Coefficient of Thermal Expansion of RCA Concrete Made by Equivalent Mortar Volume

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Program

2.1. RCA Productions

2.2. Aggregates Properties

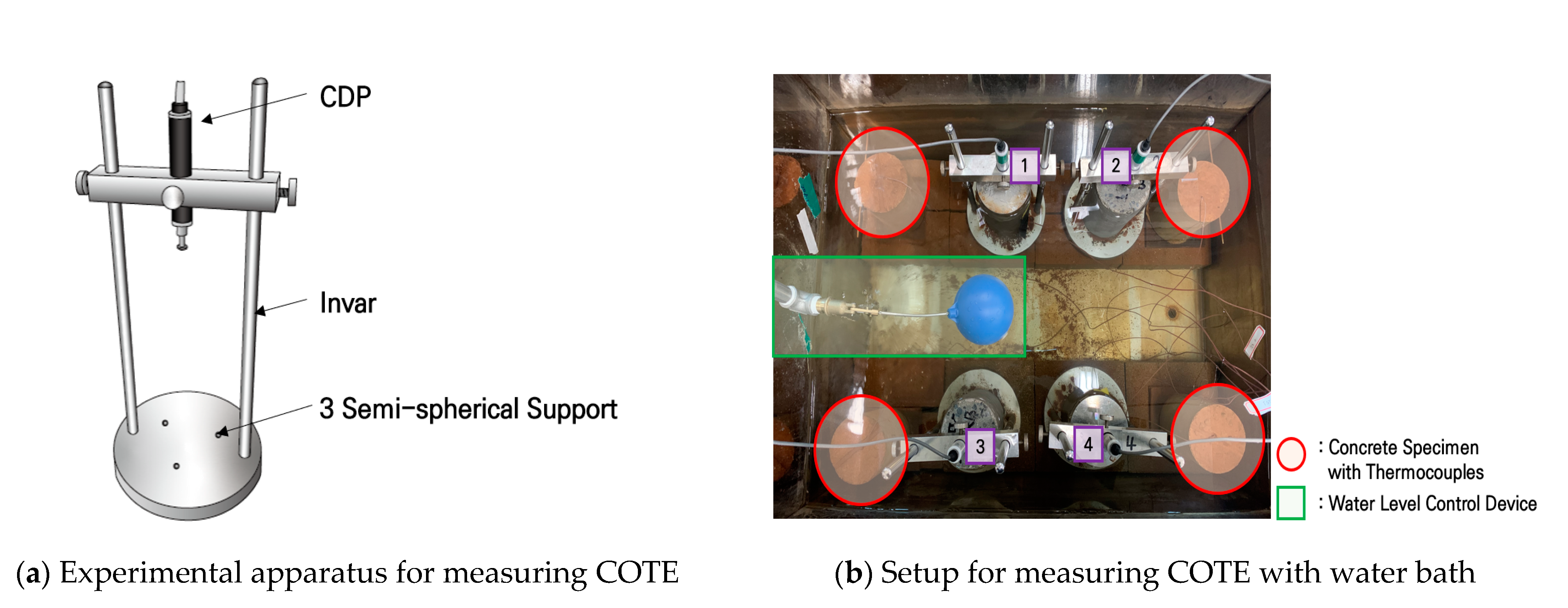

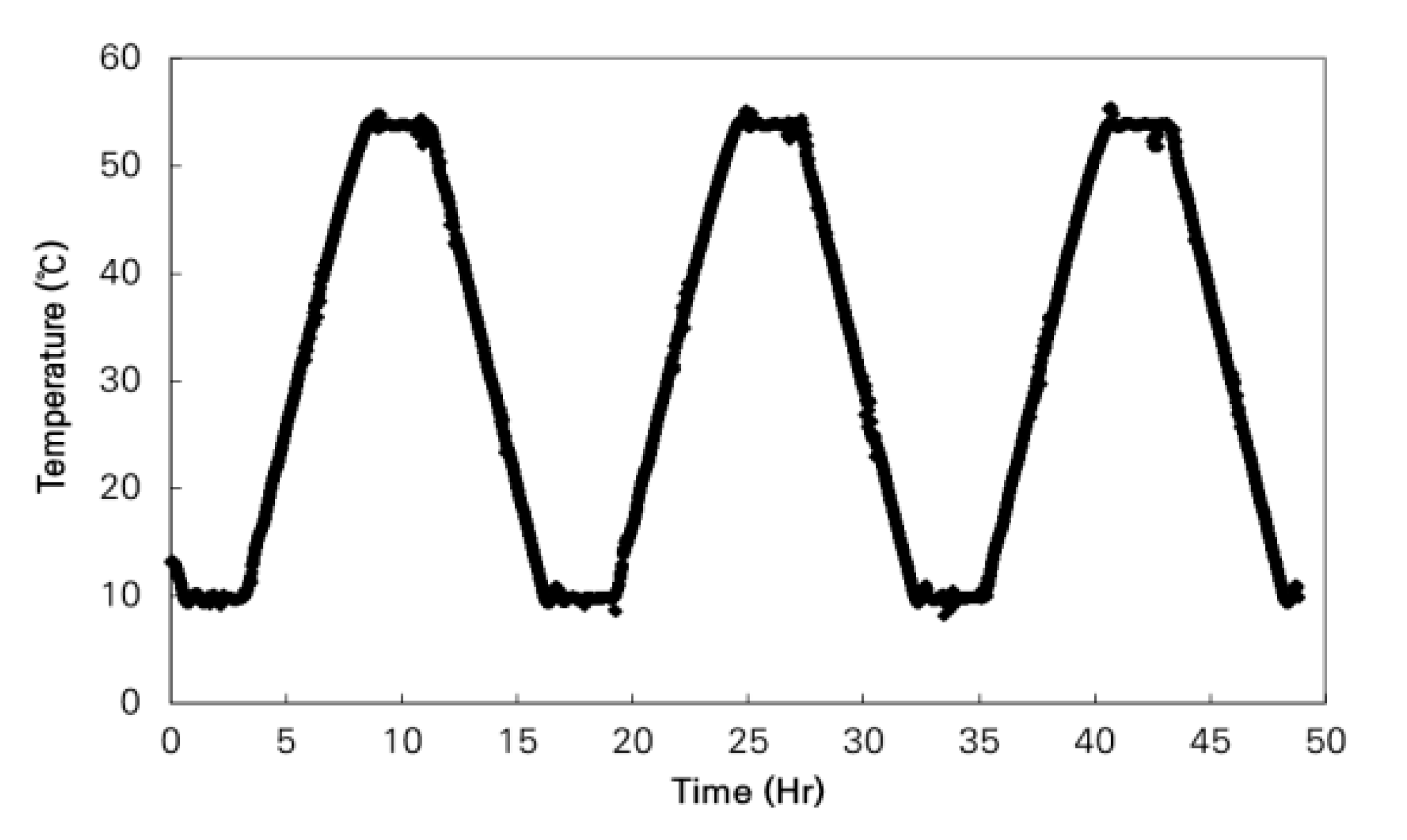

3. Experimental Tests

3.1. Mix Design

3.2. Specimen Preparation

4. Test Results

4.1. Basic Properties

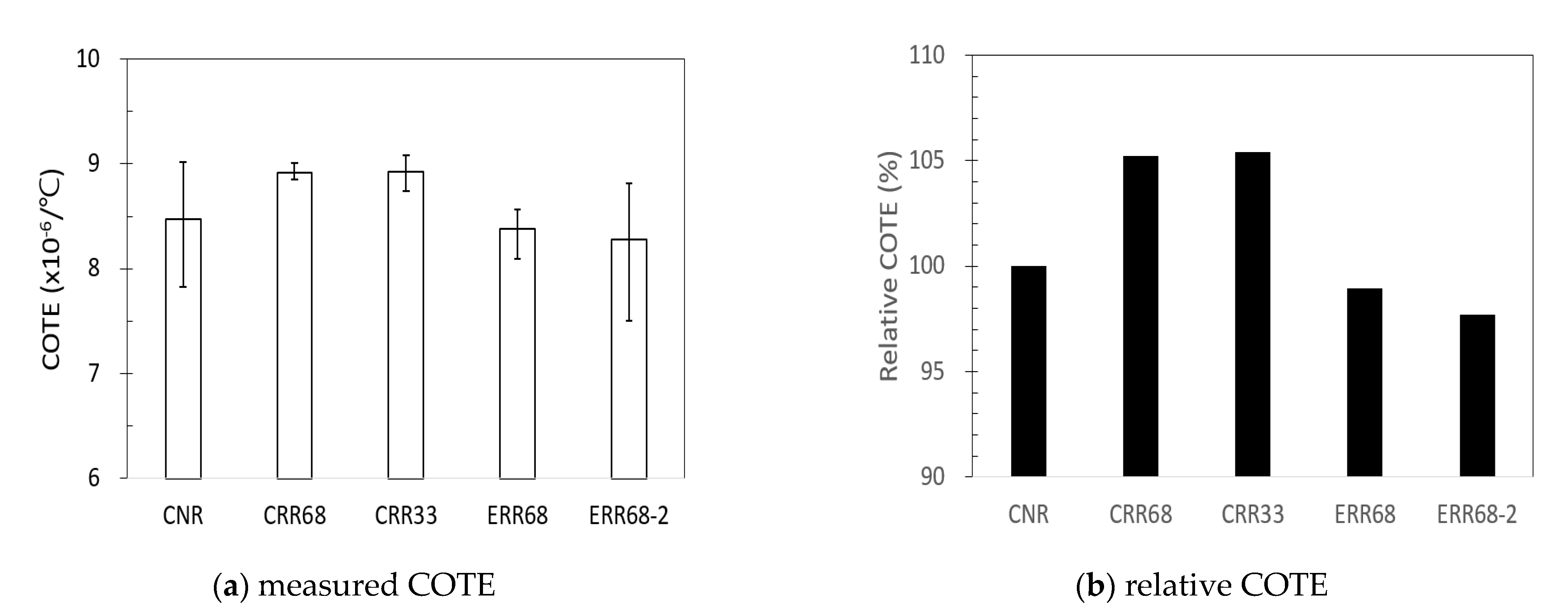

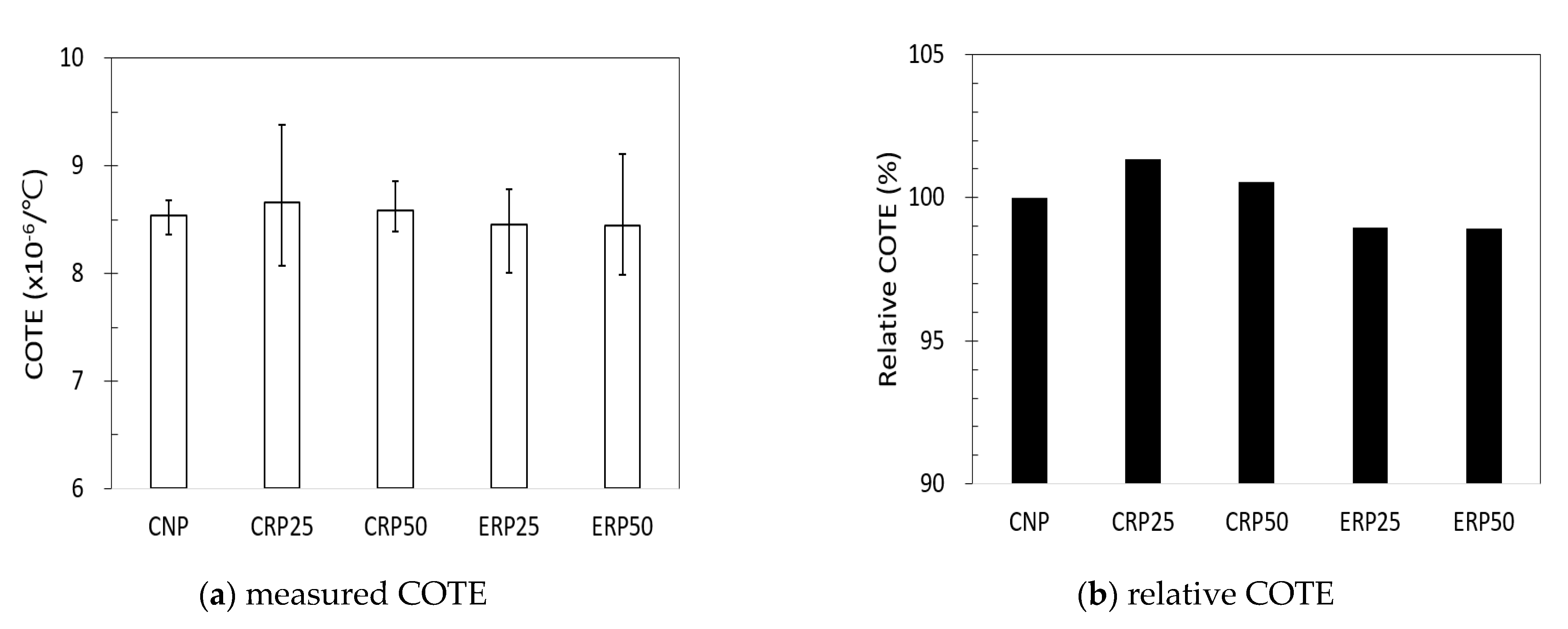

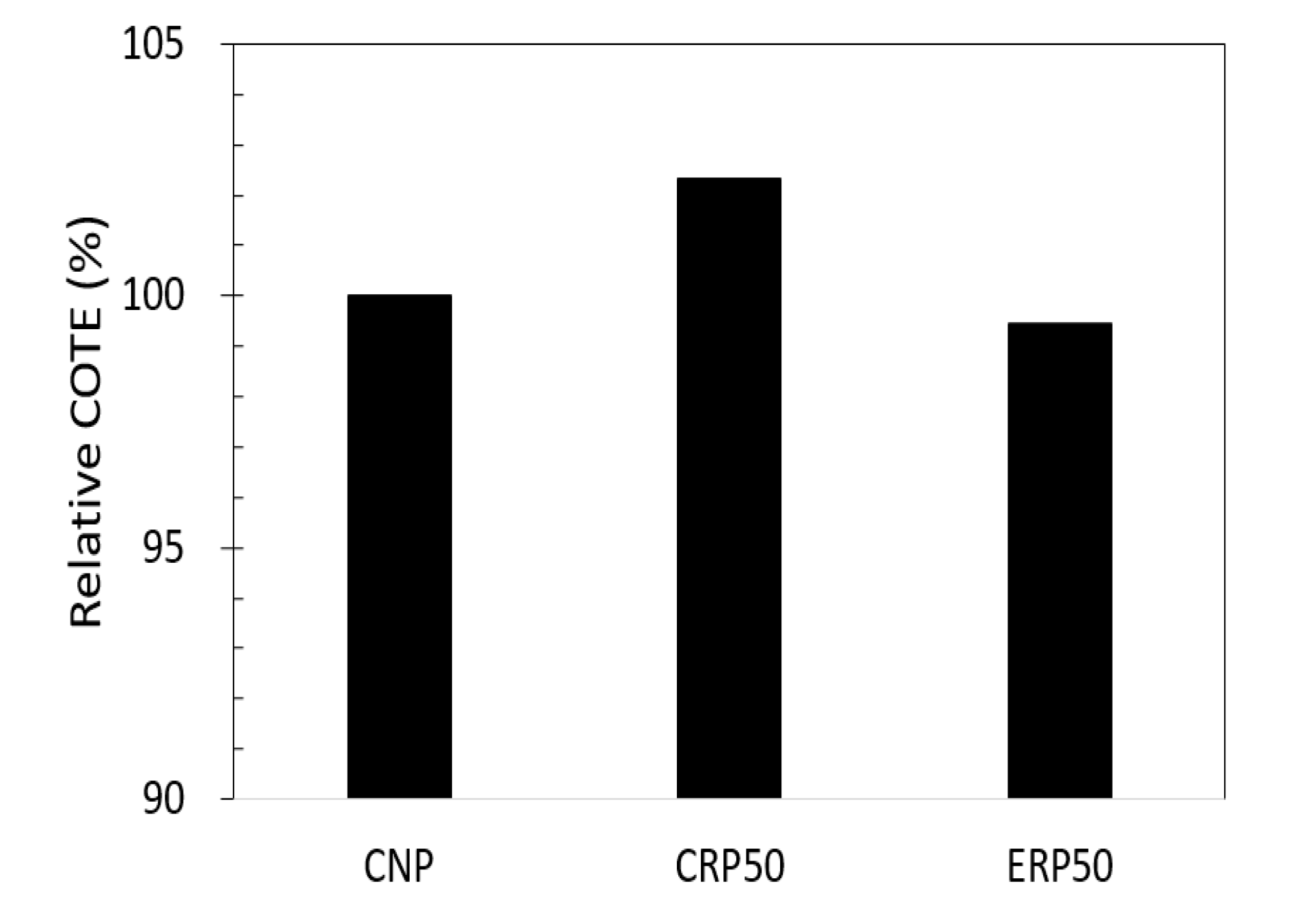

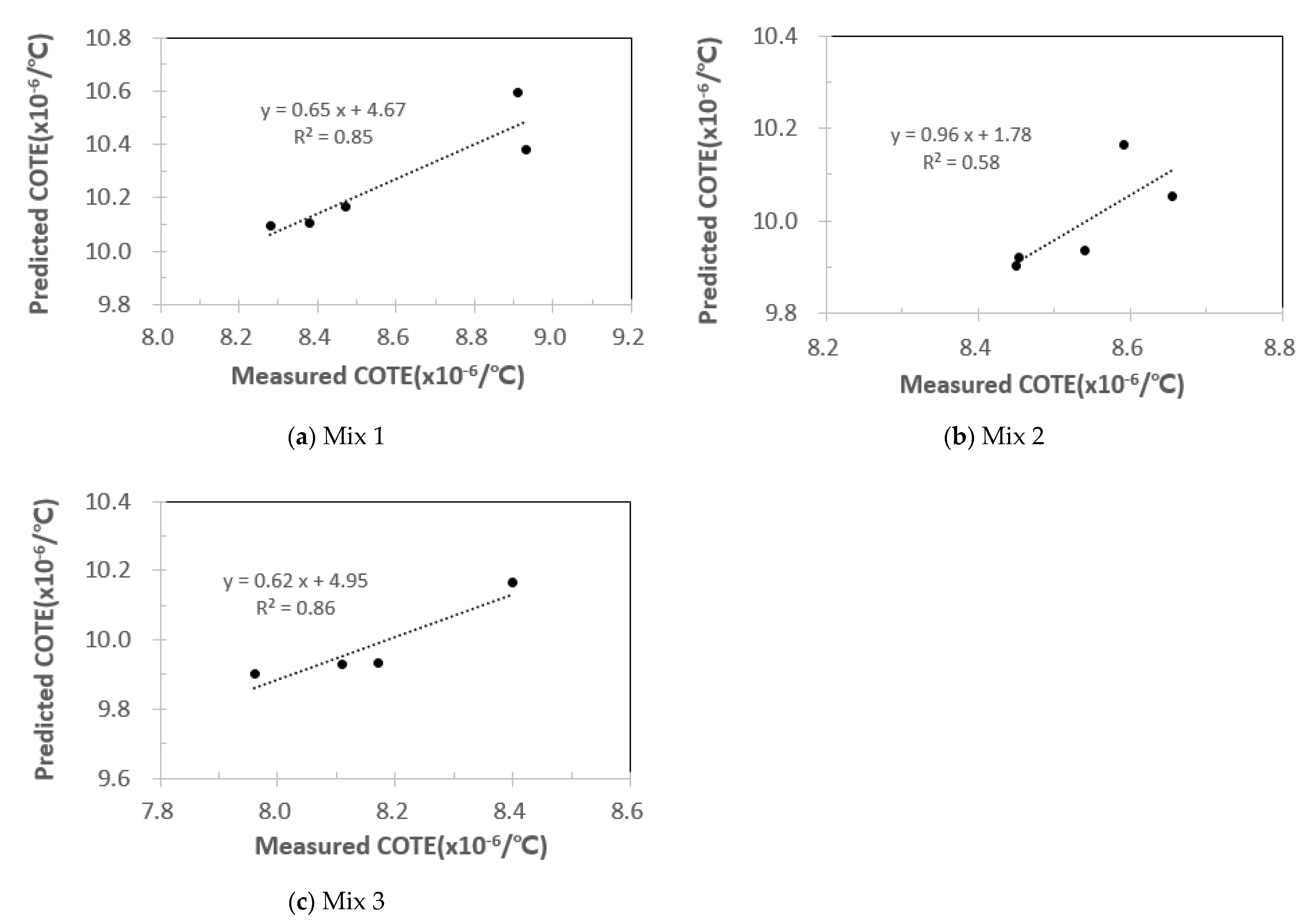

4.2. Concrete COTE Test Results

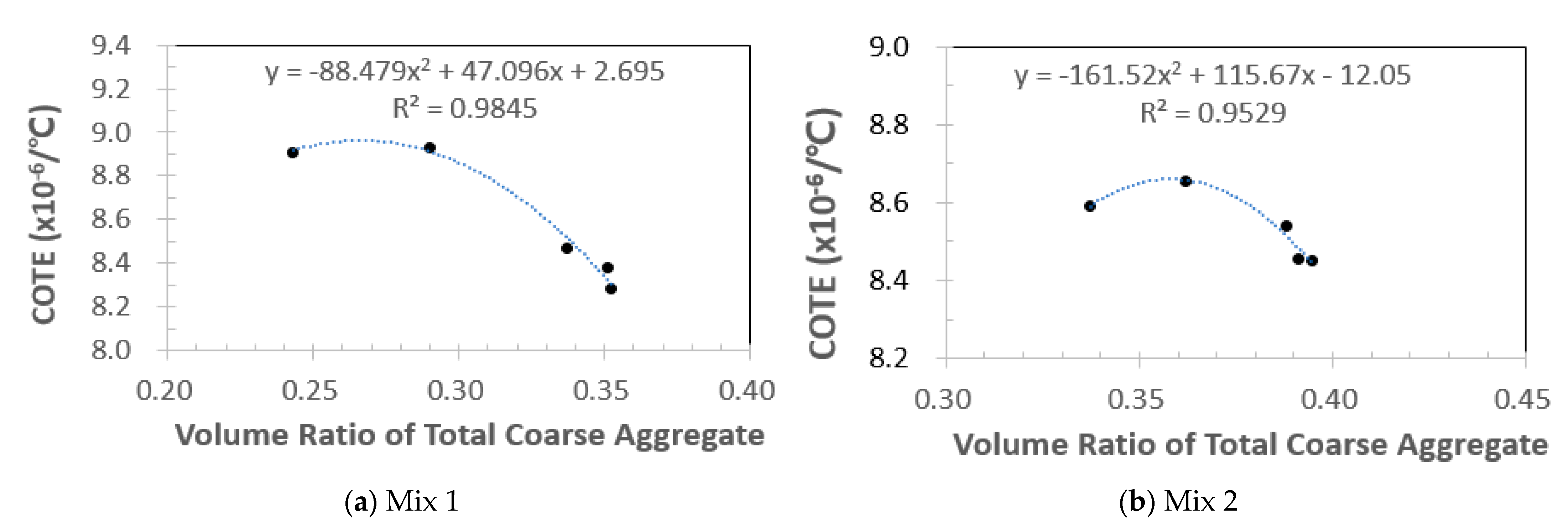

4.2.1. Dependence of Total Coarse Aggregate Volume

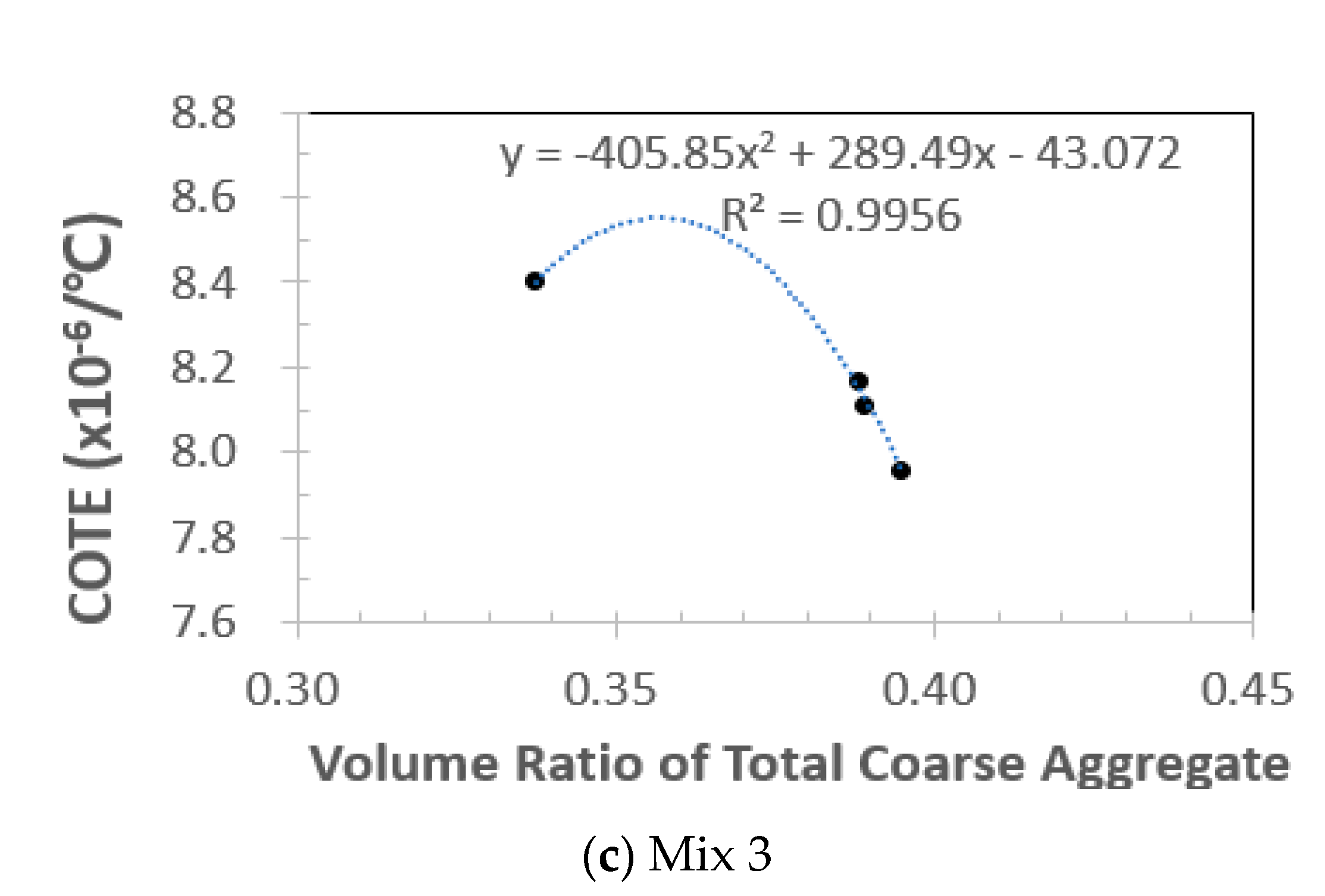

4.2.2. Predicted COTE Values

5. Conclusions

- (1)

- At the same RCA replacement ratio (volumetric ratio of RCA in the total coarse aggregate) of 68%, the COTE of RCA concrete prepared by EMV mix design was over 6–7% lower than that of RCA concrete prepared by conventional mix method, and it was similar to or 1–2% lower than that of the reference natural coarse aggregate concrete.

- (2)

- For RCA concrete prepared by conventional mix method, which does not take into account the residual mortar content (RMC) attached to RCA, the volumetric ratio of the original virgin aggregate was relatively small and the volumetric ratio of the mortar (or cement paste) was relatively high, and thus the COTE may have increased.

- (3)

- The COTE of RCA concrete is represented in terms of the volumetric ratio of coarse aggregate of the individual mixes by the best fit quadratic curves. However, further study is needed to verify if the COTE value of concrete is linear or nonlinear to the volume ratio of total coarse aggregate.

- (4)

- Finally, the predicted COTE obtained by applying the composite series model was slightly higher than the measured COTE, but the determination coefficient was higher than usual, indicating that experimental results obtained in this study are reliable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, J.; Yang, S.; Kim, N. Influencing factor on thermal coefficient of concrete due to aggregate types. Spring Conf. Korea Concr. Inst. 2003, 15, 249–254. [Google Scholar]

- Park, J. Mechanical Strength and Durability Tests on Concrete Mixes Using Recycled Aggregates. Master’s Thesis, Hongik University, Sejong, Korea, 2013. [Google Scholar]

- McCullough, B.; Dossey, T. Consideration for high-performance of concrete paving: Recommendations from 20 years of field experience in Texas. Transp. Res. Rec. 1999, 1684, 17–24. [Google Scholar] [CrossRef]

- Du, L.; Lukefah, E. Coefficient of Thermal Expansion of Concrete with Different Coarse Aggregates. Presented at the Annual Symposium of the International Center for Aggregate Research, Austin, TX, USA, 12 April 2007. [Google Scholar]

- Lee, J.; Son, D.; Ryu, S.; Park, Y. A Study on Preventing Methods of Blow-up for Improving Safety on Expressway; KHC-2020-39-534.9607; Korea Highway Corporation: Gimcheon, Korea, 2020. [Google Scholar]

- Chhay, L.; Kim, Y.; Lee, S. Evaluation of trigger temperature for concrete pavement growth based on joint movement data. Constr. Build. Mater. 2021, 278, 121790. [Google Scholar] [CrossRef]

- Arulrajah, A.; Ghorbani, B.; Narsilio, G.; Horpibulsuk, S.; Leong, M. Thermal performance of geothermal pavements constructed with demolition wastes. Geomech. Energy Environ. 2021, 28, 100253. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Ni, S.; Liu, L.; Walubita, L. Mechanical performance and environmental impacts of self-compacting concrete with recycled demolished concrete blocks. J. Clean. Prod. 2021, 293, 126129. [Google Scholar] [CrossRef]

- Hraboa, K.; Lehner, P.; Ghosh, P.; Konecny, P.; Teply, B. Sustainability levels in comparison with mechanical properties and durability of pumice high-performance concrete. Appl. Sci. 2021, 11, 4964. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.; Darwin, D. Concrete, 2nd ed.; Prentice Hall: Hoboken, NJ, USA, 2003. [Google Scholar]

- Nerville, A. Properties of Concrete, 4th ed.; John Wiley &Sons, Inc.: Hoboken, NJ, USA, 1996. [Google Scholar]

- Byfors, J. Plain Concrete at Early Ages; Swedish Cement and Concrete Research: Göteborg, Sweden, 1980. [Google Scholar]

- Kim, J.; Jook, D.; Choi, J.; Kim, G. State-of-arts of primary concrete degradation behaviors due to high temperature and radiation in spent fuel dry storage. J. Nucl. Fuel Cycle Waste Tech. 2018, 16, 243–260. [Google Scholar] [CrossRef]

- Alexanderson, J. Strength Losses in Heat Cured Concrete; Swedish Cement and Concrete Research Institute: Stockholm, Sweden, 1972; p. 135. [Google Scholar]

- Weigler, H.; Karl, S. Junger Beton: Beanspruchung, Festigkeit, Verformung. Betonwerk Fertigkeit Technik. 1974, 40, 392. [Google Scholar]

- Khayat, K. Deterioration of lightweight fly ash concrete due to gradual cryogenic frost cycles. ACI Mater. J. 1991, 77, 233–239. [Google Scholar]

- Zolnders, N. Thermal Properties of Concrete under Sustain Elevated Temperature; SP-25; American Concrete Institute: Detroit, Michigan, 1971; pp. 1–31. [Google Scholar]

- AASHTO TP 60-00. Standard Test Method for the Concrete Atmospheric Pressure. In State-of-the-ART, Manual of Concrete Practice; ACI: Washington, DC, USA, 2000. [Google Scholar]

- Helmuth, R.A. Dimensional changes of hardened Portland cement pastes caused by temperature changes. In Proceedings of the Fortieth Annual Meeting of the Highway Research Board, Washington, DC, USA, 9–13 January 1961; Volume 40, pp. 315–366. [Google Scholar]

- Won, M. Improvements of testing procedures for concrete coefficient of thermal expansion. Transp. Res. Rec. 2005, 1919, 23–28. [Google Scholar] [CrossRef]

- Hobbs, D. The dependence of the bulk modulus, Young’s modulus, creep, shrinkage and thermal expansion of concrete upon aggregate volume concentration. Mater. Const. 1971, 4, 107–114. [Google Scholar] [CrossRef]

- FHWA. Coefficient of Thermal Expansion in Concrete Pavement Design; ACPT Tech Brief-FHWA-HIE-09-105; U.S. Department of Transportation; Federal Highway Administration: Washington, DC, USA, 2011. [Google Scholar]

- Bamforth, P.; Chisholm, D.; Gibbs, J.; Harrison, T. Properties of concrete for Use in Eurocode 2; The Concrete Center: London, UK, 2008. [Google Scholar]

- Zhou, C.; Feng, D.; Wu, X.; Cao, P.; Fan, X. Prediction of concrete coefficient of thermal expansion by effective self-consistent method considering coarse aggregate shape. J. Mater. Civ. Eng. 2018, 30, 04018312. [Google Scholar] [CrossRef]

- Yang, S.; Lee, H.; Kim, N. Measurement for coefficient of thermal expansion of concretes made with recycled concrete aggregates. Int. J. Highw. Eng. 2015, 17, 7–16. [Google Scholar] [CrossRef]

- Hansen, T. Recycled aggregates and recycled aggregate concrete second state-of-the-art report developments 1945–1985. Mater. Struct. 1986, 19, 201–246. [Google Scholar] [CrossRef]

- Recycling Concrete Pavement, Concrete Paving Technology; EB-043P; American Concrete Pavement Association: Washington, DC, USA, 2009.

- NCHRPP Synthesis 435. Reclaimed Asphalt Pavement, Recycled Concrete Aggregate and Construction Demolition Waste. In Recycled Materials and Byproducts in Highway Applications; Transportation Research Board: Washington, DC, USA, 2013; Volume 6. [Google Scholar]

- Cuttel, D.; Snyder, M.; Vandenbossche, J.; Wade, M. Performance of Rigid Pavements Containing Recycled Concrete Aggregates, Transportation Research Record 1574; Transportation Research Board: Washington, DC, USA, 1997. [Google Scholar]

- Gress, D.; Snyder, M.; Sturtevant, J. Performance of rigid pavements containing recycled concrete aggregates-2006 update. In Proceedings of the Transportation Research Board 86th Annual Meeting, Washington, DC, USA, 21–25 January 2007; pp. 1–28. [Google Scholar]

- Sadati, S.; Khayat, K. Field performance of concrete pavement incorporating recycled concrete aggregate. Constr. Build. Mater. 2016, 126, 691–700. [Google Scholar] [CrossRef]

- Won, M. Performance of Continuously Reinforced Concrete Pavement Containing Recycled Concrete Aggregate; FHWA/TX-01-1753-1 Report; Texas Department of Transportation: Austin, TX, USA, 2001. [Google Scholar]

- Choi, S.; Moon, W. Performance of continuously reinforced concrete pavement containing recycled concrete aggregate. In Proceedings of the GeoHunan International Conference, Changsha, China, 9–11 June 2011; pp. 165–172. [Google Scholar]

- Khayat, K.; Sadati, S. High-Volume Recycled Materials for Sustainable Pavement Construction; RECAST UTC #00046727 Report; U.S. Department of Transportation: Washington, DC, USA, 2020; Volume I. [Google Scholar]

- Bekoe, P.A.; Tia, M.; Bergin, M.J. Concrete containing recycled concrete aggregate for use in concrete pavement. Transp. Res. Rec. 2010, 2164, 113–121. [Google Scholar] [CrossRef]

- Smith, J. Recycled Concrete Aggregate—A Viable Aggregate Source for Concrete Pavements. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2009. [Google Scholar]

- Smith, J.T.; Tighe, S.L. Recycled concrete aggregate coefficient of thermal expansion: Characterization, variability, and impacts on pavement performance. Transp. Res. Rec. 2009, 2113, 53–61. [Google Scholar] [CrossRef]

- Pickel, D. Recycled Concrete Aggregate: Influence of Aggregate Pre-Saturation and Curing Conditions on the Hardened Properties of Concrete. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2014. [Google Scholar]

- Wen, H.; McLean, D.; Boyle, S.; Spry, T.; Mjelde, D. Evaluation of Recycled Concrete as Aggregate in New Concrete Pavement; WA-RD 826.1 Report; Washington State Department of Transportation: Spokane, WA, USA, 2014. [Google Scholar]

- KRS TR 0008-15(RR), Pre-Stressed Concrete sleeper. Korean Railway Standards. 2006. Available online: www.kric.go.kr (accessed on 31 August 2021).

- Juan, M.; Gutierrez, P. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Yang, S.; Lim, Y. Mechanical strength and drying shrinkage properties of RCA concretes produced from old railway concrete sleepers using by a modified EMV method. Constr. Build. Mater. 2018, 185, 499–507. [Google Scholar] [CrossRef]

- Yang, S.; Lee, H. Drying shrinkage and rapid chloride penetration resistance of recycled aggregate concretes using cement paste dissociation agent. Materials 2021, 14, 1–18. [Google Scholar]

- ASTM C192, Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2012.

- Lee, H. An Experimental Study on the Thermal Expansion Coefficient and Rapid Chloride Penetration Resistance of Recycled Aggregate Concrete. Master’s Thesis, Hongik University, Sejong, Korea, 2021. [Google Scholar]

- Hirsh, T. Modulus of elasticity of concrete affected by elastic moduli of cement paste matrix and aggregate. J. Am. Concr. Inst. 1962, 59, 427–451. [Google Scholar]

| Test Items | RR a | RP b | RA c | NCA1 | NCA2 | Fine Agg1 | Fine Agg2 |

|---|---|---|---|---|---|---|---|

| Specific gravity | 2.48 | 2.60 | 2.52 | 2.65 | 2.71 | 2.56 | 2.60 |

| Absorption ration (%) | 4.53 | 2.62 | 3.82 | 0.70 | 0.37 | 1.10 | 0.95 |

| RMC (%) | 39.9 | 20.0 | 25.0 | - | - | - |

| Test Series | Mix | W/C | S/a | RCA wt % | Mix Proportions (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| W | C | S | F/A | NCA | RCA | Admixture | |||||

| 1 | CNR | 0.39 | 45.3 | 0 | 187 | 480 | 739 | - | 894 | 0 | 4.80 |

| CRR68 | 0.39 | 46.5 | 68 | 187 | 480 | 739 | - | 275 | 575 | 4.80 | |

| CRR33 | 0.39 | 45.9 | 33 | 187 | 480 | 739 | - | 584 | 287 | 4.80 | |

| ERR68 | 0.39 | 31.9 | 68 | 145 | 373 | 574 | - | 397 | 830 | 4.99 | |

| ERR68-2 | 0.40 | 38.9 | 68 | 172 | 428 | 658 | - | 335 | 700 | 4.79 | |

| 2 | CNP | 0.36 | 39.1 | 0 | 158 | 396 | 675 | 44.0 | 1051 | 0 | 2.56 |

| CRP25 | 0.36 | 40.4 | 25 | 158 | 396 | 694 | 44.0 | 767 | 256 | 2.49 | |

| CRP50 | 0.36 | 41.7 | 50 | 158 | 396 | 712 | 44.0 | 499 | 498 | 2.49 | |

| ERP25 | 0.36 | 37.0 | 25 | 152 | 380 | 648 | 42.3 | 830 | 276 | 2.60 | |

| ERP50 | 0.36 | 34.6 | 50 | 145 | 363 | 619 | 40.3 | 584 | 583 | 2.61 | |

| 3 | CNP | 0.36 | 39.1 | 0 | 158 | 396 | 675 | 44 | 1051 | 0 | 2.56 |

| CRP50 | 0.36 | 41.7 | 50 | 158 | 396 | 712 | 44 | 499 | 498 | 2.49 | |

| ERP50 | 0.36 | 34.6 | 50 | 145 | 363 | 619 | 40.3 | 584 | 583 | 2.61 | |

| ERA50 | 0.36 | 34.6 | 50 | 145 | 363 | 619 | 40.3 | 584 | 583 | 2.61 | |

| Specimens | Notations | COTE (×10−6/°C) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | Average | Coefficient of Variation (%) | ||

| SUS-304 | 15.790 | 15.778 | 15.858 | 15.81 | 0.002 | |

| Cement paste | 19.726 | 21.258 | 18.658 | 19.88 | 1.71 | |

| Mortar 1 | 11.332 | 12.164 | - | 11.75 | 0.35 | |

| Mortar 2 | 12.084 | 12.430 | - | 12.26 | 0.06 | |

| NCA | 7.079 | 7.226 | - | 7.15 | 0.01 | |

| RP | 8.705 | 9.825 | - | 9.26 | 0.63 | |

| Specimens | Notation | Elastic Modulus, GPa | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | Avg. | Coefficient of Variation (%) | ||

| Mortar 1 | 25.3 | 26.2 | 26.6 | 26.0 | 0.44 | |

| Mortar 2 | 25.1 | 26.0 | 25.4 | 25.5 | 0.21 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Lee, H. Coefficient of Thermal Expansion of RCA Concrete Made by Equivalent Mortar Volume. Appl. Sci. 2021, 11, 8214. https://doi.org/10.3390/app11178214

Yang S, Lee H. Coefficient of Thermal Expansion of RCA Concrete Made by Equivalent Mortar Volume. Applied Sciences. 2021; 11(17):8214. https://doi.org/10.3390/app11178214

Chicago/Turabian StyleYang, Sungchul, and Hyewon Lee. 2021. "Coefficient of Thermal Expansion of RCA Concrete Made by Equivalent Mortar Volume" Applied Sciences 11, no. 17: 8214. https://doi.org/10.3390/app11178214

APA StyleYang, S., & Lee, H. (2021). Coefficient of Thermal Expansion of RCA Concrete Made by Equivalent Mortar Volume. Applied Sciences, 11(17), 8214. https://doi.org/10.3390/app11178214