1. Introduction

A great deal of the applications in the modern industry is composed of electromechanical systems or kinematic chains that generally involve electrical rotating machinery. In fact, it has been reported by the International Energy Agency (IEA) that electric motors demand more than half of the global electricity [

1,

2]; additionally, it has been estimated that such electrical demand may grow approximately 2.1% per year. On the other side, it is expected that electric motors used in the industry will represent more than 30% of the total growth until 2040 [

2,

3]. In this regard, the Induction Motor (IM) is the most used electric machine in the industrial sector; although IM is included in a wide range of industrial applications due to its reliability, robustness, and efficiency, the occurrence of faults during its operation represents a critical issue since unexpected stoppages are produced and affect the efficiency of the production lines [

4,

5,

6]. Consequently, aiming to face these issues, the development of condition monitoring strategies focused on fault detection and identification in IM, and its linked components, is being one of the priorities addressed by new research works.

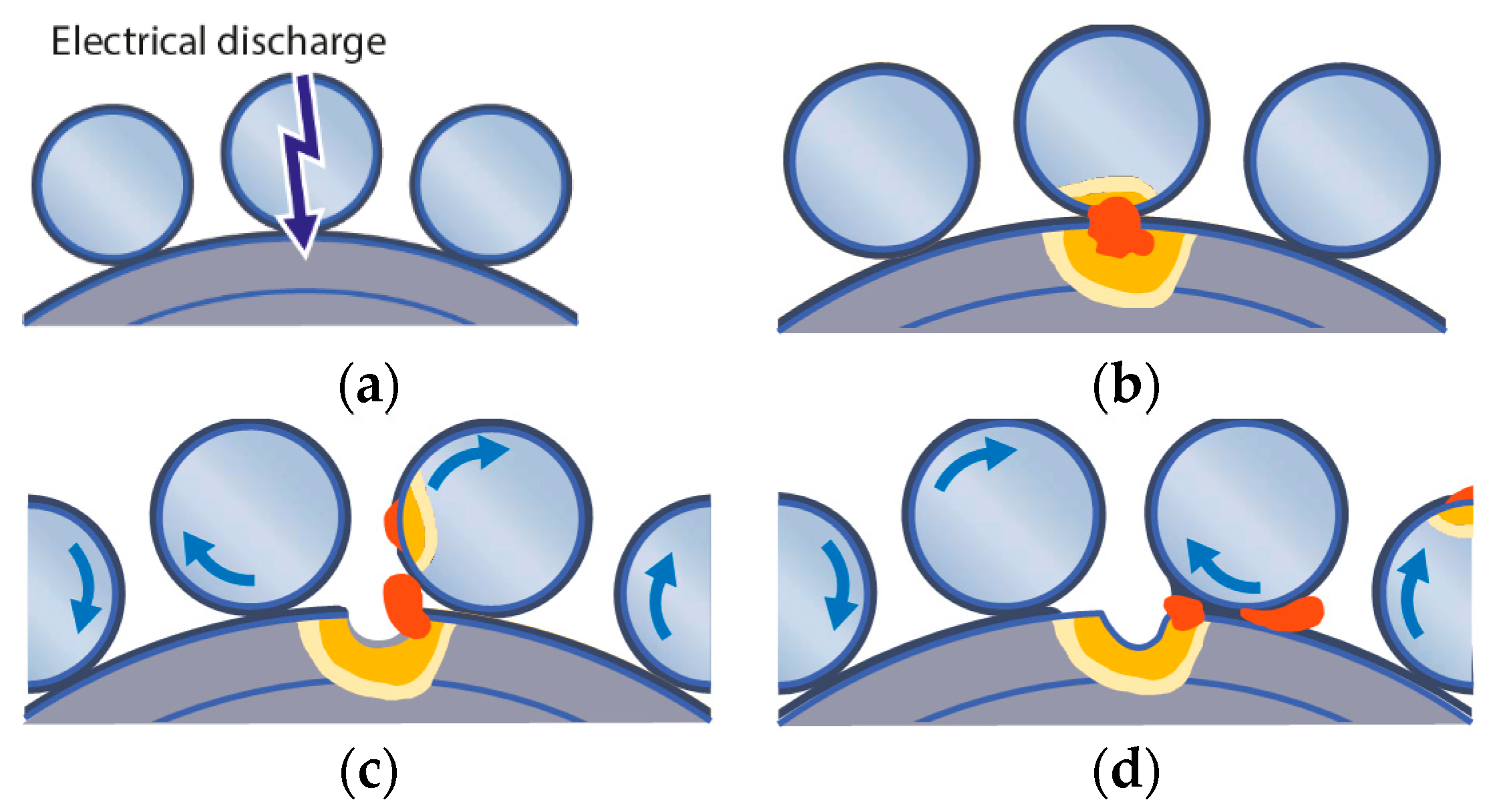

The IM faults occurrence is commonly produced by electrical or mechanical stresses that finally produce damages over the mechanical or electrical parts of the IM. Thus, within the most common faults that influence the IM operation are those damages that affect the stator, rotor, and the bearing elements [

7,

8,

9]; specifically, the occurrence of faults in IMs is mainly associated with these elements (stator, rotor, and bearings) representing around 32%, 10%, and 40%, respectively [

10,

11]. That is, a high percentage of fault occurrence in IMs is produced by its associated bearings; consequently, bearings play an important key role that may affect the operation, reliability, and efficiency of IMs. As it has been reported in the literature, bearings have finite life that is limited by their resistance to fatigue; thus, the occurrence of faults is inherent to its operation, even under ideal operating conditions [

12,

13]. In this sense, most of the common faults in bearing may be attributed to the following causes: (i) overload, which may be generated by static load and/or unbalances or misalignments; (ii) excessive or insufficient lubrication; (iii) external contamination; (iv) inappropriate installation and/or design; and (v) electrical discharges passing through the bearing [

14,

15]. Hence, electrical discharges are considered one of the most critical causes that may produce the gradual degradation of bearings in IMs.

A large number of diagnosis strategies have been proposed and focused on the identification and diagnosis of bearing failures, where the acquisition of different signals such as the occurrence of vibrations, stator current signatures, voltages, temperatures, and thermal imagining have been analyzed aiming to provide the condition assessment of bearings [

16,

17,

18,

19]. Despite different signals may be analyzed to achieve the fault diagnosis in bearings, the vibrations signals remain the most preferred that has been accepted by the industrial sector [

5,

20,

21]. In this regard, in [

22], a diagnosis strategy to identify impulsive bearing failures from variable-speed vibrations by means of measuring the short-term spectral components from vibration signals is proposed; although effective results are obtained through the application of the method, additional knowledge is mandatory for setting the optimum parameters that are required for the considered techniques in order to obtain high-performance results. Similarly, in [

23], the combination of the spectral and permutation entropy of vibrations signal for assessing different types of damage on bearings during low-speed conditions is analyzed; despite different bearing conditions may be assessed, the proposed method seems to be designed to face the fault identification for specific operation conditions, such as continuous speed and load. On the other side, the identification of faults in bearings can be also performed through classical approaches based on MCSA (Motor-Current Signature Analysis); in this sense, in [

24], stator current-based bearing fault diagnosis using fractional wavelet denoising and deep learning algorithms is presented; although through the proposed method is possible to identify the damage of outer and inner races of bearings, the application of the methods is focused on the detection of a unique fault severity. Likewise, in [

25], a novel methodology for fault size estimation of ball bearings using stator current signals is proposed, where the fault-excited harmonic components and amplitudes in stator current are estimated, and the FHD (Fault-excited Harmonic Distortion) evaluated to achieve the fault size estimation. Even though different fault sizes can be detected, the estimation of undesired frequency components that may appear overlapped with the fault-related components may lead to infeasible detections. Therefore, the separate analysis of vibrations and stator currents may lead to the identification and detection of bearing damages, and the analysis of both signals present particular advantages that may contribute to improving the condition assessment of bearing faults if both signals are analyzed together. Although several works have been proposed to perform the bearing fault detection and diagnosis, some challenges still exist that have not been addressed in the field of bearing fault assessment, which are (i) the bearing fault detection from the viewpoint of severity detection has not been extensively studied; thus, the identification of fault graduality may be difficult whether physical magnitudes, such as stator current, show small changes and/or variations in amplitude, and (ii) the occurrence of bearing faults may be confused with other faulty components since fault-related patterns overlapping is a common effect in rotating machines.

Additionally, it must be mentioned that others have tried to overcome these challenges through ensemble learning, parallel Neural Networks, and transfer learning-based solutions; however, complex condition monitoring structures are needed to achieve good performance results. In this regard, for example, in [

26], a diagnosis method that first includes a higher-order spectral analysis and multitask learning-based convolutional neural network is proposed for the identification of the bearing health condition, and second, identifying bearing fault conditions by means of a transfer learning-based approach in the presence of multiple crack conditions. However, although this proposal leads to the efficient diagnosis of bearing faults, prior knowledge about the implementation and configuration of deep learning (DL) techniques is the main limitation to develop complex structures that are also based on ensemble learning approaches [

27]. Moreover, recent DL-based approaches have to overcome some challenges that must be avoided for practical applications. These limitations are: (i) the operation is limited to the amount of data that are not easy to obtain in industrial sites; (ii) difficulties and unclear understandable interpretation for practitioners; (iii) generalization-based approaches to avoid overfitted responses and solutions; and (iv) the strategical hyper-parameter tuning procedures to enable its easy access and configuration. Nevertheless, even though good performance results are obtained, the use of ensemble learning-based on DL results in a complicated task; thus, these challenges can be overcome by the proposal of strategies that incorporate proper processing techniques, i.e., analysis in the time-domain and frequency-domain, and by considering multiple signals that contain different information, but its fusion leads to highlighting those representative fault-related patterns.

Most of the proposed studies that have analyzed and identified the occurrence of faults in bearings are commonly focused on analyzing those faults that are related to the electrical erosion phenomenon [

13,

15,

28]. In this regard, in the research field, the faults produced by electrical erosion are artificially produced by drilling a hole in the outer race, inner race and/or by damaging the rolling elements of the bearing [

29,

30,

31]. Additionally, most of the times, the initial damage of bearings can start with small holes that may grow gradually until producing irreversible damages; thereby, the importance of studying the evolution of faults in bearings is an interesting topic that should continue to be studied. On the other side, it should be highlighted that most of the reported works in regard to the detection of different severities of bearing faults are validated under experimental datasets, where critical damages are produced on the bearing elements, i.e., excessive damages produced by drilling holes in the outer race with a diameter higher than 6 mm [

32]. During the analysis of the occurrence of bearing faults, it would be interesting to study the evolution of the fault occurrence, which is a more gradual effect that can happen in industrial environments.

The proposal of condition monitoring strategies have been supported by the use of different signal processing techniques that can be based on different domain analyses, i.e., time-domain [

33,

34], frequency-domain [

21], and time-frequency domain analysis [

35]. For the time-domain analysis, the estimation of statistical time-domain features is taken into account for many of the proposed diagnosis methods. Statistical time-domain features are preferred due to its simplicity of calculation and its effectiveness to model changes and trends of signals [

18,

33]. Despite that, most of the classical approaches aim to perform the diagnosis of bearing faults by carrying out the analysis of the characteristic fault-related frequency components through the FFT (Fast Fourier Transform) [

34]. Furthermore, although the analysis of the fault-related frequency components produced by bearing failures leads to achieving the occurrence of faults, additional knowledge and experience is necessary to distinguish between multiple frequency components that tend to appear as the fault-related frequency patterns. Additionally, time-frequency analysis represented by complex techniques, such as the Hilbert transform, has been included in condition monitoring strategies [

8]. In this regard, Artificial Intelligence (AI) algorithms and Machine Learning (ML) techniques have been also incorporated in condition-monitoring strategies; thus, diagnosis and classification structures can be based on Neural Networks (NNs), Support Vector Machines (SVMs), decision trees, among others, to achieve the automatic fault diagnosis [

16,

35,

36]. Conversely, the use of ML techniques is implemented as feature extraction and feature reduction techniques [

37]. Even heuristic search algorithms, such as Genetic Algorithms (GA), are also used in condition monitoring approaches to solve optimization problems that commonly focus on procedures to select those significant features [

38]. Accordingly, the consideration of both AI algorithms and ML techniques in condition monitoring strategies can lead to improve the resulting fault diagnosis; even more, if the proposal of condition monitoring methods is based on the fusion of information.

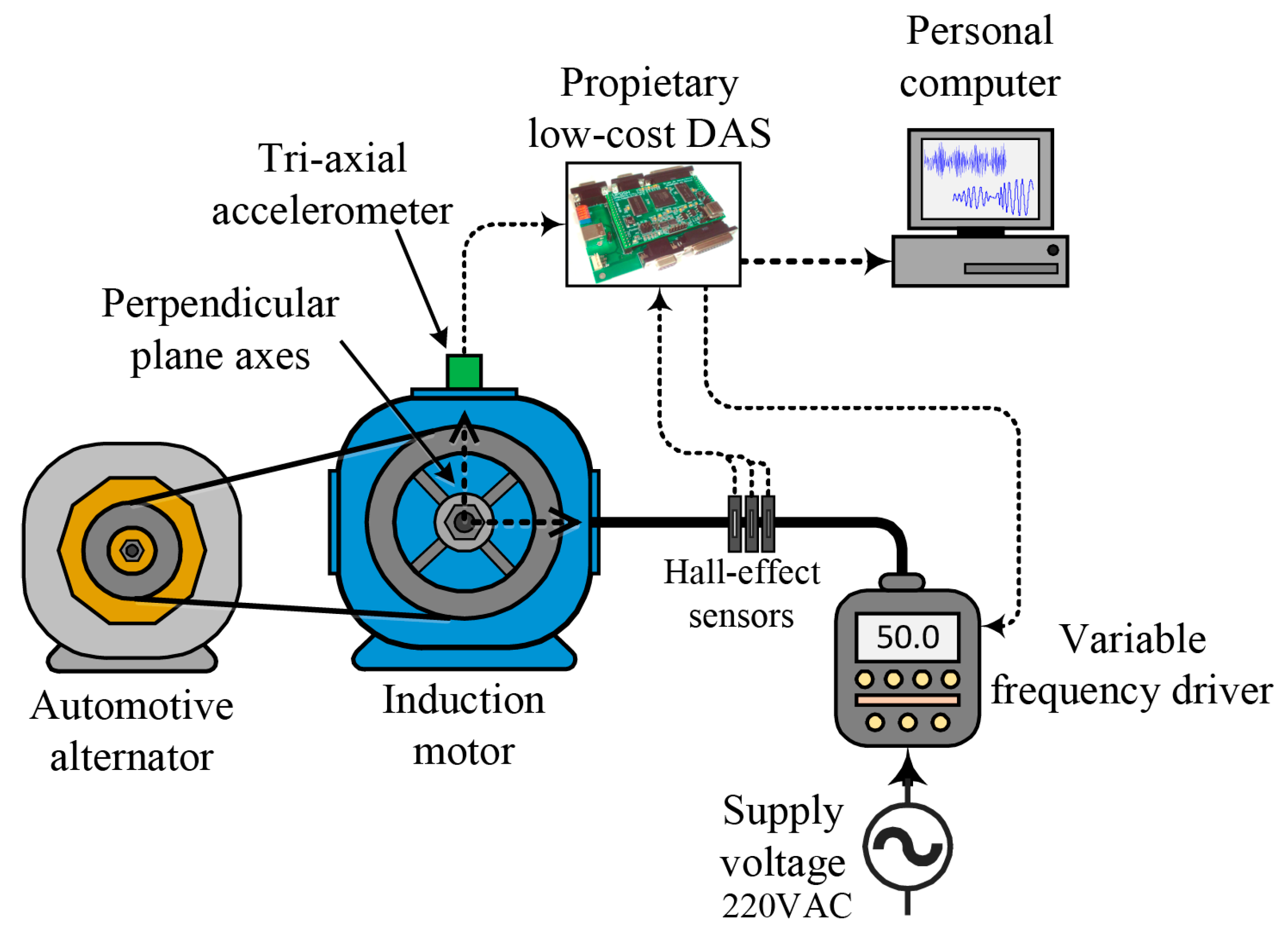

Bearings are the elements that allow the rotating movement in rotating machines, and the sudden occurrence of faults is inherent to its operation. Additionally, the occurrence of faults in bearings may initially occur by its degradation, and then, several damages may appear over the inner race, outer race, and the balls of the bearing. Thus, there are different fault severities that occur from the initial failure to its most critical degree. In this regard, a condition monitoring methodology designed for identifying different severities of the outer race bearing fault in an IM is proposed in this work. The proposed method is supported by tools, such as Machine Learning (ML) techniques and Artificial Intelligence (AI), that facilitate the fusion information of different physical magnitudes. Indeed, the contribution and novelty of this proposal include the processing of different signals through different domain analyses, that is, the time-domain and frequency-domain. In fact, an important aspect of this approach is the calculation of statistical features that are obtained to characterize the acquired vibration and stator current signals; the estimation of statistical features in different domain analyses leads to a high-performance signal characterization. Additionally, the fusion of vibrations with stator current information is carried out by subjecting their characteristic statistical features to a dimensionality reduction procedure. Thereby, the dimensionality reduction is achieved by the LDA, which is classic technique that leads to achieve the maximum linear separation between multiple classes and allows the visual representation into a 2D space. Finally, the automatic diagnosis and fault severity identification is performed through a classical NN-based classifier. The proposed method is validated under a complete set of experimental data that was acquired from a self-designed test bench. Moreover, the effectiveness of this proposal is proved since six different bearing conditions are effectively diagnosed and identified. The assessed conditions comprise a healthy condition and five different severities of fault that appear in the outer race of a bearing with a damage of 1 mm, 2 mm, 3 mm, 4 mm, and 5 mm, respectively.

3. Proposed Method

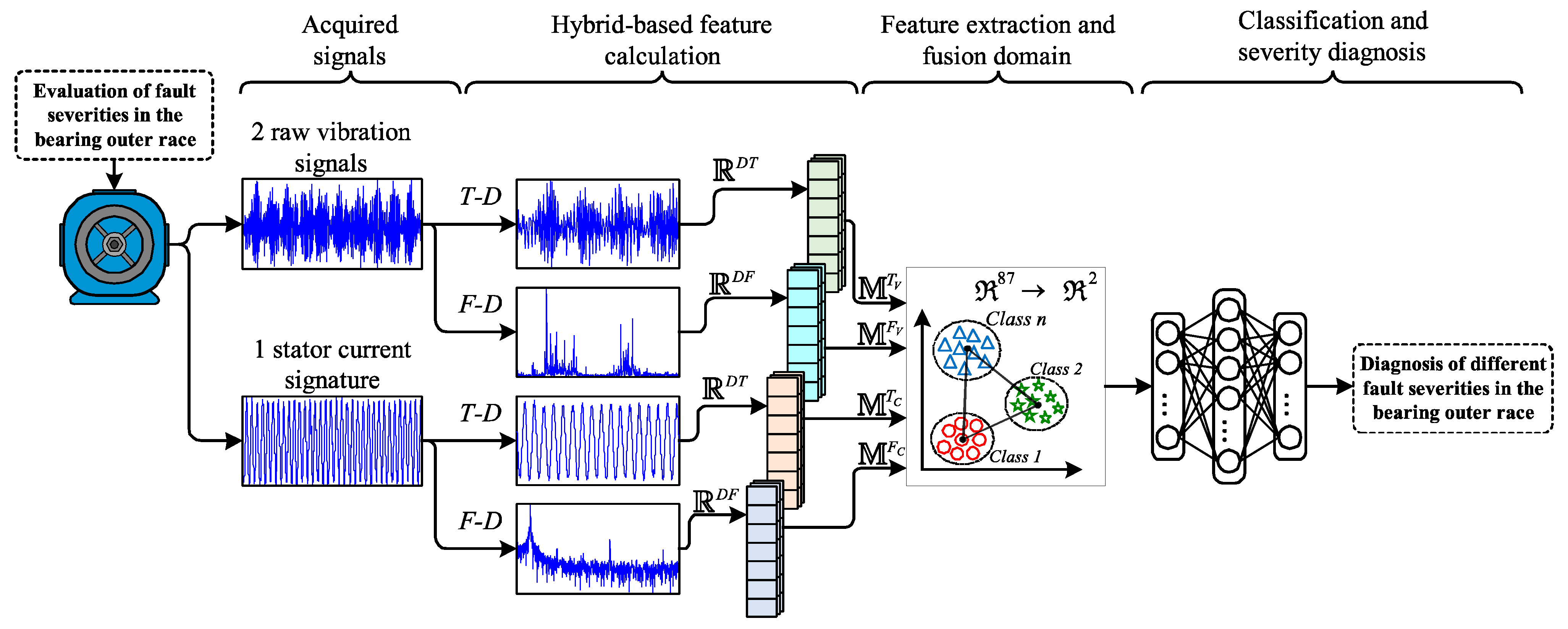

The proposed condition monitoring method for the detection of different fault severities in the outer race of bearings is based on the flowchart in

Figure 2. The assessment of different fault severities in the outer race of bearings is carried out by characterizing the available physical magnitudes, vibrations, and stator current through the estimation of a significant set of hybrid features that include statistical features from different domains. Moreover, the information fusion and data compression are considered fundamental parts of the proposed method. In this sense, the estimated hybrid features are fusioned and represented in a 2-dimensional space by means of applying one of the most well-known machine learning techniques, the LDA. Finally, the automatic assessment and detection of different fault severities on the outer race bearing of an IM are achieved by means of an NN-based classifier. The diagnosis methodology is proposed by following a step-by-step scheme that allows its practical application over electromechanical systems that are related to rotating machinery, such as IM, gearboxes, shafts, among others. Under this consideration, the proposed diagnosis methodology represents an approach that leads to the characterization of the bearing operation and its posterior recognition.

3.1. Hybrid-Based Feature Calculation

The proposed method supports different or multiple physical magnitudes, despite vibration signals being the most preferred physical magnitude to diagnose the fault occurrence in bearings. In this proposal, the processing of different signals to achieve an improved characterization of the electromechanical system condition is considered, which, in turn, is related to the bearing condition. Thus, in the first stage, the three available signals (two vibration signals and one stator current) are characterized with the aim of computing a meaningful set of hybrid features. Subsequently, the processing of the available signals is carried out in two domains, that is, the time-domain (TD) and frequency-domain (FD). During the characterization procedure, the acquired signals are segmented into equal parts of one second; the consideration of this temporal period guarantees sufficient statistical consistency in most of the practical applications.

In this regard, for the TD analysis, the available signals are characterized by estimating a set of T = 15 statistical features, and as a result, two representative T-dimensional feature matrices are obtained from the considered signals. Thereby, the characteristic feature matrix in the TD for the vibrations signals is and for the stator current is , where T ∈ ℝT. On the other side, for the FD analysis, from each segmented part of the available signals, its corresponding frequency spectrum is computed through the classical application of the FFT technique. Subsequently, from each achieved frequency spectrum for each considered signal, a set of F = 14 statistical features is estimated aiming to obtain a numerical representation of the previously estimated frequency spectra. After applying the FD analysis, two significant F-dimensional feature matrices are obtained separately for the vibration signals and the stator current. The characteristic feature matrices in the FD are for vibrations and for stator current, where F ∈ ℝF.

The characterization of signals by means of its processing through different domain analyses, such as TD and FD, allows improving the characterization of the fault-related patterns because it has been proved to ensure that promising results are achieved in the condition assessment when a meaningful set of hybrid features is estimated. Regarding the statistical features that are proposed to be estimated during the processing of the vibration and stator current signals in TD and FD analyses, the corresponding mathematical equations of the proposed sets of statistical features are summarized in

Table 1 and

Table 2; these proposed sets of features have been usually considered in several condition monitoring approaches [

33,

34,

35]. Thus, the statistical features computed in the TD are represented by Equations (3)–(17), while those computed in the FD are represented by Equations (18)–(30). The estimation of these sets of statistical features provides several advantages in condition monitoring strategies, that is, high-performance signal characterization due to its ability of modeling trends and changes in signals when its estimation is performed in TD, whereas the calculation of statistical features in FD allows modeling changes in the main frequency components with a high convergence to the power spectrum. Furthermore, in regard to the computational burden, the easy computation of statistical features shows an advantage over other complex signal processing, such as DWT and MUSIC, among others [

10,

21].

3.2. Feature Extraction and Fusion Domain

The second stage of the proposed method is focused on performing the information fusion and data compression by means of the LDA technique. In this sense, it must be highlighted that the evaluated condition is represented by the available signals that are characterized by a high-dimensional set of hybrid features, where this meaningful set of features comprises the characteristic patterns of the available signals that are processed in different domains. Even though the characterization of signals through a hybrid set of features leads to a high-performance characterization in condition monitoring strategies, the estimation of correlated and non-useful information is inevitable even if complex signal processing is implemented.

In this regard, the LDA technique is applied over all the resulting feature matrices (, , , and ) estimated from analyzing the vibration and stator current signals in two different domains, TD and FD. The main objective of the LDA is reducing the original high-dimensional space of the hybrid set of features into a low-dimensional space, where the features of the hybrid set are fusioned during the dimensionality reduction procedure. The information fusion and/or feature fusion is symbolized by the linear combination, in different weights, of the original set of features (high-dimensional set of hybrid features) that is intended to be projected into a new and reduced dimensional space (i.e., 2D or 3D spaces). The new resulting features projected in the new reduced space are also known as the extracted features.

Consequently, the fusion of vibrations and the stator current is represented by the new extracted features, and the resulting projection contains the fusion of information provided by statistical features estimated from different signal processings in both domains, TD and FD. On the other hand, the LDA is a suitable machine learning technique to be applied in condition monitoring methodologies due to the projection of the extracted features into a 2D space allows the visualization of all considered conditions. Additionally, it may deal with multi-class problems, but this peculiarity is an advantage since the LDA may maximize the linear separation as much as possible between clusters of different classes.

3.3. Classification and Severity Diagnosis

Finally, in the third stage, the automatic fault detection and severity diagnosis by means of a classical NN-based structure are performed. It should be highlighted that an interesting advantage of the proposed hybrid-based feature calculation in conjunction with the feature extraction and fusion domain is that it leads to a reduction in the complexity related to the configuration of the required classification algorithm; that is, a high-performance pattern characterization of the considered conditions is achieved facilitating the classification task.

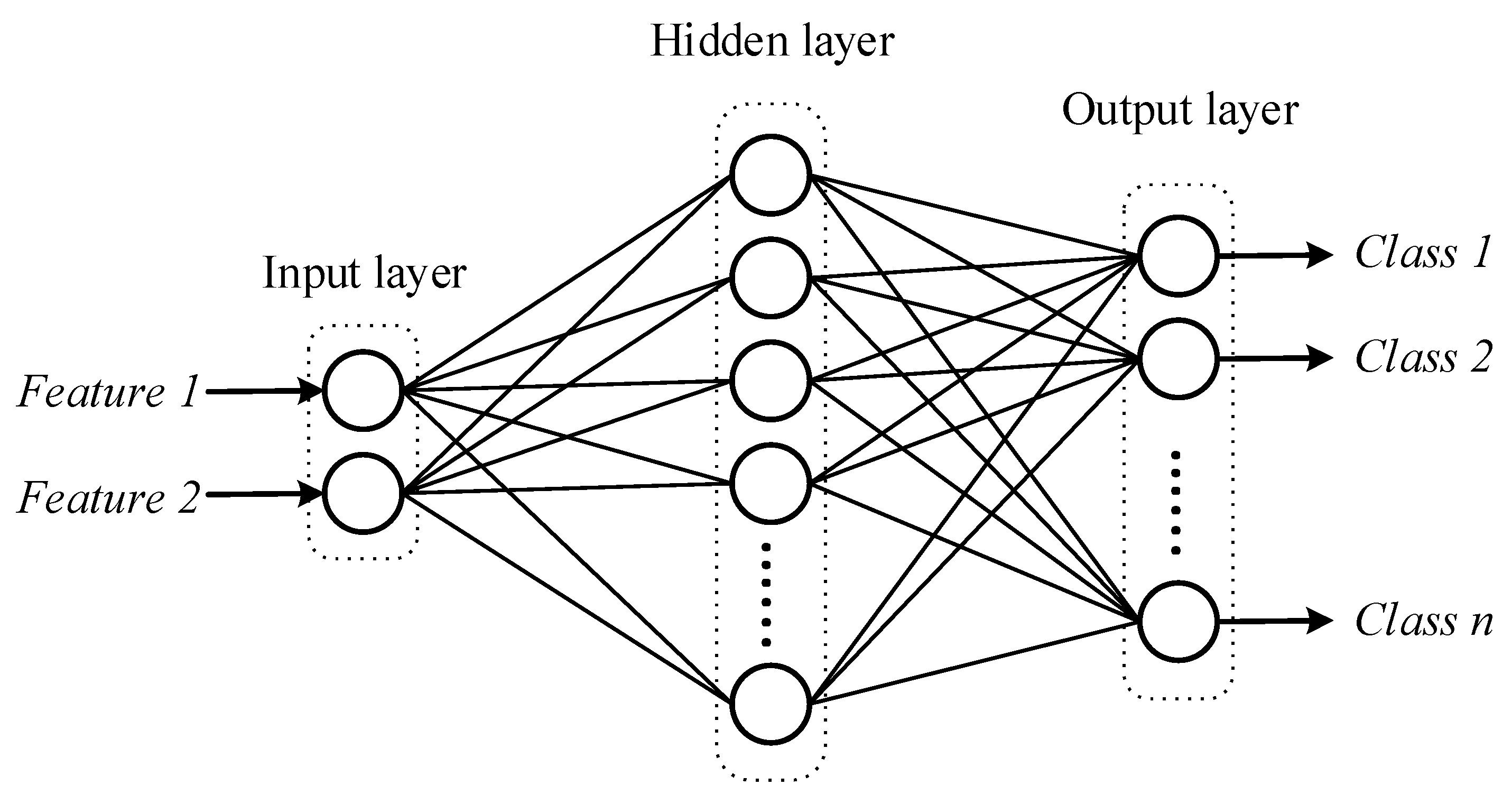

In this regard, the following parameters are taken into account for the proposed NN-based classifier: (i) the structure consists of a simple multi-layer NN that comprises three-layers: the input, hidden, and output layers; (ii) the number if neurons for each layer are defined as two, ten, and six neurons for the input, hidden, and output layer, respectively; (iii) the backpropagation is used as the training algorithm; (iv) the sigmoid function is used as the activation function; (v) 50 epochs are the number of iterations. Specifically, the number of neurons considered in the input layer is equal to the number of features extracted by means of the LDA technique, and for this proposed work, the features extracted by the LDA are represented in a 2D space. For the hidden layer, the number of neurons is fixed to ten neurons, which have been defined by following the literature suggestions [

43,

44]. Such literature suggestions are supported by the results obtained in practices of performance analysis based on trial and error for the selection of the number of neurons in the hidden layer [

45]. In the output layer, a number of neurons equal to six are considered, where each neuron considered in the output layer represents each one of the evaluated conditions that are associated to a particular fault severity in the outer race of bearings. Moreover, it should be mentioned that the proposed NN-based classifier is trained and tested under a

k-fold cross-validation scheme to obtain statistical and significant results. During the training and testing of the NN-based classifier, the sigmoid function is used as the activation function, and the backpropagation is used as the training algorithm during 50 epochs. Additionally, even though optimization algorithms can be optionally used to improve the performance of some NN-structures during the training procedure. The proposed multi-layered NN-based classifier is not supported by any optimizer algorithm since it is a simple multi-layer construction. In

Figure 3, the structure of the proposed multi-layer NN-based classifier is shown.

5. Results and Discussions

To validate the effectiveness of the proposed method in front of the diagnosis and detection of the different severities of bearing faults, the method is applied to the available signals that are acquired from the pulley-belt electromechanical system; such signals are the two vibration signals and the stator current signature. Hence, as described in

Section 3.1, these signals were acquired during 150 s of the continuous operation of the IM, and its processing is carried out under Matlab, which is a dedicated software used in a great deal of engineering applications. According to the proposed method, each one of the acquired signals is segmented into equal 1-second parts to generate a consecutive set of samples; afterward, the multi-domain analysis is performed over each one of the segmented parts of the signals to perform the signal characterization in two different domains, that is, DT and DF. Moreover, the proposed multi-domain analysis leads to achieve high-performance characterization of the electromechanical system operation, which, in turn, is associated with the different bearing conditions.

In this regard, for the TD analysis, the set of 15 statistical features is computed from each segment of each available signal; thus, for both vibration signals, a feature matrix with 30 statistical features and 150 samples (dim() = (150 × 30)) is achieved; meanwhile, the feature matrix achieved from the stator current consists of 15 statistical features with 150 samples (dim() = (150 × 15)). On the other hand, in the FD analysis, from each segmented part of each available signal, the corresponding frequency spectrum is estimated by means of applying the FFT technique, and then, from each resulting spectrum, the set of 14 statistical features is calculated to characterize each corresponding spectrum into a set of representative numerical values. Thereby, for both vibrations signals analyzed in FD, a feature matrix with 28 statistical features and 150 samples (dim() = (150 × 28)) is computed; whereas, for the analysis in FD of the stator current signature, a characteristic feature matrix that contains 14 statistical features with 150 samples (dim() = (150 × 14)) is achieved. Consequently, for each evaluated condition, a high-dimensional set of hybrid features that contain the characteristic patterns is computed. The high-dimensional set of hybrid features includes the four representative feature matrices: , , and , which are estimated after analyzing each one of the available signals in two different domains (TD and FD). Hence, the resulting dimension by concatenating the features matrices consist of 87 statistical features in TD and FD with 150 consecutive samples (dim([, , , ]) = (150 × 87)). Additionally, it should be clarified that these representative feature matrices are estimated for each one of the considered conditions that is experimentally tested under the considered supply frequencies fixed in the VFD (5 Hz, 15 Hz, and 50 Hz).

In order to carry out the information fusion and data compression, the high-dimensional set of hybrid features are subjected to the feature extraction procedure by means of applying the LDA technique. In this sense, the whole resulting feature matrices, considering all supply frequencies and all bearing conditions, are concatenated, as shown in

Table 3. From

Table 3, it must be noted that all considered conditions, HC, S1, S2, S3, S4, and S5, are concatenated as row elements, where each condition includes its corresponding feature matrices achieved by analyzing the vibration signals in TD and FD,

and

, respectively, and also includes its corresponding feature matrices achieved by analyzing the stator current signature in TD and FD,

and

, respectively. In regard to the domain of analysis, the resulting feature matrices are concatenated as column elements, as shown in

Table 3. Additionally, for the different values of supply frequency, each tested condition includes the corresponding feature matrices that are particularly estimated from the vibrations and stator current signals when the frequencies in the VFD are set to 5 Hz, 15 Hz, and 50 Hz. Such supply frequencies are addressed in

Table 3 as @5 Hz, @15 Hz and @50 Hz, respectively.

Subsequently, the LDA technique is applied over all concatenated matrices, aiming to perform the fusion of information, that is, the fusion of statistical features estimated from multiple signals analyzed in both domain analyses, DT and DF. The information fusion stage is achieved because the LDA is based on a linear transformation that projects the information of the original feature space (87-dimensional space) into a new and reduced feature space (2-dimensional space). The resulting projection symbolizes the linear combination, in different weights, of the original set of features (high-dimensional set of hybrid features), where the most representative information of all considered features is retained. In fact, those features that have a high weight, in the linear combination, have a high influence over the resulting projection. In contrast, those insignificant features may have a lower influence and a low weight that does not have significant influence over the resulting projection.

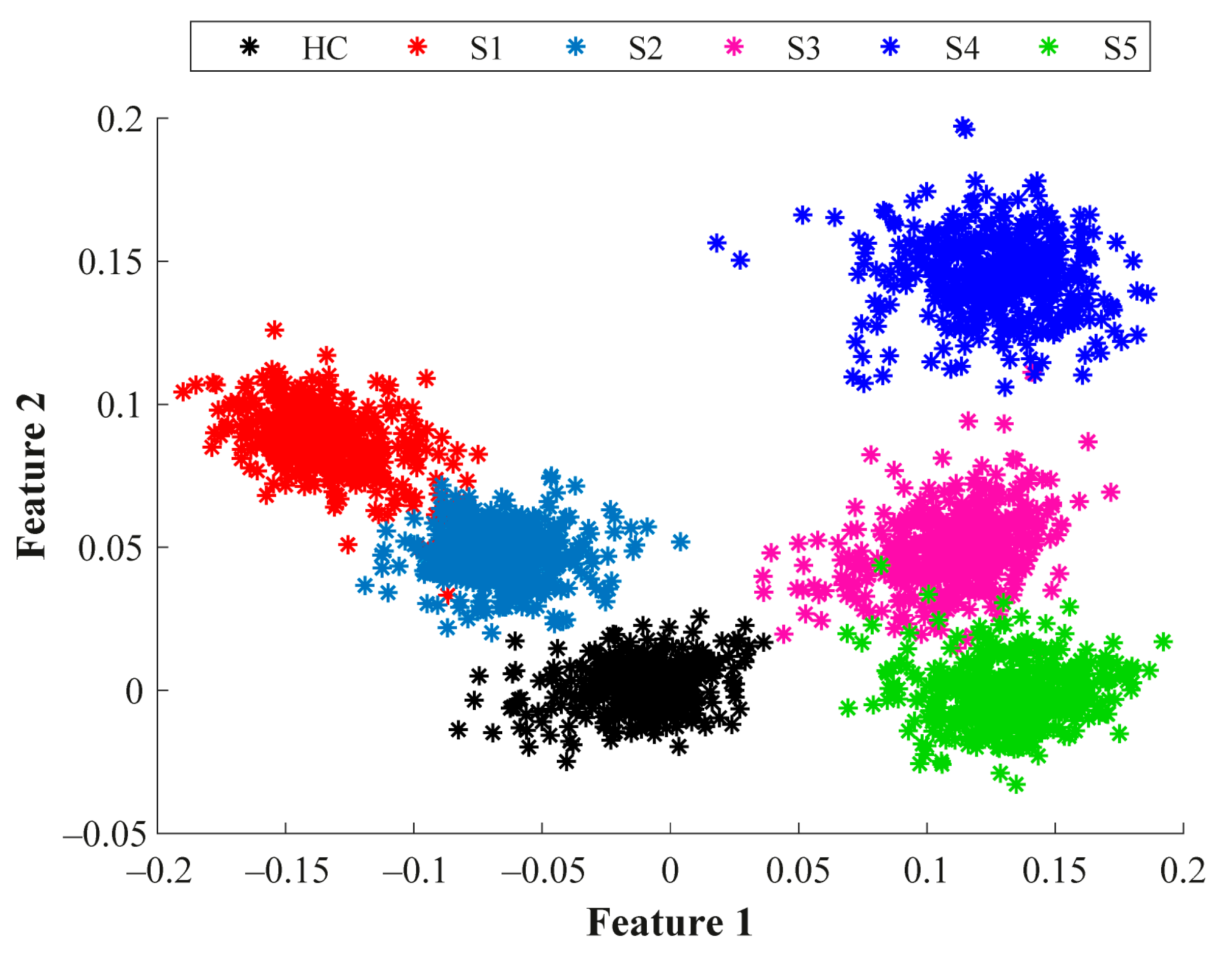

After applying the LDA technique over the hybrid set of features of all considered conditions, the original 87-dimensional feature space is projected into a 2-dimensional space, where the projected features belong to the new set of extracted features. In

Figure 6, a visual representation of the new extracted features achieved by means of the LDA technique is shown. From this resulting projection, it can be appreciated that different clusters appear separated between them; each cluster represents each one of the considered conditions evaluated under different operating supply frequencies (5 Hz, 15 Hz, and 50 Hz). Moreover, although the clear separation between all considered conditions is desired, a slight overlapping appears between the conditions S3 and S5; such overlapping may lead to achieving a lower performance of classification performance during the condition assessment. However, on the other hand, it should be highlighted that the HC is well separated from all faulty conditions, and this fact results in avoiding false negatives during the condition assessment, which is an advantage because the proper working condition of rotating electrical machines is assured. From the obtained projection of

Figure 6, it must be highlighted that the proposed signal characterization by means of the statistical features estimated from different signals in different domains, and its fusion and compression through the LDA can lead to a wide range of operating frequencies that, in industrial environments, cover the common ranges of rotating speeds for any considered electrical machine.

Previous to the application of the automatic diagnosis and severity detection, aiming to emphasize the effectiveness of the proposed method in regards to the consideration of different signals and in regards to their processing in different domains, in

Figure 7a,b the qualitative representations are shown, which were achieved by means of a PCA projection over the representative feature matrices estimated from analyzing the vibrations signals in both domains, TD and FD, respectively. In both resulting projections, the data distributions of all considered conditions can be appreciated, and from

Figure 7a,b, it can be also seen that the characterization of vibration signals in the TD may contribute to the separation of the S2, S3, S4, and S5 conditions. Conversely, the characterization of the vibrations signals through the FD leads to the separation of S1, S2, S3, and S4 conditions. Therefore, the fusion of the information calculated from different signals and different domains will improve the contribution in the face of the separation of the considered conditions.

Subsequently, the automatic condition assessment and fault severity identification is carried out by means of the proposed NN-based classifier; thereby, the new features extracted by the application of the LDA are evaluated through the proposed classifier. As mentioned previously, the NN-based structure consists of three layers, where the input, hidden, and output layers have a number of neurons defined as 2, 10, and 6, respectively. Additionally, the NN-based classifier is trained and tested under a

k-fold cross-validations scheme with a number of

k = 5 folds, and the NN is trained and tested during 50 epochs through a probabilistic sigmoid function that is used as the activation function. Hence, each considered condition is represented by a total number of samples equal to 450, from which 360 samples are used for training purposes and the remaining 90 samples are used for validation purposes. As a result, during the training and validations of the proposed NN, global classification ratios around 98.9% and 98.7% are achieved, respectively. In

Table 4, the confusion matrix that summarizes the individual classification scores performed by the NN-based classifier is shown. As can be seen, most of the misclassifications are between faulty conditions, which proves that the prediction of false negatives is avoided.

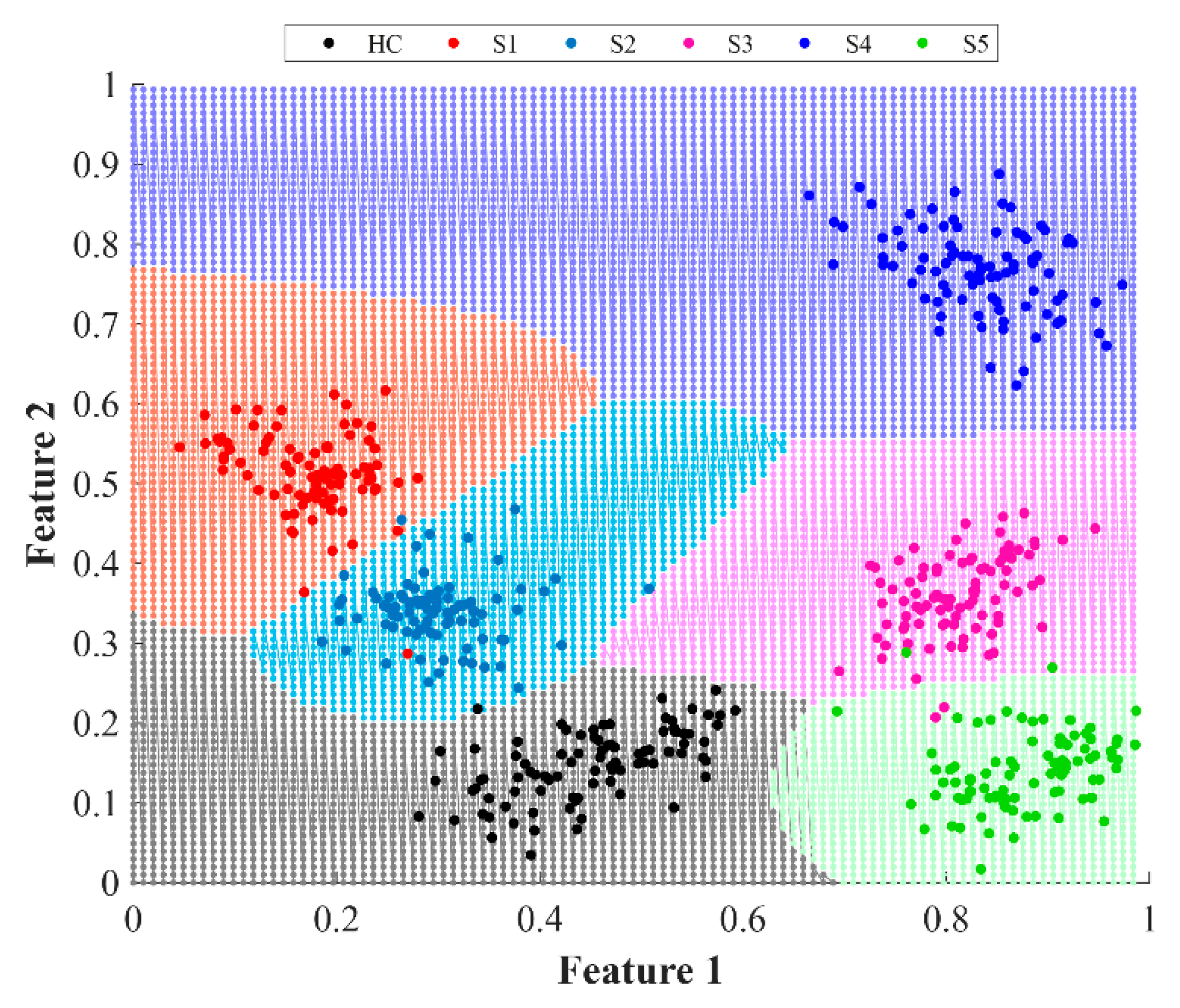

Additionally, for the training of the NN-based classifier, the decision regions of all considered conditions are modeled and estimated to be projected over a 2D plane. Subsequently, in

Figure 8, the resulting decision regions is shown, and over these regions, the set of samples that have been considered during the validation process are projected. On the other side, the associated diagnosis probability can also be estimated for those samples that are associated with misclassification problems, and the analysis of such associated diagnosis probability may lead to a re-classification by assigning its appropriated true class.

6. Conclusions

Most industrial machines are based on electromechanical systems or kinematic chains that are mainly driven by electrical rotating machines, such as IMs, where bearings are the elements that allow its rotating movement, and the sudden appearance of faults is inherent to its operation. In this regard, in this work, a condition monitoring methodology designed for identifying different severities of the outer race bearing fault in an IM is proposed. The proposed method is supported by tools, such as Machine Learning (ML) techniques and Artificial Intelligence (AI), that facilitates the fusion information of different physical magnitudes and that leads to high-performance pattern characterization. Specifically, this work proposes the fusion information of different physical magnitudes, such as vibrations and stator current, which are characterized through a hybrid set of statistical features that is estimated by the signal processing in two different domains: the time-domain and frequency-domain. This proposal aims to promote the detection of different fault severities in the outer race of a bearing can be effectively performed by the use of multiple physical magnitudes, such as vibrations and stator current, that are processed in multiple domains, leading to high-performance signal characterization. In fact, the detection and evolution assessment of incipient faults that appear in bearings can be a complex task since the fault-related patterns may not show significant changes compared to when several damages are induced; that is, the identification of fault graduality may be difficult whether physical magnitudes, such as stator current, show small changes and/or variations in amplitude. Thus, the main contributions of this work include the use of different physical magnitudes for estimating the characteristic patterns associated to the bearing condition; indeed, the estimation of statistical features through different domain analyses results in high-performance signal characterization. Moreover, the use of ML techniques, such as the LDA, allows performing the fusion of information because the compression and reduction of information is carried out by mapping, with different weights, the original feature space into a new space of lower dimension (i.e., 2D). Consequently, the characterization of vibration and stator current signal through statistical features from different domains, together with its fusion through the LDA technique, facilitates the classification task performed by the NN-based classifier. In this regard, it is proved that, by means of the proposed method, a global classification ratio higher than 98.7% is obtained during the diagnosis of different fault severities that may appear in the bearing outer race. On the other side, the proposed approach presents a coherent design of the structure that includes Machine Learning and Artificial Intelligence that, in comparison with other related works that propose ensemble learning structures based on Deep Learning, allows correctly identifying different severities in the outer race of bearings. Moreover, it should be highlighted that this proposed methodology has been designed to overcome and face the occurrence of unexpected faults that may appear insignificant but may gradually increase until producing irreversible damages. The proposed method is validated under a complete set of experimental data that considered a healthy condition (HC) and five severities in the outer race of a bearing (S1, S2, S3, S4, and S5). For future work, the analysis of the remaining useful life remains a research topic that must be addressed, and the analysis of combined faults that may occur simultaneously in different parts of bearings also needs to be addressed. Additionally, it has been detected that the proposal of condition monitoring strategies that may be capable of assessing the bearing condition independently of the bearing technology, i.e., metallic, hybrid, and full ceramic bearings, is also necessary. The obtained results make the proposed method suitable for application to condition assessments of machinery involved in industrial applications.