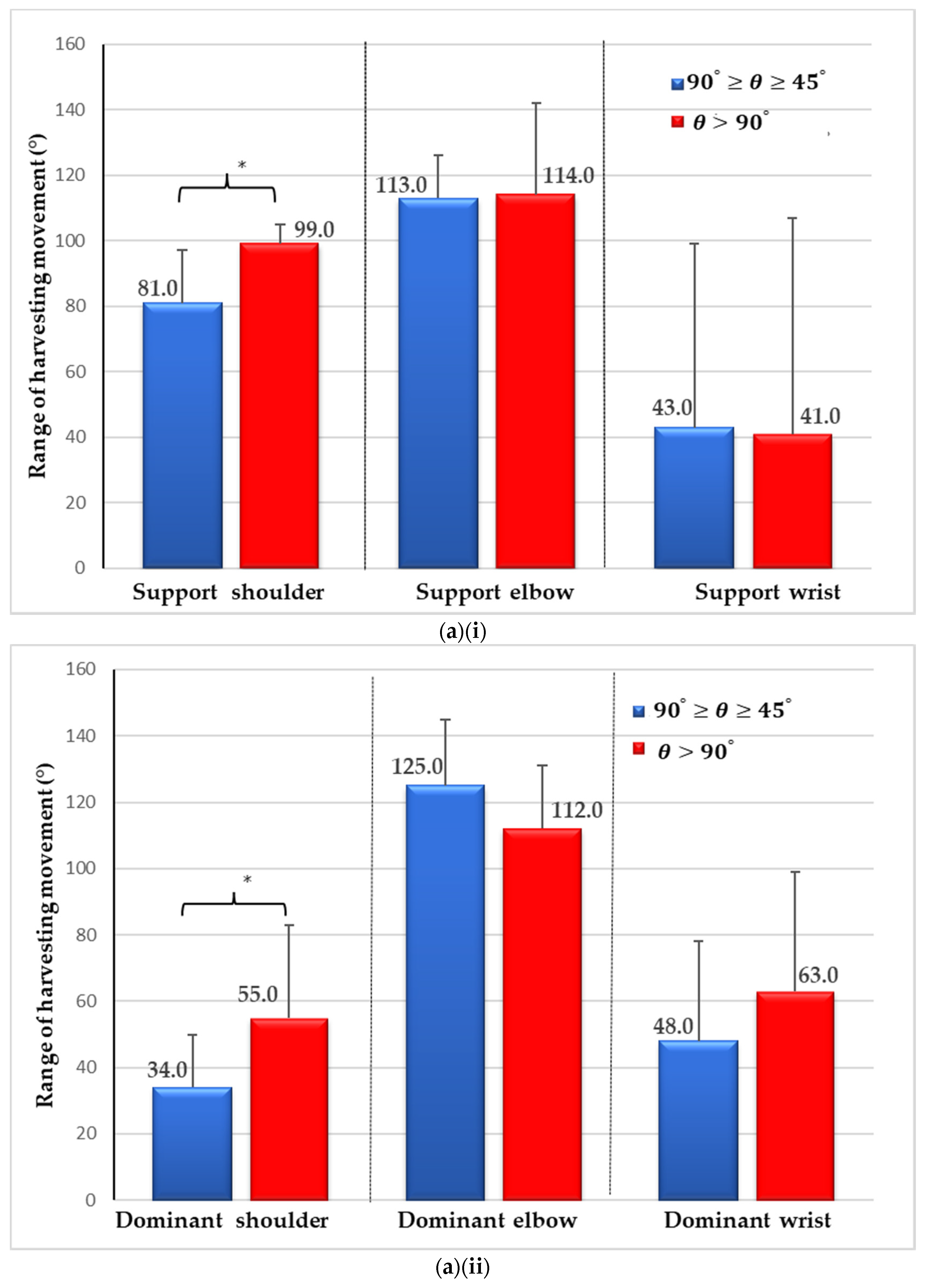

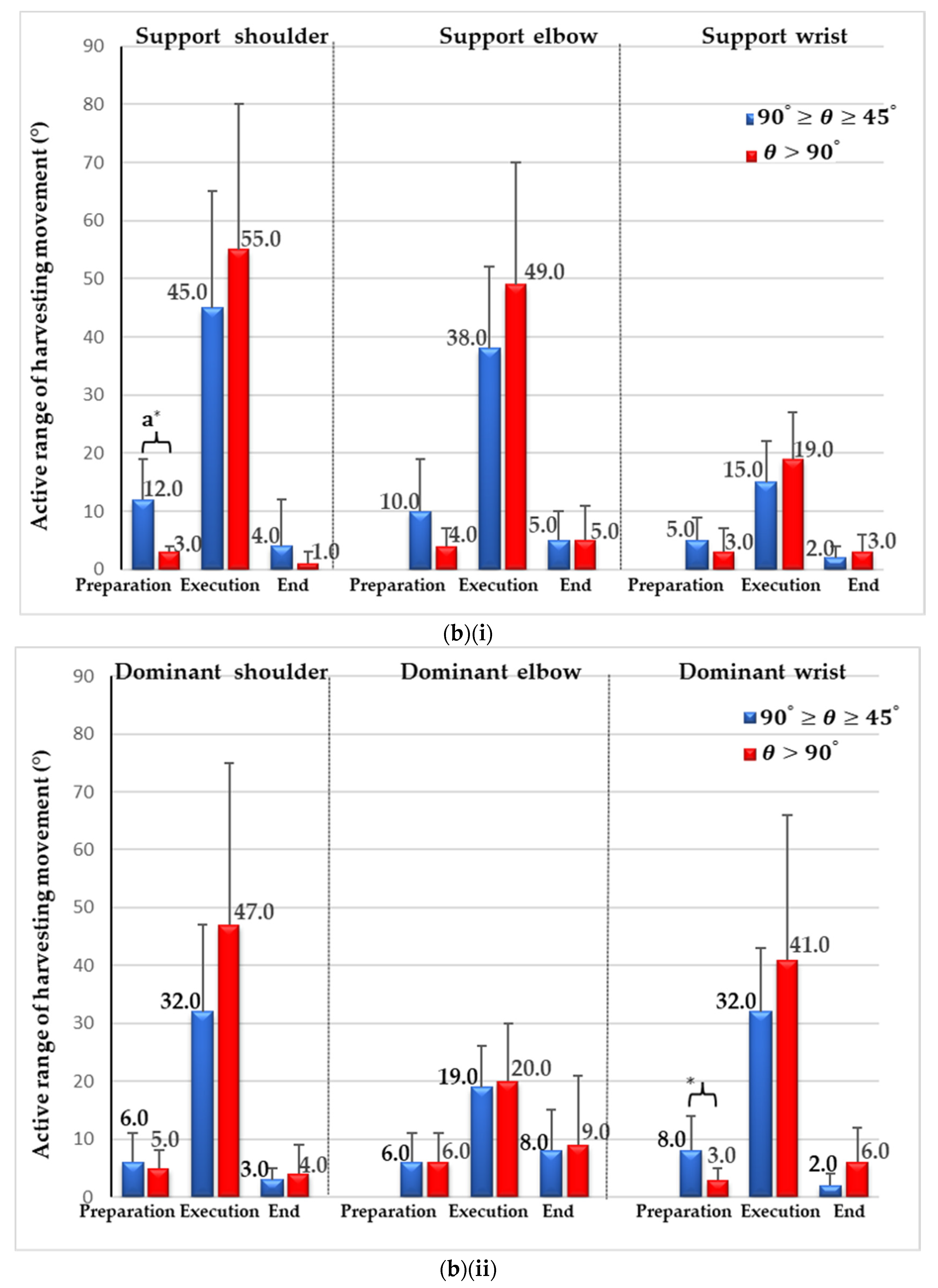

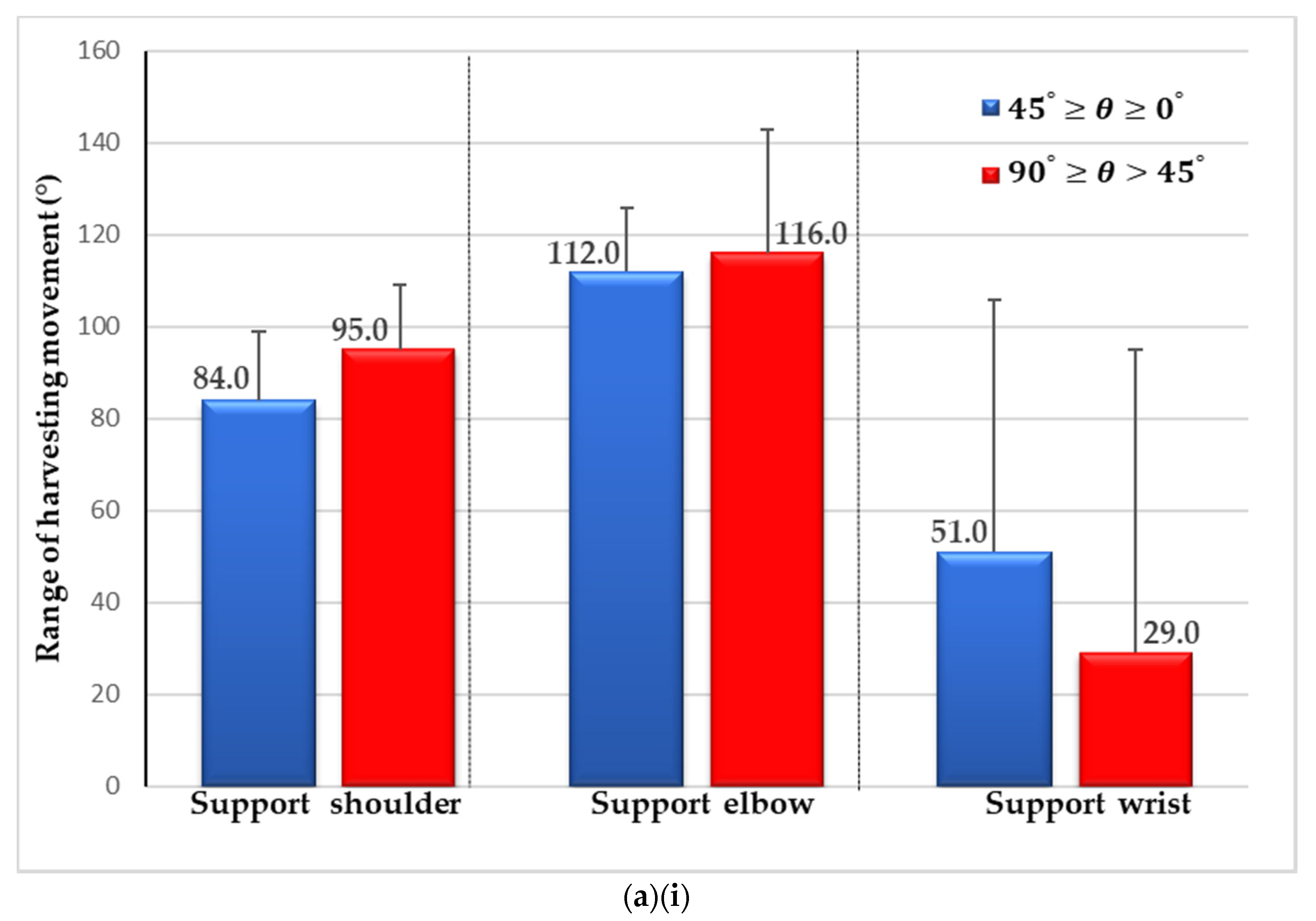

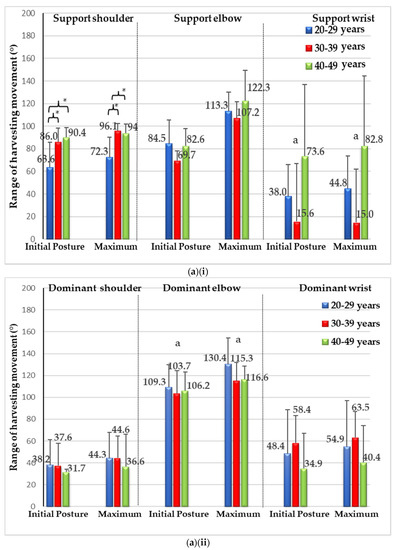

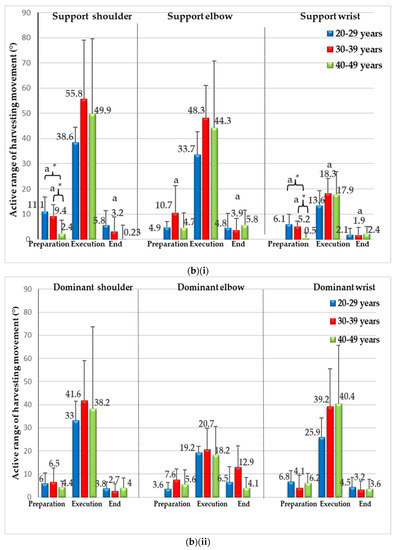

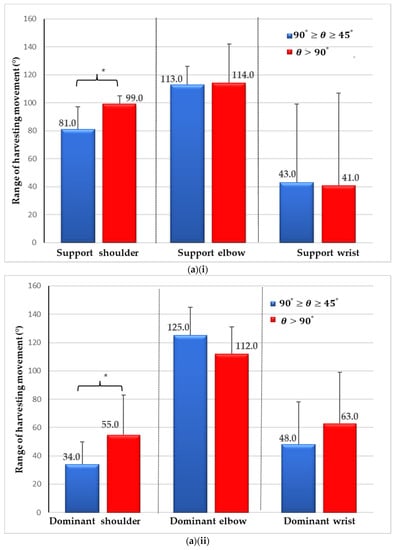

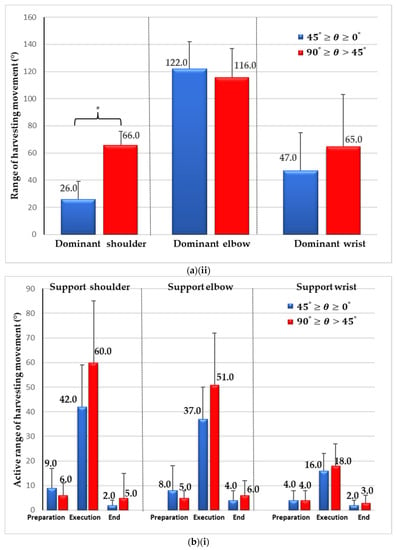

Figure 7 shows the mean and standard deviation values of the initial and maximum posture range of harvesting movements from the standing position. It also presents the active range of harvesting movements of the six joint motions through all the three phases based on the initial posture. Figure 8 and Figure 9 display similar summaries for the six joint motions, but for two different factors: the initial support shoulder group (Figure 8) and the initial dominant shoulder group (Figure 9). The error bars indicate standard deviations. Furthermore, the ANOVA revealed statistically significant results for the group mean variances, as indicated with asterisks.

Figure 7.

(a) The range of harvesting movements for initial and maximum postures and (b) the active range of harvesting movements during the three phases of the push-pull-cutting movement by age group for (i) the support arm and (ii) the dominant arm. The asterisk * denotes statistically significant differences and the letter a denotes that the measures were transformed into normal distributions.

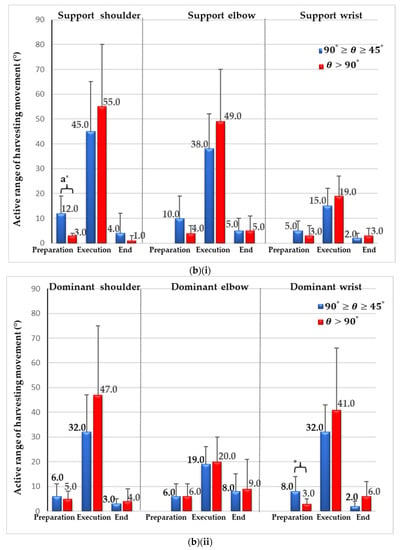

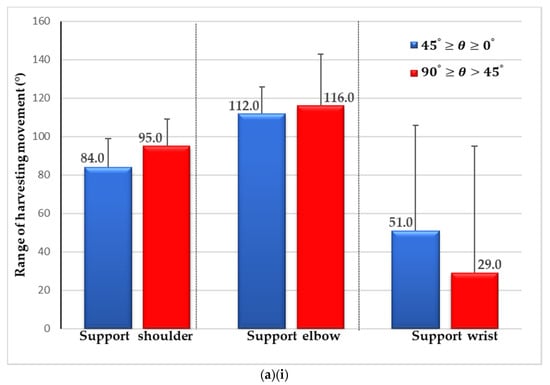

Figure 8.

(a) Maximum posture range of harvesting movements and (b) the active range of harvesting movements during the three phases of the push-pull-cutting movement, grouped by initial support shoulder for (i) the support arm and (ii) the dominant arm. The asterisk * denotes statistically significant differences and the letter a denotes that the measures were transformed into normal distributions.

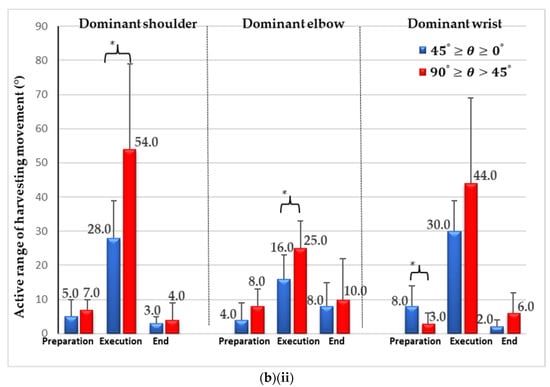

Figure 9.

(a) Maximum posture range of harvesting movements and (b) active range of harvesting movements during the three phases of the push-pull-cutting movement of twenty participants by initial dominant shoulder group for (i) the support arm and (ii) the dominant arm. The asterisk * denotes statistically significant differences.

Figure 7a shows that the initial and maximum posture range of harvesting movements in the supporting elbow and wrist joints, and all three joints of the dominant arm did not significantly differ between the three age groups. However, there were significant differences in the range of harvesting movements of the initial support shoulder posture and the maximum support shoulder posture between the three age groups. The post-hoc test suggested that participants in the age group of 40–49 and 30–39 years of age exhibited a greater range of harvesting movements at the initial posture in the support shoulder compared with those in the age group of 20–29 years of age (63.6°). Similarly, the older participants in the age group of 40–49 and 30–39 years of age exhibited a greater range of harvesting movements at the maximum posture in the support shoulder compared with the younger participants (.

Figure 7(ai) shows that the participants 40–49 years of age had a greater range of harvesting movements at initial and maximum postures compared with the other two age groups. The result was particularly prominent in the supporting wrist, in which the range of harvesting movements at the initial and maximum postures were and , respectively. This was also observed for the range of harvesting movements of support elbow at the maximum posture (). However, these differences were not statistically significant. Furthermore, Figure 7b shows that the active range of harvesting movements during the three phases of the push-pull-cutting movement in the supporting elbow and all three joints of the dominant arm did not differ significantly between the three age groups. However, there were significant differences in the active range of harvesting movements of the support shoulder and wrist at the preparation phase between the three age groups. The post-hoc test suggested that participants in the age group of 40–49 years of age (2.4°) recorded a significantly smaller active range of harvesting movements in the support shoulder at the preparation phase compared with those in the age groups of 30–39 and 20–29 years of age. Similarly, the participants in the age group of 40–49 years of age (0.5°) had a significantly smaller active range of harvesting movements in the support wrist at the preparation phase compared with those 30–39 and 20–29 years of age.

Regarding the maximum posture range of harvesting movement, mean values, and range of harvesting movement during the three phases based on the initial support shoulder, the variances for the elbow motion for the initial support shoulder posture were not statistically significant (Figure 8). Regarding the shoulder and wrist motions, a significant finding was obtained from the initial support shoulder posture for the maximum posture range of harvesting movement mean value for the support and dominant shoulders. The same was observed for the support shoulder and dominant wrists range of harvesting movement during the three phases. The initial support shoulder posture at had a significantly greater maximum support and dominant shoulder range of harvesting movements compared with In fact, the initial support shoulder posture at was linked to an increased range of harvesting movements for both the maximum support and dominant shoulder range of harvesting movements at and respectively (Figure 8(ai,aii)). Nevertheless, the initial support shoulder posture of was associated with a significantly smaller active range of harvesting movements for the support shoulder (t = 3.443, p = 0.010) and dominant wrist at the preparation phase. Figure 8b shows that the initial support shoulder posture at displayed a reduced active range of harvesting movements for the support shoulder and dominant wrist motion at the preparation phase with and respectively.

Next, significant variances were also found for the maximum posture range of harvesting movements and the active range of harvesting movement during the three phases based on the initial dominant shoulder posture as illustrated in Figure 9. The initial dominant shoulder posture at 90° ≥ exhibited a significantly greater maximum range of harvesting movement and it was also linked to an increased mean value of the maximum range of harvesting movements at the dominant shoulder. Furthermore, the initial dominant shoulder posture at displayed a significantly greater active range of harvesting movements for both the dominant shoulder and elbow compared with at the execution phase. In addition, the initial dominant shoulder posture for was associated with an increased mean value of the active range of harvesting movements for the dominant shoulder and elbow, at and , respectively, during the execution phase. Nonetheless, the initial dominant shoulder posture at had a statistically significantly smaller active range of harvesting movements for the dominant wrist (t = −2.305, p = 0.033) at the preparation phase. The initial dominant shoulder posture at was associated with a reduced range of harvesting movements for the dominant wrist, which was during the preparation phase.

5. Discussion

The data on upper arm angular displacements are indispensable in the determination of the range of harvesting movements of the three main arm joints. However, very few studies have reported on the significance of angular displacements of all three arm joints during the push-pull-cutting technique used by oil palm harvesters. Thus, this study objectively investigated the angular displacements and range of harvesting movements, as well as the active range of harvesting movements of the arm joints. Moreover, the effects of age and initial shoulder posture on the harvesting movements on the arm joints were analysed.

This study provided fundamental evidence on the movement patterns associated with the three phases of the push-pull-cutting technique, namely pushing, pulling, and end phases. During the preparation phase, the participants tended to push the harvesting tool to create a gap in the pulling range before executing the pulling technique. At the same time, there was a slight change in the angle at the end of the phase due to the forceful reaction from the FFB. Such shifts may imply a change in the force and muscle fibre length throughout these dynamic stages, subsequently influencing the underlying muscle activities [29]. The largest change in the angular displacement occurred at the execution phase. Based on the investigation performed by [30] on the muscle activity of the medial and posterior deltoid muscles all the infraspinatus, trapezius, and supraspinatus muscles exerted a 35% increase in electromyography activity when the arm was in flexion [30]. This study showed that the harvester tends to experience greater electromyography activity at the infraspinatus, trapezius, and supraspinatus muscles during the execution phase.

This study provided the initial and maximum posture data in terms of the range of harvesting movement, as well as the performance data of pushing and pulling movement through the three phases. Compared with the previous study, [24] did not consider the phases that exist in the harvesting movement. However, [24] considered the movement directions such as flexion and extension of shoulder joint in terms of ROM. In this study, pushing and pulling were studied in terms of the active range of movement. The active range of movement was measured by phases which were preparation, execution and end phase. At the preparation phase, the active range of movement was measured through the determination of the angle difference between the angular displacements produced during placing the harvesting tool and the maximum posture of the three joints. Next, at the execution phase, the active range of movement was measured through the determination of angle difference between the angular displacements produced during maximum posture and after the pulling movement. Last, at the end phase the active range of movement was measured through the determination of angle difference between the angular displacements produced after the pulling movement and the final posture caused by the forceful reaction from the FFB. In this study, the range of harvesting movement and active range of harvesting movement were used to the study the effects that affect the harvesting movement.

In many researches, RULA has been extensively utilised to evaluate the exposure of individual workers to the ergonomic risk factors associated with upper extremity MSDs. The RULA worksheet is used to evaluate the required body posture, force, and repetition to complete an action. Section A of RULA is used for the evaluation of the arm and wrist. Elevation of the shoulder at an angle of and above results in a score of four that indicates a higher risk of MSD. Elevation of the shoulder at an angle of provides a score of three, followed by that provides a score of two and that provides a score of one. The findings from this study revealed that harvesters 40–49 years of age experienced a higher risk of MSDs at the support shoulder region compared with those 20–29 years of age when placing the harvesting tool at the targeted FFB. Harvesters in the age groups of 40–49 and 30–39 years of age also tended to experience a higher risk of MSDs at the support shoulder region during their maximum posture of harvesting movement. This can be attributed to the fact that harvesters 40–49 and 30–39 years of age can be considered as more experienced harvesters, who were not practicing the proper manual handling of oil palm harvesting. This trend was also found by [3], 81% of the surveyed harvesters in an oil palm plantation were aware of the correct procedure and method of manual handling and lifting. However, only 17.1% of the harvesters practised the right method. According to [3], the reason that the harvesters were resisting to the proper manual handling was because the changes would slow down their work pace and they also felt uncomfortable in applying it. This may be the same case for this study. In this study there was a notable decline in the active harvesting movement with age. Harvesters 40–49 years of age were found to have a smaller active range of harvesting movements during the preparation phase at the support shoulder and wrist regions, with angles of 2.4° and 0.5°, respectively. This result was consistent with a previous study [22] in which age was also associated with a declining performance of motor tasks. However, in this study the trend is not due to performance or ability to perform tasks as previously reported. The decrease in the active range of movement is influenced by the initial shoulder posture exhibited by the age groups of 40–49 and 30–39 years of age. The result showed that the initial and maximum posture at the support shoulder of these age groups were greater than to those 20–29 years of age which indicate that the age groups of 40–49 and 30–39 years of age were more capable in placing the harvesting tool at the higher target of FFB. Furthermore, the age categorization in this study was different from the age categorization in [22].

It was previously reported that the characteristics of oil palm trees affected the placement of the harvesting tool on the targeted FFBs. During the harvesting, harvesters must align their initial posture to obtain a suitable position to start the harvesting process. This may predispose the workers to unfavourable and awkward postures at the beginning of the process and subsequently result in MSDs. With the aim of collecting the data required in the design of ergonomic harvesting tools, this study evaluated the effect of the initial posture position on the maximum posture range of harvesting movements and range of harvesting movements during the three phases of the push-pull-cutting movement of upper arm among the oil palm harvesters. The results from previously published studies showed that those who worked with an initial support shoulder range of harvesting movements of θ > 90° commonly experienced shoulder discomfort [31,32,33]. These groups of workers also had a greater maximum range of harvesting movements on the support and dominant shoulders in this study. Thus, they tended to continue elevating their arms and creating a greater risk of developing MSDs compared with those who worked at an initial support shoulder range of harvesting movements of 90° ≥ θ ≥ 45°.

Furthermore, working with an initial support shoulder range of harvesting movements of θ > 90° generated a reduction in the support shoulder flexion and the ulnar deviation active range of harvesting movements of the dominant wrist at the preparation phase, by 9.0° and 5.0°, respectively. Nevertheless, this study found that the initial dominant shoulder posture did not exert any effect on the active range of harvesting movements of the support arm. However, there was an effect from the initial dominant shoulder posture on the maximum range of harvesting movements of the dominant shoulder and the active range of the harvesting movement values of both the dominant shoulder extension and elbow flexion at the execution phase. However, there was no reduction in the active range of harvesting movements in the dominant shoulder and elbow, with the increase observed for the initial dominant shoulder range of harvesting movement.

As for the wrist joint, the active range of the harvesting movement of the dominant wrist ulnar deviation declined as the initial dominant shoulder range of harvesting movements increased during the preparation phase. Hence, this concurred with another study that the wrist might be in a non-neutral position if the ulnar and the radial deviation were observed [34]. Even though the reduction in the active range of harvesting movements observed in this study was small, other researchers have reported a minor deviation in the ulnar by 5.0°–7.0° with higher electromyography activity [35]. Besides, this study established the presence of movement difficulties for support shoulder flexion and both support and dominant wrist ulnar deviations at the preparation phase. This information can prove beneficial for the early detection of MSDs.

Although the sample size of the present study allowed statistical testing for the age, initial shoulder posture effects, and the demographic characteristics of oil palm harvesters, it is undeniable that the sample size was small. As such, future studies with a larger sample size would be beneficial to confirm the findings of this study. In addition, the range of harvesting movements analysis should be extended to examine joint motion on both the frontal and transverse planes. Future studies should also include other variables such as anthropometry, tool handle orientation, and muscle strength. A full 3-D analysis and calculations of angles, forces, and motion speeds are needed to provide the dynamic data for the evaluation of the movement performed by oil palm harvesters.

6. Conclusions

This study produced valuable data related to the ROM pattern characteristics of oil palm harvesters. The results showed a slight increase at the preparation phase, decrease at the execution phase and a slight increase at the end phase in terms of the angular displacement of shoulder and wrist joints. The opposite pattern was observed for the elbow joint. This study also provided data on the active ROM of the upper joints based on the three phases involved in harvesting FFBs. The findings demonstrated that the age of oil palm harvesters can affect the pushing performance of the support shoulder and wrist during harvesting. It also showed that even the older and more experienced oil palm harvesters failed to practise the proper manual handling in oil palm harvesting. Additionally, a reduced active range of harvesting flexion movement at the support shoulder joint during the preparation phase was associated with an initial support shoulder of θ > 90°. The elevation of angles for both the initial support and dominant shoulders at the MSDs risk level were associated with reduced ulnar deviation, active range of harvesting movements of the dominant wrist at the preparation phase. Thus, this highlights the importance of considering age and initial shoulder posture when incorporating ergonomic designs in oil palm harvesting tools and workplaces. This study also contributed fundamental information towards the development of the human motion simulation model that can accommodate various population groups.

Author Contributions

N.P.T., B.M.D. and A.S.R. conceptualized the study; N.P.T. and A.S.R. developed the methodology; N.P.T. conducted the experiment; N.P.T. performed data analysis and wrote article; A.S.R. and B.M.D. supervised and reviewed the article; and N.P.T. edited and revised the article. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful to UKM and the Malaysian Government for a STEM grant under RMK-11 with a code ST-2019-016.

Institutional Review Board Statement

The study was conducted according to the guidelines of the Declaration of Helsinki, and approved by the Ethics Committee of UKM (PPI/111/8/JEP-2016-558) on 28 October 2016.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The datasets used and/or analysed during the current study will be made available upon reasonable request to the author, N.P.T.

Acknowledgments

We would like to express our appreciation to the Department of Mathematical Sciences, Faculty of Science and Technology, UKM for their support and assistance throughout this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nawi, N.S.M.; Deros, B.M.; Ab-Rahman, M.N.; Sukadarin, E.H.; Nordin, N. Malaysian oil palm workers are in pain: Hazards identification and ergonomics related problems. Malays. J. Public Health Med. 2016, 16, 50–57. [Google Scholar]

- Ng, Y.G.; Tamrin, S.B.M.; Md Yusoff, I.S.; Mori, I.; Hashim, Z. Ergonomics observation: Harvesting tasks at oil palm plantation. J. Occup. Health 2013, 55, 405–414. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deros, B.M.; Ali, M.H.; Mohamad, D.; Darius, D.D.I. Ergonomic risk assessment on oil palm industry workers. Iran. J. Public Health 2016, 45, 44–51. [Google Scholar]

- Ng, Y.G.; Tamrin, S.B.M.; Md Yusoff, I.S.; Hashim, Z.; Deros, B.M.; Bakar, S.A.; How, V. Risk factors of musculoskeletal disorders among oil palm fruit harvesters during early harvesting stage. Ann. Agric. Environ. Med. 2015, 22, 286–292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guturu, K.; Sahitya, K.; Komali, V.N.; Kiran, B.R.; Satyanarayana, C.V.V. Design and Fabrication of prototype telescopic raising platform for harvesting oil palm fresh fruit bunches. Indian J. Sci. Technol. 2015, 8, 1–5. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, W.; Chablat, D.; Bennis, F.; Guillaume, F. Multi-objective optimisation method for posture prediction and analysis with consideration of fatigue effect and its application case. Comput. Ind. Eng. 2009, 57, 1235–1246. [Google Scholar] [CrossRef] [Green Version]

- Rahman, A.; Mohamaddan, S.; Majid, N.A.A.; Munot, M.A.; Yusuf, M.; Ngie, D.C.S.; Deros, B.M. Investigation of human arm musculoskeletal model using aluminium pole in palm oil harvesting process. In Proceedings of the 2016 IEEE EMBS Conference on Biomedical Engineering and Sciences (IECBES), Kuala Lumpur, Malaysia, 5–7 December 2016; pp. 394–399. [Google Scholar]

- Sukadarin, E.H.; Deros, B.M.; Nawi, N.S.M.; Ghani, J.A.; Ismail, A.R.; Zakaria, J. Back pain and the observed factors among oil palm workers. Int. J. Eng. Technol. Sci. 2016, 3, 70–78. [Google Scholar] [CrossRef]

- Bernard, C.; Courouve, L.; Bouée, S.; Adjémian, A.; Chrétien, J.-C.; Niedhammer, I. Biomechanical and psychosocial work exposures and musculoskeletal symptoms among vineyard workers. J. Occup. Health 2011, 53, 297–311. [Google Scholar] [CrossRef] [Green Version]

- Gustafsson, B.; Pinzke, S.; Isberg, P.E. Musculoskeletal symptoms in swedish dairy farmers. Swed. J. Agric. Res. 1994, 24, 177–188. [Google Scholar]

- Hildebrandt, V.H. Musculoskeletal symptoms and workload in 12 branches of Dutch agriculture. Ergonomics 1995, 38, 2576–2587. [Google Scholar] [CrossRef]

- McCurdy, S.A.; Samuels, S.J.; Carroll, D.J.; Beaumont, J.J.; Morrin, L.A. Agricultural injury in California migrant Hispanic farm workers. Am. J. Ind. Med. 2003, 44, 225–235. [Google Scholar] [CrossRef]

- Park, H.; Sprince, N.L.; Ma, P.S.W.; Burmeister, L.F.; Zwerling, C. Risk factors for back pain among male farmers: Analysis of Iowa farm family health and hazard surveillance study. Am. J. Ind. Med. 2001, 40, 646–654. [Google Scholar] [CrossRef]

- Xiang, H.; Stallones, L.; Keefe, T.J. Back pain and agricultural work among farmers: An analysis of the Colorado farm family health and hazard surveillance survey. Am. J. Ind. Med. 1999, 35, 310–316. [Google Scholar] [CrossRef]

- Latko, W.A.; Armstrong, T.J.; Franzblau, A.; Ulin, S.S.; Werner, R.A.; Albers, J.W. Cross-sectional study of the relationship between repetitive work and the prevalence of upper limb musculoskeletal disorders. Am. J. Ind. Med. 1999, 36, 248–259. [Google Scholar] [CrossRef]

- Marcus, M.; Gerr, F.; Monteilh, C.; Ortiz, D.J.; Gentry, E.; Cohen, S.; Ma, A.E.; Ensor, C.; Kleinbaum, D. A prospective study of computer users: II. Postural risk factors for musculoskeletal symptoms and disorders. Am. J. Ind. Med. 2002, 41, 236–249. [Google Scholar] [CrossRef]

- Md Yusoff, I.S.; Tamrin, S.B.M.; Mat-Said, A.; Ng, Y.G.; Mori, I. Oil palm workers: Designing ergonomics harvesting tool using user centered design approach to reducing awkward body posture by Catia simulation. Iran. J. Public Health 2014, 43, 72–80. [Google Scholar]

- Sukadarin, E.H.; Deros, B.M.; Ghani, J.A.; Ismail, A.R.; Nawi, N.S.M.; Abdull, N. Validity test for simple ergonomics risk assessment (Sera). Malays. J. Public Health Med. 2016, 16, 134–143. [Google Scholar]

- Chaffin, D.B.; Faraway, J.J.; Zhang, X.; Woolley, C. Stature, age, and gender effects on reach motion postures. Hum. Factors 2000, 42, 408–420. [Google Scholar] [CrossRef] [Green Version]

- Karniel, A.; Inbar, G.F. A model for learning human reaching movements. Biol. Cybern. 1997, 77, 173–183. [Google Scholar] [CrossRef]

- Chaffin, D.B. On simulating human reach motions for ergonomics analyses. Hum. Factors Ergon. Manuf. 2002, 12, 235–247. [Google Scholar] [CrossRef] [Green Version]

- Chateauroux, E.; Wang, X. Effects of Age, gender, and target location on seated reach capacity and posture. Hum. Factors 2008, 50, 211–226. [Google Scholar] [CrossRef]

- Chaffin, D.B.; Faraway, J.; Zhang, X. Simulating Reach Motions, SAE Technical Paper 1999-01-1916; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef] [Green Version]

- Syuaib, M.F. Ergonomic of the manual harvesting tasks of oil-palm plantation in Indonesia based on anthropometric, postures and work motions analyses. Agric. Eng. Int. CIGR J. 2015, 17, 248–262. [Google Scholar]

- Kroemer, K.H.; Grandjean, E. Fitting the Task to the Human, 5th ed.; Taylor & Francis: Philadelphia, PA, USA, 1997; ISBN 020348391X. [Google Scholar]

- Openshaw, S.; Taylor, E. Ergonomics and Design: A Refererence Guide; Allsteel Inc.: Muscatine, IA, USA, 2006. [Google Scholar]

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Templeton, G.F. A two-step approach for transforming continuous variables to normal: Implications and recommendations for IS research. Commun. Assoc. Inf. Syst. 2011, 28, 4. [Google Scholar] [CrossRef] [Green Version]

- Larsson, B.; Månsson, B.; Karlberg, C.; Syvertsson, P.; Elert, J.; Gerdle, B. Reproducibility of surface EMG variables and peak torque during three sets of ten dynamic contractions. J. Electromyogr. Kinesiol. 1999, 9, 351–357. [Google Scholar] [CrossRef]

- Herberts, P.; Kadefors, R.; Högfors, C.; Sigholm, G. Shoulder pain and heavy manual labor. Clin. Orthop. Relat. Res. 1984, 191, 166–178. [Google Scholar] [CrossRef]

- Punnett, L.; Fine, L.J.; Keyserling, W.M.; Herrin, G.D.; Don, B.; Monroe, W.; Herrin, D.; Fine, J. Articles original in automobile work disorders and postural shoulder assembly. Scand. J. Work Environ. Health 2000, 26, 283–291. [Google Scholar] [CrossRef] [Green Version]

- Svendsen, S.W.; Bonde, J.P.; Mathiassen, E.S.; Stengaard-Pedersen, K.; Frich, L.H. Work related shoulder disorders: Quantitative exposure-response relations with reference to arm posture. Occup. Environ. Med. 2004, 61, 844–853. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hanvold, T.N.; Waersted, M.; Mengshoel, A.M.; Bjertness, E.; Veiersted, K.B. Work with prolonged arm elevation as a risk factor for shoulder pain: A longitudinal study among young adults. Appl. Ergon. 2015, 47, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Gold, J.; Driban, J.; Thomas, N.; Chakravarty, T.; Channell, V.; Komaroff, E. Postures, typing strategies, and gender differences in mobile device usage: An observational study. Appl. Ergon. 2012, 43, 408–412. [Google Scholar] [CrossRef]

- Fagarasanu, M.; Kumar, S.; Narayan, Y. Measurement of angular wrist neutral zone and forearm muscle activity. Clin. Biomech. 2004, 19, 671–677. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).