2.2. Back Propagation Neural Networks

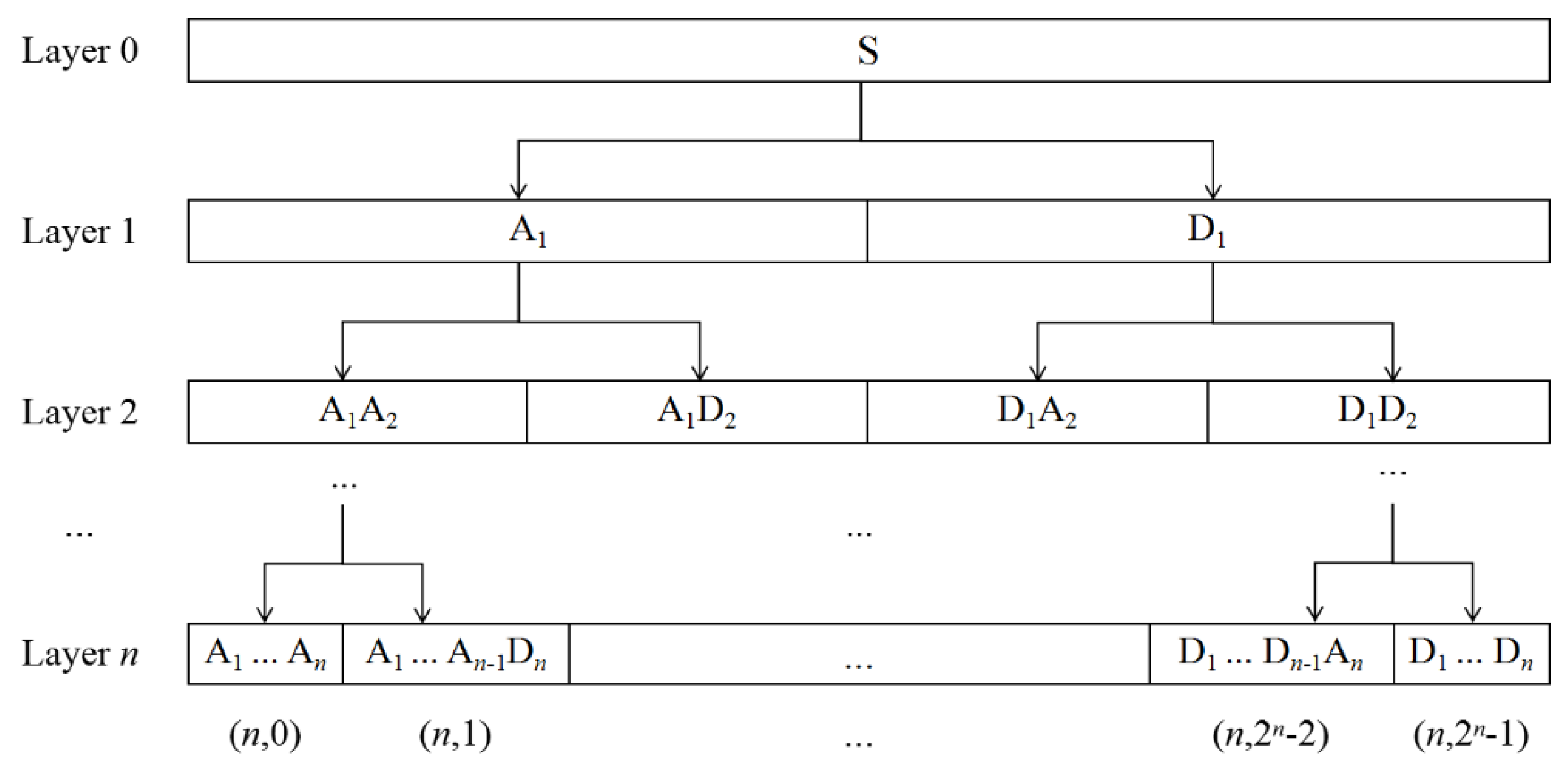

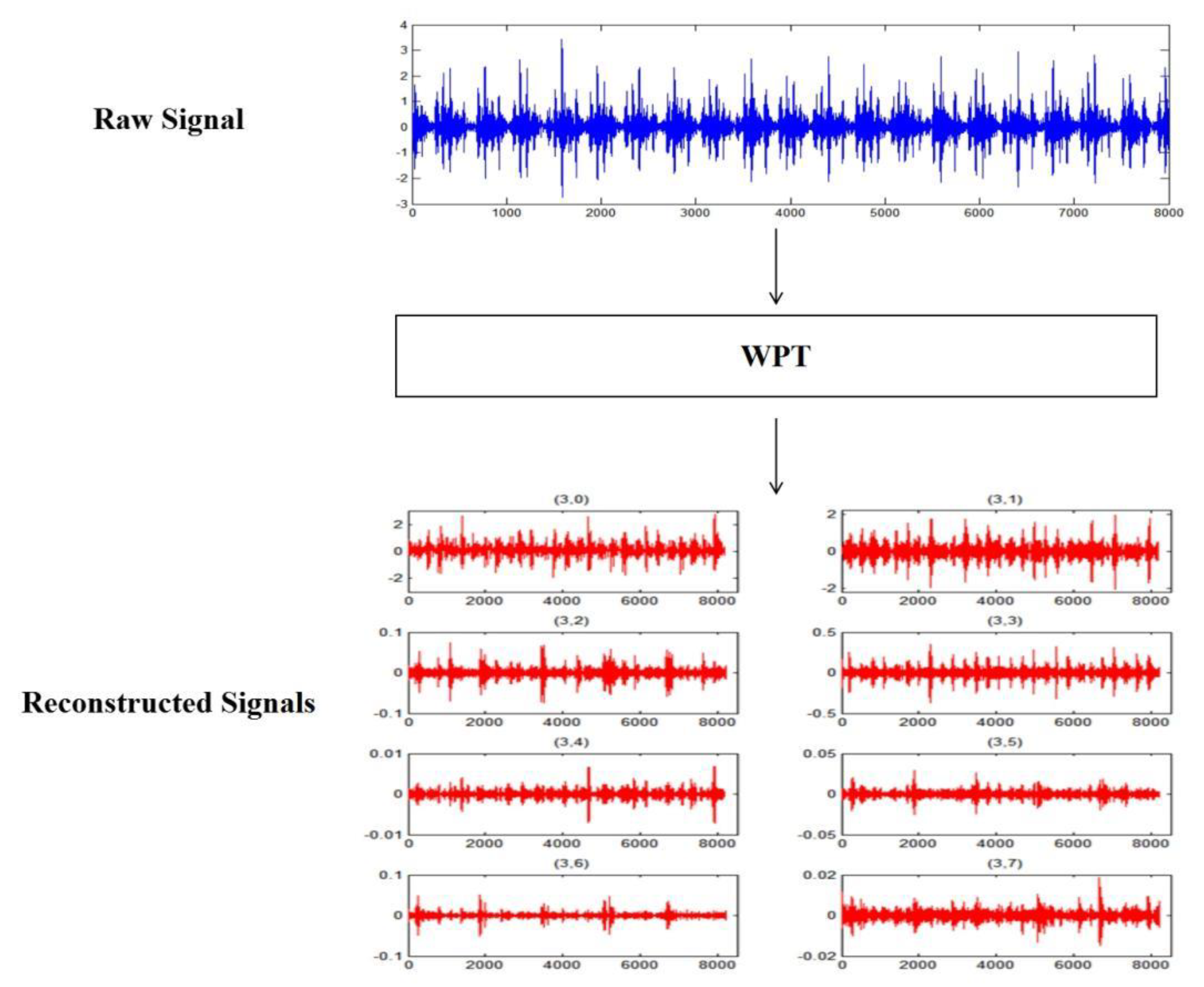

The raw vibration signals are decomposed by a wavelet packet with

n layers, producing

s reconstructed signals. Features with the quantity of

m are extracted from each reconstructed signal, forming the feature set

F = {

F1,

F2, …,

Fm}.

Fj is normalized to

Xj = {

Xj1,

Xj2, …,

Xjs}

T, which is the input of the

jth BPNN. The number of output layer nodes is set to

h, and the corresponding output is

Dj = {

Dj1,

Dj2, …,

Djh}

T. The

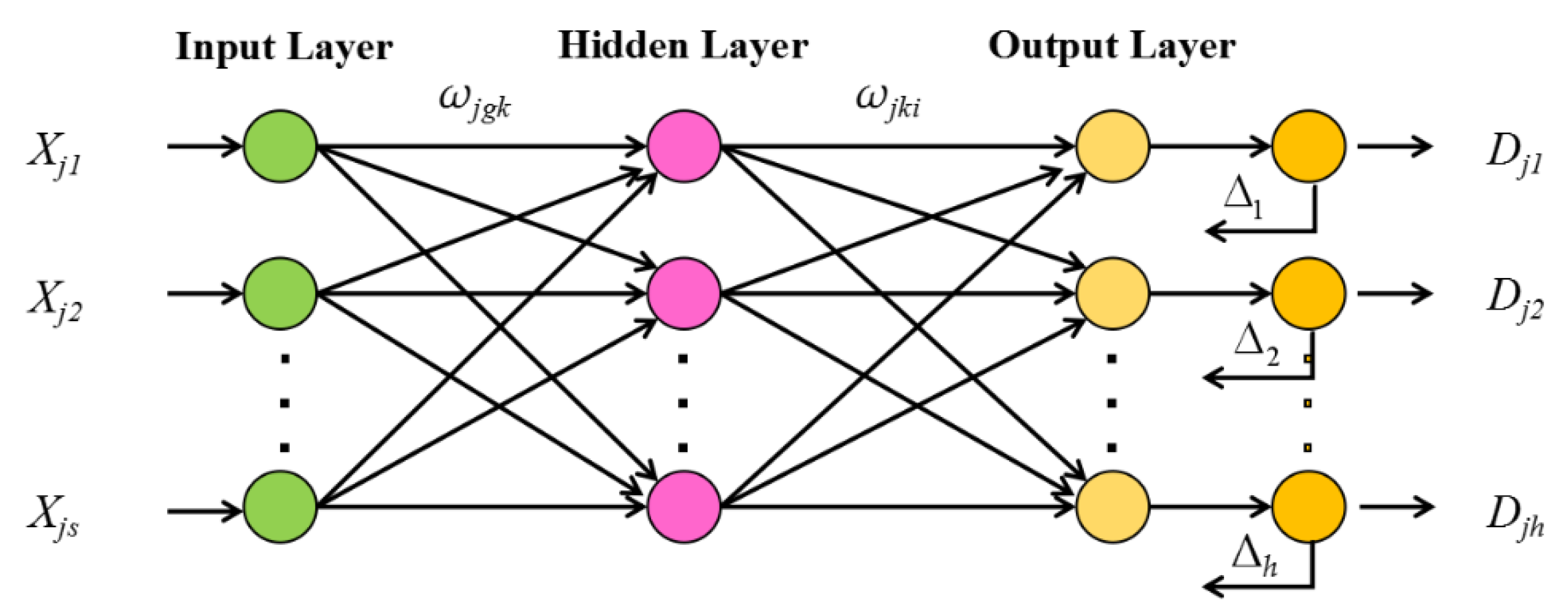

jth BPNN consists of an input layer, hidden layer and output layer, as shown in

Figure 2.

In this paper, the training process of the jth BPNN consists of the following steps:

Step 1: Initialization.

The number of neurons in the hidden layer l is selected empirically. The weight ωjgk connects the input layer with the hidden layer, and the weight ωjki connects the hidden layer with the output layer. Then, the hidden layer threshold aj and the output layer threshold bj are initialized. The learning rate and neuronal excitation function are given in advance.

Step 2: Hidden layer calculation.

The output

Hj of the hidden layer is calculated according to the input vector

X, weight

ωjgk and hidden layer threshold

aj.

where

f is the hidden layer excitation function. There are many excitation functions for the hidden layer, and the excitation function used in this paper is:

Step 3: The output calculation of the output layer.

The output of the

jth BPNN

Dj is calculated by the hidden layer output

Hj, weight

ωjki and threshold

bj.

Step 4: Error calculation.

The network prediction error

ej is calculated based on the network prediction output

Dj and the expected output

Yj.

Step 5: Weight update.

The network connection weights

ωjgk and

ωjki are updated by the network prediction error

ej.

where

is the learning ratio.

Step 6: Threshold update.

The network node threshold

aj and

bj are updated by the network prediction error

ej.

Step 7: Iteration judgement.

Determining whether the algorithm iteration ends, and if not, returning to step 2.

A desired accuracy, , is set. N is the sample number. If , a hidden neuron is added and the process returns to the second step; if , the calculation is stopped.

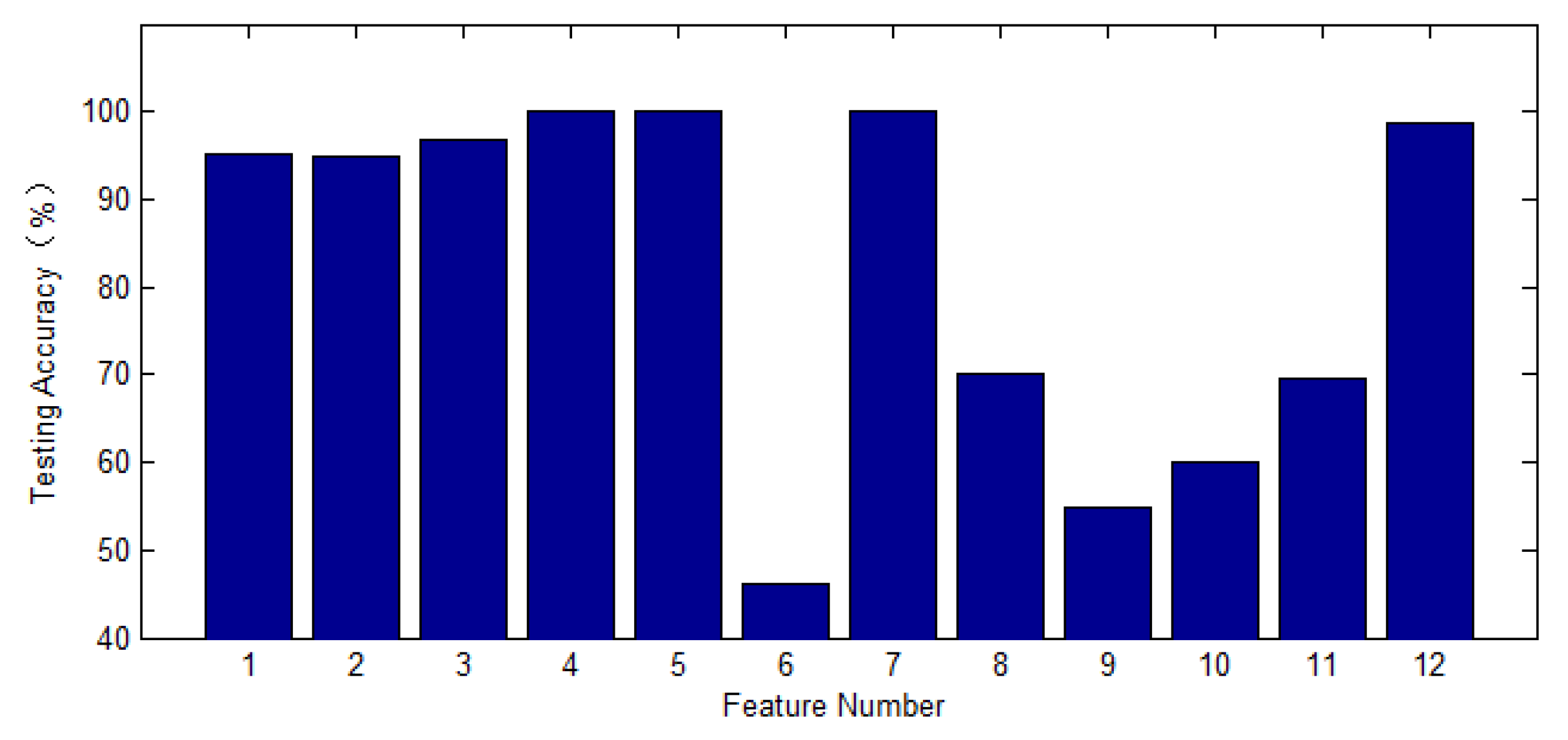

2.3. Decision Fusion Based on the Voting Method

The idea of decision fusion comes from ensemble learning. Ensemble learning is not a single machine learning algorithm, but a method completing the task by building and combining multiple machine learning algorithms, which can be applied for classification problem integration, regression problem integration, feature selection integration, abnormal detection integration and so on [

31,

32]. For feature selection, Tripathi et al. [

33] applied the data set with selected features to five base learners and aggregated the outputs obtained by the base classifier by a weighted voting method to predict the final output. A deep neural network algorithm, support vector machine (SVM) and decision tree c4.5 base classifiers were adopted by Asadi et al. [

31], and the decision strategy based on the maximum number of votes was used to identify and classify botnets. Each ensemble learner produces a result, so it is necessary to integrate the results of each base learner to obtain the final decision result. A simple and effective way is to obtain the final decision result of multiple machine learning algorithms by the voting method. The voting method mainly includes the majority voting method [

34] and the weighted voting method [

33].

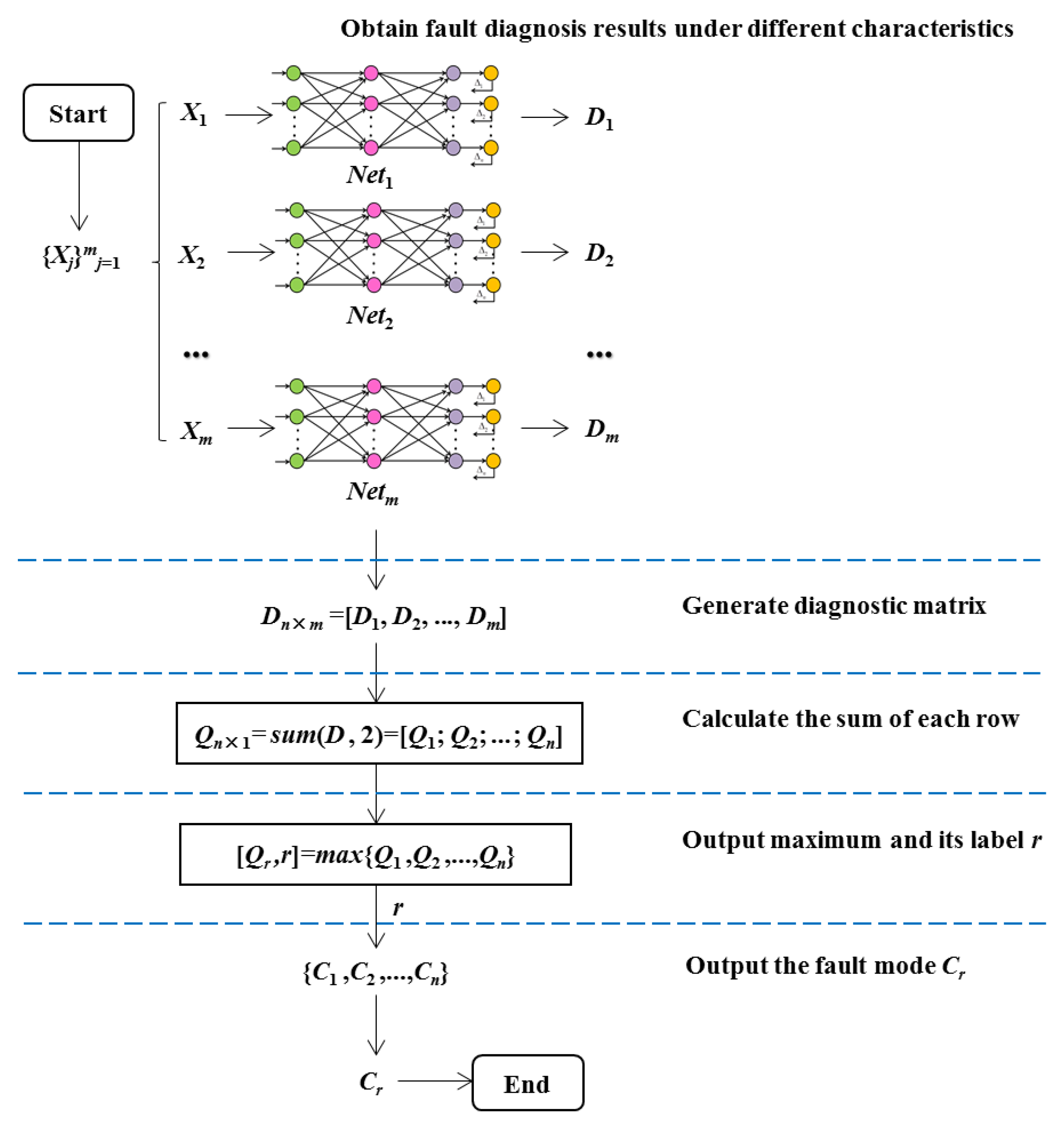

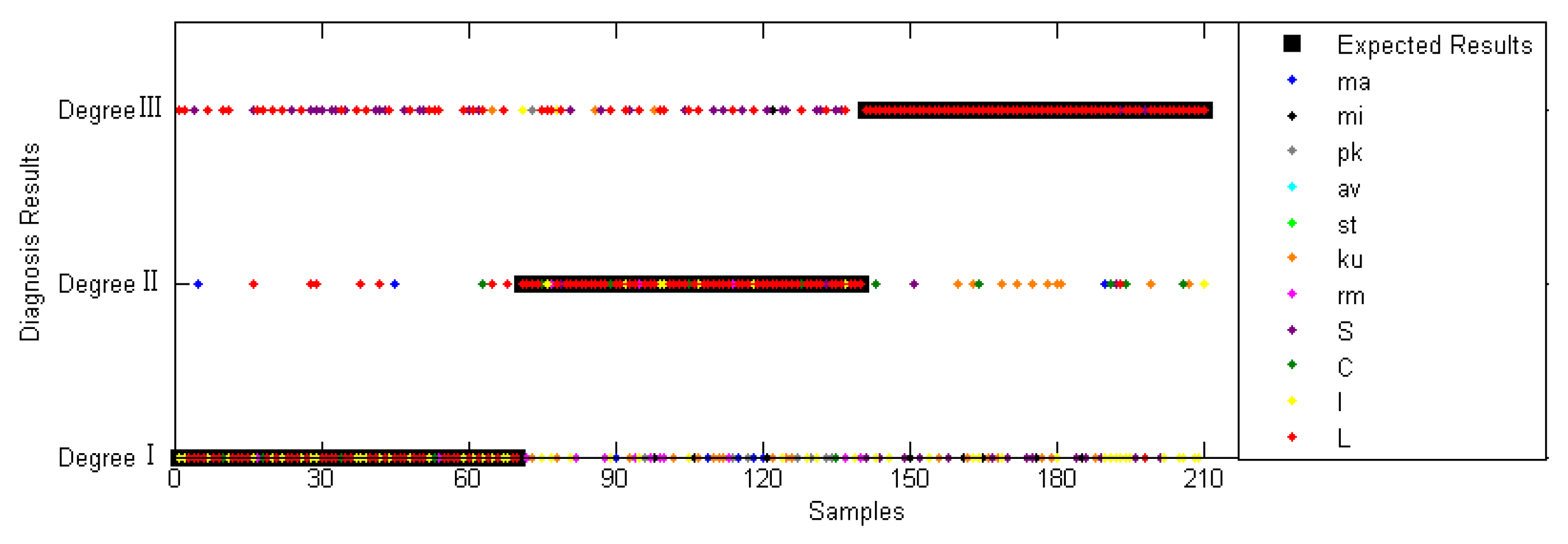

Inspired by the ensemble learning method, this paper makes use of the majority voting method to fuse the diagnosis results of multiple BPNN classifiers trained by a single feature set, which are extracted from all layers based on wavelet packet decomposition. Then, they are sorted from most to least. Finally, based on the principle that the minority obeys the majority, the diagnosis result with the largest number of votes is regarded as the decision fusion diagnosis result. The decision fusion algorithm based on the voting method is shown in

Figure 3.

In

Figure 3,

m characteristics

F1,

F2, …,

Fm are extracted from the vibration signals and are normalized to

X1,

X2, …,

Xm as the input of

m BPNN models

Net1,

Net2, …,

Netm, and then

h kinds of fault modes of bearings are recognized, The output results

D1,

D2, …,

Dm are Synthesized into a diagnostic matrix

Dh×m. Then, each row of the matrix

Dh×m is summed in order to get the scoring matrix

Qh×1 = {

Q1;

Q2; …;

Qh}. Each

Qi (

i = 1, 2, …,

h) represents the score of the fault mode

i, respectively. Finally, the highest score

Qr is the output, which is the maximum of the output

Q1,

Q2, …,

Qh.

Setting fault discrimination matrix

C:

where

Ci (

i = 1, 2, …,

h) represents the fault mode and

Ih×h is an

h-dimensional identity matrix.

h is the total number of bearing state modes, which determines the number of output layer nodes.

The corresponding fault mode of the fault discrimination matrix C is found according to the angle mark r of the highest score, which is the decision fusion diagnosis result of the current state.

It can be seen that decision fusion is the fusion of multiple bearing fault diagnosis results based on a single time-domain feature. It is not necessary to screen the features, and the diagnostic results under each feature contribute to the final decision results. The decision fusion method takes into account the diagnostic advantages of each single time-domain feature for rolling bearing signals, and the diagnostic results based on the reasoning of each single time-domain feature will be comprehensively analyzed. To some extent, it can avoid the misdiagnosis and missed diagnosis of rolling bearing faults caused by the sudden change of environmental or human factors, which is helpful in reflecting the healthy condition of rolling bearings more comprehensively and accurately.

In addition, this paper adopts the winner-take-all strategy, which is suitable for single faults. For multi-fault cases, a feasible method is to sort according to the score of Q1, Q2, …, Qh, from high to low, and output the order of the possibility of the fault mode, which can realize simultaneous fault diagnosis.

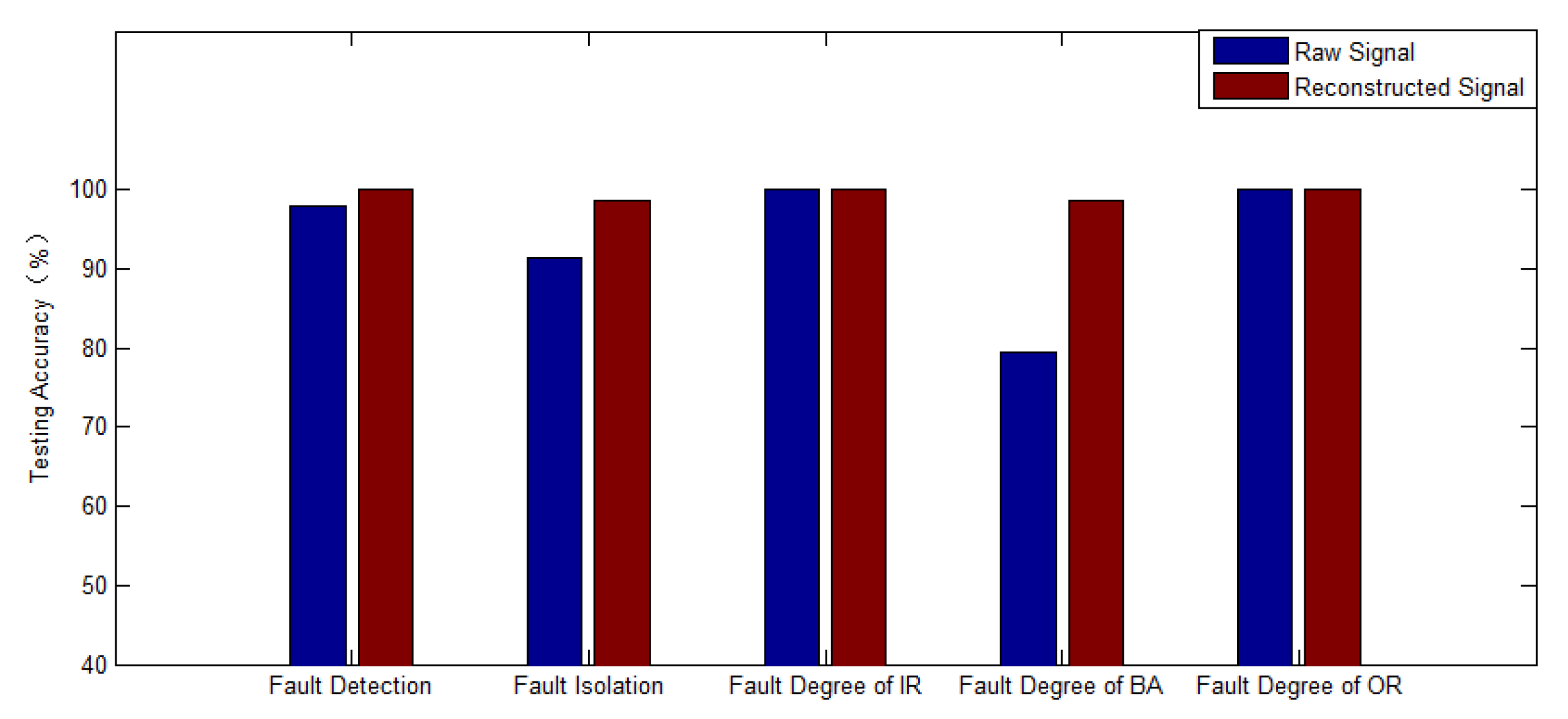

2.4. Hierarchical Fault Diagnosis Strategy

The traditional fault diagnosis method based on machine learning is to consider the fault position and severity synthetically. However, most of the rolling bearings are in normal condition, the fault occurs by chance and the evolution of the fault degree is nonlinear. In addition, in the actual process, the complete bearing fault samples are difficult to obtain. In this case, the fault diagnosis network that can judge the fault at the same time is often difficult to train because of the complexity of its network structure. In this paper, the hierarchical fault diagnosis architecture of rolling bearings is proposed, and the hierarchical diagnosis of rolling bearings is carried out in the progressive way. Further, the fault diagnosis of rolling bearings is divided into three layers: the first layer is the fault detection layer, which is used to judge whether the current state of the bearing is normal or not. The second layer is the fault isolation layer, and its goal is to identify the fault position of the bearing diagnosed as having a faulty state in the first layer. The third layer is the fault degree estimation layer, which is to further estimate the severity of the fault position of the rolling bearing.

The advantages of the hierarchical diagnosis proposed in this paper are as follows: the function of each layer of the neural network is relatively simple, the corresponding level of fault diagnosis network is trained by using the obtained fault samples, and the network training time is reduced. It is also relatively easy to improve the accuracy of fault identification. In addition, updating the fault algorithm is relatively easy, as it is only necessary to retrain the affected neural network to achieve the algorithm update, compared with the traditional diagnosis method; it also has better flexibility. Hierarchical decision fusion fault diagnosis methods include a training stage and a diagnosis stage.

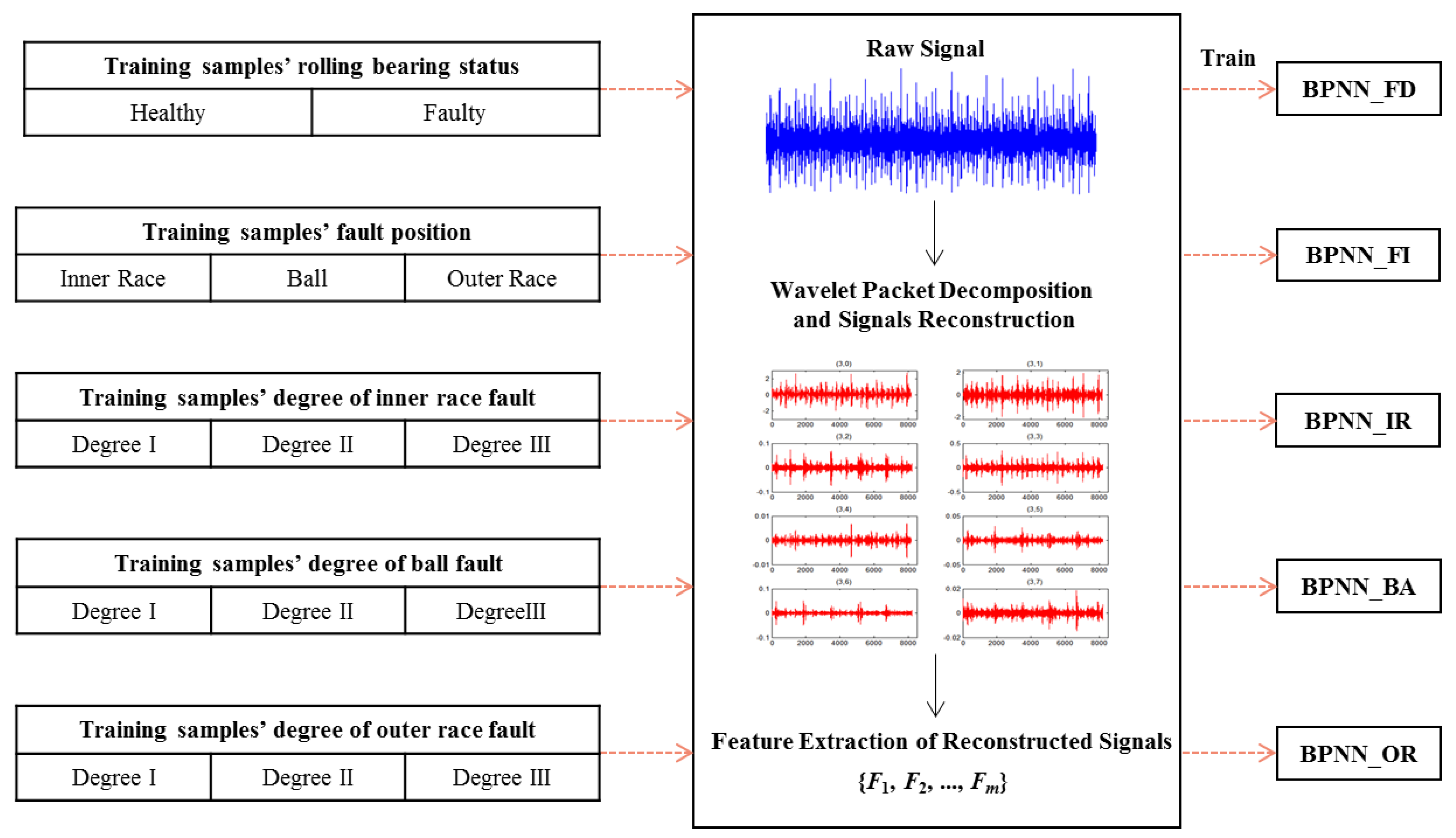

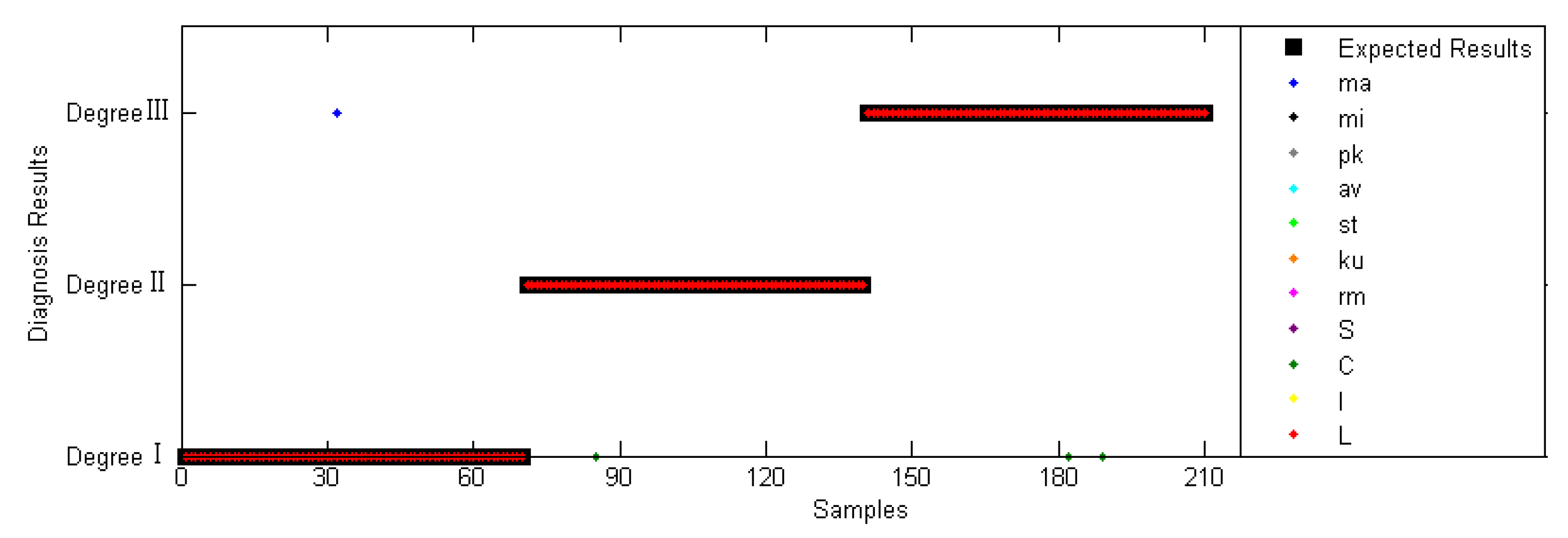

(1) Training Stage

The training stage of the hierarchical decision fusion fault diagnosis method is shown in

Figure 4.

Step 1: Generate training samples.

According to the hierarchical fault diagnosis architecture, five kinds of training samples are designed, including a bearing state training sample, fault position training sample, inner race fault degree training sample, ball fault degree training sample and an outer race fault degree training sample.

Step 2: Wavelet packet decomposition.

Selecting the appropriate wavelet basis and the number of decomposition layers, each kind of sample data is decomposed into a wavelet packet, and the raw signal is decomposed into a series of reconstructed signals with equal bandwidth.

Step 3: Feature extraction.

There are m features extracted from the wavelet packet reconstruction signal, and the feature set F = {F1, F2,…, Fm} is obtained. The dimension of the feature subset Fj (j = 1, 2, …, m) depends on the number of decomposition layers n by the wavelet packet. In this paper, all the training samples are decomposed by three-layer wavelet packets. Hence, s = 8, and the feature subset can be described as Fj = {Fj1, Fj2, …, Fj8}T.

Step 4: Normalization.

Because neurons are highly sensitive to numbers in the range of [−1, 1], the bearing feature data cannot be directly input into the BPNN, so it is necessary to normalize the feature set. The min–max normalization method is used in this paper.

where

u and

are the original data of the feature set and the normalized data, respectively.

umax is the maximum value in the original feature set, and

umin is the minimum value in the original feature set. Here,

u represents the feature value

Fjs and

represents the normalized eigenvalue

Xjs.

Step 5: Train BPNNs.

Using the training process detailed in

Section 2.2, 5 kinds of training samples are studied, including the bearing state training sample, the fault position training sample, the inner race fault degree training sample, the ball fault degree training sample and the outer race fault degree training sample. A hierarchical decision fusion network of rolling bearings is established capable of fault detection, isolation and fault degree estimation.

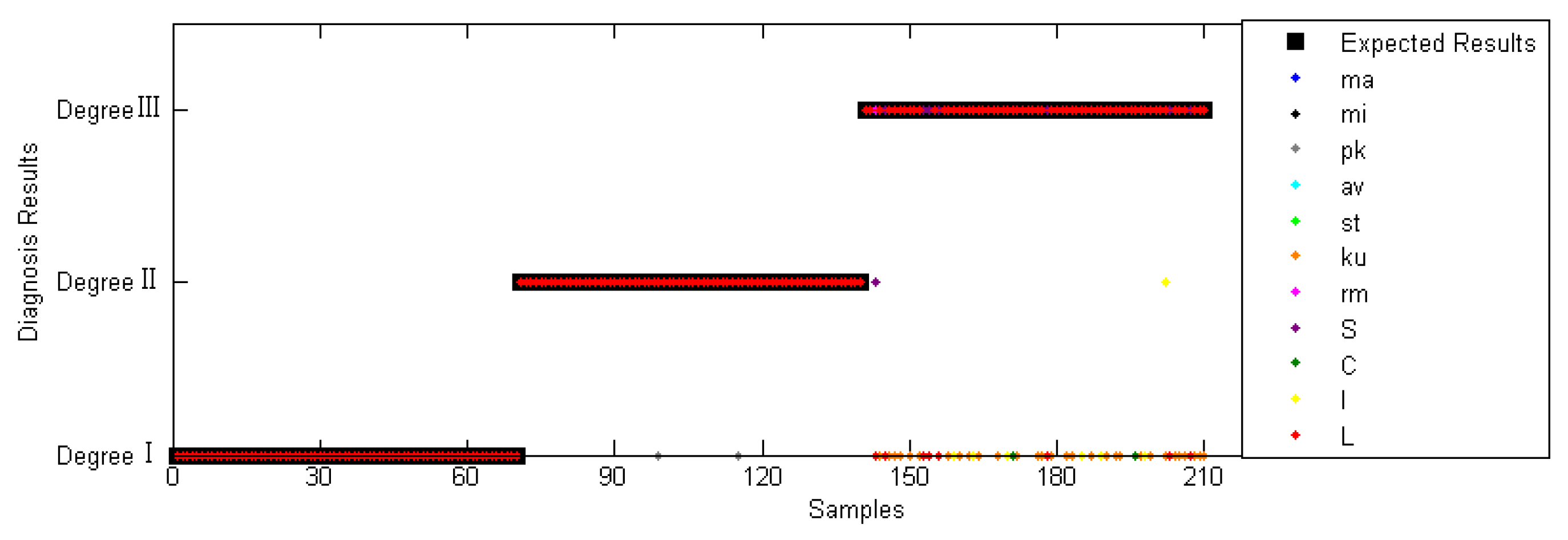

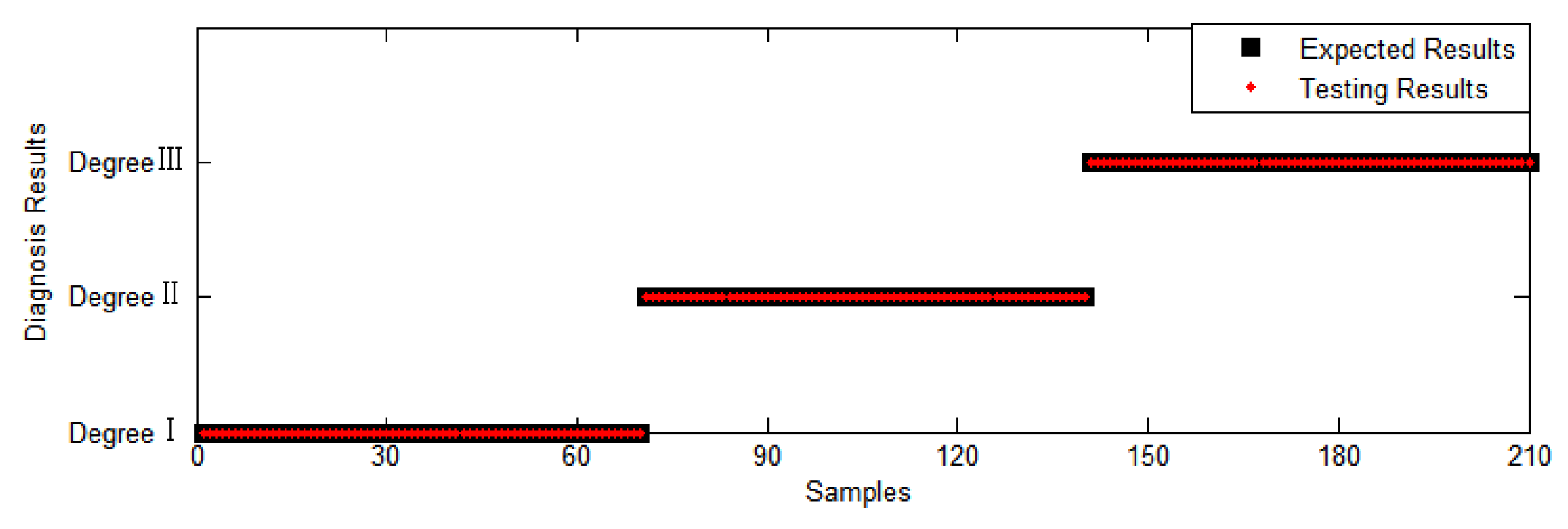

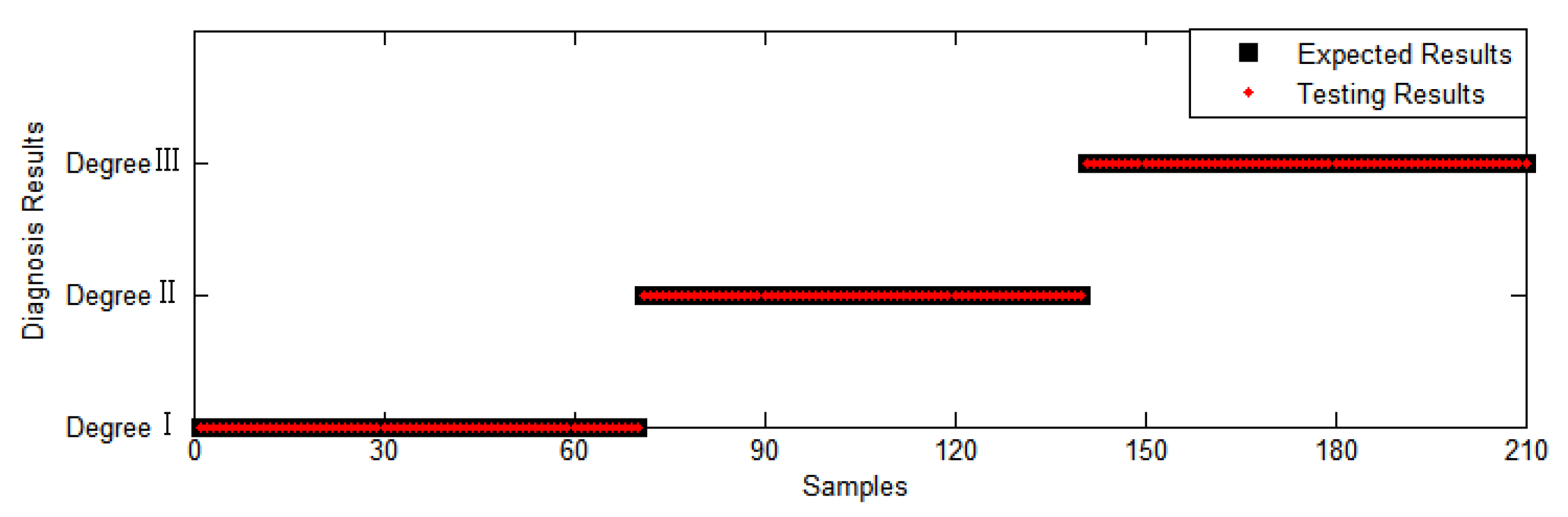

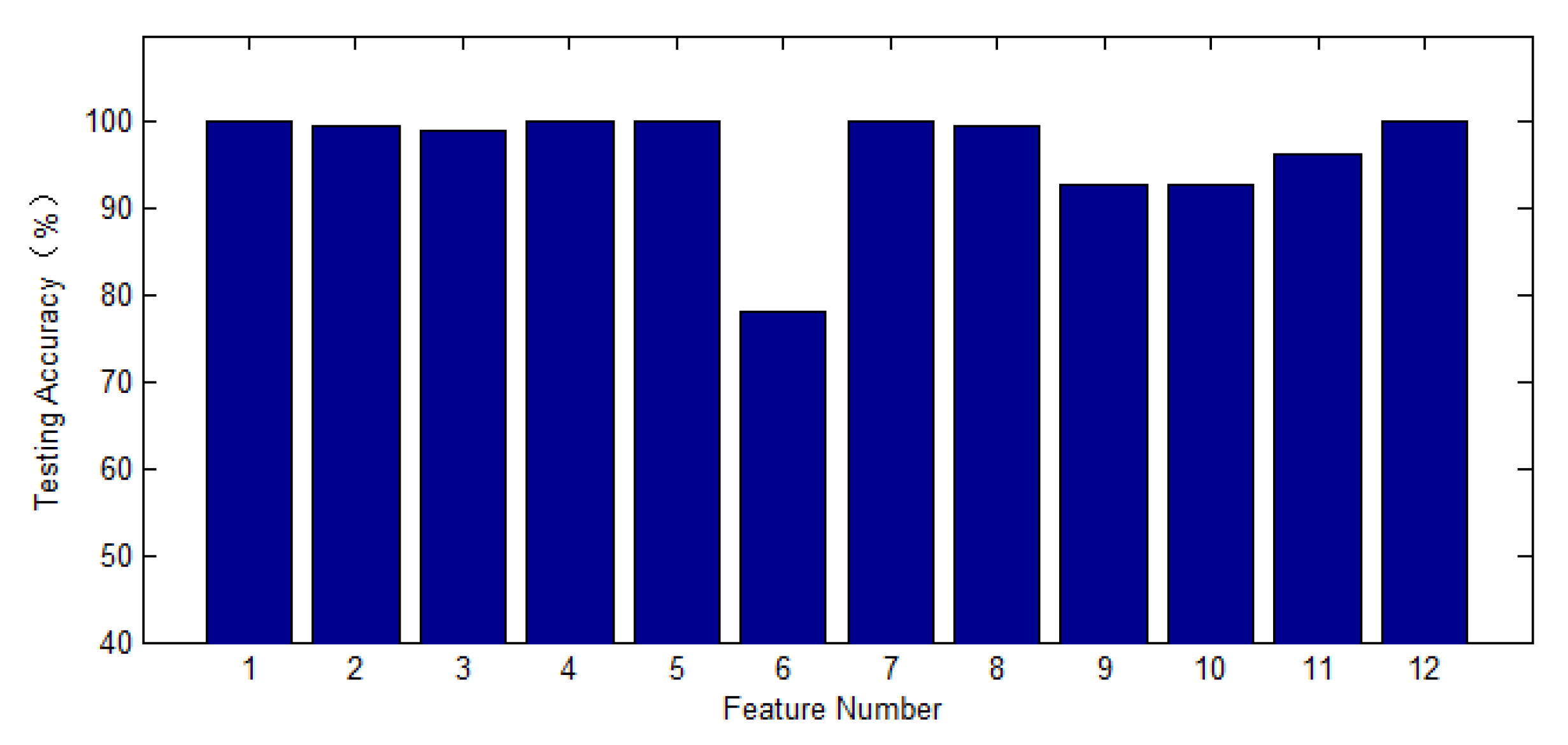

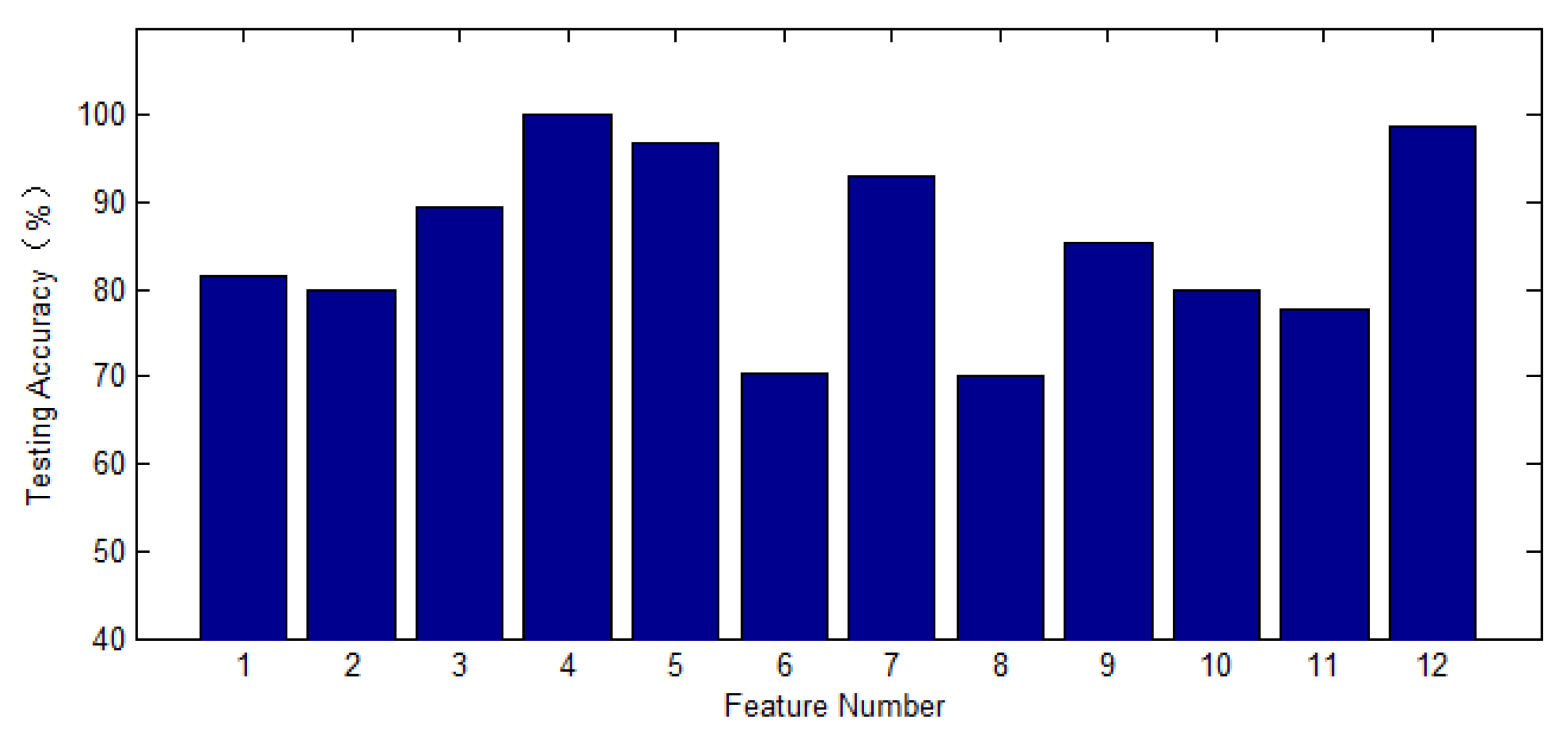

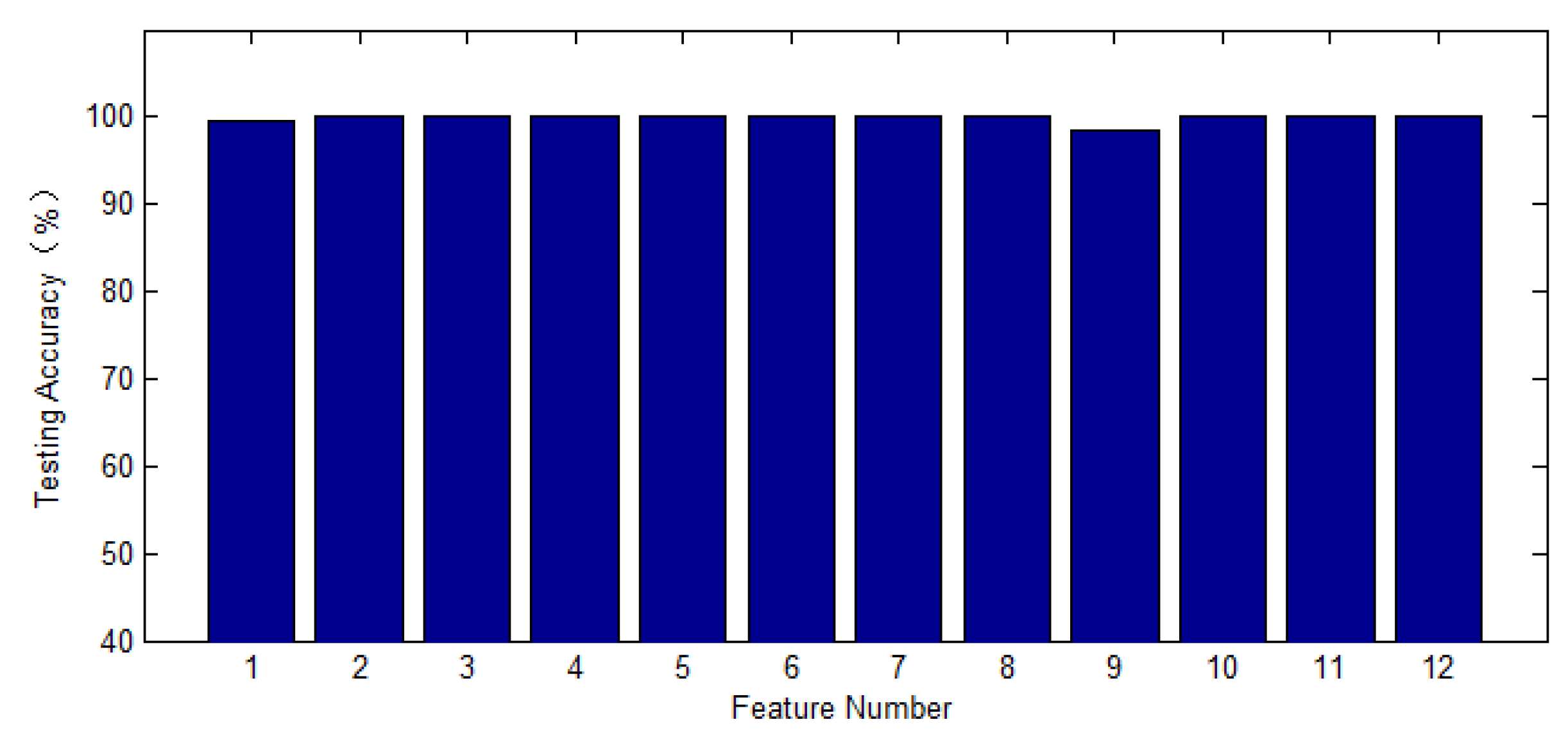

(2) Diagnosis Stage

In the application stage, the flow of the hierarchical decision fusion fault diagnosis method is shown in

Figure 5.

Step 1: Database collection and feature extraction

The vibration signals of the rolling bearing are collected in real time. N samples of the same length are randomly sampled from the raw vibration signal. Wavelet packet decomposition and signal reconstruction of data samples are carried out to extract m kinds of features of reconstructed signals and form feature vectors [F1, F2, …, Fm]. Finally, the feature vector is normalized.

Step 2: Fault detection

m normalized feature vectors are input into m fault detection neural networks (BPNN_FD), and the current state of the bearing is judged by decision fusion. Step 2 and Step 3 are entered into only when the bearing is in a faulty state. Because most of the bearings are in the normal state during use, such a processing method will reduce the operational burden of the algorithm.

Step 3: Fault isolation

When a bearing is detected as being in a faulty state, m normalized feature vectors are input into m fault isolation neural networks (BPNN_FI). After decision fusion, it can be determined whether the bearing fault has occurred in the inner race, ball or outer race.

Step 4: Fault severity estimation

After identifying the location where the bearing fault has occurred, m normalized feature vectors are input to m fault severity estimation neural networks corresponding to the fault location. After decision fusion, the severity of the fault location (degree I, degree II, degree III) is determined. In this paper, there are 11 inner race fault severity estimation neural networks (BPNN_IR), 11 ball fault severity estimation neural networks (BPNN_BA) and 11 outer race fault severity estimation neural networks (BPNN_OR).