Featured Application

The results of this study could increase the lifetime of tool steels in their specific application.

Abstract

It is desirable to improve tool steel wear resistance to produce pieces with precise dimensions and increase the lifetime of tools. The aim of this work was to modify the surface of 1.2344 (X40CrMoV5-1) hot work tool steel to improve the wear properties. Surface modification was achieved in three steps: first, hardening was applied, followed by plasma nitridation and, finally, physical vapor deposition (PVD) was employed to produce a TiN/AlTiN multilayer coating. The microhardness and the wear coefficient of the surfaces were measured. PVD coating showed the highest hardness value, 2938 HV0.01, whereas plasma nitridation followed by PVD resulted in 2679 HV0.01. The surface modification resulted in an increase in surface roughness in all cases compared to the hardened sample. However, the wear coefficient showed a significant decrease for the surface treated samples. The lowest wear coefficient of K = 1.47 × 10−10 mm3/Nm, which is a magnitude lower than the reference hardened sample (K = 6.32 × 10−9 mm3/Nm), was achieved employing both plasma nitridation and PVD. The results confirm that the use of a combined surface modification of plasma nitridation and PVD significantly improve the wear resistance of the treated samples.

1. Introduction

Improving the wear resistance of tool steels is a pressing requirement. Better wear resistance means longer tool lifetime, which directly influences the production rate and ultimately the price of the manufactured products. Thus, high productivity requires tool steels with long lifetime and high performance. The required properties of tool steels are high strength at elevated temperatures, high impact strength, hot wear resistance, good toughness, and good hardenability. Despite high strength tool steels having good hot working capabilities, at elevated temperatures during the manufacturing process they suffer from surface oxidation, decarbonization, chemical interactions between oxides, tribological contacts as well as thermal and mechanical loads [,,]. High strength tool steels, such as 1.2344 (X40CrMoV5-1), are widely used in hot-working processes (above 200°C). Most commonly, this tool steel is used in the process of developing casting tools for light metal alloys for the automotive industry. To ensure consistent production quality at high volume productions, the surface roughness and wear properties of such tools need to be superior. Surface modification is commonly used to improve the wear resistance of tool steels. Tool steel 1.2344 was selected for this study because it fulfils the requirement of good hardenability at high temperatures before the surface modification.

Common industrial processes to improve the wear resistance and the mechanical properties of the surface of tool steels are nitridation, surface hardening, laser surface treatment and surface coating []. Different research groups have shown the improvement possibilities of lifetime and performance of hot work tools by applying surface treatment processes, such as plasma nitriding, PVD coating or a combination of both treatments [,,,]. During plasma nitridation, a nitride layer is formed on the surface of the used metal, which significantly improves the hardness of the surface []. PVD is used to develop layers of CrN, TiN, CrAlN or TiAlN depending on the chemical composition of the steel to improve surface hardness []. The improvement of PVD technology allows the development of multi-layer systems and the surface modification after nitridation [].

Coated and heat-treated surface characterization was published by a different research group [,,,]. The improvement of wear resistance can be attributed to the combined effects of surface roughness, surface hardness and stiffness. Based on fracture mechanics and crack propagation theories the damaging process usually starts with the failure of the surface. []. The authors found that with increasing surface roughness the fatigue limit of the surface layer declines. The literature discusses multiple methods to modify surface characteristic of different materials, however all the methods and characterization methodology are specially optimized to produce suitable results [,,]. Further studies investigate the improvement possibilities of wear resistance of tool steel. These studies clearly indicate that surface toughness by itself does not provide a definite indication of wear resistance. Furthermore, to obtain the desired wear properties several layers are required with different stiffness and elasticity [,,].

TiN monolayer deposited by PVD has inferior mechanical and wear properties compared to TiN/Ti or TiN/TiCN multilayers [,]. The monolayers are more brittle than the multilayer systems and the damaging process starts sooner []. Thus, the development of a multilayer system by PVD to improve wear resistance is more advantageous. Tribological property investigation of TiAlN, CrAlN, Al2O3, SiC and B4C PVD coatings have shown that the performance of the treated tools depends on several parameters such as substrate chemical composition and microstructure, substrate mechanical properties, deposition method and chemical composition of the deposited layer [,,,,,,,,,]. The friction and wear properties can be enhanced by the deposition of TiN, TiAlN, AlTiN and CrAlN layers by PVD []. The other way to increase the performance of tool steel is nanolayer technology and duplex coating treatments []. The duplex PVD process is also a suitable technology to create high strength surface layers [,,]. Different layers of the surface as a function of the coating thickness and chemical composition (nano multilayer PVD coating) increase the wear resistance and lifetime of the tools []. Based on the literature review and the material science studies, it can be concluded that increasing the lifetime of tool steels must be a complex treatment and the substrate’s mechanical and chemical properties are extremely important [].

This research is an experimental study to investigate the complex heat-treated and surface-treated tool steel tribological properties. Based on the literature review, we hypothesize that a combination of surface layer treatments is needed to increase the wear resistance of high strength tool steels. Thus, heat treatment was combined with nitriding as well as the PVD process. The surfaces were characterized with scanning electron microscopy and a microhardness test, whereas the wear resistance was investigated with the modified ball cratering test.

2. Materials and Methods

2.1. Material

Table 1 shows the chemical composition of 1.2344 (X40CrMoV5-1) tool steel. The hardness of the steel sample was 229 HB. The tested disk-shaped samples had a Ф 15 mm × 3 mm dimension.

Table 1.

Chemical composition of the used steel in weight percentage (w/w%).

2.2. Hardening by Heat-Treating

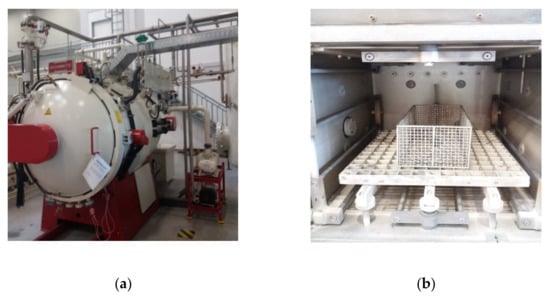

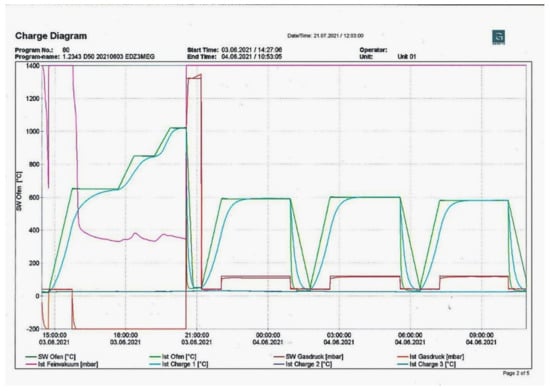

The heat treatment process was carried out in a vacuum furnace (Schmetz IU 72/1F 2RV 60 × 60 × 40 10bar Cool Plus, IVA Schmetz GmbH, Germany), as shown in Figure 1. The hardening process involved quenching and tempering three times under N2 as illustrated by Figure 2. The samples were heated to 650 °C and kept at this temperature for equalization between the surface and the center of the samples. The second holding time during the heating was at 850 °C. Between 650 °C and the austenitization, the treatment was performed at 10−2 mbar. The austenitization was carried out at 1030 °C for 10 min, whereas N2 gas was used as cooling media at 9 bar pressure. The quenching was followed by tempering at 550, 580 and 540 °C, respectively, for 2 hours at each temperature in N2 at 1.5 bar.

Figure 1.

Schmetz vacuum furnace: (a) furnace setup and (b) furnace chamber and sample holder.

Figure 2.

The heat-treatment process. (green line—programmed and measured temperature in the furnace, blue line—temperature at the middle of the sample, purple line—vacuum, red line—pressure of N2).

2.3. Plasma Nitriding

To improve the surface hardness, the hardened samples were subsequently subjected to plasma nitridation in two steps. The samples were placed into the plasma nitriding furnace right after heat treatment, where a cleaning cycle was performed. The first step was performed at 480 °C using N-H-PN: H2 a gas mixture of nitrogen, hydrogen and argon at flow rates of 1 l/h, 40 l/h and 5 l/h, respectively, for 2 hrs. The second step was carried out at 520 °C for 24 hrs employing a gas mixture of hydrogen and nitrogen at flow rates of 120 l/h and 40 l/h, respectively. The cooling process at 180 °C was performed under the same atmosphere. The plasma nitridation resulted in a 200 µm thick nitride layer, measured by Vickers microhardness instrument (Bühler 1105).

2.4. Physical Vapor Deposition (PVD)

All test samples were ultrasonically cleaned vigorously in alkaline solution and water-based degreasing soap solution followed by DI water rinsing and oven drying for 30 min at ~80 °C. Samples were loaded into a cathodic arc physical vapor deposition (CA-PVD) vacuum chamber having multiple cathodes. The temperature of the substrates was held at approximately 400 °C inside the vacuum chamber. PVD was employed to prepare a TiN/AlTiN multilayer. The PVD coating was made by Surface Modification Technologies Pvt. Ltd. Vasai, India. After achieving a base vacuum of 8.0 × 10−3 Pa, the samples were etched (in situ cleanings) with Ti ions (60 A current) by applying bias voltage (450 V to 500 V) between the substrate and the chamber. This process was carried out in ultra-high purity argon atmosphere. After that, TiN layer was deposited at 150 V bias for 4 min to improve the adhesion. AlTi (67:33 %) composition cathodes (at 70 A current) were used in ultra-high pure N2 gas to form the aluminum titanium nitride layer. The deposition time was 4 min. By switching the targets, TiN/AlTiN nano-layered coating was deposited. During the deposition process, the bias voltage was kept in a range of 100 V to 150 V at 1.3 Pa chamber pressure.

2.5. Surface Characterization

Surface preparation for testing was grinding and polishing to achieve an Ra = 0.015 ± 0.002 μm surface roughness. The surface roughness of the test samples was investigated by GD120 MarSurf. The microhardness investigation was carried out by a CSM Microindentation Tester (Vickers indenter) at 100 mN. SEM was performed on a Jeol JSM 5310 instrument. In the case of PVD-coated samples, Au coating ensured the increased conductivity during the SEM investigation.

The TiN/AlTiN layer thickness was measured using a Neophot 2 Optical Microscope (Jena, Germany, Carl Zeiss) at 1000x magnification after Nital etching. In order to determine the layer thickness, 15 datapoints were averaged.

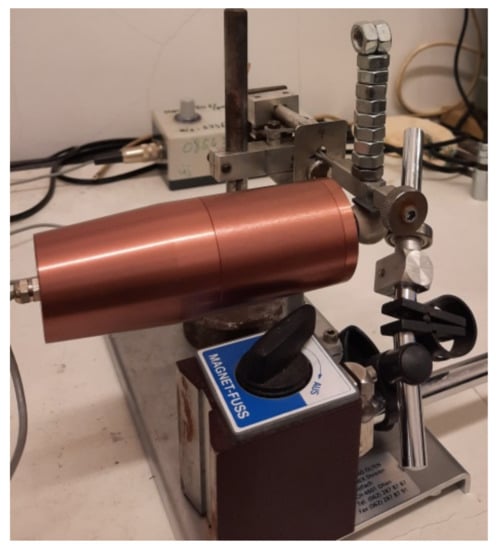

2.6. Wear Resistance

Wear resistance tests were carried out on a modified ball-cratering tribotester (the ball-cratering tribometer was manufactured by Óbuda University Bánki Donát Mechanical and Safety Engineering laboratory in a tribology research project [,]), shown in Figure 3. The used load was Nc = 0.86 N and the test time was 5 min. The wear cratering tool was an Al2O3 ceramic ball with a radius of R = 10 mm, whereas the rotation speed of the ball was n = 570 rot/min. The wear coefficient was determined using the dimensions of the resulting crater and the test parameters according to Equation (4).

Figure 3.

Ball cratering tribotester.

h (mm) is the depth of the wear crater determined by Equation (1), where R (mm) is the ball radius, r (mm) is the radius of the wear crater:

The wear volume Vv (mm3) was determined by Equation (2):

The test way length (m) was determined by Equation (3), where n (rot/min) was the speed of the ball, t (min) was the test time and R (mm) was the diameter of the ball:

The wear coefficient K (mm3/Nm) was determined by Equation (4), where S (m) was the test way length, Nc (N) was the normal load and V (mm3) was the lost wear volume:

3. Results and Discussion

In order to investigate the effect of different layer systems on the wear resistance, samples were prepared with different surface modification procedures, as shown in Table 2.

Table 2.

Sample treatments and designated sample names.

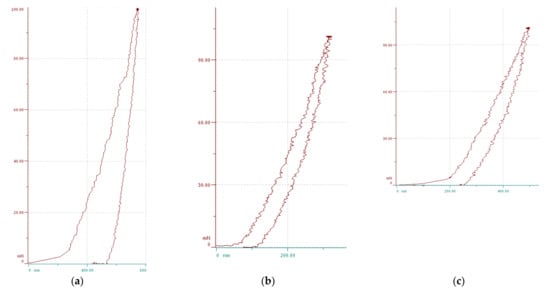

3.1. Microhardness

Figure 4 shows the microhardness results of the surface-treated samples. The loading and unloading curves show the plastic elastic behavior of the surface layers. The measured microhardness and the determined elastic modulus of the samples are shown in Table 3. The hardness test loading and unloading curves show different gradients and, therefore, a different elastic modulus. The results are in line with the literature: 1) the hardness of TiAlN based on [] is 22.7 ± 0.9 GPa, whereas the hardness of N-H-PVD is 2938 HV0,01, corresponding to approximately 28.81 GPa; 2) the elastic modulus of TiAlN layer based on [] is E = 304 ± 11 GPa, correlating well with our measurement of sample N-H-PVD of E = 202 GPa.

Figure 4.

The loading-unloading test results carried out on (a) N-H-PN (b) N-H-PVD and (c) N-H-PN-PVD.

Table 3.

The measured hardness and the elastic modulus.

3.2. Surface Roughness

The surface roughness is an important parameter in the wear process. The surface of the samples in all cases was polished to Ra = 0.01 ± 0.002 µm, but the nitridation and the PVD coating modified it. Table 4 shows the surface roughness of the treated samples. For PVD coatings, the literature reports values between Ra = 0.09– 0.3 µm [], thus our results correlate well with reported values.

Table 4.

The surface roughness of the tested samples.

3.3. Characterization of PVD Surface Layer by SEM

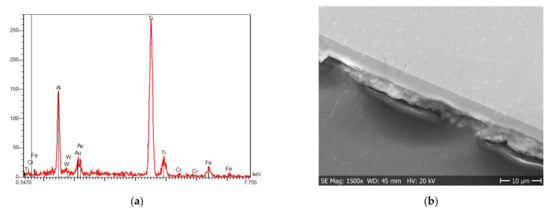

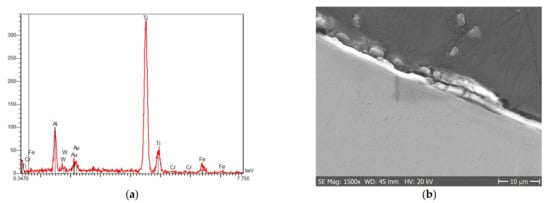

The chemical composition of PVD layers was investigated by SEM. As Figure 5a and Figure 6a illustrate, Al and Ti are present in the PVD-coated samples. In Figure 5b and Figure 6b, the SEM images illustrates the joint between the bulk material and the coated layer.

Figure 5.

SEM results of the N-H-PVD test sample: (a) chemical composition and (b) SEM image.

Figure 6.

SEM results of the N-H-PN-PVD test sample: (a) chemical composition and (b) SEM image.

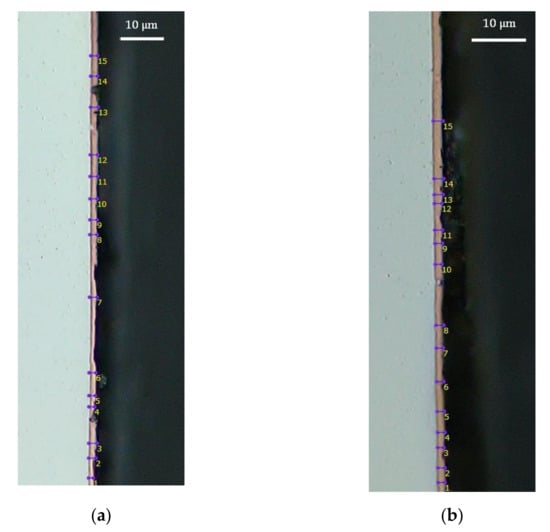

3.4. Microscopy of PVD-Coated Samples

The surface layer cross-section of N-H-PVD and N-H-PN-PVD can be seen in Figure 7a,b, respectively. To measure the layer thickness, Nital etching was performed. 15 measurements were averaged and resulted in an average layer thickness of 1.66 μm and 1.45 μm for N-H-PVD and N-H-PN-PVD, respectively. The tabulated data can be found in Table 5. The difference in layer thickness could be attributed to the starting sample (N-H and N-H-PN) surface characteristics.

Figure 7.

The cross-section microscopy of Nital etched (a) N-H-PVD test sample and (b) N-H-PN-PVD test sample.

Table 5.

Surface layer thicknesses of N-H-PVD and N-H-PN-PVD samples.

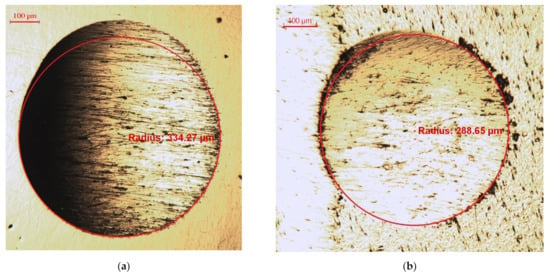

3.5. Wear Coefficient

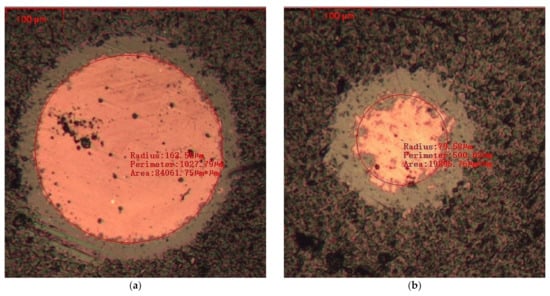

Figure 8a,b show the wear crater for samples N-H and N-H-PN, respectively, created by the ball during the wear resistance test. To determine the radius of the crater and apply it in Equations (1) and (2) a circle was fitted on the crater, represented in red in the figures. Figure 9a,b show the wear crater for samples N-H-PVD and N-H-PN-PVD, respectively.

Figure 8.

The wear crater of (a) N-H and (b) N-H-PN test samples.

Figure 9.

The wear crater of (a) N-H-PVD and (b) N-H-PN-PVD test samples.

The calculated wear coefficient results are based on Equation (4) and presented in Table 6. Nitridation reduced the wear coefficient compared to the hardened sample by ~70%, from 6.23 × 10−9 mm3/Nm to 1.95 × 10−9 mm3/Nm. This is a significant result; however, when PVD coating was applied, the results decreased by one order of magnitude. This illustrates the effectiveness of PVD coating in contrast to the nitride layer. It can also be noticed that, when PVD coating was applied onto the nitride layer, the wear coefficient was close to six times lower than when it was applied only on the hardened sample. The above-mentioned result correlates well with the elastic modulus of the surface layers, indicating the importance of elastic behavior, thus dampening effect of the coating system. The more energy can be dissipated by the surface layer the better the wear resistance. This also suggests that surface hardness is a necessary by not satisfactory parameter when determining the wear resistance. The data in Table 6 also indicate the necessity of a complex surface layer system to improve the wear resistance. The previously applied hardening process or surface treatment significantly influences the wear properties of the final layer.

Table 6.

The wear coefficient of the tested samples.

The work performed provides valuable information for practicing designers and engineers regarding the wear properties of the applied materials. Special attention should be attributed to determine the correct hardening conditions and surface treatment. The hardening temperature and time should be determined based on chemical composition and geometrical parameters. It is advisable to perform the hardening under vacuum or in inert atmosphere to eliminate decarbonization and oxidation of the surface. The lifetime of tools can be significantly increased by the combined application of nitriding and PVD surface modification techniques.

4. Conclusions

In conclusion, we have successfully prepared surface modified samples with plasma nitriding and PVD methods. The results indicate both methods significantly increase the surface hardness of the sample. Namely, the highest value for surface hardness was obtained when only PVD TiN/AlTiN coating was employed, 2938HV0.01, followed by 2679 HV0.01 when both plasma nitridation and PVD coating was applied. In the case of the elastic modulus, the reverse trend can be observed with 166 GPa for the plasma nitrited and PVD-coated sample and 202 GPa for the PVD-coated sample. Surface roughness was lower, Ra = 0.1895 µm, for the duplex coating in contrast to the PVD coating alone, Ra = 0.23335 µm. The lowest wear coefficients, thus higher wear resistance, were measured when PVD coating was applied. Wear coefficients of K= 1.47 × 10−10 mm3/Nm and K= 8.46 × 10−10 mm3/Nm were measured for PVD/plasma nitrited and PVD coatings, respectively. These values are an order of magnitude lower, than that of plasma nitrited sample. The duplex system shows better wear resistance, which in our case correlates well with the elastic modulus of the tested surfaces, whereas the hardness values and the surface roughness for both PVD-coated samples were similar. Thus, the wear properties of a layer are dependent on the structural and mechanical properties of the previously applied layer. Hardening, plasma nitriding and PVD surface modification in sequence provide surfaces with lower elastic modulus and high toughness resulting in superior wear resistance.

Author Contributions

Conceptualization, E.B. and T.A.K.; methodology, L.T.; software, Z.N.; validation, L.T., and T.A.K.; formal analysis, A.L.G.; investigation, L.T.; resources, L.T.; data curation, Z.N.; writing—original draft preparation, E.B.; writing—review and editing, A.L.G.; visualization, T.A.K.; supervision, E.B.; project administration, E.B.; funding acquisition, E.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by THE HUNGARIAN STATE, NATIONAL RESEARCH, DEVELOPMENT AND INNOVATION OFFICE, grant number 2019-2.1.11-TÉT-2019-00093. The APC was funded by Transylvanian Museum Society.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors wish to thank Mihály Réger and András Mucsi for their technical support related to surface characterization. The authors acknowledge Surface Modification Technologies Pvt. Ltd (SMTPL) India, especially Umesh Mhatre, for providing the PVD-coated samples.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Mesquita, R.A. Tool Steels: Properties and Performance; Taylor & Francis Group, LLC: Abingdon, UK, 2017; pp. 59–144. [Google Scholar]

- Heck, S.C.; Pires Fernandes, F.A.; Gomes Pereira, R.; Totten, G.E.; Casteletti, L.C. Influence of the Ion Nitriding Temperature in the Wear Resistance of AISI H13 Tool Steel. In Proceedings of the 18th IFHTSSE Congress, Rio de Janeiro, RJ, Brazil, 26 July 2010; pp. 5125–5130. [Google Scholar]

- Zhou, Z.C.; Du, J.; Yan, Y.; Shen, C. The Recent Development of Study on H13 Hot-Work Die Steel. Solid State Phenom. 2018, 279, 55–59. [Google Scholar] [CrossRef]

- Lee, J.-H.; Jang, J.-H.; Joo, B.-D.; Son, Y.-M.; Moon, Y.-H. Laser surface hardening of AISI H13 tool steel. Trans. Nonferrous Met. Soc. China 2009, 19, 917–920. [Google Scholar] [CrossRef]

- Zeghni, A.E.; Hashmi, M.S.J. The effect of coating and nitriding on the wear behaviour of tool steels. J. Mater. Process. Technol. 2004, 155–156, 1918–1922. [Google Scholar] [CrossRef]

- Chang, S.-H.; Huang, K.-T.; Wang, Y.-H. Effects of Thermal Erosion and Wear Resistance on AISI H13 Tool Steel by Various Surface Treatments. Mater. Trans. 2012, 53, 745–751. [Google Scholar] [CrossRef] [Green Version]

- Holleck, H.; Schier, V. Multilayer PVD coatings for wear protection. Surf. Coat. Technol. 1995, 76–77, 328–336. [Google Scholar] [CrossRef]

- Rechverger, J.; Brunner, P. High performance cutting tools with solids lubricants PVD coatings. Surf. Coat. Technol. 1993, 62, 393–398. [Google Scholar] [CrossRef]

- Karimoto, T.; Nishimoto, A. Plasma-Nitriding Properties of CoCrFeMnNi High-Entropy Alloys Produced by Spark Plasma Sintering. Metals 2020, 10, 761. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Amrutwar, S. Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels. Materials 2019, 12, 795. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azizpour, A.; Hahn, R.; Klimashin, F.F.; Wojcik, T.; Poursaeidi, E.; Mayrhofer, P.H. Deformation and Cracking Mechanism in CrN/TiN Multilayer Coatings. Coatings 2019, 9, 363. [Google Scholar] [CrossRef] [Green Version]

- Candido Recco, A.A.; Tschiptschin, A.P. Structural and Mechanical Characterization of Duplex Multilayer Coatings Deposited onto H13 Tool Steel. J. Mater. Res. Technol. 2012, 1, 182–188. [Google Scholar] [CrossRef] [Green Version]

- Bouzakis, K.D.; Michailidis, N.; Skoradris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. CIRP Ann. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Ávila, R.; Mancosu, R.; Machado, A.; Vecchio, S.; Da Silva, R.; Vieira, J. Comparative analysis of wear on PVD TiN and (Ti1−x Alx)N coatings in machining process. Wear 2013, 302, 1192–1200. [Google Scholar] [CrossRef]

- Yang, B.; Chen, L.; Chang, K.K.; Pan, W.; Peng, Y.B.; Du, Y.; Liu, Y. Thermal and thermo-mechanical properties of Ti–Al–N and Cr–Al–N coatings. Int. J. Refract. Met. Hard Mater. 2012, 35, 235–240. [Google Scholar] [CrossRef]

- Alang, N.A.; Razak, N.A.; Miskam, A.K. Effect of Surface Roughness on Fatigue Life of Notched Carbon Steel. Int. J. Eng. Technol. IJET-IJENS 2011, 11, 161–163. [Google Scholar]

- Amin, A.; Abdul-Rani, A.; Danish, M.; Rubaiee, S.; Mahfouz, A.; Thompson, H.; Ali, S.; Unune, D.; Sulaiman, M. Investigation of Coatings, Corrosion and Wear Characteristics of Machined Biomaterials through Hydroxyapatite Mixed-EDM Process: A Review. Materials 2021, 14, 3597. [Google Scholar] [CrossRef]

- Bendarma, A.; Jankowiak, T.; Rusinek, A.; Lodygowski, T.; Jia, B.; Miguélez, M.H.; Klosak, M. Dynamic Behavior of Aluminum Alloy Aw 5005 Undergoing Interfacial Friction and Specimen Configuration in Split Hopkinson Pressure Bar System at High Strain Rates and Temperatures. Materials 2020, 13, 4614. [Google Scholar] [CrossRef]

- Padmavathi, G.; Sarada, B.N.; Shanmuganathan, S.P.; Krishnamurthy, R.; Padmini, B.V. Investigation of HVOF processed carbide based coating on AISI-4340. AIP Conf. Proc. 2021, 2317, 020013. [Google Scholar] [CrossRef]

- Awan, A.; Pasha, R.A.; Butt, M.S.; Malik, R.A.; Alarifi, I.M.; Alzaid, M.; Latif, M.; Naseer, A.; Saleem, M.; Alrobei, H. Corrosion and wear behavior of TiN PVD coated 304 stainless-steel. J. Mech. Sci. Technol. 2020, 34, 3227–3232. [Google Scholar] [CrossRef]

- Tlili, B. Fretting Wear Performance of PVD Thin Films; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Sousa, V.; Da Silva, F.; Pinto, G.; Baptista, A.; Alexandre, R. Characteristics and Wear Mechanisms of TiAlN-Based Coatings for Machining Applications: A Comprehensive Review. Metals 2021, 11, 260. [Google Scholar] [CrossRef]

- Smallman, R.E.; Ngan, A.H.W. Oxidation, Corrosion and Surface Engineering, in Modern Physical Metallurgy, 8th ed.; Butterworths: London, UK, 2014. [Google Scholar]

- Krella, A.K. Degradation of protective PVD coatings. In Handbook of Materials Failure Analysis with Case Studies from the Chemicals, Concrete and Power Industries; Elsevier: Oxford, UK, 2016. [Google Scholar]

- Paldey, S.; Deevi, S.C. Single layer and multilayer resistant coatings of (TiAl)N: A review. Mat. Sci. Eng. 2002, 342, 58–79. [Google Scholar] [CrossRef]

- Bai, Y.; Xi, Y.; Gao, K.; Yanh, H.; Pang, X.; Volinsky, A.A. Residual stress control in CrAlN coatings deposited on Ti alloys. Ceram. Int. 2018, 44, 4653–4659. [Google Scholar] [CrossRef]

- Manivannan, R.; Sundararaj, S.; Dheenasagar, R.; Giridharan, K.; Sivaraman, P.R.; Udhayarani, V. Influence of Al2O3, SiC and B4C covalent multilayer PVD coating on surface properties of HSS rod. Mater. Today Proc. 2021, 39, 700–707. [Google Scholar] [CrossRef]

- Aihua, L.; Jianxin, D.; Haibing, C.; Yangyang, C.; Jun, Z. Friction and wear properties of TiN, TiAlN, AlTiN and CrAlN PVD nitride coatings. Int. J. Refract. Met. Hard Mater. 2012, 31, 82–88. [Google Scholar] [CrossRef]

- Rosso, M.; Ugues, D.; Torres, E.; Perucca, M.; Kapranos, P. Performance enhancements of die casting tools trough PVD nanocoatings. Int. J. Mater. Form. 2008, 1, 1259–1262. [Google Scholar] [CrossRef]

- Navinšek, B.; Panjan, P.; Urankar, I.; Cvahte, P.; Gorenjak, F. Improvement of hot-working processes with PVD coatings and duplex treatment. Surf. Coat. Technol. 2001, 142–144, 1148–1154. [Google Scholar] [CrossRef]

- Panjan, P.; Urankar, I.; Navinšek, B.; Terčelj, M.; Turk, R.; Čekada, M.; Leskovšek, V. Improvement of hot forging tools with duplex treatment. Surf. Coat. Technol. 2002, 151–152, 505–509. [Google Scholar] [CrossRef]

- Haftlang, F.; Habibolahzadeh, A. Influence of Treatment Sequence on Tribological Performance of Duplex Surface-Treated AISI 1045 Steel. Acta Met. Sin. Engl. Lett. 2019, 32, 1227–1236. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, S.; Beake, B.D.; Yamamoto, K.; Bose, B.; Aguirre, M.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Improvement of Wear Performance of Nano-Multilayer PVD Coatings under Dry Hard End Milling Conditions Based on Their Architectural Development. Coatings 2018, 8, 59. [Google Scholar] [CrossRef] [Green Version]

- Tillmann, W.; Stangier, D.; Denkena, B.; Grove, T.; Lucas, H. Influence of PVD-coating technology and pretreatments on residual stresses for sheet-bulk metal forming tools. Prod. Eng. 2015, 10, 17–24. [Google Scholar] [CrossRef]

- Gee, M.; Gant, A.; Hutchings, I.; Bethke, R.; Schiffman, K.; Van Acker, K.; Poulat, S.; Gachon, Y.; von Stebut, J. Progress towards standardisation of ball cratering. Wear 2003, 255, 1–13. [Google Scholar] [CrossRef]

- Silva, W.M.; Souza, P.S.; Carneiro, J.R. Methods of data analysis for the ball cratering test on TiN and DLC coated steel. Mater. Res. 2016, 19, 9–17. [Google Scholar] [CrossRef] [Green Version]

- Sousa, V.F.; Silva, F.; Alexandre, R.; Fecheira, J. Study of the wear behaviour of TiAlSiN and TiAlN PVD coated tools on milling operations of pre-hardened tool steel. Wear 2021, 476, 203695. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).