QHAR: Q-Holonic-Based ARchitecture for Self-Configuration of Cyber–Physical Production Systems

Abstract

:1. Introduction

2. Related Work

- Resources considered—to support reconfiguration, all production resources involved in the reconfiguration must be taken into account by the architecture (e.g., machinery, raw materials, energy, personnel);

- Scope of the architecture—the trigger for the reconfiguration may be internal (e.g., breakdown, absence) or external (e.g., change in customer requirements, failure of a supplier or subcontractor). Reconfiguration can impact internal entities (e.g., machines, staff), as well as external actors (e.g., customers, subcontractors). It is, therefore, essential that the scope of the architecture includes those entities and actors that may cause or be affected by reconfiguration;

- Level of detail—the level of detail of the description of entities/actors must be sufficiently rich to provide the necessary information for a reconfiguration algorithm. However, it should not be too detailed, as this could make it unnecessarily complex;

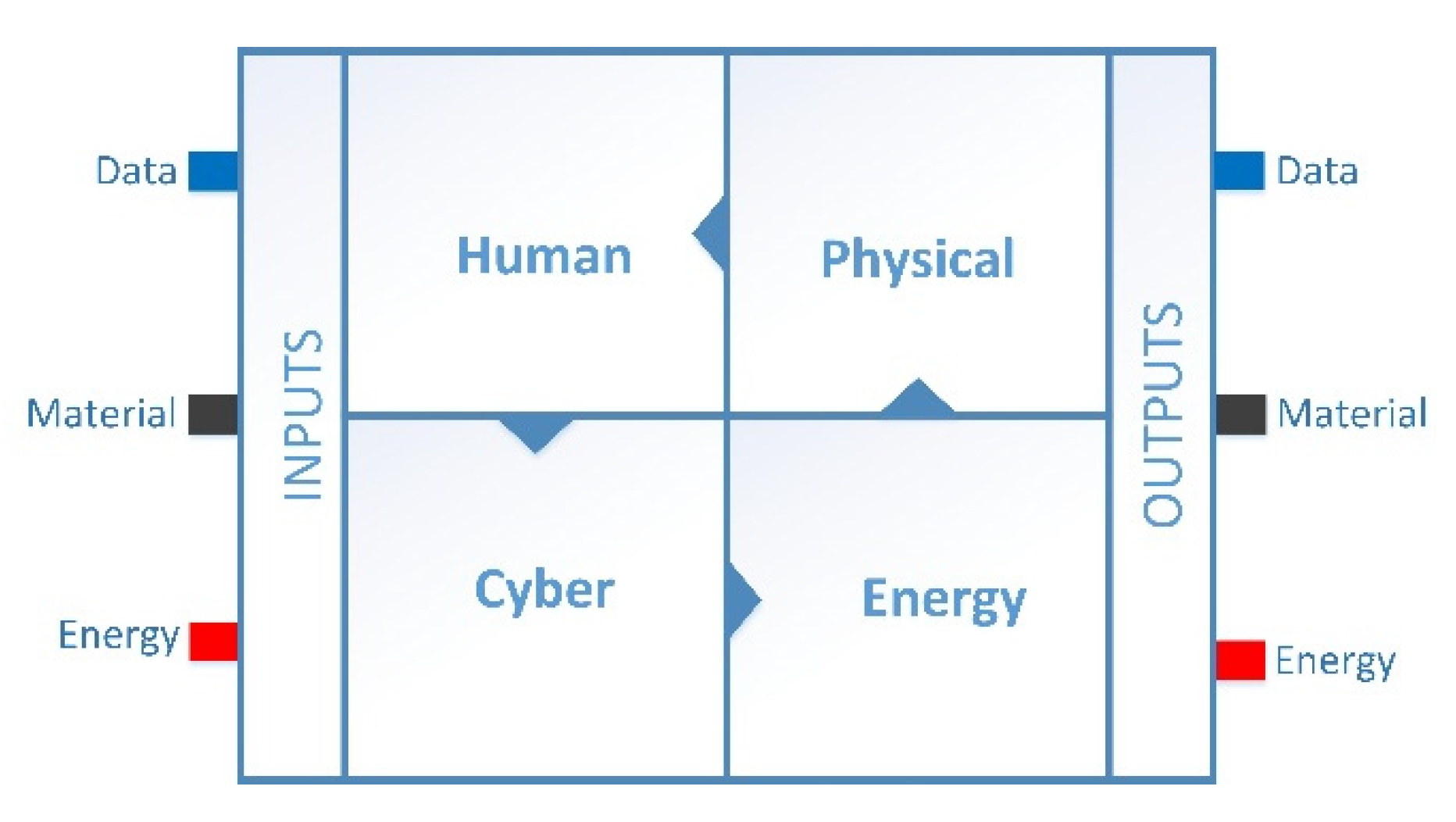

- Exchanged flows considered—interaction between entities/actors takes place not only through the exchange of data/information, but also through the exchange of material and energy flows. It is, therefore, essential that these different flows are considered by the architecture;

- Flow exchange methods/protocols—different exchange methods/protocols exist. The aim here is to identify those that are used or recommended by the different architectures;

- Type of integration—the proposed architectures generally adopt a hierarchical representation and assign the entities/actors of the system to the different levels. Interactions can take place not only between entities/actors of the same level (horizontal integration), but also between entities/actors belonging to different levels (vertical integration). As reconfiguration can modify both types of integration, a hierarchical architecture must explicitly support them;

2.1. RAMI 4.0 Architecture

2.2. 5C Architecture

2.3. 8C Architecture

2.4. ACPA4SF Architecture

2.5. 3C Architecture

2.6. PROSA

2.7. ADACOR

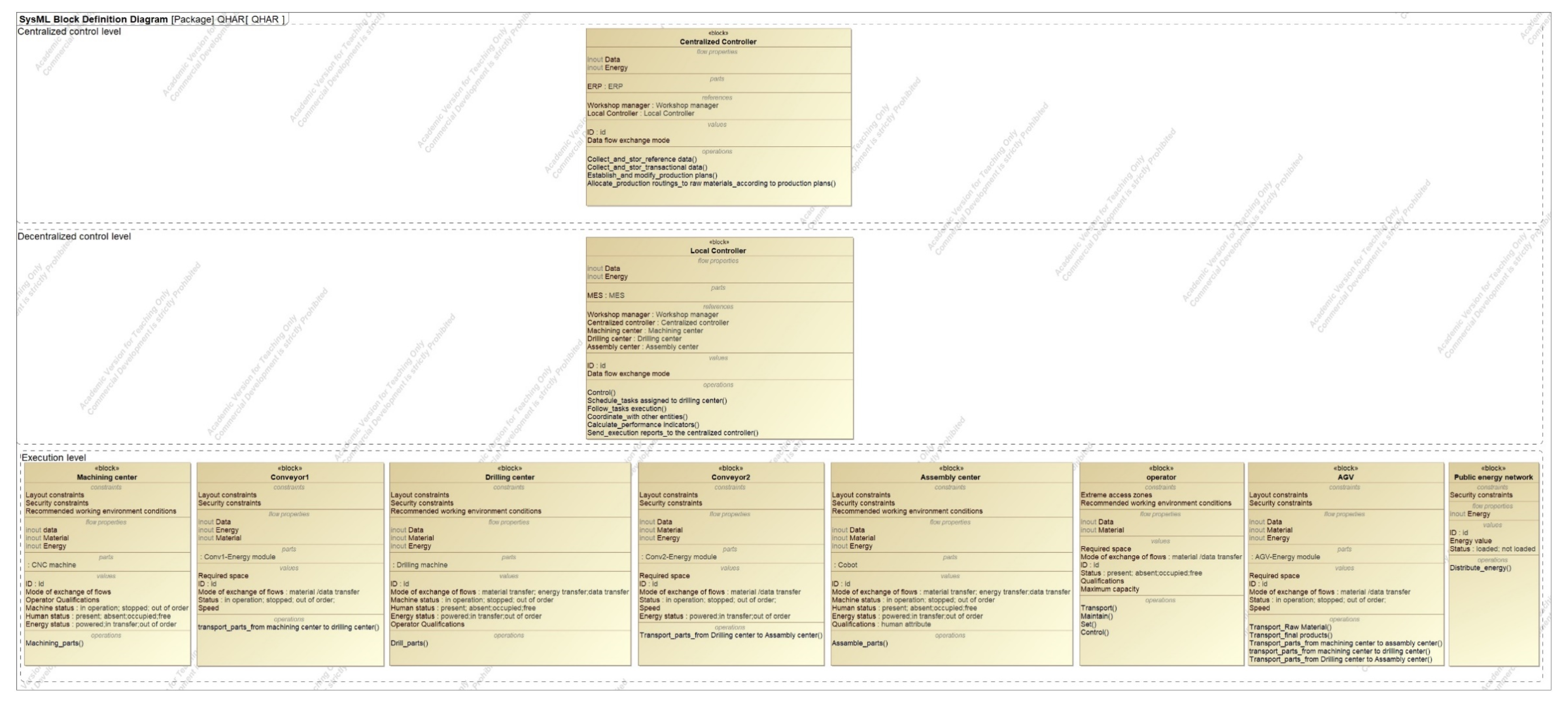

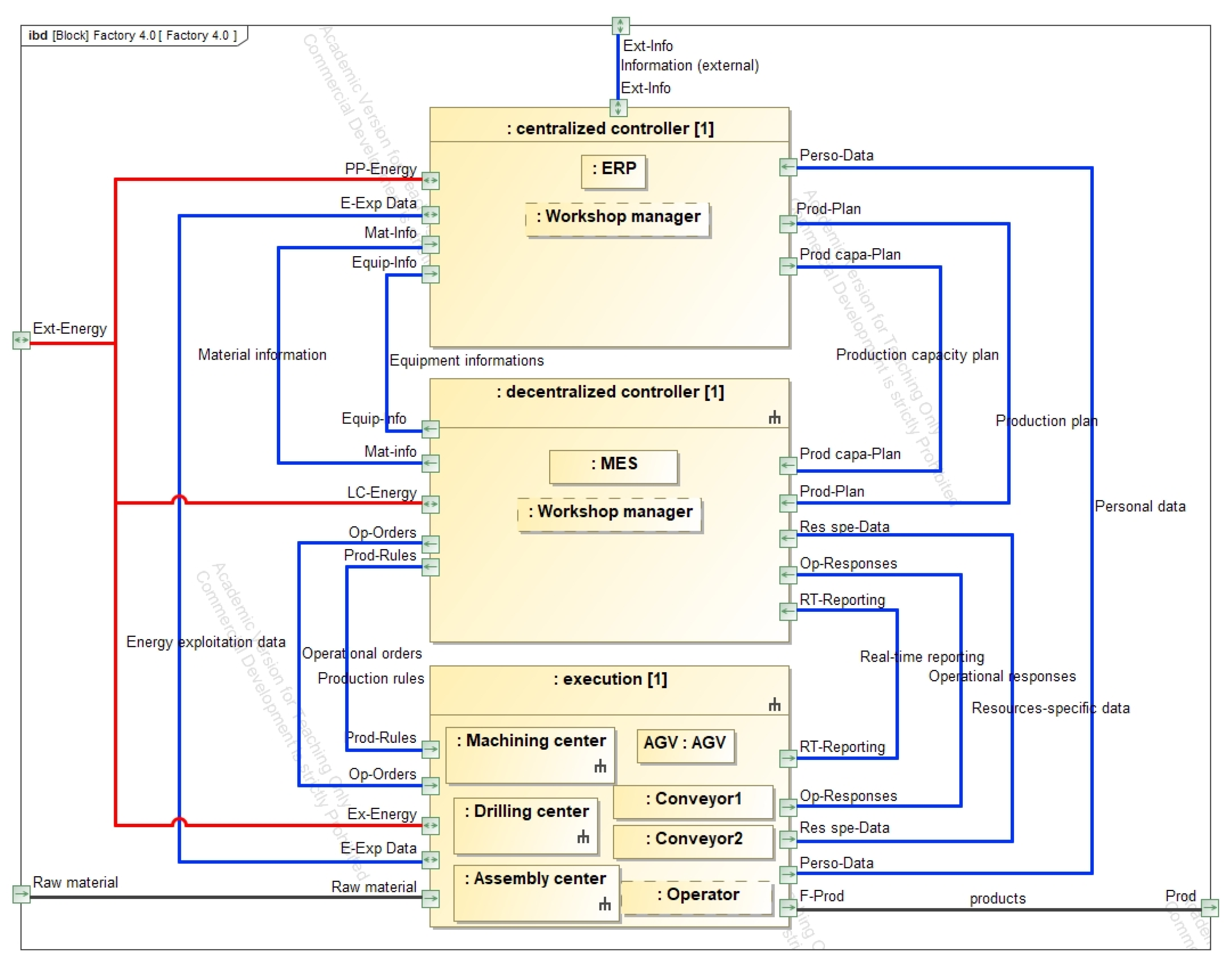

3. The Q-Holonic-Based ARchitecture (QHAR)

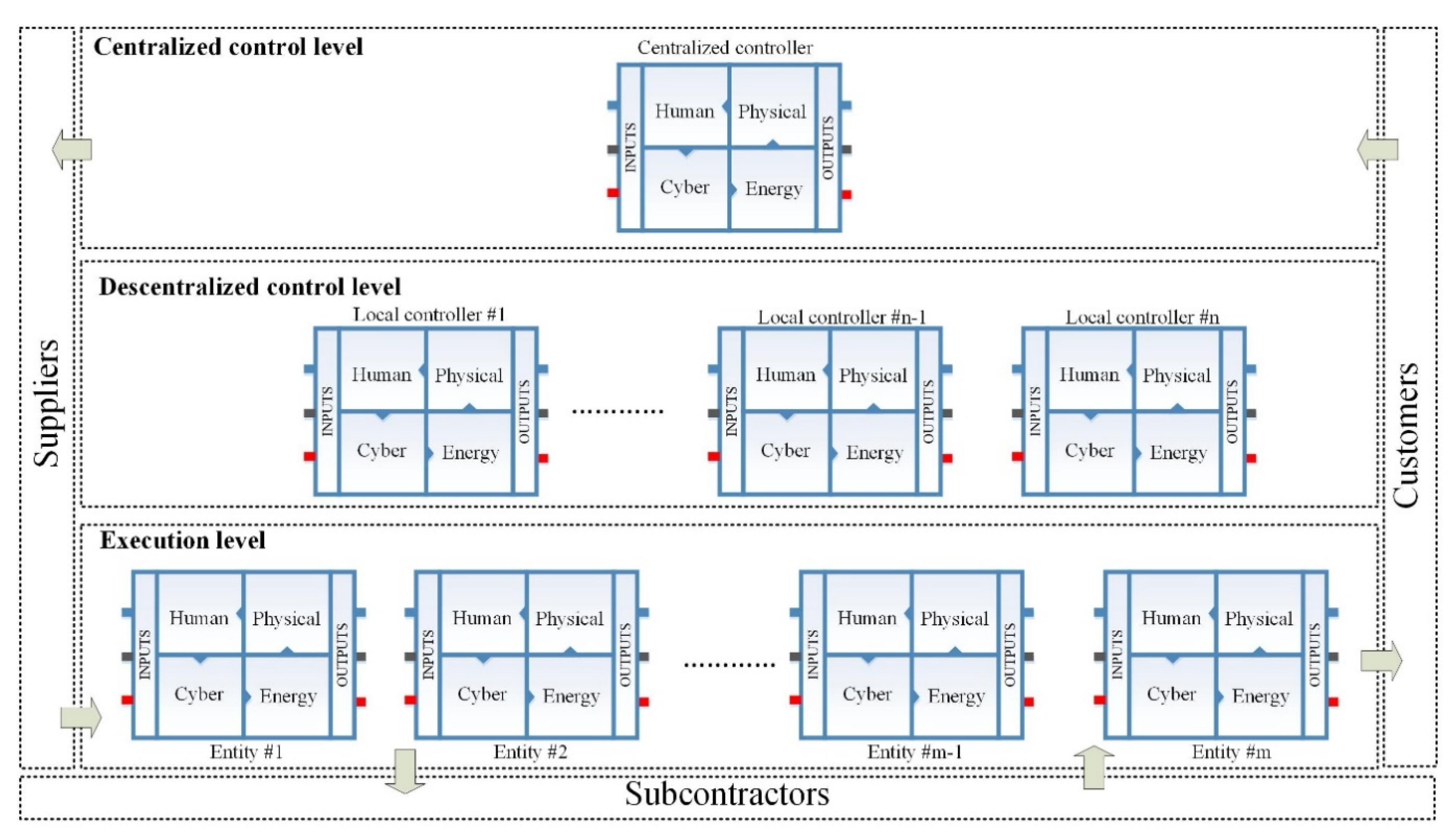

3.1. General Overview of the Q-Holonic-Based ARchitecture (QHAR)

3.1.1. Centralized Control Level

3.1.2. Decentralized Control Level

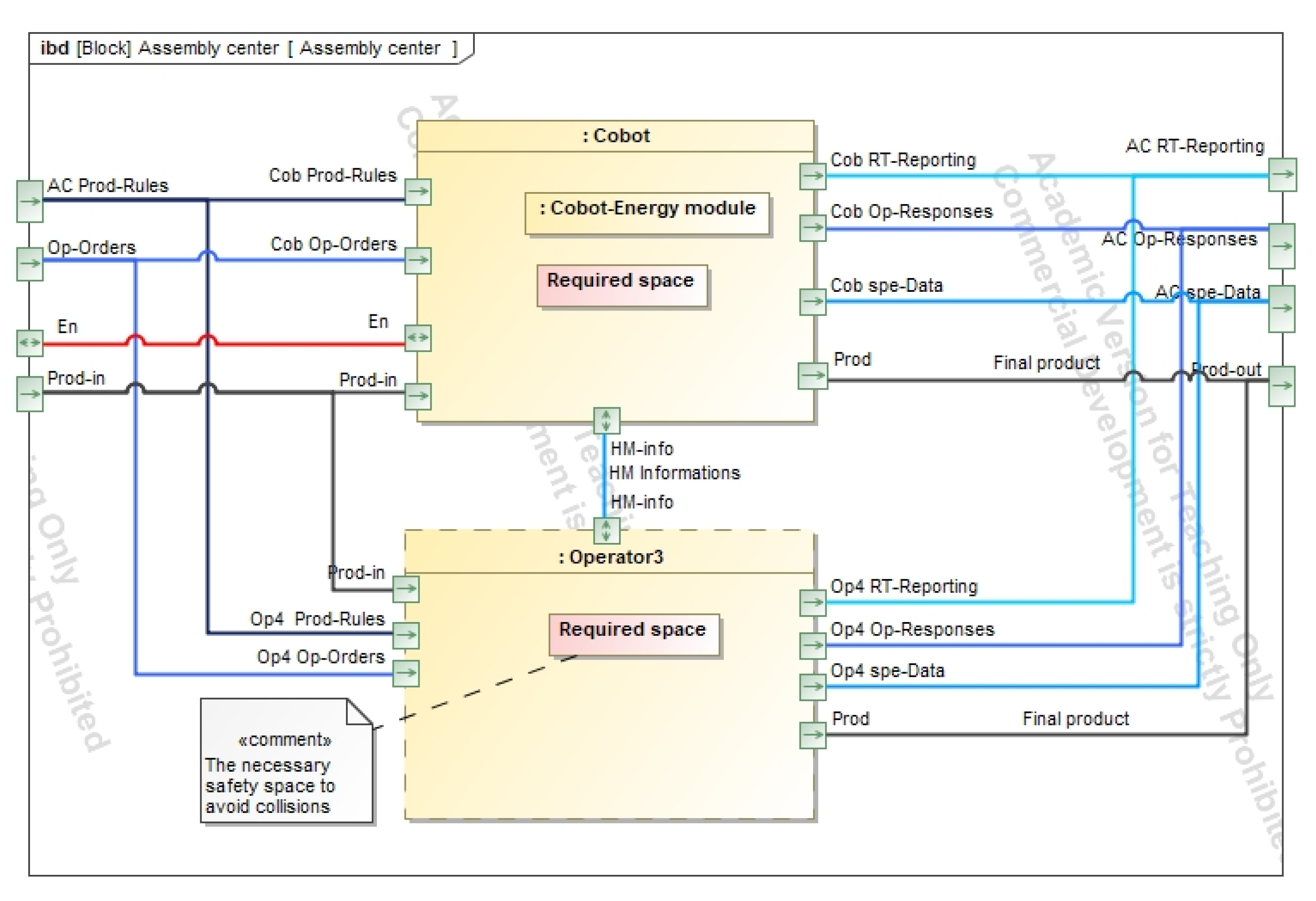

3.1.3. Execution Level

3.2. Representation of Entities and Actors by Q-Holons

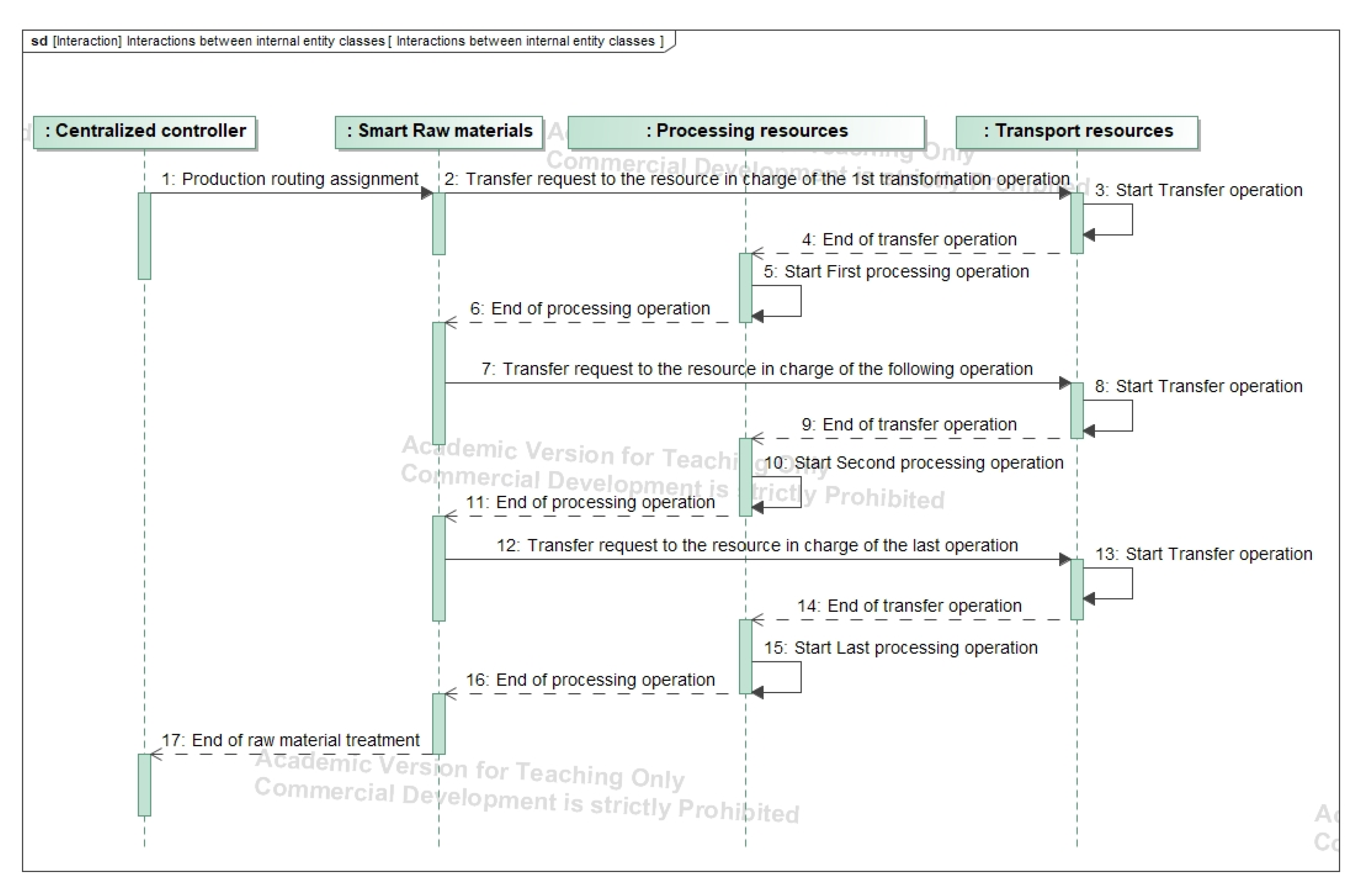

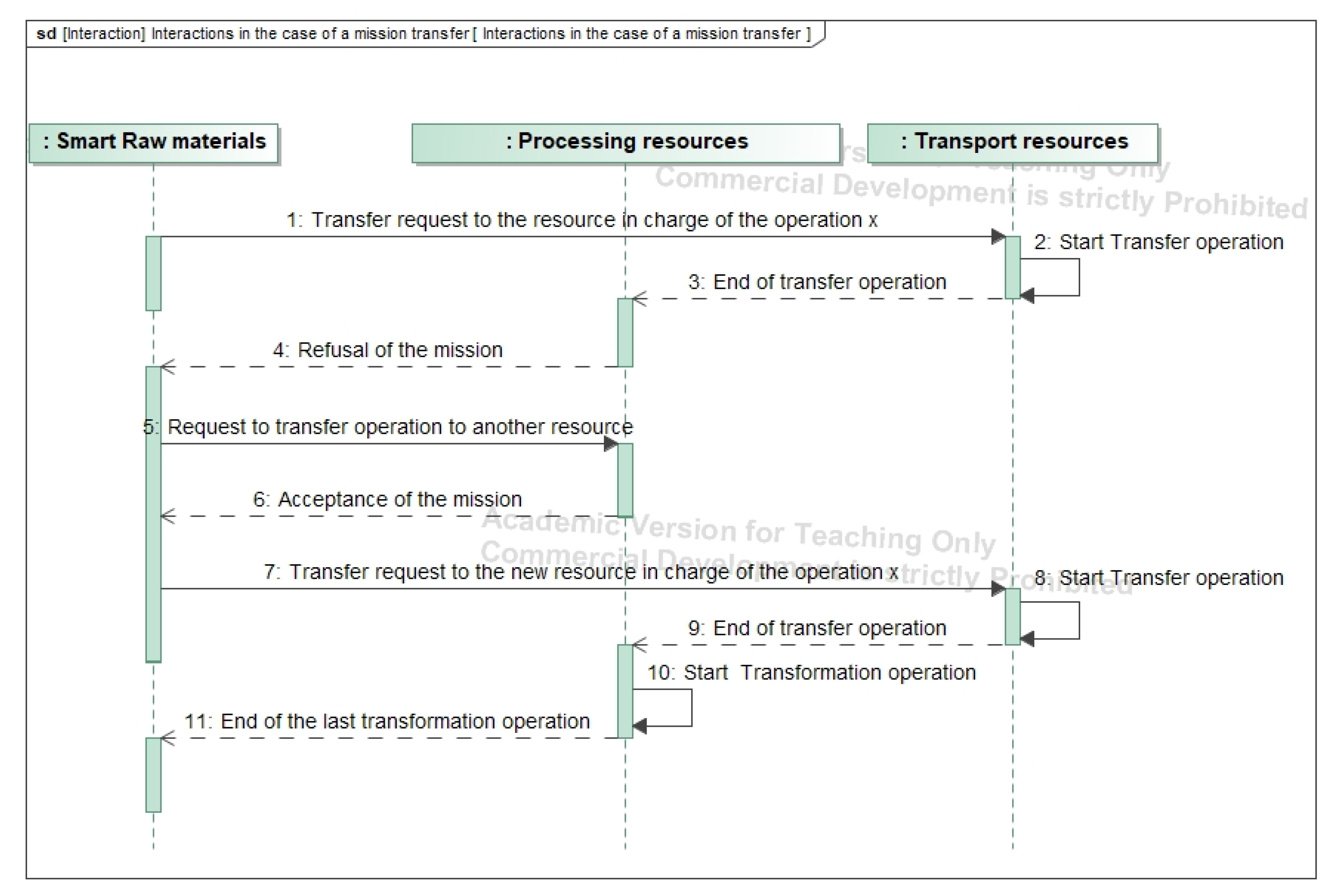

3.3. Interaction between Different Production System Components

4. Case study

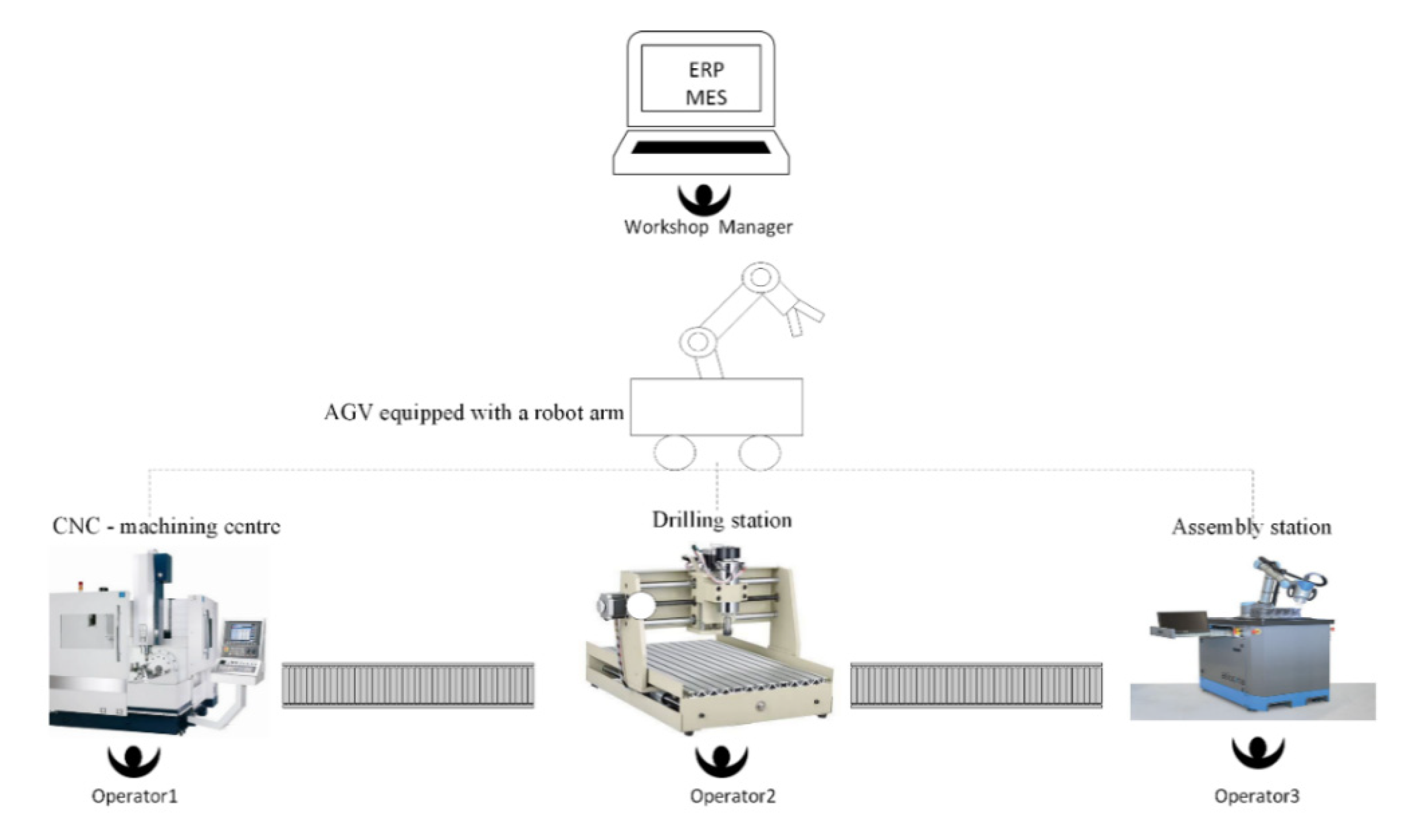

4.1. General Presentation

- Three workstations:

- ○

- A CNC–machining center, capable of machining different parts and driven by an operator;

- ○

- a drilling station, held by an operator;

- ○

- an assembly station, driven by an operator assisted by a cobot, and

- an AGV equipped with a robot arm.

4.2. Modeling of Workshop Entities by Q-Holons and Their Assignment to the Three Levels of the QHAR

4.3. How Could the Implementation of the Proposed Architecture, QHAR, Support Self-Reconfiguration?

- Detection of the need for reconfiguration—this is the preliminary phase of the actual reconfiguration process. With regard to faults, several advances were made in the implementation of self-diagnostic functions for certain faults [34,35]. This generally concerns foreseen defaults [31]. For unforeseen defects or external disturbances, further progress is still needed [31]. QHAR could be used to help diagnose such unforeseen faults. Indeed, the proper functioning of an entity can be characterized by the values of the attributes/properties of its four possible dimensions (human, cyber, energy, physical), those of its three possible incoming and outgoing flows (data, physical, energy), and by the operations it is supposed to perform. The failure of any of these parameters might be a sign of failure of the entity in question. This failure may be noted by the entity itself, its local controller, or the central controller. The monitoring of all these parameters by the entity itself, its local controller, and/or the centralized controller can ensure that practically all potential defects can be detected. As far as external disturbances are concerned, they are detected by the centralized controller. In the case of a change in customer demand, for example, the centralized controller ascertains whether the current installation is capable of handling the new order. If it is not guaranteed, this may indicate the need to change the current configuration.

- Determination of the entities needed for the new configuration—the need for reconfiguration detected earlier usually involves a change in the composition of the production system. This involves choosing the most appropriate entities for the current need. This choice may require decision support tools/methods and the definition of selection criteria. The first selection criteria are those relating to the operational capabilities and properties of the entities, where the operational capabilities and properties of each entity can be defined using the Q-Holon that represents it.

- Definition of a new layout—this involves determining the location of the entities and the interconnections to be established between them. Thanks to the attributes/properties of the entities—in particular, the physical/spatial dimension—the best location can be defined for each entity. The interaction between entities can be characterized by the flows (material, data, and energy) they exchange. Thus, entities that exchange flows may be permanently or temporarily interconnected.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Bortolini, M.; Galizia, F.G.; Mora, C. Reconfigurable manufacturing systems: Literature review and research trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar] [CrossRef]

- Garbie, H. A methodology for the reconfiguration process in manufacturing systems. J. Manuf. Technol. Manag. 2014, 25, 891–915. [Google Scholar] [CrossRef]

- Huang, S.; Wang, G.; Shang, X.; Yan, Y. Reconfiguration point decision method based on dynamic complexity for reconfigurable manufacturing system (RMS). J. Intell. Manuf. 2018, 29, 1031–1043. [Google Scholar] [CrossRef] [Green Version]

- Järvenpää, E.; Siltala, N.; Lanz, M. Formal resource and capability descriptions supporting rapid reconfiguration of assembly systems. In Proceedings of the 2016 IEEE International Symposium on Assembly and Manufacturing, Fort Worth, TX, USA, 21–22 August 2016; pp. 120–125. [Google Scholar]

- Jiang, J.-R. An improved Cyber-Physical Systems architecture for Industry 4.0 smart factories. In Proceedings of the 2017 International Conference on Applied System Innovation (ICASI), Sapporo, Japan, 13–17 May 2017; pp. 918–920. [Google Scholar] [CrossRef]

- Pirvu, B.-C.; Zamfirescu, C.-B.; Gorecky, D. Engineering insights from an anthropocentric cyber-physical system: A case study for an assembly station. Mechatronics 2016, 34, 147–159. [Google Scholar] [CrossRef]

- Van Brussel, H.; Wyns, J.; Valckenaers, P.; Bongaerts, L.; Peeters, P. Reference architecture for holonic manufacturing systems: PROSA. Comput. Ind. 1998, 37, 255–274. [Google Scholar] [CrossRef]

- Leitão, P.; Restivo, F. ADACOR: A holonic architecture for agile and adaptive manufacturing control. Comput. Ind. 2006, 57, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Shen, W.; Norrie, D.H. Agent-Based Systems for Intelligent Manufacturing: A State-of-the-Art Survey. Knowl. Inf. Syst. 1999, 1, 129–156. [Google Scholar] [CrossRef]

- Macherki, D.; Diallo, T.M.; Choley, J.-Y.; Guizani, A.; Barkallah, M.; Haddar, M. The Q-Holon: A quadridimensional holon to design and operate an adaptive and scalable architecture for CPPS. In Proceedings of the 2020 21st International Conference on Research and Education in Mechatronics (REM), Cracow, Poland, 9–11 December 2020; pp. 1–6. [Google Scholar]

- Yli-Ojanperä, M.; Sierla, S.; Papakonstantinou, N.; Vyatkin, V. Adapting an agile manufacturing concept to the reference architecture model industry 4.0: A survey and case study. J. Ind. Inf. Integr. 2019, 15, 147–160. [Google Scholar] [CrossRef]

- Derigent, W.; Cardin, O.; Trentesaux, D. Industry 4.0: Contributions of holonic manufacturing control architectures and future challenges. J. Intell. Manuf. 2020, 32, 1797–1818. [Google Scholar] [CrossRef] [Green Version]

- Zezulka, F.; Marcon, P.; Vesely, I.; Sajdl, O. Industry 4.0—An Introduction in the phenomenon. IFAC-PapersOnLine 2016, 49, 8–12. [Google Scholar] [CrossRef]

- Bagheri, B.; Yang, S.; Kao, H.-A.; Lee, J. Cyber-physical Systems Architecture for Self-Aware Machines in Industry 4.0 Environment. IFAC-PapersOnLine 2015, 48, 1622–1627. [Google Scholar] [CrossRef]

- Steindl, G.; Stagl, M.; Kasper, L.; Kastner, W.; Hofmann, R. Generic Digital Twin Architecture for Industrial Energy Systems. Appl. Sci. 2020, 10, 8903. [Google Scholar] [CrossRef]

- Bagheri, B.; Rezapoor, M.; Lee, J. A unified data security framework for federated prognostics and health management in smart manufacturing. Manuf. Lett. 2020, 24, 136–139. [Google Scholar] [CrossRef]

- Ahmadi, A.; Sodhro, A.H.; Cherifi, C.; Cheutet, V.; Ouzrout, Y. Evolution of 3C Cyber-Physical Systems Architecture for Industry 4.0. In Service Orientation in Holonic and Multi-Agent Manufacturing; Borangiu, T., Trentesaux, D., Thomas, A., Cavalieri, S., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 448–459. [Google Scholar] [CrossRef] [Green Version]

- Cardin, O.; Derigent, W.; Trentesaux, D. Evolution of holonic control architectures towards Industry 4.0: A short overview. IFAC-PapersOnLine 2018, 51, 1243–1248. [Google Scholar] [CrossRef]

- Valckenaers, P. ARTI Reference Architecture-PROSA revisited, Service Orientation in Holonic and Multi-Agent Manufacturing, Service Orientation in Holonic and Multi-Agent Manufacturing. Stud. Comput. Intell. 2019, 803, 119. [Google Scholar]

- Valckenaers, P. Perspective on holonic manufacturing systems: PROSA becomes ARTI. Comput. Ind. 2020, 120, 103226. [Google Scholar] [CrossRef]

- Barbosa, J.; Leitão, P.; Adam, E.; Trentesaux, D. Dynamic self-organization in holonic multi-agent manufacturing systems: The ADACOR evolution. Comput. Ind. 2015, 66, 99–111. [Google Scholar] [CrossRef] [Green Version]

- Chirn, J.-L.; McFarlane, D.C. A holonic component-based approach to reconfigurable manufacturing control architecture. In Proceedings of the 11th International Workshop on Database and Expert Systems Applications, London, UK, 4–8 September 2000; pp. 219–223. [Google Scholar]

- Pach, C.; Berger, T.; Bonte, T.; Trentesaux, D. ORCA-FMS: A dynamic architecture for the optimized and reactive control of flexible manufacturing scheduling. Comput. Ind. 2014, 65, 706–720. [Google Scholar] [CrossRef]

- Jimenez, J.-F.; Bekrar, A.; Zambrano-Rey, G.; Trentesaux, D.; Leitão, P. Pollux: A dynamic hybrid control architecture for flexible job shop systems. Int. J. Prod. Res. 2017, 55, 4229–4247. [Google Scholar] [CrossRef] [Green Version]

- Cruz Salazar, L.A.; Ryashentseva, D.; Lüder, A.; Vogel-Heuser, B. Cyber-physical production systems architecture based on multi-agent’s design pattern—Comparison of selected approaches mapping four agent patterns. Int. J. Adv. Manuf. Technol. 2019, 105, 4005–4034. [Google Scholar] [CrossRef] [Green Version]

- Williams, T.J. The Purdue Enterprise Reference Architecture. IFAC Proc. Vol. 1993, 26, 559–564. [Google Scholar] [CrossRef]

- Kosanke, K. CIMOSA—Overview and status. Comput. Ind. 1995, 27, 101–109. [Google Scholar] [CrossRef]

- Jeschke, S.; Brecher, C.; Meisen, T.; Özdemir, D.; Eschert, T. Industrial internof things and cyber manufacturing systems. In Industrial Internof Things; Springer: Berlin/Heidelberg, Germany, 2017; pp. 3–19. [Google Scholar]

- Brennan, R.W.; Balasubramanian, S.; Norrie, D.H. Dynamic control architecture for metamorphic control of advanced manufacturing systems. In Architectures, Networks, and Intelligent Systems for Manufacturing Integration; Division of Manufacturing Engineering, The University of Calgary 2500 University Dr. NW: Calgary, AB, Canada, 1997. [Google Scholar] [CrossRef]

- Meissner, H.; Ilsen, R.; Aurich, J.C. Analysis of Control Architectures in the Context of Industry 4.0. Procedia CIRP 2017, 62, 165–169. [Google Scholar] [CrossRef]

- Balzereit, K.; Niggemann, O. Automated reconfiguration of cyber-physical production systems using satisfiability modulo theories. In Proceedings of the 2020 IEEE Conference on Industrial Cyberphysical Systems (ICPS), Tampere, Finland, 10–12 June 2020; Volume 1, pp. 461–468. [Google Scholar]

- Müller, T.; Walth, S.; Jazdi, N.; Weyrich, M. Identification of Reconfiguration Demand and Generation of Alternative Configurations for Cyber-Physical Production Systems. In Advances in Automotive Production Technology—Theory and Application; Springer: Berlin/Heidelberg, Germany, 2021; pp. 63–70. [Google Scholar]

- Müller, T.; Lindemann, B.; Jung, T.; Jazdi, N.; Weyrich, M. Enhancing an Intelligent Digital Twin with a Self-organized Reconfiguration Management based on Adaptive Process Models. arXiv 2021. [Google Scholar] [CrossRef]

- Epureanu, B.I.; Li, X.; Nassehi, A.; Koren, Y. Self-repair of smart manufacturing systems by deep reinforcement learning. CIRP Ann. 2020, 69, 421–424. [Google Scholar] [CrossRef]

- Xu, P.; Xu, S.; Yin, H. Application of self-organizing competitive neural network in fault diagnosis of suck rod pumping system. J. Pet. Sci. Eng. 2007, 58, 43–48. [Google Scholar] [CrossRef]

| Architecture | RAMI 4.0 | 5C | 8C | ACPA4SF | 3C | PROSA | ADACOR |

|---|---|---|---|---|---|---|---|

| Architecture goal | Its aim is to provide a common framework and terminology to all participants involved in Industry 4.0 discussions and activities | It is intended as an approach or methodology for the deployment of CPS in production systems. | Guideline to build cyber-physical systems for smart factories | CPPS description and design | It aims to improve intelligent manufacturing in Industry 4.0 | Management of customer order realization and reconfiguration following the addition of a new resource. | Improvement of the manufacturing control systems performance, in terms of the agile reaction to emergence and change |

| Resources taken into account | Physical and virtual assets | It refers to the resources contributing to the data collection (e.g., sensors, information system). | Considers value chain resources (e.g., supply, production, storage, distribution) | Production resource in the broadest sense (e.g., manufacturing, transport, storage) | Physical Components (PCs), Cyber Components (CCs), and Human Components (HCs). | Material production resources | Production resources (e.g., machines, operators) |

| Architecture Scope | Internal entities and external actors | Internal entities only. It does not take into account external actors, such as suppliers and customers. | Internal entities (e.g., machines, managers) and external actors (e.g., suppliers, customers). In addition to resources, it is also interested in the product. | Partly internal entities and external actors (customers, by customer order information) | Internal entities (humans, machines). | Partly internal entities and external actors (customers, by customer order information) | Internal entities |

| Level of detail | From global level (extended enterprise) to product level, but without description of attributes/properties. | Generic presentation. No detailed description. | Generic presentation. No detailed description. | From global level (factory) to component level, but without description of attributes/properties | Generic presentation. No detailed description. | From the global level (factory) to the elementary entity level (task, machine). Attributes and functions of each entity. | From the global level (factory) to the elementary entity level (product, task, machine). |

| Exchanged flows taken into account | Data and information flows | Data and information flows | Data and information flows | Data and information flows | Data and information flows | Data and information flows | Data and information flows |

| Flow exchange (protocol) or interaction methods | OPC UA | Communication protocol (MTConnect is given as an example) | Communication protocol (e.g., OPC UA, Ethernet, MQTT) | The agent concept or communication protocols (e.g., MTConnect), ontologies, and the Semantic Web. | Connectors (e.g., ERNI connectors, ERmet 2.0 HM, Modular Jacks and Plugs: RJ45, RJ11, RJ25, and so on) and interface protocols (Profibus, Profinet, OPC-UA Fieldbus, Ethernet Powerlink) | Contract Net Protocol | Ontology |

| Decomposition mode | Functional and structural | Functional | Functional | Functional | Structural | Functional and structural | Functional and structural |

| Integration type | Vertical and Horizontal | Vertical | Vertical and Horizontal | Vertical | Horizontal | Vertical and Horizontal | Vertical and Horizontal |

| (a) | ||||||

| Master Production Schedule | ||||||

| Product | Quantity to Produce | Delivery Date | ||||

| Product 1 | Q1 | D1 | ||||

| Product 2 | Q2 | D2 | ||||

| … | … | … | ||||

| Product n | Qn | Dn | ||||

| (b) | ||||||

| Production Routing | ||||||

| NO | Operation | Resource | Total Time | Due Date | Alternative Resources | Status |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macherki, D.; Diallo, T.M.L.; Choley, J.-Y.; Guizani, A.; Barkallah, M.; Haddar, M. QHAR: Q-Holonic-Based ARchitecture for Self-Configuration of Cyber–Physical Production Systems. Appl. Sci. 2021, 11, 9013. https://doi.org/10.3390/app11199013

Macherki D, Diallo TML, Choley J-Y, Guizani A, Barkallah M, Haddar M. QHAR: Q-Holonic-Based ARchitecture for Self-Configuration of Cyber–Physical Production Systems. Applied Sciences. 2021; 11(19):9013. https://doi.org/10.3390/app11199013

Chicago/Turabian StyleMacherki, Douha, Thierno M. L. Diallo, Jean-Yves Choley, Amir Guizani, Maher Barkallah, and Mohamed Haddar. 2021. "QHAR: Q-Holonic-Based ARchitecture for Self-Configuration of Cyber–Physical Production Systems" Applied Sciences 11, no. 19: 9013. https://doi.org/10.3390/app11199013

APA StyleMacherki, D., Diallo, T. M. L., Choley, J.-Y., Guizani, A., Barkallah, M., & Haddar, M. (2021). QHAR: Q-Holonic-Based ARchitecture for Self-Configuration of Cyber–Physical Production Systems. Applied Sciences, 11(19), 9013. https://doi.org/10.3390/app11199013