Comparison of the Mechanical Behavior of Concrete Containing Recycled CFRP Fibers and Polypropylene Fibers

Abstract

:1. Introduction

2. Materials and Methods

- −

- −

- −

- −

- Drinking water from the Canal de Isabel II Madrid region’s main water supply, which complies with the technical specifications for its use in structural concrete.

- −

- Macro synthetic polypropylene fibers (SikaFiber T-48). These fibers comply with the specifications of regulation UNE-EN 14889-2: 2008 [54] with regard to the conformity requirements for polymer fibers for concrete.

- −

- Recycled carbon fibers manually extracted from wooden elements measuring 80 mm × 155 mm × 1000 mm. It was previously tested in the materials laboratory at the Escuela Técnica Superior de Edificación as part of the doctoral thesis of Enrique Gómez and used by way of reinforcement in U-shaped flexural test [55].

- −

- Superplasticizer based on polycarboxylates (MasterGlenium SKY 604), adding 0.7% of the superplasticizer in relation to the cement weight. The additive used complies with regulation UNE-EN 934-2:2010 + A1 [56].

- τ = fracture energy expressed in joules;

- P = pendulum mass expressed in kilograms (2.70 kg);

- L = length from the pendulum arm to its point of impact (0.64 m);

- β = initial pendulum height from which it is released;

- α = final height reached by the pendulum after hitting the specimen; and

- g = gravitational acceleration (9.80665 m/s2).

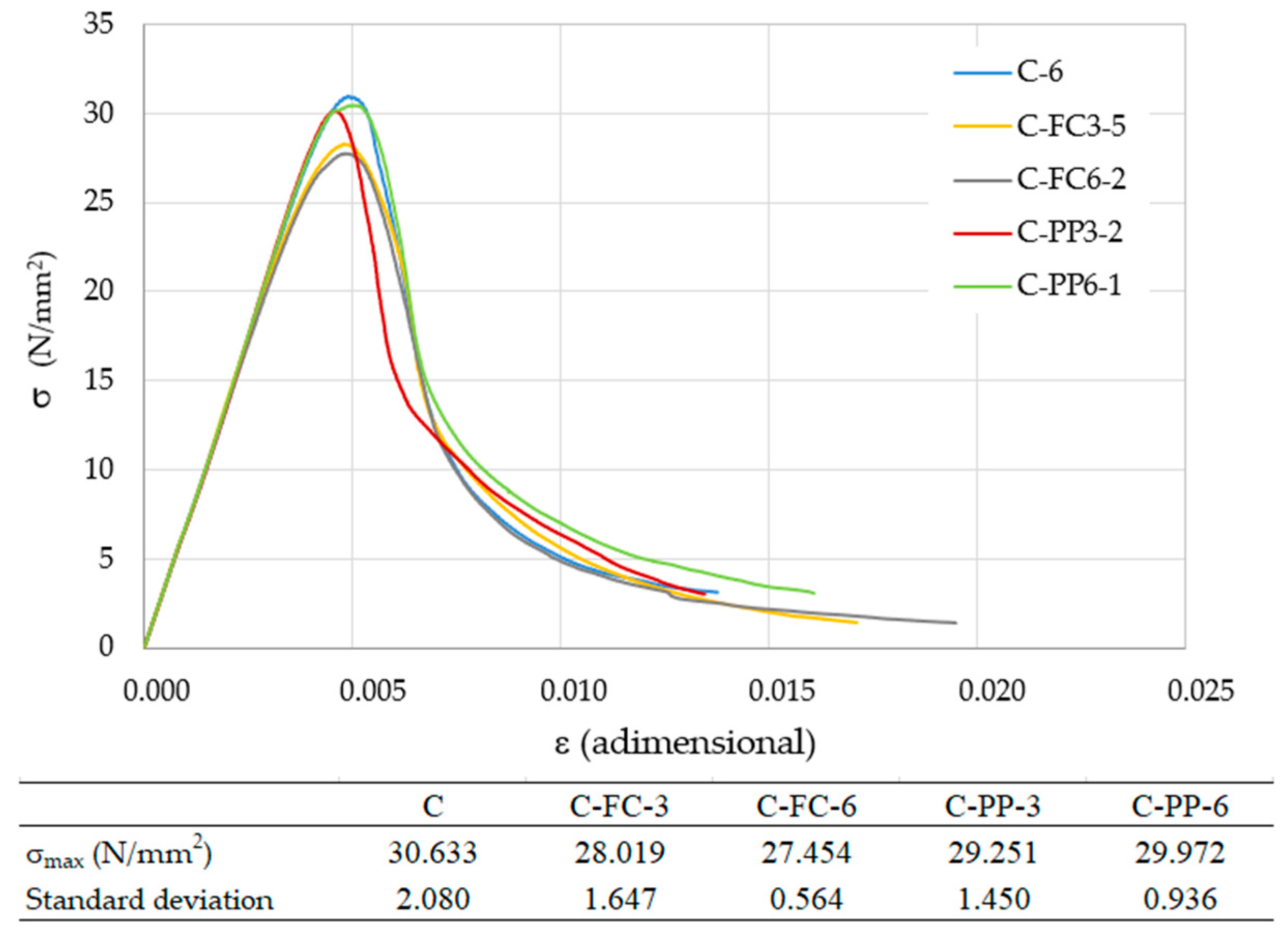

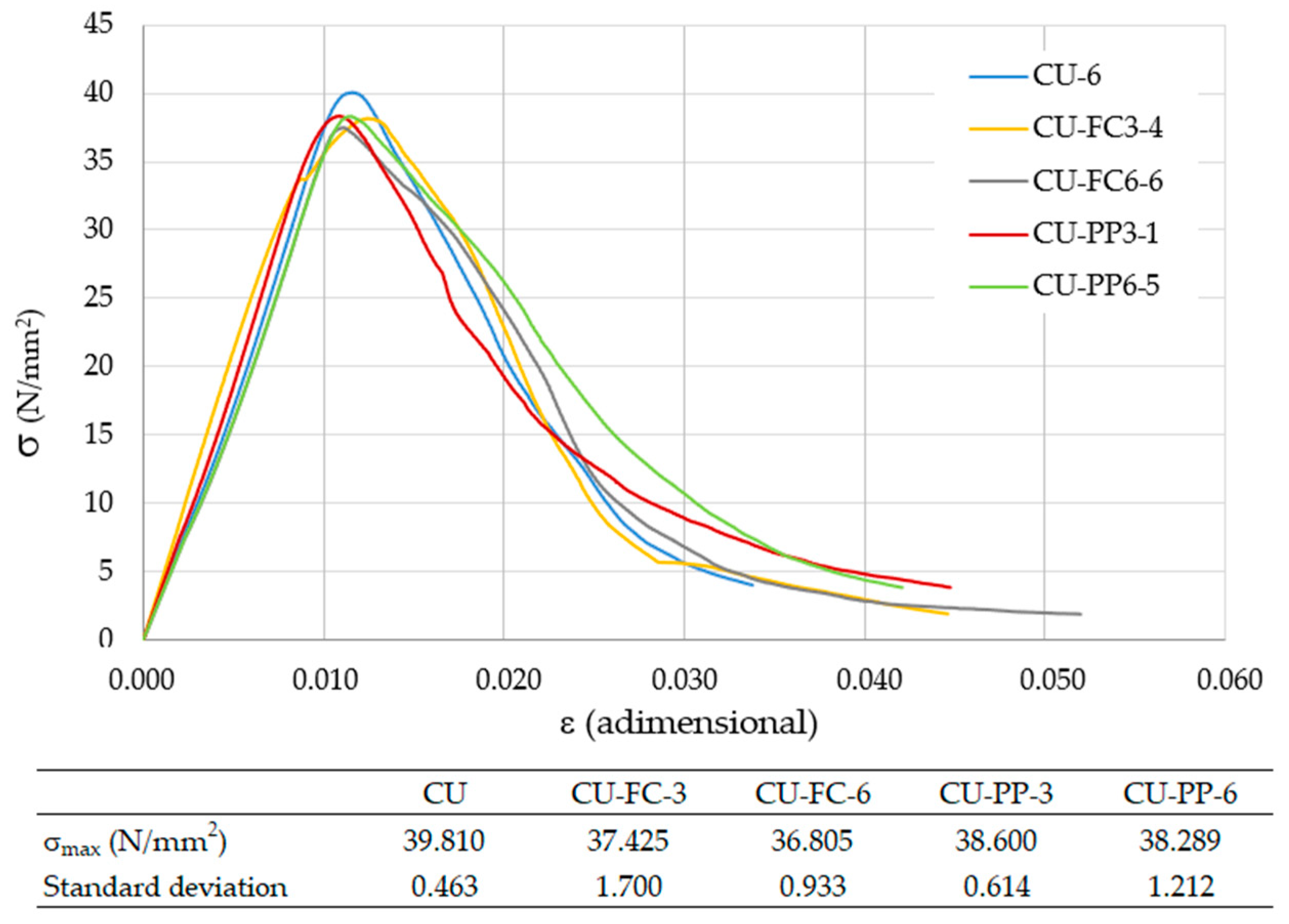

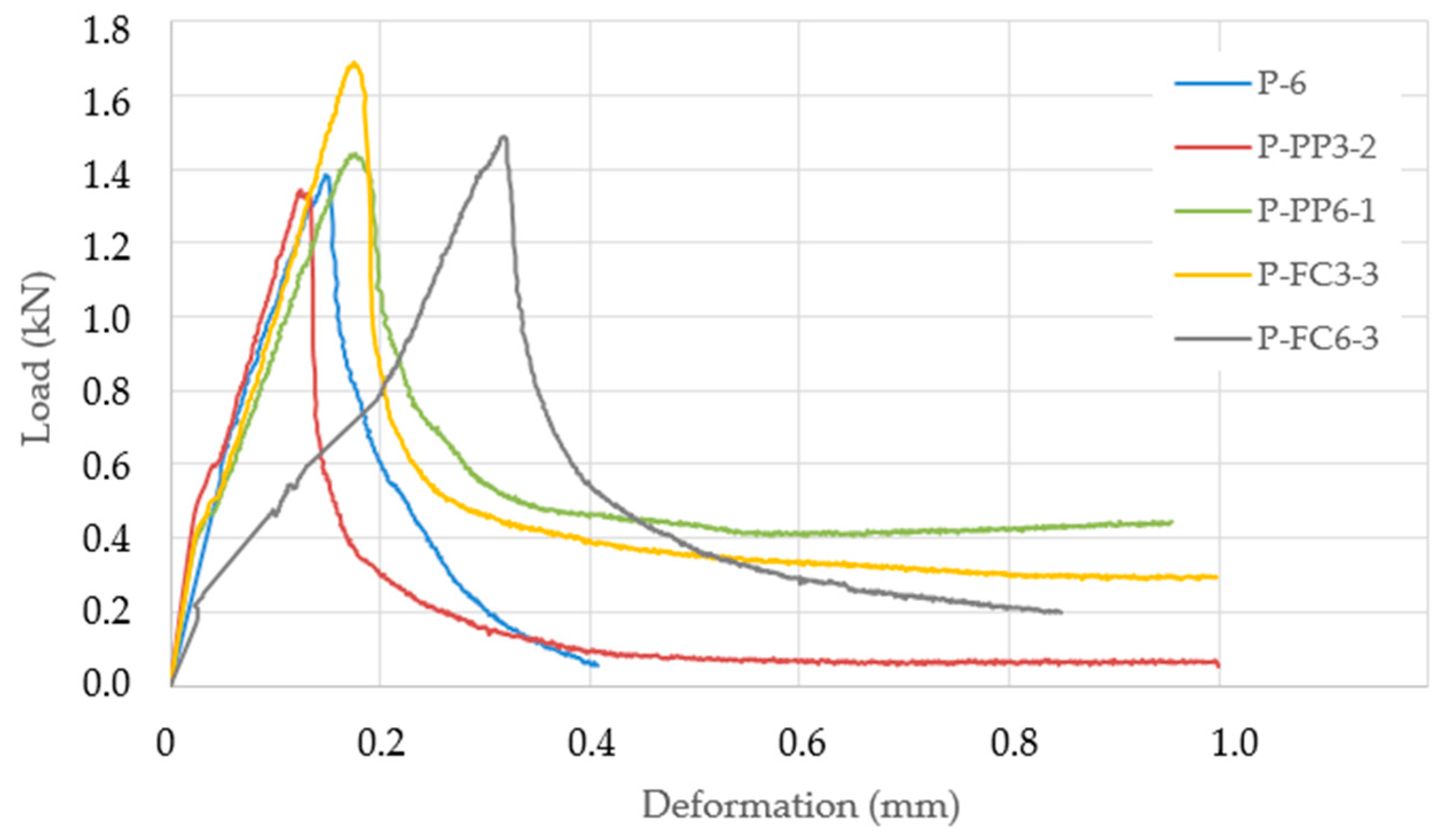

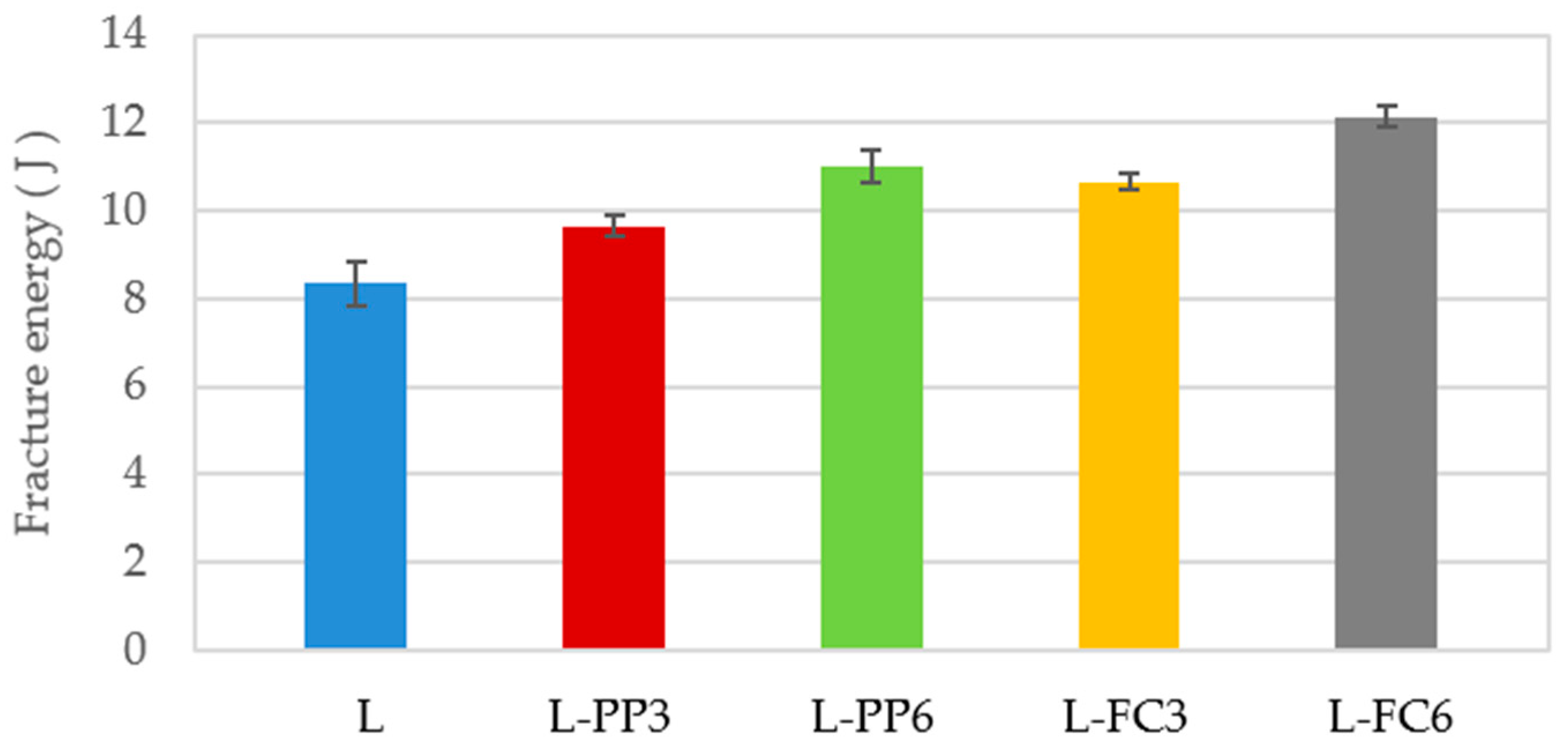

3. Results and Discussion

4. Conclusions

- −

- Despite displaying worse compressive behavior than concretes without added fibers, those containing recycled carbon fibers do not differ greatly from concretes containing polypropylene fibers, achieving strengths of more than 25 N/mm2 and thus making them viable for use in building construction.

- −

- Adding fibers to concrete reduces the spalling effect; concretes that do not contain fibers display greater premature cracking as well as greater flaking of surface fragments during testing.

- −

- The flexural tests offered encouraging results for recycled carbon fibers, as these obtained the best results for maximum strengths and good results for residual strengths, with a minimum number of fibers present in the region of rupture.

- −

- The impact resistance test results for concretes containing recycled carbon fibers displayed great uniformity in addition to substantially improving the energy absorption capacity when compared to conventional concretes and those containing polypropylene fibers.

- −

- The results obtained have revealed the good performance of these fibers despite their reduced number in the region of rupture of some of the specimens. Ensuring a larger quantity of fibers in the areas experiencing greater strain by reducing their size or adding a larger amount of fibers per m3 makes it possible to increase the potential that these fibers can offer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, D.; Gu, Z.; Wei, C.; Wu, C.; Pang, Y. Effects of fiber clustering on fatigue behavior of steel fiber reinforced concrete beams. Constr. Build. Mater. 2021, 301, 124070. [Google Scholar] [CrossRef]

- Chen, G.; Gao, D.; Zhu, H.; Yan, J.S.; Xiao, X.; Wang, W. Effects of novel multiple hooked-end steel fibres on flexural tensile behaviour of notched concrete beams with various strength grades. Structures 2021, 33, 3644–3654. [Google Scholar] [CrossRef]

- Huang, M.; Zihao Wan, Z.; Lei, Y.; Shi, X.; Shu, G. Experimental and analytical study of a new kind of steel-pva hybrid fiber concrete in the anchorage zone of a bridge expansion and contraction installation. Mater. Technol. 2021, 55, 183–194. [Google Scholar] [CrossRef]

- Paktiawal, A.; Alam, M. Alkali-resistant glass fiber high strength concrete and its durability parameters. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Orouji, M.; Zahrai, S.M.; Najaf, E. Effect of glass powder & polypropylene fibers on compressive and flexural strengths, toughness and ductility of concrete: An environmental approach. Structures 2021, 33, 4616–4628. [Google Scholar] [CrossRef]

- Asim, M.; Uddin, G.M.; Jamshaid, H.; Raza, A.; Tahir, Z.R.; Hussain, U.; Satti, A.N.; Hayat, N.; Arafat, S.M. Comparative experimental investigation of natural fibers reinforced light weight concrete as thermally efficient building materials. J. Build. Eng. 2020, 31, 101411. [Google Scholar] [CrossRef]

- Nambiar, R.A.; Haridharan, M.K. Mechanical and durability study of high performance concrete with addition of natural fiber (jute). Mater. Today Proc. 2020, 46, 4941–4947. [Google Scholar] [CrossRef]

- George, M.; Sathyan, D.; Mini, K.M. Investigations on effect of different fibers on the properties of engineered cementitious composites. Mater. Today Proc. 2021, 42, 1417–1421. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- Aslani, F.; Nejadi, S. Self-compacting concrete incorporating steel and polypropylene fibers: Compressive and tensile strengths, moduli of elasticity and rupture, compressive stress–Strain curve, and energy dissipated under compression. Compos. Part B Eng. 2013, 53, 21–33. [Google Scholar] [CrossRef]

- Trabucchi, I.; Tiberti, G.; Conforti, A.; Medeghini, F.; Plizzari, G.A. Experimental study on Steel Fiber Reinforced Concrete and Reinforced Concrete elements under concentrated loads. Constr. Build. Mater. 2021, 307, 124834. [Google Scholar] [CrossRef]

- Akid, A.S.M.; Hossain, S.; Munshi, M.I.U.; Elahi, M.M.A.; Sobuz, M.H.R.; Tam, V.W.Y.; Islam, M.S. Assessing the influence of fly ash and polypropylene fiber on fresh, mechanical and durability properties of concrete. J. King Saud Univ.–Eng. Sci. 2021, in press. [Google Scholar] [CrossRef]

- Bhogone, M.V.; Subramaniam, K.V.L. Early-age tensile constitutive relationships for steel and polypropylene fiber reinforced concrete. Eng. Fract. Mech. 2021, 244, 107556. [Google Scholar] [CrossRef]

- Shi, F.; Pham, T.M.; Hao, H.; Hao, Y. Post-cracking behaviour of basalt and macro polypropylene hybrid fibre reinforced concrete with different compressive strengths. Constr. Build. Mater. 2020, 262, 120108. [Google Scholar] [CrossRef]

- Kheyroddin, A.; Arshadi, H.; Ahadi, M.R.; Taban, G.; Kioumarsi, M. The impact resistance of Fiber-Reinforced concrete with polypropylene fibers and GFRP wrapping. Mater. Today Proc. 2021, 45, 5433–5438. [Google Scholar] [CrossRef]

- Rai, B.; Singh, N.K. Statistical and experimental study to evaluate the variability and reliability of impact strength of steel-polypropylene hybrid fiber reinforced concrete. J. Build. Eng. 2021, 44, 102937. [Google Scholar] [CrossRef]

- Li, Y.; Su, Y.; Tan, K.H.; Zheng, X.; Sheng, J. Pore structure and splitting tensile strength of hybrid Basalt-Polypropylene fiber reinforced concrete subjected to carbonation. Constr. Build. Mater. 2021, 297, 123779. [Google Scholar] [CrossRef]

- Serrano, R.; Cobo, A.; Prieto, M.I.; González, M.N. Analysis of fire resistance of concrete with polypropylene or steel fibers. Constr. Build. Mater. 2016, 122, 302–309. [Google Scholar] [CrossRef] [Green Version]

- Roig, M.; Lucio, T.; Alonso, M.C.; Guerreiro, L. Evolution of thermo-mechanical properties of concrete with calcium aluminate cement and special aggregates for energy storage. Cem. Concr. Res. 2021, 141, 106323. [Google Scholar] [CrossRef]

- Algourdin, N.; Pliya, P.; Beaucour, A.L.; Simon, A.; Noumowé, A. Influence of polypropylene and steel fibres on thermal spalling and physical-mechanical properties of concrete under different heating rates. Constr. Build. Mater. 2020, 259, 119690. [Google Scholar] [CrossRef]

- Hussain, I.; Alib, B.; Akhtar, T.; Jameel, M.S.; Raza, S.S. Comparison of mechanical properties of concrete and design thickness of pavement with different types of fiber-reinforcements (steel, glass, and polypropylene). Case Stud. Constr. Mater. 2020, 13, e00429. [Google Scholar] [CrossRef]

- Figueroa, M. Comparativa de la Tenacidad Entre Hormigón Convencional, Hormigón Reforzado Con Fibras de Acero y Hormigón Reforzado Con Fibras de Polipropileno. Master’s Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2013. [Google Scholar]

- Afroughsabet, V.; Biolzi, L.; Monteiro, P.J.M. The effect of steel and polypropylene fibers on the chloride diffusivity and drying shrinkage of high-strength concrete. Compos. Part B 2018, 139, 84–96. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I. Effect of macro-synthetic fibers on the fracture energy and mechanical behavior. Constr. Build. Mater. 2018, 189, 857–868. [Google Scholar] [CrossRef]

- Amin, A.; Foster, S.J.; Gilbert, R.I.; Kaufmann, W. Material characterisation of macro synthetic fibre reinforced concrete. Cem. Concr. Compos. 2017, 84, 124–133. [Google Scholar] [CrossRef]

- Buratti, N.; Mazzotti, C.; Savoia, M. Post-cracking behaviour of steel and macrosynthetic fibre-reinforced concretes. Constr. Build. Mater. 2011, 25, 2713–2722. [Google Scholar] [CrossRef]

- Alani, A.M.; Beckett, D. Mechanical properties of a large scale synthetic fibre reinforced concrete ground slab. Constr. Build. Mater. 2013, 41, 335–344. [Google Scholar] [CrossRef]

- Lin, G. Global Carbon Fibre Composites Market Report; ATA Carbon Fiber Tech. Guangzhou Co., Ltd.: Germany, 2016. [Google Scholar]

- Lin, L.; Schlarb, A.K. Recycled carbon fibers as reinforcements for hybrid PEEK composites with excellent friction and wear performance. Wear 2019, 432–433, 202928. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.H. Current status of carbon fibre and carbon fibre composites recycling. Compos. B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing life cycle energy and global warming potential of carbon fiber composite recycling technologies and waste management options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Tuner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A-Appl. Sci. Manuf. 2018, 100, 206–214. [Google Scholar] [CrossRef]

- Carbon Conversions. Available online: http://www.carbonconversions.com (accessed on 15 August 2021).

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent progress in recycling carbon fibre reinforced composites and dry carbon fibre wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Sauer, M.; Kuhnel, M.; Witten, E. Composites Market Report 2017-Market Developments, Trends, Outlook and Challenges; Germany, 2017. [Google Scholar]

- Vo Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef] [Green Version]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, M.; Manson, J.A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Li, X.; Bai, R.; McKechnie, J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J. Clean. Prod. 2016, 127, 451–460. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, T.S. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market Outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [Green Version]

- Newcomb, B.A. Processing, structure, and properties of carbon fibers. Compos. Part A-Appl. Sci. Manuf. 2016, 91, 262–282. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of the reinforced self-compacting concrete incorporating recycled CFRP fiber with different lengths and dosages. Compos. Part B Eng. 2017, 112, 74–92. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. The impact resistance and mechanical properties of self-compacting concrete reinforced with recycled CFRP pieces. Compos. B. Eng. 2016, 92, 360–376. [Google Scholar] [CrossRef]

- Nguyen, H.; Carvelli, V.; Fujii, T.; Okubo, K. Cement mortar reinforced with reclaimed carbon fibres, CFRP waste or prepreg carbon waste. Constr. Build. Mater. 2016, 126, 321–333. [Google Scholar] [CrossRef]

- Faneca, G.; Segura, I.; Torrents, J.M.; Aguado, A. Development of conductive cementitious materials using recycled carbon fibres. Cem. Concr. Compos. 2018, 92, 135–144. [Google Scholar] [CrossRef]

- Ogi, K.; Shinoda, T.; Mizui, M. Strength in concrete reinforced with recycled CFRP pieces. Compos. Part A Appl. Sci. Manuf. 2005, 36, 893–902. [Google Scholar] [CrossRef]

- Xiong, C.; Li, Q.; Lan, T.; Li, H.; Long, W.; Xing, F. Sustainable use of recycled carbon fiber reinforced polymer and crumb rubber in concrete: Mechanical properties and ecological evaluation. J. Clean. Prod. 2021, 279, 123624. [Google Scholar] [CrossRef]

- Mastali, M.; Abdollahnejad, Z.; Dalvand, A.; Sattarifard, A.; Illikainen, M. Comparative effects of using recycled CFRP and GFRP fibers on fresh- and hardened-state properties of self-compacting concretes: A review. J. Mater. Civil Eng. 2020, 643–655. [Google Scholar] [CrossRef]

- Asociación Española de Normalización. Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements (UNE-EN 197). 2011. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0048623 (accessed on 25 January 2021).

- Cement Reception Instruction (RC-16). Ministry of Public Works, Secretaría General Técnica, Standing Committee of Cement, Spain. 2016. Available online: https://www.mitma.gob.es/recursos_mfom/rc16_ingles_0.pdf (accessed on 12 February 2021).

- Asociación Española de Normalización. Quality Management Systems-Requirements (ISO 9001). 2015. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0055469 (accessed on 20 February 2021).

- Asociación Española de Normalización. Environmental Management Systems-Requirements with Guidance for Use (ISO 14001). 2015. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0055418 (accessed on 20 February 2021).

- Asociación Española de Normalización. Aggregates for Concrete (UNE-EN 12620:2003+A1). 2009. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0043155 (accessed on 25 January 2021).

- Asociación Española de Normalización. Aggregates for Mortar (UNE-EN 13139). 2003. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0028815 (accessed on 25 January 2021).

- Asociación Española de Normalización. Fibres for Concrete-Part 2: Polymer fibres-Definitions, Specifications and Conformity (UNE-EN 14889-2). 2008. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0040618 (accessed on 25 January 2021).

- Gómez, E. Refuerzo y Reparación Con FRP de Vigas de Madera Aserradas Sometidas a Flexión. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2017. Available online: http://oa.upm.es/46658/ (accessed on 25 January 2021).

- Asociación Española de Normalización. Admixtures for Concrete, Mortar and Grout-Part 2: Concrete Admixtures-Definitions, Requirements, Conformity, Marking and Labelling (UNE-EN 934-2:2010+A1). 2012. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0050511 (accessed on 25 January 2021).

- Ministerio de Fomento. Instrucción Para el Hormigón Estructural (EHE-08). Con Comentarios de la Comisión Permanente del Hormigón, Madrid, Spain. 2010. Available online: https://www.mitma.gob.es/recursos_mfom/1820100.pdf (accessed on 12 February 2021).

- BASF. Ficha Técnica: MasterGlenium SKY 604. Available online: https://www.master-builderssolutions-basf.es (accessed on 29 January 2021).

- Asociación Española de Normalización. Testing Fresh Concrete-Part 2: Slump Test (UNE-EN 12350-2). 2020. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0063378 (accessed on 25 January 2021).

- Asociación Española de Normalización. Testing Hardened Concrete-Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds (UNE-EN 12390-1). 2013. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?Tipo=N&c=N0051722 (accessed on 25 January 2021).

- Asociación Española de Normalización. Testing Hardened Concrete-Part 2: Making and Curing Specimens for Strength Tests (UNE-EN 12390-2). 2020. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0064329. (accessed on 25 January 2021).

- Asociación Española de Normalización. Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens (UNE-EN 12390-3). 2020. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0063272 (accessed on 25 January 2021).

- Asociación Española de Normalización. Testing Hardened Concrete-Part 5: Flexural Strength of Test Specimens (UNE-EN 12390-5). 2020. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0063273 (accessed on 27 February 2021).

| Materials | Characteristics |

|---|---|

| Two-way CFRP fabric (0°/90°) | Grade: 160 ± 5% (g/m2) |

| Length: 48 mm | |

| Thickness: 0.04 mm | |

| Width: 2 mm | |

| Modulus of elasticity: 208,590 N/mm2 | |

| Tensile strength: 4757 N/mm2 | |

| Polypropylene fibers | Density: 0.91 kg/L (+20 °C) |

| Quantity (units/kg): 102 million | |

| Length: 48 mm | |

| Equivalent diameter: 0.93 mm | |

| Slenderness ratio: 51.61 | |

| Tensile strength: 400 N/mm2 | |

| Modulus of elasticity: 6.2 N/mm2 | |

| Melting point: 170 °C |

| Specimen/Mix | Reference | Carbon Fiber 3 kg/m3 | Carbon Fiber 6 kg/m3 | Polypropylene Fiber 3 kg/m3 | Polypropylene Fiber 6 kg/m3 |

|---|---|---|---|---|---|

| Cylindrical specimens ϕ100 mm × 200 mm | 6 | 6 | 6 | 6 | 6 |

| Cubic specimens 100 mm × 100 mm × 100 mm | 6 | 6 | 6 | 6 | 6 |

| Prismatic specimens 500 mm × 50 mm × 50 mm | 6 | 6 | 6 | 6 | 6 |

| Slabs 520 mm × 100 mm × 30 mm | 6 | 6 | 6 | 6 | 6 |

| TOTAL | 24 | 24 | 24 | 24 | 24 |

| Specimen/Mix | Reference | Carbon Fiber 3 kg/m3 | Carbon Fiber 6 kg/m3 | Polypropylene Fiber 3 kg/m3 | Polypropylene Fiber 6 kg/m3 |

|---|---|---|---|---|---|

| Cement (kg) | 12.21 | 12.21 | 12.21 | 12.21 | 12.21 |

| Sand (kg) | 25.43 | 25.43 | 25.43 | 25.43 | 25.43 |

| Gravel (kg) | 44.20 | 44.20 | 44.20 | 44.20 | 44.20 |

| Water (L) | 5.60 | 5.60 | 5.60 | 5.60 | 5.60 |

| Additive (g) | 85.5 | 85.5 | 85.5 | 85.5 | 85.5 |

| Addition (g) | ----- | 73.80 | 147.60 | 73.80 | 147.60 |

| Specimens/Test | Reference | Carbon 3 kg/m3 | Carbon 6 kg/m3 | Polypropylene 3 kg/m3 | Polypropylene 6 kg/m3 |

|---|---|---|---|---|---|

| Cylindrical specimens Compression tests | C-1 | C-FC3-1 | C-FC6-1 | C-PP3-1 | C-PP6-1 |

| C-2 | C-FC3-2 | C-FC6-2 | C-PP3-2 | C-PP6-2 | |

| C-3 | C-FC3-3 | C-FC6-3 | C-PP3-3 | C-PP6-3 | |

| C-4 | C-FC3-4 | C-FC6-4 | C-PP3-4 | C-PP6-4 | |

| C-5 | C-FC3-5 | C-FC6-5 | C-PP3-5 | C-PP6-5 | |

| C-6 | C-FC3-6 | C-FC6-6 | C-PP3-6 | C-PP6-6 | |

| Cubic specimens Compression tests | CU-1 | CU-FC3-1 | CU-FC6-1 | CU-PP3-1 | CU-PP6-1 |

| CU-2 | CU-FC3-2 | CU-FC6-2 | CU-PP3-2 | CU-PP6-2 | |

| CU-3 | CU-FC3-3 | CU-FC6-3 | CU-PP3-3 | CU-PP6-3 | |

| CU-4 | CU-FC3-4 | CU-FC6-4 | CU-PP3-4 | CU-PP6-4 | |

| CU-5 | CU-FC3-5 | CU-FC6-5 | CU-PP3-5 | CU-PP6-5 | |

| CU-6 | CU-FC3-6 | CU-FC6-6 | CU-PP3-6 | CU-PP6-6 | |

| Prismatic specimens Flexural tests | P-1 | P-FC3-1 | P-FC6-1 | P-PP3-1 | P-PP6-1 |

| P-2 | P-FC3-2 | P-FC6-2 | P-PP3-2 | P-PP6-2 | |

| P-3 | P-FC3-3 | P-FC6-3 | P-PP3-3 | P-PP6-3 | |

| P-4 | P-FC3-4 | P-FC6-4 | P-PP3-4 | P-PP6-4 | |

| P-5 | P-FC3-5 | P-FC6-5 | P-PP3-5 | P-PP6-5 | |

| P-6 | P-FC3-6 | P-FC6-6 | P-PP3-6 | P-PP6-6 | |

| Slabs Impact tests | L-1 | L-FC3-1 | L-FC6-1 | L-PP3-1 | L-PP6-1 |

| L-2 | L-FC3-2 | L-FC6-2 | L-PP3-2 | L-PP6-2 | |

| L-3 | L-FC3-3 | L-FC6-3 | L-PP3-3 | L-PP6-3 | |

| L-4 | L-FC3-4 | L-FC6-4 | L-PP3-4 | L-PP6-4 | |

| L-5 | L-FC3-5 | L-FC6-5 | L-PP3-5 | L-PP6-5 | |

| L-6 | L-FC3-6 | L-FC6-6 | L-PP3-6 | L-PP6-6 |

| Specimens | Mean Value | EHE Coefficient | Conversion | Real Coefficient |

|---|---|---|---|---|

| C | 30.663 | 0.970 | 29.743 | 0.970 |

| C-PP3 | 29.251 | 0.970 | 28.373 | 0.925 |

| C-PP6 | 29.972 | 0.970 | 29.073 | 0.948 |

| C-FC3 | 28.019 | 0.970 | 27.178 | 0.886 |

| C-FC6 | 27.454 | 0.970 | 26.630 | 0.868 |

| CU | 39.812 | 0.800 | 31.849 | 0.800 |

| CU-PP3 | 38.600 | 0.800 | 30.880 | 0.776 |

| CU-PP6 | 38.280 | 0.800 | 30.624 | 0.769 |

| CU-FC3 | 37.425 | 0.800 | 29.940 | 0.752 |

| CU-FC6 | 36.805 | 0.800 | 29.444 | 0.740 |

| Compression Test (Cylindrical Specimens) | Compression Test (Cubic Specimens) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | C-PP3 | C-PP6 | C-FC3 | C-FC6 | CU | CU-PP3 | CU-PP6 | CU-FC3 | CU-FC6 | ||

| C | ----- | −4.60 | −2.25 | −8.62 | −10.46 | ----- | −3.04 | −3.84 | −5.99 | −7.55 | CU |

| P | ----- | −1.81 | +3.99 | +22.76 | +6.10 | ----- | +15.82 | +32.01 | +27.93 | +45.68 | L |

| P | P-PP3 | P-PP6 | P-FC3 | P-FC6 | L | L-PP3 | L-PP6 | L-FC3 | L-FC6 | ||

| Flexural test | Impact test | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prieto, M.I.; González, M.d.l.N.; Cobo, A.; Alonso, D. Comparison of the Mechanical Behavior of Concrete Containing Recycled CFRP Fibers and Polypropylene Fibers. Appl. Sci. 2021, 11, 10226. https://doi.org/10.3390/app112110226

Prieto MI, González MdlN, Cobo A, Alonso D. Comparison of the Mechanical Behavior of Concrete Containing Recycled CFRP Fibers and Polypropylene Fibers. Applied Sciences. 2021; 11(21):10226. https://doi.org/10.3390/app112110226

Chicago/Turabian StylePrieto, María Isabel, María de las Nieves González, Alfonso Cobo, and David Alonso. 2021. "Comparison of the Mechanical Behavior of Concrete Containing Recycled CFRP Fibers and Polypropylene Fibers" Applied Sciences 11, no. 21: 10226. https://doi.org/10.3390/app112110226

APA StylePrieto, M. I., González, M. d. l. N., Cobo, A., & Alonso, D. (2021). Comparison of the Mechanical Behavior of Concrete Containing Recycled CFRP Fibers and Polypropylene Fibers. Applied Sciences, 11(21), 10226. https://doi.org/10.3390/app112110226