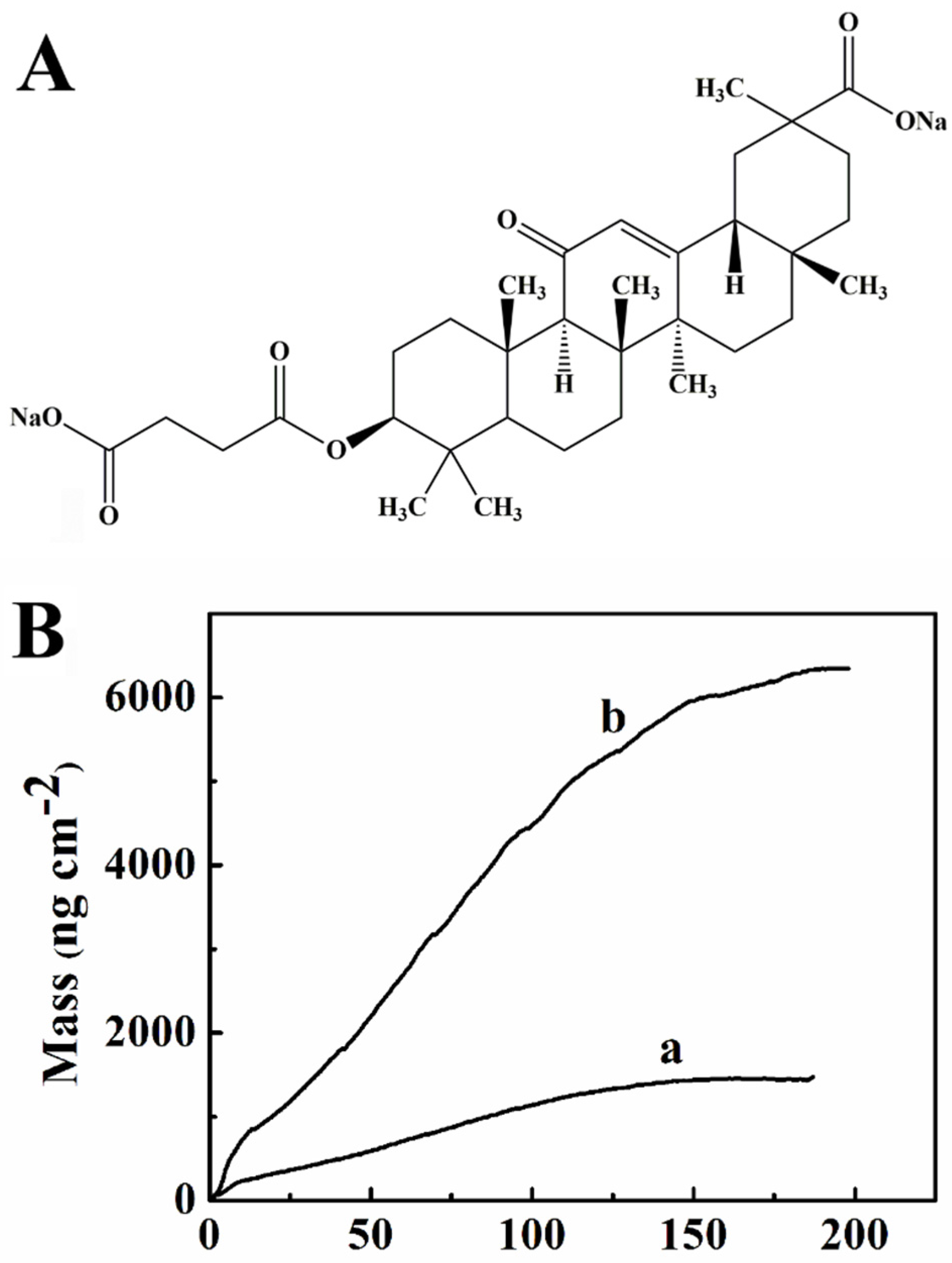

Carbenoxolone as a Multifunctional Vehicle for Electrodeposition of Materials

Abstract

1. Introduction

2. Materials and Methods

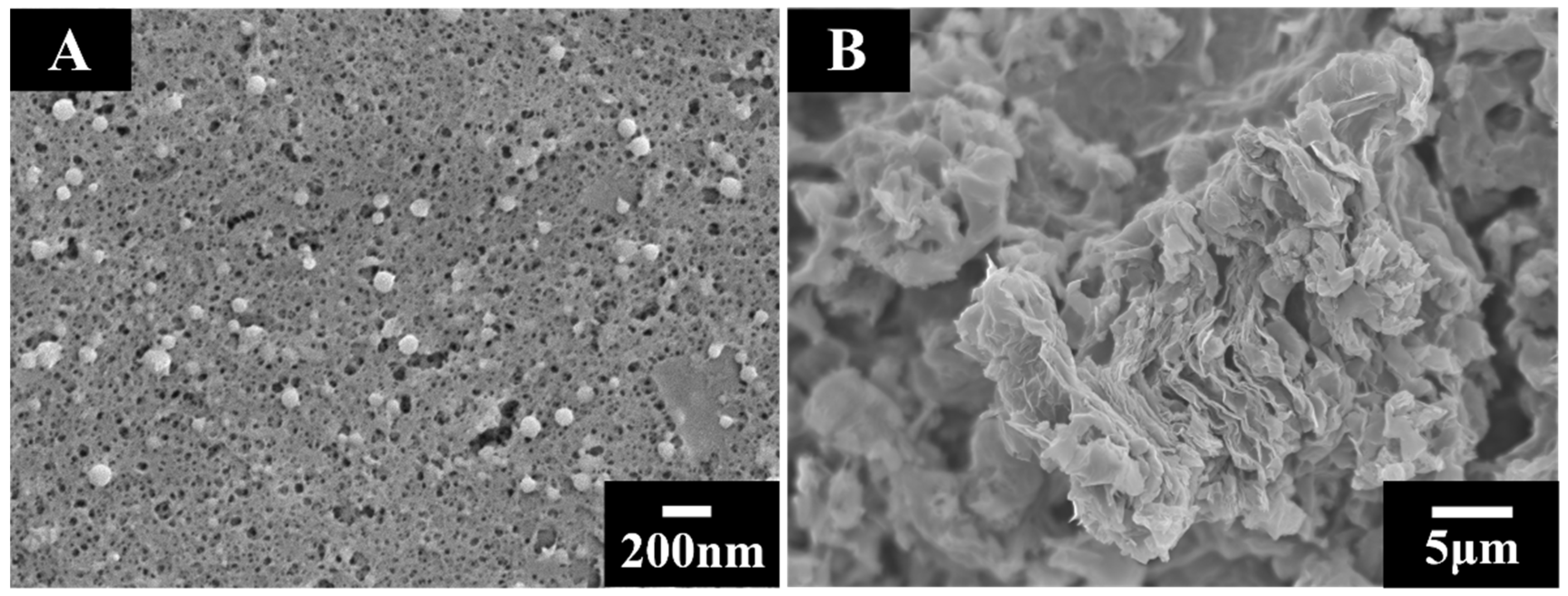

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheong, M.; Zhitomirsky, I. Electrophoretic deposition of manganese oxide films. Surf. Eng. 2009, 25, 346–352. [Google Scholar] [CrossRef]

- Argüello, J.A.; Cerpa, A.; Moreno, R. Reinforcing effect of graphene nanoplatelets in the electrochemical behaviour of manganese oxide-based supercapacitors produced by EPD. Ceram. Int. 2019, 45, 14316–14321. [Google Scholar] [CrossRef]

- Yus, J.; Bravo, Y.; Sanchez-Herencia, A.J.; Ferrari, B.; Gonzalez, Z. Electrophoretic deposition of RGO-NiO core-shell nanostructures driven by heterocoagulation method with high electrochemical performance. Electrochim. Acta 2019, 308, 363–372. [Google Scholar] [CrossRef]

- Jin, C.; Wang, Y.; Yang, Z.; Wang, D. C/C composite surface modified by electrophoretic depositing SiC nanowires and its brazing to Nb. Ceram. Int. 2020, 46, 204–211. [Google Scholar] [CrossRef]

- Boudaira, R.; Meglali, O.; Bouraiou, A.; Attaf, N.; Sedrati, C.; Aida, M. Optimization of sulphurization temperature for the production of single-phase CZTS kesterite layers synthesized by electrodeposition. Surf. Eng. 2020, 36, 1000–1011. [Google Scholar] [CrossRef]

- Mandal, P.; Mondal, S.C. Enhancement of electro-thermal and mechanical properties for Cu-SWCNT coated 6061Al. Surf. Eng. 2020, 36, 135–143. [Google Scholar] [CrossRef]

- Yang, L.; Pang, X.; Fox-Rabinovich, G.; Veldhuis, S.; Zhitomirsky, I. Electrophoretic deposition of polymer and composite films. Surf. Eng. 2012, 28, 585–589. [Google Scholar] [CrossRef]

- Sun, Y.; Ata, M.; Zhitomirsky, I. Electrophoretic deposition of linear polyethylenimine and composite films. Surf. Eng. 2013, 29, 495–499. [Google Scholar] [CrossRef]

- Jabbari, Z.; Nassernejad, B.; Fallah, N.; Javanbakht, M.; Afsham, N. Fabrication of novel binderless anode via electrophoretic deposition for HT-PEMFC. Surf. Eng. 2019, 35, 1013–1020. [Google Scholar] [CrossRef]

- Emarati, S.M.; Mozammel, M. Fabrication of superhydrophobic titanium dioxide coating on AISI 316L stainless steel by electrophoretic deposition and using trimethoxy (propyl) silane modification. Surf. Eng. 2019, 35, 456–465. [Google Scholar] [CrossRef]

- Rousta, A.; Dorranian, D.; Elahi, M. Electrophoretic deposition of cobalt oxide nanoparticles on aluminium substrate. Surf. Eng. 2020, 36, 919–928. [Google Scholar] [CrossRef]

- Saadati, A.; Hesarikia, H.; Nourani, M.R.; Taheri, R.A. Electrophoretic deposition of hydroxyapatite coating on biodegradable Mg–4Zn–4Sn–0.6 Ca–0.5 Mn alloy. Surf. Eng. 2020, 36, 908–918. [Google Scholar] [CrossRef]

- Gorji, M.; Sanjabi, S.; Edtmaier, C. Combination of electrophoretic and electroless depositions to fabricate Ni/TiC cladding. Surf. Eng. 2020, 36, 929–935. [Google Scholar] [CrossRef]

- Tiwari, P.; Ferson, N.D.; Andrew, J.S. Elucidating the role of electrophoretic mobility for increasing yield in the electrophoretic deposition of nanomaterials. J. Colloid Interface Sci. 2020, 570, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Arguello, J.A.; Rojo, J.M.; Moreno, R. Electrophoretic deposition of manganese oxide and graphene nanoplatelets on graphite paper for the manufacture of supercapacitor electrodes. Electrochim. Acta 2019, 294, 102–109. [Google Scholar] [CrossRef]

- Choudhary, B.; Anwar, S.; Besra, L.; Anwar, S. Electrophoretic deposition studies of Ba (Zr-Ce-Y) O3 ceramic coating. Int. J. Appl. Ceram. Technol. 2019, 16, 1022–1031. [Google Scholar] [CrossRef]

- Jafarpour, M.; Aghajani, H.; Ajabshir, A.G. Stability and electrophoretic deposition of nano-SiC assisted by PEI. J. Dispers. Sci. Technol. 2019, 40, 1715–1724. [Google Scholar] [CrossRef]

- Avcu, E.; Baştan, F.E.; Abdullah, H.Z.; Rehman, M.A.U.; Avcu, Y.Y.; Boccaccini, A.R. Electrophoretic deposition of chitosan-based composite coatings for biomedical applications: A review. Prog. Mater. Sci. 2019, 103, 69–108. [Google Scholar] [CrossRef]

- Sikkema, R.; Baker, K.; Zhitomirsky, I. Electrophoretic deposition of polymers and proteins for biomedical applications. Adv. Colloid Interface Sci. 2020, 284, 102272. [Google Scholar] [CrossRef]

- Deen, I.; Pang, X.; Zhitomirsky, I. Electrophoretic deposition of composite chitosan–halloysite nanotube–hydroxyapatite films. Colloids Surf. A Physicochem. Eng. Asp. 2012, 410, 38–44. [Google Scholar] [CrossRef]

- Amiri, S.; Hayes, R.E.; Sarkar, P. Evolution of electronic conductivity in a Ni/YSZ electrode fabricated by electrophoretic deposition. Can. J. Chem. Eng. 2019, 97, 1114–1120. [Google Scholar] [CrossRef]

- Pang, X.; Zhitomirsky, I.; Niewczas, M. Cathodic electrolytic deposition of zirconia films. Surf. Coat. Technol. 2005, 195, 138–146. [Google Scholar] [CrossRef]

- Zhitomirsky, I.; Petric, A. Electrochemical deposition of yttrium oxide. J. Mater. Chem. 2000, 10, 1215–1218. [Google Scholar] [CrossRef]

- Ata, M.; Zhitomirsky, I. Colloidal methods for the fabrication of carbon nanotube–manganese dioxide and carbon nanotube–polypyrrole composites using bile acids. J. Colloid Interface Sci. 2015, 454, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Ata, M.; Sun, Y.; Li, X.; Zhitomirsky, I. Electrophoretic deposition of graphene, carbon nanotubes and composites using aluminon as charging and film forming agent. Colloids Surf. A Physicochem. Eng. Asp. 2012, 398, 9–16. [Google Scholar] [CrossRef]

- Van der Biest, O.O.; Vandeperre, L.J. Electrophoretic deposition of materials. Annu. Rev. Mater. Sci. 1999, 29, 327–352. [Google Scholar] [CrossRef]

- Ferrari, B.; Moreno, R. EPD kinetics: A review. J. Eur. Ceram. Soc. 2010, 30, 1069–1078. [Google Scholar] [CrossRef]

- Li, J.; Wojtal, P.; Wallar, C.; Zhitomirsky, I. Electrochemical deposition of polypyrrole–carbon nanotube films using steroid dispersants. Mater. Manuf. Process. 2018, 33, 1062–1066. [Google Scholar] [CrossRef]

- Duax, W.; Ghosh, D.; Pletnev, V.; Griffin, J. Three-dimensional structures of steroids and their protein targets. Pure Appl. Chem. 1996, 68, 1297–1302. [Google Scholar] [CrossRef][Green Version]

- Hou, H.; Banks, C.E.; Jing, M.; Zhang, Y.; Ji, X. Carbon Quantum Dots and Their Derivative 3D Porous Carbon Frameworks for Sodium-Ion Batteries with Ultralong Cycle Life. Adv. Mater. 2015, 27, 7861–7866. [Google Scholar] [CrossRef]

- Ammam, M. Electrophoretic deposition under modulated electric fields: A review. RSC Adv. 2012, 2, 7633–7646. [Google Scholar] [CrossRef]

- Hu, S.; Li, W.; Li, W.; Zhang, N.; Qi, H.; Finklea, H.; Liu, X. Aqueous electrophoretic deposition of gadolinium doped ceria. Colloids Surf. A Physicochem. Eng. Asp. 2019, 579, 123717. [Google Scholar] [CrossRef]

- Sikkema, R.; Keohan, B.; Zhitomirsky, I. Hyaluronic-Acid-Based Organic-Inorganic Composites for Biomedical Applications. Materials 2021, 14, 4982. [Google Scholar] [CrossRef] [PubMed]

- Sikkema, R.; Keohan, B.; Zhitomirsky, I. Alginic Acid Polymer-Hydroxyapatite Composites for Bone Tissue Engineering. Polymers 2021, 13, 3070. [Google Scholar] [CrossRef]

- Zhitomirsky, I.; Gal-Or, L. Formation of hollow fibers by electrophoretic deposition. Mater. Lett. 1999, 38, 10–17. [Google Scholar] [CrossRef]

- Wojtal, P.; Zhitomirsky, I. Surface modification and electrophoretic deposition of materials using 2, 2′-biquinoline-4, 4′-dicarboxylic acid. Mater. Lett. 2016, 174, 44–47. [Google Scholar] [CrossRef]

- Su, Y.; Zhitomirsky, I. Electrophoretic assembly of organic molecules and composites for electrochemical supercapacitors. J. Colloid Interface Sci. 2013, 392, 247–255. [Google Scholar] [CrossRef] [PubMed]

- Cheong, M.; Zhitomirsky, I. Electrodeposition of alginic acid and composite films. Colloids Surf. A Physicochem. Eng. Asp. 2008, 328, 73–78. [Google Scholar] [CrossRef]

- Ata, M.S.; Poon, R.; Syed, A.M.; Milne, J.; Zhitomirsky, I. New developments in non-covalent surface modification, dispersion and electrophoretic deposition of carbon nanotubes. Carbon 2018, 130, 584–598. [Google Scholar] [CrossRef]

- Wang, R.; Xu, G.; He, Y. Structure and properties of polytetrafluoroethylene (PTFE) fibers. e-Polymers 2017, 17, 215–220. [Google Scholar] [CrossRef]

- Ahn, S.; Lee, J.; Kim, H.; Kim, J. A study on the quantitative determination of through-coating porosity in PVD-grown coatings. Appl. Surf. Sci. 2004, 233, 105–114. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Veldhuis, S.; Mathews, R.; Zhitomirsky, I. Carbenoxolone as a Multifunctional Vehicle for Electrodeposition of Materials. Appl. Sci. 2021, 11, 9110. https://doi.org/10.3390/app11199110

Liu X, Veldhuis S, Mathews R, Zhitomirsky I. Carbenoxolone as a Multifunctional Vehicle for Electrodeposition of Materials. Applied Sciences. 2021; 11(19):9110. https://doi.org/10.3390/app11199110

Chicago/Turabian StyleLiu, Xinqian, Stephen Veldhuis, Ritch Mathews, and Igor Zhitomirsky. 2021. "Carbenoxolone as a Multifunctional Vehicle for Electrodeposition of Materials" Applied Sciences 11, no. 19: 9110. https://doi.org/10.3390/app11199110

APA StyleLiu, X., Veldhuis, S., Mathews, R., & Zhitomirsky, I. (2021). Carbenoxolone as a Multifunctional Vehicle for Electrodeposition of Materials. Applied Sciences, 11(19), 9110. https://doi.org/10.3390/app11199110