1. Introduction

Pyroelectric infrared sensors, consisting of a thin film of ferroelectric crystal material sandwiched between two electrodes, produce an electrical voltage (or current) in response to temperature variation and have found widespread use in recent years for many applications, including thermal comfort monitoring, infrared light detection and imaging, fire detection, intruder alarms, body temperature monitoring, and so on [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10]. Many studies have reported that the sensitivity of pyroelectric sensors can be improved by reducing heat losses from the sensing elements to the supporting substrate or environment [

11,

12,

13,

14,

15]. It has been shown that this can be readily achieved by using bulk micromachining techniques to realize freestanding sensing structures, such as floating membranes, cantilever beams and bridges, which are effectively suspended above the supporting silicon substrate and shielded from the environment [

16]. Moreover, pyroelectric sensors can be easily integrated with modern IC circuits on the same chip to realize sophisticated system-on-chip (SoC) devices for a wide variety of sensing and detection applications [

17,

18].

Hashimoto et al. [

19] constructed a people-counting system based on a pyroelectric array detector for detecting the moving direction and number of passersby at a door. The pyroelectric detector incorporated a thin PbTiO

3 bulk ceramic film with a thickness of approximately 40 μm and was driven by a supply voltage of 5 V. The detector showed a maximum voltage sensitivity of 23 mV/mW at a chopping frequency of 10 Hz. Chang and Tang [

20] fabricated an integrated pyroelectric sensor consisting of a PZT thin film and a Si JFET. The device was characterized over a modulation frequency range of 0.2 to 10 Hz and was found to have a voltage sensitivity of 191 mV/mW at a modulation frequency of 1 Hz when implemented with a 500 μm thick silicon substrate. Some other ferroelectric ceramics (e.g., (Bi, Na)TiO

3, (Sr, Ba)NbO

3, Pb(Sc, Ta)O

3 (Ba, Sr)TiO

3 and Pb(Zr, Sn, Ti)O

3) were investigated to be suitable for pyroelectric detection applications, recently [

21]. Lienhard and Heepmann [

22] investigated the transmittance of thin nickel (Ni) films deposited on pyroelectric polyvinylidene fluoride (PVDF) films over the infrared spectral range of 2–50 μm. It was shown that the absorbance characteristics of the pyroelectric sensor could be effectively controlled through an appropriate specification of the Ni film thickness. Chong et al. [

23] fabricated a thin-film pyroelectric sensor array consisting of 16 sensing elements made of metal–ZnO–metal sandwiched layers with dimensions of 200 μm × 200 μm. The sensor response was enhanced by depositing the sensing elements on a thermally isolated and freestanding Si

3N

4/SiO

2 membrane created by removing the underside of the SiO

2 substrate using a conventional back-etching technique. The experimental results showed that the device achieved a maximum voltage sensitivity of 110 mV/mW at a cutoff frequency of 20 Hz. Hsiao et al. [

24] used a two-step radio frequency (RF) sputtering technique to fabricate a ZnO pyroelectric sensor on a back-etched silicon wafer. The use of the two-step deposition process was found to produce a ZnO film with a preferred c-axis orientation and an enhanced voltage response. It was shown that the sensor achieved a maximum voltage sensitivity of 8.6 mV/mW at a cutoff frequency of 500 Hz when implemented with a Ni coating on the uncovered part of the ZnO film in order to enhance the absorption of the incident energy. Wei et al. [

25] fabricated ZnO pyroelectric sensors with partially covered and fully covered electrodes, respectively. The experimental results showed that the responsivity of the partially covered device was around four times higher than that of the fully covered device for incident light frequencies in the range of 10–1000 Hz. Liu et al. [

26] deposited a thin Ni layer on the surface of a PZT pyroelectric sensor as both the top electrode and a selective absorption layer. The maximum absorption coefficient of the resulting sensor was found to be 0.8 at a wavelength of 0.664 μm and 0.7 at a wavelength of 4 μm. Gaur et al. [

27] presented a pyroelectric detector consisting of a polycrystalline AlN thin film and a SiO

2 layer with a thickness of 1.0 μm which served as both a thermal isolation layer and a diaphragm to support the sensor. It was shown that the absorptivity of the device could be enhanced by sputtering an additional Au film with a thickness of 160 nm on top of the AlN layer. Overall, the characterization results showed that the device achieved a response time of 8.0 ms and a pyroelectric current responsivity of 2.5 × 10

−6 A/W.

Recently, Luo et al. [

28] proposed a method to leverage the synergy between location and motion information to realize human simultaneous tracking and activity recognition by constructing a wireless sensor network and the sensor nodes of pyroelectric infrared sensor arrays. Yan et al. [

29] examined various factors influencing human identification based on pyroelectric infrared sensor. They found that distance, human target, sensor design, body type, human moving velocity, and signal modulation mask are all important factors in the mechanism. Wu et al. [

30] presented pyroelectric detection and sensing signal processing algorithms to create a non-wearable cooperative indoor human localization system based on pyroelectric sensor networks.

While the studies above provide many useful insights into the design, fabrication and characterization of pyroelectric sensors fabricated with various metallic layers, the effects of the substrate thickness on the performance of pyroelectric sensors have thus far attracted only little attention in the literature. Accordingly, the present study fabricates pyroelectric sensors consisting of suspended zinc oxide (ZnO) pyroelectric films with substrate thicknesses ranging from 1 to 500 μm supported on thermally insulated back-etched silicon substrates. The temperature variation and voltage response of the various sensors are evaluated numerically and experimentally for an infrared laser source with a power of 10 mW and a wavelength of 765 nm. In general, the results show that the performance of the proposed sensor improves as the thickness of the substrate reduces.

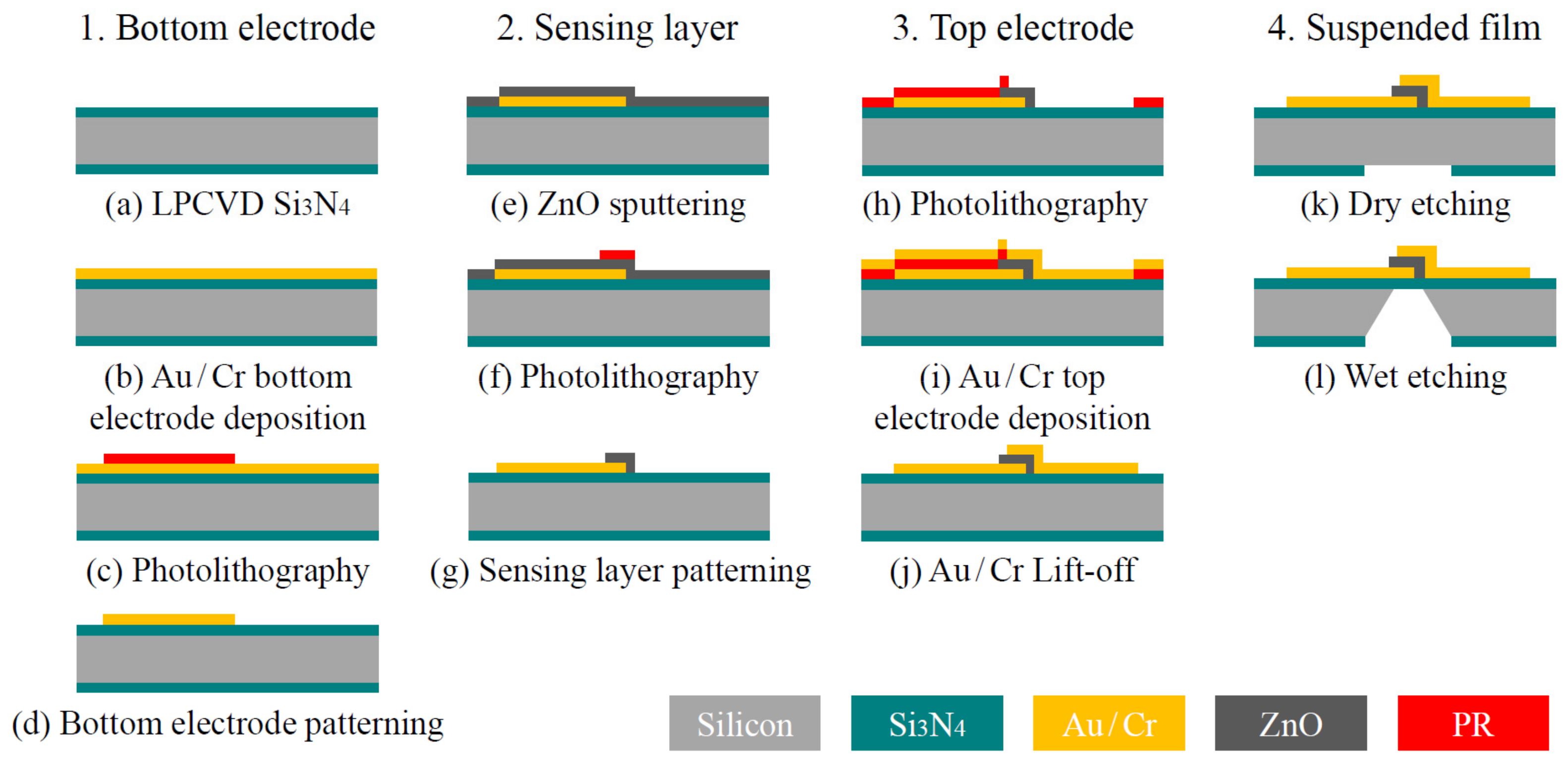

2. Principles and Designs

The analysis of any pyroelectric detector requires a careful consideration of both its thermal characteristics and its electrical response. Assume that infrared light with a power

W(

t) sinusoidally modulated at a frequency

is incident on the surface of a pyroelectric sensing element with an electrode area

A, thickness

d and surrounding temperature

T. The incident power can be formulated mathematically as follows [

31]:

Assume further that the sensing element has a thermal capacity

HT, and the thermal conductance to the surroundings is denoted as

GT, giving a thermal time constant of

. Given an emissivity

, the temperature difference between the element and its surroundings,

, can be described as [

28]:

which has the solution [

31]:

Differentiating Equation (3), the rate of the temperature difference between the element and its surrounding is obtained as:

Quantitatively, the pyroelectric effect can be evaluated as the product of the pyroelectric coefficient

p of the sensing material and the rate of change of the temperature difference, i.e.,

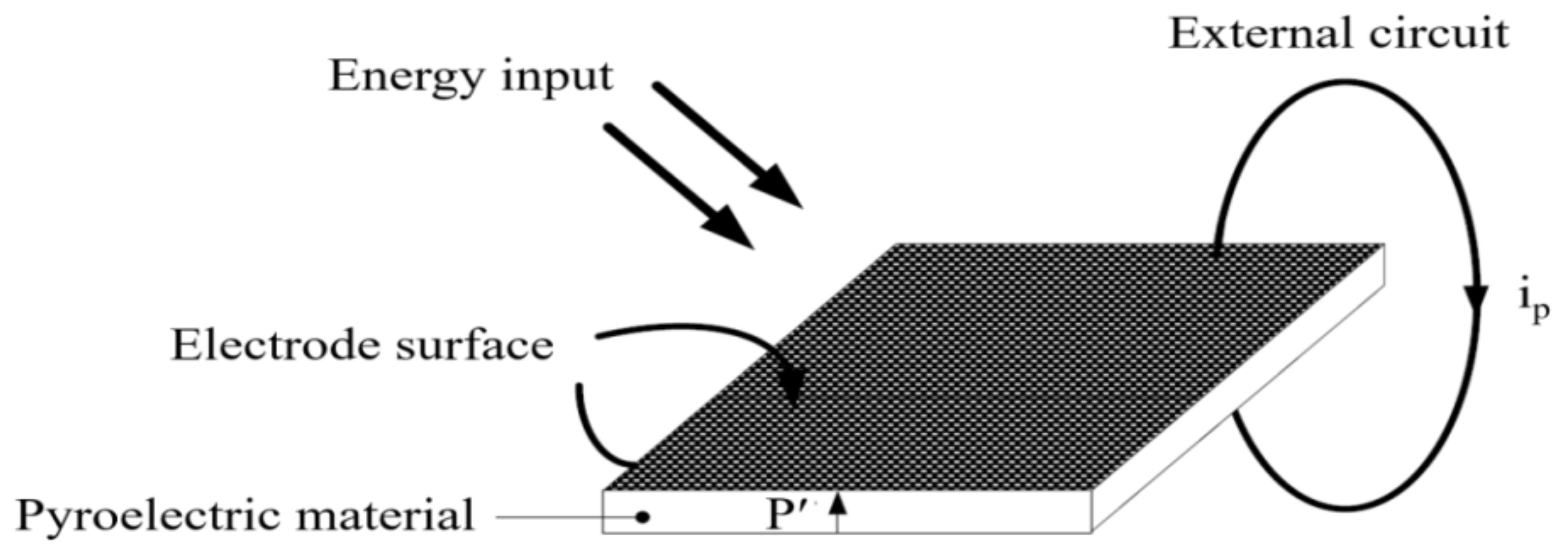

When the top surface of a thin-film pyroelectric sensor is exposed to a heat source, the resulting temperature variation in the pyroelectric film manifests itself as a release of charge at the surface of the material and the subsequent production of a small voltage. Assuming that the pyroelectric coefficient

of the sensing element has a component

in the direction perpendicular to the electrode surface (with area

A), the resulting charge can be detected as a current,

, flowing through the external circuit (see

Figure 1). The magnitude of this charge is given by [

31] as:

In other words, the sensor is “AC coupled” to any input energy flux which generates a change in temperature, where this input may take the form of either electromagnetic radiation absorbed in the pyroelectric material or heat generated by the reaction of chemical species on a suitable catalyst deposited on the element surface.

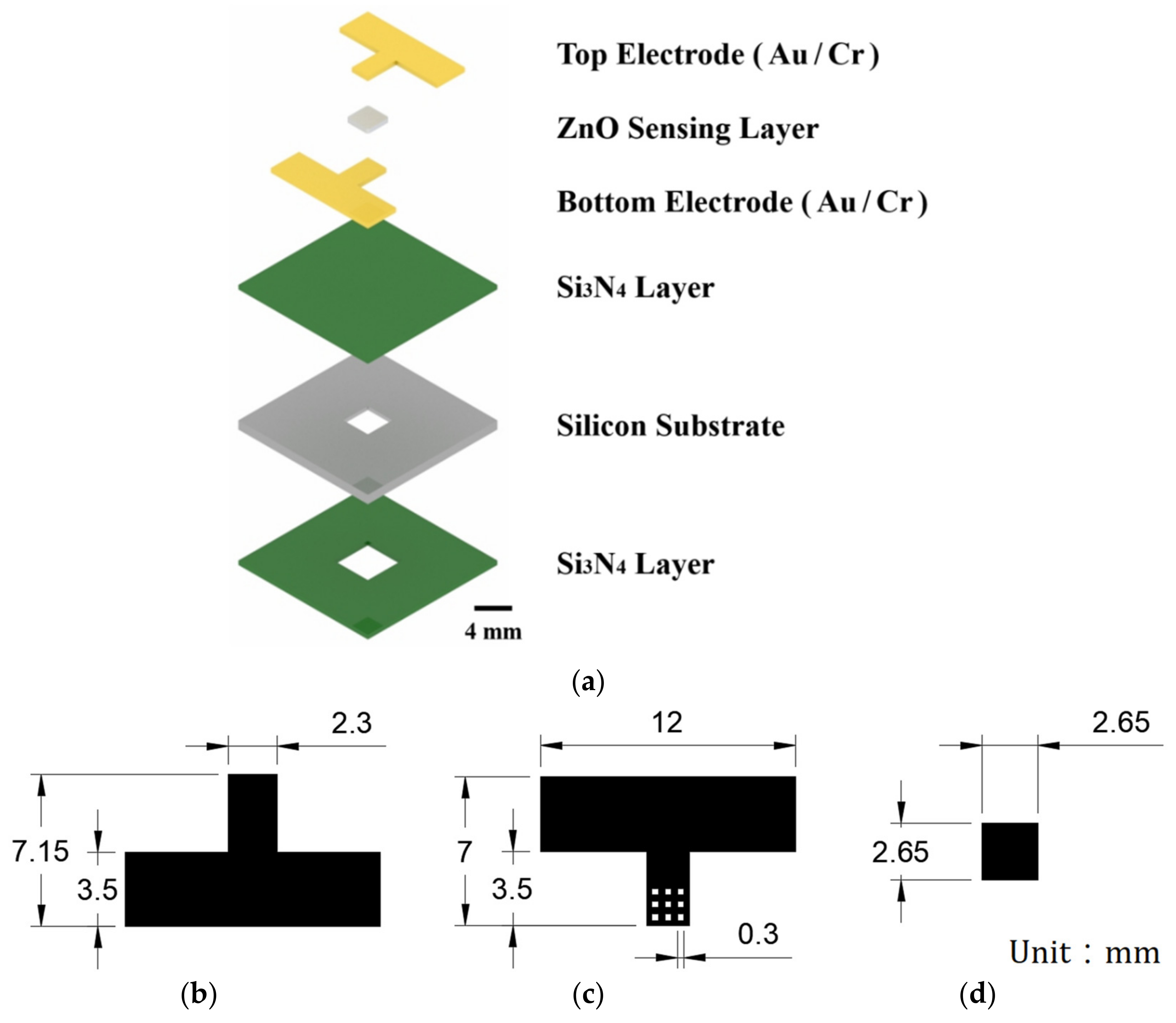

Figure 2 illustrates the basic structure and dimensions of the ZnO thin-film pyroelectric sensor considered in the present study. From Equation (6), it can be seen that a higher temperature variation rate in the ZnO layer leads to a higher response current. Moreover, a partially covered top electrode yields a greater responsivity than a fully covered electrode since the uncovered part of the ZnO sensing element is directly exposed to the heat source and, therefore, experiences a larger heat absorption. Intuitively, a larger covered top electrode area reduces the temperature variation rate in the ZnO layer. By contrast, a larger uncovered top electrode area increases the temperature variation rate but decreases the responsivity since the resulting smaller top electrode area has a reduced ability to hold electric charge. Consequently, as shown in

Figure 2c, the ZnO pyroelectric sensor considered in the present study was designed with a mesh-type partially covered top electrode in order to achieve a trade-off between the temperature variation rate and the charge storage ability of the electrode.

4. Results and Discussion

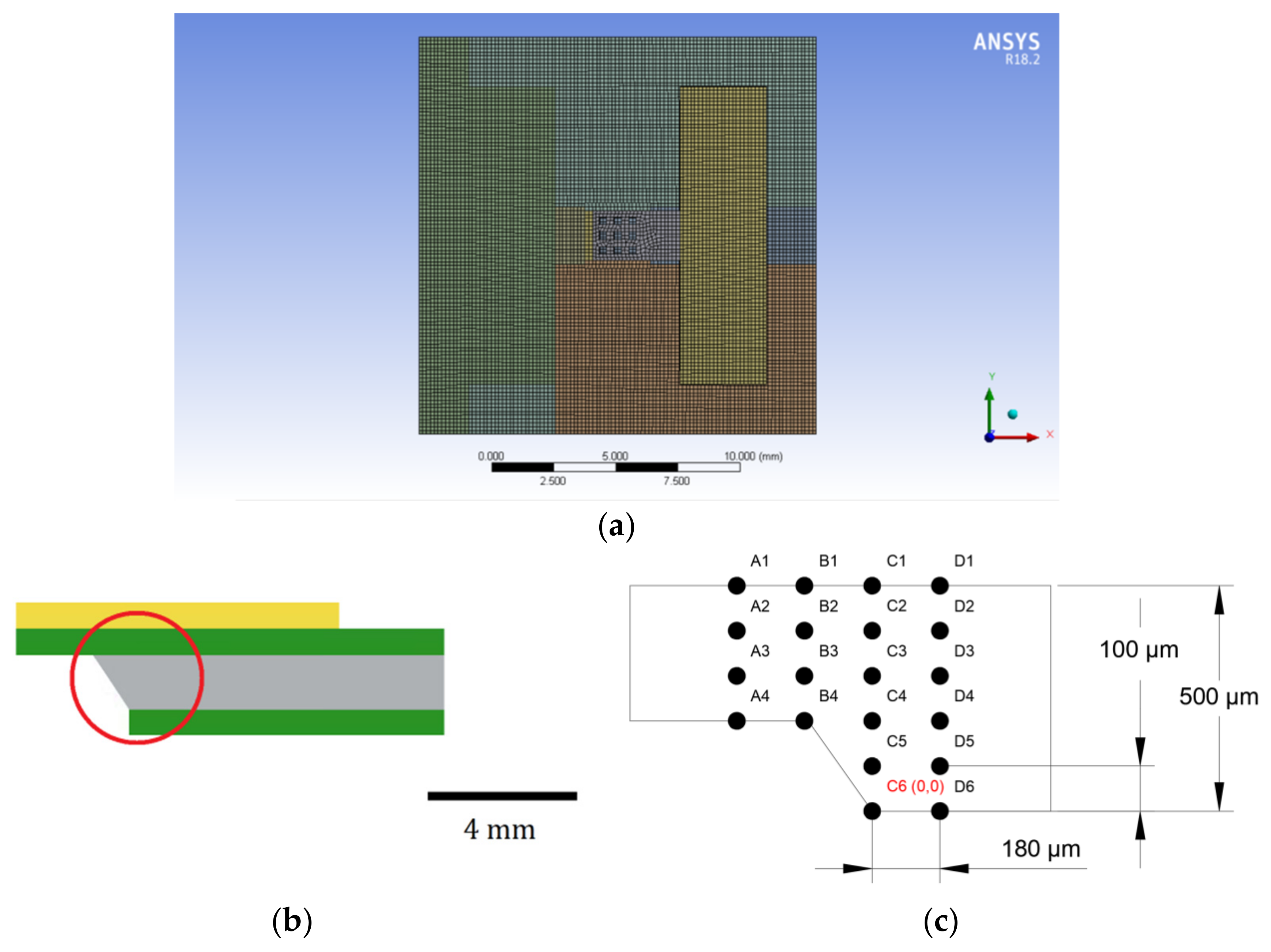

For the pyroelectric sensor considered in the present study, the output voltage scales proportionally with the temperature variation within the ZnO layer. Hence, the study commenced by performing COMSOL FLUENT simulations to determine the temperature variation at each of the node points shown in

Figure 3c.

Figure 5 shows the corresponding results obtained for the temperature variation at node point A1 given five different thicknesses of substrate (i.e., 100, 200, 300, 400 and 500 μm, respectively). Note that the boundary condition for the temperature is set as 36.5 °C in every case. The results show that the rate of change of the temperature at point A1 increases with a decreasing substrate thickness. In other words, as the thickness of the substrate reduces, the time required to reach steady-state temperature conditions also decreases.

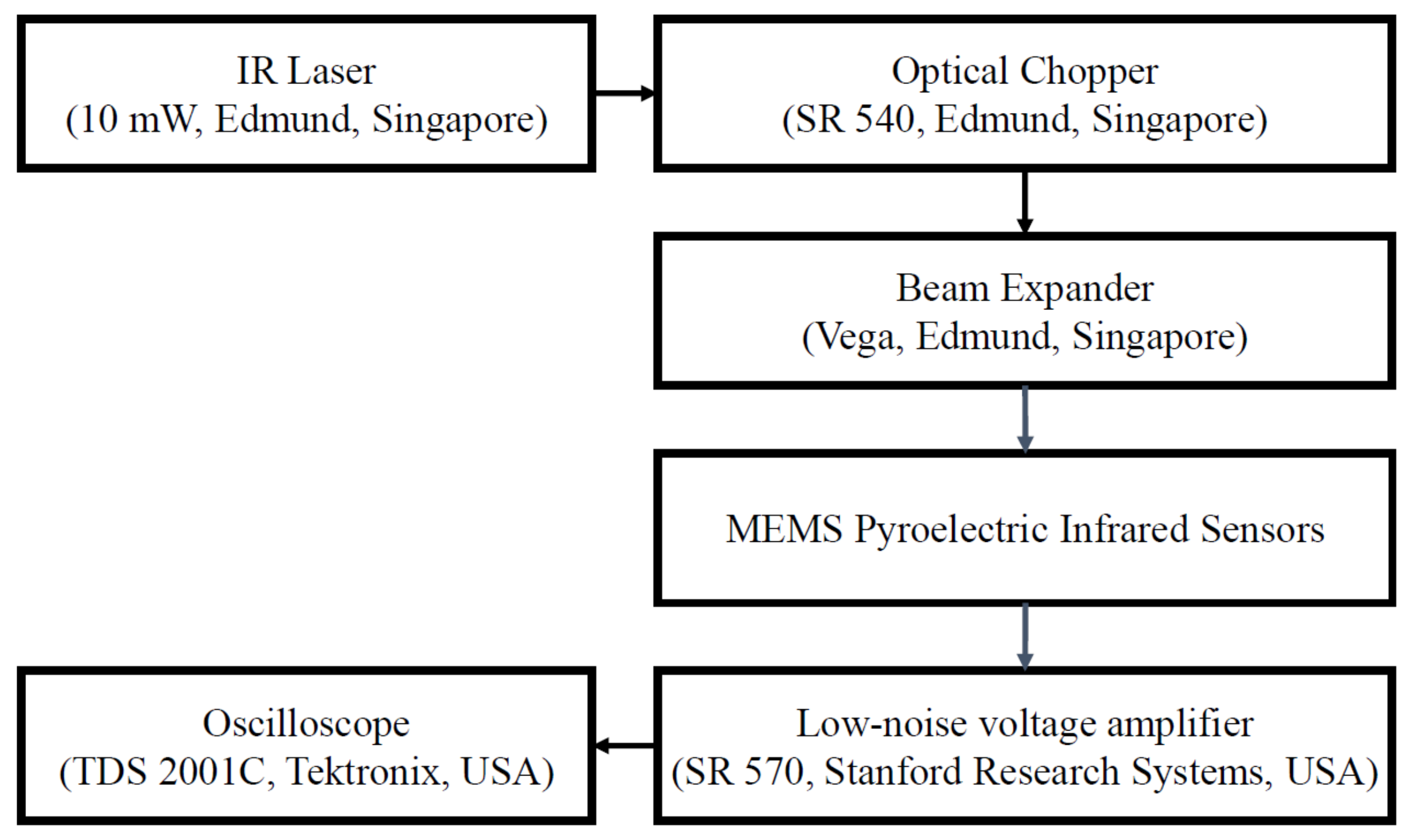

An experimental responsivity measurement system was established to further evaluate the performance of the ZnO pyroelectric sensors (see

Figure 6). The radiation source had the form of a calibrated infrared (IR) laser with a maximum power of 10 mW and a wavelength of 765 nm. The laser beam was chopped and molded as a wave with a modulated frequency of

w by an optical chopper and was then expanded by a beam expander such that the beam spot diameter had a size of 3 mm and thus covered the entire region of the patterned top electrode of the sensor. In performing the experiments, the distance between the infrared source and the sensing layer was set as 15 cm unless specified otherwise, and the output voltage of the sensor was amplified using an SR570 low-noise voltage amplifier. Finally, the output signal of the sensor was displayed and recorded using a digital oscilloscope.

For ZnO pyroelectric material, there exists a strong relation between the intensity of the (002) crystal peak and the responsivity of the pyroelectric sensor, where a higher value of the crystal peak indicates a higher quality of the crystal structure. In order to investigate the crystal orientation of the present ZnO sensing layer, ZnO films with a thickness of 889 nm were deposited on silicon substrates in an argon atmosphere with an RF sputtering power of 150 W and a working pressure of 5 × 10−3 Torr. The films were then annealed at various temperatures in the range of 300 to 600 °C for 4 h. The structures of the annealed films were characterized by X-ray power diffraction with a scanning angle of 30–60°; an operating voltage and current of 40 kV and 40 mA, respectively, and Cu Kα1 radiation ( = 0.154 nm). For each film, the sampling interval angle was set as 0.03° and the sampling time was 0.45 s.

Figure 7 shows that XRD patterns of the ZnO films annealed at temperatures of 300, 400, 500 and 600 °C, respectively. For reference purposes, the figure also shows the XRD pattern of an as-deposited (non-annealed) film. It is seen that the intensity of the (002) peak increases as the annealing temperature is increased to 500 °C, but then decreases as the temperature is further increased to 600 °C.

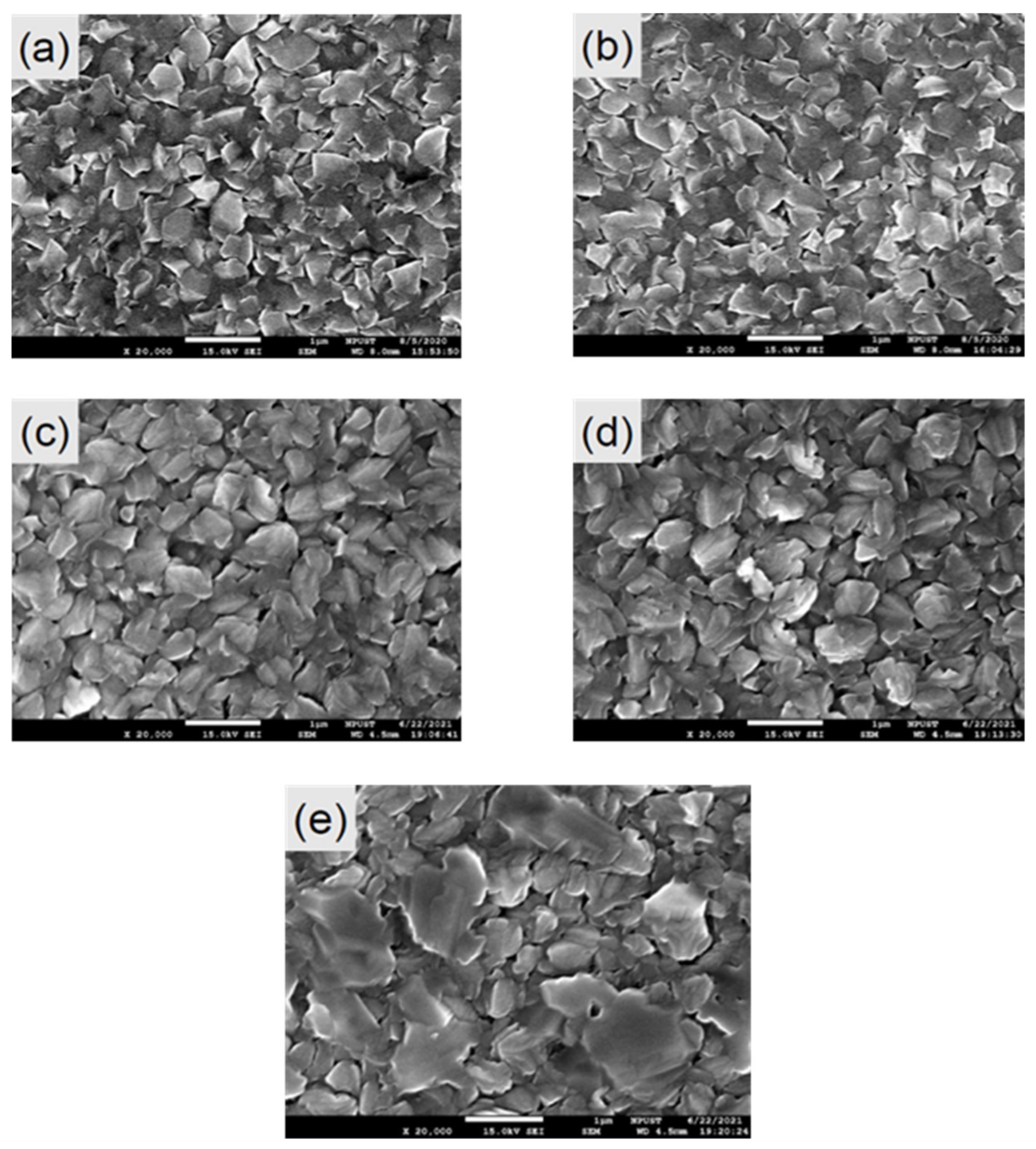

Figure 8 presents top-view SEM micrographs of the ZnO films shown in

Figure 7. As shown in

Figure 8a, the non-annealed sample has a flaky surface morphology with a small crystal size. For the sample annealed at 300 °C, the crystal size increases as a result of grain growth (

Figure 8b). As the annealing temperature is increased to 400 °C, the ZnO grain size continues to increase. However, some pores are evident in the crystal structure (

Figure 8c). For the sample annealed at 500 °C, the ZnO grain size increases once again. Moreover, the crystal structure is more dense, and fewer voids are observed (

Figure 8d). Finally, at an annealing temperature of 600 °C, the ZnO grain size continues to increase and the crystal structure becomes even more dense (

Figure 8e). Overall, the results presented in

Figure 8 show that both the grain size and the densification of the ZnO film increase with an increasing annealing temperature. As a result, the thermal conduction performance of the ZnO sensing layer improves, leading to an enhanced sensing performance. However, despite the better grain growth at 600 °C (see

Figure 8e), the XRD results presented in

Figure 7 show that the intensity of the (002) peak at 600 °C is lower than that at 500 °C. Thus, the optimal annealing temperature was determined to be 500 °C.

The element composition of the ZnO film annealed at 500 °C was examined by energy-dispersive X-ray spectroscopy (EDS). The corresponding results are presented in

Figure 9 and show that the film consists of 22.39 wt. % O and 77.61 wt. % Zn. Notably, the stoichiometry ratio of Zn to O is not 1:1 since the annealing environment is not oxygen free and hence the content of O atoms is slightly increased.

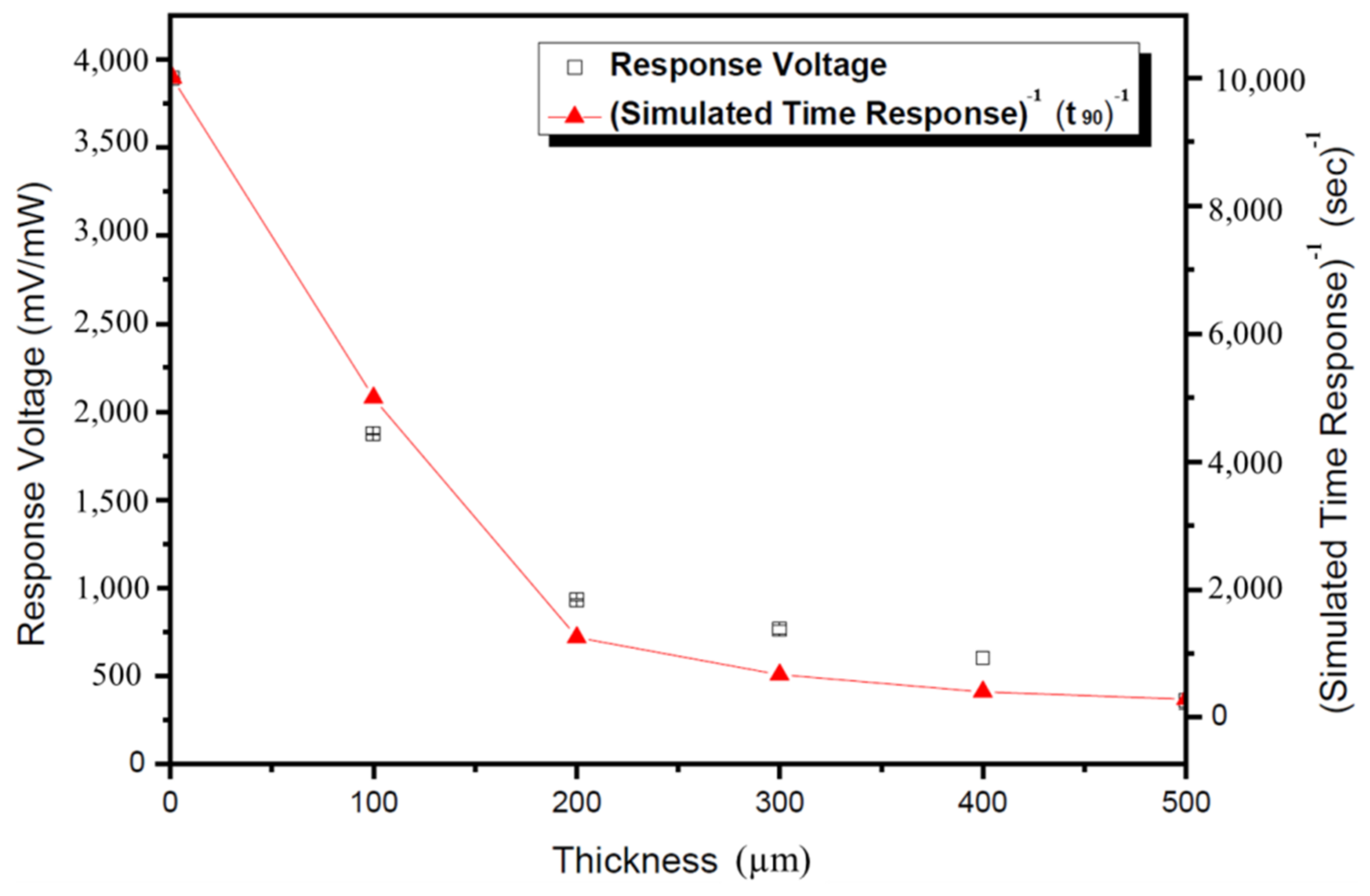

Figure 10 shows the experimental results obtained for the voltage responsivities of the ZnO pyroelectric sensors with different substrate thicknesses of 1, 100, 200, 300, 400, and 500 μm, respectively, at cutoff frequencies in the range of 0–3500 Hz. For comparison purposes, the responsivity of a packaged sensor is also shown. Note that the voltage responsivity is defined here as the ratio of the output voltage of the sensor to the input power of the incident heat source. As expected, the voltage responsivity increases with a reducing substrate thickness as a result of the greater temperature variation within the ZnO film. From inspection, the maximum voltage sensitivity is equal to 3800 mV/mW and is obtained for a substrate thickness of 1 μm and a cutoff frequency of 400 Hz. It is noted that the packaged sensor has a low voltage responsivity of just 3100 mV/mW due to connection losses and internal resistance losses, respectively.

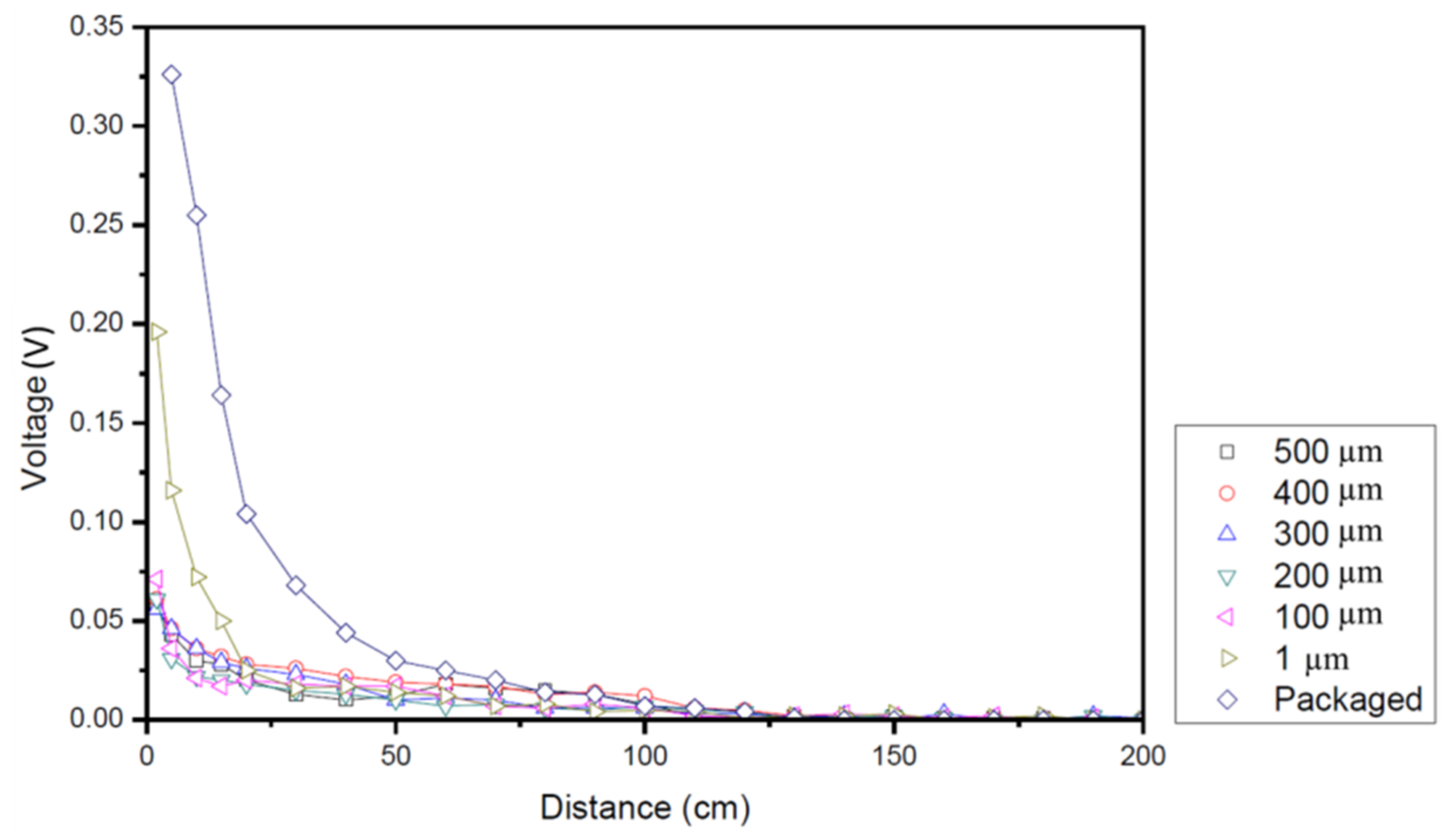

Figure 11 shows the output voltages of the various sensors at a cutoff frequency of 400 Hz for various distances of the sensor from the infrared power source in the range of 0–200 cm. For distances of less than 100 cm, the packaged sensor provides the highest voltage output among all the sensors. However, the sensor with a ZnO thickness of 1 μm also provides a reasonable response at sensing distances less than approximately 25 cm. For all of the sensors, the output voltage reduces to zero as the sensing distance increases beyond 100 cm.

Figure 12 shows the experimental results obtained for the output voltages of the various sensors at a cutoff frequency of 400 Hz and the simulation results obtained for the temperature variation within the corresponding sensing layers. In general, a good agreement is observed between the two sets of results, thereby confirming the validity of Equation (6) in

Section 2.