Featured Application

A potential application of the study is the use of the technology described in the construction of bridges, in particular for the construction of retaining structures within abutments.

Abstract

This study considered the possibility of using steel gabion baskets made of welded mesh for a soil-strengthening function. Examples of such applications are known for meshes made of wires with diameters from 6.3 to 12.7 mm and mesh openings from 125 to 225 mm. In the case of a welded grid, the pulling resistance of fine-grained soil consists of two factors: frictional resistance and bearing resistance. Therefore, for the purposes of this issue, a simplified laboratory pullout test was carried out with four types of welded steel grid (common in Europe) embedded in the fine sand. The geometry of the grid (opening size: 76.2 × 76.2 mm), the type of steel (low carbon steel, tensile strength from 500 to 700 MPa), the diameter of the wire (2.7–4.5 mm) and its cover (ZN + PVC or ZnAl) were taken into account during the analysis. It was unequivocally stated that as the stiffness of the steel grid itself increases, its strength increases during the pullout test, which is not so obvious in the case of popular steel woven meshes. In addition, it has been shown that steel welded meshes with wire diameters less than 6 mm are suitable for soil reinforcement in structures with gabion facing, and the determined apparent friction coefficient (μk = 0.39–1.47) takes values similar to the friction coefficient given in references for welded meshes of larger diameters. This is a positive premise for starting further research on the use of wires of smaller diameters for welded mesh production used as soil reinforcement.

1. Introduction

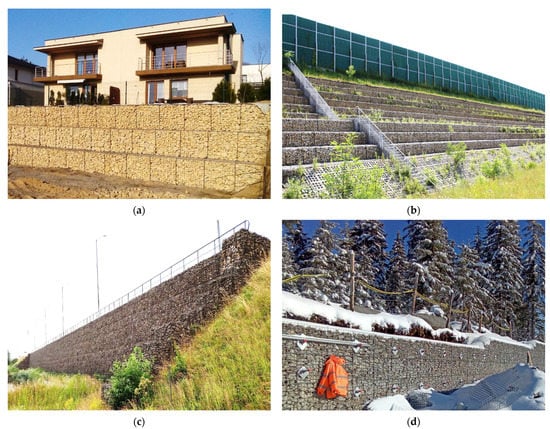

Retaining structures are used in the case of construction of buildings where there is a difference in ground level. A special place for the use of such structures are infrastructure projects, such as the construction of roads, railroads, bridges, or airports. Examples of existing implementations in Poland are depicted in Figure 1. Another innovative solution is the use of gabion baskets in the design of a highly sustainable agricultural building (with a cellar), located in a farm in the south of the Tuscany region, Italy. Gabions and natural stones were used for the realization of the foundations, the ground retaining walls, and all other bearing walls, including the external wall, which remains entirely above ground [1].

Figure 1.

Examples of the use of gabion baskets in Poland (own pictures): (a) gravity retaining wall made of gabion baskets; (b) the slope of a motorway embankment reinforced with gabions; (c) gravity retaining wall supporting a motorway embankment; (d) an example of a gabion wall erected in harmony with the environment.

Retaining structures made of gabion baskets, i.e., cuboidal steel mesh baskets filled with ballast material, constitute a method of direct reinforcement for the mechanical protection of slopes [2]. The history of their use in construction dates to the time of the pharaohs (c. 5000 B.C.), when reed and rock elements were used to build dams and to prevent erosion and strengthen the banks of the Nile [3]. Similar structures were erected in China around 1000 B.C. along the Yellow River [4]. It is believed that the first modern wire mesh gabions were made in the Bologna area of Italy around 1879 [5].

The use of gabions filled with stones is environmentally friendly (Figure 1d) [6]. The main reason for the limited impact on the environment is the reduction in the materials used compared to traditional reinforced concrete structures, especially steel and concrete, the manufacture of which requires the use of cement, which is a highly energy-consuming raw material to produce. It is true that the steel of the gabion baskets is also an energetically expensive material, both in terms of production and the recycling process. However, it has the feature of being able to be totally recycled an unlimited number of times. Even the zinc used for steel galvanization is fully recyclable [1]. Both natural and recycled materials or alternative materials—e.g., clothing and plastic—can be used as ballast material for gabion baskets [7,8]. The development of anticorrosion protection techniques has made steel wire structures durable. Their durability is estimated at over 100 years [9,10,11].

The fact that about 30–40% of the volume of gabions are air voids has a positive influence on the durability of the gabion structures, thanks to which they are characterized by excellent water permeability (hydraulic conductivity k > 2.5 × 10−3 m/s), which facilitates the drainage of water from behind the retaining structure and prevents its level from rising [10,11,12,13,14,15,16].

Phenomena related to the influence of water on retaining structures are often neglected or treated with insufficient care when analysing the surroundings of bridge structures, which leads to numerous minor failures that are difficult to eliminate due to the scale of earthworks. The importance of proper drainage system implementation is often underestimated, both at the design and execution stages [17]. A geotechnical engineer should always be consulted for design solutions in such situations, and it should be noted that gabion retaining structures, apart from their structural function, also drain water from the soil medium.

An additional advantage is the fact that the gabion structures are deformable, thanks to which they do not break, but adapt to changing external conditions [18], which allows the use of gabions in areas of mining damage (e.g., retaining structure by the motorway in Ruda Śląska, in Silesia, a vast area of mining activity in southern Poland [19]). Gabions also have the ability to absorb noise [20], which allows them to be used for sound-absorbing partitions (e.g., noise barriers on the railroad in The Hague, Netherlands). Furthermore, the gabion revetments have the capacity for vegetation restoration (it provides a good habitat for floral, faunal, and microbial growth) and resist periodic flood disturbance [21,22]. Gabion structures are easy to assemble and do not require extensive construction site facilities, and their landscape and architectural aesthetics allow them to be adapted to the surrounding natural terrain (e.g., retaining structures on Victoria Road in Cape Town, South Africa).

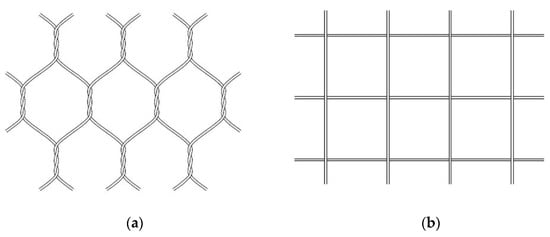

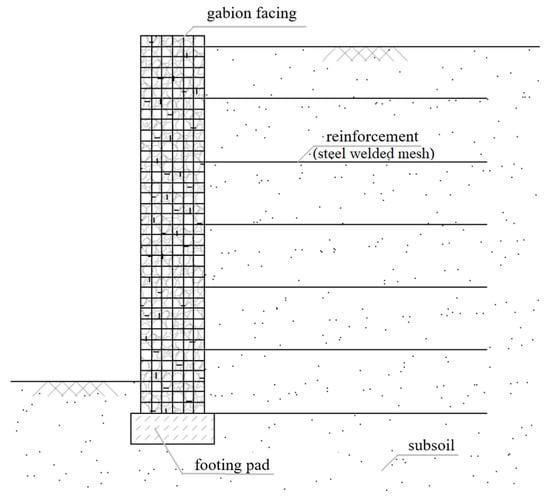

Gabion structures made for the purpose of soil reinforcement technology deserve special attention. The whole structure is made of woven mesh, more precisely double-woven mesh (Figure 2a) [23]. Gabion retaining structures made using welded meshes (Figure 2b) appear mainly as gravity structures (e.g., Figure 1a,c) or as structures made of soil reinforced with geosynthetics (e.g., Figure 1b) [24]. The use of welded steel meshes as backfill reinforcement seems to be the next step in the development of this technology. A diagram of such a solution is presented in Figure 3.

Figure 2.

Comparison of the mesh opening: (a) woven (double-woven) mesh; (b) welded mesh.

Figure 3.

Diagram of a gabion retaining structure for soil reinforcement technology.

In addition, lower demand for steel mesh, the considerably lower consumption of ballast material for filling the gabions, the reduction of the necessary transportation, as well as the lower labour demand constitute other advantages of such gabion structures. Structures using soil reinforcement technology are ultimately 25% to 60% cheaper to build than massive structures [24,25,26,27,28]. Ciomcia [25] carried out a meticulous analysis of costs and construction time on the example of the construction of a typical bridge abutment, showing that the construction of the bridge abutment using soil reinforcement technology with steel elements is 35% to 37% cheaper and takes from 38% to as much as 63% less time, compared to the construction of the abutment in the traditional monolithic form. Jayasree [26] analysed the costs of erecting retaining structures with a height of 1 to 10 m, showing that the construction of gabions, both massive and with soil reinforcement, is about 30% cheaper than the construction of RCC (reinforced cement concrete) retaining walls. For higher structures from 5.5 to 10.0 m, the savings range from 48% to 52% for massive structures and from 70% to 78% for reinforced soil gabion structures).

Gabion baskets made of woven or welded mesh are always selected on the basis of their deformability, which is a function of wire thickness, mesh size, type, and the grain size of the ballast material, as well as the construction of the gabion basket itself. The same parameters determine the selection of an appropriate gabion mattress solution for the regulation of riverbeds depending on the speed of flowing water [11].

In turn, the additional use of steel meshes as soil reinforcement requires the determination of their deformability after building in the soil medium, the force pulling them out of the soil, and the friction coefficient between the reinforcement and the soil, which also directly affects the length of the anchorage. Woven mesh, when stretched in the air (without building into the ground), tends to narrow, which is a result of the geometry of the mesh openings. This phenomenon drastically increases the tensile elongation of the woven mesh. It does not occur when stretching welded mesh with rectangular openings, because the force is transmitted along the wires and their cross-sectional area directly affects the mesh elongation during its stretching. It turns out that after building in the soil medium, both types of mesh (woven and welded) are characterized by similar values of relative deformation. Pullout tests are dedicated to the determination of tensile forces, and consist of building a reinforcement mesh in a box with soil, applying a vertical load, simulating the weight of the entire geotechnical structure, and then slowly ejecting the reinforcement through the slot in the box, while simultaneously measuring both force and displacement. In this type of research, woven meshes exhibit a different mechanism of cooperation with the ground from welded meshes [29].

All these premises were the starting point for this research paper, which focuses on the observation of the behaviour of welded steel mesh during a simplified pullout test in fine sand. Pullout tests are performed to determine the coefficient of friction between the reinforcement and the soil, the value of which is essential for the correct and safe design of reinforced soil structures [30].

In construction site practice, woven and welded meshes are commonly used in the construction of gabion retaining structures. In the case of retaining structures with soil reinforcement, a double-woven mesh is typically used if the baskets are also made of it, or geosynthetics, regardless of the material of the gabion basket. Gabion welded mesh for soil reinforcement was not used. Although welded mesh has been successfully used to reinforce soil in light retaining structures since the 1980s, it is made of wires with a much larger diameter than those used for gabion basket production.

The essential issue in the design, performance, and durability of the use of a structure with soil reinforcement is the connection of the wall facing with the soil reinforcement. This connection is often the weakest point in terms of strength, effectively limiting the use of the total load-bearing capacity of the soil reinforcement, and is the site of potential failure during use. Integrating the facing with the reinforcement (e.g., extending the base of the gabion to such a length that it is also the reinforcement of the soil) makes it possible to eliminate the problematic connection, as is currently the case in structures where woven meshes are used to make gabions and reinforce soil.

The use of welded steel meshes as backfill reinforcement seems to be, of course, the next step in the development of this technology. This is important because welded meshes can achieve higher tensile strength than braided meshes due to the technological possibility of using thicker wire for their production.

2. Materials and Methods

Soil reinforcement with steel welded meshes identical or similar to those used for gabion structures is a field for discussion among researchers dealing with these issues. There are many indications that the use of this type of reinforcement is possible and justified [29]. In this study, it was decided to explore the subject of the cooperation of the soil reinforcement system in a simplified laboratory pullout test. For this purpose, four types of welded steel mesh and one type of coarse-grained soil were used, and the mesh was built in that soil. The question to be investigated was how the different types of reinforcement in a particular soil type affect the force required to pull the reinforcement out of the soil during the test.

2.1. Fine Sand

During laboratory tests, dry fine sand (FSa) with the following parameters was used: grey-yellow colour, calcium carbonate content CaCO3 < 1%, angle of internal friction ø = 24.0°, cohesion c = 0.9 kPa, coefficient of uniformity Cu = 2.57, coefficient of curvature Cc = 0.71, optimum water content (OWC) wopt = 8.6%, maximum dry density ρds = 1.76 g/cm3. A detailed description of studies identifying the fine sand under consideration was presented by Sułkowska [31].

2.2. Welded Steel Grid

Welded meshes are manufactured of steel wire with a tensile strength of 500–700 MPa in accordance with the PN-EN 10223-8 standard [32]. Wires with a diameter of 2.2 mm to 5.0 mm are used, and the edge wire may be the same or thicker than the filling wire. The opening is rectangular and its most common sizes are 50 × 50 mm, 50 × 100 mm, 75 × 75 mm or 100 × 100 mm, as well as 76.2 × 76.2 mm (3 × 3 inches).

A commonly used anticorrosion protection of welded meshes is used to cover the wire, with one of three types of coating according to the PN-EN 10244-2 [33] and 10245-2 [34] standards:

- -

- type 1: thick zinc coating,

- -

- type 2: zinc–aluminium alloy layer up to 350 g/m2,

- -

- type 3: a coating consisting of a pure zinc layer and an additional polymer layer, usually PVC.

Laboratory tests were conducted on four types of welded meshes, which differed with respect to wire diameter as well as the type of anticorrosion coating used during production. They had been chosen as they are widely used for the production of gabion baskets available on the European market. It is worth mentioning here that soil reinforcement with gratings made of thick steel rods (6.3–12.8 mm in diameter) is used in practice in the North American market [35]. However, soil reinforcement with both gratings made of steel rods and welded steel meshes made of thinner wire (such as those used in the production of gabions) is an innovative method on a European scale.

In the series of tests, sheets with dimensions of 762 × 1676 mm, consisting of 11 tensile longitudinal wires and 23 transverse wires, are used, and in the case of the largest diameter wire mesh, also sheets with dimensions of 305 × 1676 mm, consisting of 5 and 23 wires, respectively. The smaller number of wires was the result of the limitation of the maximum force that could be applied during the test. The choice of meshes with type 2 and type 3 coatings was based on the manufacturer’s guaranteed long-term protection against corrosion under the conditions prevailing in the soil or in contact with the soil. This period is 80–100 years, and even more than 120 years respectively. The types of meshes are presented in Table 1.

Table 1.

Basic geometrical parameters of the welded meshes used in the test.

3. Test Procedure

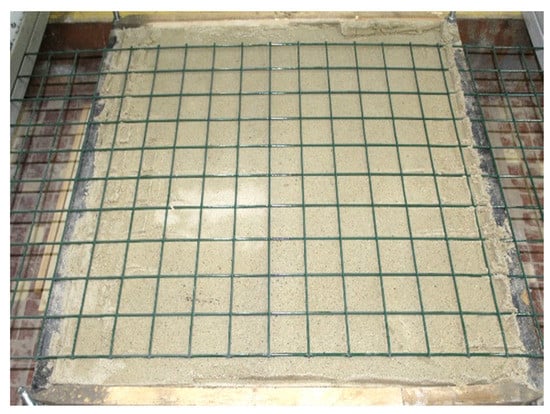

The basic pullout type test is carried out in accordance with the EN 13738 standard [36] in a large-scale pullout apparatus with a box with internal dimensions of 1600 mm × 600 mm × 360 mm (length × width × height). The test consists of pulling the reinforcement uniformly out of the soil at a speed not exceeding 10 mm/min, at a given vertical tension (up to 200 kPa). The displacement of the reinforcement points inside the box is monitored by linear variable differential transformers (LVDT) with the corresponding value of the pullout force. Both values are recorded continuously in the computer system [37]. Originally, the pullout test was dedicated to geosynthetics, but eventually it also came to be used to study the interaction between soil and reinforcement in the form of welded or woven steel mesh. As a result, many researchers conduct tests that are called simplified ones, in a suitably modified apparatus and according to a procedure adapted to the situation (e.g., [38,39,40,41]). In this study, the authors carried out a simplified pullout test. This test is consistent with the concept of the standard method; however, the simplification is related to the way force and displacement were measured. The pullout force was set and not measured, and the displacements were measured at the extreme nodes of the reinforcement and mounting brackets, which were not embedded in soil. Finally, the test was conducted in accordance with the following procedure:

- fill the steel box with soil in layers of approximately 100 mm,

- add an appropriate amount of water to the soil and mix evenly if it is necessary to obtain a water content close to the optimum water content (OWC),

- compact the soil using an electric plate compactor,

- the box should be filled according to points 1–3 until the height at which the slot in the box is reached Figure 4

Figure 4. Mesh installed on the level of the slot height in the box.

Figure 4. Mesh installed on the level of the slot height in the box. - insert the steel mesh and the mounting flat into the clamping jaw and screw the two parts of the jaw gently together,

- remove the gap in the clamping jaws manually by pulling the mesh towards the steel box,

- make sure that the welded mesh does not touch any part of the steel box,

- screw the two parts of the mounting jaws tightly together,

- continue filling the steel box according to points 1–3, until a height of approximately 45 mm below the top edge of the steel box is reached,

- level the upper soil surface and install the cover, the force gauge, and hydraulic actuator No 2,

- apply a vertical load,

- place the hydraulic actuator No 1 in the load frame,

- check the correct position of the welded mesh in the box slot,

- install the electronic dial displacement sensors and reset them,

- apply the horizontal load gradually every 3.1 kN and after each load is applied and the reading stabilizes on the jaw displacement sensors, note indications of these sensors,

- conduct the test until the damage of the welded mesh or until the moment at which the indication on the hydraulic actuator No 1 stops increasing despite the mesh continuing to move out of the ground (reaching the maximum anchoring force) or the maximum extension of this hydraulic actuator is reached,

- recoil the hydraulic actuator, disassemble all elements of the stand, pull the two parts of the loading frame towards each other using a lashing strap to the original position, and start another test from point 1 of this procedure.

During the test, a total of four tests were carried out according to the above procedure, one for each type of welded steel mesh.

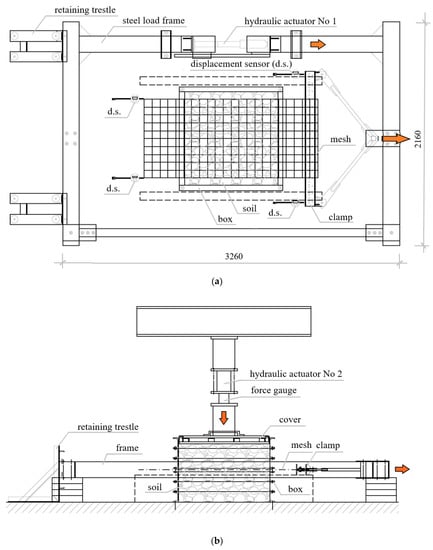

3.1. Test Stand

For this research, a stand was constructed (Figure 5). The test stand was originally intended for the tests of geosynthetics (geogrids) carried out by Kawalec [42]. Then it was adapted for pullout tests by the authors of this study. It consisted of typical pullout test equipment such as two hydraulic actuators, a force gauge, four electronic dial displacement sensors with a range of 0–100 mm, and a steel load frame (length 3260 mm × width 2160 mm), welding mesh mounting brackets, and a steel soil box with internal dimensions of 900 mm × 900 mm × 630 mm (length × width × height) and sturdy retaining trestles. The dimensions of the soil box were selected on the basis of the observations of Kim [43] and Prashanth et al. [39], who used boxes ranging from 400 to 2000 mm in length, 200 to 1100 mm in width and 100 to 1100 mm in height. The whole structure was fixed to a concrete floor, ensuring the sliding of the frame elements in the horizontal plane. The geometry of the frame, especially the position of the axis of the hydraulic actuator and the axis of the force that stretches the welded mesh in relation to the articulated joint of the frame, causes the force that stretches the mesh to be exactly twice as large as the force applied by the hydraulic actuator. Displacement sensors were applied to the clamping jaws in such a way that the average displacement for each jaw showed displacement both in the plane of the mesh itself and half the width of the mesh. This method of mounting the sensors facilitated their installation and did not require the installation of sensors inside the box with the soil.

Figure 5.

Schematic of the test stand for pulling meshes embedded in the soil: (a) top view; (b) longitudinal section.

The mounting brackets were constructed in such a way that there were two bolts on each side of each of the tensile wires of the welded mesh to twist the independent parts of the bracket. The tensile force from the bracket to the steel mesh was transmitted through a 30 × 5 mm steel flat bar, which ensured an even distribution of force across the whole width of the mesh.

The aforementioned retaining trestles made of steel channel bars allowed one of the arms of the loading frame to be anchored to the floor. Thanks to this solution, it was possible to expand only one side of the frame and thus to pull the steel mesh out of the soil in the central part of the test stand. Horizontal load was applied gradually every 3.1 kN and after each load was applied and the reading stabilizes on the jaw displacement sensors, the indication of these sensors was noted.

The vertical load was applied once to the value corresponding to the stress of approx. 60 kPa in the level of the reinforcement. The force was applied using a hydraulic actuator, which from the top rested against a very thick and durable reinforced concrete ceiling, and from below it transferred the force to the ground by means of a strongly ribbed steel cover, which ensured the even distribution of force over the entire surface of the box in the box. After the indication of the vertical force, measuring force was stabilized, the reinforcement was pulled out of the soil.

A view of the test stand is shown in Figure 5. To get as much information as possible from this test, it was also decided to install digital displacement dial sensors directly to the grid, but on the opposite side to the mounting jaws.

The test stand during the work is shown in Figure 6.

Figure 6.

The test stand for pulling meshes embedded in the soil.

3.2. Test Conditions

The test was conducted in a dry and closed room at room temperature. The soil water content was controlled during its construction. If necessary, water was added in sufficient quantity to obtain the optimum water content. The soil was compacted manually using an electric plate compactor. An important factor to be taken into account when analysing the issue of meshes embedded in soil is the state of normal stress in the soil at the level of the tested reinforcement. The intention of the authors was to illustrate the stress induced in an embankment of approximately 3–4 m height. Using hydraulic actuator 2, a vertical stress at the level of the reinforcing steel mesh of about 60 kPa was obtained, which meets the assumptions adopted by the authors of this study.

4. Results and Discussion

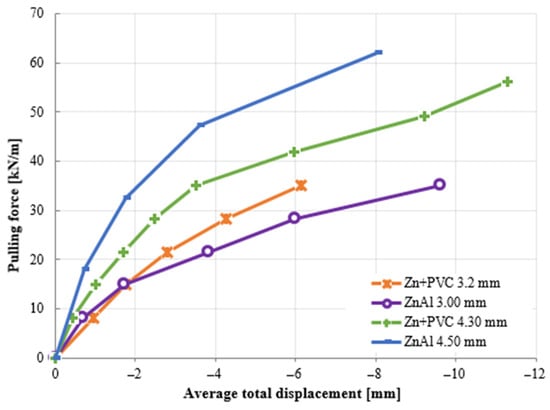

During the test, the test with the Zn + PVC 3.20 mm mesh resulted in the destruction of the mesh in the form of its tearing outside the box with the soil. In other cases, ejection of the reinforcement from the fine sand was achieved. For easier interpretation, the results obtained from the test were converted to unit width reinforcement, and these are presented in Figure 7.

Figure 7.

Force–displacement diagram from a simplified pullout test for fine sand.

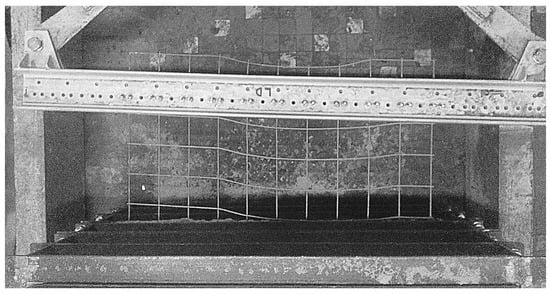

On the basis of the test results, it can be unequivocally stated that in the case of the Zn + PVC 3.20 mm mesh, the key parameter is its low strength, as it was the destruction of the mesh that caused the termination of the test (Figure 8). In the case of the remaining three meshes, the condition for termination of the test was that the load bearing capacity of the soil reinforcement system was reached (i.e., the mesh ejection from the soil).

Figure 8.

Damage of Zn + PVC 3.20 mm mesh after the pullout test—large displacements of the wires that were broken during the test are visible (the photo is greyed out for better visibility of the mesh against the floor).

The approximate values of the unit force necessary to damage the soil reinforcement system during a pullout test were also determined, and the results are presented in Table 2.

Table 2.

List of forces pulling the reinforcement in the form of welded meshes.

It has also been shown that as the stiffness of the reinforcement increases, the pullout resistance of this reinforcement increases as well, which is consistent with the observations of Yuan and Chua [44].

The values obtained for fine sand are similar to those presented in [44,45,46,47]. The authors of [44,45,46,47] also carried out similar tests in sands (or soil containing a lot of sand fraction in the case of [46]), with similar values of normal σn (the overall range is 2–140 kPa), but for different types of reinforcement, proving the validity of the conducted test. A summary of the test conditions is presented in Table 3.

Table 3.

Summary of selected test conditions.

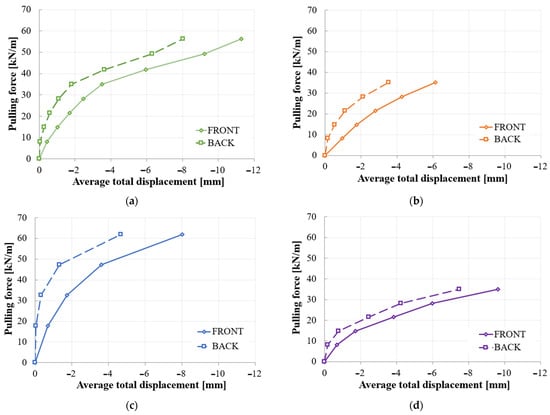

Furthermore, the decrease in the displacements along the length of the reinforcement embedded in soil during pullout tests of whole meshes embedded in soil medium was analysed. In the tests performed in fine sand, it was found that the displacements recorded on the sensors behind the box (BACK) were smaller than those recorded on the sensors at the force application side (FRONT) by about 30–40%, as presented in Figure 9.

Figure 9.

Recorded displacements at the front and back of the box for: (a) 4.30 mm Zn + PVC mesh; (b) 3.20 mm Zn + PVC mesh; (c) 4.50 mm ZnAl mesh; (d) 3.00 mm ZnAl mesh.

The relationship described above clearly indicates that the type of mesh affects the anchorage length in the passive zone. On the basis of the studies of Teerawattanasuk et al. [48], it is known that the displacements along the length of the reinforcement decrease in a curvilinear manner with increasing distance from the face of the tested structure. As the authors of this study only have the value of this displacement at two points, assuming its rectilinear slope, the anchorage length (for the maximum pullout forces applied in the tests) for the fine sand tested is approximately 2.3 to 3.0 m. These lengths are certainly underestimated, as the displacement value does not decrease in a linear way. Unfortunately, due to the lack of a third measurement point along the length of the reinforcement, the exact course of the curve describing this phenomenon cannot be determined.

It is worth noting that, on the basis of the research carried out, it is possible to easily determine the value of the apparent friction coefficient μk using Relationship (1):

where:

Tmax—a maximum pulling force [kN] (according to Table 2),

S—a mesh area [m2] (0.34 m2 for ZnAl, 4.50 mm and 0.75 m2 for others),

σv—a vertical stress at the level of the reinforcing steel mesh [kPa] (60 kPa in test).

The summary of the friction coefficients between the reinforcement and the soil μk calculated according to the above formula is presented in Table 4. The obtained values of the friction coefficient 0.39–1.47 are similar to those given by Lajevardi et al. [45], who reported values of the coefficient μk equal to 0.31–0.72. It is worth noting that in this study, for a steel mesh with a wire diameter of 4.5 mm, the friction coefficient (μk = 1.47) is much greater than that of Lajevardi et al. [45] for a steel grid with a wire diameter of 12 mm (μk = 0.72). This can be explained by the fact that the friction coefficient is determined not only by the diameter of the mesh wire (the larger it is, the greater the coefficient of friction is), but also the mesh opening (the smaller it is, the greater the friction coefficient is, because more wires are located on the same surface across the force action). In this study, we used 76.2 × 76.2 mm mesh opening, while Lajevardi et al. [45] examined grids with the mesh opening from 125 × 140 mm to 125 × 505 mm. On the other hand, Bergado et al. [46] showed coefficients of friction equal to μk = 1.04–1.78 for welded meshes with a wire diameter of 6.3–12.7 mm and a mesh opening from 152 × 152 mm to 152 × 225 mm. At the same time, it was confirmed that the coating type of the mesh wire affects the friction coefficient. The zinc-coated wires of the same diameter (or similar) to the polyvinyl chloride (PVC)-coated ones are characterized by a higher coefficient of friction, which is consistent with the results of the hexagonal wire mesh studies realised by Teerawattanasuk et al. [48]. By comparison, Bergado and Teerawattanasuk [47] demonstrated for woven meshes (with a similar geometry as in Lajevardi et al. [45] and Bergado et al. [40]) a coefficient of friction equal to μk = 0.2–0.30. This clearly shows that the welded meshes are more suitable for soil reinforcement than the commonly used woven meshes.

Table 4.

Coefficient of friction between reinforcement and soil μk based on the presented tests.

5. Conclusions

This study deals with the interaction of welded steel mesh, used for the production of gabions, with the soil depending on (1) the soil type (in this case fine sand FSa) and (2) the mesh parameters. The tested meshes (four types) were differentiated with respect to the diameter of the steel wire (2.7–4.5 mm) as well as the type of anticorrosion coating (Zn + PVC or ZnAl). Each of them had the same opening size: 76.2 × 76.2 mm. For the analysis, a proprietary stand was constructed (based on the geogrid test stand) to carry out a simplified pullout test.

Undoubtedly, it can be concluded that it is possible to make a retaining structure using soil reinforcement technology using steel welded meshes with a much smaller diameter (3.0, 3.8 and 4.5 mm) than 6–12 mm, used for the production of gabion baskets. This is the basic premise for the application of sustainable geotechnical principles in practice.

To confirm the above statement, a trial design replacement of the retaining structure with an extension of the abutment was performed using the parameters obtained during the tests described in this study. Originally, the retaining wall was designed using soil reinforced with flat steel bars with a facing of precast concrete elements. The wall has a height of 9.50 m from the top of the foundation to the highest point of the backfill. The replacement design of this retaining wall assumes that it will be made of gabions of a welded mesh made of Zn + PVC 4.30 mm wire. The facing made of gabion baskets is vertical. Facing basket reinforcement 1.0 m thick and 9.0 m long were adopted at a spacing of 0.75 m between the three lowest reinforcement layers and 1.0 m between the higher layers of soil reinforcement. A detailed description of the design process, the solutions adopted, and the geometry of the structure is presented in [29,49]. It is hereby shown that gabion retaining structures with welded meshes made using reinforced soil technology are possible for use in infrastructure construction applications.

Furthermore, on the basis of the conducted tests and the analysis of the obtained results, it can stated that the low deformability (hence greater stiffness) of the tensile welded meshes embedded in soil allows them to be used for soil reinforcement in all types of reinforced soil structures, including the abutments of engineering facilities (the maximum deformation in the elastic work phase was only equal to 0.35%). In the case of woven meshes, this type of use is not so obvious.

Another valuable observation is the dependence whereby the mesh with higher stiffness (e.g., made of a thicker wire, with smaller opening or stiff welded node), during the pullout test, obtained higher resistance to pulling from the soil compared to a less stiff mesh. This is a favourable phenomenon from the point of view of the use of retaining structures. The reinforcement effect can be explained by the favourable phenomenon of mesh wedging between soil grains. Taking into account that fine sand was considered in this study, it may be assumed that the effect will be greater in soils with a larger grain size. The authors plan to continue the initiated series of studies using other soils.

In addition, the obtained results are a good basis for further model tests both in the laboratory and in situ on welded meshes in function of reinforcing soil. The main objective is to propose all coefficients necessary for the design of the engineering structures mentioned above in the future. In this study, the first of such parameters was determined—the apparent friction coefficient μk. The next ones require more advanced research.

Author Contributions

Conceptualization, methodology, M.J. and M.Ć.; investigation, validation, research tests, M.Ć.; formal analysis, M.J. and M.Ć.; writing—original draft preparation, M.J. and M.Ć.; visualization, writing—review and editing, M.J.; funding acquisition, M.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. The APC was partially funded by the professor’s grant No 03/070/RGP19/0125 awarded by the Rector of the Silesian University of Technology (Gliwice, Poland).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study is available in the source materials included in the References.

Acknowledgments

The authors would like to express their gratitude to the company BETAFENCE Sp. z o.o. which delivered the steel welded grids for this study free of charge, and the company CzekAmet PL Sp. z o.o. Sp. k. delivered clamping jaws for this study free of charge.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Conti, L.; Barbari, M.; Monti, M. Design of sustainable agricultural buildings. A case study of a wine cellar in Tuscany, Italy. Buildings 2016, 6, 17. [Google Scholar] [CrossRef] [Green Version]

- Kania, M. Safe escarpment and slopes. Geoinżynieria Drog. Mosty Tunele 2013, 42, 28–33. Available online: https://inzynieria.com/geoinzynieria/artykuly/33008,bezpieczne-skarpy-i-zbocza (accessed on 20 February 2013). (In Polish).

- Nevečerel, H.; Pavešić, K.; Murgić, I.; Papa, I.; Landekić, M.; Lepoglavec, K. Possibilities of gabion application. Nova Meh. Sumar. 2016, 37, 59–68. Available online: https://hrcak.srce.hr/index.php?show=clanak&id_clanak_jezik=256570 (accessed on 1 September 2021). (In Croatian).

- Bouafia, A. Conception et Calcul des Ouvrages Géotechniques; Editions Pages Bleues Internationales: Bab Ezzouar, Algeria, 2011. (In French) [Google Scholar]

- Surowiecki, A. About the designing of gabion structures in communication construction. Drogownictwo 2001, 3, 81–86. Available online: http://drogownictwo.sitkrp.org.pl/index.php?option=com_content&view=article&id=136:streszczenia-abstract-do-numeru-3-2001-r&catid=10&Itemid=105&lang=pl (accessed on 1 September 2021). (In Polish).

- Toprak, B.; Sevim, Ö.; Kalkan, İ. Gabion walls and their use. Int. J. Adv. Mech. Civ. Eng. 2016, 3, 56–58. Available online: http://ijamce.iraj.in/paper_detail.php?paper_id=5392&name=Gabion_Walls_and_Their_Use (accessed on 1 September 2021).

- Surowiecki, A.; Kozłowski, W. Gabion retaining walls stabilizing road embankments in the light of model studies. Geoinżynieria Drog. Mosty Tunele 2011, 5, 34–38. Available online: https://inzynieria.com/geoinzynieria/artykuly/27232,gabionowe-sciany-oporowe-jako-stabilizacja-nasypow-komunikacyjnych-w-swietle-badan-modelowych (accessed on 1 September 2021). (In Polish).

- Craswell, T.; Akib, S. Reducing bridge pier scour using gabion mattresses filled with recycled and alternative materials. Eng 2020, 1, 188–210. [Google Scholar] [CrossRef]

- Jarominiak, A. Lightweight Retaining Structures, 3rd ed.; WKiŁ: Warsaw, Poland, 2000; Available online: https://www.naukowa.pl/Ksiazki/lekkie-konstrukcje-oporowe-173495 (accessed on 1 September 2021). (In Polish)

- Kosiński, T. Maccaferri solutions in the stabilization and reconstruction of landslides. Geoinżynieria Drog. Mosty Tunele 2013, 42, 34–38. Available online: https://inzynieria.com/geoinzynieria/artykuly/33009,rozwiazania-maccaferri-w-stabilizacji-i-rekonstrukcji-osuwisk (accessed on 1 September 2021). (In Polish).

- Najder, T.; Najder, A. Gabions and gabion mattresses as elements of environmentally friendly construction. Mater. Bud. 2005, 1, 87–91. Available online: https://www.sigma-not.pl/publikacja-10410-gabiony-i-materace-gabionowe-jako-elementy-budownictwa-przyjaznego-%C5%9Brodowisku-materialy-budowlane-2005-1.html (accessed on 1 September 2021). (In Polish).

- Balawejder, A.; Surowiecki, A.; Kozłowski, W. The embankment with gabion wall slope built-slope, damming up water. Drog. Lądowe Powietrzne Wodne 2011, 6, 36–43. (In Polish) [Google Scholar]

- Kosiński, T.; Michalski, T.; Bosak, J. Terramesh as a source of savings in the reconstruction of road embankments. Górnictwo i Geoinżynieria 2010, 34, 405–413. Available online: https://journals.bg.agh.edu.pl/GORNICTWO/index.php?vol=2010-02 (accessed on 1 September 2021). (In Polish).

- Kuc, M. Properties of gabions made of woven or welded mesh. Mag. Autostrady 2012, 7, 18–20. Available online: https://autostrady.elamed.pl/uploads/mau/articles/autostrady_artykul_2012_07_36125.pdf (accessed on 1 September 2021). (In Polish).

- Kuc, M.; Mika, A. Gabion retaining wall in the area of mining damage. Mater. Bud. 2004, 10, 85–86. Available online: https://www.sigma-not.pl/publikacja-2767-gabionowy-mur-oporowy-na-terenie-szk%C3%B3d-g%C3%B3rniczych-materialy-budowlane-2004-10.html (accessed on 1 September 2021). (In Polish).

- Pisarczyk, S. Geoengineering-Methods of Soil Modification, 3rd ed.; Oficyna Wydawnicza Politechniki Warszawskiej (OWPW): Warsaw, Poland, 2020; Available online: https://www.ibuk.pl/fiszka/221801/geoinzynieria-metody-modyfikacji-podloza-gruntowego.html (accessed on 1 September 2021). (In Polish)

- Sobala, D.; Rybak, J. Role to be played by independent geotechnical supervision in the foundation for bridge construction. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022073. [Google Scholar] [CrossRef]

- Campelo, N.; Filho, M.; Valadares, O.; Paes, M.; Aragao, A. Georeferenced monitoring of displacements of gabion walls. Geotech. Eng. 2018, 171, 64–77. [Google Scholar] [CrossRef]

- Construction Report 2014: Gabion Retaining Structure, A4 Motorway Ruda Śląska, Poland; Maccaferri Company Poland: Warsaw, Poland, 2014; Available online: https://www.maccaferri.com/pl/produkty/gabiony-2/. (accessed on 1 September 2021). (In Polish)

- Koussa, F.; Defrance, J.; Jean, P.; Blanc-Benon, P. Acoustic performance of gabions noise barriers: Numerical and experimental approaches. Appl. Acoust. 2013, 74, 189–197. [Google Scholar] [CrossRef]

- Tang, V.T.; Fu, D.; Ngoc Binh, T.; Rene, E.R.; Sang, T.T.T.; Singh, R.P. An investigation on performance and structure of ecological revetment in a sub-tropical area: A case study on Cuatien River, Vinh City, Vietnam. Water 2018, 10, 636. [Google Scholar] [CrossRef] [Green Version]

- Fan, Y.; Yang, Z.; Li, M.; Zhang, Z.; Li, D. Comparative analysis on environmental adaptability of two types of bank stabilization structures along the middle and lower reaches of the Yangtze River. Sustainability 2020, 12, 7991. [Google Scholar] [CrossRef]

- Lin, Y.L.; Yang, G.L.; Li, Y.; Zhao, L.H. Engineering behaviors of reinforced gabion retaining wall based on laboratory test. J. Cent. South Univ. 2010, 17, 1351–1356. [Google Scholar] [CrossRef]

- Kosiński, T. Retaining Structures and Embankments Made of Soil Reinforced with Steel Elements. In seminar materials of IBDiM and PZWFS on Steel Structures in Geotechnics; unpublished. (In Polish)

- Ciomcia, B. Bridgeheads of the engineering structures made of a reinforced soil. Mag. Autostrady 2014, 8-9, 64–67. Available online: https://autostrady.elamed.pl/uploads/mau/articles/20956/64-67.pdf. (accessed on 1 September 2021).

- Jayasree, P.K. Performance of Gabion Faced Reinforced Earth Retaining Walls. Ph.D. Thesis, Cochin University of Science and Technology, Kochi, India, 2008. Available online: http://dyuthi.cusat.ac.in/purl/2821 (accessed on 1 April 2008).

- Koerner, R.M. Designing with Geosynthetics, 5th ed.; Pearson College Div: Prentice-Hall, NJ, USA, 18 April 2005; Available online: https://www.slideshare.net/AgungNoorsamsi/designing-with-geosynthetics-by-koerner-5th-edition-2005. (accessed on 1 September 2021).

- Koerner, R.M.; Soong, T.Y. Geosynthetic reinforced segmental retaining walls. Geotext. Geomembr. 2001, 19, 359–386. [Google Scholar] [CrossRef]

- Ćwirko, M. The Analysis of the Cooperation of Steel Welded Meshes with Soil in Retaining Structures of Gabion Walls Technology. Ph.D. Thesis, Silesian University of Technology, Gliwice, Poland, 1 September 2019. Available online: https://www.researchgate.net/publication/336141586_Analiza_wspolpracy_stalowych_siatek_zgrzewanych_z_gruntem_w_konstrukcjach_oporowych_wykonanych_w_technologii_murow_gabionowych (accessed on 1 September 2021). (In Polish).

- Bilgin, Ö. Failure mechanisms governing reinforcement length of geogrid reinforced soil retaining walls. Eng. Struct. 2009, 31, 1967–1975. [Google Scholar] [CrossRef]

- Sułkowska, A. The Model Tensil Tests Analysis of the Welded Meshes in the ZincAlu Coating or Coated with PVC, Embedded in a Fine Sand. M.Sc. Thesis, Silesian University of Technology, Gliwice, Poland, 2018. (In Polish). [Google Scholar]

- PN-EN 10223-8:2014-03. Steel Wire and Wire Products for Fencing and Netting. In Welded Mesh Gabion Products; PKN: Warszawa, Poland, 2014. (In Polish) [Google Scholar]

- PN-EN 10244-2:2010. Steel Wire and Wire Products. Non-ferrous Metallic Coatings on Steel Wire. In Zinc or Zinc Alloy Coatings; PKN: Warszawa, Poland, 2010. (In Polish) [Google Scholar]

- PN-EN 10245-2:2011. Steel Wire and Wire Products. Organic Coatings on Steel Wire. In PVC Finished Wire; PKN: Warszawa, Poland, 2011. (In Polish) [Google Scholar]

- Sampaco, C.L. Behavior of Welded Wire Mesh Reinforced Soil Walls from Field Evaluation and Finite Element Simulation. Ph.D. Thesis, Utah State University, Logan, UT, USA, 1996. Available online: http://rizal.library.ateneo.edu/index.php/node/9734. (accessed on 1 September 2021).

- PN-EN 13738:2006. Geotextiles and Geotextile-Related Products. In Determination of Pullout Resistance in Soil; PKN: Warszawa, Poland, 2006. (In Polish) [Google Scholar]

- Bolt, A.; Duszyńska, A. Pullout testing of geosynthetics embedded in soil in large scale pullout apparatus. Zesz. Nauk. Politech. Śląskiej 2003, 1573, 387–394. Available online: http://delibra.bg.polsl.pl/Content/40386/BCPS_44148_2003_Badania-oporu-geosyn.pdf. (accessed on 1 September 2021). (In Polish).

- Ezzein, F.M.; Bathurst, R.J. A new approach to evaluate soil-geosynthetic interaction using a novel pullout test apparatus and transparent granular soil. Geotext. Geomembr. 2014, 42, 246–255. [Google Scholar] [CrossRef]

- Prashanth, V.; Murali Krishna, A.; Dash, S.K. Pullout tests using modified direct shear test setup for measuring soil–geosynthetic interaction parameters. Int. J. Geosynth. Ground Eng. 2016, 2, 10. [Google Scholar] [CrossRef] [Green Version]

- Park, J.B.; Kim, D.K.; Yang, S.B.; Kim, J.H. Pullout characteristics of geosynthetics reinforced earth using multilayer spreading pullout test. Adv. Mater. Sci. Eng. 2017, 2017, 9485826. [Google Scholar] [CrossRef] [Green Version]

- Rahmaninezhad, S.; Han, J.; Kakrasul, J.; Weldu, M. Stress distributions and pullout responses of extensible and inextensible reinforcement in soil using different normal loading methods. Geotech. Test. J. 2019, 42, 1606–1623. [Google Scholar] [CrossRef]

- Kawalec, J. Aggregate–Geogrid Interaction in Stabilisation Applications. How far Standard Laboratory Index Test Results are from Reality. In In Proceedings of the 11th International Conference on Geosynthetics 2018 (11ICG), Seoul, Korea, 16–21 September 2018; Korean Geosynthetics Society: Seoul, Korea, 2018; Volume 4, pp. 3142–3149. Available online: https://www.researchgate.net/publication/328289757_Aggregate-geogrid_interaction_in_stabilisation_applications_How_far_standard_laboratory_index_test_results_are_from_reality (accessed on 1 September 2021).

- Kim, J. Development and Applicability of Multi-layer Pullout Apparatus System. Ph.D. Thesis, Sunchon National University, Suncheon, Korea, 2008. [Google Scholar]

- Yuan, Z.; Chua, K.M. Numerical evaluation the pullout box method for studying soil-reinforcement interaction. Transp. Res. Rec. 1990, 1278, 116–124. Available online: http://onlinepubs.trb.org/Onlinepubs/trr/1990/1278/1278-015.pdf. (accessed on 1 September 2021).

- Lajevardi, S.H.; Dias, D.; Racinais, J. Analysis of soil-welded steel mesh reinforcement interface interaction by pull-out tests. Geotext. Geomembr. 2013, 40, 48–57. [Google Scholar] [CrossRef]

- Bergado, D.T.; Macatol, K.C.; Amin, N.U.; Chai, J.C.; Alfaro, M.C.; Anderson, L.R. Interaction of lateritic soil and steel grid reinforcement. Can. Geotech. J. 2011, 30, 376–384. [Google Scholar] [CrossRef]

- Bergado, D.T.; Teerawattanasuk, C. Analytical models for predicting the pullout capacity and interaction between hexagonal wire mesh and silty sand backfill. J. Appl. Sci. Eng. 2001, 4, 227–238. [Google Scholar] [CrossRef]

- Teerawattanasuk, C.; Bergado, D.T.; Kongkitkul, W. Analytical and numerical modeling of pullout capacity and interaction between hexagonal wire mesh and silty sand backfill under an in-soil pullout test. Can. Geotech. J. 2003, 40, 886–899. [Google Scholar] [CrossRef]

- Woźniak, L. A Retaining Wall Made of Reinforced Soil in the Technology of a Gabion Wall Reinforced with a Steel Welded Mesh. M.Sc. Thesis, Silesian University of Technology, Gliwice, Poland, 2019. (In Polish). [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).