Conceptual Design and Multi-Disciplinary Computational Investigations of Multirotor Unmanned Aerial Vehicle for Environmental Applications

Abstract

:1. Introduction

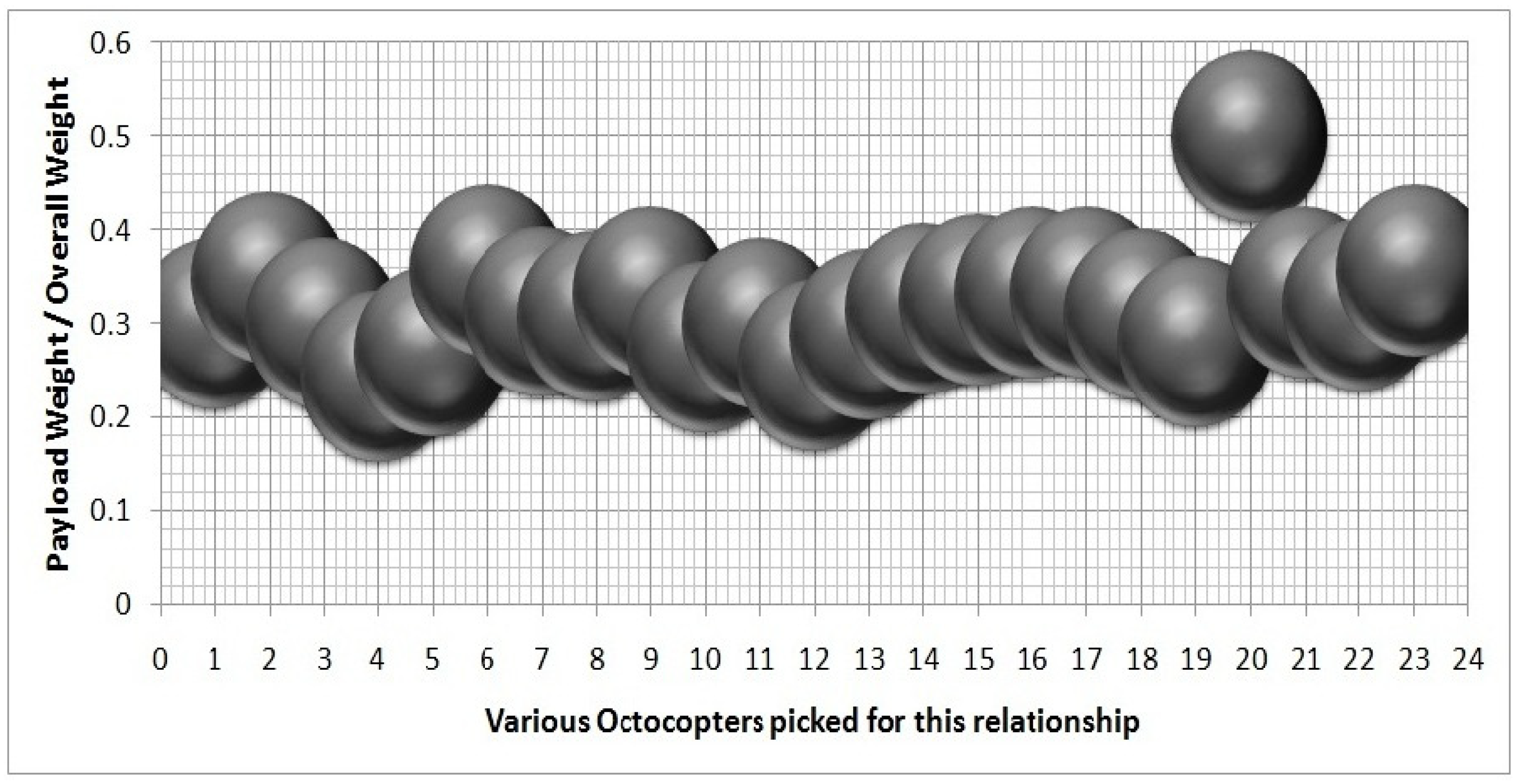

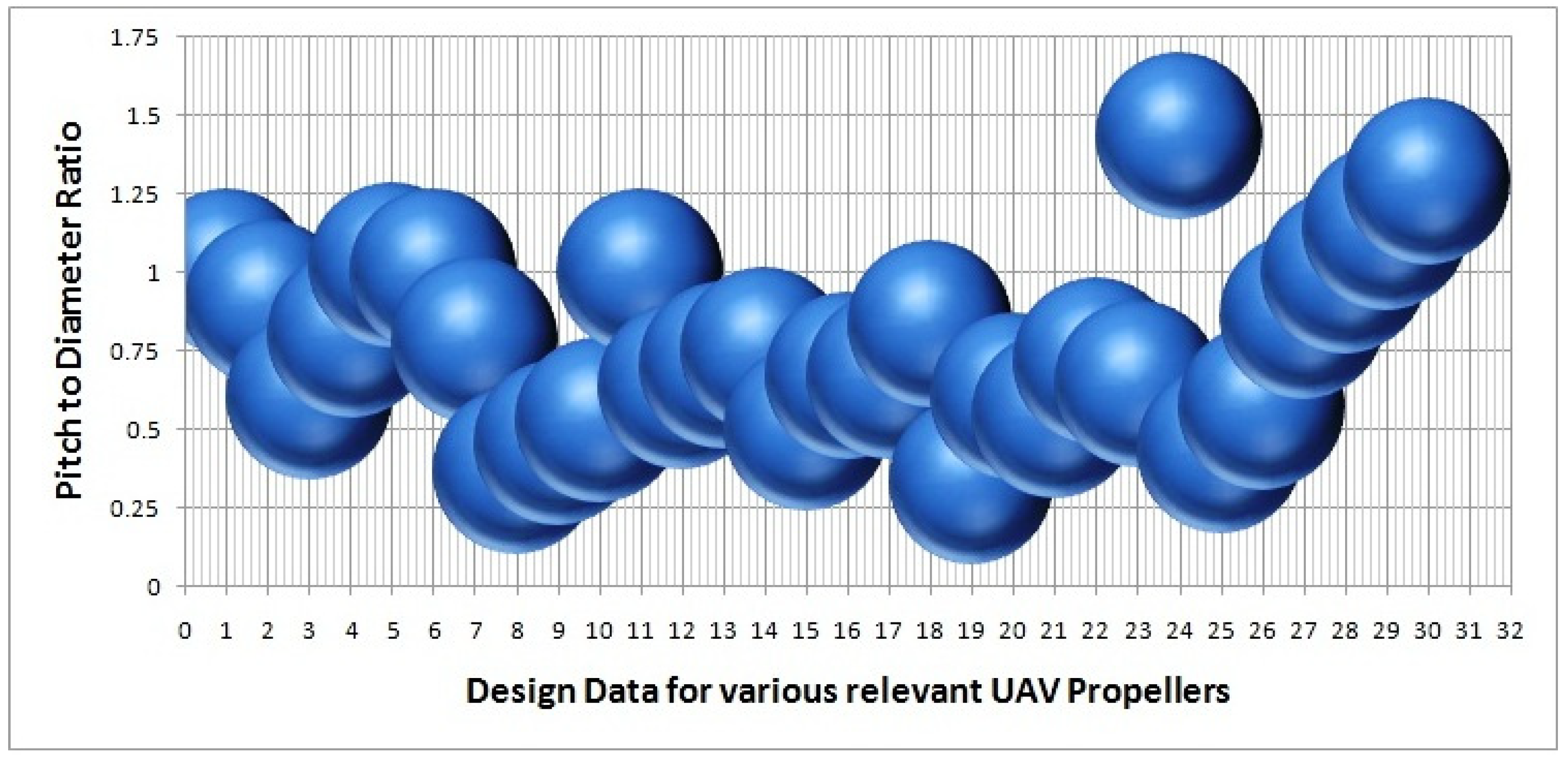

2. Literature Survey

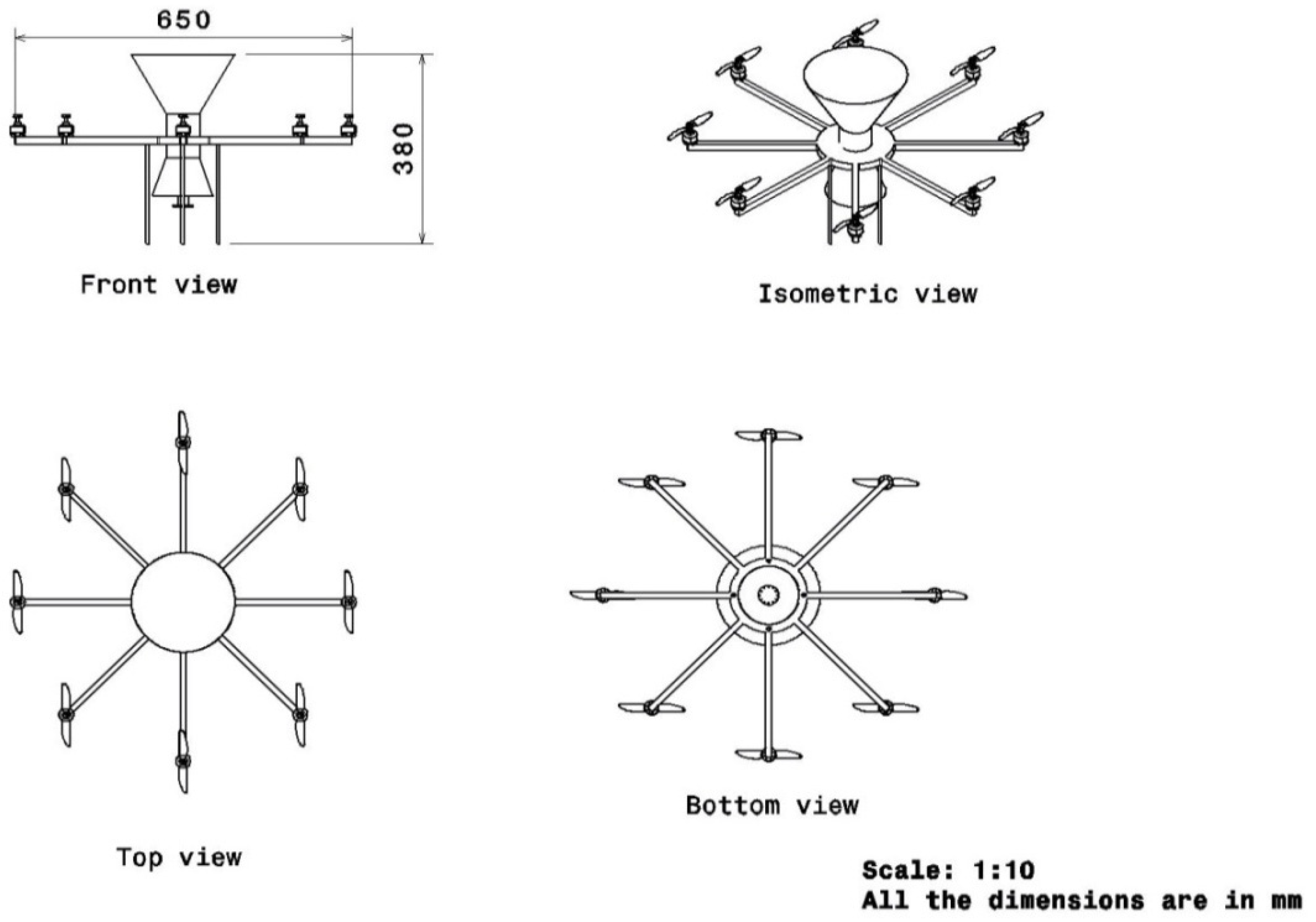

3. Component Selection and Criteria

3.1. Theoretical Calculation

3.2. Frame Design and Weight Estimation

3.3. Landing Gear Design and Weight Estimation

3.4. Estimation of Thrust and Specifications

4. Conceptual Design of the Octocopter

4.1. Outline of Conceptual Design

4.2. The Octocopter

4.3. Estimation of CL, CD, and Moment of Inertia

4.3.1. Vertical Take-Off

4.3.2. Forward Maneuvering

4.3.3. Estimation of Moment of Inertia

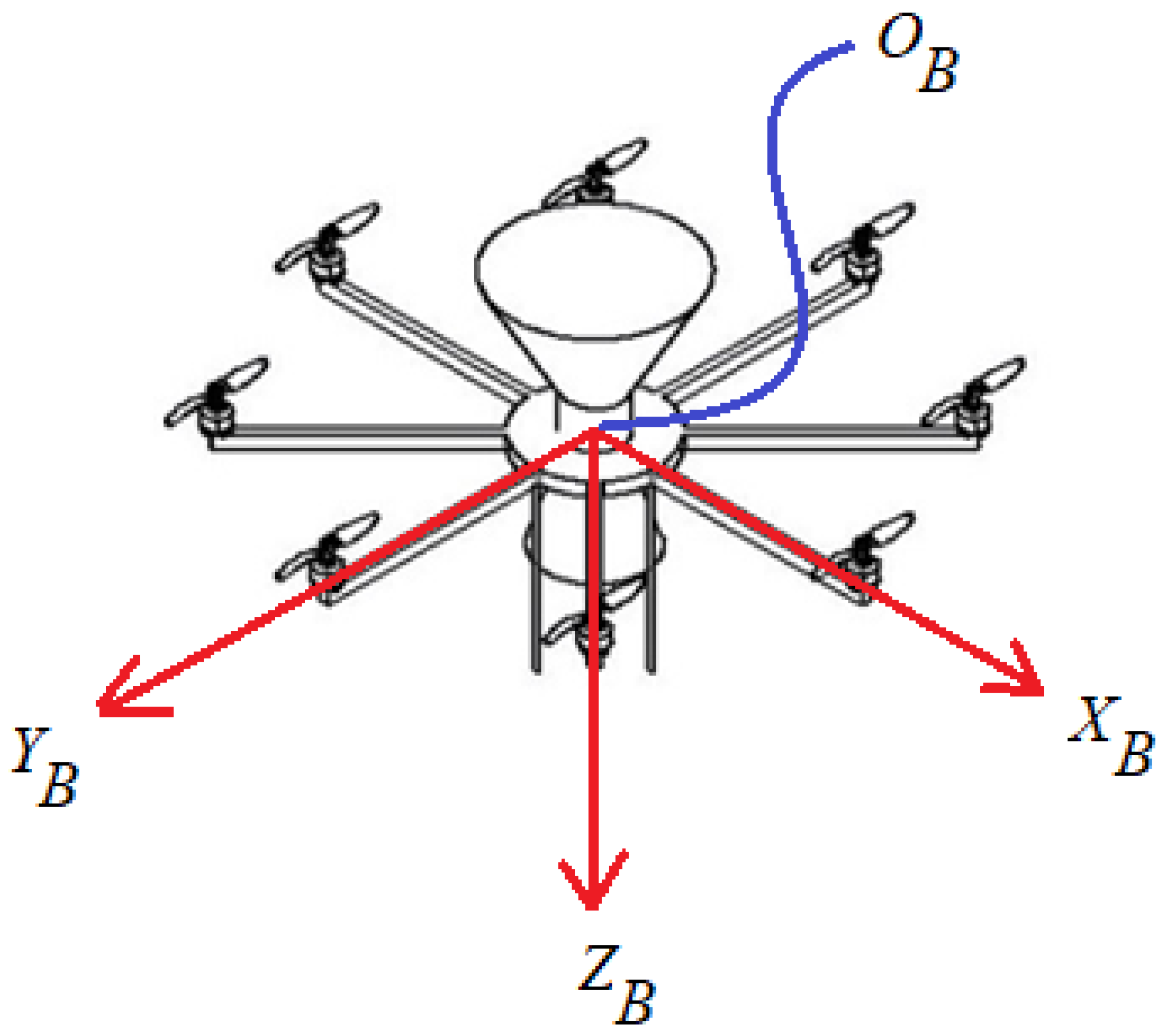

5. Mathematical Modeling and the Control of Attitude Dynamics

- ○

- The X-axis (XB) is pointing forward along the structure.

- ○

- The Y-axis (YB) points along the structure to the right.

- ○

- The Z-axis (ZB) points downward to complete a right-handed system.

5.1. Linearized Model of Attitude Dynamics

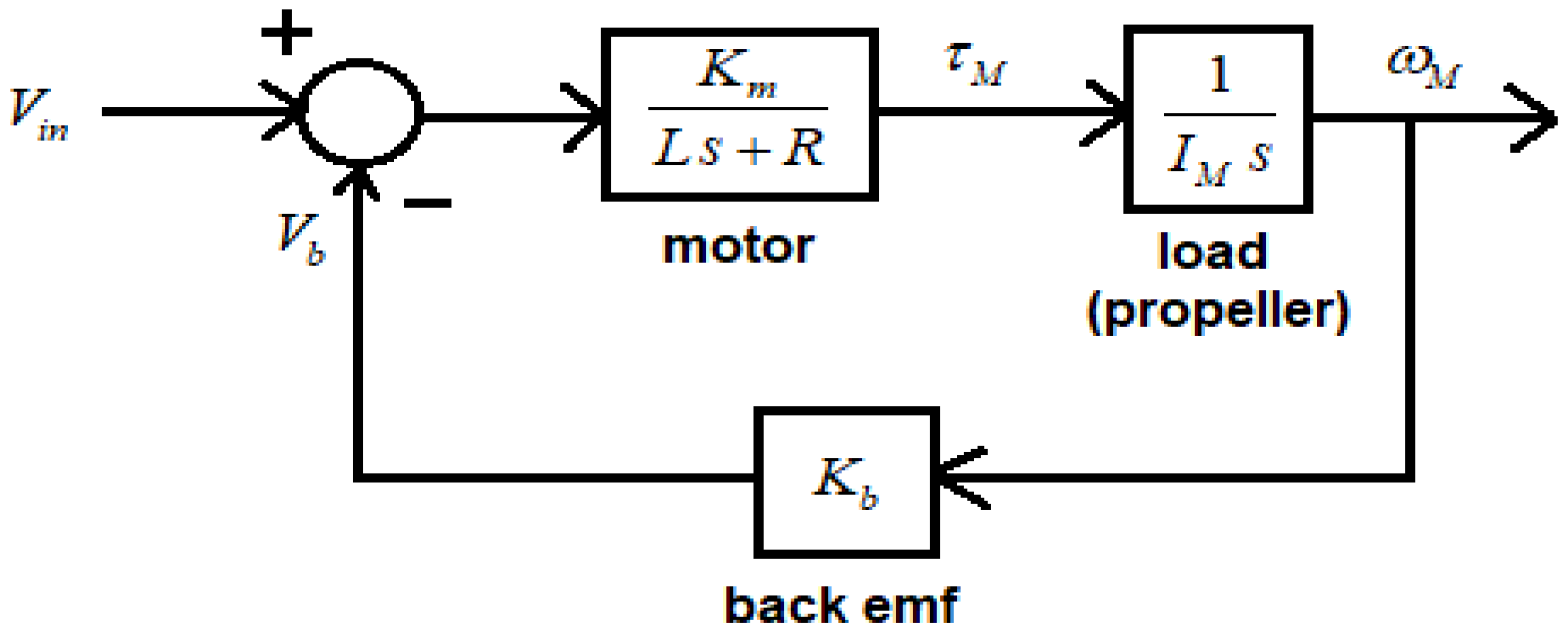

5.2. Motor Dynamics

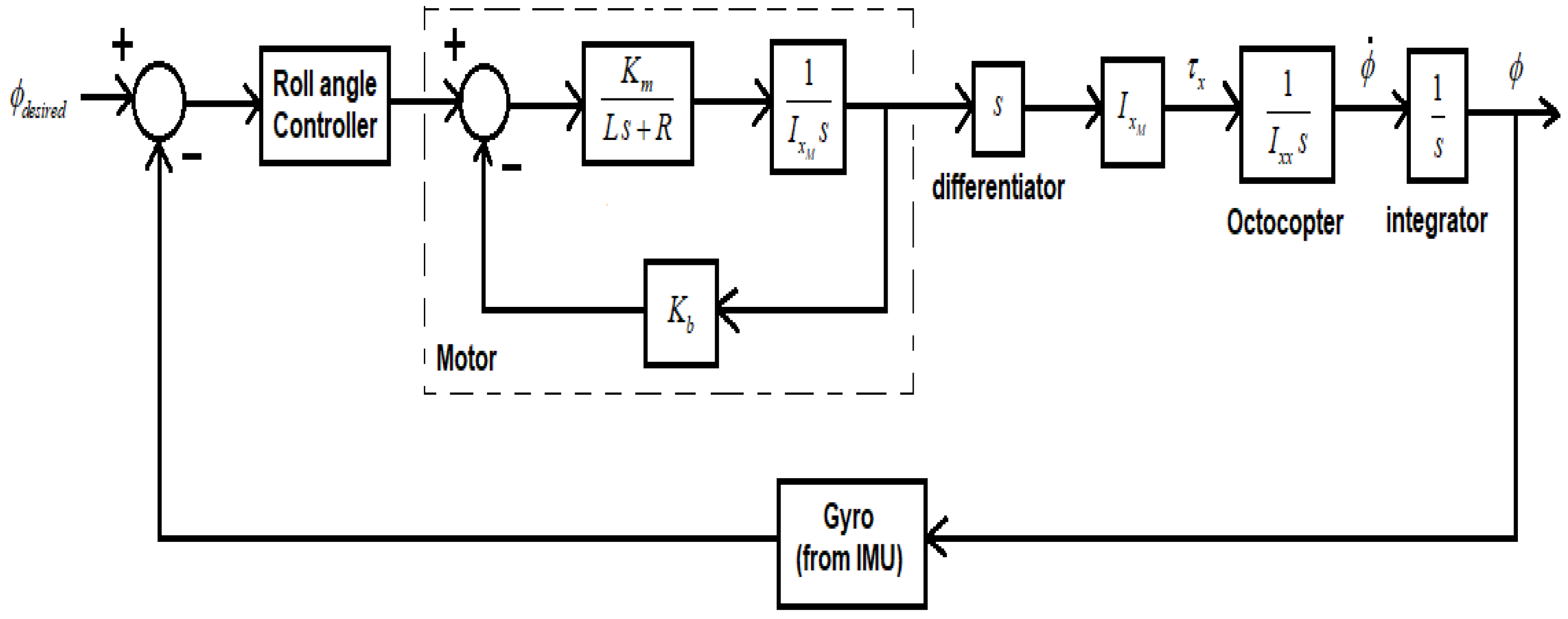

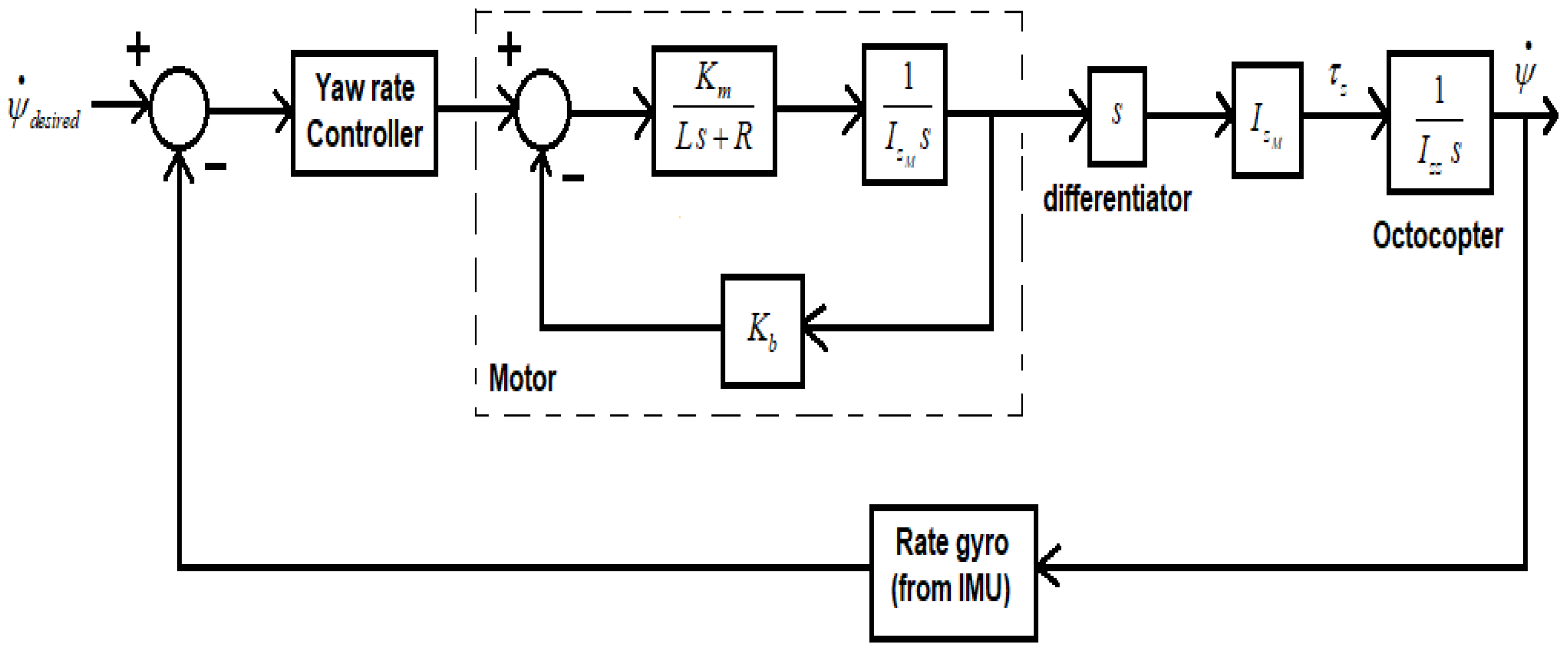

5.3. Attitude-Control Loops

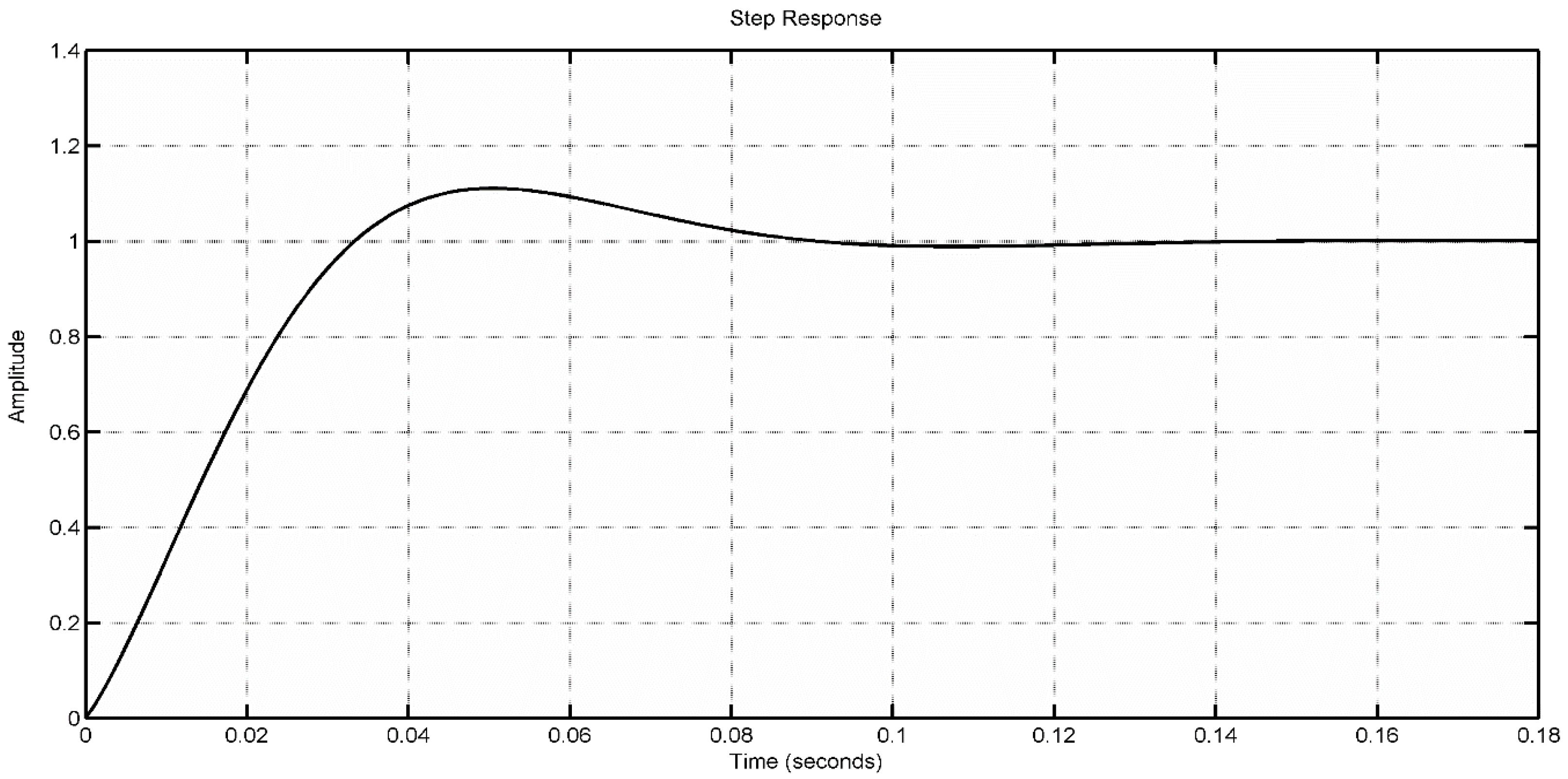

5.4. Controller Design

5.4.1. Roll Attitude Controller

5.4.2. Pitch Attitude Controller

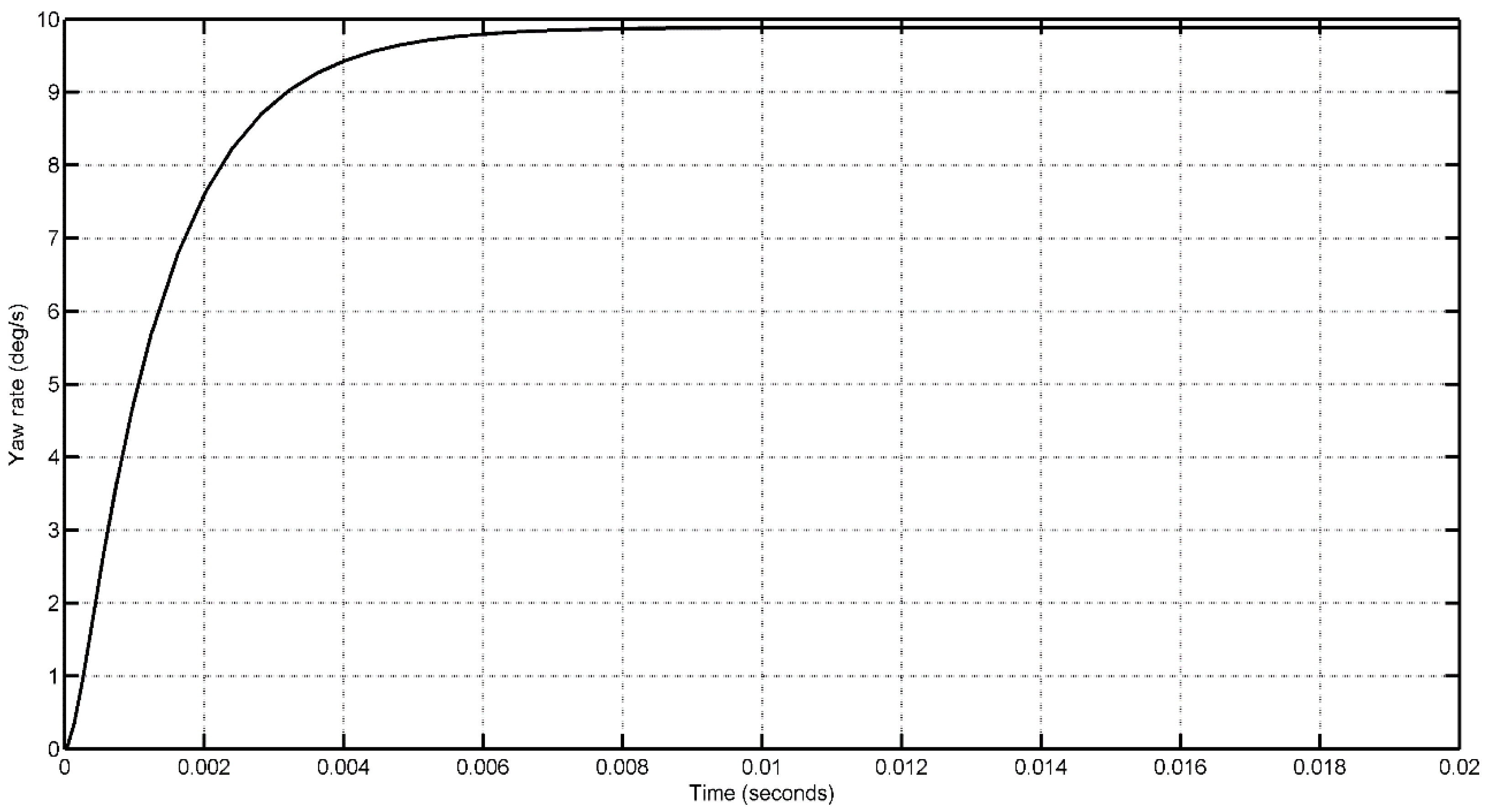

5.4.3. Yaw-Rate Controller

6. Computational Fluid–Structural Results and Discussions

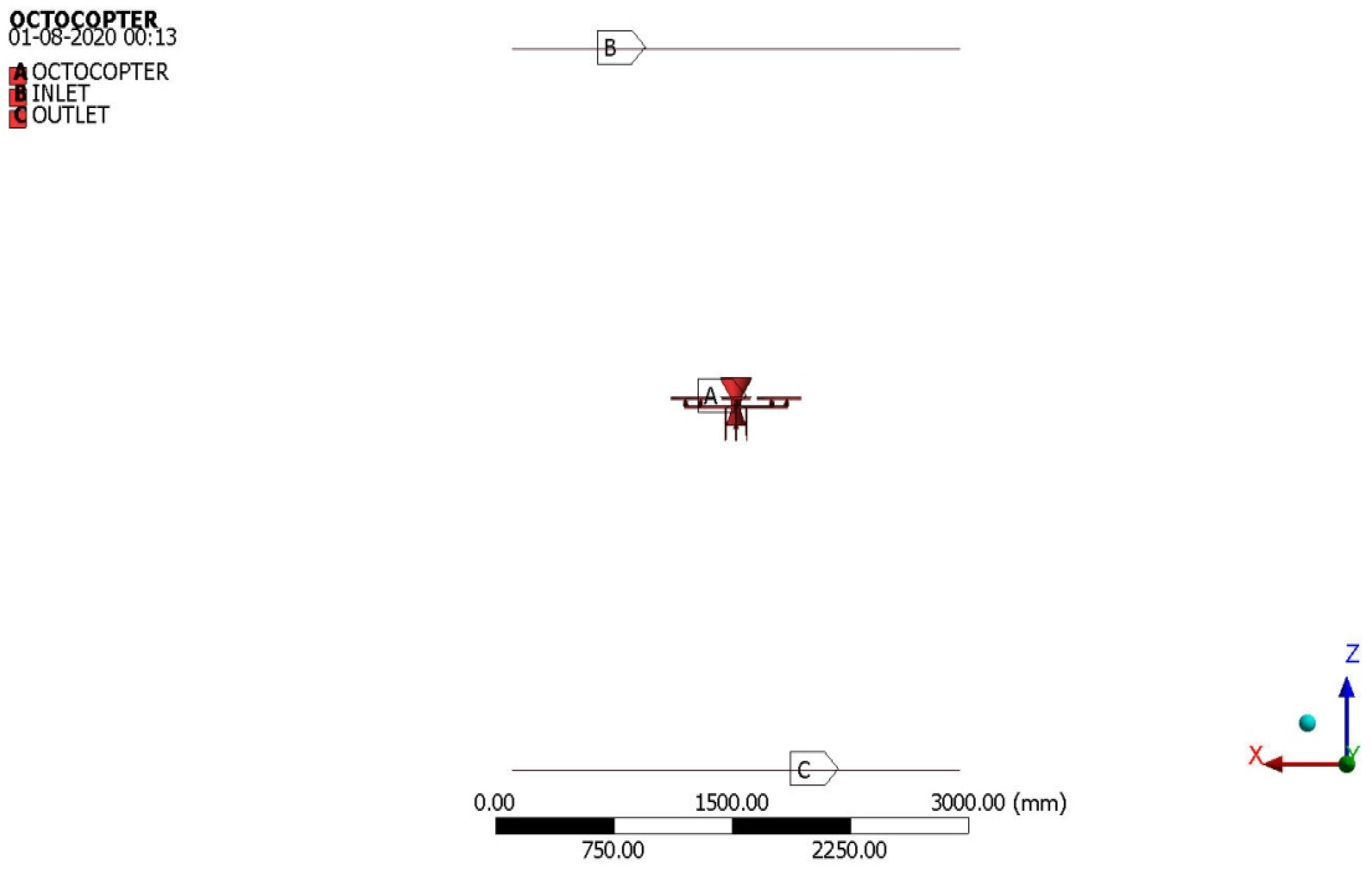

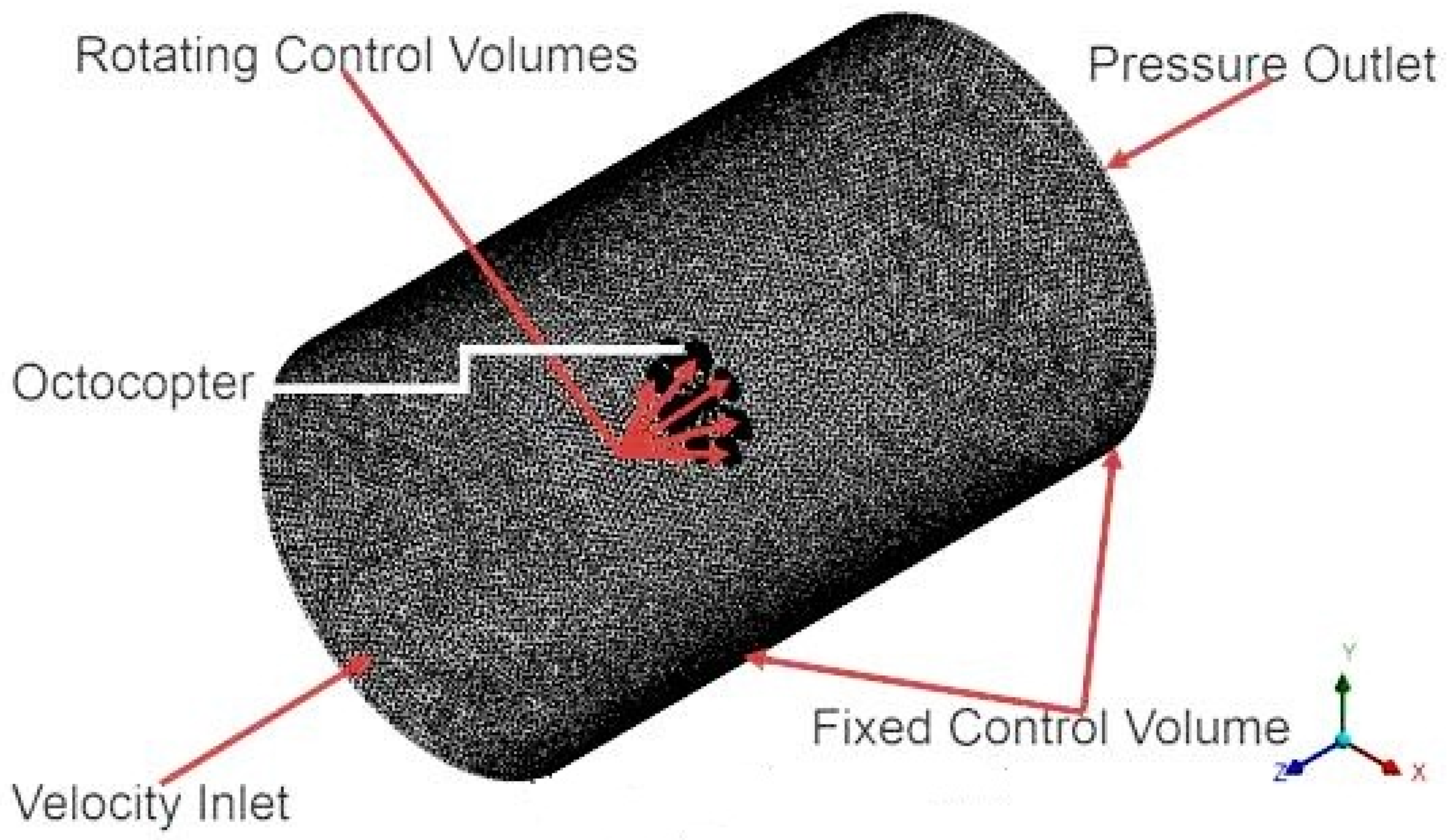

6.1. Computational Model

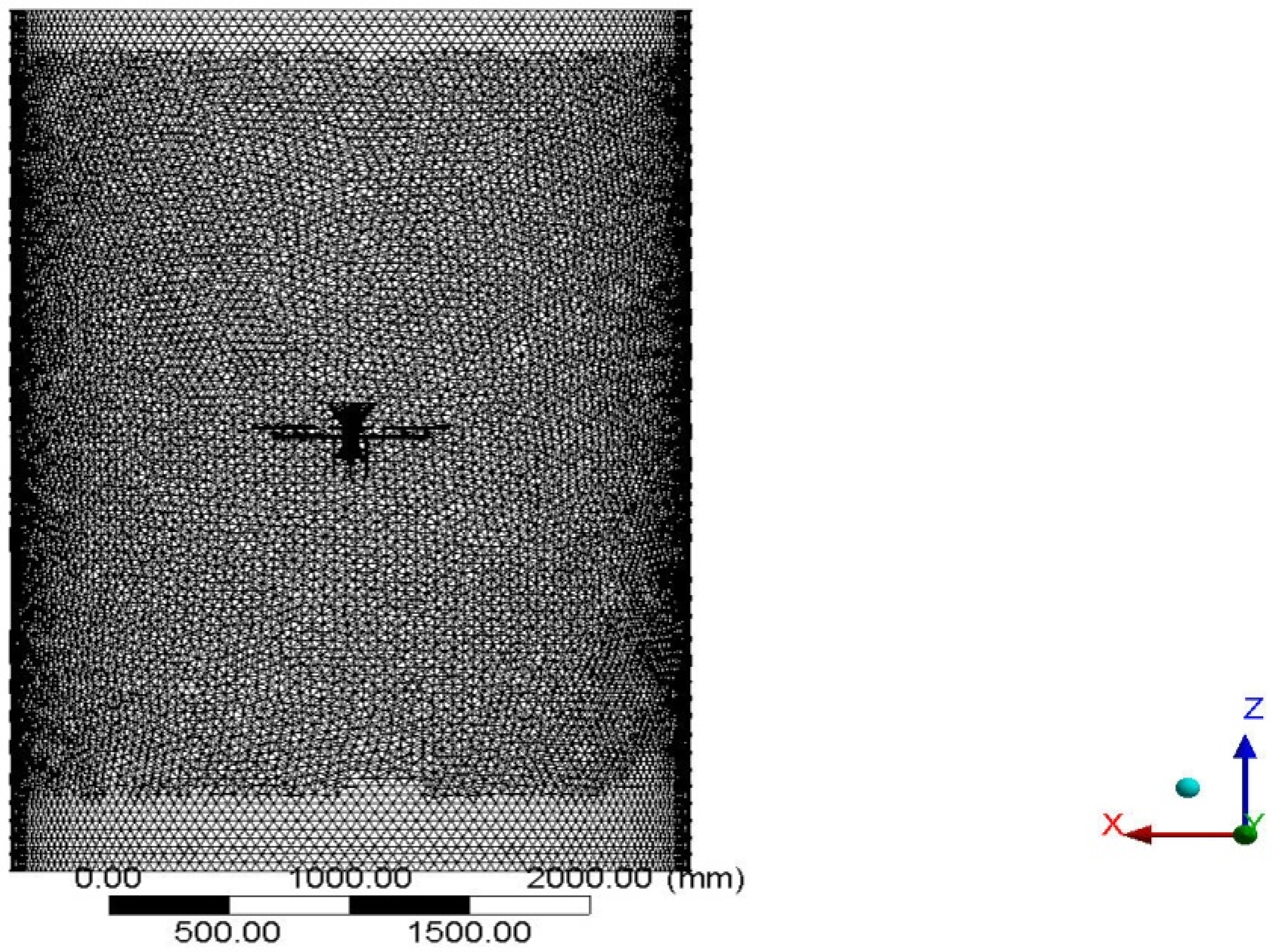

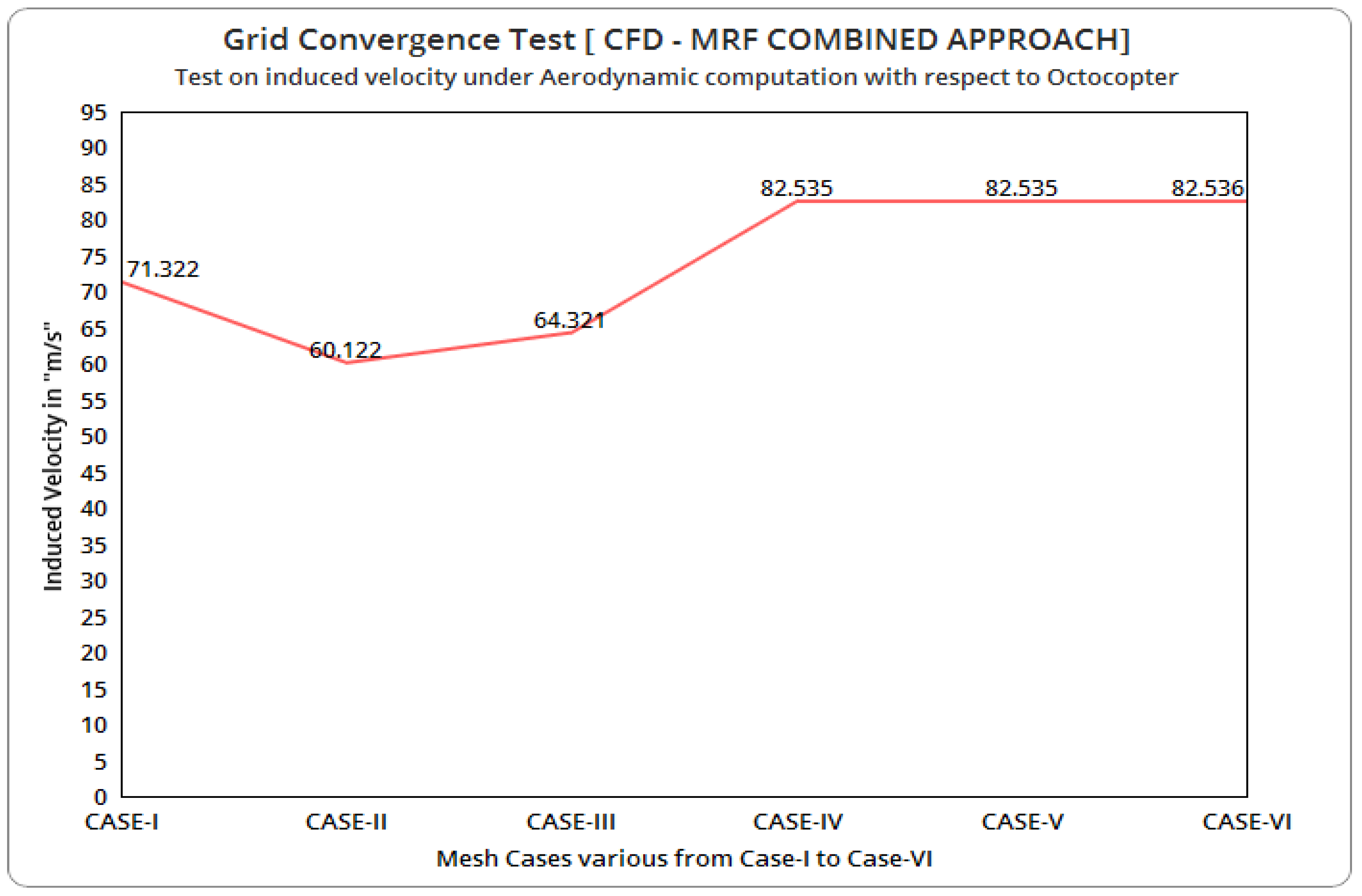

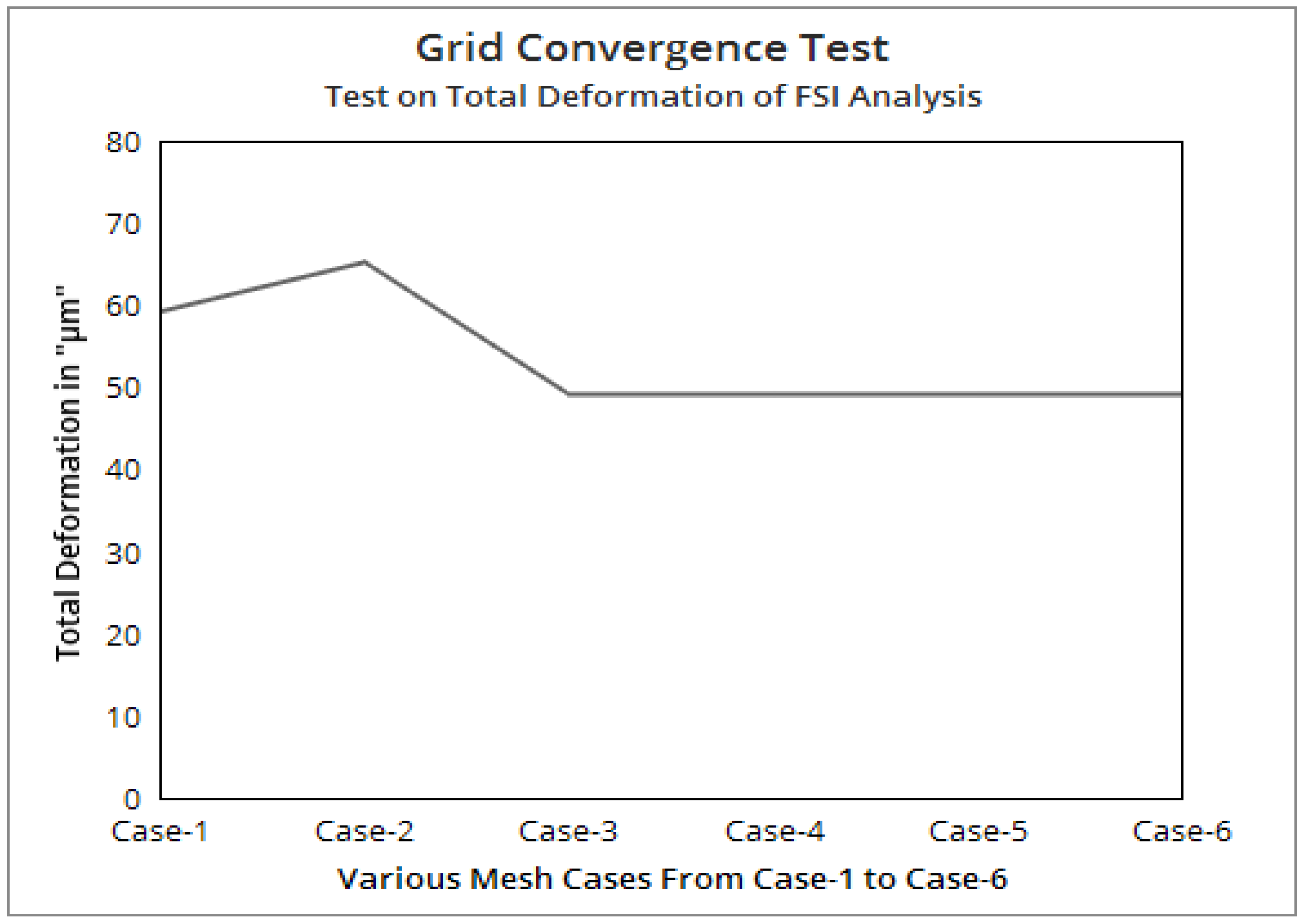

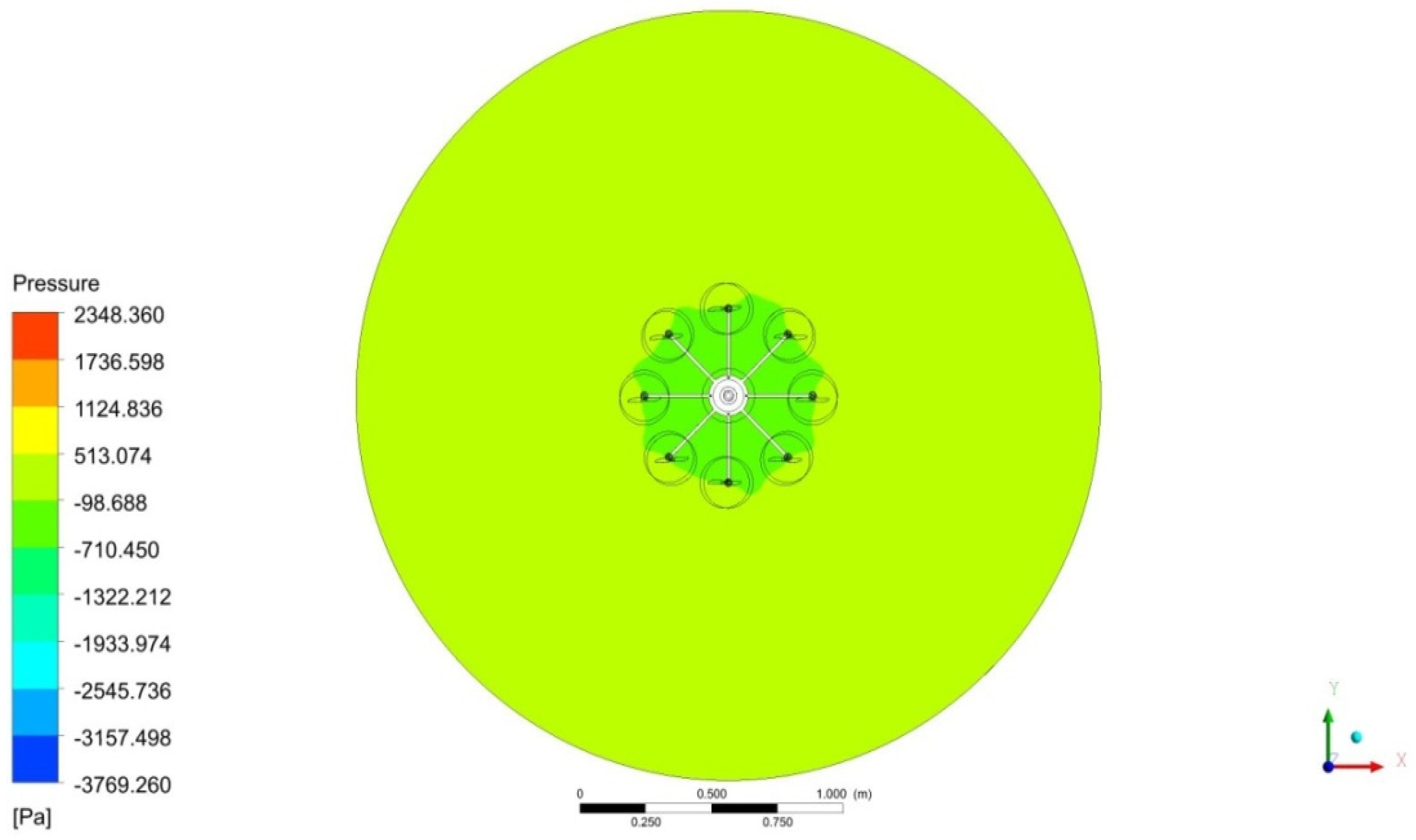

6.2. Discretization

6.3. Boundary Conditions

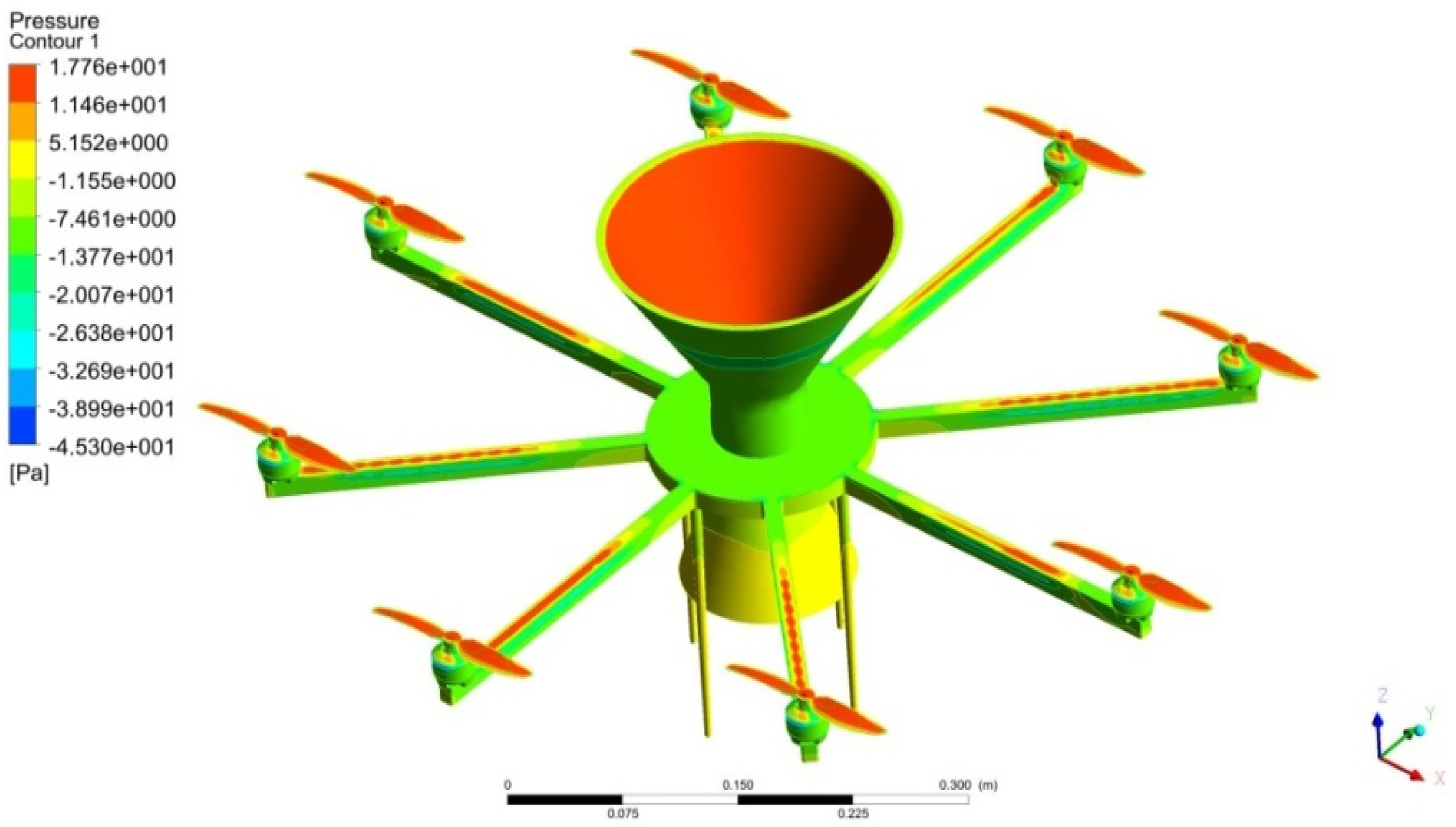

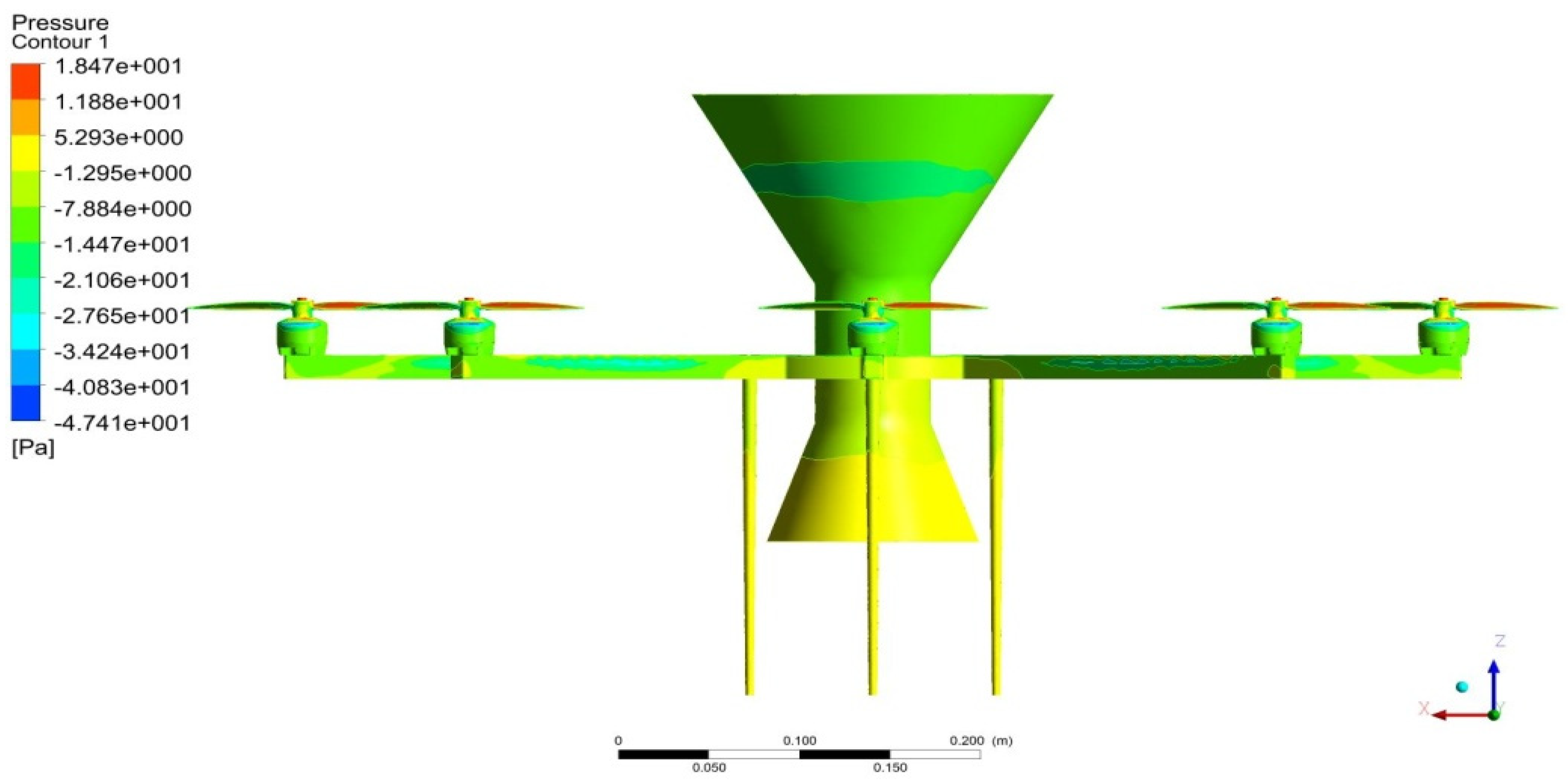

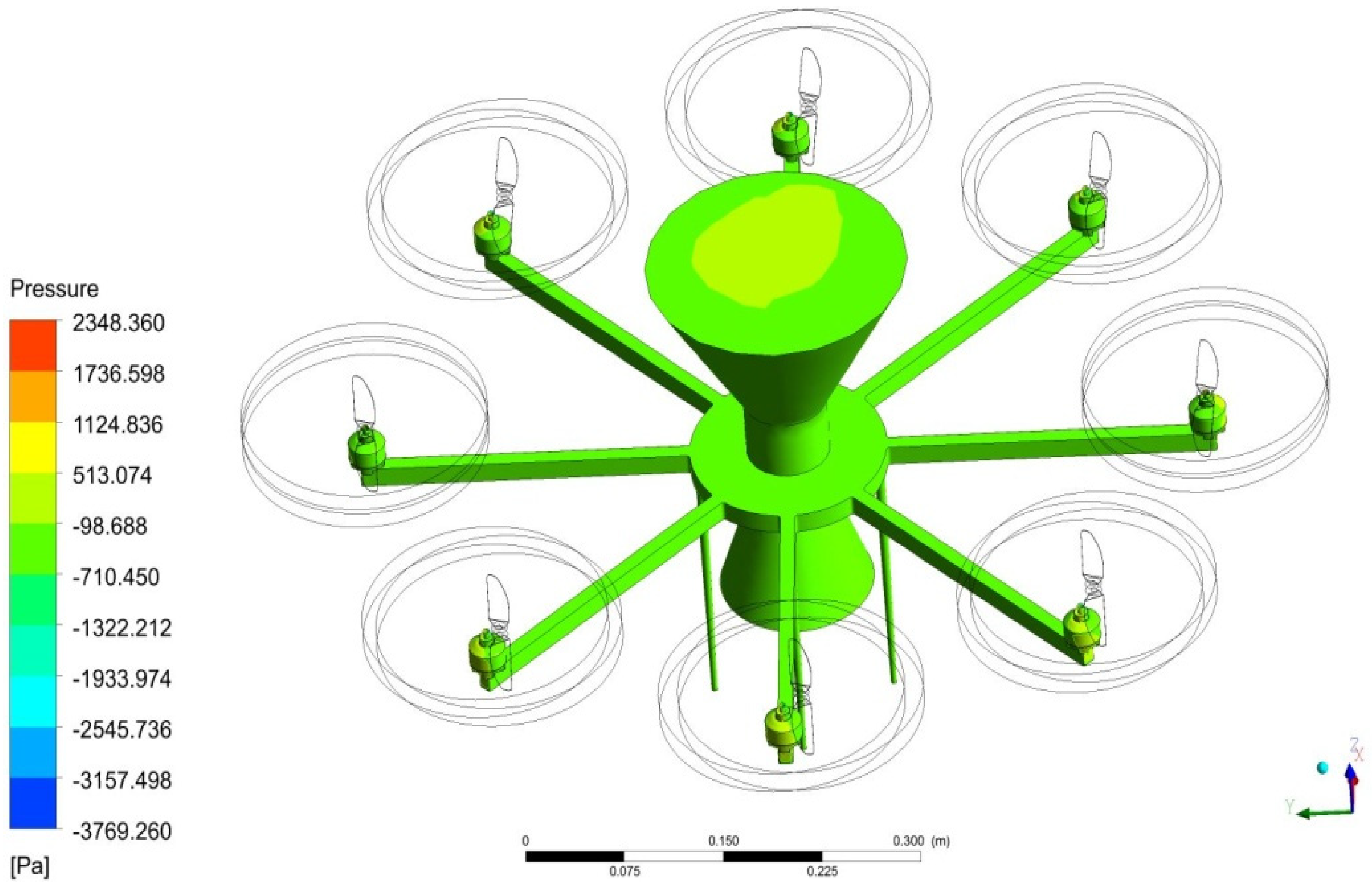

6.4. Computational Aerostatic Results

6.5. Computational Aerodynamic Results in Foggy Environments

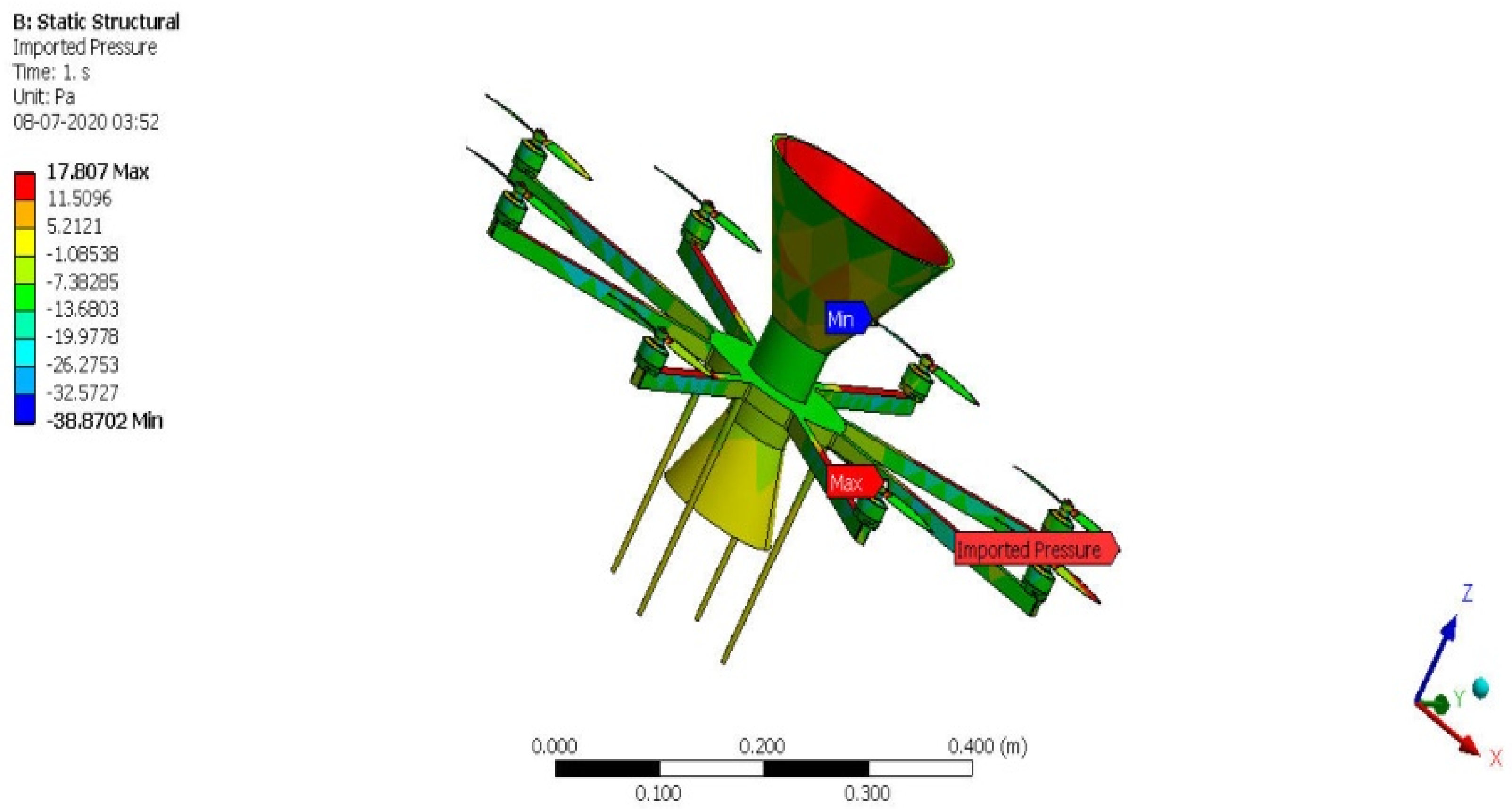

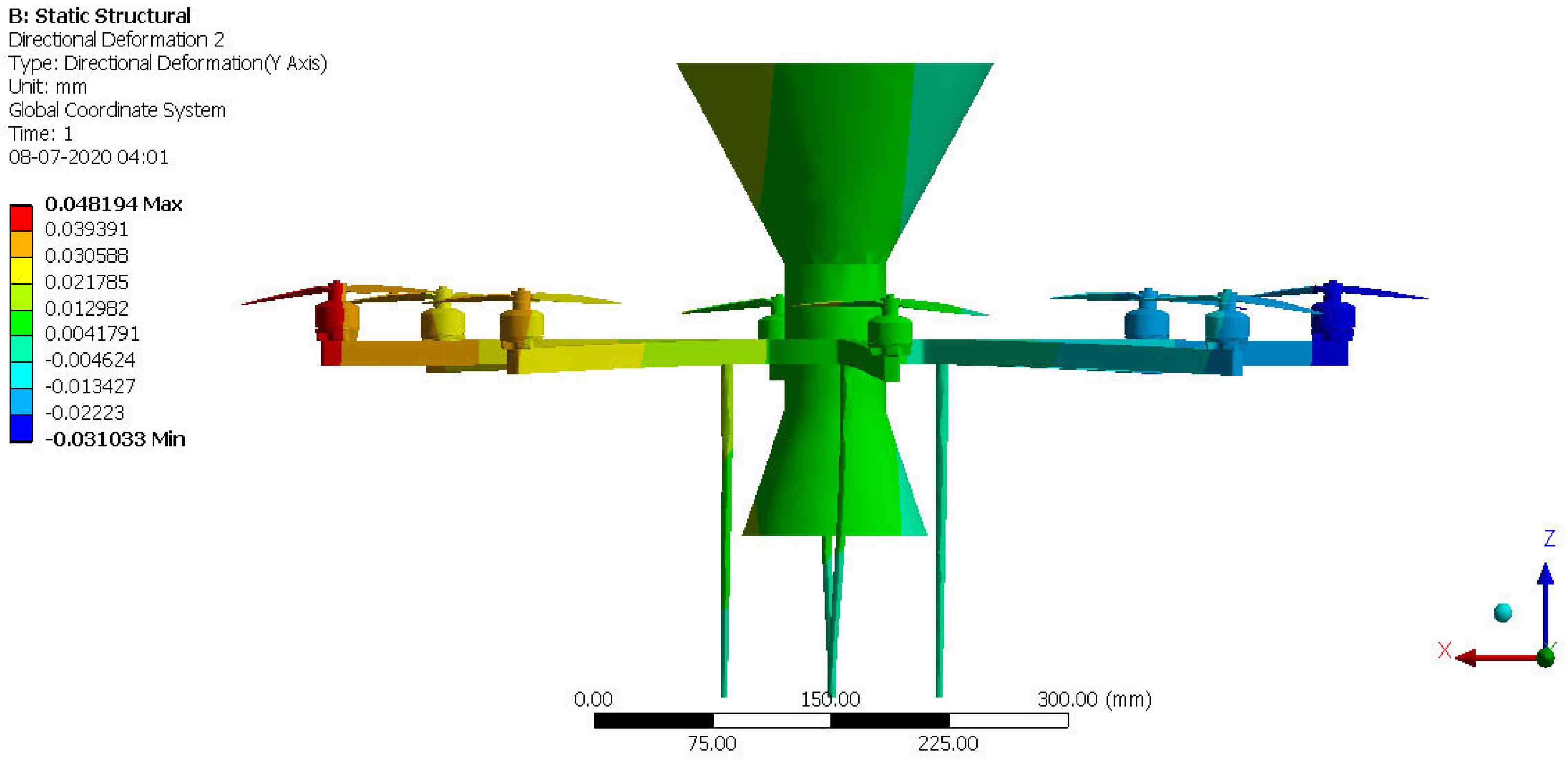

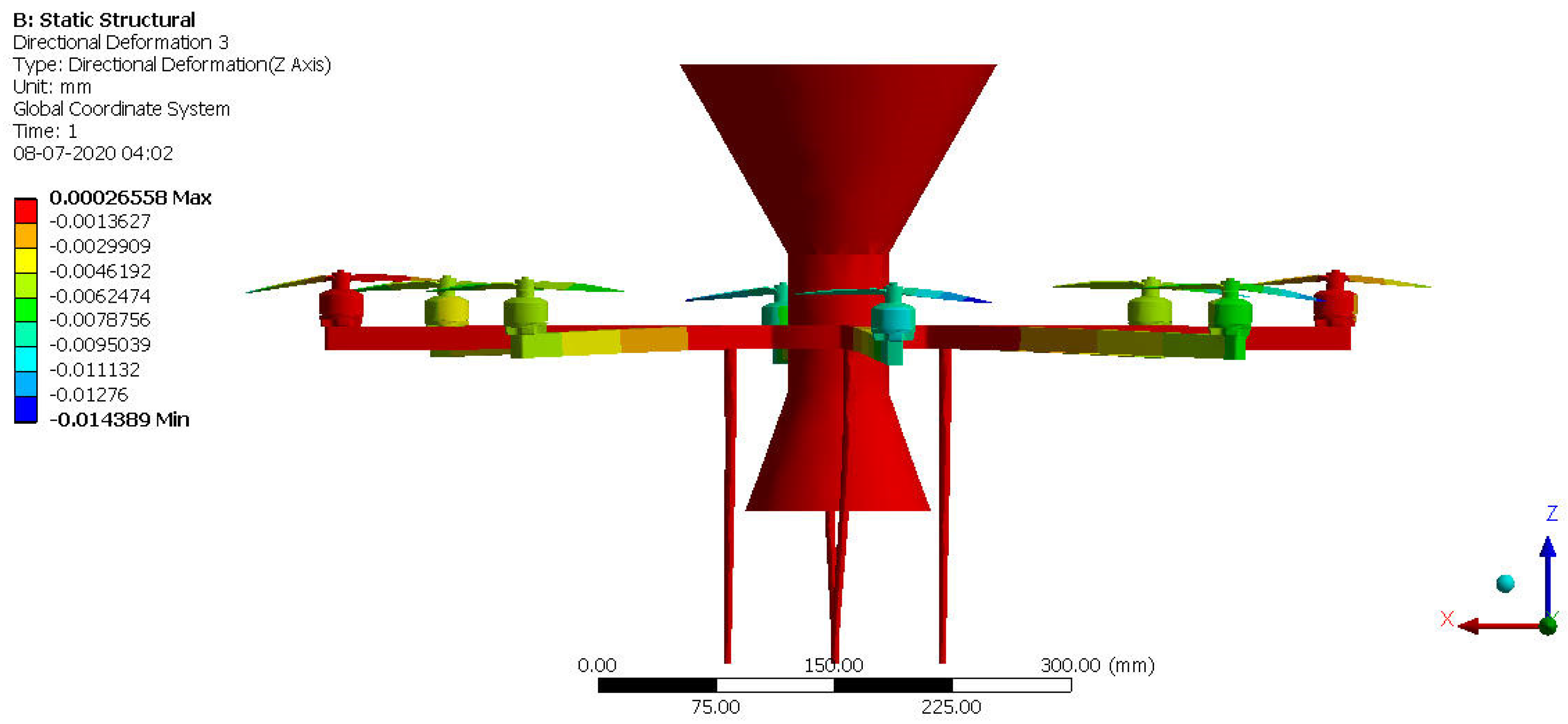

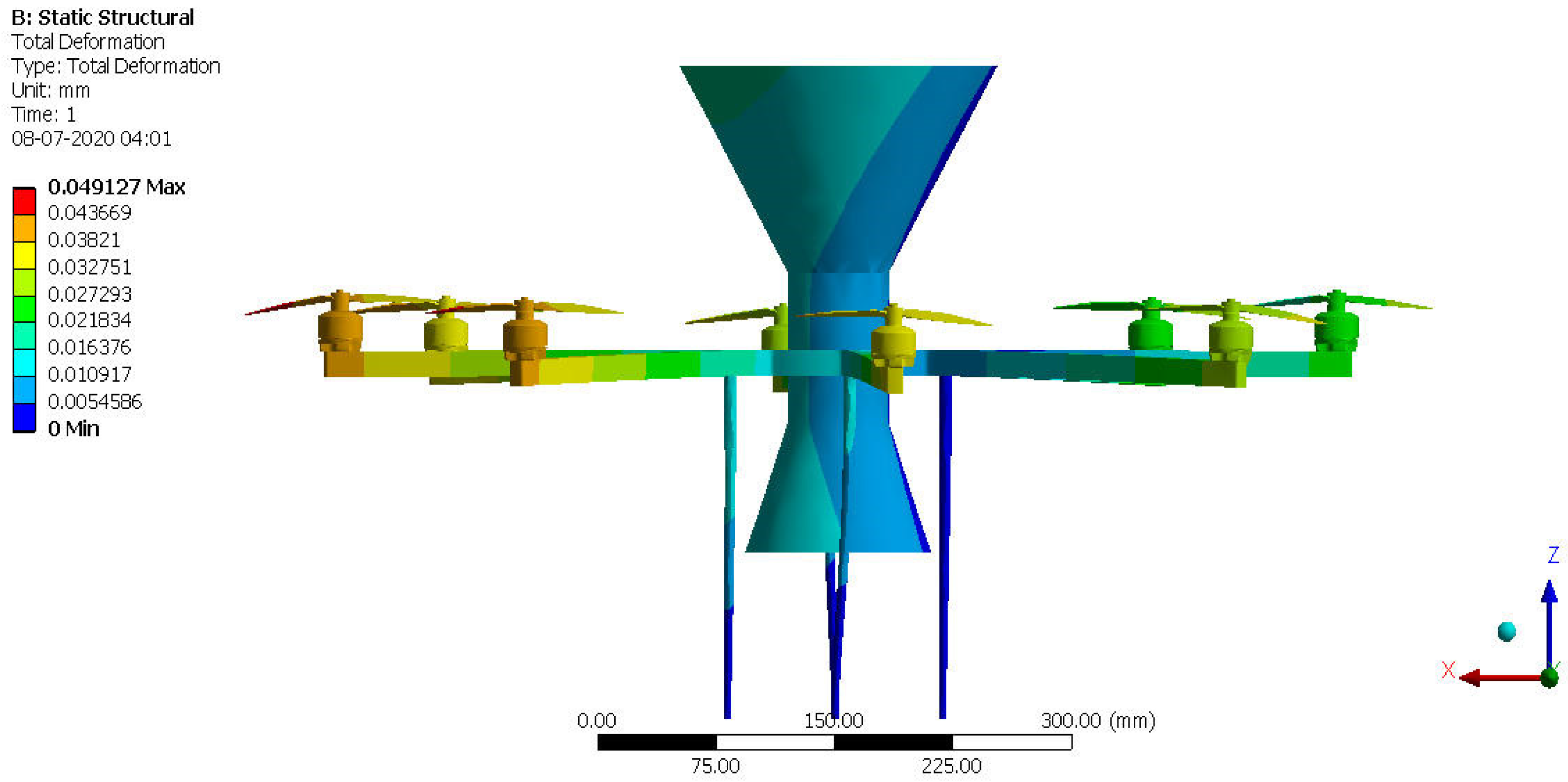

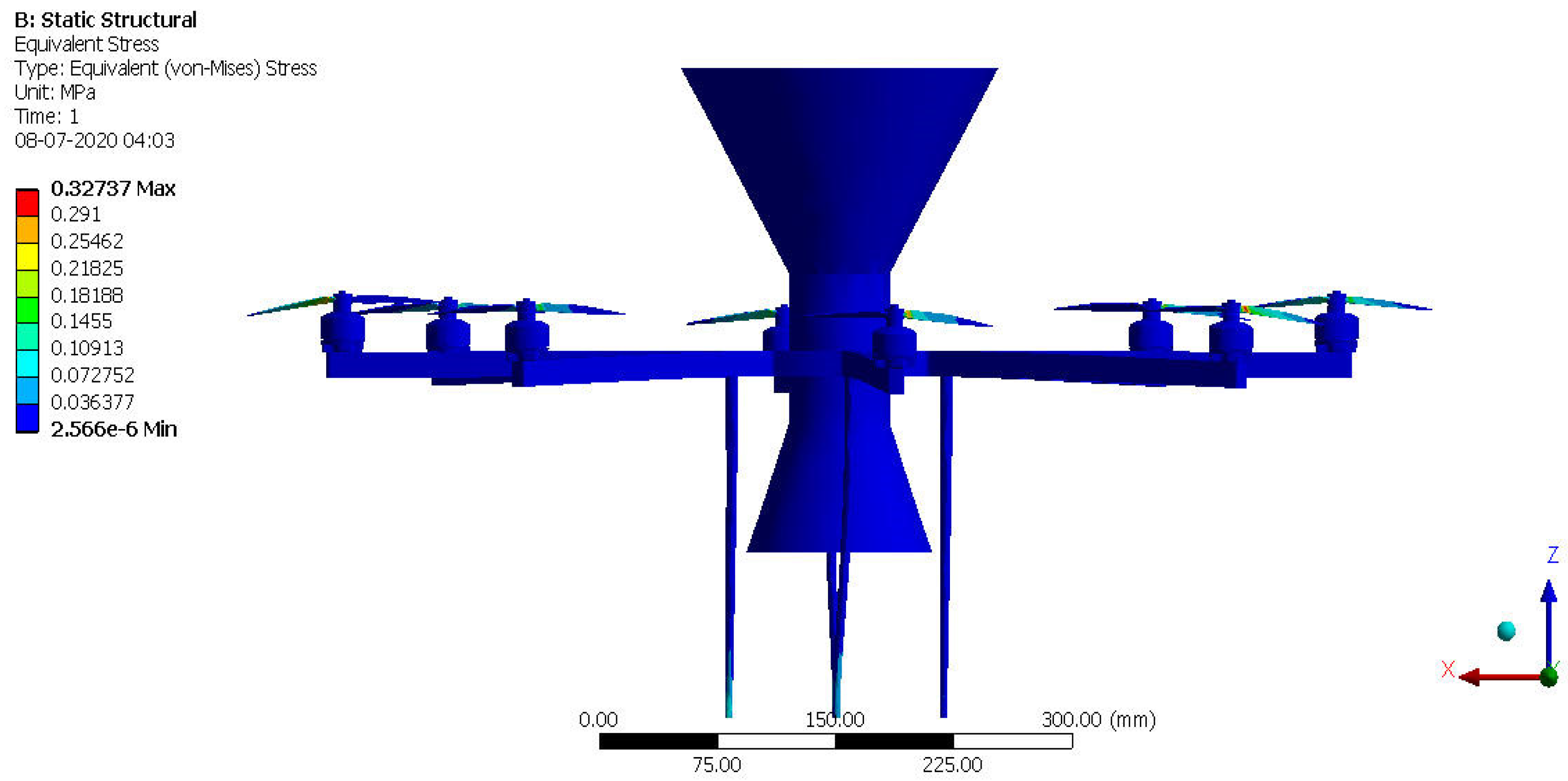

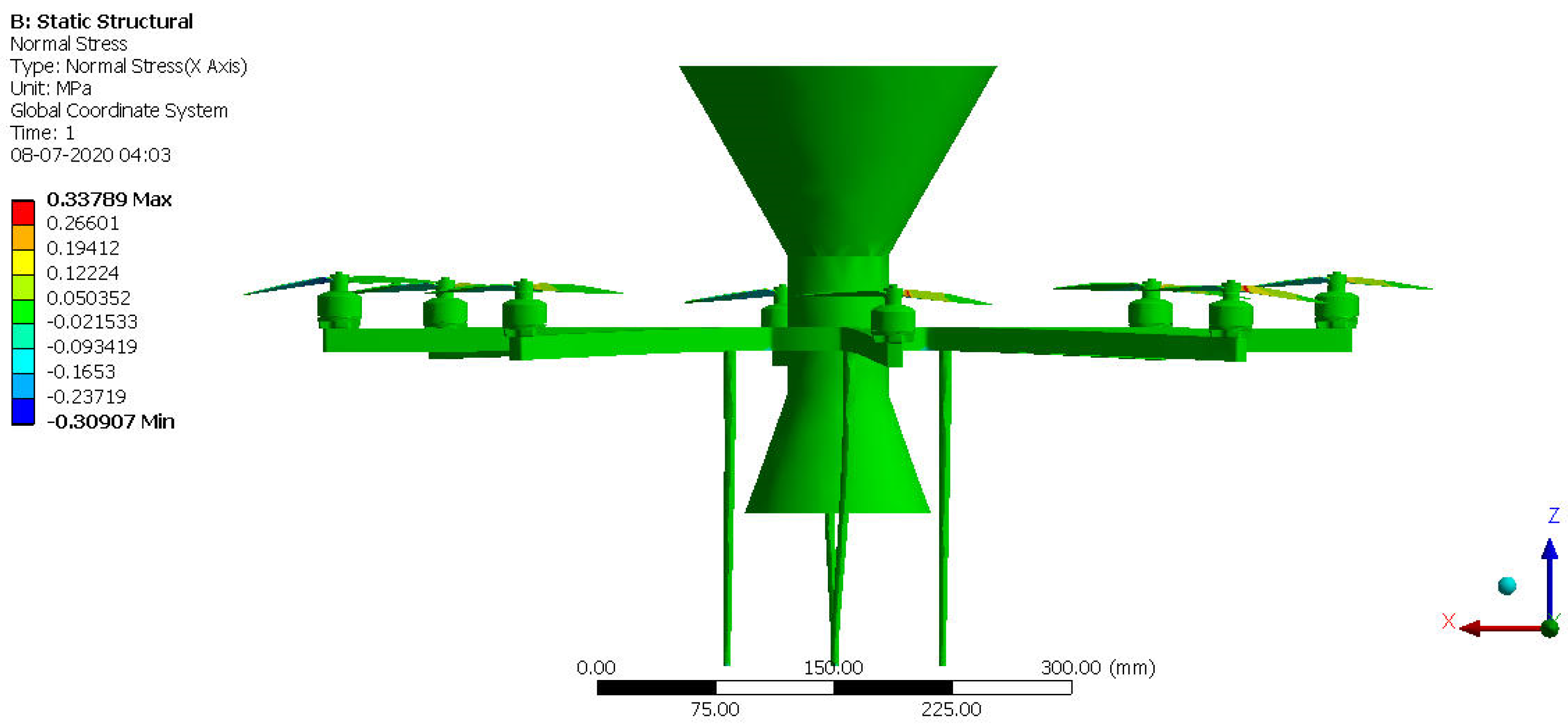

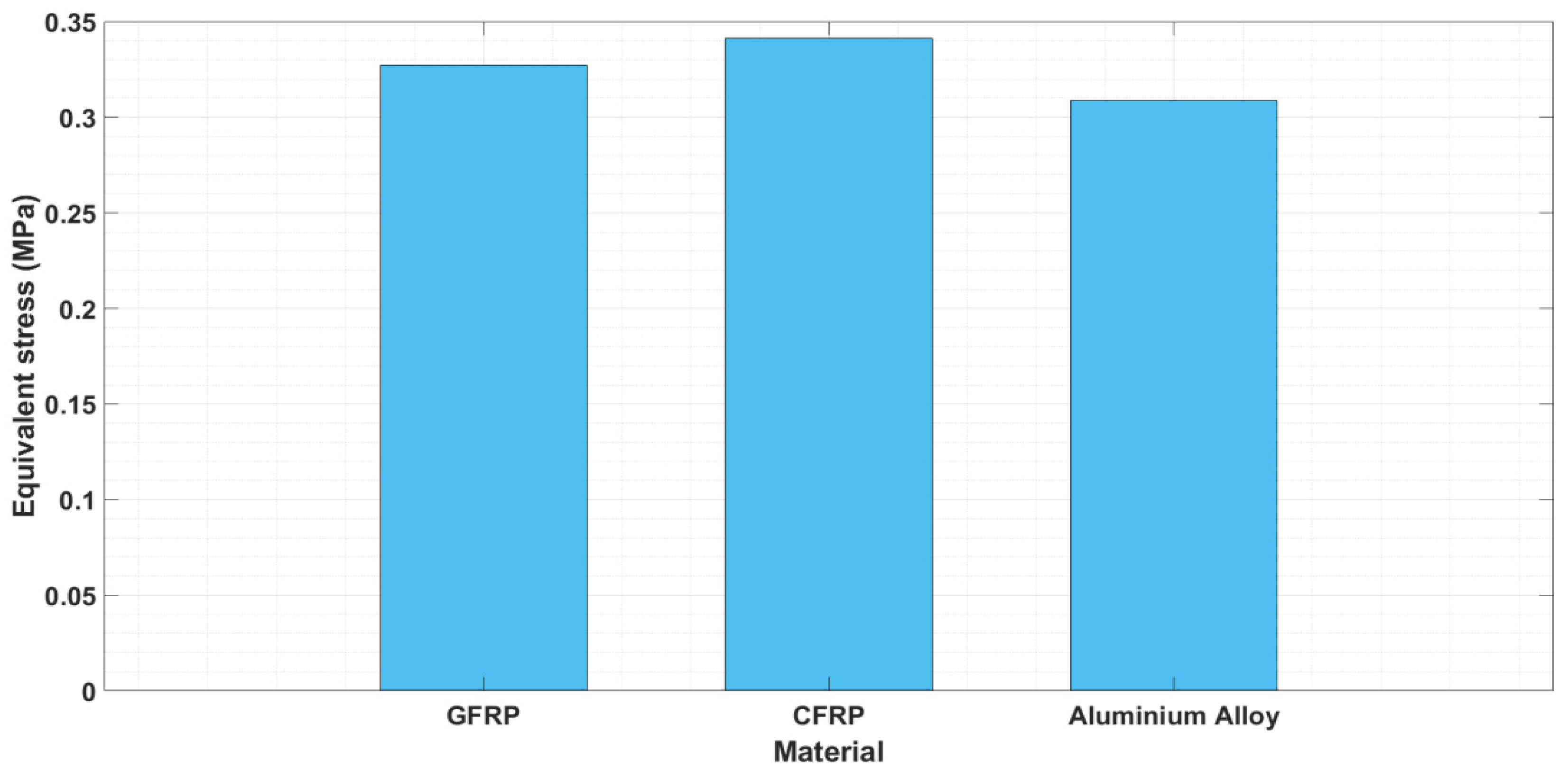

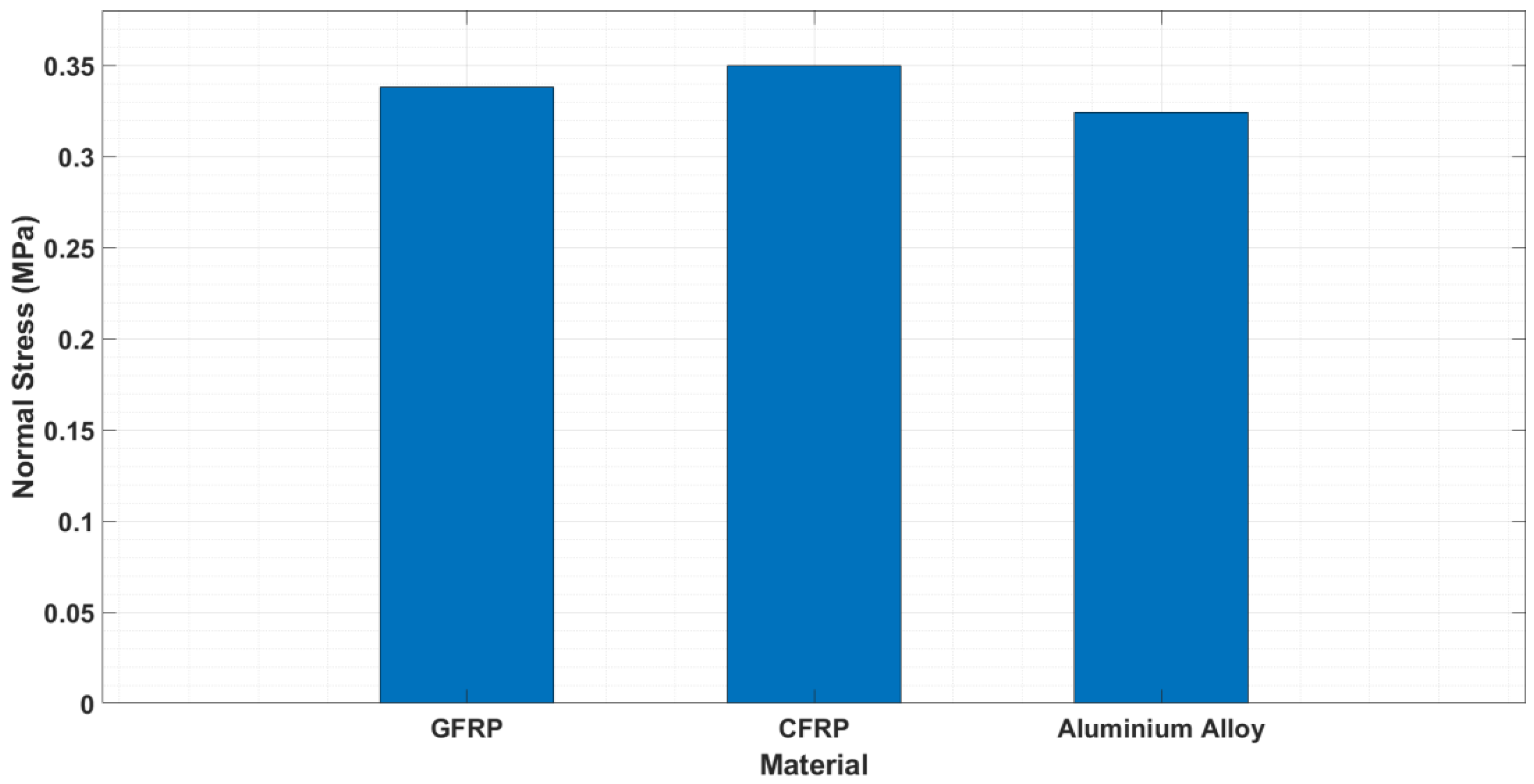

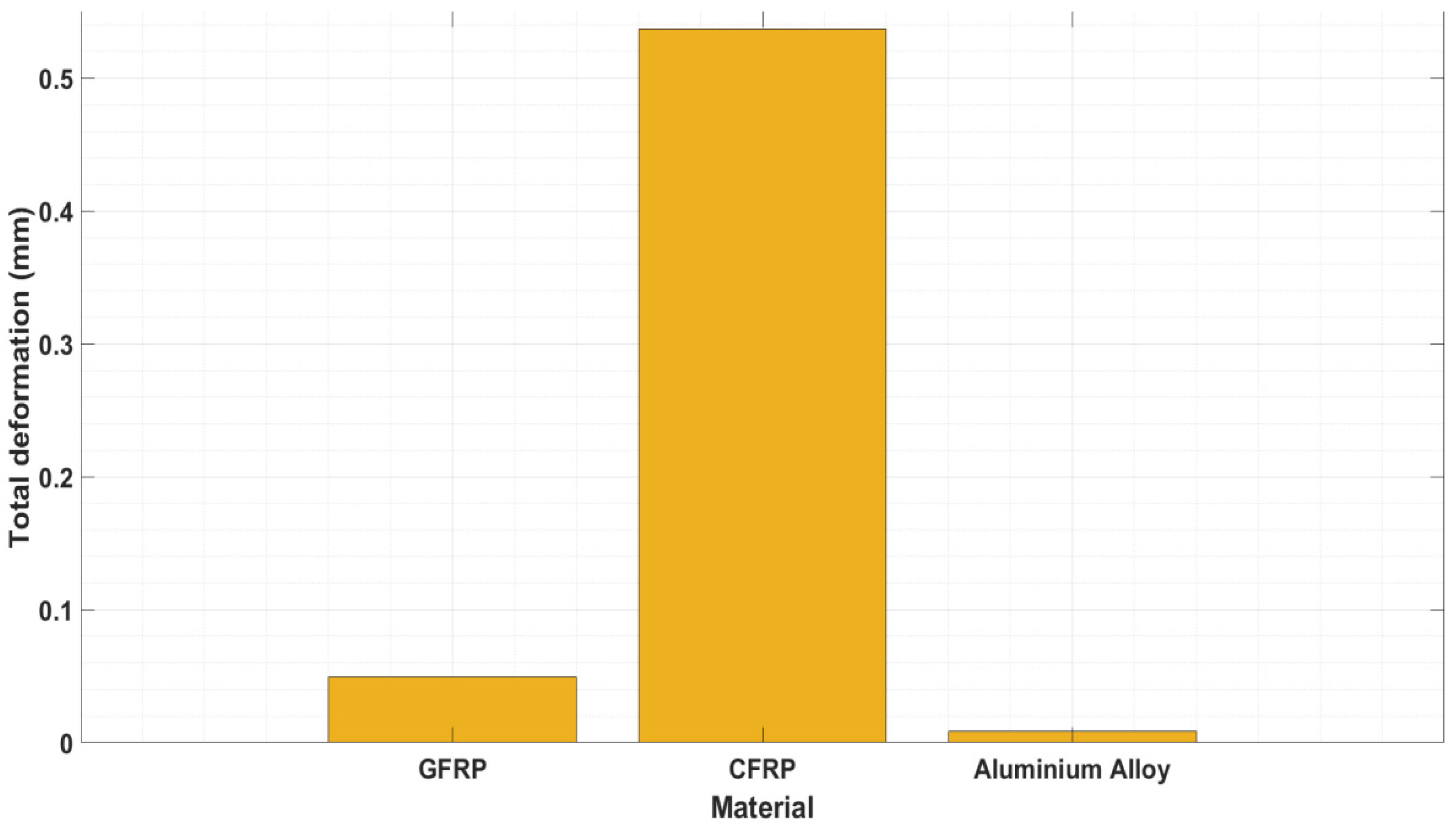

6.6. Fluid-Structure Interaction (FSI) Results

6.7. Discussions

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yeong, S.P.; Dol, S.S. Aerodynamic Optimization of Micro Aerial, Vehicle. J. Appl. Fluid Mech. 2016, 9, 2111–2121. [Google Scholar] [CrossRef]

- Ong, W.; Srigrarom, S.; Hesse, H. Design Methodology for Heavy-Lift Unmanned Aerial Vehicles with Coaxial Rotors. In Proceedings of the AIAA SciTech Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Krznar, M.; Kotarski, D.; Piljek, P.; Pavković, D. On-Lıneınertıa measurement of unmanned aerial vehicles using onboard sensors and a bifilar pendulum. Interdiscip. Descr. Complex Syst. 2018, 16, 149–161. [Google Scholar] [CrossRef] [Green Version]

- Mikkelsen, M. Development, Modelling and Control of a Multirotor Vehicle. Master’s Thesis, Umeå University, Umeå, Sweden, 2015. [Google Scholar]

- Bergman, K.; Ekström, J. Modeling, Estimation and Attitude Control of an Octorotor Using PID and L1 Adaptive Control Techniques. Master’s Thesis, Linköping University, Linköping, Sweden, 2014. [Google Scholar]

- Artale, V.; Angela, R.; Milazzo, C. Mathematical Modeling of Hexacopter. Appl. Math. Sci. 2013, 7, 4805–4811. [Google Scholar] [CrossRef]

- Lei, Y.; Huang, Y.; Wang, H. Aerodynamic performance of an octorotor SUAV with different rotor spacing in Hover. Processes 2020, 8, 1364. [Google Scholar] [CrossRef]

- Vijayakumar, M.; Vijayanandh, R.; Ramesh, M.; Senthil Kumar, M.; Raj Kumar, G.; Sivaranjani, S.; Jung, D.W. Conceptual Design and Numerical analysis of an Unmanned Amphibious Vehicle. In Proceedings of the AIAA Scitech 2021 Forum, Online, 11–15 & 19–21 January 2021. [Google Scholar]

- Balaji, S.; Prabhagaran, P.; Vijayanandh, R. Comparative Analysis of Propulsive System in Multi-Rotor Unmanned Aerial Vehicle. In Proceedings of the ASME 2019 Gas Turbine India Conference—GTINDIA2019, IITM Chennai, Tamil Nadu, India, 5–6 December 2019. [Google Scholar]

- Balaji, S.; Prabhagaran, P.; Vijayanandh, R.; Senthil Kumar, M.; Raj Kumar, R. Comparative computational analysis on high stable filter for long-range applications. Lect. Notes Civ. Eng. 2020, 31, 369–391. [Google Scholar]

- Ramesh, M.; Vijayanandh, R. Acoustic Investigation on Unmanned Aerial Vehicle’s Rotor Using CFD-MRF Approach, IITM Chennai. In Proceedings of the ASME 2019 Gas Turbine India Conference—GTINDIA2019, Tamil Nadu, India, 5–6 December 2019. [Google Scholar]

- Lichota, P. Multi-Axis Inputs for Identification of a Reconfigurable Fixed-Wing UAV. Aerospace 2020, 7, 113. [Google Scholar] [CrossRef]

- Kaan, T.O. Dynamic Model and Control of a New Quadrotor Unmanned Aerial Vehicle with Tilt-Wing Mechanism. Int. J. Aerosp. Mech. Eng. 2008, 2, 1008–1013. [Google Scholar]

- Senthil Kumar, S.; Vijayanandh, R. A Dynamic Response and Stability Analysis of Hybrid UAV with the Linear Controllers. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 330–342. [Google Scholar]

- Bin Junaid, A.; Diaz De Cerio Sanchez, A.; Betancor Bosch, J.; Vitzilaios, N.; Zweiri, Y. Design and Implementation of a Dual-Axis Tilting Quadcopter. Robotics 2018, 7, 65. [Google Scholar] [CrossRef] [Green Version]

- Senthil Kumar, S.; Vijayanandh, R.; Mano, S. 2018. Mathematical Modelling and Attitude Control of Quadcopter based on Classical Controller. Int. J. Veh. Struct. Syst. 2018, 10, 318–323. [Google Scholar]

- Hoshiba, K.; Washizaki, K.; Wakabayashi, M.; Ishiki, T.; Kumon, M.; Bando, Y.; Gabriel, D.; Nakadai, K.; Okuno, H.G. Design of UAV-Embedded Microphone Array System for Sound Source Localization in Outdoor Environments. Sensors 2017, 17, 2535. [Google Scholar] [CrossRef] [Green Version]

- Masuda, K.; Uchiyama, K. Robust Control Design for Quad Tilt-Wing UAV. Aerospace 2018, 5, 17. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Zhu, Y.; Wang, Z.; Li, C.; Peng, Z.-R.; Ge, L. Use of Multi-Rotor Unmanned Aerial Vehicles for Radioactive Source Search. Remote Sens. 2018, 10, 728. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Zhang, S.; Luo, C.; Li, W.; Liao, Y. Design and Experimentation of an Aerial Seeding System for Rapeseed Based on an Air-Assisted Centralized Metering Device and a Multi-Rotor Crop Protection UAV. Appl. Sci. 2020, 10, 8854. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, J. Aerodynamic Performance of Quadrotor UAV with Non-Planar Rotors. Appl. Sci. 2019, 9, 2779. [Google Scholar] [CrossRef] [Green Version]

- Piljek, P.; Kotarski, D.; Krznar, M. Method for Characterization of a Multirotor UAV Electric Propulsion System. Appl. Sci. 2020, 10, 8229. [Google Scholar] [CrossRef]

- Kotarski, D.; Piljek, P.; Pranjić, M.; Grlj, C.G.; Kasać, J. A Modular Multirotor Unmanned Aerial Vehicle Design Approach for Development of an Engineering Education Platform. Sensors 2021, 21, 2737. [Google Scholar] [CrossRef]

- Vijayanandh, R.; Senthil Kumar, M.; Naveen Kumar, K.; Raj Kumar, G.; Naveen Kumar, R. Design optimization of advanced multi-rotor unmanned aircraft system using FSI. Lect. Notes Mech. Eng. 2018, 28, 299–310. [Google Scholar]

- Vijayanandh, R.; Kiran, P.; Indira Prasanth, S.; Raj Kumar, G.; Balaji, S. Conceptual Design and Optimization of Flexible Landing Gear for Tilt-Hexacopter Using CFD. Lect. Notes Civ. Eng. 2020, 15, 151–174. [Google Scholar]

- Jagadeeshwaran, P.; Natarajan, V.; Vijayanandh, R.; Senthil Kumar, M.; Raj Kumar, G. Numerical Estimation of Ultimate Specification of Advanced Multi-Rotor Unmanned Aerial Vehicle. Int. J. Sci. Technol. Res. 2020, 9, 3681–3687. [Google Scholar]

- Shukla, D.; Komerath, N. Multirotor Drone Aerodynamic Interaction Investigation. Drones 2018, 2, 43. [Google Scholar] [CrossRef] [Green Version]

- Chu, T.; Starek, M.J.; Berryhill, J.; Quiroga, C.; Pashaei, M. Simulation and Characterization of Wind Impacts on sUAS Flight Performance for Crash Scene Reconstruction. Drones 2021, 5, 67. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Phase resistance, R | 0.128 Ohms |

| Phase inductance, L | 0.0000184 H |

| Phase inductance, L | 0.0000184 H |

| Torque constant, Km | 0.008 Nm/A |

| Back emf constant, Kb | 0.00955 Volts/(rad/s) |

| Rotor inertia, I | |

| About x, y-axes | 8.5 × 10−6 kg·m2 |

| About z-axis | 4.964 × 10−6 kg·m2 |

| Specifications | Roll and Pitch Controllers |

|---|---|

| settling time | ≤0.1 s |

| overshoot | ≤10% |

| steady-state error | zero |

| Specifications | Value |

|---|---|

| settling time | 0.005 s |

| overshoot | zero |

| steady-state error | zero |

| Controller | Gains | ||

|---|---|---|---|

| Proportional Gain, KP | Integral Gain, KI | Derivative Gain, KD | |

| roll controller | 2240.28 | - | 12.6 |

| pitch controller | 1105 | - | 38 |

| yaw-rate controller | 355 | 3.55 | - |

| Performance Specifications | Roll Response | Pitch Response | Yaw Rate Response | |||

|---|---|---|---|---|---|---|

| Without Controller | With Controller | Without Controller | With Controller | Without Controller | With Controller | |

| Settling time | 104 s | 0.0811 s | 14.9 s | 0.09 s | 0.398 s | 0.006 s |

| Rise time | 58.4 s | 0.0244 s | 8.32 s | 0.13s | 0.223 s | 0.0029 s |

| Overshoot | zero | 11% | zero | 0.4% | zero | zero |

| Steady-state error | zero | zero | zero | zero | 79.9% | zero |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raja, V.; Solaiappan, S.K.; Rajendran, P.; Madasamy, S.K.; Jung, S. Conceptual Design and Multi-Disciplinary Computational Investigations of Multirotor Unmanned Aerial Vehicle for Environmental Applications. Appl. Sci. 2021, 11, 8364. https://doi.org/10.3390/app11188364

Raja V, Solaiappan SK, Rajendran P, Madasamy SK, Jung S. Conceptual Design and Multi-Disciplinary Computational Investigations of Multirotor Unmanned Aerial Vehicle for Environmental Applications. Applied Sciences. 2021; 11(18):8364. https://doi.org/10.3390/app11188364

Chicago/Turabian StyleRaja, Vijayanandh, Senthil Kumar Solaiappan, Parvathy Rajendran, Senthil Kumar Madasamy, and Sunghun Jung. 2021. "Conceptual Design and Multi-Disciplinary Computational Investigations of Multirotor Unmanned Aerial Vehicle for Environmental Applications" Applied Sciences 11, no. 18: 8364. https://doi.org/10.3390/app11188364

APA StyleRaja, V., Solaiappan, S. K., Rajendran, P., Madasamy, S. K., & Jung, S. (2021). Conceptual Design and Multi-Disciplinary Computational Investigations of Multirotor Unmanned Aerial Vehicle for Environmental Applications. Applied Sciences, 11(18), 8364. https://doi.org/10.3390/app11188364