Effects of Crop Protection Unmanned Aerial System Flight Speed, Height on Effective Spraying Width, Droplet Deposition and Penetration Rate, and Control Effect Analysis on Wheat Aphids, Powdery Mildew, and Head Blight

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Site, Wheat Characteristics, and Weather Conditions

2.2. CPUAS and Experimental Materials

2.3. Experimental Treatments

2.3.1. Experiment Design

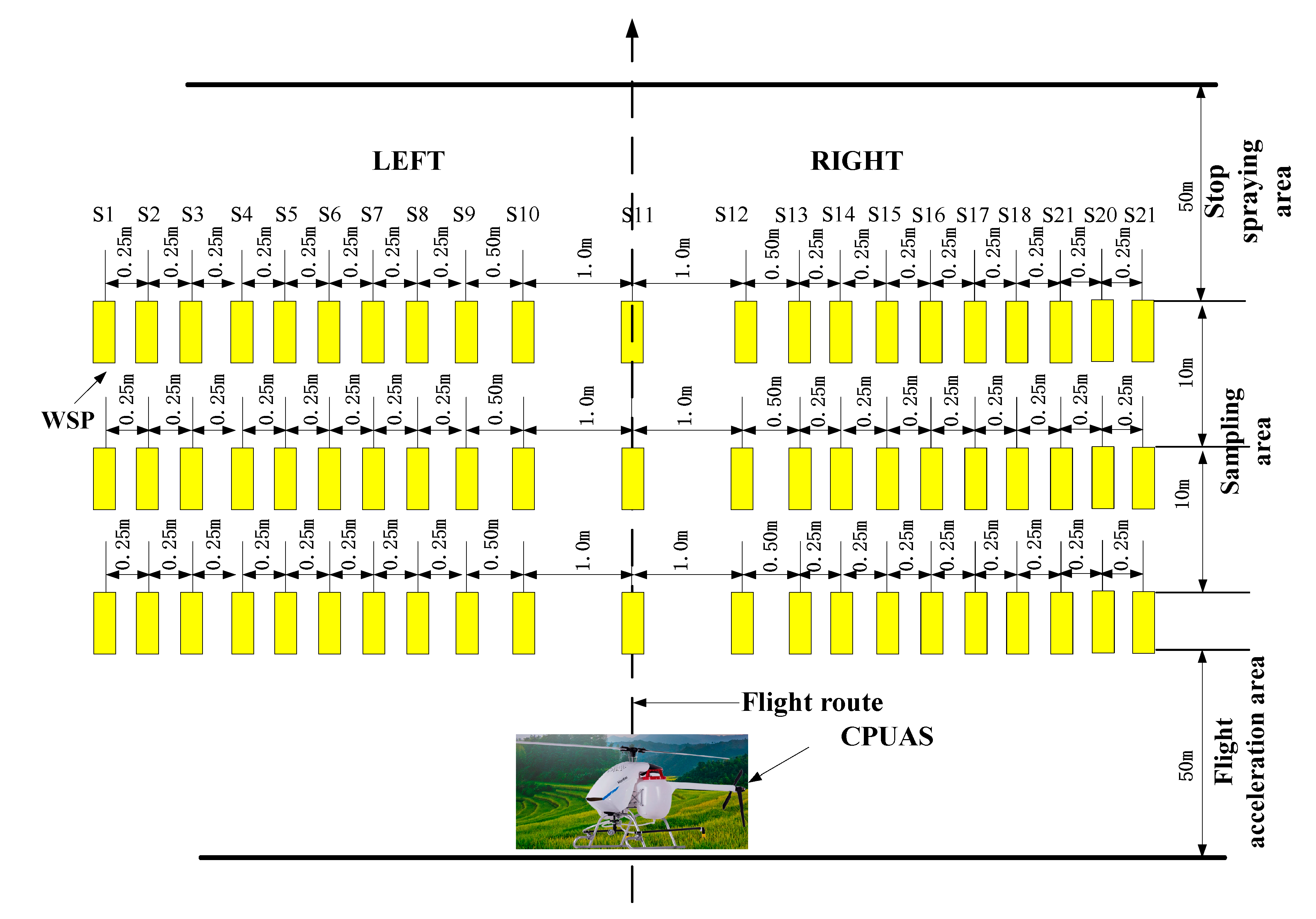

2.3.2. Sampling Point Arrangements

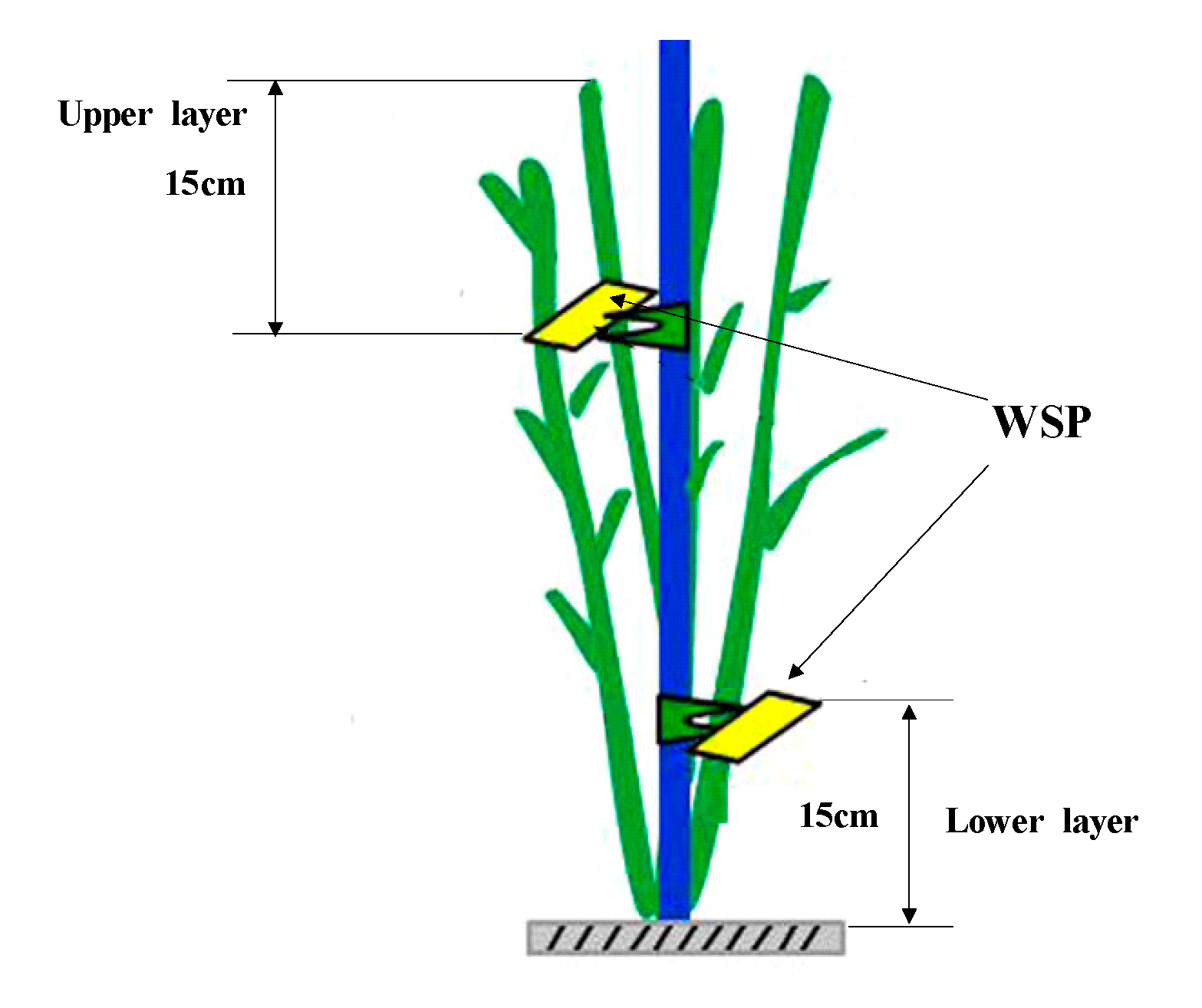

2.4. Evaluation Method of ESW and Droplet Deposition

2.5. Control Effect Survey of Aphids, Powdery Mildew, and Head Blight

3. Results

3.1. Test Data Statistics

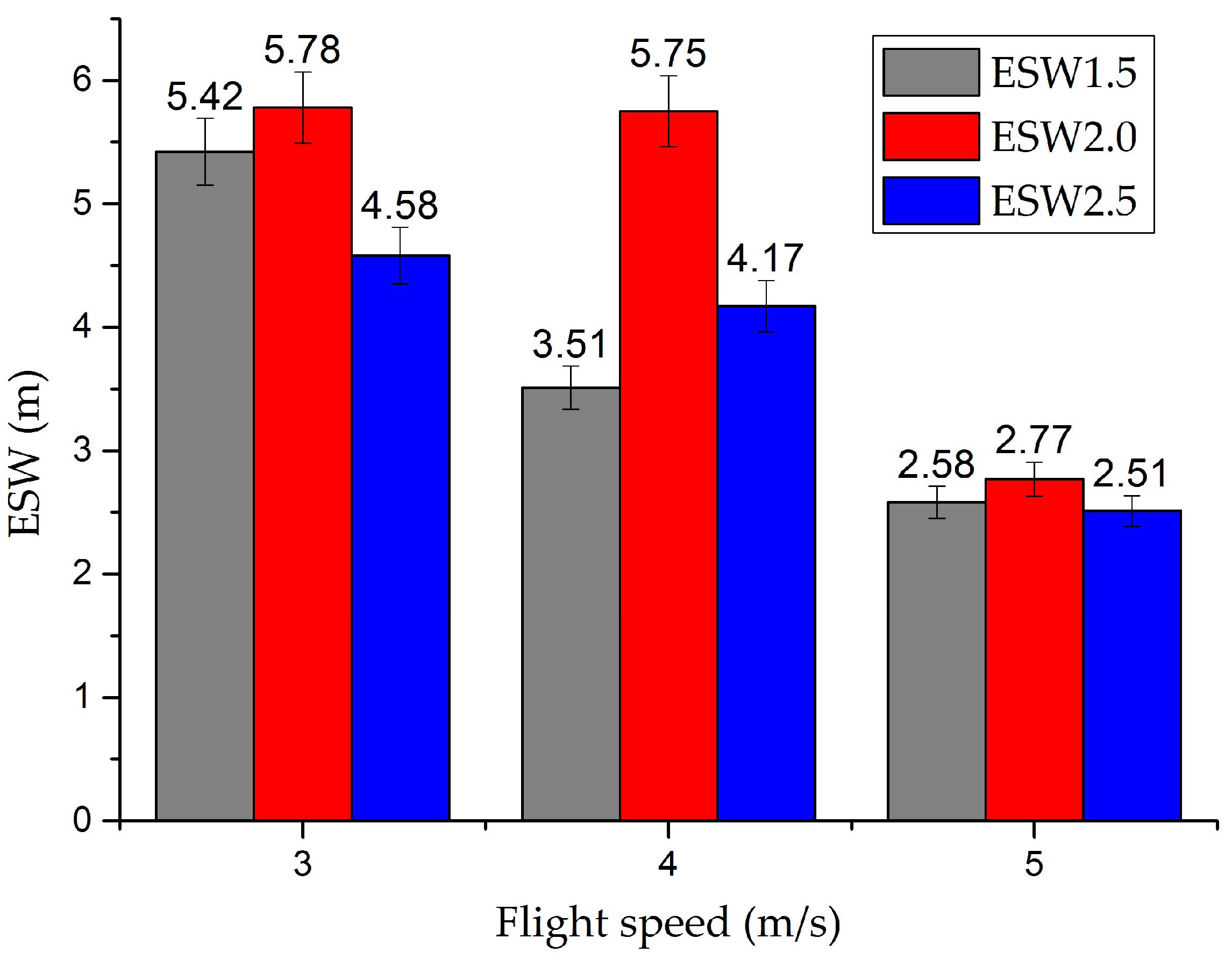

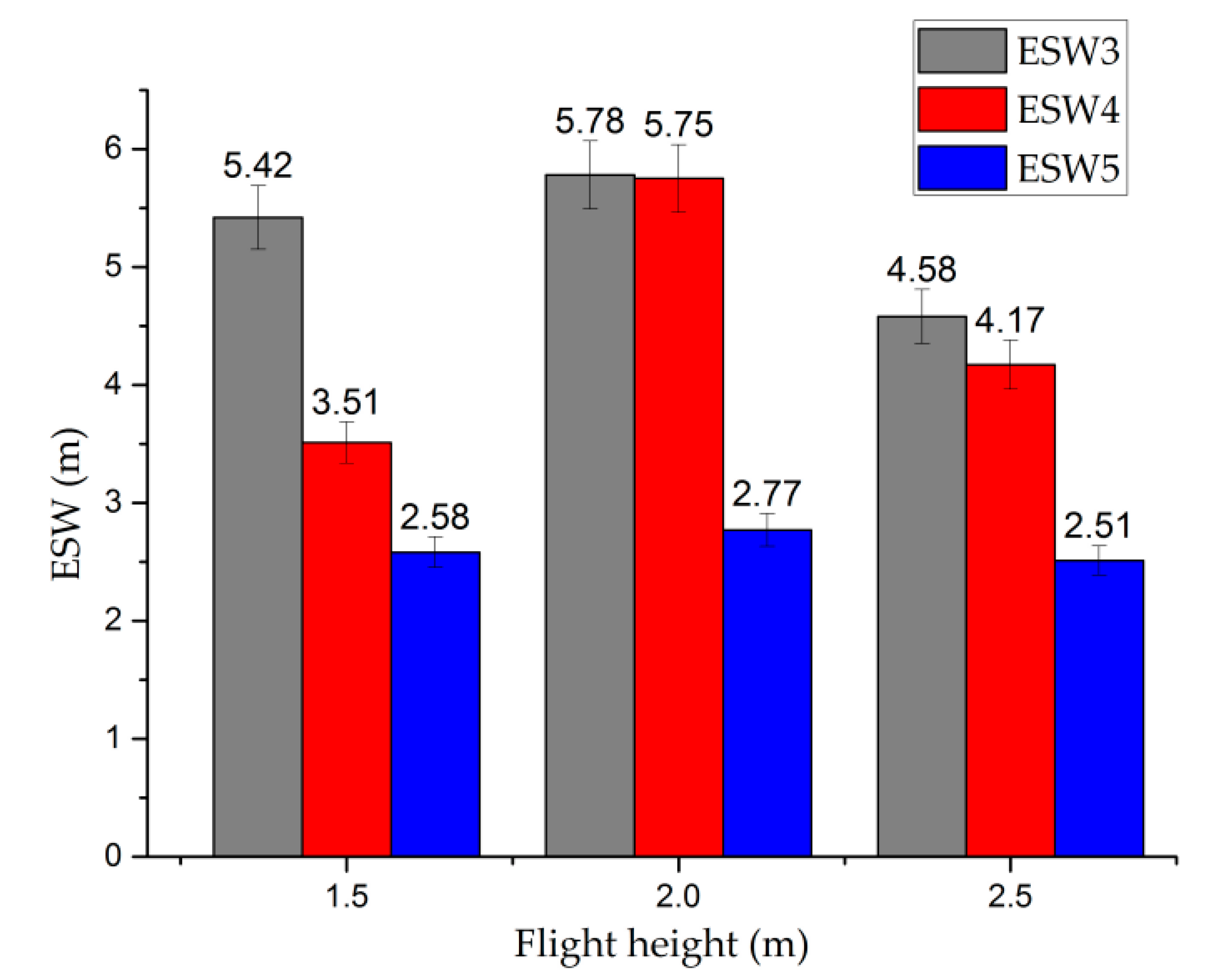

3.2. The ESW Analyses

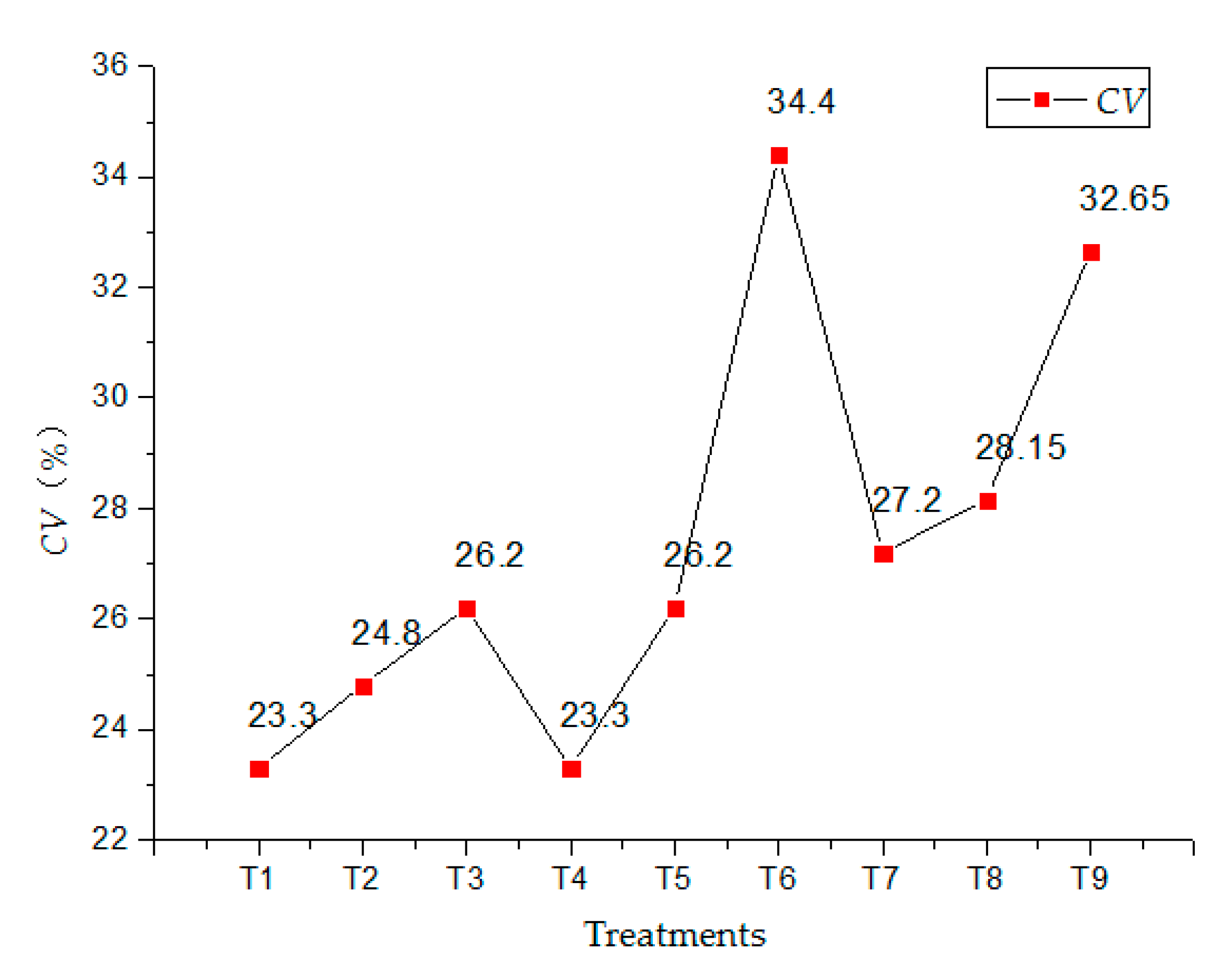

3.3. The Deposition Uniformity Analyses

3.4. The DPR Analyses

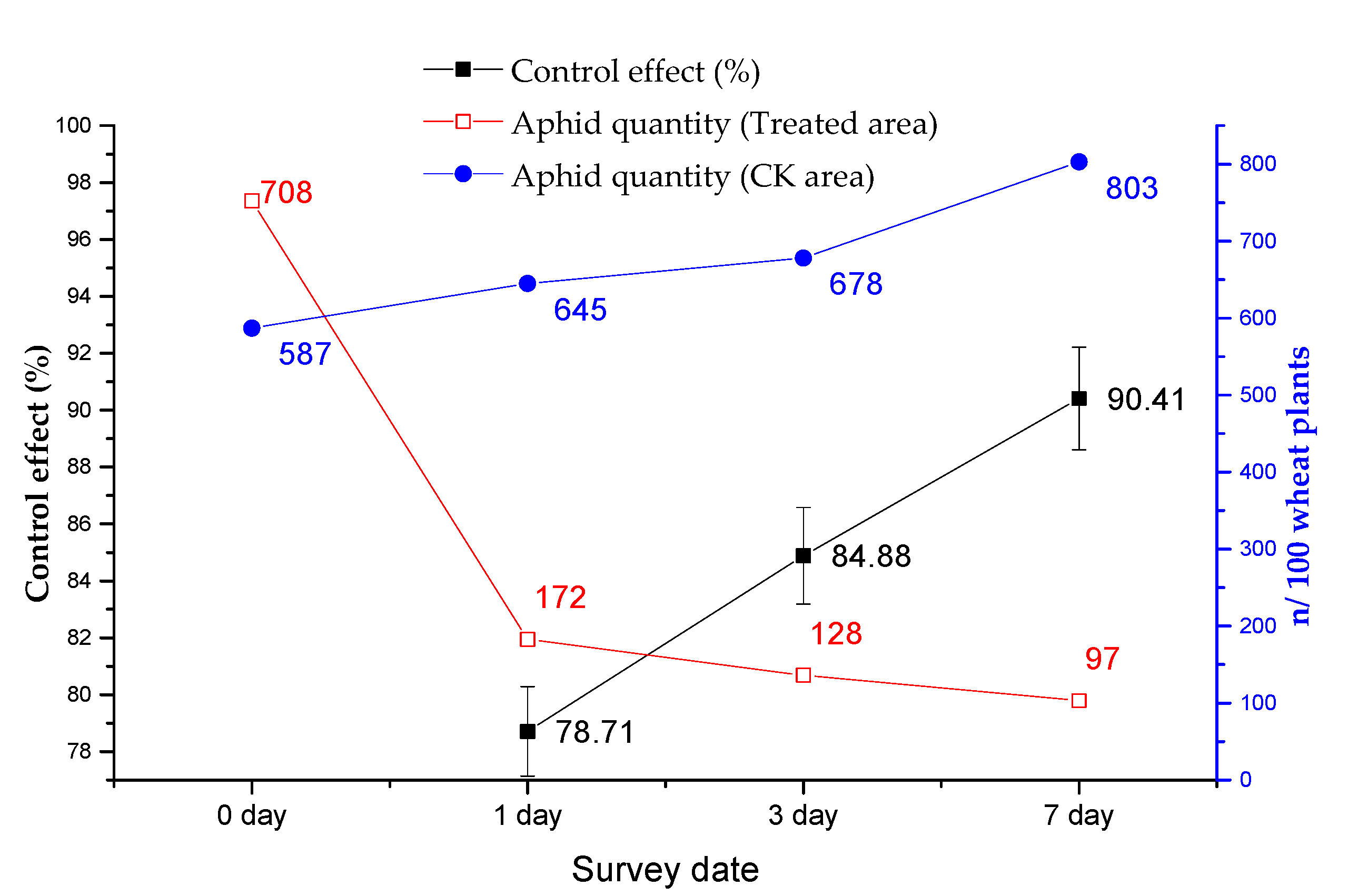

3.5. The Control Effect Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Q.; Fan, J.; Sun, J.; Zhang, Y.; Chen, J. Anti-plant defense response strategies mediated by the secondary symbiont hamiltonella defensa in the wheat aphid sitobion miscanthi. Front. Microbiol. 2019, 10, 2419. [Google Scholar] [CrossRef]

- Li, Y.; Li, Z.; Zhao, L.; Hu, Z.; Zhao, H. Development of a wheat aphid population dynamics model based on cusp catastrophe theory. Int. J. Biomath. 2020, 2050078. [Google Scholar] [CrossRef]

- Li, T. Research progress of wheat powdery mildew forecasting method. Meteor. Environ. Sci. 2013, 36, 44–48. (In Chinese) [Google Scholar]

- Zou, Y.; Qiao, H.; Cao, X.; Liu, W.; Fan, J.; Song, Y. Regionalization of wheat powdery mildew oversummering in China based on digital elevation. J. Integr. Agric. 2018, 17, 901–910. [Google Scholar] [CrossRef]

- Huang, C.; Jiang, Y.; Wu, J.; Qiu, K.; Yang, J. Occurrence and characteristics and reason analysis of wheat head blight in 2018 in China. Plant Prot. 2019, 4, 160–163. (In Chinese) [Google Scholar]

- Lan, Y.; Wang, G. Development situation and prospects of China’s crop protection UAV industry. Agric. Eng. Technol. 2018, 38, 17–27. (In Chinese) [Google Scholar]

- Lan, Y.; Chen, S. Current status and trends of plant protection UAV and its spraying technology in China. Int. J. Precis. Agric. Aviat. 2018, 1, 1–9. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Sun, T.; Gu, W.; Zhang, C.; Peng, B.; Sun, X. Evaluation and comparison of two typical kinds UAAS based on the first industry standard of China. Int. Agric. Eng. J. 2020, 29, 331–340. [Google Scholar]

- He, X.; Bonds, J.; Herbst, A.; Langenakens, J. Recent development of unmanned aerial vehicle for plant protection in East Asia. Int. J. Agric. Biol. Eng. 2017, 10, 18–30. [Google Scholar]

- Yang, F.; Xue, X.; Cai, C.; Sun, Z.; Zhou, Q. Numerical simulation and analysis on spray drift movement of multirotor plant protection unmanned aerial vehicle. Energies 2018, 11, 2399. [Google Scholar] [CrossRef]

- Wang, L.; Lan, Y.; Zhang, Y.; Zhang, H.; Tahir, M.; Ou, S.; Liu, X.; Chen, P. Applications and prospects of agricultural Unmanned aerial vehicle obstacle avoidance technology in China. Sensors 2019, 19, 642. [Google Scholar] [CrossRef] [PubMed]

- Lan, Y.; Chen, S.; Fritz, B.K. Current status and future trends of precision agricultural aviation technologies. Int. J. Agric. Biol. Eng. 2017, 10, 1–17. [Google Scholar]

- Cao, G.; Li, Y.; Nan, F.; Liu, D.; Chen, C.; Zhang, J. Development and analysis of plant protection control system and route planning research. Chin. Soc. Agric. Mach. 2020, 8, 1–16. (In Chinese) [Google Scholar]

- Wang, G.; Han, Y.; Li, X.; Andaloro, J.; Chen, P.; Hoffmann, W.; Han, X.; Chen, S.; Lan, Y. Field evaluation of spray drift and environmental impact using an agricultural unmanned aerial vehicle (UAV) sprayer. Sci. Total Environ. 2020, 737, 139793. [Google Scholar] [CrossRef]

- Al-Heidary, M.; Douzals, J.; Sinfort, C.; Vallet, A. Influence of spray characteristics on potential spray drift of field crop sprayers: A literature review. Crop Prot. 2014, 63, 120–130. [Google Scholar] [CrossRef]

- Qiu, B.; Wang, L.; Cai, D.; Wu, J.; Ding, G.; Guan, X. Effects of flight altitude and speed of unmanned helicopter on spray deposition uniform. Chin. Soc. Agric. Eng. 2013, 29, 25–32. (In Chinese) [Google Scholar]

- Zhang, S.; Qiu, B.; Xue, X.; Sun, T.; Peng, B. Parameters optimization of crop protection UAS based on the first industry standard of China. Int. J. Agric. Biol. Eng. 2020, 13, 29–35. [Google Scholar] [CrossRef]

- Qin, W.; Qiu, B.; Xue, X.; Chen, C.; Xu, Z.; Zhou, Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Xiao, Q.; Du, R.; Yang, L.; Han, X.; Lan, Y. Comparison of droplet deposition control efficacy on phytophthora capsica and aphids in the processing pepper field of the unmanned aerial vehicle and knapsack sprayer. Agronomy 2020, 10, 215. [Google Scholar] [CrossRef]

- Lou, Z.; Xin, F.; Han, X.; Lan, Y.; Fu, W. Effect of unmanned aerial vehicle flight height on droplet distribution, drift and control of cotton aphids and spider mites. Agronomy 2018, 8, 187. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Li, J.; Zhou, Z.; Jin, J.; Liu, A. Effect of spray parameters of small unmanned helicopter on distribution regularity of droplet deposition in hybrid rice canopy. Trans. Chin. Soc. Agric. Eng. 2016, 32, 40–46. (In Chinese) [Google Scholar]

- Wang, C.; Song, J.; He, X.; Wang, Z.; Wang, S.; Meng, Y. Effect of flight parameters on distribution characteristics of pesticide spraying droplets deposition of plant-protection unmanned aerial vehicle. Trans. Chin. Soc. Agric. Eng. 2017, 33, 109–116. (In Chinese) [Google Scholar]

- Wang, G.; Lan, Y.; Qi, H.; Chen, P.; Hewitt, A.; Han, Y. Field evaluation of an unmanned aerial vehicle (UAV) sprayer: Effect of spray volume on deposition and the control of pests and disease in wheat. Pest Manag. Sci. 2019, 75, 1546–1555. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Lan, Y.; Huang, X.; Qi, H.; Wang, G.; Wang, J.; Wang, L.; Xiao, H. Droplet deposition and control of planthoppers of different nozzles in two-stage rice with a quadrotor unmanned aerial vehicle. Agronomy 2020, 10, 303. [Google Scholar] [CrossRef]

- Zhu, H.; Li, H.; Zhang, C.; Li, J.; Zhang, H. Performance Characterization of the UAV Chemical Application Based on CFD Simulation. Agronomy 2019, 9, 308. [Google Scholar] [CrossRef]

- Meng, Y.; Zhou, G.; Wu, C. Discussion on application and promotion of agricultural plant protection unmanned aerial vehicle in China. China Plant Prot. 2014, 34, 33–39. [Google Scholar]

- Shang, C.Y.; Cai, J.F.; Huang, S.J.; Pan, H.L.; Zhong, F.L. Applications status and prospect analysis of agricultural UAVs in China. J. Anhui Agric. Sci. 2017, 45, 193–195. [Google Scholar]

- Xue, X.; Lan, Y.; Sun, Z.; Chang, C.; Hoffmann, W. Develop an unmanned aerial vehicle based automatic aerial spraying system. Comput. Electron. Agric. 2016, 128, 58–66. [Google Scholar] [CrossRef]

- Zhu, H.; Salyani, M.; Fox, R. A portable scanning system for evaluation of spray deposit distribution. Comput. Electron. Agric. 2011, 76, 38–43. [Google Scholar] [CrossRef]

- NY/T 3213-2018. Chinese Standard: Technical Specification of Quality Evaluation for Crop Protection UAS; The Ministry of Agriculture and Rural Affairs of the People’s Republic of China: Beijing, China, 2018. (In Chinese)

- Smith, D. Uniformity and recovery of broadcast spray using fan nozzles. Trans. ASAE 1992, 35, 39–44. [Google Scholar] [CrossRef]

- NY/T 612-2002. Rules for Investigation and Forecast of Wheat Aphides; The Ministry of Agriculture and Rural Affairs of the People’s Republic of China: Beijing, China, 2002. (In Chinese)

- Yuan, W.; Xu, B.; Ran, G.C.; Chen, H.P.; Zhao, P.Y.; Huang, Q.L. Application of imidacloprid controlled-release granules to enhance the utilization rate and control wheat aphid on winter wheat. J. Integr. Agric. 2020, 19, 3045–3053. [Google Scholar] [CrossRef]

- Wang, G.; Lan, Y.; Yuan, H.; Qi, H.; Chen, P.; Ouyang, F.; Han, Y. Comparison of spray deposition, control efficacy on wheat aphids and working efficiency in the wheat field of the unmanned aerial vehicle with boom sprayer and two conventional knapsack sprayers. Appl. Sci. 2019, 9, 218. [Google Scholar] [CrossRef]

- NY/T 613-2002. Rules for Investigation and Forecast of Wheat Powdery Mildew [Blumeria Graminis (DC.) Speer]; The Ministry of Agriculture and Rual Affairs of the People’s Republic of China: Beijing, China, 2002. (In Chinese)

- Qin, W.; Xue, X.; Zhang, S.; Gu, W.; Wang, B. Droplet deposition and efficiency of fungicides sprayed with small uav against wheat powdery mildew. Int. J. Agric. Biol. Eng. 2018, 11, 27–32. [Google Scholar] [CrossRef]

- GB/T 15796-2011. Rules for Monitoring and Forecast of the Wheat Head Blight (Fusarium Graminearum Schw./Gibberella Zeae(Schw.) Petch); General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, National Standardization Administration of China: Beijing, China, 2011. (In Chinese)

- Yobo, K.; Mngadi, Z.; Laing, M. Efficacy of two potassium silicate formulations and two trichoderma strains on fusarium head blight of wheat. Proc. Natl. Acad. Sci. India. B 2019, 89, 185–190. [Google Scholar] [CrossRef]

- Ma, Z. Researches and control of wheat stripe rust in China. J. Plant. Protect. 2018, 45, 1–6. (In Chinese) [Google Scholar]

- Cao, S.; Luo, H.; Jin, M.; Jin, S.; Duan, X.; Zhou, Y. Intercropping influenced the occurrence of stripe rust and powdery mildew in wheat. Crop Prot. 2015, 70, 40–46. [Google Scholar] [CrossRef]

- Dweba, C.; Figlan, S.; Shimelis, H.; Motaung, T.; Sydenham, S.; Mwadzingeni, L. Fusarium head blight of wheat: Pathogenesis and control strategies. Crop Prot. 2017, 91, 114–122. [Google Scholar] [CrossRef]

- Meng, Y.; Su, J.; Song, J.; Chen, W.; Lan, Y. Experimental evaluation of uav spraying for peach trees of different shapes: Effects of operational parameters on droplet distribution. Comput. Electron. Agric. 2020, 170, 105282. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Li, J.; Zhou, Z.; Liu, A.; Mao, Y. Effect of wind field below unmanned helicopter on droplet deposition distribution of aerial spraying. Int. J. Agric. Biol. Eng. 2017, 10, 67–77. [Google Scholar]

- Li, J.; Shi, Y.; Lan, Y.; Guo, S. Vertical distribution and vortex structure of rotor wind field under the influence of rice canopy. Comput. Electron. Agric. 2019, 159, 140–146. [Google Scholar] [CrossRef]

| Test Time | Growth Period | Mean Height | Mean Leaf Area Index | Mean Wind Speed | Mean Temperature | Mean Relative Humidity |

|---|---|---|---|---|---|---|

| 11 March 2019 | Turning green stage | 13.5 cm | 1.05 | 1.2 ± 0.20 m/s | 12.6 ± 0.30 °C | 65.2 ± 1.55% |

| 14 April 2019 | Heading stage | 51.4 cm | 4.35 | 0.8 ± 0.15 m/s | 22.3 ± 0.40 °C | 45.6 ± 0.15% |

| 16 May 2019 | Blooming stage | 68.7 cm | 5.47 | 1.4 ± 0.25 m/s | 28.6 ± 0.20 °C | 52.8 ± 0.76% |

| Items | Parameters |

|---|---|

| UAAS size | 1880 mm × 618 mm × 758 mm |

| Rotor diameter | 2388 mm |

| Battery capacity | 28,000 mAh × 2 |

| Boom length | 1442 mm |

| Maximum load | 20 L |

| Number of nozzles | 2 |

| Type of nozzles | Hydraulic |

| Arrangement of nozzles | 800 mm on both sides of the fuselage |

| Spraying volume | 2.0 L/min |

| Spraying width | 3–5 m |

| Treatments | FS | FH | Spraying Volume |

|---|---|---|---|

| T1 | 3.0 m/s | 1.5 m | 2.0 L/min |

| T2 | 3.0 m/s | 2.0 m | 2.0 L/min |

| T3 | 3.0 m/s | 2.5 m | 2.0 L/min |

| T4 | 4.0 m/s | 1.5 m | 2.0 L/min |

| T5 | 4.0 m/s | 2.0 m | 2.0 L/min |

| T6 | 4.0 m/s | 2.5 m | 2.0 L/min |

| T7 | 5.0 m/s | 1.5 m | 2.0 L/min |

| T8 | 5.0 m/s | 2.0 m | 2.0 L/min |

| T9 | 5.0 m/s | 2.5 m | 2.0 L/min |

| Spraying Date | Pest and Disease | Pesticides and Dosage |

|---|---|---|

| 12 March 2019 | Aphids | Abamectin cypermethrin, Emulsion, 4.50 g a.i./ha |

| 15 April 2019 | Powdery mildew | Phenamacril, Suspension concentrate, 375 g a.i./ha Epoxiconazole, Suspension concentrate (SC), 15.75 g a.i./ha |

| 17 May 2019 | Head blight | Tebuconazole and Prochloraz, Emulsion in Water (EW), 202.5 g a.i./ha Phenamacril, Suspension concentrate (SC), 375 g a.i./ha |

| Treatment Number | ESW | CV |

|---|---|---|

| T1 | 5.42 m | 23.30% |

| T2 | 5.78 m | 24.80% |

| T3 | 4.58 m | 26.20% |

| T4 | 3.51 m | 23.30% |

| T5 | 5.75 m | 26.20% |

| T6 | 4.17 m | 34.40% |

| T7 | 2.58 m | 27.20% |

| T8 | 2.77 m | 28.15% |

| T9 | 2.51 m | 32.65% |

| Source of Variance | df | F | p-Value | Significance |

|---|---|---|---|---|

| FS | 2 | 2.23 | 0.0033 | ** 1 |

| FH | 2 | 12.93 | 0.136 | NS 2 |

| FS × FH | 4 | 0.91 | 0.906 | NS |

| Source of Variance | df | F | p-Value | Significance |

|---|---|---|---|---|

| FS | 2 | 2.23 | 0.827 | NS 1 |

| FH | 2 | 12.93 | 0.019 | * 2 |

| FS × FH | 4 | 0.91 | 0.032 | * |

| Disease | Period | Date | Control Effect |

|---|---|---|---|

| Powdery mildew | Heading stage | 7 d | 77.17 ± 1.15% |

| 14 d | 82.83 ± 2.98% | ||

| Head blight | Blooming stage | 20 d | 88.32 ± 1.50% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Qiu, B.; Xue, X.; Sun, T.; Gu, W.; Zhou, F.; Sun, X. Effects of Crop Protection Unmanned Aerial System Flight Speed, Height on Effective Spraying Width, Droplet Deposition and Penetration Rate, and Control Effect Analysis on Wheat Aphids, Powdery Mildew, and Head Blight. Appl. Sci. 2021, 11, 712. https://doi.org/10.3390/app11020712

Zhang S, Qiu B, Xue X, Sun T, Gu W, Zhou F, Sun X. Effects of Crop Protection Unmanned Aerial System Flight Speed, Height on Effective Spraying Width, Droplet Deposition and Penetration Rate, and Control Effect Analysis on Wheat Aphids, Powdery Mildew, and Head Blight. Applied Sciences. 2021; 11(2):712. https://doi.org/10.3390/app11020712

Chicago/Turabian StyleZhang, Songchao, Baijing Qiu, Xinyu Xue, Tao Sun, Wei Gu, Fuliang Zhou, and Xiangdong Sun. 2021. "Effects of Crop Protection Unmanned Aerial System Flight Speed, Height on Effective Spraying Width, Droplet Deposition and Penetration Rate, and Control Effect Analysis on Wheat Aphids, Powdery Mildew, and Head Blight" Applied Sciences 11, no. 2: 712. https://doi.org/10.3390/app11020712

APA StyleZhang, S., Qiu, B., Xue, X., Sun, T., Gu, W., Zhou, F., & Sun, X. (2021). Effects of Crop Protection Unmanned Aerial System Flight Speed, Height on Effective Spraying Width, Droplet Deposition and Penetration Rate, and Control Effect Analysis on Wheat Aphids, Powdery Mildew, and Head Blight. Applied Sciences, 11(2), 712. https://doi.org/10.3390/app11020712