Machine Learning Approach to Develop a Novel Multi-Objective Optimization Method for Pavement Material Proportion

Abstract

1. Introduction

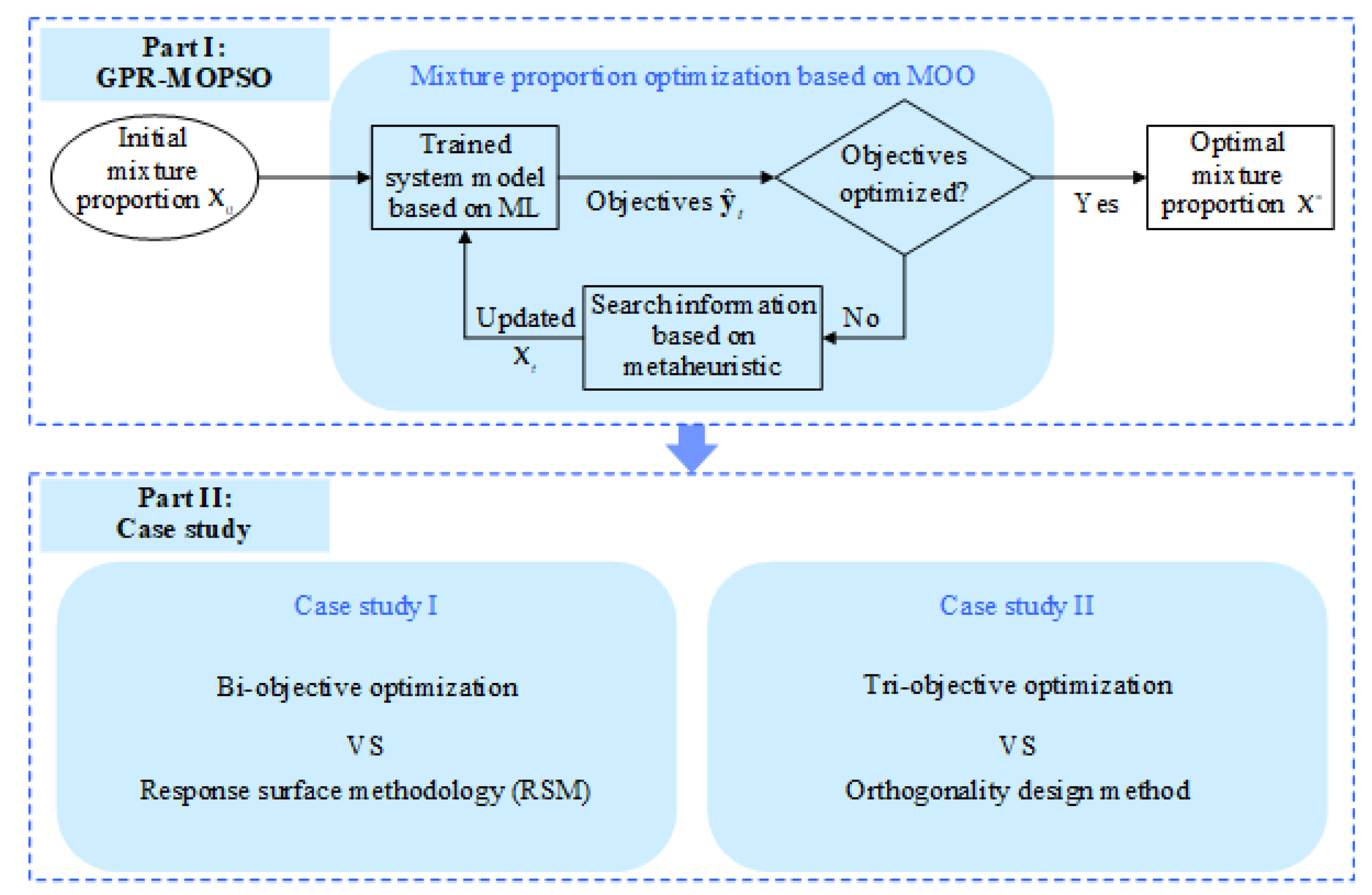

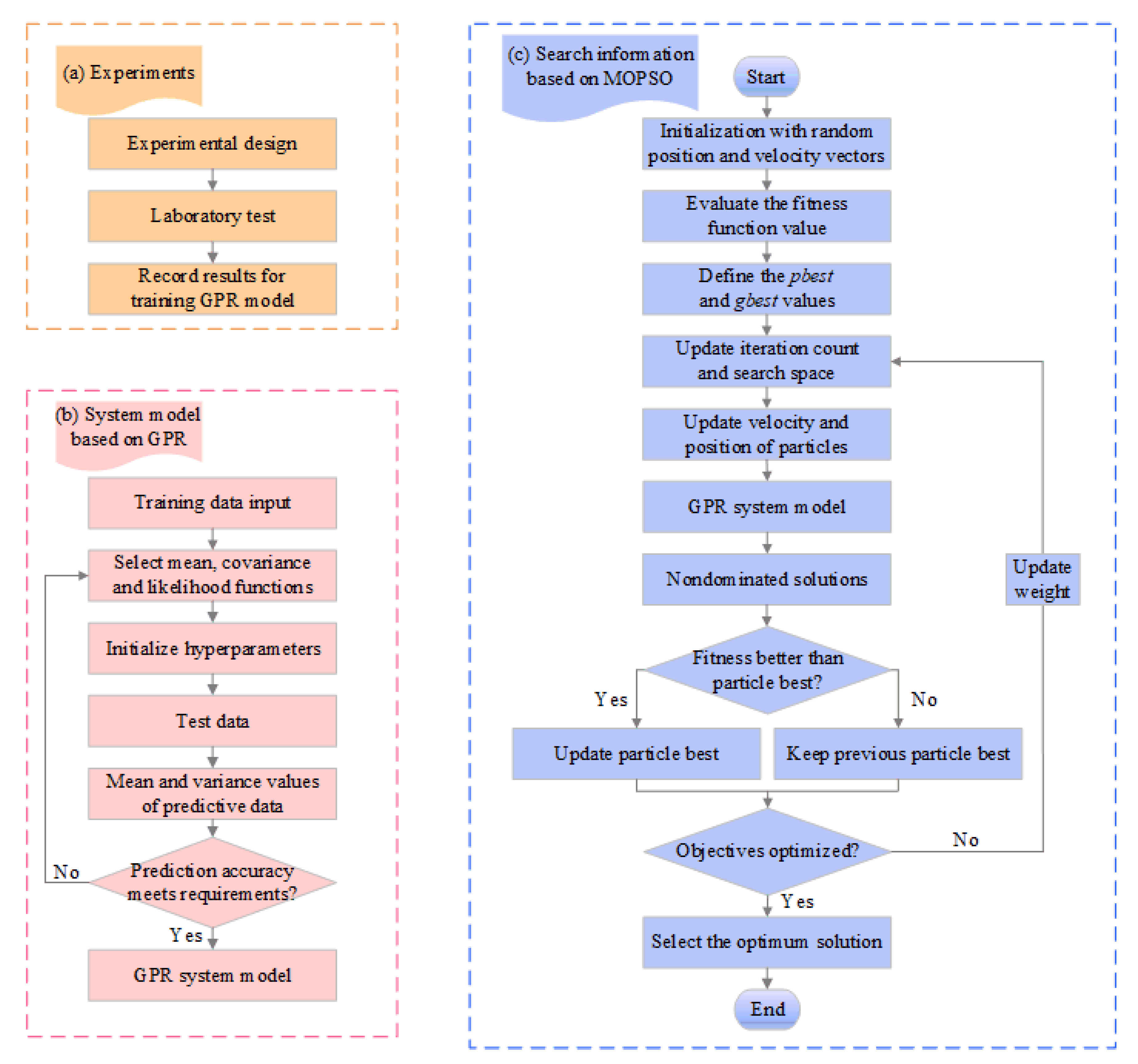

2. Methodology

2.1. Definition for Multi-Objective Optimization (MOO) Problem

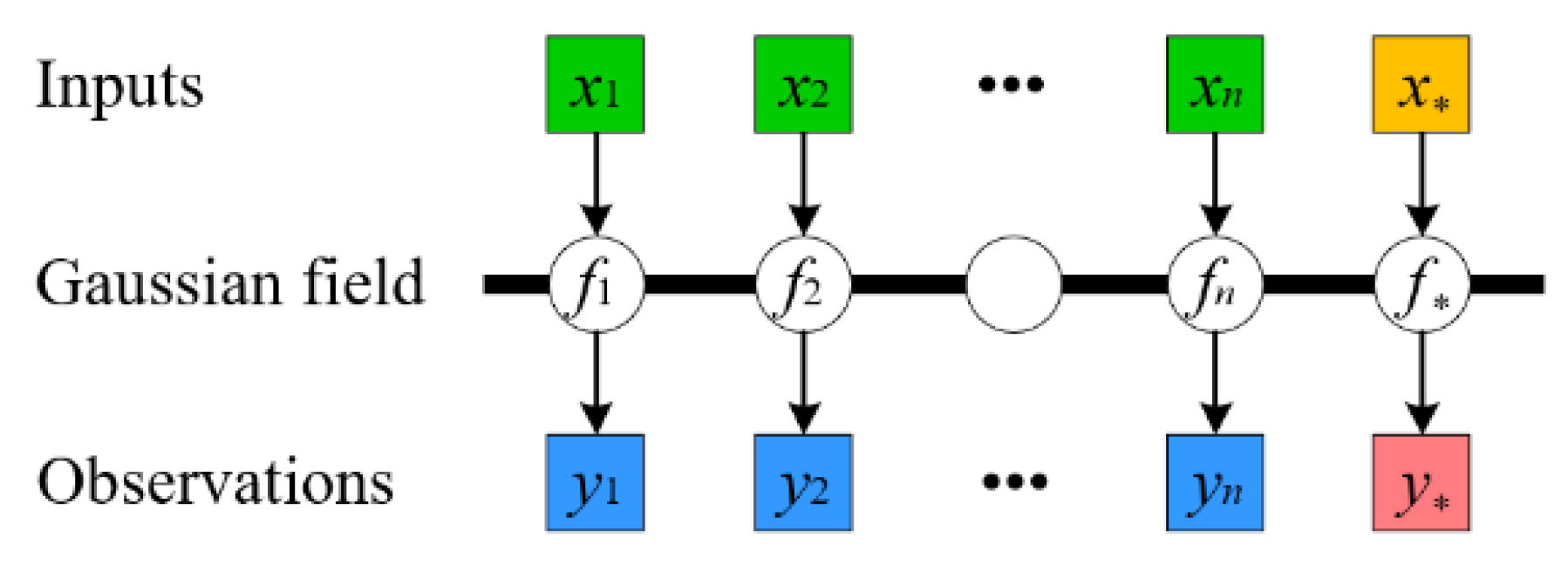

2.2. System Modeling Based on Machine Learning (ML) Method-Gaussian Process Regression (GPR)

2.3. Search Information Updating Based on Metaheuristic Algorithm Adaptive Weight Multi-Objective Particle Swarm Optimization (AWMOPSO)

2.4. Choice Criteria for MOO Problems

3. Computational Examples and Analysis

3.1. Case Study I: Bi-Objective Optimization

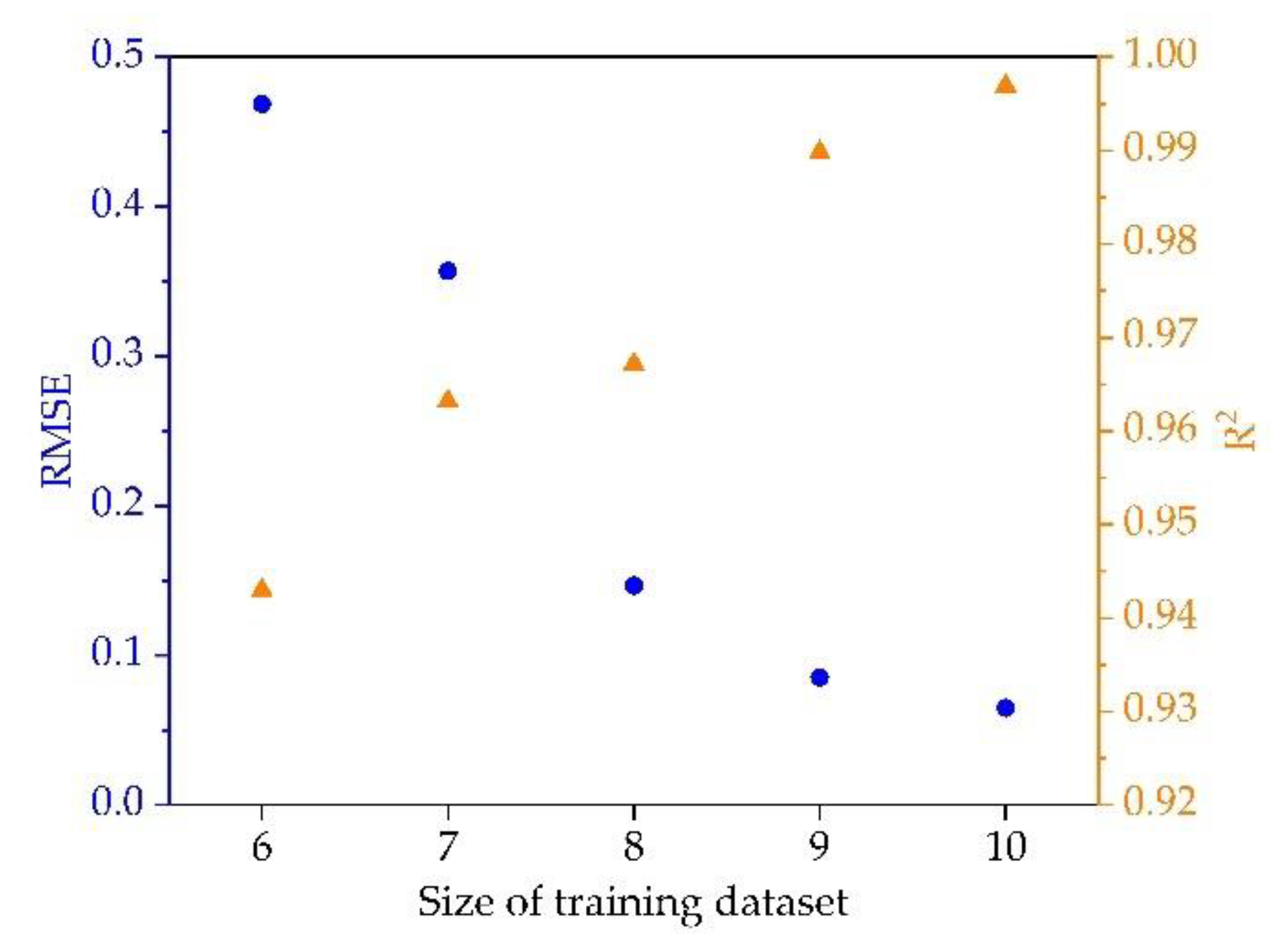

3.1.1. Data Description

3.1.2. MOO Problem Formulation for Basalt Fibre-Modified Asphalt Mixture

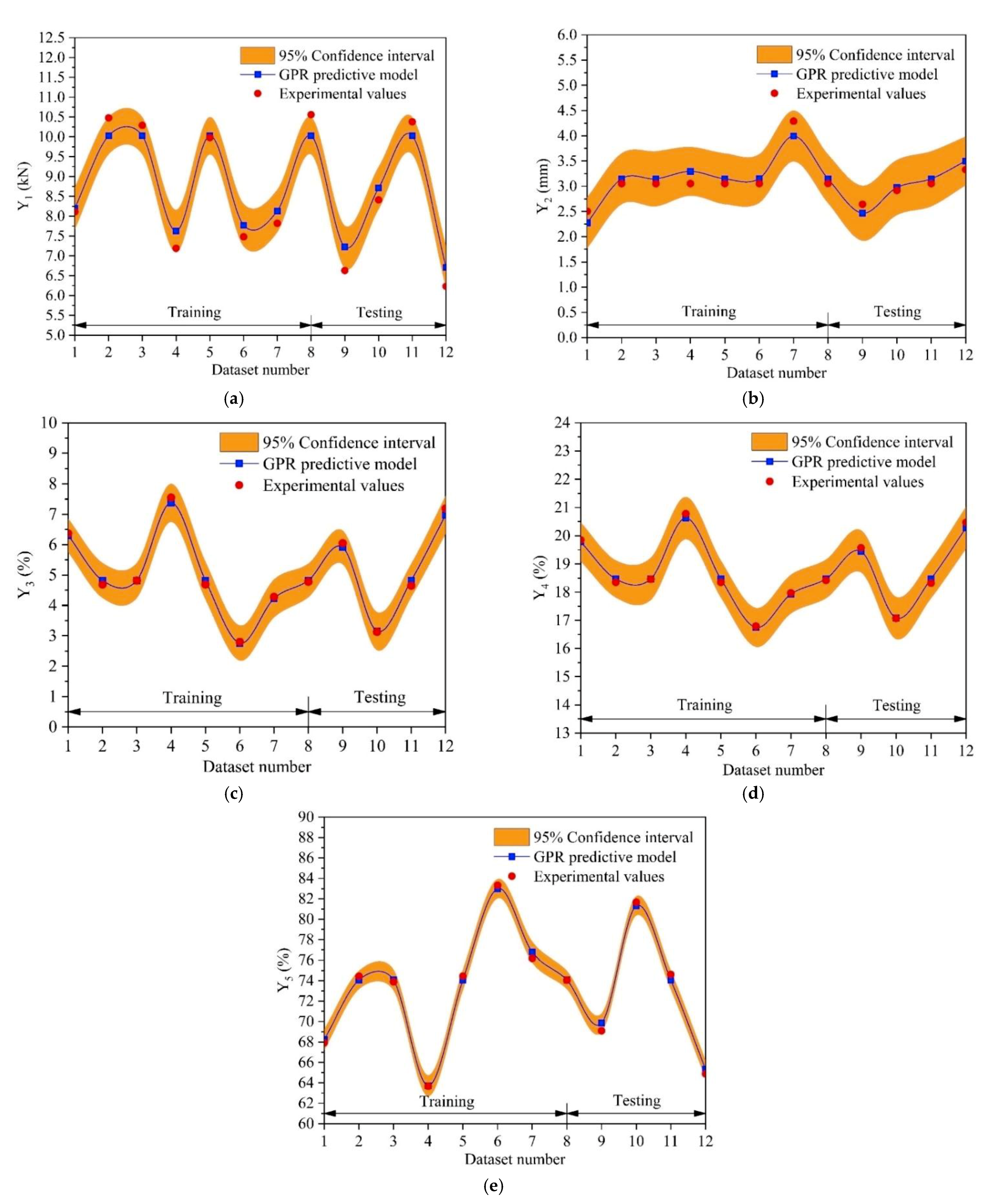

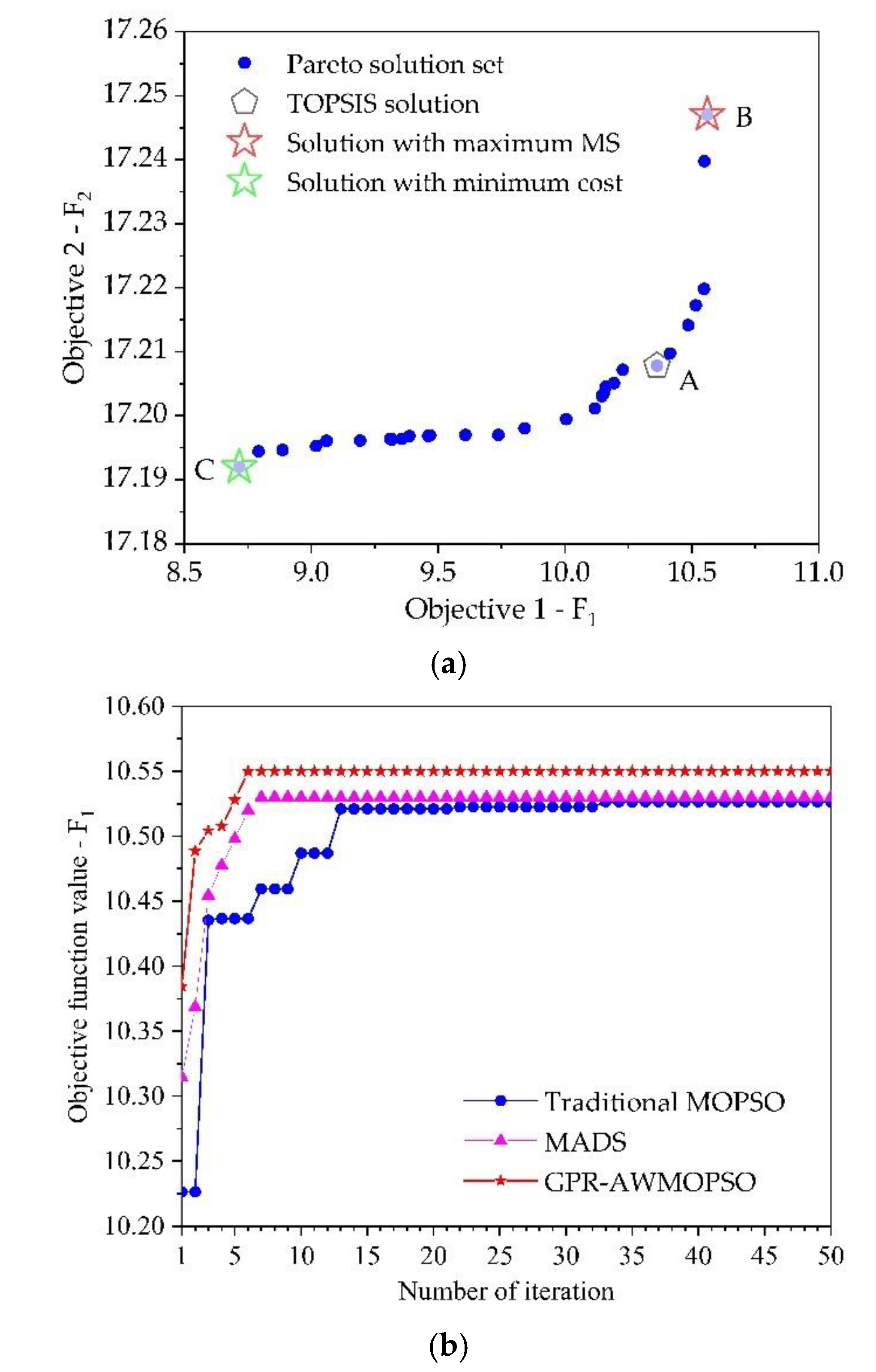

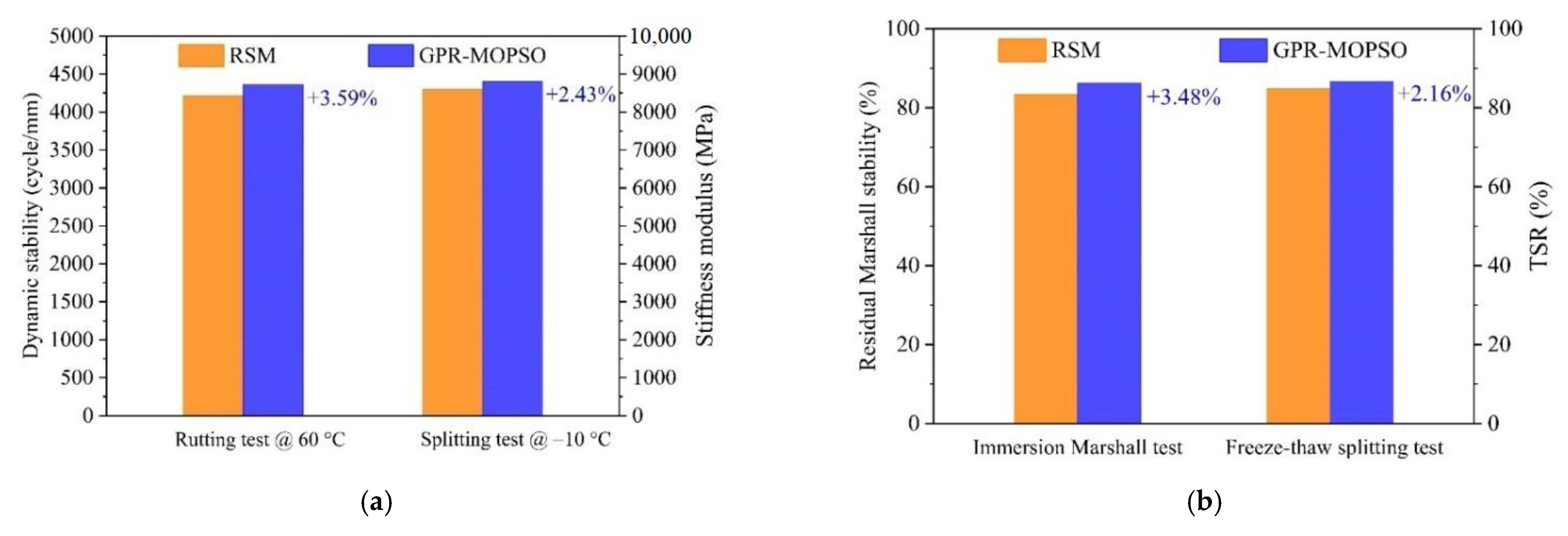

3.1.3. Results of Asphalt Mixture Proportion Optimization Using GPR-AWMOPSO

3.2. Case Study II: Tri-Objective Optimization

3.2.1. Data Description

3.2.2. MOO Problem Formulation for Diatomite-Basalt Fibre Composite Modified Asphalt Mixture

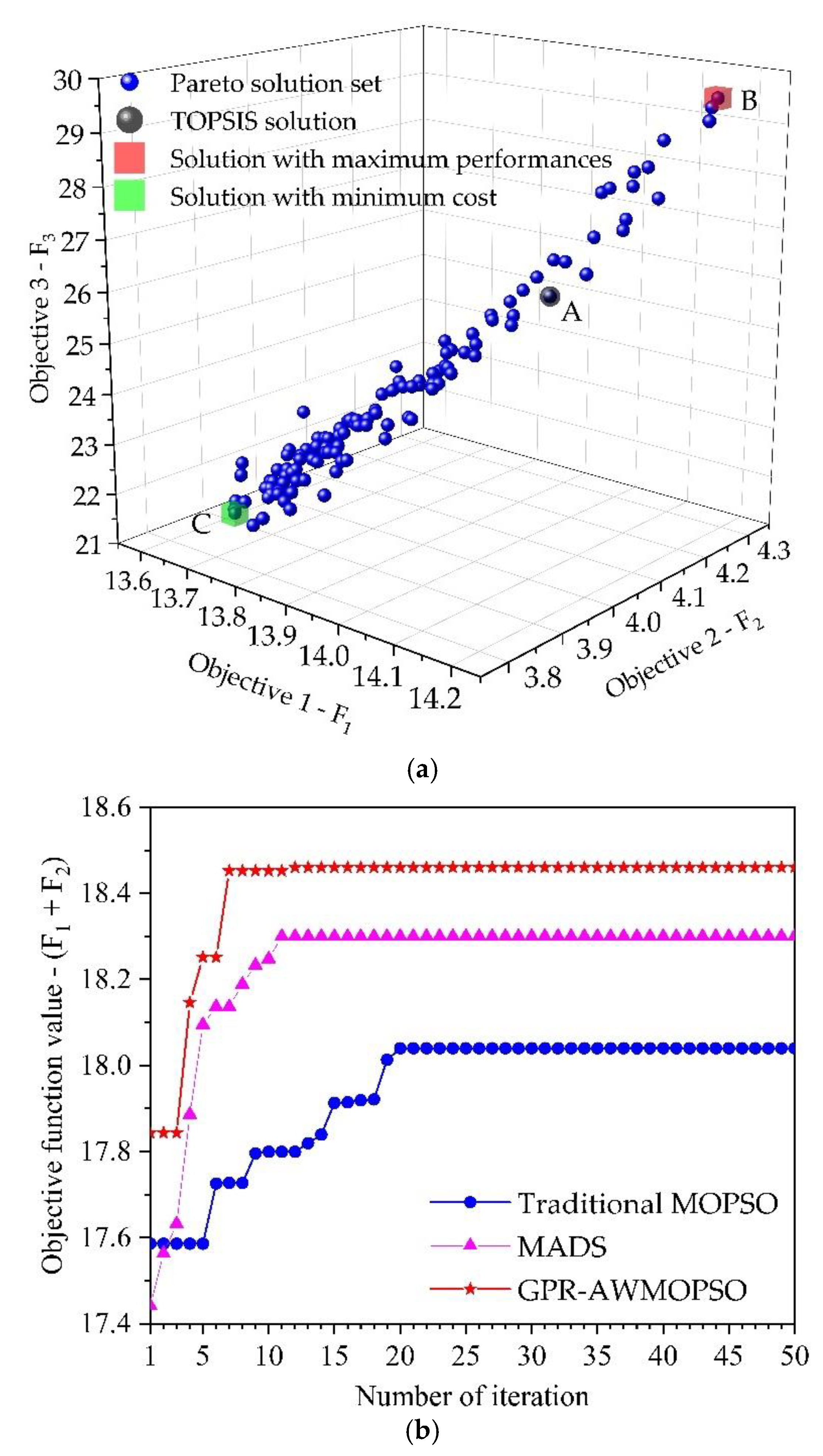

3.2.3. Results of Asphalt Mixture Proportion Optimization using GPR-AWMOPSO

3.3. Case Study III: Optimization with Four Objectives

3.3.1. Data Description

3.3.2. MOO Problem Formulation for Rubber-Basalt Fibre Composite Modified Concrete

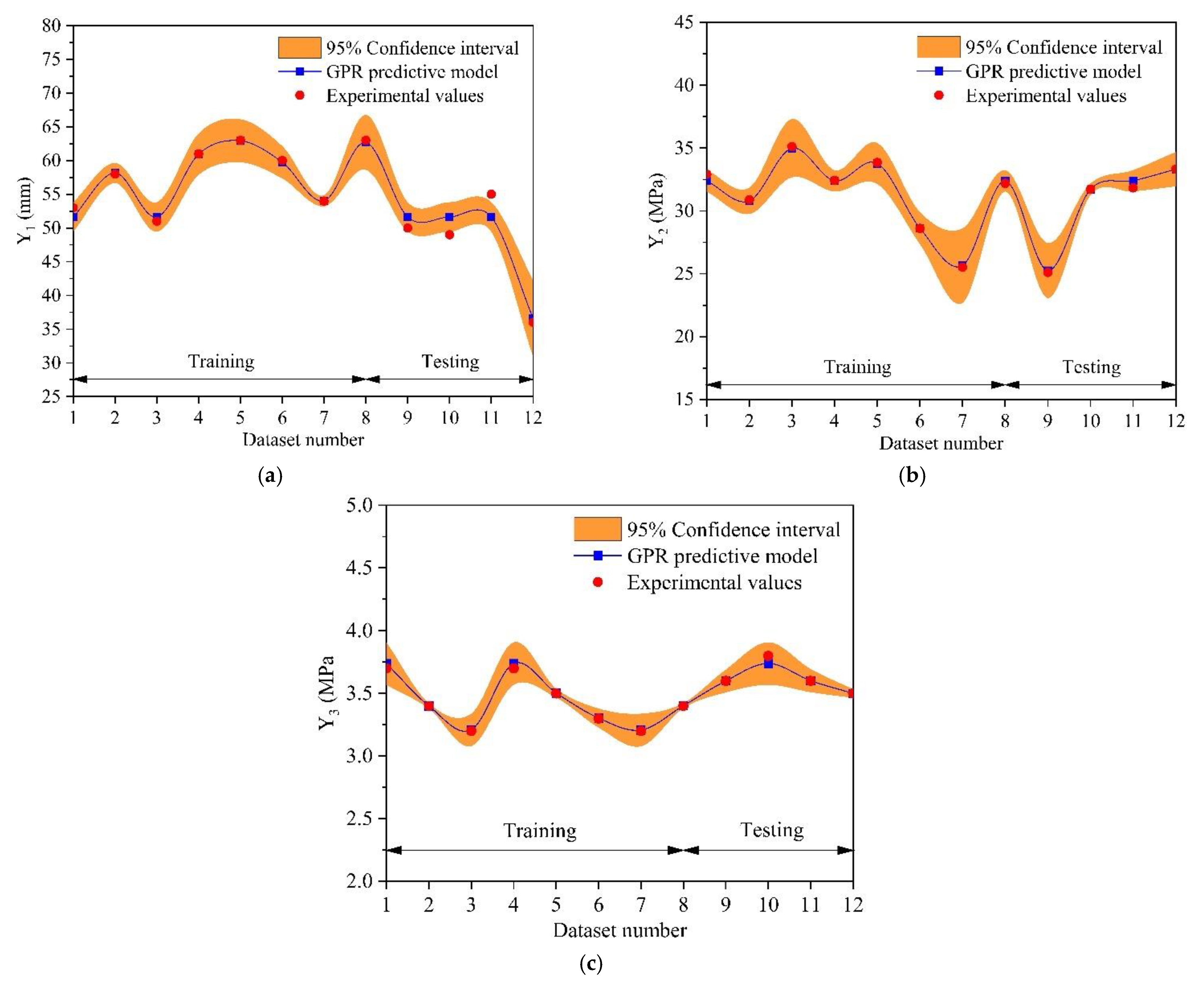

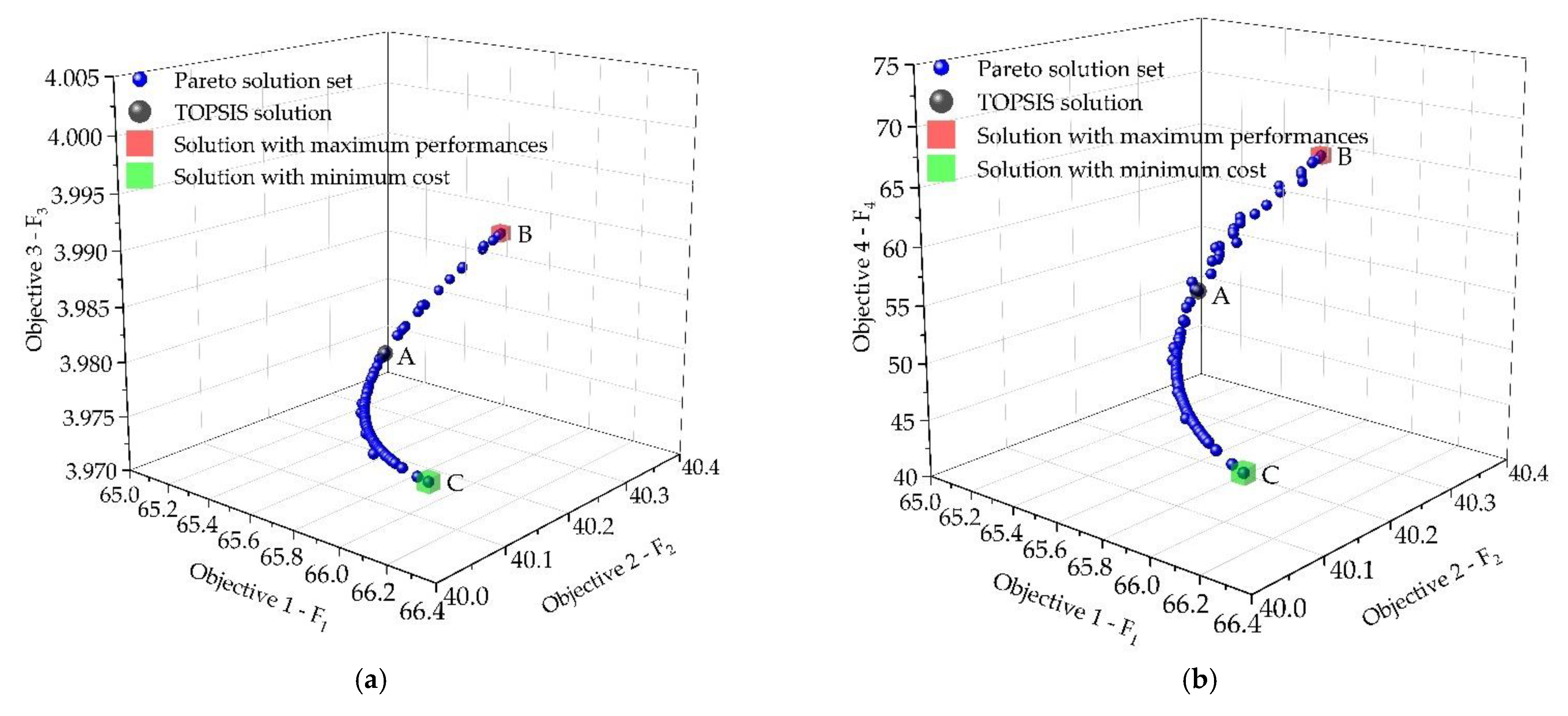

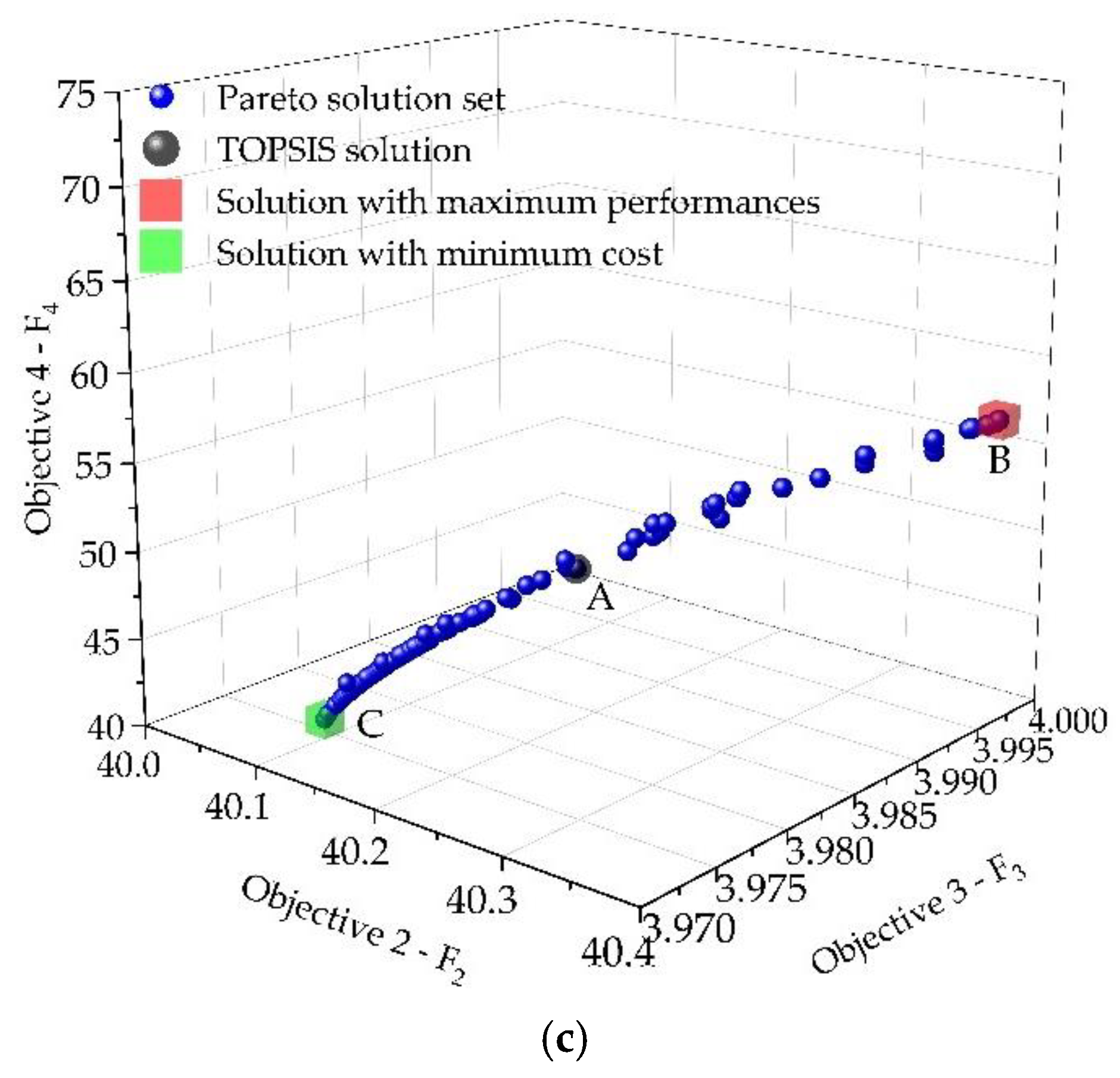

3.3.3. Results of Concrete Mix Proportion Optimization using GPR-AWMOPSO

4. Conclusions

- (1)

- The GPR-AWMOPSO algorithm can be used to develop the objective functions without knowing the explicit relationships between variables and objectives.

- (2)

- The selected metaheuristic algorithm could solve the problem and find the global optimal solution for multiple competing objectives.

- (3)

- The GPR-AWMOPSO algorithm has higher accuracy to balance the competing objectives with the ML model as objective functions, which can serve as guidance for the proportion optimization design of asphalt mixture.

- (4)

- The GPR-AWMOPSO algorithm has advantages of less computational time and fewer samples to avoid the limitation that the traditional experimental design method cannot effectively deal with lots of variables and levels. In addition, the proposed GPR-AWMOPSO algorithm can be extended to other practical design problems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ren, J.; Xue, B.; Zhang, L.; Liu, W.; Li, D.; Xu, Y. Characterization and prediction of rutting resistance of rock asphalt mixture under the coupling effect of water and high-temperature. Constr. Build. Mater. 2020, 254. [Google Scholar] [CrossRef]

- Li, Y.; He, X.; Sun, H.; Tan, Y. Effects of freeze-thaw on dynamic mechanical behavior of cement emulsified asphalt composite binder. Constr. Build. Mater. 2019, 213, 608–616. [Google Scholar] [CrossRef]

- Hasan, M.M.; Tarefder, R.A. A mixture design approach for mitigating cracking issue of asphalt concrete pavement. Constr. Build. Mater. 2020, 260. [Google Scholar] [CrossRef]

- Tong, J.; Ma, T.; Shen, K.; Zhang, H.; Wu, S. A criterion of asphalt pavement rutting based on the thermal-visco-elastic-plastic model. Int. J. Pavement. Eng. 2020, 1–11. [Google Scholar] [CrossRef]

- Islam, M.R.; Rahman, A.S.M.A.; Tarefder, R.A. Open Graded Friction Course in Resisting Low-Temperature Transverse Cracking in Asphalt Pavement. J. Cold Reg. Eng. 2018, 32, 04018006. [Google Scholar] [CrossRef]

- Li, Y.L.; Sun, H.J.; He, X.; Tan, Y.Q. Freeze-thaw damage and creep behavior of cement asphalt composite binder. Constr. Build. Mater. 2020, 245. [Google Scholar] [CrossRef]

- Zhu, J.Q.; Ma, T.; Fan, J.W.; Fang, Z.Y.; Chen, T.; Zhou, Y. Experimental study of high modulus asphalt mixture containing reclaimed asphalt pavement. J. Clean. Prod. 2020, 263. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, Z.; Liu, P.; Li, Y.; Hu, J.; Gao, Y.; Li, X. Influence of basalt fiber on mode I and II fracture properties of asphalt mixture at medium and low temperatures. Theor. Appl. Fract. Mec. 2021, 112, 102884. [Google Scholar] [CrossRef]

- Wu, C.; Li, L.; Wang, W.; Gu, Z. Experimental Characterization of Viscoelastic Behaviors of Nano-TiO2/CaCO3 Modified Asphalt and Asphalt Mixture. Nanomaterials 2021, 11, 106. [Google Scholar] [CrossRef]

- Guo, Q.; Li, L.; Cheng, Y.; Jiao, Y.; Xu, C. Laboratory evaluation on performance of diatomite and glass fiber compound modified asphalt mixture. Mater. Design. 2015, 66, 51–59. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A. Assessment of mechanical properties of rice husk ash modified asphalt mixture. Constr. Build. Mater. 2017, 149, 350–358. [Google Scholar] [CrossRef]

- Arabani, M.; Shabani, A. Evaluation of the ceramic fiber modified asphalt binder. Constr. Build. Mater. 2019, 205, 377–386. [Google Scholar] [CrossRef]

- Ma, T.; Wang, H.; He, L.; Zhao, Y.; Huang, X.; Chen, J. Property Characterization of Asphalt Binders and Mixtures Modified by Different Crumb Rubbers. J. Mater. Civil. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Tan, Y.-Q.; Zhang, L.; Zhang, X.-Y. Investigation of low-temperature properties of diatomite-modified asphalt mixtures. Constr. Build. Mater. 2012, 36, 787–795. [Google Scholar] [CrossRef]

- Alfalah, A.; Offenbacker, D.; Ali, A.; Decarlo, C.; Lein, W.; Mehta, Y.; Elshaer, M. Assessment of the Impact of Fiber Types on the Performance of Fiber-Reinforced Hot Mix Asphalt. Transport. Res. Record. 2020, 2674, 337–347. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, Y.; Tan, G. Design Optimization of SBS-Modified Asphalt Mixture Reinforced with Eco-Friendly Basalt Fiber Based on Response Surface Methodology. Materials 2018, 11, 1311. [Google Scholar] [CrossRef]

- Tang, F.; Ma, T.; Zhang, J.; Guan, Y.; Chen, L. Integrating three-dimensional road design and pavement structure analysis based on BIM. Autom. Constr. 2020, 113, 103152. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Wang, Y.; Ma, G. Multi-objective optimization of concrete mixture proportions using machine learning and metaheuristic algorithms. Constr. Build. Mater. 2020, 253. [Google Scholar] [CrossRef]

- Ren, J.; Wang, S.; Zang, G. Effects of recycled aggregate composition on the mechanical characteristics and material design of cement stabilized cold recycling mixtures using road milling materials. Constr. Build. Mater. 2020, 244. [Google Scholar] [CrossRef]

- DeRousseau, M.A.; Kasprzyk, J.R.; Srubar, W.V. Computational design optimization of concrete mixtures: A review. Cem. Concr. Res. 2018, 109, 42–53. [Google Scholar] [CrossRef]

- Behnood, A.; Behnood, V.; Modiri Gharehveran, M.; Alyamac, K.E. Prediction of the compressive strength of normal and high-performance concretes using M5P model tree algorithm. Constr. Build. Mater. 2017, 142, 199–207. [Google Scholar] [CrossRef]

- Qadir, A.; Gazder, U.; Choudhary, K.U.N. Artificial Neural Network Models for Performance Design of Asphalt Pavements Reinforced with Geosynthetics. Transport. Res. Record. 2020, 2674, 319–326. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, J.; Li, G.; Wang, Y.; Sun, J.; Jiang, C. Optimized neural network using beetle antennae search for predicting the unconfined compressive strength of jet grouting coalcretes. Int. J. Numer. Anal. Methods Geomech. 2019, 43, 801–813. [Google Scholar] [CrossRef]

- Hong, X.; Ding, Y.; Ren, L.; Chen, L.; Huang, B. A weighted heteroscedastic Gaussian Process Modelling via particle swarm optimization. Chemom. Intell. Lab. Syst. 2018, 172, 129–138. [Google Scholar] [CrossRef]

- Lee, S.-C. Prediction of concrete strength using artificial neural networks. Eng. Struct. 2003, 25, 849–857. [Google Scholar] [CrossRef]

- Gupta, S.M. Support Vector Machines based Modelling of Concrete Strength. Proc. World Acad. Sci. E 2007, 26, 782–788. [Google Scholar]

- Erdal, H.I. Two-level and hybrid ensembles of decision trees for high performance concrete compressive strength prediction. Eng. Appl. Artif. Intell. 2013, 26, 1689–1697. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A. A multi-objective evolutionary algorithm for solving traveling salesman problems: Application to the design of polymer extruders. Spring Comput. Sci. 2005. [Google Scholar] [CrossRef]

- Fleming, P.J.; Purshouse, R.C.; Lygoe, R.J. Many-objective optimization: An engineering design perspective. Lect. Notes Comput. Sc. 2005, 3410, 14–32. [Google Scholar]

- Lyu, Z.H.; Shen, A.Q.; Qin, X.; Yang, X.L.; Li, Y. Grey target optimization and the mechanism of cold recycled asphalt mixture with comprehensive performance. Constr. Build. Mater. 2019, 198, 269–277. [Google Scholar] [CrossRef]

- Coello, C.A.C.; Pulido, G.T.; Lechuga, M.S. Handling multiple objectives with particle swarm optimization. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Fang, H.; Rais-Rohani, M.; Liu, Z.; Horstemeyer, M.F. A comparative study of metamodeling methods for multiobjective crashworthiness optimization. Comput. Struct. 2005, 83, 2121–2136. [Google Scholar] [CrossRef]

- Sun, G.; Zhang, H.; Fang, J.; Li, G.; Li, Q. A new multi-objective discrete robust optimization algorithm for engineering design. Appl. Math. Model. 2018, 53, 602–621. [Google Scholar] [CrossRef]

- Aftab, W.; Hostettler, R.; De Freitas, A.; Arvaneh, M.; Mihaylova, L. Spatio-Temporal Gaussian Process Models for Extended and Group Object Tracking With Irregular Shapes. IEEE Trans. Veh. Technol. 2019, 68, 2137–2151. [Google Scholar] [CrossRef]

- Sarkka, S.; Alvarez, M.A.; Lawrence, N.D. Gaussian Process Latent Force Models for Learning and Stochastic Control of Physical Systems. IEEE Trans. Autom. Control 2019, 64, 2953–2960. [Google Scholar] [CrossRef]

- Blackwell, T.; Kennedy, J. Impact of Communication Topology in Particle Swarm Optimization. IEEE Trans. Evol. Comput. 2019, 23, 689–702. [Google Scholar] [CrossRef]

- Mashhadban, H.; Kutanaei, S.S.; Sayarinejad, M.A. Prediction and modeling of mechanical properties in fiber reinforced self-compacting concrete using particle swarm optimization algorithm and artificial neural network. Constr. Build. Mater. 2016, 119, 277–287. [Google Scholar] [CrossRef]

- Chen, H.T.; Wang, W.C.; Chen, X.N.; Qiu, L. Multi-objective reservoir operation using particle swarm optimization with adaptive random inertia weights. Water Sci. Eng. 2020, 13, 136–144. [Google Scholar] [CrossRef]

- Mendez, M.; Frutos, M.; Miguel, F.; Aguasca-Colomo, R. TOPSIS Decision on Approximate Pareto Fronts by Using Evolutionary Algorithms: Application to an Engineering Design Problem. Mathematics 2020, 8. [Google Scholar] [CrossRef]

- Rehman, S.; Khan, S.A.; Alhems, L.M. Application of TOPSIS Approach to Multi-Criteria Selection of Wind Turbines for On-Shore Sites. Appl. Sci. 2020, 10. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Wang, H.; Guo, Y.; Wu, H. Effect of basalt fiber on the low-temperature performance of an asphalt mixture in a heavily frozen area. Constr. Build. Mater. 2020, 253. [Google Scholar] [CrossRef]

- Hyndman, R.J.; Koehler, A.B. Another look at measures of forecast accuracy. Int. J. Forecast. 2006, 22, 679–688. [Google Scholar] [CrossRef]

- Yoshida, H.; Kawata, K.; Fukuyama, Y.; Takayama, S.; Nakanishi, Y. A particle swarm optimization for reactive power and voltage control considering voltage security assessment. IEEE Trans. Power Syst. 2000, 15, 1232–1239. [Google Scholar] [CrossRef]

- Ourique, C.O.; Biscaia, E.C.; Pinto, J.C. The use of particle swarm optimization for dynamical analysis in chemical processes. Comput. Chem. Eng. 2002, 26, 1783–1793. [Google Scholar] [CrossRef]

- Pulido, G.T.; Coello, C.A.C. Using clustering techniques to improve the performance of a multi-objective particle swarm optimizer. Lect. Notes Comput. Sci. 2004, 3102, 225–237. [Google Scholar]

- Burmen, A.; Fajfar, I. Mesh adaptive direct search with simplicial Hessian update. Comput. Optim. Appl. 2019, 74, 645–667. [Google Scholar] [CrossRef]

- Audet, C.; Le Digabel, S.; Tribes, C. The Mesh Adaptive Direct Search Algorithm for Granular and Discrete Variables. Siam. J. Optim. 2019, 29, 1164–1189. [Google Scholar] [CrossRef]

- Huang, W.H.; Sun, K.; Qi, J.J.; Ning, J.X. Optimisation of dynamic reactive power sources using mesh adaptive direct search. IET Gener. Transm. Dis. 2017, 11, 3675–3682. [Google Scholar] [CrossRef]

- Shukry, N.A.M.; Hassan, N.A.; Abdullah, M.E.; Hainin, M.R.; Yusoff, N.I.M.; Mahmud, M.Z.H.; Jaya, R.P.; Warid, M.N.M.; Satar, M.K.I.M. Influence of diatomite filler on rheological properties of porous asphalt mastic. Int. J. Pavement Eng. 2020, 21, 428–436. [Google Scholar] [CrossRef]

- Yang, C.; Xie, J.; Zhou, X.J.; Liu, Q.T.; Pang, L. Performance Evaluation and Improving Mechanisms of Diatomite-Modified Asphalt Mixture. Materials 2018, 11. [Google Scholar] [CrossRef]

- Wang, W.S.; Cheng, Y.C.; Chen, H.P.; Tan, G.J.; Lv, Z.H.; Bai, Y.S. Study on the Performances of Waste Crumb Rubber Modified Asphalt Mixture with Eco-Friendly Diatomite and Basalt Fiber. Sustainability 2019, 11. [Google Scholar] [CrossRef]

- Davar, A.; Tanzadeh, J.; Fadaee, O. Experimental evaluation of the basalt fibers and diatomite powder compound on enhanced fatigue life and tensile strength of hot mix asphalt at low temperatures. Constr. Build. Mater. 2017, 153, 238–246. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Li, L.D.; Zhou, P.L.; Zhang, Y.W.; Liu, H.B. Multi-Objective Optimization Design and Test of Compound Diatomite and Basalt Fiber Asphalt Mixture. Materials 2019, 12. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.F.; Song, J.X.; Lin, S.Y.; Yang, J.X.; He, Y.; Tan, G.J. Design Optimization of Rubber-Basalt Fiber- Modified Concrete Mix Ratios Based on a Response Surface Method. Appl. Sci. 2020, 10. [Google Scholar] [CrossRef]

| No. | Preparation Parameters | Responses or Dependent Variables | ||||||

|---|---|---|---|---|---|---|---|---|

| X1 (%) | X2 (mm) | X3 (%) | Y1 (kN) | Y2 (mm) | Y3 (%) | Y4 (%) | Y5 (%) | |

| 1 | 0.40 | 6 | 6.6 | 9.98 | 3.052 | 4.69 | 18.35 | 74.45 |

| 2 | 0.25 | 3 | 6.4 | 7.48 | 3.053 | 2.80 | 16.79 | 83.32 |

| 3 | 0.55 | 3 | 6.8 | 6.23 | 3.328 | 7.19 | 20.47 | 64.88 |

| 4 | 0.55 | 6 | 6.6 | 9.92 | 2.778 | 5.99 | 19.46 | 69.22 |

| 5 | 0.40 | 6 | 6.8 | 9.33 | 4.153 | 5.89 | 19.36 | 69.58 |

| 6 | 0.40 | 6 | 6.6 | 10.56 | 3.054 | 4.78 | 18.42 | 74.05 |

| 7 | 0.55 | 9 | 6.8 | 7.19 | 3.053 | 7.55 | 20.78 | 63.67 |

| 8 | 0.25 | 6 | 6.6 | 10.21 | 3.190 | 2.75 | 16.69 | 83.52 |

| 9 | 0.40 | 3 | 6.6 | 8.72 | 3.191 | 4.37 | 18.08 | 75.83 |

| 10 | 0.40 | 6 | 6.6 | 10.48 | 3.053 | 4.69 | 18.35 | 74.44 |

| 11 | 0.40 | 6 | 6.6 | 10.29 | 3.051 | 4.82 | 18.46 | 73.89 |

| 12 | 0.55 | 3 | 6.4 | 6.63 | 2.641 | 6.05 | 19.57 | 69.09 |

| 13 | 0.25 | 9 | 6.8 | 7.82 | 4.291 | 4.28 | 17.97 | 76.18 |

| 14 | 0.25 | 9 | 6.4 | 8.41 | 2.916 | 3.13 | 17.07 | 81.66 |

| 15 | 0.25 | 3 | 6.8 | 6.89 | 4.428 | 3.96 | 17.70 | 77.63 |

| 16 | 0.40 | 6 | 6.6 | 10.38 | 3.053 | 4.65 | 18.32 | 74.62 |

| 17 | 0.40 | 6 | 6.4 | 9.61 | 2.916 | 5.07 | 18.73 | 72.93 |

| 18 | 0.40 | 9 | 6.6 | 9.04 | 2.915 | 5.02 | 18.63 | 73.05 |

| 19 | 0.55 | 9 | 6.4 | 8.11 | 2.503 | 6.37 | 19.85 | 67.91 |

| Input Variables | Lower Bound | Medium | Upper Bound | |

|---|---|---|---|---|

| X1 | % | 0.25 | 0.40 | 0.55 |

| X2 | mm | 3 | 6 | 9 |

| X3 | % | 6.4 | 6.6 | 6.8 |

| Output Variables | Y1 | Y2 | Y3 | Y4 | Y5 |

|---|---|---|---|---|---|

| Specification | Maximize | 2~5 | 3~4 | ≥17 | 75~85 |

| Unit | kN | mm | % | % | % |

| Output Variables | RMSE | R2 | ||

|---|---|---|---|---|

| Training | Testing | Training | Testing | |

| Y1 | 0.242 | 0.145 | 0.984 | 0.992 |

| Y2 | 0.174 | 0.134 | 0.865 | 0.988 |

| Y3 | 0.096 | 0.154 | 0.996 | 0.995 |

| Y4 | 0.087 | 0.133 | 0.995 | 0.994 |

| Y5 | 0.135 | 0.154 | 0.996 | 0.996 |

| Optimization Methods | Input Variables | Output Variables | ||||||

|---|---|---|---|---|---|---|---|---|

| X1 (%) | X2 (mm) | X3 (%) | Y1 (kN) | Y2 (mm) | Y3 (%) | Y4 (%) | Y5 (%) | |

| RSM [16] | 0.34 | 6.41 | 6.57 | 10.49 | 3.113 | 4 | 17.7 | 77.43 |

| Traditional MOPSO | 0.3472 | 6 | 6.62 | 10.51 | 3.164 | 4 | 17.9 | 77.67 |

| MADS | 0.3529 | 6 | 6.62 | 10.53 | 3.169 | 4 | 18.1 | 77.88 |

| GPR-AWMOPSO | 0.3547 | 6 | 6.61 | 10.55 | 3.181 | 4 | 18.1 | 77.91 |

| No. | Preparation Parameters | Responses or Dependent Variables | ||||||

|---|---|---|---|---|---|---|---|---|

| X1 (%) | X2 (%) | X3 (%) | Y1 (%) | Y2 (%) | Y3 (%) | Y4 (kN) | Y5 (MPa) | |

| 1 | 5 | 0.2 | 4.9 | 4.02 | 74.01 | 15.47 | 12.46 | 2.81 |

| 2 | 5 | 0.3 | 5.2 | 3.85 | 75.85 | 15.94 | 13.38 | 3.50 |

| 3 | 5 | 0.4 | 5.5 | 3.80 | 76.99 | 16.51 | 13.27 | 3.58 |

| 4 | 5 | 0.5 | 5.8 | 3.99 | 76.93 | 17.30 | 12.40 | 3.25 |

| 5 | 10 | 0.2 | 5.5 | 3.44 | 78.76 | 16.20 | 13.32 | 3.89 |

| 6 | 10 | 0.3 | 5.8 | 3.36 | 79.94 | 16.75 | 13.06 | 3.91 |

| 7 | 10 | 0.4 | 4.9 | 4.77 | 70.40 | 16.11 | 13.27 | 3.69 |

| 8 | 10 | 0.5 | 5.2 | 4.76 | 71.55 | 16.73 | 13.35 | 3.66 |

| 9 | 15 | 0.2 | 5.8 | 3.73 | 78.14 | 17.06 | 12.67 | 3.57 |

| 10 | 15 | 0.3 | 5.5 | 4.39 | 74.20 | 17.02 | 14.02 | 4.30 |

| 11 | 15 | 0.4 | 5.2 | 4.21 | 74.06 | 16.23 | 13.57 | 3.82 |

| 12 | 15 | 0.5 | 4.9 | 5.86 | 65.67 | 17.07 | 13.14 | 3.56 |

| 13 | 20 | 0.2 | 5.2 | 4.58 | 72.36 | 16.57 | 12.85 | 3.22 |

| 14 | 20 | 0.3 | 4.9 | 5.39 | 67.63 | 16.65 | 13.36 | 3.48 |

| 15 | 20 | 0.4 | 5.8 | 4.49 | 74.61 | 17.68 | 12.65 | 3.56 |

| 16 | 20 | 0.5 | 5.5 | 5.49 | 69.41 | 17.95 | 13.07 | 3.70 |

| Input Variables | Lower Bound | Upper Bound | |

|---|---|---|---|

| X1 | % | 5 | 20 |

| X2 | % | 0.2 | 0.5 |

| X3 | % | 4.9 | 5.8 |

| Output Variables | Y1 | Y2 | Y3 | Y4 | Y5 |

|---|---|---|---|---|---|

| Specification | 3~6 | 65~75 | ≥14 | ≥8 (Maximize) | Maximize |

| Unit | % | % | % | kN | MPa |

| Output Variables | RMSE | R2 | ||

|---|---|---|---|---|

| Training | Testing | Training | Testing | |

| Y1 | 0.209 | 0.170 | 0.938 | 0.849 |

| Y2 | 0.959 | 0.914 | 0.887 | 0.959 |

| Y3 | 0.176 | 0.177 | 0.937 | 0.991 |

| Y4 | 0.160 | 0.132 | 0.804 | 0.886 |

| Y5 | 0.108 | 0.102 | 0.864 | 0.922 |

| Optimization Methods | Input Variables | Output Variables | ||||||

|---|---|---|---|---|---|---|---|---|

| X1 (%) | X2 (%) | X3 (%) | Y1 (%) | Y2 (%) | Y3 (%) | Y4 (kN) | Y5 (MPa) | |

| Orthogonal | 14 | 0.32 | 5.45 | 4.25 | 74.68 | 16.78 | 13.30 | 3.86 |

| Traditional MOPSO | 14.234 | 0.36 | 5.57 | 4.23 | 74.76 | 16.75 | 13.91 | 4.13 |

| MADS | 14 | 0.34 | 5.52 | 4.24 | 74.87 | 16.80 | 14.06 | 4.24 |

| GPR-AWMOPSO | 13.9 | 0.34 | 5.51 | 4.22 | 75.02 | 16.87 | 14.18 | 4.28 |

| Optimization Methods | Input Variables | Output Variables | ||||

|---|---|---|---|---|---|---|

| X1 | X2 (kg/m3) | X3 (%) | Y1 (mm) | Y2 (MPa) | Y3 (MPa) | |

| Orthogonal | 0.39 | 4.56 | 10 | 64 | 39.96 | 3.8 |

| Traditional MOPSO | 0.3978 | 4.5762 | 10.6711 | 65.1515 | 38.7927 | 3.8367 |

| MADS | 0.4012 | 4.5886 | 10.7919 | 65.5083 | 40.0506 | 3.9598 |

| GPR-AWMOPSO | 0.4049 | 4.5802 | 10.6861 | 65.3504 | 40.2792 | 3.9766 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, C.; Xu, X.; Chen, H.; Wang, W.; Zheng, K.; Tan, G.; Gu, Z.; Zhang, H. Machine Learning Approach to Develop a Novel Multi-Objective Optimization Method for Pavement Material Proportion. Appl. Sci. 2021, 11, 835. https://doi.org/10.3390/app11020835

Liang C, Xu X, Chen H, Wang W, Zheng K, Tan G, Gu Z, Zhang H. Machine Learning Approach to Develop a Novel Multi-Objective Optimization Method for Pavement Material Proportion. Applied Sciences. 2021; 11(2):835. https://doi.org/10.3390/app11020835

Chicago/Turabian StyleLiang, Chunyu, Xin Xu, Heping Chen, Wensheng Wang, Kunkun Zheng, Guojin Tan, Zhengwei Gu, and Hao Zhang. 2021. "Machine Learning Approach to Develop a Novel Multi-Objective Optimization Method for Pavement Material Proportion" Applied Sciences 11, no. 2: 835. https://doi.org/10.3390/app11020835

APA StyleLiang, C., Xu, X., Chen, H., Wang, W., Zheng, K., Tan, G., Gu, Z., & Zhang, H. (2021). Machine Learning Approach to Develop a Novel Multi-Objective Optimization Method for Pavement Material Proportion. Applied Sciences, 11(2), 835. https://doi.org/10.3390/app11020835

_Chen.png)