The Effect of Different Frying Methods and the Addition of Potassium Aluminum Sulfate on Sensory Properties, Acrylamide, and Oil Content of Fried Bread (Youtiao)

Abstract

1. Introduction

2. Materials and Methods

2.1. Youtiao Preparation

2.2. Method for Extracting and Measuring Reducing Sugar and Acrylamide in Fried Bread Youtiao

2.3. Sensory Evaluation

2.4. Statistical Analysis

3. Results and Discussion

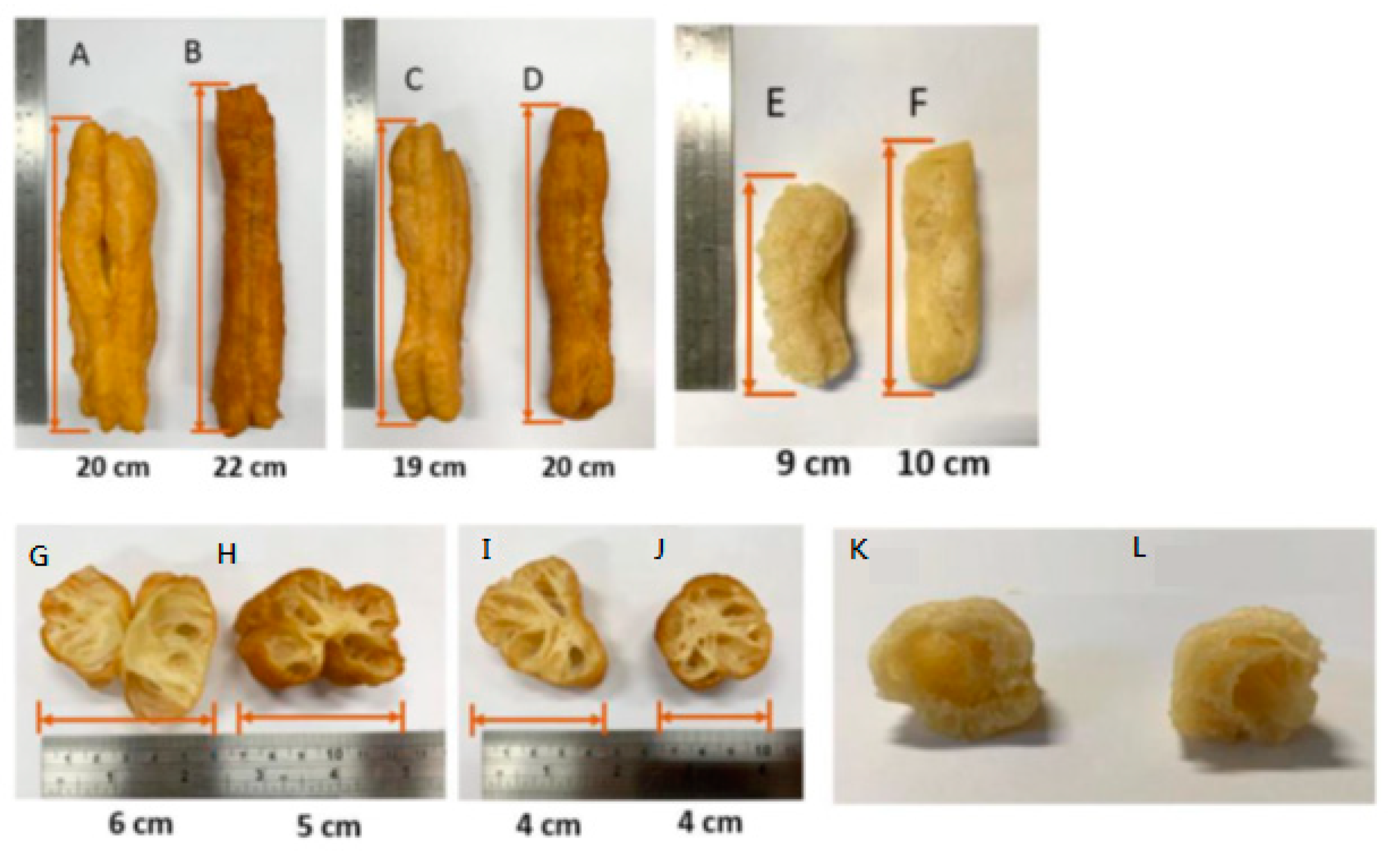

Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Wu, S.; Zeng, J.; Wang, L.; Yu, W. Effect of frying and aluminum on the levels and migration of parent and oxygenate PAHs in a popular Chinese fried bread youtiao. Food Chem. 2016, 209, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Zhao, X.; Wu, S.; Hua, H.; Wang, Q.; Zhang, Z. Dietary exposure to aluminum in the popular Chinese fried bread youtiao. Food Addit. Contam. Part A 2017, 34, 972–979. [Google Scholar] [CrossRef] [PubMed]

- Costello, S.; Eisen, E.A.; Brown, D.; Hammond, S.K.; Cullen, M. Incident ischemic heart disease and occupational exposure to particulate matter in aluminum manufacturing workers. Am. J. Epidmiol. 2012, 175, S139. [Google Scholar] [CrossRef]

- Di Paolo, C.; Reverte, I.; Colomina, M.T.; Domingo, J.I.; Gomez, M. Chronic exposure to aluminum and melatonin through the diet: Neurobehavioral effects in a transgenic mouse model of Alzheimer disease. Food Chem. Toxicol. 2014, 69, 320–329. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Hu, C.; Zhu, Y.; Sun, H.; Li, Y.; Zhang, Z. Effects of aluminum exposure on bone mineral density, mineral, and trace elements in rats. Biol. Trace Elem. Res. 2011, 143, 378–385. [Google Scholar] [CrossRef]

- Malloux, R.J.; Lemire, J.; Appanna, V.D. Hepatic response to aluminum toxicity: Dyslipidemia and liver diseases. Exp. Cell Res. 2011, 317, 2231–2238. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; Liu, D.W.; Liu, Z.Y.; Ki, Y.F. Impact of aluminum exposure on the immune system: A mini review. Environ. Toxicol. Pharmacol. 2013, 35, 82–87. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; Sun, H.; Fu, Y.; Wang, J.; Song, M.; Li, M.; Li, Y.F.; Miao, L.G. Effects of subchronic aluminum chloride on spermatogenesis and testicular enzymatic activity in male rats. Life Sci. 2014, 102, 36–40. [Google Scholar] [CrossRef]

- Lineback, D.R.; Coughlin, J.R.; Stadler, R.H. Acrylamide in Foods: A review of the science and future considerations. Annu. Rev. Food Sci. Technol. 2012, 3, 15–35. [Google Scholar] [CrossRef]

- Amrein, T.M.; Schonbachler, B.; Escher, F.; Amado, R. Acrylamide in gingerbread: Critical factors for formation and possible ways for reduction. J. Agric. Food Chem. 2004, 52, 4282–4288. [Google Scholar] [CrossRef]

- Baardseth, P.; Blom, H.; Skrede, G.; Mydland, L.T.; Skrede, A.; Slinde, E. Lactic acid fermentation reduces acrylamide formation and other Maillard reactions in French fries. J. Food Sci. 2006, 71, C28–C33. [Google Scholar] [CrossRef]

- Biedermann, M.; Grob, K. Model studies on acrylamide formaition in potato, wheat flour and corn starch; ways to reduce acrylamide contents in bakery ware. Mitt. Lebensm. Hyg. 2003, 94, 406–422. [Google Scholar]

- Brathen, E.; Kita, A.; Knutsen, S.H.; Wicklund, T. Addition of glycine reduces the content of acrylamide in cereal and potato products. J. Agric. Food Chem. 2005, 53, 3259–3264. [Google Scholar] [CrossRef] [PubMed]

- Fiselier, K.; Grob, K. Legal limit for reducing sugars in prefabricates targeting 50 g/kg acrylamide in French fries. Eur. Food Res. Technol. 2005, 220, 451–458. [Google Scholar] [CrossRef]

- Granda, C.; Moreira, R.G.; Tichy, S.E. Reduction of acrylamide formation in potato chips by low-temperature vacuum frying. J. Food Sci. 2004, 69, E405–E411. [Google Scholar] [CrossRef]

- Jung, M.Y.; Choi, D.S.; Ju, J.W. A novel technique for limitation of acrylamide formation in fried and baked corn chips and in French fries. J. Food Sci. 2003, 68, 1287–1290. [Google Scholar] [CrossRef]

- Levine, R.A.; Smith, R.E. Sources of variability of acrylamide levels in cracker model. J. Agric. Food Chem. 2005, 53, 4410–4416. [Google Scholar] [CrossRef]

- Pedreschi, F.; Kaack, K.; Granby, K. The effect of asparaginase on acrylamide formation in French fries. Food Chem. 2008, 109, 386–392. [Google Scholar] [CrossRef]

- Chang, Y.W.; Zeng, X.Y.; Sung, W.C. Effect of chitooligosaccharide and different low molecular weight chitosans on the formation of acrylamide and 5-hydroxymethylfurfural and Maillard reaction products in glucose/fructose-asparagine medel systems. LWT-Food Sci. Technol. 2020, 119, 108879. [Google Scholar] [CrossRef]

- Huang, W.; Yu, S.; Zou, Q.; Tilley, R. Effects of frying condtions and yeast fermentation on the acrylamide content in you-tiao, a traditional Chinese, fried, twisted dough-roll. Food Res. Int. 2008, 41, 918–923. [Google Scholar] [CrossRef]

- Sayon-Orea, C.; Bes-Rastrollo, M.; Basterra-Gortari, F.J.; Beunza, J.J.; Gatallar-Gastillon, P.; De la Fuente-Arrillaga, C.; Martinez-Gonzalez, M.A. Consumption of fried foods and weight gain in Mediterranean cohort: The SUN project. Nutr. Metab. Cardiovasc. Dis. 2013, 23, 144–150. [Google Scholar] [CrossRef]

- DENBA Technology. Available online: http://www.denba-global.com/en/ (accessed on 3 January 2021).

- Shyu, S.L.; Hau, L.B.; Hwang, L.S. Effect of vacuum frying on the oxidative stability of oils. J. Am. Oil Chem. Soc. 1998, 75, 1393–1398. [Google Scholar] [CrossRef]

- Andres-Bello, A.; Garcia-Segovia, P.; Martinez-Monzo, J. Vacuum frying: An alternative to obtain high-quality dried products. Food Eng. Rev. 2011, 3, 66–78. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, M.; Zhang, W.; Adhikari, B.; Yang, Z. Application of novel microwave-assisted vacuum frying to reduce the oil uptake and improve the quality of potato chips. LWT-Food Sci. Technol. 2016, 73, 490–497. [Google Scholar] [CrossRef]

- Fang, M.; Huang, G.J.; Sung, W.C. Mass transfer and texture characteristics of fish skin during deep-fat frying, electrostatic frying, air frying and vacuum frying. LWT-Food Sci. Technol. 2021, 137, 110494. Available online: https://www.x-mol.com/paperRedirect/1323384428045766656 (accessed on 2 January 2021). [CrossRef]

- Navarro, M.; Morales, F.J. Effect of hydroxytyrosol and olive leaf extract on 1, 2-dicarbonyl compounds, hydroxymethylfurfural and advanced glycation endproducts in a biscuit model. Food Chem. 2007, 217, 602–609. [Google Scholar] [CrossRef]

- Zoulias, E.I.; Oreopoulou, V.; Kounalaki, E. Effect of fat and sugar replacement on cookie properties. J. Sci. Food Agric. 2002, 82, 1637–1644. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 16th ed.; Sidney, W., Ed.; AOAC: Washington, DC, USA, 1998. [Google Scholar]

- Chen, T.Y.; Luo, H.M.; Hsu, P.H.; Sung, W.C. Effects of calcium supplements on the quality and acrylamide content of puffed shrimp chips. J. Food Drug Anal. 2016, 24, 164–172. [Google Scholar] [CrossRef]

- Ve´lez-Ruiz, J.F.; Sosa-Morales, M.E. Evaluation of physical properties of dough of donuts during deep-fat frying at different temperatures. Int. J. Food Prop. 2003, 2, 341–353. [Google Scholar] [CrossRef]

- Dinc, S.; Javidipour, I.; Ozbas, O.; Tekin, A. Utilization of zero-trans non-interesterified and interesterified shortenings in cookie production. J. Food Sci. Technol. 2014, 51, 365–370. [Google Scholar] [CrossRef]

- James, C.S. Analytical Chemistry of Foods; Chapman and Hall: New York, NY, USA, 1995. [Google Scholar]

- Barber, D.S.; Hunt, J.R.; Ehrich, M.F.; Lehning, E.J.; LoPachin, R.M. Metabolism, toxicokinetics and hemoglobin adduct formation in rats following subacute and subchronic acrylamide dosing. Neurotoxicology 2001, 22, 341–353. [Google Scholar] [CrossRef]

- Chang, Y.W.; Sung, W.C.; Chen, J.Y. Effect of different molecular weight chitosans on the mitigation of acrylamide formation and the functional properties of the resultant Maillard reaction products. Food Chem. 2016, 199, 581–589. [Google Scholar] [CrossRef] [PubMed]

- Martins, S.I.; Van Boekel, M.A. A kinetic model for the glucose/glycine Maillard reaction pathways. Food Chem. 2005, 90, 257–269. [Google Scholar] [CrossRef]

- Pedreschi, F.; Moyano, P.; Kaock, K.; Granby, K. Colour changes and acrylamide formation in fried potato slices. Food Res. Int. 2005, 38, 1–9. [Google Scholar] [CrossRef]

| Treatments | Fat Content ** (%) | Moisture (%) | Water Activity | pH | Specific Volume | Hardness (N) |

|---|---|---|---|---|---|---|

| Control | 13.36 ± 4.05 a | 22.93 ± 4.82 a | 0.87 ± 0.02 a | 6.36 ± 0.08 bc | 4.19 ± 0.58 a | 3.56 ± 1.17 ab |

| TnA | 17.41 ± 4.14 a | 20.85 ± 1.68 a | 0.87 ± 0.02 a | 6.58 ± 0.15 c | 4.98 ± 0.51 b | 2.74 ± 1.64 a |

| EA | 21.26 ± 4.66 ab | 19.71 ± 3.31 a | 0.88 ± 0.03 a | 6.23 ± 0.13 a | 4.16 ± 0.80 a | 4.97 ± 2.36 b |

| EnA | 20.16 ± 3.98 ab | 19.87 ± 1.71 a | 0.89 ± 0.01 a | 6.62 ± 0.06 a | 3.63 ± 0.27 a | 4.27 ± 1.15 ab |

| VA | 20.73 ± 4.64 a | 14.96 ± 13.91 a | 0.33 ± 0.02 b | 5.87 ± 0.0 d | ND | 3.71 ± 1.71 ab |

| VnA | 25.18 ± 0.75 b | 18.12 ± 13.84 a | 0.30 ± 0.04 b | 6.49 ± 0.0 ab | ND | 6.35 ± 3.37 b |

| Treatments | L* | a* | b* | △E | BI |

|---|---|---|---|---|---|

| Control | 75.23 ± 4.88 a | −6.32 ± 2.92 a | 51.72 ± 3.92 a | 0 | 99.37 |

| TnA | 65.63 ± 10.99 a | −2.24 ± 2.22 ab | 51.10 ± 5.58 a | 10.54 | 129.60 |

| EA | 71.53 ± 8.5 a | −6.54 ± 2.68 a | 49.67 ± 4.30 a | 4.24 | 101.62 |

| EnA | 69.81 ± 8.44 a | −4.67 ± 3.10 ab | 49.65 ± 4.27 a | 6.03 | 108.15 |

| VA | 76.59 ± 0.26 a | −7.49 ± 0.04 a | 51.64 ± 0.05 a | 1.80 | 94.02 |

| VnA | 70.61 ± 0.17 a | −5.70 ± 0.04 a | 51.23 ± 0.10 a | 4.69 | 108.22 |

| Treatments | Acrylamide (ppb) | Reducing Sugar (%) |

|---|---|---|

| Control | 421.61 ± 48.63 b | 11.5 ± 1.15 b |

| TnA | 2095.20 ± 133.46 a | 13.99 ± 3.52 ab |

| EA | 667.37 ± 42.98 b | 12.04 ± 1.17 ab |

| EnA | 1147.13 ± 676.84 ab | 11.77 ± 2.21 ab |

| VA | 1084.98 ± 0.0 ab | 13.33 ± 0.0 ab |

| VnA | 1530.26 ± 0.0 ab | 14.52 ± 0.0 a |

| Sample | Sensory Score * | ||||

|---|---|---|---|---|---|

| Color | Texture | Appearance | Flavor | Overall Acceptability | |

| Control | 1.97 ± 0.91 a | 2.34 ± 1.09 a | 2.23 ± 1.24 a | 2.11 ± 1.03 a | 1.92 ± 0.91 a |

| TnA | 3.16 ± 1.0 b | 2.22 ± 1.20 a | 2.92 ± 1.07 b | 2.77 ± 1.18 b | 2.62 ± 1.06 a |

| EA | 1.97 ± 1.02 a | 2.74 ± 1.46 b | 1.93 ± 0.83 a | 2.44 ± 0.94 b | 2.19 ± 1.00 a |

| EnA | 2.9 ± 0.98 b | 2.60 ± 1.02 b | 2.99 ± 0.88 b | 2.71 ± 1.18 b | 3.21 ± 0.99 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shyu, Y.-S.; Hwang, J.-Y.; Shen, S.-T.; Sung, W.-C. The Effect of Different Frying Methods and the Addition of Potassium Aluminum Sulfate on Sensory Properties, Acrylamide, and Oil Content of Fried Bread (Youtiao). Appl. Sci. 2021, 11, 549. https://doi.org/10.3390/app11020549

Shyu Y-S, Hwang J-Y, Shen S-T, Sung W-C. The Effect of Different Frying Methods and the Addition of Potassium Aluminum Sulfate on Sensory Properties, Acrylamide, and Oil Content of Fried Bread (Youtiao). Applied Sciences. 2021; 11(2):549. https://doi.org/10.3390/app11020549

Chicago/Turabian StyleShyu, Yung-Shin, Jean-Yu Hwang, Shih-Ting Shen, and Wen-Chieh Sung. 2021. "The Effect of Different Frying Methods and the Addition of Potassium Aluminum Sulfate on Sensory Properties, Acrylamide, and Oil Content of Fried Bread (Youtiao)" Applied Sciences 11, no. 2: 549. https://doi.org/10.3390/app11020549

APA StyleShyu, Y.-S., Hwang, J.-Y., Shen, S.-T., & Sung, W.-C. (2021). The Effect of Different Frying Methods and the Addition of Potassium Aluminum Sulfate on Sensory Properties, Acrylamide, and Oil Content of Fried Bread (Youtiao). Applied Sciences, 11(2), 549. https://doi.org/10.3390/app11020549