Microstructure and Wear Behavior of TiC/AISI 1020 Metal Matrix Composites Produced by Liquid Pressing Infiltration

Abstract

:1. Introduction

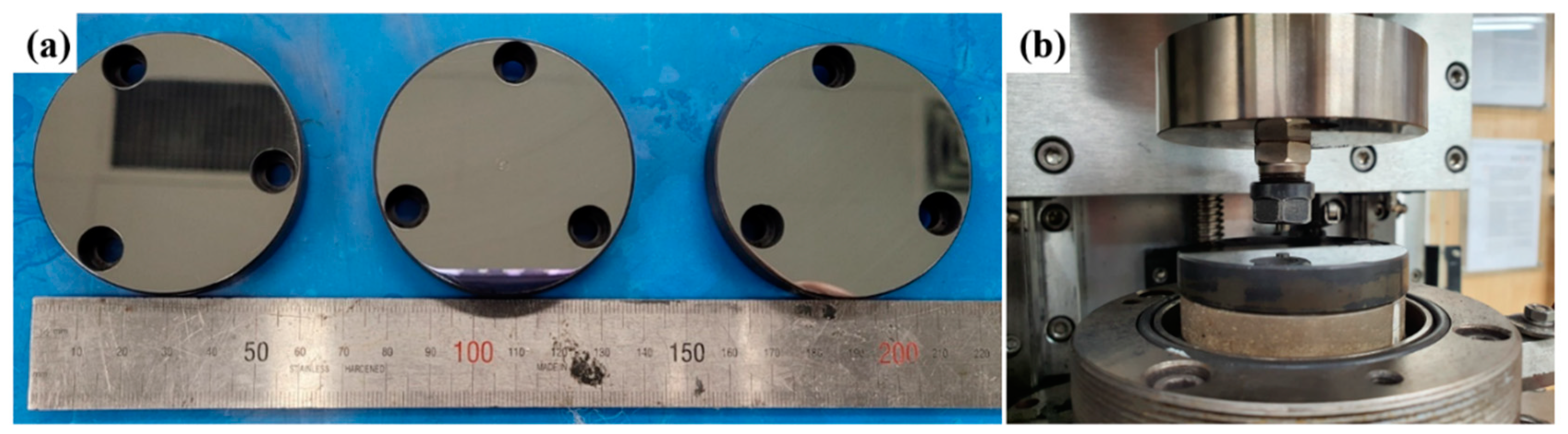

2. Materials and Methods

2.1. Materials and Liquid Pressing Infiltration Process

2.2. Characterization

3. Results and Discussion

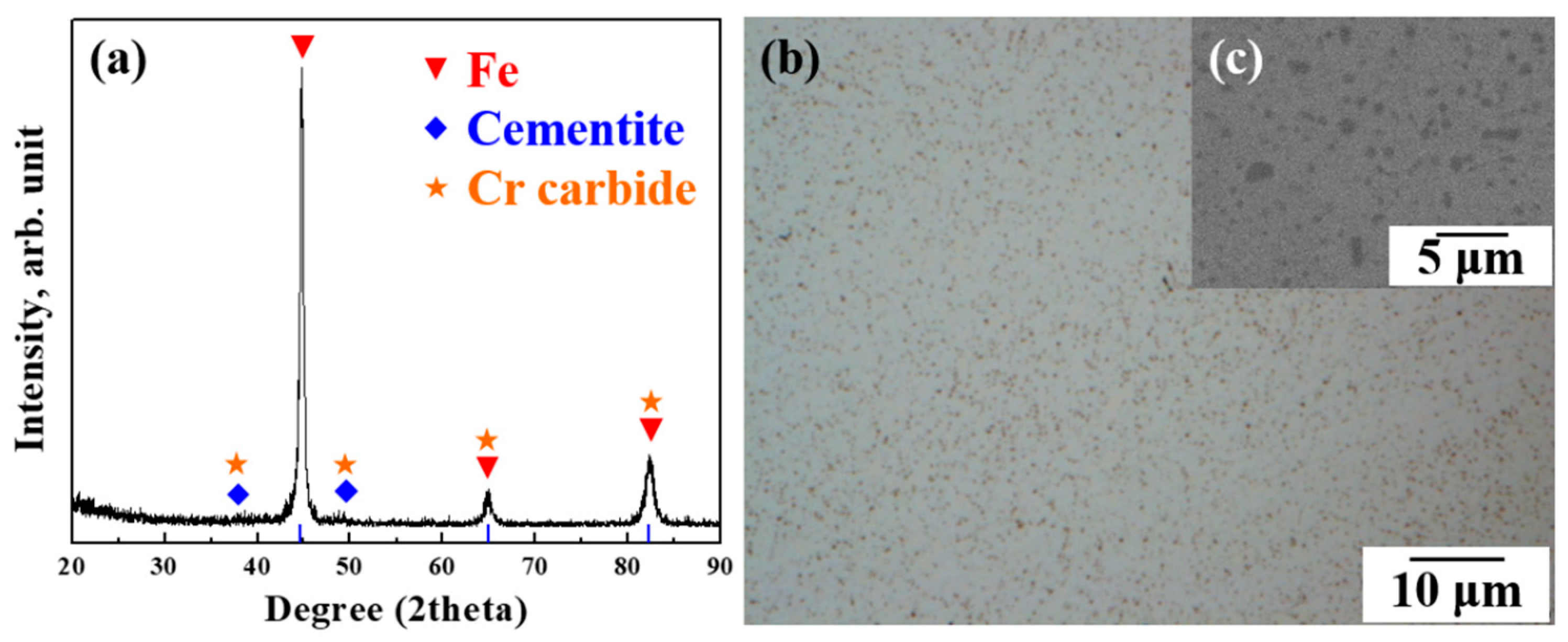

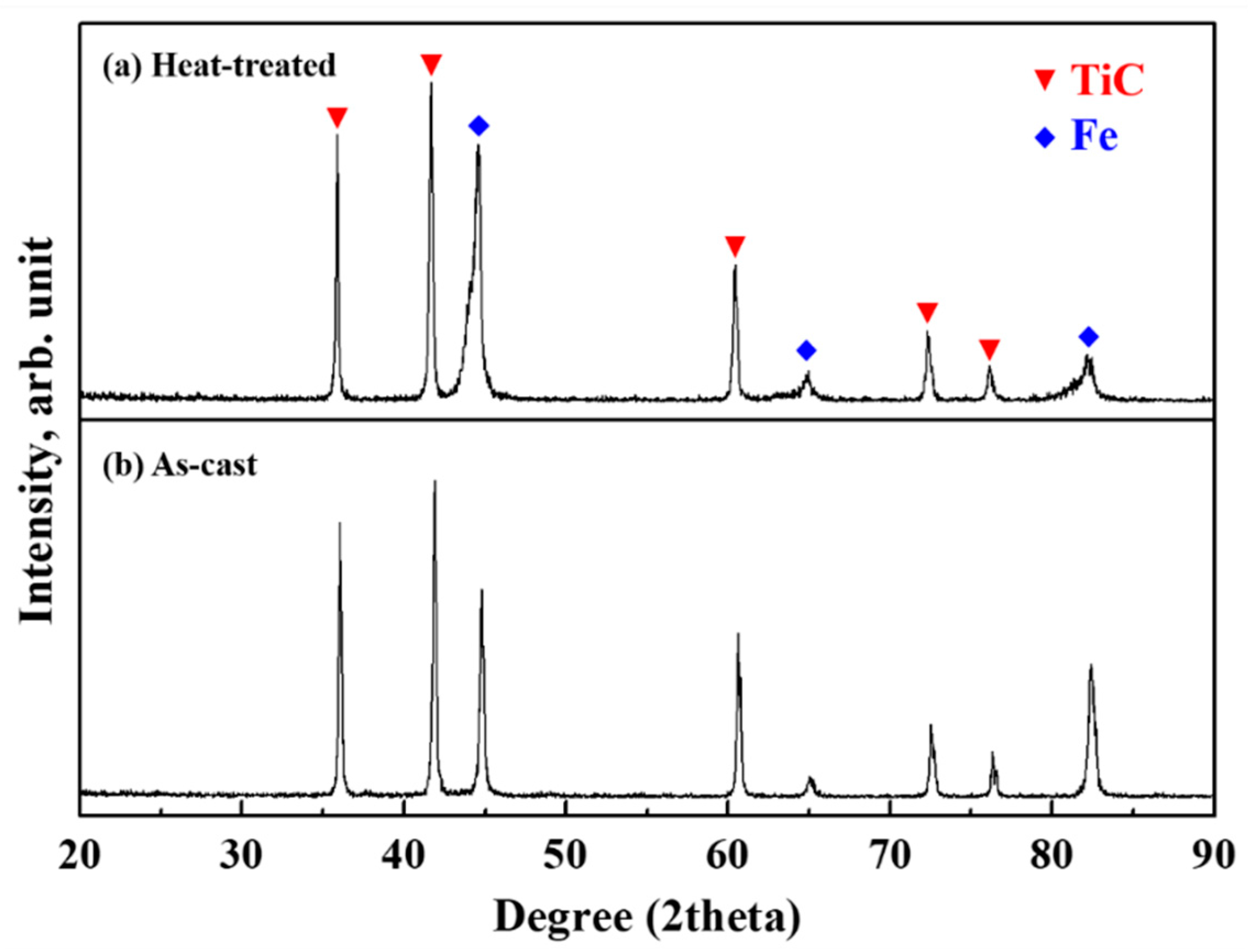

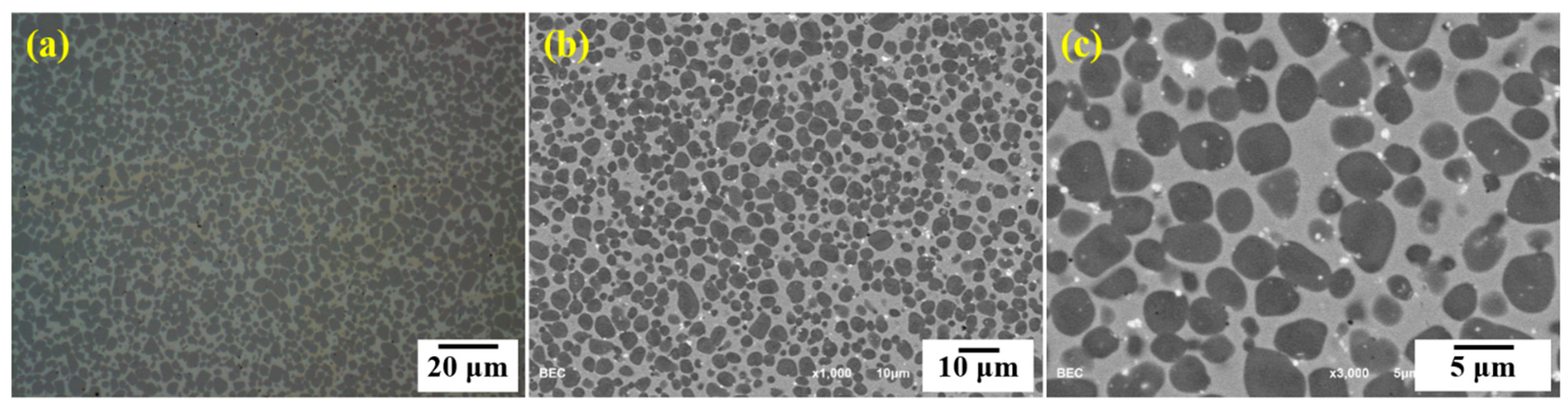

3.1. Crystal and Microstructure

3.2. Wear Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Averbeck, S.; Spriestersbach, D.; Kerscher, E. Mechanism of fine granular area and white etching crack formation in AISI 52100 bearing steel. Theor. Appl. Fract. Mech. 2020, 108, 102664. [Google Scholar] [CrossRef]

- Panda, A.; Sahoo, A.K.; Kumar, R.; Das, R.K. A review on machinability aspects for AISI 52100 bearing steel. Mater. Today Proc. 2020, 23, 617–621. [Google Scholar] [CrossRef]

- Spille, J.; Wranik, J.; Barteldes, S.; Mayer, J.; Schwedt, A.; Zürcher, M.; Lutz, T.; Wang, L.; Holweger, W. A study on the initiation processes of white etching cracks (WECs) in AISI 52100 bearing steel. Wear 2021, 477, 203864. [Google Scholar] [CrossRef]

- Pena, L.V.W.; Wang, L.; Mellor, B.G.; Huang, Y. White etching structues in annealed 52100 bearing steel arising from high-pressure torsion tests. Tribol. Int. 2021, 164, 107187. [Google Scholar] [CrossRef]

- Jayakanth, J.J.; Chandrasekaran, M.; Pugazhenthi, R. Impulse excitation analysis of material defects in ball bearing. Mater. Today Proc. 2021, 39, 717–724. [Google Scholar] [CrossRef]

- Gould, B.; Greco, A.; Stadler, K.; Xiao, X. An analysis of premature cracking associated with microstructural alterations in an AISI 52100 failed wind turbine bearing using X-ray tomography. Mater. Des. 2017, 117, 417–429. [Google Scholar] [CrossRef] [Green Version]

- Ozturk, K.; Gecu, R.; Karaaslan, A. Microstructure, wear and corrosion characteristics of multiple-reinforced (SiC–B4C–Al2O3) Al matrix composites produced by liquid metal infiltration. Ceram. Int. 2021, 47, 18274–18285. [Google Scholar] [CrossRef]

- Ghandvar, H.; Jabbar, M.A.; Koloor, S.S.R.; Petru, M.; Bahador, A.; Baker, T.A.A.; Kondoh, K. Role B4C Addition on Microstructure, Mechanical, and Wear Characteristics of Al-20%Mg2Si Hybrid Metal Matrix Composite. Appl. Sci. 2021, 11, 3047. [Google Scholar] [CrossRef]

- Akhtar, F. Microstructure evolution and wear properties of in situ synthesized TiB2 and TiC reinforced steel matrix composites. J. Alloys Compd. 2008, 459, 491–497. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, T.; He, X.; Shao, H.; Tang, B.; Qu, X. Fabrication and properties of the TiC reinforced high-strength steel matrix composite. Int. J. Refract. Metals Hard Meter. 2016, 58, 14–21. [Google Scholar] [CrossRef]

- Dunstan, M.K.; Paramore, J.D.; Fang, Z.Z. The effects of microstructure and porosity on the competing fatigue failure mechanisms in powder metallurgy Ti-6Al-4V. Int. J. Fatigue 2018, 116, 584–591. [Google Scholar] [CrossRef]

- Fan, K.C.; Chen, S.H.; Chen, J.Y.; Liao, W.B. Development of auto defect classification system on porosity powder metallurgy products. NDT E Int. 2010, 43, 451–460. [Google Scholar] [CrossRef]

- Lee, Y.H.; Kim, N.; Lee, S.B.; Kim, Y.; Cho, S.; Lee, S.K.; Jo, I. Microstructure and mechanical properties of lightweight TiC-steel composite prepared by liquid pressing infiltration process. Mater. Charact. 2020, 162, 110202. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites. Ceram. Int. 2018, 44, 20599–20612. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials: A review. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Gülsoy, H.Ö. Production of injection moulded 316L stainless steels reinforced with TiC(N) particles. Mater. Sci. Technol. 2008, 24, 1484–1491. [Google Scholar] [CrossRef]

- Cho, S.; Lee, Y.H.; Ko, S.; Park, H.; Lee, D.; Shin, S.; Jo, I.; Kim, Y.; Lee, S.B.; Lee, S.K. Enhanced high-temperature compressive strength of TiC reinforced stainless steel matrix composites fabricated by liquid pressing infiltration process. J. Alloys Compd. 2020, 817, 152714. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | P | S | Cu | Ni | Cr | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| AISI 52100 wt. % | 0.95 ~1.1 | 1.5 ~3.5 | 0.5 | 0.25 | 0.25 | 0.25 | 0.25 | 1.3~1.6 | 0.08 | Bal. |

| AISI 1020 wt. % | 0.18 ~0.23 | 0.15 ~0.35 | 0.3 ~0.6 | 0.03 max. | 0.035 max. | 0.3 max. | 0.2 max. | 0.2 max. | - | Bal. |

| HRC | AISI 52100 | TiC/AISI 1020 (As-Cast) | TiC/AISI 1020 (Heat-Treated) | Pin (H13) |

|---|---|---|---|---|

| #1 | 62.6 | 62.5 | 76.4 | 57.0 |

| #2 | 62.5 | 61.8 | 76.9 | 58.7 |

| #3 | 62.3 | 63.9 | 76.6 | 58.4 |

| #4 | 62.5 | 62.8 | 76.7 | 58.2 |

| #5 | 62.2 | 63.2 | 76.6 | 58.1 |

| Average | 62.42 | 62.84 | 76.64 | 58.08 |

| At. % | C | O | Mg | Al | Si | Mo | Cr | Mn | Fe |

|---|---|---|---|---|---|---|---|---|---|

| A | 5.44 | 43.73 | 0 | 0 | 1.01 | 0.31 | 1.97 | 0.65 | 46.88 |

| B | 23.26 | 32.22 | 1.15 | 19.77 | 11.00 | 0 | 0 | 0 | 12.60 |

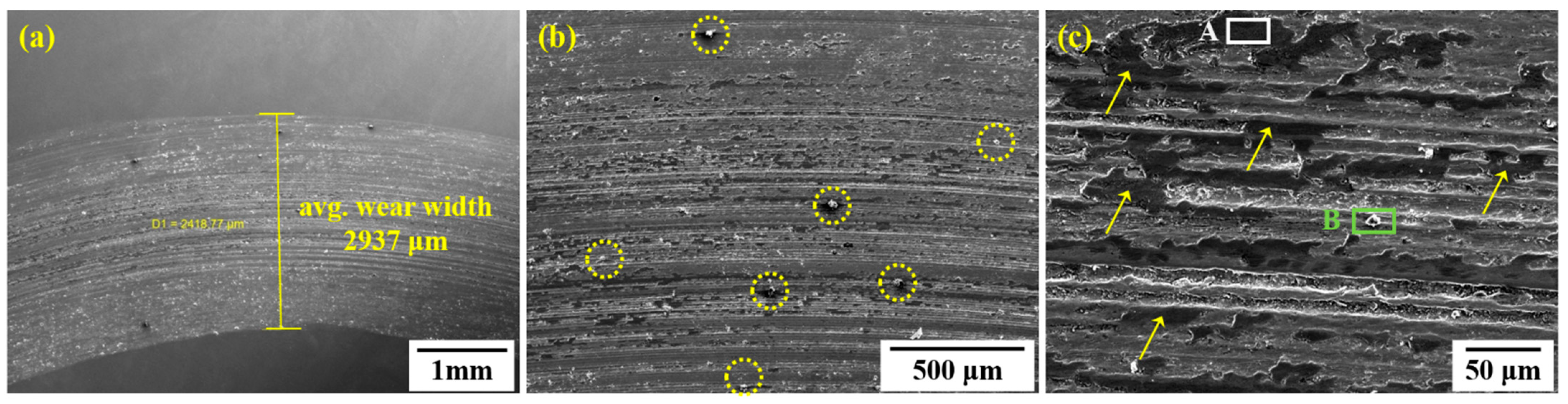

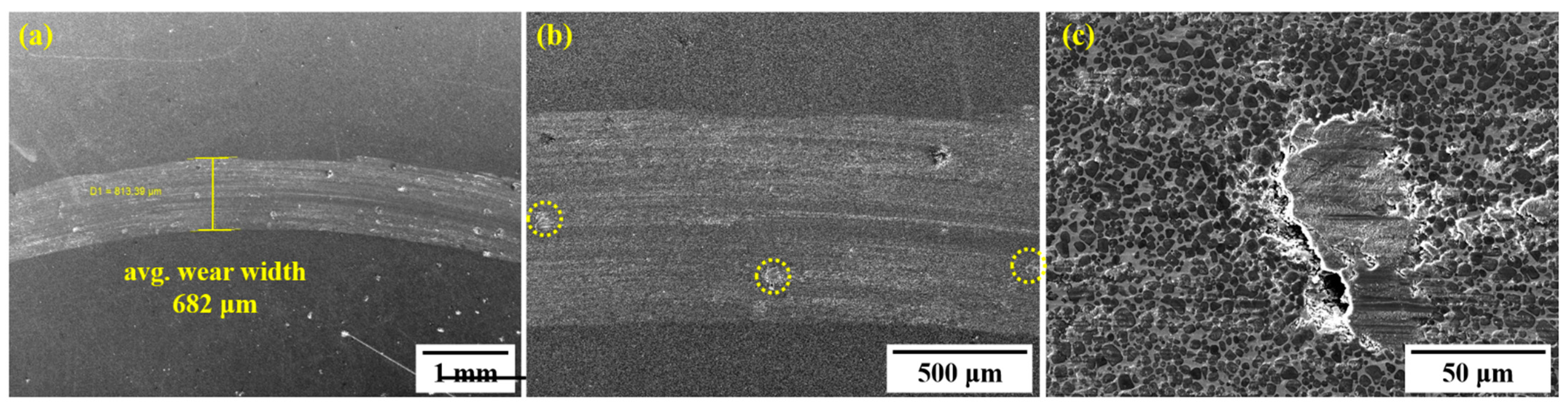

| AISI 52100 | AISI 1020/TiC | |

|---|---|---|

| Wear width, μm | 2937 | 682 |

| Wear depth, μm | 2.6 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Park, J.; Shin, S.; Cho, S.; Kim, J.; Bae, D.-S.; Jo, I. Microstructure and Wear Behavior of TiC/AISI 1020 Metal Matrix Composites Produced by Liquid Pressing Infiltration. Appl. Sci. 2021, 11, 9682. https://doi.org/10.3390/app11209682

Kim H, Park J, Shin S, Cho S, Kim J, Bae D-S, Jo I. Microstructure and Wear Behavior of TiC/AISI 1020 Metal Matrix Composites Produced by Liquid Pressing Infiltration. Applied Sciences. 2021; 11(20):9682. https://doi.org/10.3390/app11209682

Chicago/Turabian StyleKim, Heejeong, Jungyu Park, Sangmin Shin, Seungchan Cho, Junghwan Kim, Dong-Su Bae, and Ilguk Jo. 2021. "Microstructure and Wear Behavior of TiC/AISI 1020 Metal Matrix Composites Produced by Liquid Pressing Infiltration" Applied Sciences 11, no. 20: 9682. https://doi.org/10.3390/app11209682

APA StyleKim, H., Park, J., Shin, S., Cho, S., Kim, J., Bae, D.-S., & Jo, I. (2021). Microstructure and Wear Behavior of TiC/AISI 1020 Metal Matrix Composites Produced by Liquid Pressing Infiltration. Applied Sciences, 11(20), 9682. https://doi.org/10.3390/app11209682