High Vacuum Packaging of MEMS Devices Containing Heterogeneous Discrete Components

Abstract

:Featured Application

Abstract

1. Introduction

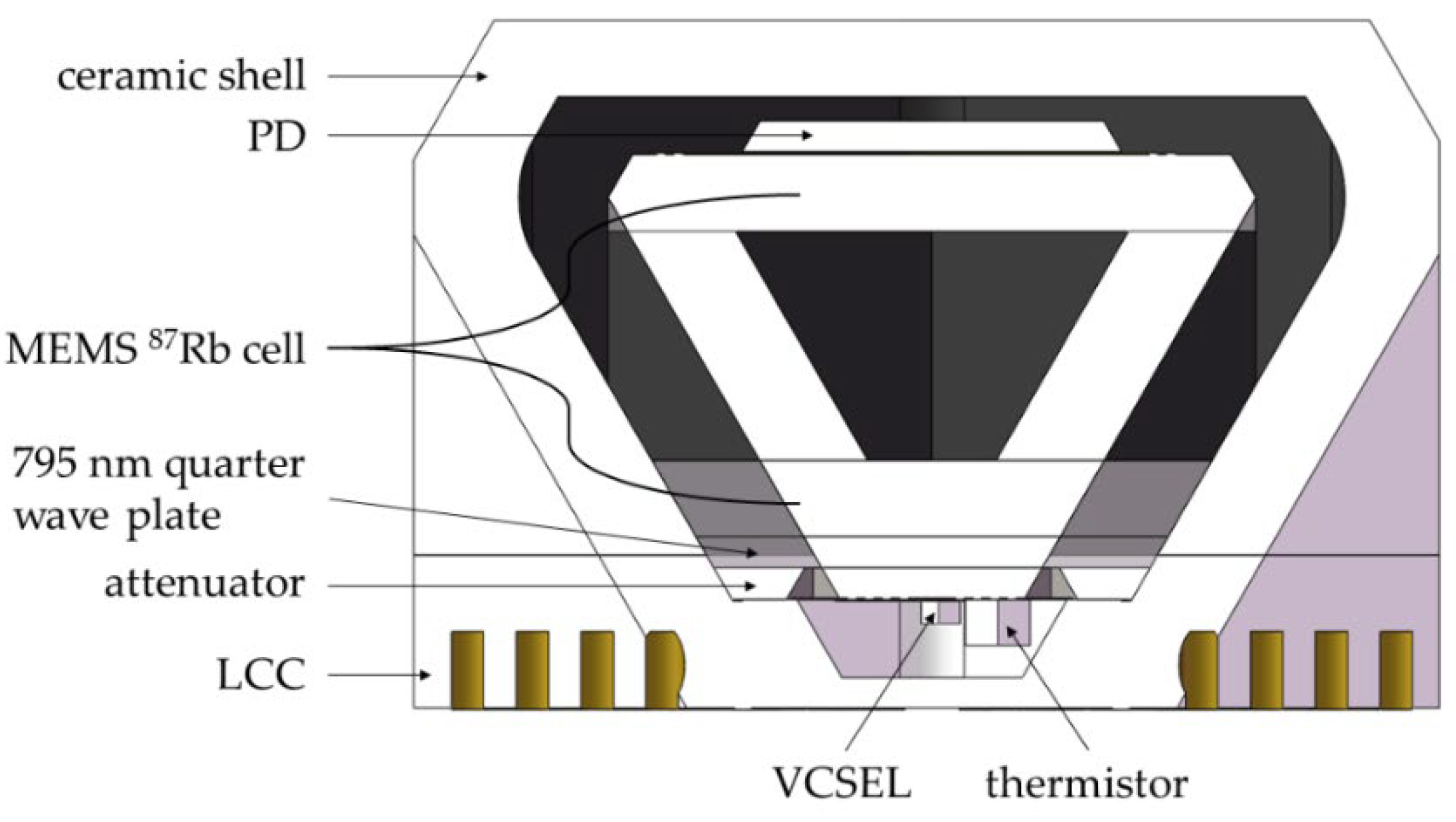

2. Design and Integration of Physics Package

3. Vacuum Packaging

3.1. Hermeticity of LCC and Ceramic Shell

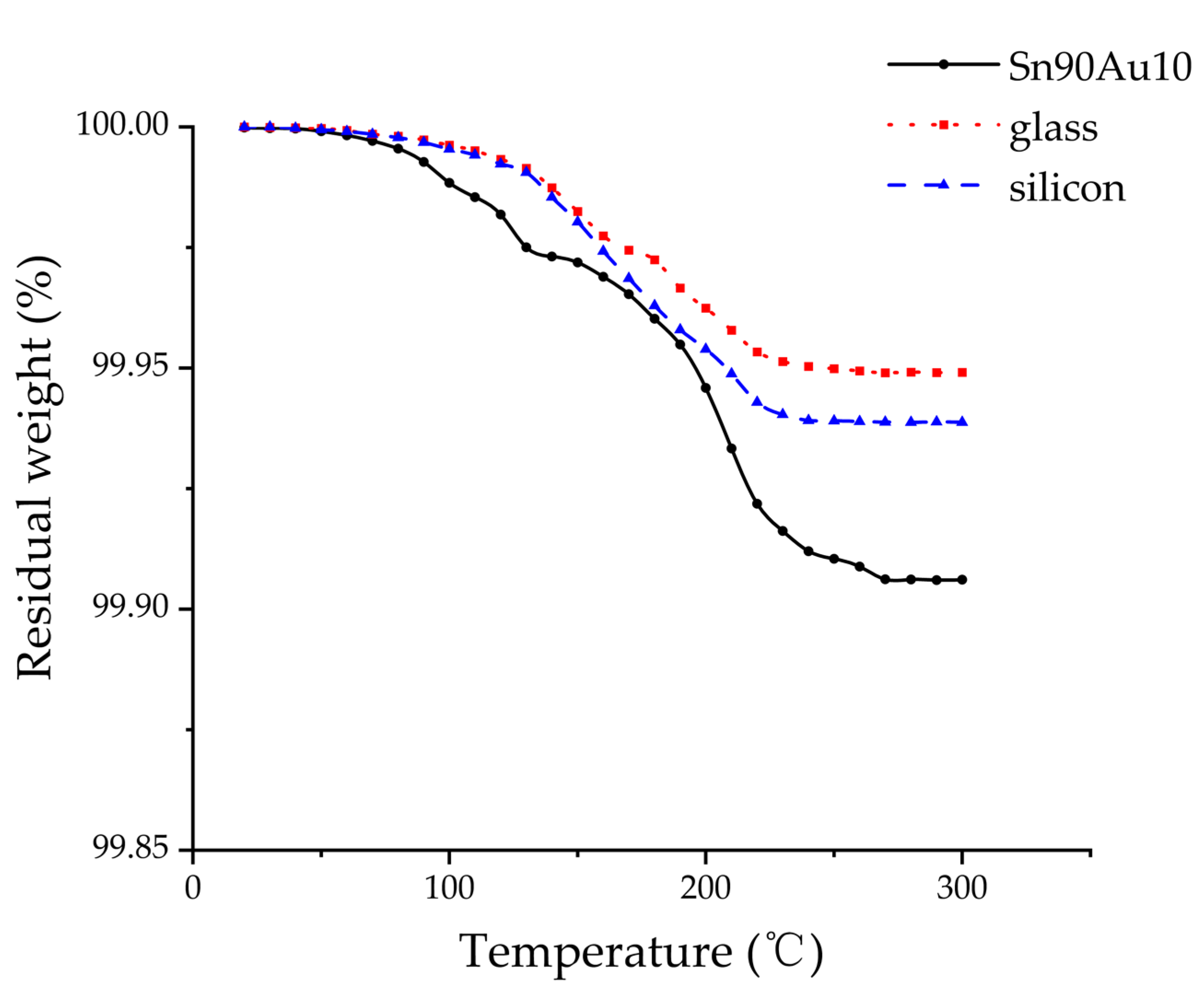

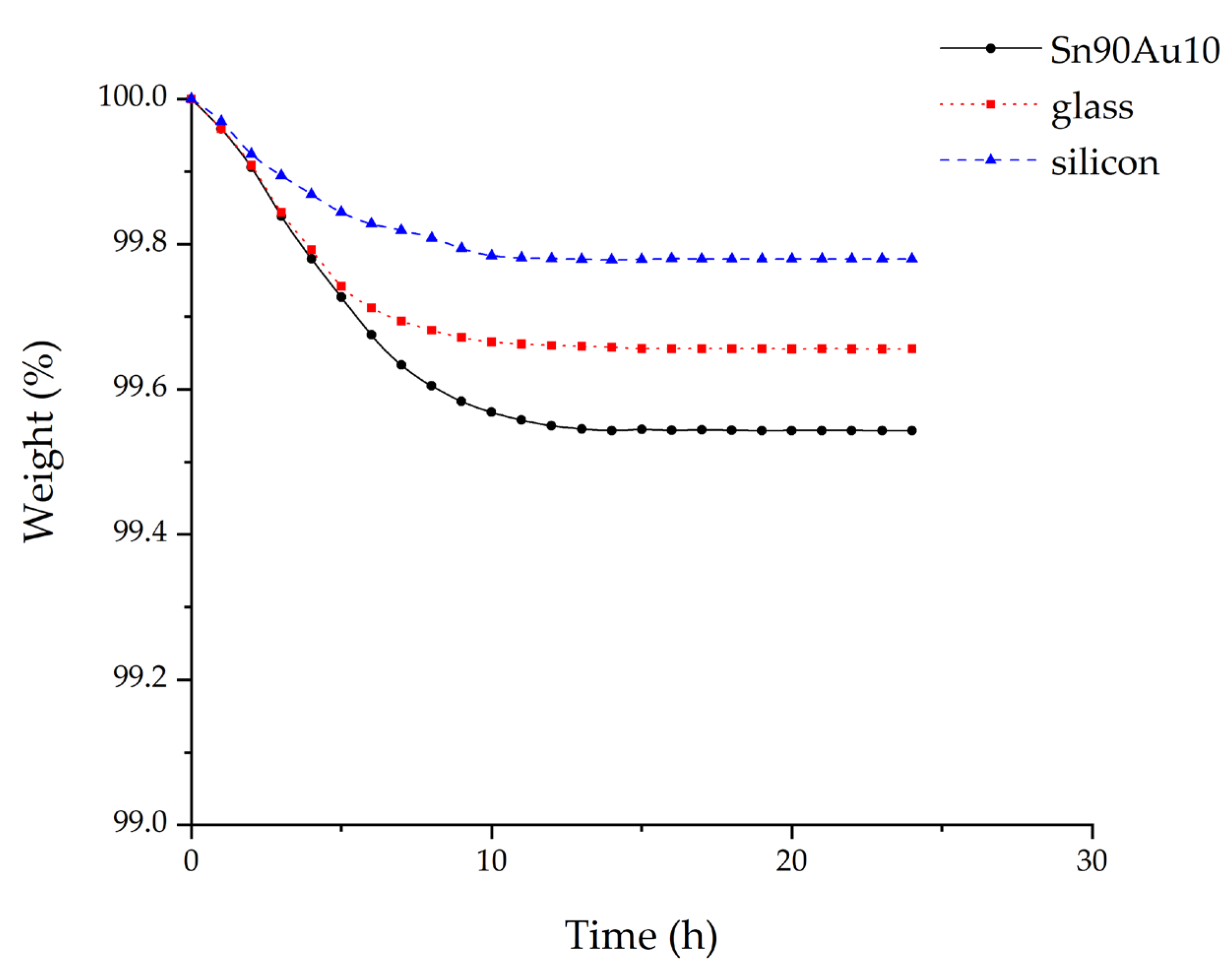

3.2. Outgassing of Materials Used in Physics Package

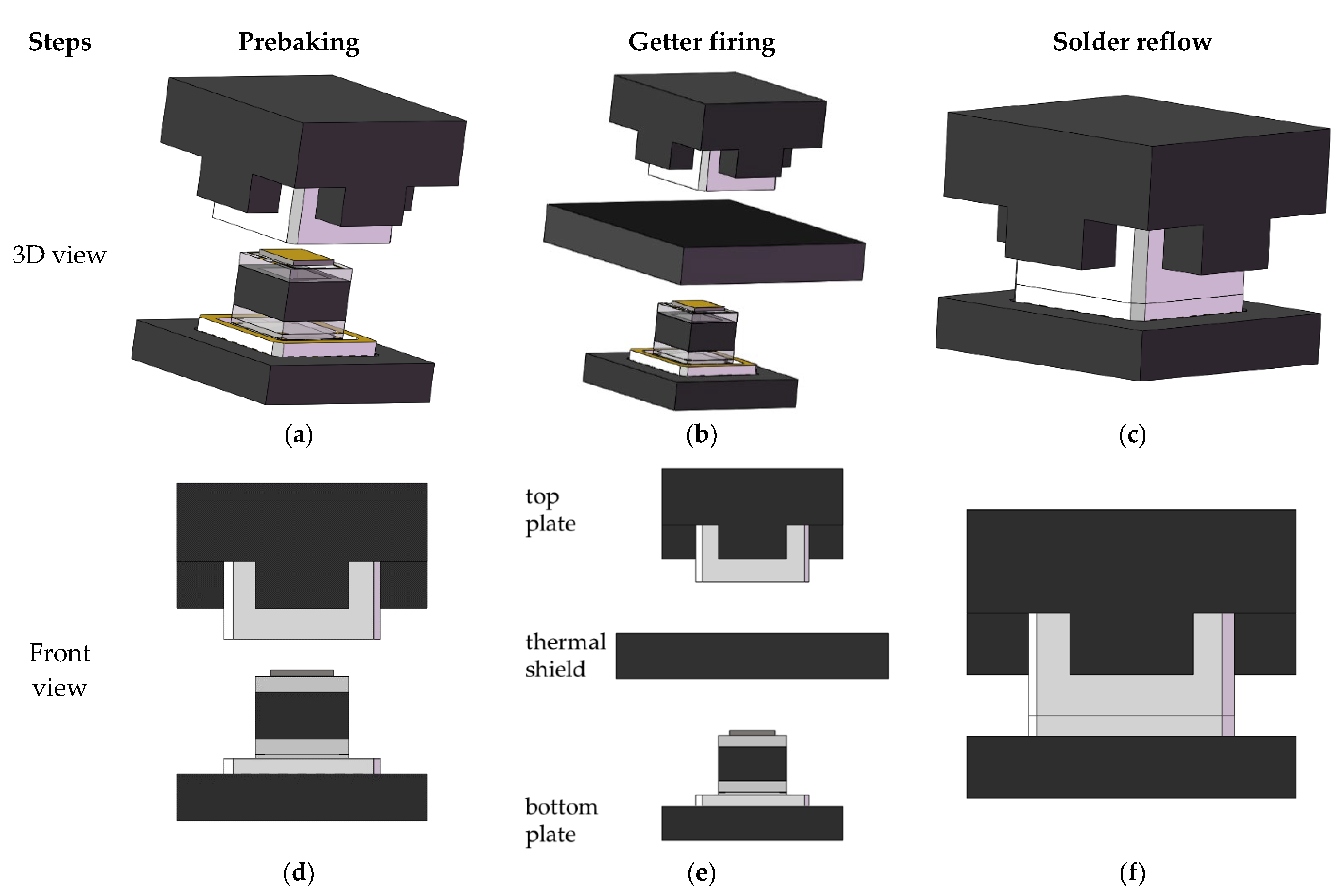

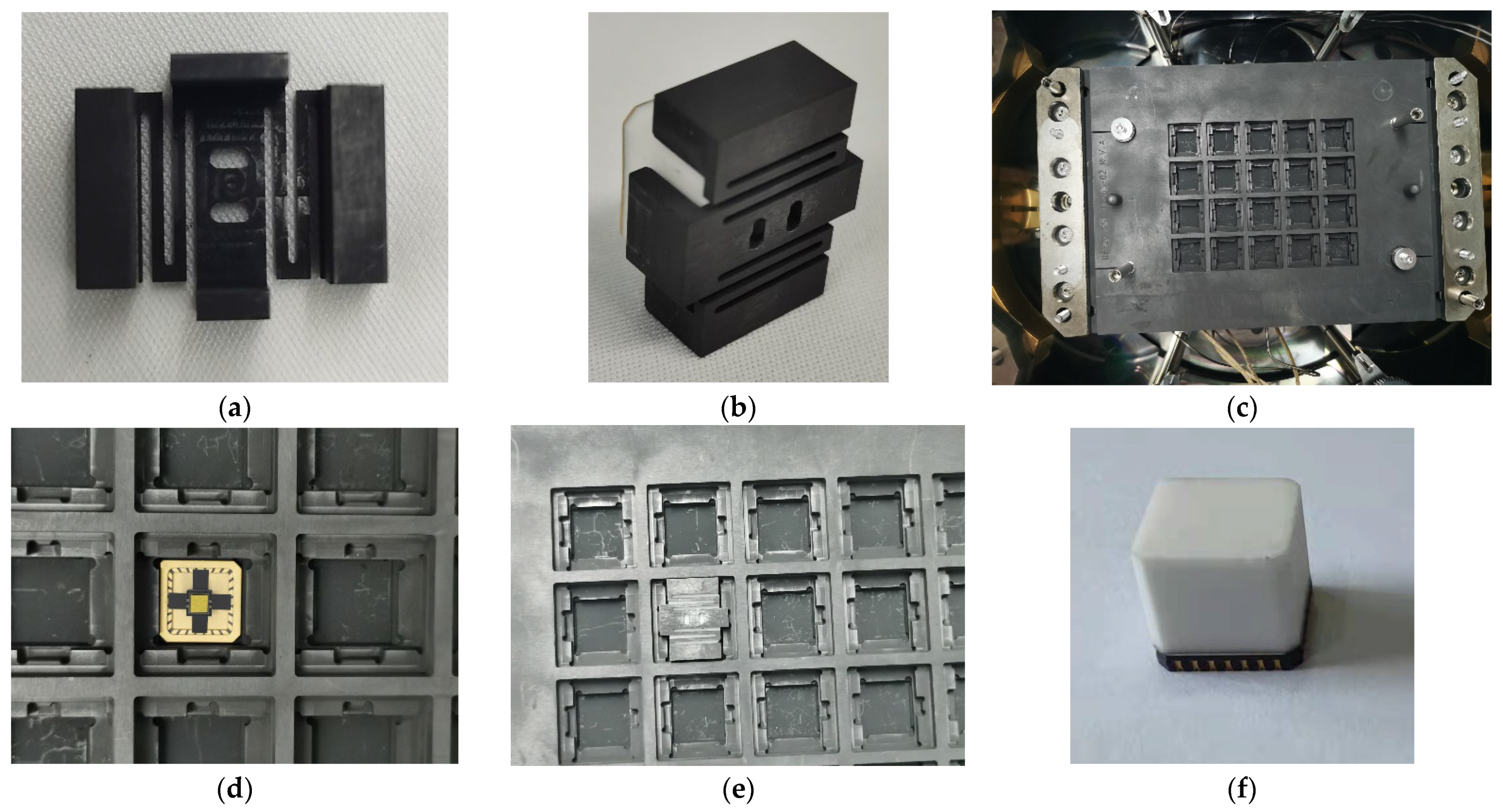

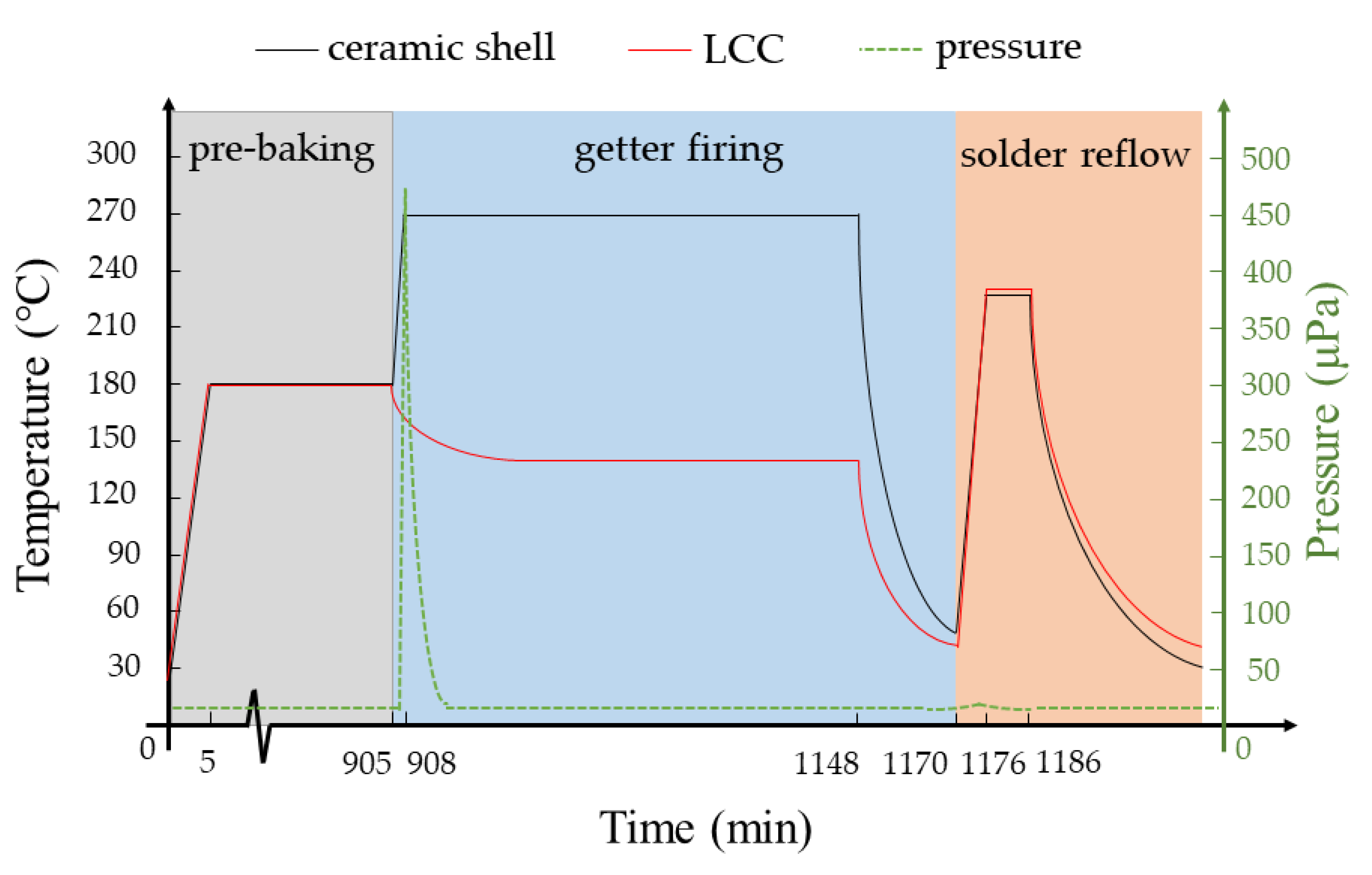

3.3. Vacuum Sealing

3.4. Leak Rate Test and Residual Gas Analysis

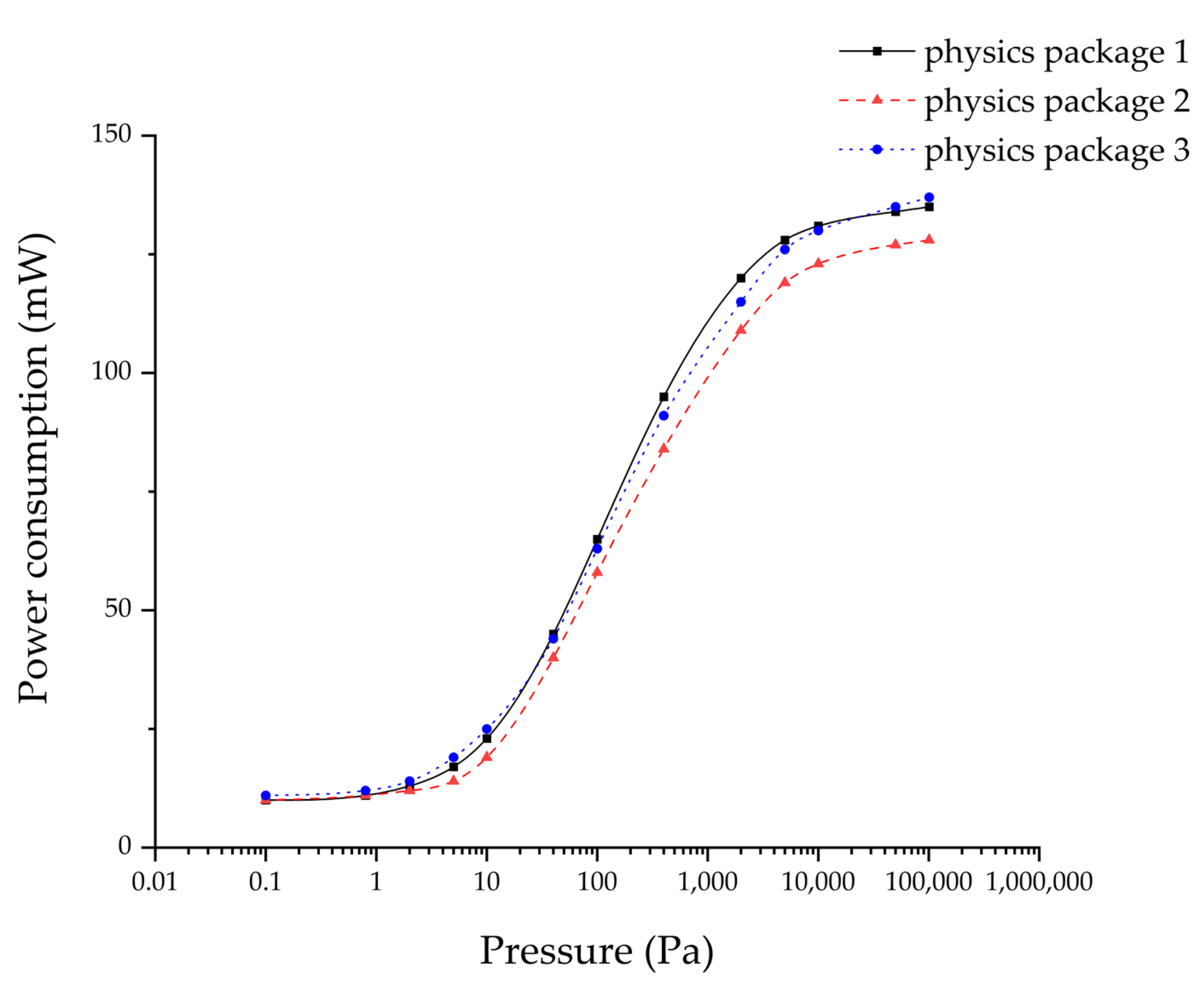

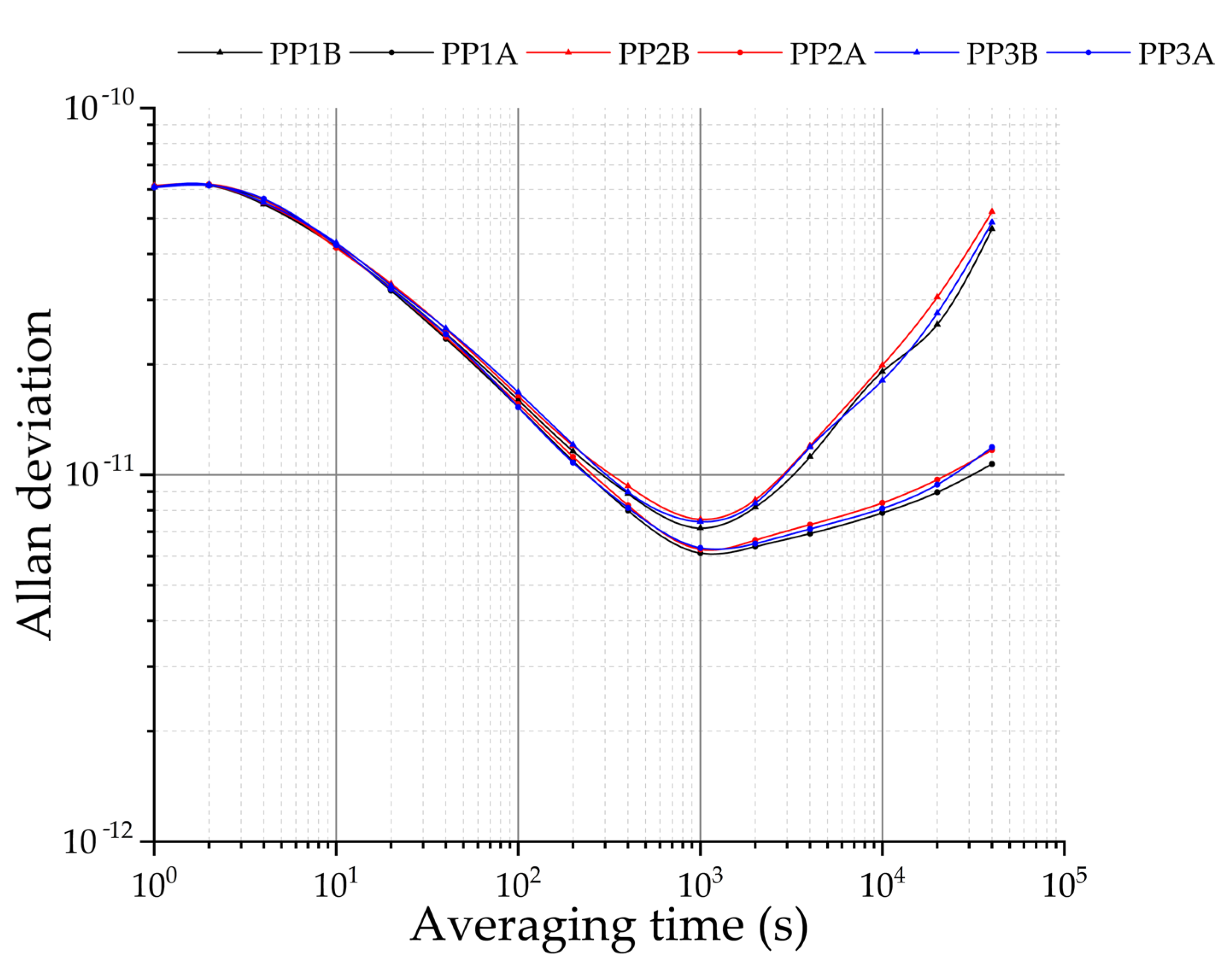

4. Results

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, S.H.; Mitchell, J.; Welch, W.; Lee, S.; Najafi, K. Wafer-level vacuum/hermetic packaging technologies for MEMS. In Reliability, Packaging, Testing, and Characterization of MEMS/MOEMS and Nanodevices IX; SPIE: San Francisco, CA, USA, 2010; Volume 7592, p. 759205. [Google Scholar] [CrossRef]

- Moelders, N.; Daly, J.T.; Greenwald, A.C.; Johnson, E.A.; McNeal, M.P. Localized, in-situ vacuum measurements for MEMS packaging. Mat. Res. Soc. Symp. Proc. 2003, 782. [Google Scholar] [CrossRef]

- Knowles, K.M.; Van Helvoort, A.T. Anodic bonding. Int. Mater. Rev. 2006, 51, 273–311. [Google Scholar] [CrossRef]

- Henmi, H.; Shoji, S.; Shoji, Y.; Yoshimi, K.; Esashi, M. Vacuum packaging for microsensors by glass-silicon anodic bonding. Sens. Actuators A 1994, 43, 243–248. [Google Scholar] [CrossRef]

- Knapkiewicz, P. Technological assessment of MEMS alkali vapor cells for atomic references. Micromachines 2019, 10, 25. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Choa, S.H.; Kim, W.; Hwang, J.; Ham, S.; Moon, C. Application of Au-Sn eutectic bonding in hermetic radio-frequency microelectromechanical system wafer level packaging. J. Elec. Materi. 2006, 35, 425–432. [Google Scholar] [CrossRef]

- Knechtel, R.; Wiemer, M.; Frömel, J. Wafer level encapsulation of microsystems using glass frit bonding. Microsyst. Technol. 2006, 12, 468–472. [Google Scholar] [CrossRef]

- Sparks, D.; Massoud-Ansari, S.; Najafi, N. Long-term evaluation of hermetically glass frit sealed silicon to Pyrex wafers with feedthroughs. J. Micromech. Microeng. 2005, 15, 1560. [Google Scholar] [CrossRef]

- Walsh, C.A. Laser Welding-Literature Review; University of Cambridge: Cambridge, UK, 2002. [Google Scholar]

- Di Cioccio, L.; Gueguen, P.; Taibi, R.; Landru, D.; Gaudin, G.; Chappaz, C.; Rieutord, F.; de Crecy, F.; Radu, I.; Chapelon, L.L.; et al. An overview of patterned metal/dielectric surface bonding: Mechanism, alignment and characterization. J. Electrochem. Soc. 2011, 158, 81. [Google Scholar] [CrossRef] [Green Version]

- Lee, S. Fundamentals of thermal compression bonding technology and process materials for 2.5/3D packages. In 3D Microelectronic Packaging; Springer: Cham, Switzerland, 2017; pp. 157–203. [Google Scholar] [CrossRef]

- Den Besten, C.; Van Hal, R.E.; Munoz, J.; Bergveld, P. Polymer bonding of micro-machined silicon structures. In Proceedings of the IEEE Micro Electro Mechanical Systems, Travemünde, Germany, 4–7 February 1992; pp. 104–109. [Google Scholar] [CrossRef] [Green Version]

- Borzenko, T.; Tormen, M.; Schmidt, G.; Molenkamp, L.W.; Janssen, H. Polymer bonding process for nanolithography. Appl. Phys. Lett. 2001, 79, 2246–2248. [Google Scholar] [CrossRef]

- Jiang, M.; Tao, W.; Chen, Y. Laser welding under vacuum: A review. Appl. Sci. 2017, 7, 909. [Google Scholar] [CrossRef] [Green Version]

- Qin, Y.; Howlader, M.M.; Deen, M.J.; Haddara, Y.M.; Selvaganapathy, P.R. Polymer integration for packaging of implantable sensors. Sens. Actuators B 2014, 202, 758–778. [Google Scholar] [CrossRef]

- Higurashi, E.; Suga, T. Review of low-temperature bonding technologies and their application in optoelectronic devices. Electron. Comm. Jpn. 2016, 99, 63–71. [Google Scholar] [CrossRef]

- Knechtel, R. Glass frit bonding: An universal technology for wafer level encapsulation and packaging. Microsyst. Technol. 2005, 12, 63–68. [Google Scholar] [CrossRef]

- Shimatsu, T.; Uomoto, M. Room temperature bonding of wafers with thin nanocrystalline metal films. ECS Trans. 2010, 33, 61. [Google Scholar] [CrossRef]

- Xie, J.; Lu, S.; Du, Y.; Hu, W.; Mao, Y. Microstructural evolution and orientation-correlated origin of the coarsening behaviors in Au–Sn eutectic alloys. J. Alloys Compd. 2019, 806, 1285–1291. [Google Scholar] [CrossRef]

- Peng, J.; Liu, H.S.; Ma, H.B.; Shi, X.M.; Wang, R.C. Microstructure evolution and mechanical reliability of Cu/Au–Sn/Cu joints during transient liquid phase bonding. J. Mater. Sci. 2018, 53, 9287–9296. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, D.; Xiong, J.; Chen, C.; Song, T.; Liu, L.; Huang, S. Microstructure evolution and properties of rapidly solidified Au-20Sn eutectic solder prepared by single-roll technology. J. Alloys Compd. 2019, 781, 873–882. [Google Scholar] [CrossRef]

- Wen, L.; Xue, S.; Wang, L.; Liu, H.; Wu, J. Microstructural evolution and shear performance of AuSn20 solder joint under gamma-ray irradiation and thermal cycling. J. Mater. Sci. Mater. Electron. 2020, 31, 7200–7210. [Google Scholar] [CrossRef]

- Kuhmann, J.F.; Preuss, A.; Adolphi, B.; Maly, K.; Wirth, T.; Oesterle, W.; Pittroff, W.; Weyer, G.; Fanciulli, M. Oxidation and reduction of eutectic SnPb, InSn, and AuSn: A knowledge base for fluxless solder bonding applications. IEEE Trans. Compon. Pack. Manuf. Tech. 1998, 21, 134–141. [Google Scholar] [CrossRef]

- Tepolt, G.B.; Mescher, M.J.; LeBlanc, J.J.; Lutwak, R.; Vargheses, M. Hermetic vacuum sealing of MEMS devices containing organic components. In SPIE Reliability, Packaging, Testing, and Characterization of MEMS/MOEMS and Nanodevices IX; SPIE: San Francisco, CA, USA, 2010; Volume 7592. [Google Scholar] [CrossRef]

- Prakash, S.; Yeom, J. Advanced fabrication methods and techniques. In Nanofluidics and Microfluidics: Systems and Applications, 1st ed.; William Andrew: Waltham, MA, USA, 2014; pp. 87–170. [Google Scholar]

- MatWeb. Available online: http://matweb.com (accessed on 21 July 2021).

- Jiang, G.; Zhou, D.D. Technology advances and challenges in hermetic packaging for implantable medical devices. In Implantable Neutral Prostheses, 2nd ed.; Springer: New York, NY, USA, 2009; pp. 27–61. [Google Scholar]

- Goeke, R.S.; Grubbs, R.K.; Yazzie, D.; Casias, A.L.; Peterson, K.A. Gas permeation measurements on low temperature cofired ceramics. Addit. Conf. Device Packag. HiTEC HiTEN CICMT 2012, 2012, 3232–3327. [Google Scholar] [CrossRef]

- Kitching, J.; Knappe, S.; Schwindt, P.D.; Shah, V.; Hollberg, L.; Liew, L.A.; Moreland, J. Power dissipation in a vertically integrated chip-scale atomic clock. In Proceedings of the 2004 IEEE International Frequency Control Symposium and Exposition, Montreal, QC, Canada, 23–27 August 2004; pp. 781–784. [Google Scholar] [CrossRef]

- Marinis, T.F.; Soucy, J.W. Vacuum packaging of MEMS inertial sensors. In Proceedings-SPIE the International Society for Optical Engineering; SPIE: Boston, MA, USA, 2003; pp. 386–391. [Google Scholar]

- Choa, S.H. Reliability of MEMS packaging: Vacuum maintenance and packaging induce stress. Microsyst. Technol. 2005, 11, 1187–1196. [Google Scholar] [CrossRef]

- Rizzi, E.; Mauri, L.; Moraja, M.; Conte, A.; Bonucci, A.; Longoni, G.; Amiotti, M. Outgassing and gettering. In Handbook of Silicon Based MEMS Materials and Technologies, 2nd ed.; Tilli, M., Mottoka, M., Airaksinen, V.M., Franssila, S., Paulasto-Krockel, M., Lindroos, V., Eds.; Elsevier: New York, NY, USA, 2015; pp. 713–733. [Google Scholar] [CrossRef]

- Benvenuti, C.; Chiggiato, P.; Pinto, P.C.; Santana, A.E.; Hedley, T.; Mongelluzzo, A.; Ruzinov, V.; Wevers, I. Vacuum properties of TiZrV non-evaporable getter films. Vacuum 2001, 60, 57–65. [Google Scholar] [CrossRef] [Green Version]

- Benvenuti, C.; Chiggiato, P.; Cicoira, F.; Ruzinov, V. Decreasing surface outgassing by thin film getter coatings. Vacuum 1998, 50, 57–63. [Google Scholar] [CrossRef]

- Coats, A.W.; Redfern, J.P. Thermogravimetric Analysis: A review. Analyst 1963, 88, 906–924. [Google Scholar] [CrossRef]

- Prime, R.B.; Bair, H.E.; Vyazovkin, S.; Gallagher, P.K.; Riga, A. Thermogravimetric analysis (TGA). In Thermal Analysis of Polymers: Fundamentals and Applications, 1st ed.; Menczel, J.D., Prime, R.B., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 319–386. [Google Scholar]

- Costello, S.; Desmulliez, M.P.; McCracken, S. Review of test methods used for the measurement of hermeticity in packages containing small cavities. IEEE Trans. Compon. Pack. Manuf. Technol. 2021, 2, 430–438. [Google Scholar] [CrossRef] [Green Version]

- EverySpec. Available online: http://everyspec.com (accessed on 7 September 2021).

- Anufriev, G.S.; Boltenkov, B.S.; Ryabinkov, A.I. High-resolution mass spectra of the residual gas in a metallic vacuum system. Tech. Phys. 2006, 51, 100–111. [Google Scholar] [CrossRef]

- Lichtman, D. Residual gas analysis: Past, present, and future. J. Vac. Sci. Technol. A 1990, 8, 2810–2813. [Google Scholar] [CrossRef]

- Microchip (Microsemi Product Porfolio). Available online: http://microsemi.com (accessed on 8 September 2021).

- Prikhodko, I.P.; Simon, B.R.; Sharma, G.; Zotov, S.A.; Trusov, A.A.; Shkel, A.M. High and moderate-level vacuum packaging of vibratory MEMS. In Proceedings of the 46th International Symposium on Microelectronics, Orlando, FL, USA, 30 September–3 October 2013; pp. 705–710. [Google Scholar]

- Niklaus, F.; Stemme, G.; Lu, J.Q.; Gutmann, R.J. Adhesive wafer bonding. J. Appl. Phys. 2006, 99, 2. [Google Scholar] [CrossRef]

| Solder Alloy | Ingredients (Weight %) | Melting Point (°C) | Shear Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| Sn90Au10 | Sn/Au = 90/10 | 217 | 50 | 50 |

| Sn90Sb10 | Sn/Sb = 90/10 | 250 | 44 | 44 |

| Au80Sn20 | Au/Sn = 80/20 | 280 | 275.8 | 275.8 |

| Au88Ge12 | Au/Ge = 88/12 | 356 | 185 | 185 |

| Sample ID | Physics Package 1 | Physics Package 2 | Physics Package 3 | |

|---|---|---|---|---|

| Test time after vacuum packaging | months | 1 | 3 | 5 |

| Power consumption | mW | 13.6 | 15.1 | 14.9 |

| Pressure | Pa | 0.093 | 0.104 | 0.098 |

| Nitrogen | % | 99.7 | 99.2 | 99.4 |

| Oxygen | ppm | ND | ND | ND |

| Argon | ppm | <100 | 164 | 105 |

| Carbon dioxide | ppm | 1364 | 3973 | 1639 |

| Moisture | ppm | 2473 | 2184 | 1367 |

| Hydrogen | ppm | 482 | 853 | 717 |

| Ammonia | ppm | 583 | 379 | 942 |

| Fluorocarbons | ppm | 164 | 128 | 154 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, P.; Meng, H.; Dan, L.; Xu, H.; Zhao, J. High Vacuum Packaging of MEMS Devices Containing Heterogeneous Discrete Components. Appl. Sci. 2021, 11, 8536. https://doi.org/10.3390/app11188536

Guo P, Meng H, Dan L, Xu H, Zhao J. High Vacuum Packaging of MEMS Devices Containing Heterogeneous Discrete Components. Applied Sciences. 2021; 11(18):8536. https://doi.org/10.3390/app11188536

Chicago/Turabian StyleGuo, Ping, Hongling Meng, Lin Dan, Hao Xu, and Jianye Zhao. 2021. "High Vacuum Packaging of MEMS Devices Containing Heterogeneous Discrete Components" Applied Sciences 11, no. 18: 8536. https://doi.org/10.3390/app11188536

APA StyleGuo, P., Meng, H., Dan, L., Xu, H., & Zhao, J. (2021). High Vacuum Packaging of MEMS Devices Containing Heterogeneous Discrete Components. Applied Sciences, 11(18), 8536. https://doi.org/10.3390/app11188536