Abstract

As the world population increases and the need for food monoculture farms are using more and more agrochemicals, there is also an increase in the possibility of theft, misuse, environmental damage, piracy of products, and health problems. This article addresses these issues by introducing the agrochemical pervasive traceability model (APTM), which integrates machine learning, sensors, microcontrollers, gamification, and two blockchains. It contributes in two dimensions: (I) the study of the environmental, product piracy and regulatory of agrochemical control; (II) the technological dimension: application of an adequate set of sensors collecting multiple data; modeling and implementation of a system via machine learning for analyzing and predicting the behavior and use of agrochemicals; development of a scoring system via gamification for reverse use of agrochemicals; and presenting a record of transactions in a consortium of two blockchains, simultaneously. Its main advantage is to be a flexible, adaptable, and expansive model. Results indicated that the model has positive aspects, from detecting the agrochemical, its handling, and disposal, recording of transactions, and data visualization along the reverse supply chain. This study obtained a round trip time of 0.510 ms on average; data transfers between layer one and its persistence in the database were between 4 to 5 s. Thus, blockchain nodes consumed only 34 to 38% of CPU and recorded transactions between 2 to 4 s. These results point to a horizon of applicability in real situations within agricultural farms.

1. Introduction

The population growth in the world demands improvement of agricultural production. In this way, farmers directly increase investments in production systems. Agrochemicals are used both as soil correctors and as a means of defense against pests. Agrochemicals are employed on a large scale in soybean, corn, and cotton monocultures to ensure that production is not affected by soil deficiency or by a pest that may attack the plant at some stage of development (the increase of monoculture) [1,2]. These agrochemicals have unique characteristics that differentiate them from other industries chemical products, such as: high value, high toxicity against the environment and people, need for packaging return, and specific regulations (for their commercialization, transport, storage, usage, and discard) [3,4].

When farmers largely adopt this type of product, they are subject to inspection by state authorities, as well as to theft or environmental accidents (large scale problems) [5]. This causes a need for tight control of production, including the inputs involved in the production process, with great attention. It forces the farmer to invest in the security of property, products, and personnel, generating more costs. The cost in case of environmental damage should be noted. The agricultural production chain and its logistics are pretty long. In particular, the chain of commercialization and agrochemicals usage is reversed (the employed packaging must be returned to the manufacturer). Also, producers do not receive proper training in the use of agrochemicals, nor are they dedicated to reading leaflets and labels [6]. Notwithstanding, a series of minor problems can affect the production chain as a whole, such as: improper handling, application, and theft of agrochemicals; lack of detailed monitoring of the application and return of packaging; lack of location information of a specific product within the production chain; absence of control not only from the producer but also from the state (both need to have confidence in transactions and eventual audits); absence of mechanisms to indicate that the product is operating in its respective productive chain within the regulation.

Among the problems mentioned, agrochemical theft is well-mentioned [7], which indicated the need for greater attention and training via government extension offices. The piracy of chemicals is an additional problem on the regulatory bodies’ agenda, suggesting that more action is needed by the agencies and the development of strategies to reduce environmental damage. However, the technological issues are relatively neglected [8]. The Internet of Things (IoT) devices are dispersed to cyber attacks due to their vast exposure in farm environments; the study outlines a multi-level security architecture for precision agriculture [9]. The use of pirated products is also a risk, whose control is a state’s responsibility, as well as meet the demand for up-to-date information on the use of these products [10]. In other areas of logistics, frameworks have already been developed to track the textile supply chain, but without the adoption of blockchain or IoT [11]. The packaging return process has gaps in the case of not counting on the social responsibility of those involved (even in an agricultural cooperative) [12]; there is also a responsibility gap, later, when they are recorded in a private blockchain, which allows full tracking of agrochemicals packages movement.

Literature does not present solutions involving computational technologies to solve the problems of traceability of pesticide packages, even knowing the great importance of detecting movements and correct usage. As a countermeasure to piracy, sensors are envisioned to detect and manipulate products due to their intrinsic characteristics and nature [13]. The work of Gai et al. [14] uses edge networks for decentralized data collection via sensors and preprocessing, used an edge blockchain scheme to optimize transaction path selection. The work of Rejeb et al. [15] shows the occurrence that the IoT literature on supply chain management focuses on radio frequency identification (RFID), industry 4.0 technologies, and reverse logistics; it provides a better understanding of the use of IoT in the supply chain. RFID is employed to identify products, prices, among other things, facilitating product control. Reverse logistics guarantee the return of packages to origin [16]. Moreover, a blockchain is a structure of linked blocks (data structure) so that a block can point to its predecessor through a field that has a hash of the data from the previous block, and so on. These technologies mentioned here can be adopted and combined in tracking crop protection packages. It is perceived as an open research gap the lack of computational technologies integration, from sensors, processing and machine learning (ML) [17].

In the previously presented context, this article proposes the agrochemical pervasive traceability model (APTM). This model works with a technological mix involving IoT, ML, and blockchain technologies used along the reverse chain of agrochemical packaging. This model defines sensors and controllers willing to inspect the status and mobility of packages along the reverse supply chain and on the farm. The main highlight of this contribution is the processing of data received from the IoT with machine learning; gamification of the rural producer’s process, and recording information in public and private blockchains. Therefore, the proposed model allows visualization of all aspects of the agrochemicals movement, contrasting with those detected unauthorized and suspicious. The model contributes in the combination of emerging technologies (IoT, machine learning, and blockchain) with the gamification trend for cultural change while dealing with agrochemicals; this solution even offers legal protection by meeting social needs to preserve the health of workers and the environment, in addition, to avoid losses, such as the misuse of products. This proposal fills the gap in the lack of machine learning usage after IoT and data recording in two blockchain tiers, including gamification as an incentive for this process.

The main contributions are (a) in a single process unifies the use of IoT, machine learning, gamification, and blockchain. (b) proposes gamification as a contribution to changing culture in the use of agrochemicals. (c) By providing a blockchain for the farmer to enter information in the reverse chain, it allows the farmer to claim tax credits and carbon credits for farm compliance. (d) features a secure locker with IoT capabilities to keep custody of high-cost agrochemicals. (e) presents a layer of machine learning that identifies, classifies, groups, and predicts different actions by analyzing historical data. (f) this is a low-cost model, allowing farmers in developing countries to adopt it.

This article is organized as follows. Section 1 presents an introduction to the topic addressed in this work and its relevance today. Section 2 introduces a fundamental concepts section that covers three subjects required to understand our model. Section 3 discusses the related works. Section 4 presents the pervasive traceability model for agrochemicals, our main contribution. Section 6 presents APTM implementation, as well as an evaluation methodology for judging its functioning. Finally, we have the conclusion in Section 5, commenting on achieved contributions, limitations, and future work.

2. Fundamental Concepts

In this work, three important concepts are the reverse logistic chain, agrochemicals, and gamification. The concept of the supply chain was proposed by Mukhamedjanova [18]: “It defines a set of entities directly involved in the flow of products, services or information for a customer”. Conversely, in another work [19], the concept of the reverse supply chain was defined as: “the process of planning, implementing and controlling the flow of materials in a process from the point of consumption to the point of origin to recapture value and proper disposal’.’ Shamsuddoha [20] indicated that they are necessary activities for the recovery of used products from the customer, taking them to correct disposal or recovery by the manufacturer. The reverse chain can also be considered a form of waste management, maintaining a circular economy [21].

Agrochemicals are various types of chemicals from fertilizers to pesticides employed in agribusiness to increase soil fertility and manage pests, and insects [22,23]. Authors in [24] quoted, "These are chemicals used to increase production." These chemicals have used packaging that must be returned to the manufacturer for safe disposal, configuring the type of product that belongs to the reverse logistics chain. An example of a disposal location center can be seen in Figure 1.

Figure 1.

Disposal location center. The red line details empty agrochemical containers inside a warehouse.

Gamification is applied in this work as a mechanism to encourage participation and interaction among supply chain participants. It is being seen as a “pedagogical and motivational mechanism of engagement” [25]. Interactions are rewarded by the gamification engine and logged-in blockchains, securely keeping event history [26]. In addition, Blockchain operating in a consortium mode has a group of members with a leadership role, which allows the association and collaboration among affiliates. The authority is shared between members in the consortium, and specific nodes have authorizations to validate transactions [27,28,29].

3. Related Work

Related works are mentioned here that show opportunities and advances in their respective areas. These works were selected briefly from the main themes previously discussed: IoT, Blockchain, traceability, ML, AI, and RFID. Searches were performed in several electronic databases: IEEE, ACM, EBSCO, Springer, Elsevier, MDPI, Sage journals, and Wiley Online Library. Several strings were used in the searches. Among them, the following stand out: “Reverse supply chain”, “reverse logistic”, “Pesticides”, “Chemical products”, “Blockchain”, “green supply chain”, “IoT” and “Machine learning”, “Agrochemicals”, “Agrochemicals regulation”. After reading the title, we selected the articles with greater adherence to the main themes. Subsequently, keywords, abstract, body, and conclusion of the article were analyzed. We comment on the leading articles highlighted and list them below.

The work of Esmaelian et al. [21] presents the applicability of blockchain in sustainable reverse chains aimed at industry 4.0, indicating that the concept of sustainability is also related to the return of used products. Van den Berg et al. [30] presented a survey in which several gaps in the life cycle of agrochemical management and control are listed, dividing them into three large groups: regulatory control, agricultural management, and pesticide management for pest control. Imbault et al. [31] presented a case study of blockchain implementation in the Predix (Predix is GE Digital’s cloud platform for collecting and analyzing physical device data). system using a blockchain in energy production and distribution. Silva et al. [32] pointed out, through a survey, a gap related to the efficiency of the process in reducing costs and environmental strategies related to the image of companies. RFID enabled collaboration within the supply chain while requiring greater integration in Business-to-business strategies [33].

Tyagi et al. [34] conducted a survey in which they conclude that the reverse supply chain can be trusted if companies adopt them as a strategic priority, adopting easy and safe means of transportation for the reliable return of products. A study on pesticide control policies in European countries identified differences in policies and public debates, including that despite the different policies adopted, public debates and regulations are increasing, indicating the need for greater data sharing [35]. A study conducted in Bolivia pointed that the main gaps on agrochemicals reverse supply chain are lack of knowledge and precise lines for farmers [36]. Zhao et al. [37] conducted a case study creating a simulator called i-certificate, which encompasses a blockchain to promote voluntary adoption of renewable energy.

A survey of concepts overlapped in the definitions of reverse logistics provided was provided by Granlie et al. [38]. A taxonomy helped the reader visualize a significant concentration of concepts around the end of product life, recycling, and remanufacturing terms. Fuertes et al. [39]; Sila-Nowicka et al. [40] and Michelucci et al. [41] have worked to detect product package movements, as well as their correct usage throughout the supply chain. Another study was conducted on how sensors combined with the analysis of a product’s own characteristics help to understand when cases of counterfeiting occur [13]. Tiny sensors and a smaller amount of processing performed on edge networks can facilitate collecting data from these scattered sources. This can benefit the analysis of the transit of products in the supply chain [14]. RFID, blockchain, and artificial intelligence deployment throughout the logistic supply chain have been addressed by several authors, indicating the trend of the application of technology in this area of business [15,16,17,42]. Rejeb et al. [15] presented an understanding of IoT in development and logistics chain management, including food and pharmaceuticals (which may require reverse product tracking). Hu et al. [16] addressed edge and blockchain computing to build a blockchain implementation for organic products, enabling traceability at low cost. Toorajipour et al. [17] identified techniques most used in supply chain management, indicating their potential applicability in various fields such as logistics and production. Min [42] presents the limitations of AI application and explores the ability of other AI fields to solve practical supply chain management problems.

Gamification is an engagement technique that can motivate farmers to return empty containers of agrochemicals in the reverse supply chain. In this sense, Sumer [43] carried out studies on the adoption of gamification in business environments. The interest of professionals in agriculture increases by the use of gamification frameworks [44]. Also, a framework was developed as a learning environment focused on supply chain education [45]. Other studies show that even when the technology is available, its deployment is not accessible due to operational expenses, divergent or absent standards, few available suppliers, among others aspects [46,47].

The articles presented so far have been summarized in Table 1. Despite the work described in this section, none of them have contributed with an integrated solution for the traceability of agrochemicals. The aforementioned works focus on several other general aspects of the supply chain. In addition, the related works encompass technological resources as accessories along the supply chain and as an aid to the transit of products along with it. Although the technology exists, we overlook ready-made solutions in the mentioned articles or specific solutions to safely treat the reverse chain of agrochemicals. As a gap, we do not detect the combined use of preprocessing by sensors, machine learning analysis, gamification, or more than one level of blockchain for different purposes.

Table 1.

Related works and main domain topics.

4. Proposed Model

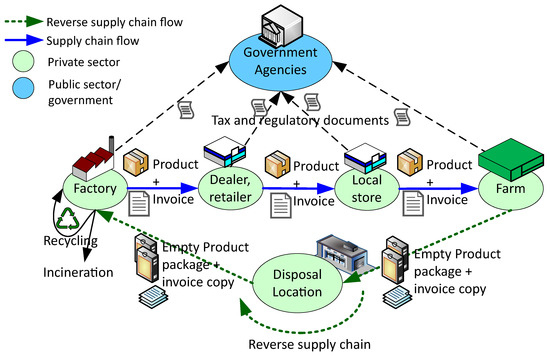

The reverse agrochemical supply chain that this model serves is illustrated in Figure 2; in this figure, dotted arrows in black represent the flow of data sending to government agencies (this data can be diverse, as taxes and regulations). The blue arrows represent the supply chain flow of agrochemicals. The dark green dotted line represents the reverse supply chain. Elements in green circles represent the participants in this reverse chain (they are: factory, dealer or retailer, local store, farm, and disposal location). Government agencies show a blue circle at the top of the figure. Note that the transit of this type of product (represented by a box) is always accompanied by an invoice (in the figure, the invoice is represented by a piece of paper). Dark-colored product boxes represent packages on the blue arrow towards returning to the factory with their respective documentation.

Figure 2.

Reverse agrochemical supply chain.

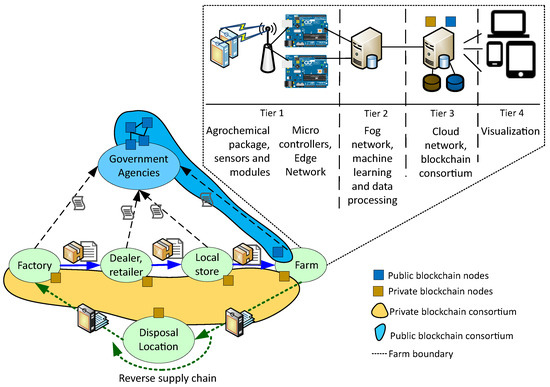

Figure 3 presents the macro vision of the Agrochemical Pervasive Traceability Model (APTM), and its detailing is described in the following sections. Figure 3 expands the previous figure by adding two new element details: (1) A yellowish-brown cloud representing the private blockchain consortium pool and a blue cloud indicating the public blockchain consortium. In these two clouds, we can see small squares representing blockchain nodes; (2) The farm bubble burst, i.e., a zoom on the internal components inside the farm, whose details are explored in the sections below. The model monitors agrochemical usage within farms using IoT, machine learning, 2-tier blockchain, and gamification.

Figure 3.

Agrochemicals Pervasive Traceability Model (APTM).

In this work, the interactions with agrochemicals and the functioning of the proposed model were designed to maintain an automated flow of information without human intervention. In the APTM model, the features were divided into tiers, each tier playing a separate role that allows for scalability. This model was designed to interact with two levels of blockchain consortia and bring features, such as machine learning and gamification. In this way, APTM is flexible enough to be adapted to other high added value products that need monitoring using several disruptive technologies such as blockchain, machine learning, gamification, and IoT.

4.1. Project Decisions

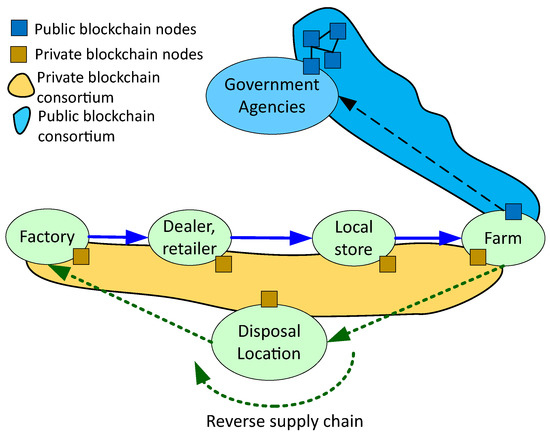

A sequence of steps must be followed throughout the model. These steps present the product transit along the reverse agrochemical supply chain. At each step, a type of processing is carried out. Each step provides available functions that handle incoming data, data storage, and data exchange to the next steps. Figure 4 presents the reverse supply chain, also indicating where the private and public blockchains are located; each circle in the figure is an actor that feeds the blockchain to which it is connected to. Government agencies monitor the movement of toxic products and must be informed of such movements. Used product packages are returned to disposal centers. Disposal centers return used and empty product packaging to the source for recycling, incineration, or safe disposal. Each agrochemical package carries its relevant documentation, such as invoices or agronomic receipts, being monitored by government agencies. The pervasive feature is the ability to monitor products and packaging within the farm area.

Figure 4.

Interactions between the farm and the public and private blockchain consortia.

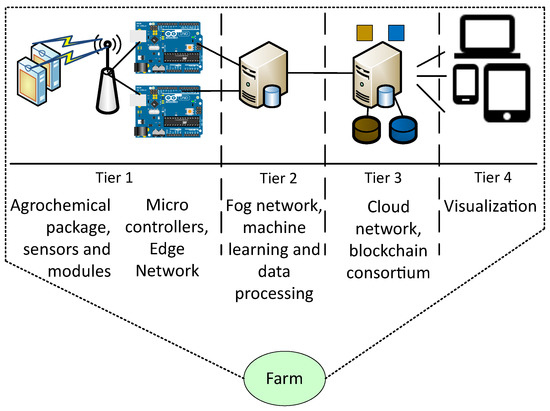

Figure 5 presents a breakdown of what happens inside the farm, its tiers, and parts of hardware and software. As for the mechanics of the model, it works like a process or pipeline in which a flow of data goes through each step and within the farm, passing through each tier. The tiers that are performed on the farm are:

Figure 5.

Detailing the tier composition inside a particular farm.

- Tier 1: Data collection is performed as the agrochemical packages are handled;

- Tier 2: Performs data recording and first processing via AI on them;

- Tier 3: Writes data to a public and private blockchain. The gamification works by recording jumps between tiers in the blockchain to keep an extract from the movement of products.

- Tier 4: Performs information visualization;

Each tier provides services to the previous tier via functions and message exchange, i.e., one tier is a client of the next tier (from tier 1 up to 4). Connectivity between tiers forms a means of communication or pipeline between all members of the tiers.

4.2. Model Structure and Functioning

In this model, the private blockchain acts in the reverse supply chain from the agrochemical factory to the farmer. After using the products, the farmer must return the empty packages of agrochemicals to the collection centers. These collection centers later send the packaging of used products to the factories (for further recycling incineration or safe disposal). This movement is of interest to a private reverse supply chain composed of private entities. During their operations of planting, buying, and selling agrochemicals, the farmers interact with government agencies. At this time, the farmer sends information to a second public blockchain. Moreover, by making it work with two tiers of blockchains, its operations are recorded simultaneously in the private reverse supply chain blockchain and the blockchain of government entities. A more detailed description of what happens in each tier inside the farm is given below (Figure 5).

Tier 1 (Agrochemical packages, sensors, and microcontrollers) is responsible for monitoring the agrochemical package. It encompasses several dispersed IoT devices (sensors and microcontrollers) that receive the events of the environment and packaging, treating these signals, sending them to the next tier. Sensors are used to detect the opening and closing movement of the container or cabinet where agrochemicals are stored. Sensors are also used to detect the movement of agrochemicals. Microcontrollers are used to receive data from sensors, perform pre-processing and move data to the next tier.

Tier 2 (Fog network) has a database that receives data from tier 1; also implemented in this tier, they are business rules in scripts. These scripts perform the following functions: classify and group data; send alerts under certain conditions (such as sending alerts to those responsible); generating predictions from perceived patterns since machine learning is located in this tier; and move data to the next tier.

Tier 3 (Cloud) has the functions of final registration of operations on two blockchains, a private blockchain consortium that belonged to the reverse supply chain—usually an economic group or association to which the farmer is a member; it also sends data to the blockchain consortium maintained by the government, informing of the safe disposal of pesticide packaging. Gamification is a process used to account for the correct movement of agrochemical packages and their registration in the blockchain. An important detail in Figure 4 is the presence of the farm as a member of two blockchain consortia, simultaneously running two nodes, one to serve each consortium. Therefore, the farm can send data to the blockchain of regulatory bodies and send data to business partners in the reverse supply chain. In addition to having a presence in these two consortia, the farm can keep a record of transactions for future use, such as carbon credit exchanges. Gamification registration is done in the last tier; an additional record is made on the private blockchain stating that a product or package of agrochemical fulfilled itself the life cycle and will be sent out to the collection and disposal center. This last transaction is that marks points of interest in the gamification process. The Ethereum blockchain was chosen as the design decision due to the possibility of using smart contracts with the Ethereum Request for Comments (ERC721) token standard and transparency and visibility in transactions. Ethereum was also chosen due to its wide acceptance and possibility of working with IoT.

Tier 4 (Visualization) enables data visualization via decentralized applications, i.e., various visualization panels. The visualization is used to present data from sensors, transactions in both blockchains and gamification points. In this tier, they are the decentralized applications (dApps) used as query tools and monitoring of the model’s operation.

For the implementation of this model, the following are necessary: (a) For private blockchains, the participants must be running a network node, in this way, the transaction record is persisted in a distributed way; (b) In the public blockchain that at least one public agency has a node with an open communication port so that the farm node can send data (internal nodes within the scope of public agencies are needed to exchange inspection data between them). Inside the farm, tier one is fully distributed in the areas for storing and handling agrochemical packaging. Tiers two and three can be implemented separately via virtual machines.

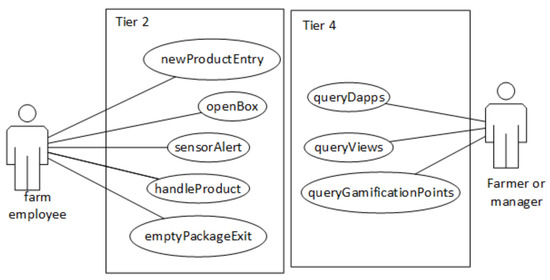

The interaction among users in the APTM is illustrated in Figure 6. openBox is performed when an employee opens the cabinet in which an agrochemical is stored. handleProduct occurs when the employee handles the products inside the property. sensorAlert are events triggered when the system informs actions perceived as incorrect by tier 2. The other operations are queries performed in the visualization tier: queryDapps are queries held in decentralized applications on blockchains; queryTier2Views are queries on operations performed in tier 2; and queryGamingPoints displays the computed score in APTM game. newProductEntry interactions insert new agrochemicals into the system and emptyPackageExit removes empty packages from the system. In this figure, it is also highlighted that some functions are merely operational, related to handling products and packaging; other functions are simpler and aimed at operational monitoring; therefore, each interaction is represented in its corresponding tier.

Figure 6.

User interactions with the model.

A network is required internally on the farm and a farm connection to two external networks (the private reverse supply chain network and the network of public agencies). Communication between elements of over tiers 1 up to 3 is done via function call or message exchange, as appropriate. Each tier 1 IoT device has a unique identification number that makes it easier to identify tier 2 events and other operations. All data movement within the farm is done using simple data types, such as numbers and strings, to prevent conversion operations and facilitate data movement between tiers. Data communication within the private blockchain is done via Javascript object notation (JSON), and the communication of data with the public blockchain is via a web service by sending an extensible markup language (XML). This model does not require activation or human interaction to get up and running or start its data processing and sending activities. Once implemented, it works alone. The only human participation is in the handling of agrochemical packaging because this operation triggers sensors were generating events and putting the system to work.

4.3. Tier 1—Sensors and Microcontrollers

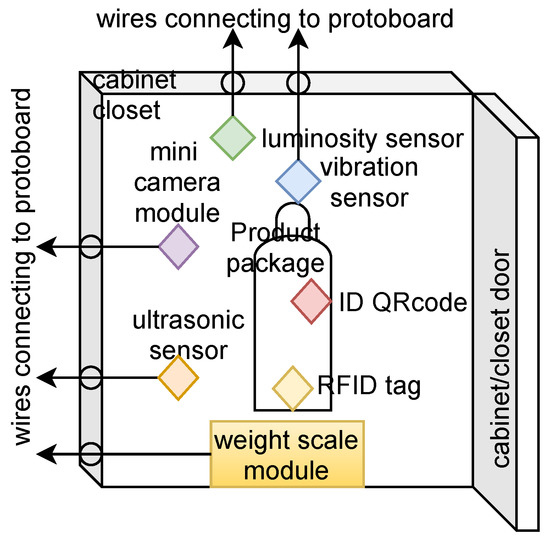

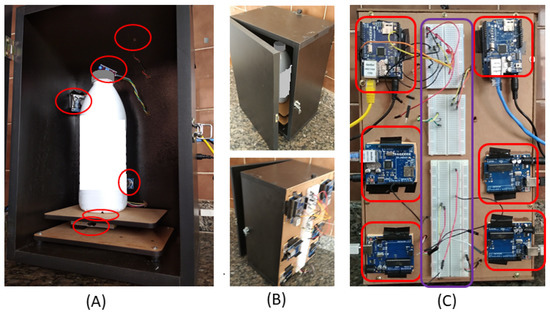

Tier 1 can work with various sensors, such as: luminosity sensor, heartbeat/pulse sensor, pressure/resistive force sensor, tilt/impact or motion sensor, temperature sensor, ultrasonic sensor, sound sensor, liquid level sensor, speed sensor, and light sensor; and other features such as: RFID, Camera, QR code or bar code and GPS. Tier 2 is a multi-sensor approach with the combination of data from several sensors that must be passed to Tier 2 to enrich its analysis and predictions. The minimum necessary sensing/reading equipment for the solution is: (a) a code reader for identification of the packaging being used (can be a QR code, bar code, or a numeric code reader); (b) RFID tag; (c) an ultrasonic sensor; (d) a vibration/movement sensor; (e) a luminosity sensor; (f) Weighing scale module; and (g) a camera. This minimal setup produces data that feeds tier 2 (Table 2) and a simple schematic is showing sensors around the package inside a cabinet in Figure 7.

Table 2.

Sensors per type of processing use in tier 2.

Figure 7.

Simple schematic showing sensors and package inside a cabinet.

The sensor list summary is the following: 1. RFID tags/chip: MFRC522 NXP. 2. Ultrasonic distance sensor HC-SR04. 3. Vibration sensor SW-420. 4. Light sensor LDR 5 mm. 5. Weight scale module analog-digital converter module HX711. 6. Camera module VGA OV7670, 30 FPS, max resolution 640 × 480 pixels.

The sensors are located in an edge network around the product package and connected in this (except for the RFID antenna network, which can stay in various parts of the farm, forming the concept of virtual fence). The primary need for the arrangement of sensors around the products is to monitor when it is collected for use, allowing them to detect forms of misuse or theft. This detection is a tier 2 function. Tier 2 data entering an SQL database may also be available to the farm’s ERP with appropriate access measures. This information is sent to tier 3 via function call to a blockchain application programming interface (API).

In layer 1, we have the following features related to safety. Here, the sensors are in safe and closed cabinets. These cabinets are inside closed rooms because agrochemicals have a high value. In addition, the values collected by the sensors are compared with known parameters, layer two can issue alerts when these values change, so any attack on layer 1 to change data can be detected at layer 2. The model was designed with Ethernet Shields o which significantly reduces attacks and interference in data collection. Microcontrollers are only running code preloaded on them and cannot execute other types of malicious code. A feature beyond the model refers to data transmission within the supply chain. The farm must be connected via the internet, and this connection must pass through a router with a firewall.

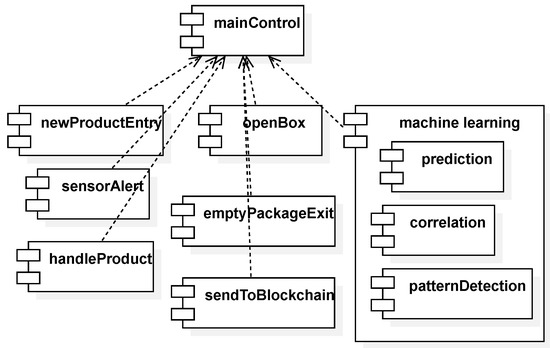

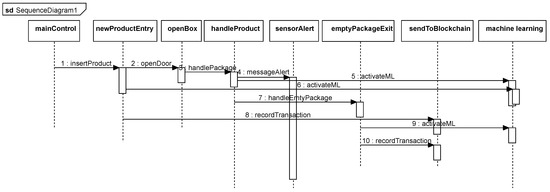

4.4. Tier 2—Data Processing and Machine Learning

Tier 2 performs intelligence work with sorting, sorting, patterns detection, and prediction operations (or any anomaly detection). Once these non-normal storage, use, and transit conditions of products are detected, a record of what has been discovered is recorded in a database, making data available to users’ applications. Scripts in python move the data generating alerts that are triggered for those responsible for doing so. These scripts also move data to the next tier. This tier has an SQL database that performs several functions among them: it receives tier 1 data and stores it in several temporary tables for intelligence operations. It is the place where scripts collect data for submission to tier 3. This database functions act as a communication hub between the 4 tiers of the solution in a farm. The functionalities of this tier in addition to the database server are depicted in Figure 8: newProductEntry, openBox, sensorAlert, handleProduct, emptyPackageExit, sendToBlockchain, prediction, correlation and patterDetection. A sequence diagram in Figure 9 illustrates interactions between tier 2 functions, along with their relationships with other modules, including the occurrence of events, their blockchains recording, and the activation of desired machine learning functions (i.e., prediction [48], classification [49] and clusterization [50]). Tier 2 has the following security properties: (a) every table has a hash field; (b) there is a shadow table in the database for auditing and backup purposes; (c) a write-only account is used, and tier four applications use a specific account with read-only permission; (d) The database server uses an encrypted disk, and the shadow tables data are written to a write-once read many (WORM) media; (e) Database server has database vault function enabled.

Figure 8.

Functionalities of tier 2 in APTM.

Figure 9.

Relationship among tier 2 functionalities in APTM.

4.5. Tier 3—Blockchain Consortium and Gamification

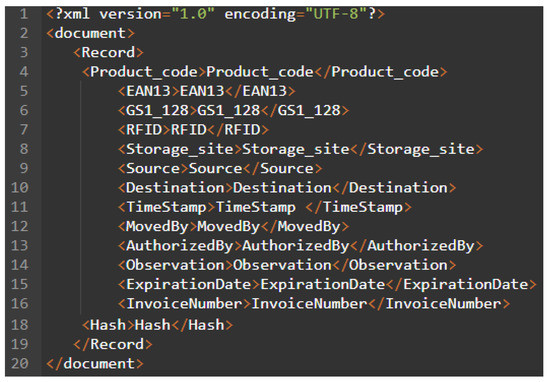

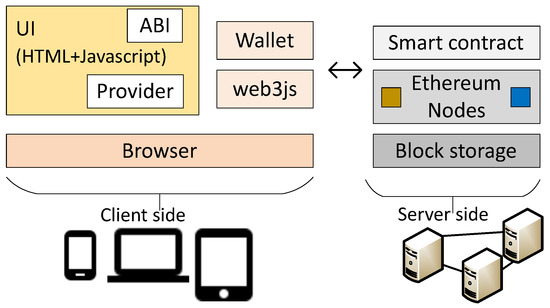

The private blockchain tier comprises companies with the “same commercial interest” or a single company with an economic interest in this reverse supply chain that autonomously and independently maintains the private blockchain. The goal of private blockchain is to maintain data that begins in the development, production, storage, sale, and return of defective products and/or packages. Mainly it deals with the transit of goods between “trading partners” of the same chain. The private blockchain exchanges data via a representational state transfer (REST) API using JSON. This tier has a class library to operate on its objects. It considers features of controlled objects that must return to their origin. This class library allows data to be written from correctly identified objects. These objects are tokens on the blockchains that follow the ERC721 token contract standard (It is a pattern used for tokenized product exchanges. Objects can be represented and uniquely identified by using ERC721 tokens. This standard is used by the Ethereum blockchain in its smart contracts and provides functionality for transfers, approvals, and quantification of token transactions between accounts). The farm also sends data to a web service maintained by the government. Behind this web service, there is a blockchain in which public supervisory bodies interconnect and monitor the movement of agrochemicals. Data is sent in XML format. The data format model used is briefly presented in the listing example in Figure 10. Data is stored outside the blockchain. Therefore what is forwarded is an extract hash code with a pointer to the complete data. Data stored outside the blockchain uses a protection scheme similar to that used in tier 2. This approach is adopted due to the intrinsic slowness of processing intelligent contracts while recording large volumes of data. The fields that make up this data are: EAN13 refers to the barcode and product identification; GS1_128 refers to the GS1 standard; RFID, code used in radio frequency tags; Storage_Site: storage location; Source: product source; Destination: The product’s next destination location; Timestamp: date and time of the event; MovedBy: an employee who made the product movement; AuthorizedBy: an employee who authorized the movement of the product; Observation: Miscellaneous comments; ExpirationDate: final product expiration date; InvoiceNumber: invoice number. Both blockchains in this work have been developed in Ethereum. Figure 11 shows the decentralized application architecture used in both blockchain consortiums in tier 3 of APTM.

Figure 10.

Data on agrochemical packages used within the farm.

Figure 11.

Decentralized application details in layer 4 (dApps on client side and server side).

One of the incentives to participate in this reverse supply chain is engagement via gamification. Participants who submit product transit data score points. This score can be divided into a scale: participation, amount of data sent, amount of information disclosed, etc. These data can be public and consulted via tier 4 in blockchains or made available via a third-party portal (https://etherscan.io/, accessed on 26 July 2021). The system that computes the score can be located in tier 2 or 3. The minimum score system can add points and medals using Table 3. The gamification and display of the score in tier 4 can lead to “green certificates” and entries into the carbon credit market. The farm becomes transparent in processes involving agrochemicals. This “green” recognition can come from the reverse private supply chain, government agencies, or displayed by the farmer himself via tier 4. Points are totaled and displayed on a panel along with the transactions issued.

Table 3.

Points, meaning and related icons.

A gamification process can support the routine treatment of agrochemicals within well-defined processes. We indicate as a benefit: (a) prove that the farm has well-defined processes and complies with regulations, and each step of these processes can earn points in gamification. (b) when the farmer has a process that generates points, these can be presented to the State to obtain tax benefits. (c) another benefit is within the agrochemical supply chain itself, where members with more points can claim discounts or other benefits.

4.6. Tier 4—Visualization

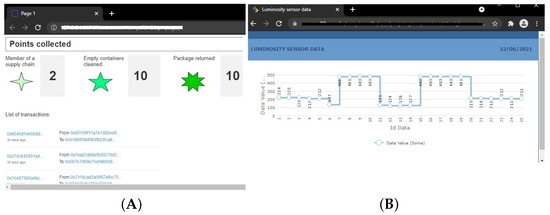

The presentation tier contains web pages, decentralized applications, and API for data exchange with pre-existing enterprise resource planning (ERP). This tier only needs a web server and a series of scripts (running in the background, like JavaScript and PHP). The objective is to show the transit of empty products and packages and points accumulated by gamification and alerts generated by tier 2. This tier is essential since it gives a "face" to the model in which the farmer can follow the model’s operation process and see the data transit. Figure 12 shows: (a) on the left, the prototype application with the points collected in the gamification process; (b) on the right, it is possible the prototype of a decentralized application (dApp) showing data from sensors sent and block data in the blockchain. Applications use internally: a connector (provider and the application binary interface—ABI), a JavaScript library web3.js that handles the data received.

Figure 12.

Visualizations: (A) points from gamification and (B) sensor data.

4.7. Particularity of the Reverse Chain of Agrochemicals for the Farm

The proposed reverse supply chain model deals with agrochemicals products that cannot be discarded anywhere or go to any dump due to their nature and intrinsic characteristics. We cite as an example the international regulation that recommends the return of empty packages to collection centers, as well as the registration of products and participants in this reverse supply as mentioned in [3,4,51]. The farm is a part of the reverse chain of the agrochemical. Within it, the following operations are carried out: (a) reception of the agrochemicals purchased; (b) guarding the agrochemicals in a container, cabinets, or safe box; (c) removal of agrochemicals for use under normal conditions of operation in the crop; (d) washing and drilling of empty packages; (e) delivery of packaging used in disposal and collection centers. Packaging with products not yet spent is the purpose of theft or misuse, therefore justifying the need to employ sensors directly on the packaging or in the containers that keep these products.

5. Implementation and Evaluation

The design and construction of a prototype were carried out to evaluate what is discussed in this article. The prototype was designed using unified modeling language (UML) diagrams (due to its popularity and universality). The prototype implementation involved modeling the tiers and separating the functions of each tier.

5.1. Deployment Aspects

In tier 1, a cabinet for the positioning of sensors and microcontrollers was created. Arduino was used as a microcontroller. Communication with tier 2 was performed using Ethernet shields. The collected data is sent via a computer network. The code that handles data received via sensors was written in C++ to run on Arduinos. An Arduino was used for each sensor. The arrangement of these sensors can be seen in Figure 13, showing a container or cabinet, sensors, microcontrollers, and agrochemical packaging. In this figure, the left side (A) is the internal part exposed, receiving various sensors, such as vibration, ultrasonic, camera, light, a package for testing purposes with an RFID tag in its base, and installed inside this cabinet the weighing scale module. The center (B) shows a perspective view from the right top. The right side (C) is the back of the cabinet where one can see the Arduino, a protoboard, network, and some wiring cables (USB/serial, network, and power supply).

Figure 13.

Front, perspective and rear view of cabinet container with sensors and agrochemical package.

All programs that run on these tiers were developed in Python. In tier 2, a SQL database (MariaDB) receives data from the first tier in a temporary table of collected data. The table stores data accordingly to pre-established patterns, i.e., depending on classification, grouping, and prediction operation. Data that will be sent to the blockchain comes from this table. In this tier, there are scripts made in Python that perform several functions, such as: logging in of new products, opening a cabinet door, sending alerts, handling products, leaving empty packaging, sending data to the blockchain. In addition, there are three machine learning operations based on the sckit-learn library. If certain conditions are detected during processing, alerts are sent to the farmer by the smtplib. Each of these functions runs as services in tier 2, triggered by the main control. This module (sendToBlockchain) activates the other functionalities of this tier. Sending data about product movement with Python is done with web3.py to interact with tier 3 Ethereum blockchains.

Tier 3 has two Ethereum nodes, one for each blockchain consortium (public and private). Each node is a link between public (regulatory bodies) and private (supply chain) networks. Every movement in tier 2 will have its representation in the form of a transaction recorded in blockchains; however, these blocks are also stored locally. A developed smart contract keeps agrochemical data and records its movement. Smart contracts are written in Solidity and adopt the ERC721 standard to represent an agrochemical package as a non-fungible token (NFT). The minimum amount of data recorded in the blockchain is the invoice number and the product code (or barcode). A web server (Apache) is also installed in this tier to receive requests from the visualization tier. Tier 4 is formed by decentralized applications (dApps) developed in HTML, JavaScript and web3.js (for access to Ethereum blockchains). Transactions performed on blockchains count as points according to the scoring system and presented together with transaction extracts, which can be tracked. Figure 12 shows data collected by sensors, and generated alerts can also be checked via panels available in this tier.

5.2. Evaluation Aspects

The evaluation consisted of building a minimal prototype with small features that could represent the small-scale operation of the model as a whole. Individual tests were carried out by tiers and on the integration between them. A laboratory scenario was defined in which the sensors were activated in different ways by opening the cabinet that contains the agrochemicals. This methodology is called scenario assessment, and it is used to assess ubiquitous environments. Scenarios represented the adoption by an operator that simulated the actions performed by employees of a farm when handling agrochemical packages. A volunteer conducted the tests. It is possible to evaluate with real data, but due to the need for displacements and costs for tests on farms, we selected to carry out equivalent laboratory tests at this stage of the project.

The objective of the evaluations was to carry out simulations in the model, trying to represent the real conditions of use within a farm. All tests were performed on virtual machines. Client applications were tested in browsers inside these virtual machines and in physical devices representing tier 4. For tiers 2 and 3, a virtual machine was instantiated for each tier. The system was tested with all virtual machines running simultaneously along with sensors and devices. The general assessment is that the APTM model seen individually or as a whole work. The transit of data from the sensors to visualization occurs simply and automatically after interactions in tier 1. In each testing scenario, a part of the model was evaluated. First, we testes door openings and evaluation of the functioning of the light sensor. Secondly, the removal of packaging and movement within the farm, as presented in Table 4.

Table 4.

Experimental evaluated scenarios and theirs objectives.

Another testing step was to direct the sensor data to a table in a MariaDB SQL database. These tests were carried out in two ways: (a) by receiving data from the sensors, minimally modifying the C++ programs integrated to employ the mariadb library, a testing connection and data to access the table; in this way, the data can be directed to the database. (b) by generating fictitious data obtained from open sites to generate mass tests (https://www.generatedata.com/ and https://www.mockaroo.com/, accessed on 26 July 2021). A structure similar to the existing table in the database was configured on these sites, and a mass of fictitious records was requested to evaluate: data load, table size, and query speed.

Each program developed to run on tier 2 was tested within the Spyder (https://www.spyder-ide.org/, accessed on 26 July 2021). Python Integrated Development Environment (IDE) to avoid warnings and alerts. The evaluation of these python scripts functionalities took place by verifying and validating three operations: access to the database, reading and manipulation of data, and movement of data to the next tier. If these operations were successfully executed in sequence, the test was terminated and accepted as finished correctly. Each module was evaluated separately and followed via execution profiling panel and variable explorer within Spyder. The communication between the programs and the database was monitored and validated using filters elaborated within the Wireshark (https://www.wireshark.org/, accessed on 26 July 2021) protocol analyzer.

The evaluations generated in tier 3 took into account both blockchains. The smart contract code has been evaluated within the Remix IDE. Interactions with the contract were evaluated via the Metamask wallet and by the Remix interface itself. During development, the Ganache virtual blockchain was used (Ganache (https://www.trufflesuite.com/ganache, accessed on 26 July 2021) simulates an Ethereum node for development). When testing with Ganache was completed, it was replaced by TestRPC. The recording of transactions in blocks was evaluated and confirmed by observing blocks generated in the file system. Another form of evaluation was to direct the smart contract to the Kovan test networks and monitored via Etherscan (https://kovan.etherscan.io/, accessed on 26 July 2021). On this site, one can check processing time, costs, among other performance metrics.

The evaluations in tier 4 were limited to receiving and running dApps inside browsers, verifying the data processed along with the APTM model. Responsiveness of applications has been tested by changing the applications and their display profiles. These evaluations have been performed by changing the display profile within browsers using the development option and physically testing them on different devices. Within browsers element loading was dropped after a simple check on network data while keeping the development options enabled within browsers.

On the evaluation of economic aspects: The estimated cost of building the secure cabinet with sensors, microcontrollers, wiring, protoboard, among other elements, ranges from US$ 250 to US$ 300. In addition, at least one microcomputer is needed to run the two virtual machines that implement layers 2 and 3; the farmer can choose to use two computers, increasing the cost of equipment. Furthermore, it is necessary to have a computer network installed at the farm’s headquarters or near the agrochemical storage depots and connect to an internet access provider for sending and receiving. Layers 2, 3, and 4 are all implemented in software. In this layer, acquiring proprietary software licenses could be an extra cost to implement the model. Hence, open-source software was adopted, making the proposed solution cheaper and facilitating its adoption by small farmers in developing countries. Main economic barriers: (a) micro farmers who do not work with large monocultures (such as soy, corn, or cotton) may find the cost of US$ 250 to US$ 300 high. (b) although the cost of internet access has dropped over the years, many rural areas do not have internet access, forcing farmers to invest in their communication structures beyond this article’s scope.

Evaluations and tests were performed in the laboratory. Anticipating the future need for field tests, we envisioned a pre-assessment via a questionnaire with the owner and manager of a small farm designed to understand the needs for the current model and prepare field tests. A questionnaire with 23 multiple choice questions was created (with answers: yes, no, and not applicable). The questionnaire was carried out on a voluntary basis. For implementing this model, the selected farm should not have internal processes with the technologies mentioned here, allowing the application of the model. The interview was carried out on a farmer with extensive and recognized experience in agricultural monoculture of soybeans and corn, aiming to carry out a proof of concept of the model. The commented questions and answers are listed in Table 5. The questions briefly present: The farmer recognizes that a special place for storing agrochemical products is needed. Empty agrochemical containers are also stored on the farm until they are taken to the disposal center, and they also need exceptional control. He recognizes that a special guardroom is needed. The need for control over the amount (in milliliters, liters, or gallons) in use is recognized. The farmer indicates interest in knowing the agrochemicals’ traffic on the farm. The opening of storage environments should issue alerts to the farmer. The farmer also shows an interest in a system for predicting and warning of future events. The farmer confirms that the farm is part of a supply chain. The farm is interested in using system data with control and inspection entities. The farmer shows interest in testing new technologies. The farmer recognizes the possibility of using the records of transactions in future operations, such as exchanges for carbon credits, tax credits, or discounts with the supplier.

Table 5.

Questionnaire with the farm owner, questions 1–23.

Positive responses indicate that the gap identified initially exists and needs to be addressed by the proposed model. It allows us to see the usefulness of the proposed model, the integration of technologies with all the players involved. We also realize the possibility of future utility, including for needs not yet demanded at the time, such as the registration of transactions for exchange for carbon credits, among others.

5.3. Main Results and Limitations

On the limitations of this work, we mention: (a) This model was not tested with farms with multiple suppliers or with multiple supply chains belonging to heterogeneous players; (b) Considering that each product must transit with an invoice, no data was collected from actors invoices prior to their arrival in the farm, since there are tax secrecy issues in companies; (c) no consideration was taken of the monetary cost with energy expenditures for the operation of both blockchain consortia; (d) This study did not consider energy and internet expenses to keep the model working.

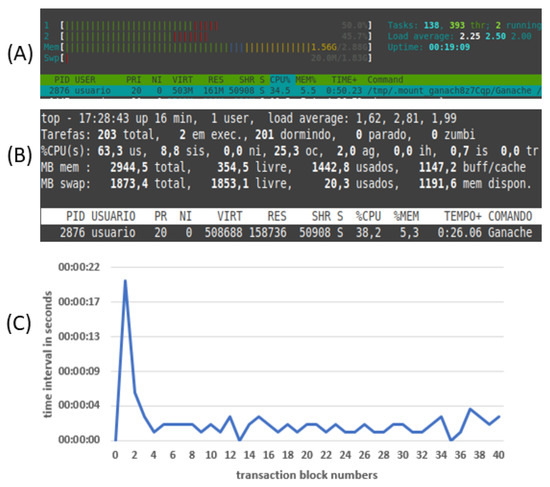

The transit of data within them observed the characteristics of the modularity of the layers. In this way, the model worked as expected. Sensors could be exchanged and added without harming the model’s operation. It was observed that layers two and three worked together or separately during the tests. Layers two and three were run and tested inside virtual machines. The observation observed that for the minimum functioning of each virtual machine, a minimum configuration of Linux 64 bit operating system, 2 vCPU, 40 GB disk space, network connection, 2500 GB RAM was necessary. Scripting performance on layers two and three was observed via operating system utilities such as top and htop and profiling within the Spyder IDE, achieving 15% usage for data transfer between layers and 28 to 31% CPU usage other python scripts. Data writes to both layers were performed using up to 41.6 Mb/s. The result of data transit was obtained by configuring a network using inside the hypervisor. There was a round trip time close to 19 ms for the external network and between layers of 0.510 ms inside this network. All data transit between layer one sensors was observed via protocol analyzer showed that data was sent as the sensors were activated. The IDE has also monitored the serial port during development and layer one code debugging. No data loss between layers one and two was noticed. Layer two spent 4.6 to 5.9 ms to perform data persistence operations on SQL databases. Blockchain nodes tests with Ganache occupied up to 34 to 38% CPU during execution. Also, blockchain data recording times were observed by transaction processing time which ranged from 2 to 4 s. In Figure 14, (A) and (B) show Ganache running between 34 to 38% of CPU time using programs top and htop; (C) is the time interval for registering the smart contract in the blockchain and sending subsequent transactions to blocks. Blockchain performance is seen in the transaction log by Ganache in layer 3 (A brief evaluation indicates the average 00:00:02, median 00:00:02 and mode 2.00.).

Figure 14.

Figures (A) and (B) show top and htop indicating CPU time and (C) transaction time in Ganache at layer 2.

6. Conclusions

This article proposed a model that can monitor the use of agrochemical products and the disposal of empty packages. We have combined technology such as IoT, machine learning, two blockchains, and gamification to accomplish this. To the best of our knowledge, we have not found a model with such a combination. This paper featured related works discussing alternatives. The proposed solution is flexible since other sensors can be added to tier 1 easily. It is scalable, divided into tiers that can be updated independently without affecting the others.

As future works, we indicate: (a) In future evaluations, IOTA Tangle may be used as an alternative for comparison with the combination of Ethereum and IoT. The private internal network may be changed from Ethereum blockchain to IOTA Tangle; (b) the development of public interconnection standards between multiple blockchains and ERPs to become auditable by an independent entity; (c) The future generation of cryptocurrencies by the farm blockchain nodes may have ballast with proof of points generated by gamification and subsidize future exchanges for carbon credits; (d) RFID tests on large monoculture plots (soybeans, corn, and cotton) creating virtual fences inside the farm borders; (e) Future implementations to evaluate the model’s energy consumption, operating costs, including installation, maintenance, and monthly internet costs for the farmer; (f) The arrival of 5G in rural areas could be explored during future applications of the model. (g) An expansion of the questionnaire should be carried out after better post-Covid-19 pandemic conditions allow, including more farmers of other monoculture cultivars. (h) A battery of statistical tests on data communication within the model and its processing time.

The novelties features in APTM are:

- Scalability: This model allows the expansion and exchange of sensors at any time, including new sensors with other functionality.

- Expandability: Sensors can be installed at multiple data collection points, virtual machines can be cloned, and more blockchain nodes can be added to the reverse supply chain.

- Auditability: Data collections at tier two can be verified from dashboards at tier 4. Blockchain transactions can also be verified via tier 4. The processing characteristics of the Ethereum blockchain ensure the secure recording of transactions.

- Visibility: Adopting a services model allows future applications to connect to service ports to create new tier-four views.

- Predictability: Adopting machine learning will allow for future actions in crop planning by the farmer and several other AI services that can be added to tier three.

- Accessible: The choice of technologies adopted in the prototype was not proprietary, allowing implementations with the most various budget constraints to adopting the model.

Finally, we conclude that the APTM model is viable and can be extended to productive farms. The model can also be adapted to treat other sensitive and costly products such as fertilizers without further modification, which proves its adaptability and flexibility. The model can also be used on a large scale as services developed in tiers 2 and 3, i.e., it can be allocated to cloud processing service providers. This model serves any farm that uses costly and highly toxic agrochemicals which need monitoring.

Author Contributions

Conceptualization, E.S.M. and R.d.R.R.; methodology, E.S.M., R.d.R.R., J.L.V.B.; formal analysis, E.S.M., R.d.R.R., J.L.V.B., A.M.A.; investigation, E.S.M.; data curation, E.S.M., R.d.R.R., J.L.V.B., A.M.A.; writing—original draft preparation, E.S.M.; writing—review and editing, E.S.M., R.d.R.R., J.L.V.B., A.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was partially supported by the following Brazilian agencies: FAPERGS (project funding 17/2551-0001208-9).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Plourde, J.D.; Pijanowski, B.C.; Pekin, B.K. Evidence for increased monoculture cropping in the Central United States. Agric. Ecosyst. Environ. 2013, 165, 50–59. [Google Scholar] [CrossRef]

- Escobar, N.; Tizado, E.J.; Ermgassen, E.K.H.J.; Löfgren, P.; Börner, J.; Godar, J. Spatially-explicit footprints of agricultural commodities: Mapping carbon emissions embodied in Brazil’s soy exports. Glob. Environ. Chang. 2020, 62, 102067. [Google Scholar] [CrossRef]

- WHO; FAO. International Code of Conduct on Pesticide Management: Guidelines on Highly Hazardous Pesticides; World Health Organization: Geneva, Switzerland; Food and Agriculture Organization of the United Nations: Rome, Italy, 2016; p. 38. ISBN 978-92-4-151581-8. Available online: https://apps.who.int/iris/handle/10665/205561 (accessed on 2 June 2021).

- WHO; FAO. International Code of Conduct on Pesticide Management—Guidelines on Pesticide Legislation; World Health Organization: Geneva, Switzerland; Food and Agriculture Organization of the United Nations: Rome, Italy, 2015; p. 68. ISBN 978-924-150967-1. Available online: https://apps.who.int/iris/handle/10665/195648 (accessed on 2 June 2021).

- Chagnon, M.; Kreutzweiser, D.; Mitchell, E.A.D.; Morrissey, C.A.; Noome, D.A.; der Sluijs, J.P.V. Risks of large-scale use of systemic insecticides to ecosystem functioning and services. Environ. Sci. Pollut Res. 2015, 22, 119–134. [Google Scholar] [CrossRef]

- Bernardi, A.C.A.; Hermes, R.; Boff, A. Management and destination of agrochemicals packaging. Perspectiva 2018, 42, 15–28. Available online: https://www.uricer.edu.br/site/pdfs/perspectiva/159_719.pdf (accessed on 4 June 2021).

- Mattah, M.M.; Mattah, P.A.; Futagbi, G. Pesticide application among farmers in the catchment of Ashaiman irrigation scheme of Ghana: Health implications. J. Environ. Public Health 2015, 2015, 547272. [Google Scholar] [CrossRef] [PubMed]

- Azoulay, D.; Hughes, L.; Malkov, M.; Maxson, P.; Rucevska, I.; Speranskaya, O. The Illegal Trade in Chemicals; United Nations, Environment Programme UNEP and GRID: Arendal, Norway, 2019; p. 110. ISBN 978-92-807-3783-7. Available online: https://www.grida.no/publications/474 (accessed on 5 June 2021).

- Gupta, M.; Abdelsalam, M.; Khorsandroo, S.; Mittal, S. Security and Privacy in Smart Farming: Challenges and Opportunities. IEEE Access 2020, 8, 34564–34584. [Google Scholar] [CrossRef]

- Zikankuba, V.L.; Mwanyika, G.; Ntwenya, J.E.; James, A.; Yildiz, F. Pesticide regulations and their malpractice implications on food and environment safety. Cogent Food Agric. 2019, 5, 1. [Google Scholar] [CrossRef]

- Kumar, V.; Hallqvist, C.; Ekwall, D. Developing a Framework for Traceability Implementation in the Textile Supply Chain. Systems 2017, 5, 33. [Google Scholar] [CrossRef]

- Johann, D.; Guimarães, J.; Severo, E.; Duarte, N. Reverse Logistics of Pesticide Packaging: The Case of an Agroindustrial Cooperative. Sci. Initiat. Postgrad. Res. Ext. Show 2017, 6, 1–16. Available online: http://www.ucs.br/etc/conferencias/index.php/mostraucsppga/xviimostrappga/paper/view/5528 (accessed on 5 June 2021).

- Blankenburg, M.; Horn, C.; Krüger, J. Detection of Counterfeit by the Usage of Product Inherent Features. Procedia CIRP 2015, 26, 430–435. [Google Scholar] [CrossRef]

- Gai, K.; Fang, Z.; Wang, R.; Zhu, L.; Jiang, P.; Choo, K. Edge Computing and Lightning Network Empowered Secure Food Supply Management. IEEE Internet Things J. 2020, 9. [Google Scholar] [CrossRef]

- Rejeb, A.; Simske, S.; Rejeb, K.; Treiblmaier, H.; Zailani, S. Internet of Things research in supply chain management and logistics: A bibliometric analysis. Internet Things 2020, 12, 100318. [Google Scholar] [CrossRef]

- Hu, S.; Huang, S.; Huang, J.; Su, J. Blockchain and edge computing technology enabling organic agricultural supply chain: A framework solution to trust crisis. Comput. Ind. Eng. 2021, 153, 107079. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. J. Bus. Res. 2020, 122, 502–517. [Google Scholar] [CrossRef]

- Mukhamedjanova, K.A. Concept of supply chain management. J. Crit. Rev. 2020, 7, 759–766. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Shamsuddoha, M. Applying Reverse Supply Chain in the Poultry Industry (November 10, 2011). In Proceedings of the CGSB Research Forum: Emerging Research Initiatives and Developments in Business, Curtin Graduate School of Business, Perth, Australia, 24–25 March 2011; ISBN 978-0-9871089-0-6. [Google Scholar] [CrossRef][Green Version]

- Esmaelian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. J. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Majeed, A. Application of Agrochemicals in Agriculture: Benefits, Risks and Responsibility of Stakeholders. J. Food Sci. Toxicol. 2018, 2, 1. Available online: https://www.imedpub.com/articles/application-of-agrochemicals-in-agriculture-benefits-risks-and-responsibility-ofstakeholders.php?aid=23278 (accessed on 5 June 2021).

- Yusoff, N. Analysis on Local Food and Agrochemical Concept. Annu. Res. Rev. Biol. 2017, 13, 1–8. [Google Scholar] [CrossRef][Green Version]

- Apeh, C.C. Farmers’ Perception of the Health Effects of Agrochemicals in Southeast Nigeria. J. Health Pollut. 2018, 8, 180901. [Google Scholar] [CrossRef]

- Alsawaier, R.S. The effect of gamification on motivation and engagement. International J. Inf. Learn. Technol. 2018, 35, 56–79. [Google Scholar] [CrossRef]

- Sultan, K.; Ruhi, U.; Lakhani, R. Conceptualizing Blockchains: Characteristics & Applications. In Proceedings of the 11th IADIS International Conference on Information Systems, Lisbon, Portugal, 14–16 April 2018; ISBN 978-989-8533-74-6. [Google Scholar]

- Zhao, W.; Lv, J.; Yao, X.; Zhao, J.; Jin, Z.; Qiang, Y.; Che, Z.; Wei, C. Consortium Blockchain-Based Microgrid Market Transaction Research. Energies 2019, 12, 3812. [Google Scholar] [CrossRef]

- Dib, O.; Brousmiche, K.; Dur, A.; Thea, E.; Hamida, E. Consortium Blockchains: Overview, Applications and Challenges. Int. J. Adv. Telecommun. 2018, 11. Available online: https://hal.archives-ouvertes.fr/hal-02271063 (accessed on 6 June 2021).

- Kapsoulis, N.; Psychas, A.; Palaiokrassas, G.; Marinakis, A.; Litke, A.; Varvarigou, T.; Bouchlis, C.; Raouzaiou, A.; Calvo, G.; Escudero Subirana, J. Consortium Blockchain Smart Contracts for Musical Rights Governance in a Collective Management Organizations (CMOs) Use Case. Future Internet 2020, 12, 134. [Google Scholar] [CrossRef]

- Van den Berg, H.; Gu, B.; Grenier, B.; Kohlschmid, E.; Al-Eryani, S.; da Silva Bezerra, H.S.; Nagpal, B.N.; Chanda, E.; Gasimov, E.; Velayudhan, R.; et al. Pesticide lifecycle management in agriculture and public health: Where are the gaps? Sci. Total. Environ. 2020, 742, 140598. [Google Scholar] [CrossRef] [PubMed]

- Imbault, F.; Swiatek, M.; de Beaufort, R.; Plana, R. The green blockchain: Managing decentralized energy production and consumption. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Milan, Italy, 6–9 June 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Silva, F.; Vaz, C.; Lezana, A. Green Supply Chain Management and Reverse Logistics: A Systematic Review of Articles. Exacta 2020, 18, 686–707. Available online: https://periodicos.uninove.br/exacta/article/view/8457 (accessed on 8 June 2021). [CrossRef]

- Bendavid, Y.; Lefebvre, É.; Lefebvre, L.; Fosso-Wamba, S. Key performance indicators for the evaluation of RFID-enabled B-to-B e-commerce applications: The case of a five-layer supply chain. Inf. Syst. Bus. Manag. 2009, 7, 1–20. [Google Scholar] [CrossRef]

- Tyagi, R.K.; Dhanda, K.K.; Young, S. An Operational Framework For Reverse Supply Chains. Int. J. Manag. Inf. Syst. 2012, 16, 137–150. [Google Scholar] [CrossRef][Green Version]

- Kristoffersen, P.; Rask, A.M.; Grundy, A.; Franzen, I.; Kempenaar, C.; Raisio, J.; Schroeder, H.; Spijker, J.; Verschwele, A.; Zarina, L. A review of pesticide policies and regulations for urban amenity areas in seven European countries. J. Weed Res. 2008, 48, 3. [Google Scholar] [CrossRef]

- Huici, O.; Skovgaard, M.; Condarco, G.; Jørs, E.; Jensen, O. Management of Empty Pesticide Containers—A Study of Practices in Santa Cruz, Bolivia. Environ. Health Insights 2017, 11, 1178630217716917. [Google Scholar] [CrossRef]

- Zhao, F.; Guo, X.; Chan, W.K. Individual Green Certificates on Blockchain: A Simulation Approach. Sustainability 2020, 12, 3942. [Google Scholar] [CrossRef]

- Granlie, M.; Hvolby, H.; Cassel, R.A.; Paula, I.C.; Soosay, C. A Taxonomy of Current Literature on Reverse Logistics. IFAC Proceedings Volumes. In Proceedings of the 11th IFAC Workshop on Intelligent Manufacturing Systems, São Paulo, Brazil, 22–24 May 2013; Volume 46, pp. 275–280. [Google Scholar] [CrossRef]

- Fuertes, G.; Soto, I.; Carrasco, R.; Vargas, M.; Sabattin, J.; Lagos, C. Intelligent Packaging Systems: Sensors and Nanosensors to Monitor Food Quality and Safety. J. Sens. 2016, 2016, 4046061. [Google Scholar] [CrossRef]

- Sila-Nowicka, K.; Thakuriah, P. Multi-sensor movement analysis for transport safety and health applications. Public Libr. Sci. 2019, 14, 1–28. [Google Scholar] [CrossRef] [PubMed]

- Michelucci, U.; Venturini, F. New Autonomous Intelligent Sensor Design Approach for Multiple Parameter Inference. Eng. Proc. 2020, 2, 96. [Google Scholar] [CrossRef]

- Min, H. Artificial intelligence in supply chain management: Theory and applications. Int. J. Logist. Res. Appl. 2010, 13, 13–39. [Google Scholar] [CrossRef]

- Sumer, M.; Aydin, C.H. Gamification in Open and Distance Learning: A Systematic Review. In Learning, Design, and Technology; Spector, M., Lockee, B., Childress, M., Eds.; Springer: Cham, Switzerland, 2018; pp. 1–16. ISBN 978-3-319-17727-4. [Google Scholar] [CrossRef]

- Kovacs, T.; Szilagyi, R.; Várallyai, L. Chapter 17—The role of gamification in sustainable agricultural higher education. In Bio-Economy and Agri-Production; Academic Press: Cambridge, MA, USA, 2021; pp. 279–288. ISBN 978-0-12-819774-5. [Google Scholar] [CrossRef]

- Wood, L.C.; Reiners, T. Gamification in logistics and supply chain education: Extending active learning. In Proceedings of the IADIS International Conference on Internet Technologies & Society 2012, Perth, Australia, 28–30 November 2012; ADIS Press: Berlin/Heidelberg, Germany, 2012. Available online: http://hdl.handle.net/10292/6202 (accessed on 6 June 2021).

- Michael, K.; McCathie, L. The pros and cons of RFID in supply chain management. In Proceedings of the International Conference on Mobile Business (ICMB’05), Sydney, Australia, 11–13 July 2005; pp. 623–629. [Google Scholar] [CrossRef]

- Zhanglin, G.; Xiaocui, Z. The application of RFID technology in the logistics supply chain. In Proceedings of the 2010 3rd International Conference on Computer Science and Information Technology, Chengdu, China, 9–11 July 2010; pp. 518–520. [Google Scholar] [CrossRef]

- Awan, F.M.; Saleem, Y.; Minerva, R.; Crespi, N. A Comparative Analysis of Machine/Deep Learning Models for Parking Space Availability Prediction. Sensors 2020, 20, 322. [Google Scholar] [CrossRef]

- Wu, Q.; Gao, T.; Lai, Z.; Li, D. Hybrid SVM-CNN Classification Technique for Human–Vehicle Targets in an Automotive LFMCW Radar. Sensors 2020, 20, 3504. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.-Y.; Raihany, U.; Kuo, S.-W.; Chen, Y.-Z. Sound Detection Monitoring Tool in CNC Milling Sounds by K-Means Clustering Algorithm. Sensors 2021, 21, 4288. [Google Scholar] [CrossRef]

- FAO; WHO. International Code of Conduct on Pesticide Management—Guidance on Management of Household Pesticides; World Health Organization: Geneva, Switzerland; Food and Agriculture Organization of the United Nations: Rome, Italy, 2020; Available online: http://www.fao.org/3/cb1339en/CB1339EN.pdf (accessed on 10 June 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).