Abstract

It is usually difficult to design a controller for a nonlinear multiple-input and multiple-output (MIMO) system. The methodological approach taken in this study is a mixed methodology based on a PID-type internal model control (IMC) method and neural network (NN) optimization algorithm. The NN controller is designed for adjusting the sole parameter in IMCPID and compensating the characteristic changes and non-linearity in stepless flow control. In this study, a simulation of a nonlinear MIMO system with strong coupling is carried out. The simulation results indicate that the proposed control method has a better performance in settle time, overshoot, robustness and set-point tracking accuracy compared with other considered methods.

1. Introduction

Reciprocating compressors are widely used in some industrial fields such as petroleum, chemical, natural gas transportation and so on. It is the main power-consuming equipment in industrial factories and it is usually run at factory setting. However, in some conditions, the outlet flow of compressors needs to be regulated with the real-time demand of the downstream production process. Therefore, it is necessary and meaningful to control the outlet flow of compressors. Many approaches have been proposed, and the by-pass regulation is the simplest and most reliable method [1]. However, this method will cause a huge waste of electricity because the reflux gas will be sent back to the inlet of the compressor to be compressed again. In comparison with the by-pass regulation, the stepless flow control method has a better energy-saving performance because excess gas will be expelled from the compression cylinder prior to the compression process. Thus, this part of the gas will not be compressed, and some power consumption can be reduced. After equipping with the stepless flow control system, the effective power of the compressor will be greatly improved, and a lot of electricity will be saved. The stepless flow control system for the reciprocating compressor should meet the following requirements [2,3]:

- The control system should be capable of continuous stepless flow regulation within 0~100% working load.

- The control system should require low investment and low energy consumption.

- The control system should be reliable, safe and convenient to operate.

- The control system should have a wide range of applications.

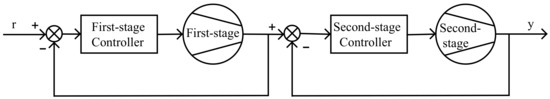

From the point of view of control science, the stepless flow control system has multiple controlled variables and multiple manipulated variables [4]. The inlet flow of each stage is the manipulated variable, and the outlet gas pressure of each stage is the controlled variable. Thus, this is a multiple-input and multiple-output (MIMO) system. The primary feature of MIMO system is the strong coupling, where each manipulated variable can affect the other controlled variables. It is harder to design the controller than the single-input and single-output (SISO) system due to the interaction process between controlled variables and manipulated variables. Thus, one of the main control objectives for a MIMO system is reducing the coupling. Many approaches have been proposed to solve this control problem in state space and transfer function matrix representations. Some frequency-based frameworks have been researched in this study including the relative gain array (RGA) measure, feed-forward decoupling method, IMCPID and neural network [5].

The Proportional Integral Derivative (PID) control has been widely used in the industrial fields due to its simple structure and stable characteristics. However, for some dynamic processes such as time-delay, nonlinearity and coupling, the PID controller does not always represent high efficiency. In the past decades, the question of how to find simpler PID tuning methods has caught a mass of interest [6]. In both academic research and engineering applications, many PID-type controller designs have been developed, such as the famous Ziegler-Nichols (ZN) tuning rules [7], the well-know H2/H∞ robust optimal design method [8], the internal model control principle [9] and neural network PID [10]. In the above methods, IMC is considered as the simplest tuning rule of PID controller. This because all the three controller parameters of PID can be obtained from the only user-defined tuning parameter of IMC called λ (λ > 0). It is easy to control the linear or nonlinear, time-delay and coupling systems for the IMC scheme due to its simple and robust performance characteristics [11].

Many studies have been conducted to obtain PID tuning methods using IMC schemes which are achieved by complex mathematical manipulations or require a filter algorithm. For the stable linear and separable nonlinear system, an IMC-based PID (IMCPID) tuning scheme employing first-order in place of second or higher-order filter is presented [12]. Some heuristic methods have also been developed to get PID parameters [13,14,15]. A IMCPID controller has been slightly modified in [16] to demonstrate the importance of mid-frequency and high-frequency robustness for tuning parameters. As some processes having model uncertainty, [17] proposed an IMC tuning method based on gain margin and maximum peak criterion.

In order to eliminate the effects of uncertainty of system parameters, some adaptive control methods have been used in industrial processes [18,19]. The model-reference adaptive control and self-tuning regulator control can effectively solve the disturbance problem in linear system [20]. The method in [21] combines IMC and adaptive PSD control. The result of applying it to the main steam temperature system shows that the method is effective. However, the parametric uncertainties and external disturbances of nonlinear systems are more sophisticated than those of linear systems. To solve this problem, some intelligent techniques [11] have been applied to adaptive controller, including neural network and fuzzy logic control, etc. Paper [22] presents an IMCPID control method to modified the weight of the set-point online with fuzzy logic, which can improve the set-point tracking performance and robustness of the system. In paper [23], the technique of the self-tuning neural network PID control for the stabilizer fin to reduce ship rolling motion is successfully developed. Because the neural network can approximate any continuous function, the adaptive controller based on neural networks has excellent online estimation characteristics [22].

In this paper, a neural network based on IMCPID control strategy is proposed to improve the performance of the stepless flow controller. A feedforward decoupling method is designed which can eliminate the coupling and transform the multiloop system into several independent single-input and single-output loops [24]. In the feedback loop, an adaptive IMCPID control method is proposed which uses the system error as the input signal of the neural network and regulates the IMCPID parameter λ by its self-learning in real time [23]. The main purpose of this paper is to solve the problem of PID parameter setting in the actual industrial field operation process, which is usually a complex job. Therefore, we proposed a more concise neural network combined with an IMCPID control method, which reduces the number of system parameters and the difficulty of parameter setting. Some researchers found out that after applying neural networks to these nonlinear systems, not only will the parameter tuning process become simpler, but also the control performance will present more excellently [25]. PID neural network will automatically adjust the control parameters due to its self-organizing, self-learning and self-adaptation characteristics [26]. The simulation experiments show that the IMCPID controller based on neural network for a stepless flow control system has better performances in set-point tracking, stability and robustness than those of the other considered controllers.

The rest of this paper is organized as follows. Section 2 gives the mathematical model for a stepless flow control system of a reciprocating compressor. In Section 3, The IMCPID-based neural network (IMCPIDNN) control scheme is presented. The simulation results of a multivariable nonlinear control system are compared and discussed in Section 4. Finally, the conclusion and some open problems are given in Section 5.

2. Problem Formulation

The stepless flow control system for a two-cylinder type reciprocating compressor [27] is shown in Figure 1, where denotes the gas to be compressed and denotes the compressed gas. In standard operating conditions, the gas satisfies the following ideal gas assumptions:

where is gas pressure, is gas density, is gas constant, is gas temperature, is gas molar mass, is derivative of gas mass, is gas volume, is derivative of the gas mass flowing into the cylinder, is derivative of the gas mass flowing out of the cylinder and and are derivatives of the gas volume and gas density, respectively. Usually, the gas volume is invariable in the buffer tank, so .

Figure 1.

The stepless flow control system for a two-stage compressor.

Combining Equations (1)–(3), the dynamic pressure change of the cylinder can be described as:

where and are process coefficients of the inlet gas or outlet gas, which are ranging from 0 to 1 depending on the gas process characteristic.

According to the mathematical model for reciprocating compressors introduced in paper [28], the gas mass flowing into the first stage cylinder and the second stage cylinder during the compressing process can be given as Equations (5) and (6), respectively.

where is pressure of inlet gas, is gas constant, is temperature of inlet gas, is temperature of buffer tank, is volume of cylinder stroke volume, is pressure coefficient, is temperature coefficient, is leakage coefficient, is volume coefficient, is pressure of buffer tank, is gas mass and is working load. The subscript indicates the cylinder number of the compressor.

The gas compressed by the first stage cylinder will be sent into the second stage cylinder. Then, we can obtain the relationship between the outlet mass of the first-stage cylinder and the inlet mass of the second-stage cylinder.

Considering the dynamic principle of the exhaust valve, the equation of the outlet mass of the second-stage cylinder can be expressed as

Combing Equations (4)–(8), the dynamic change of cylinder pressure can be presented as:

The operation parameters of a two-cylinder reciprocating compressor with a stepless flow control system are listed in Table 1.

Table 1.

Operation parameters of a two-cylinder reciprocating compressor.

Substituting the operation parameter values in Table 1 into Equations (9) and (10), the relationship between the outlet pressure and working load can be written as Equation (11), where and are outlet pressure, and are working load of each cylinder, respectively, and is the opening of outlet:

3. Controller Design

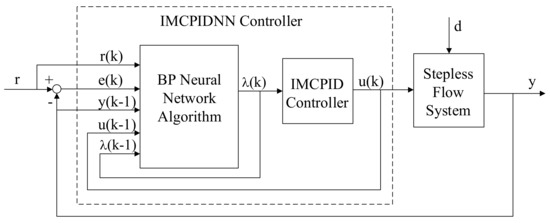

In this section, the set-point tracking and decoupling control scheme will be proposed. The basic structure of the IMCPIDNN control system is shown in Figure 2. The design process of the IMCPIDNN controller mainly consists of four parts: relative gain array, feed-forward decoupling, IMC controller based on standard PID and IMCPIDNN controller design. In the whole control system, is set-point value, is error of subtracting the output value from the set-point value, is output value, is control signal, is the only IMCPID controller parameter to be adjusted and is external disturbance. The whole control algorithm is established based on the adaptive IMCPID controller and neural network algorithm, which is presented in Algorithm 1.

| Algorithm 1 IMCPIDNN algorithm for MIMO nonlinear system. |

| Step 1: Initialize the weights of IMCPIDNN. |

| Step 2: Input the set-point value of controlled system into the controller. |

| Step 3: Regulate the compressor flow by IMCPIDNN controller. |

| Step 4: Calculate error and evaluation function. |

| Step 5: Adjust the weights of IMCPIDNN controller by back propagation algorithm. |

| Step 6: Repeat steps 3 to 5. |

| Step 7: Stop the algorithm until the error is small enough. If not, return to Step 3. |

Figure 2.

The block diagram of the IMCPIDNN control structure.

3.1. Relative Gain Array (RGA)

As we can see in Equation (11), there are two controlled variables and two manipulated variables in the presented control process. There are two ways to pair control variables with operation variables and they are and , respectively. To find which configuration has a better performance in terms of resisting the system coupling, the RGA method is proposed. For the system with n inputs and m outputs, its RGA can be calculated by:

The RGA method is proposed. For the system with n inputs and m outputs, its RGA can be calculated by:

where * is the multiplication of Hadamard.

Considering that the sum of each row and each column is 1, the RGA for a two-input and two-output system satisfies the following equation:

where and are the relative gains of main channel and and are the relative gains of coupled channel.

Therefore, the whole RGA matrix can be calculated from . In the RGA method, the value of describes the coupling degree within the system. If is close to 1, every loop can be considered to run independently. If it is close to 0, the coupling is serious. Negative must be avoided because it results in instability. Therefore, we should choose the which is positive and close to 1 to be the best configuration.

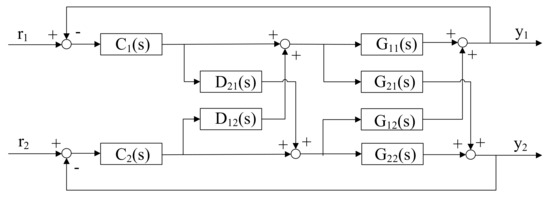

3.2. Feed-Forward Decoupling

The undesirable dynamic coupling within the system will affect the stability and control performance of the stepless control system [29]. This paper introduces a simple and efficient feed-forward decoupling method to eliminate the coupling, and the block diagram for a two-input and two-output system is shown in Figure 3 [24].

Figure 3.

The block diagram of a feed-forward decoupling structure for a two-input and two-output system.

Here, is the set-point value, is the output value, is the proposed controller, is the process plant and is the decoupler.

Supposing the system is decoupled completely, the transfer function matrix will turn into a diagonal matrix. and satisfy the following relationship:

Then, we can obtain and as:

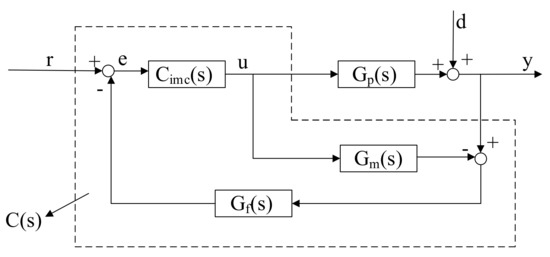

3.3. IMC Controller Design Based on Standard PID

In this part, an improved IMC control based on standard PID controller and classical feedback structures is proposed. The Standard IMC structure is presented in Figure 4, where is the process, is the process model, is the filter, is IMC controller and is the IMC controller with feedback structure.

Figure 4.

The block diagram of the IMC structure.

The closed-loop transfer function obtained from Figure 4 is:

If the process model is completely accurate, it is , and the external disturbances . Then, Equation (16) can be written as:

From Equation (17), we find an interesting property: the closed-loop transfer function can be considered as an open-loop system only related to . The designing process of the IMC controller can be regarded as the product of the inverted process and the closed-loop transfer function.

The design process of the IMCPID controller includes three steps which are shown in Algorithm 2.

| Algorithm 2 The design process of the IMCPID controller. |

| Step 1: Factorize |

| where contains the minimum phase part of the model and contains all the right half plane zeros and the time delays of . . |

| Step 2: Design and |

| where is the filter which provides good performance for set-point tracking and disturbance suppression, is the time constant of and the only tuning parameter of the IMC controller that affects the closed-loop response and stability and is the filter order decided by . |

| Step 3: Calculate the IMCPID controller and turn it into the PID-type |

| where , and are proportional gain, integral time and derivative time, respectively. |

Most industrial processes can be represented by a first-order model plus time-delay system as shown below:

where , and are open-loop gain, time constant and delay time, respectively.

Considering that the delay time is difficult to implement physically, we could replace it with first the order Pade approximation, that is, . Then, can be factorized as:

and can be obtained as:

The filter order should be consistent with the system order, that is, . Substituting Equations (19), (22) and (24) into Equation (20), the PID-type IMCPID controller can be written as:

Then, the PID parameters can be presented by the following equation:

where is proportional gain, is integral gain and is differential gain, respectively.

3.4. IMCPIDNN Controller Design

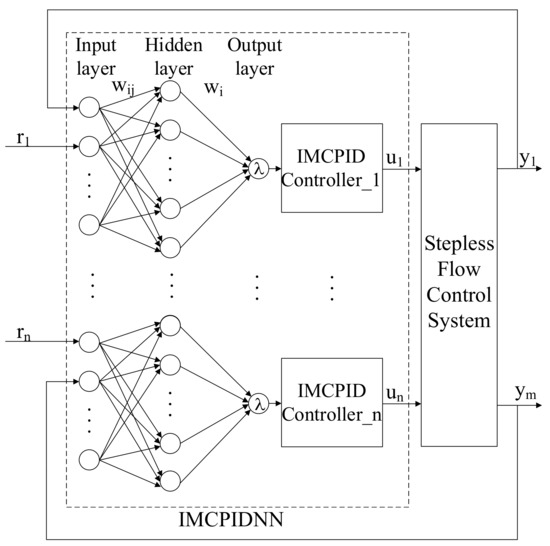

In order to compensate the nonlinearity of the stepless flow control system, the neural network algorithm based on the IMCPID control scheme is proposed [30]. The block diagram of a MIMO system with a backpropagation (BP) neural network structure is as shown in Figure 5.

Figure 5.

The block diagram of a MIMO nonlinear system with BP neural networks.

Here, and are set-point value and output value, respectively. is the network weight between the node of the input layer and the node of the hidden layer and is the network weight between the node of the hidden layer and the output layer node.

From Equation (26), the discrete PID gains can be written as:

where is the tuning coefficient to determine the flexibility of the control process.

Then, according to the incremental PID principle [31], the output of IMCPID controller can be written as:

In this article, a three-layer BP neural network is proposed as show in Figure 5. There are five input nodes, six hidden nodes and one output node in the neural network structure.

The input of the neural network is defined as:

The input of the hidden layer is defined as:

The output of the hidden layer is defined as:

where is the sigmoid function:

The input of the output layer is defined as:

The output of the output layer is defined as:

where is a non-negative sigmoid function to ensure the outputs to be positive as shown below:

The central ideal of the learning algorithm for the IMCPIDNN is to obtain a gradient vector recursively. In this study, we define energy function as:

In order to get the minimum , the iterative algorithm of can be calculated as the following equation according to the gradient descent method:

where is the learning rate, and ; is the inertial coefficient, and can be written as:

From Equation (37), we can obtain:

Considering that cannot be written [32], we use the sign function to approximate it.

Combining Equations (27) and (28), we can obtain as below:

where , and are the discrete style of , and , respectively.

From Equations (33) and (34), we can get and as:

According to Equations (37)–(43), the output layer weight change can be written as:

where

The hidden layer weights can be obtained in the same way with the following equation:

where

Through the above derivation, we obtain the weight coefficient learning algorithm for the neural network, and only the parameter can be adjusted in real time according to the above derivation. The parameters of the IMCPIDNN controller are shown in Table 2.

Table 2.

Parameters of the IMCPIDNN controller.

4. Algorithm Simulation and Results

In this section, some simulations are completed to illustrate the effect of the proposed IMCPIDNN controller in a stepless flow control system. The design and training process of IMCPIDNN and PID, IMCPID and FLSMC (feedback linearization sliding mode control) are done with the MATLAB/SIMULINK environment. Some possible external disturbances have also been taken into consideration during the simulation process. The simulation sampling time is set as 0.01s. The controller output threshold is set as to simulate the real action of the actuators. The learning rate and the inertial coefficient are set as 0.5 and 0.1, respectively. In addition, the simulation results of the control effects are compared in terms of step responses, anti-interference and robustness, which shows the superior performance of the proposed IMCPIDNN controller in all aspects.

The industrial process presented in Section 2 is a two-input and two-output system whose open-loop transfer function can be described as:

The RGA matrix is:

According to the controller design method presented in Section 3, we know that the system coupling is serious, and the best paring configuration is and . Thus, the process model can be simplified as:

The value of the filter parameter is selected as to meet the order of the model . The PID-IMC controller can be obtained as the following equation according to the controller design method given in Equations (16)–(26):

4.1. Step Response Test and Validation

To demonstrate the characteristics of the proposed IMCPIDNN controller, step response tests are made for the reciprocating compressor numerical model. The PID controller, IMCPID controller and FLSMC controller are constructed to make comparisons under the same condition. The simulations are carried out with reference pressure profile under the simulated condition to verify the control performance of the proposed controller.

In order to evaluate the performance of the proposed controllers, we use the integral of absolute value error criterion (IAE), integral of time multiplied by the absolute value of error criterion (ITAE), integral of square error criterion (ISE) and integral of time multiplied by squared error criterion (ITSE) as the evaluation function [33]. Two-system step response performance indicators have also been applied and they are and , where means the shortest time that reaches the step response steady-state value of 2% error and means the overshoot, respectively.

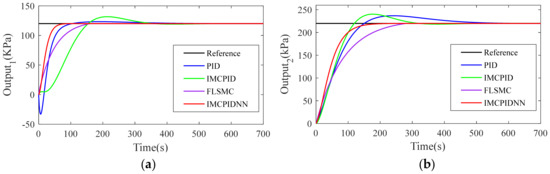

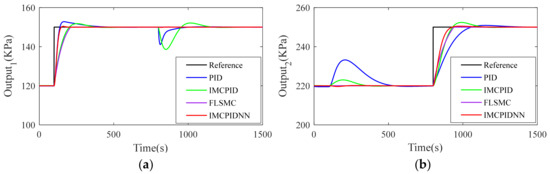

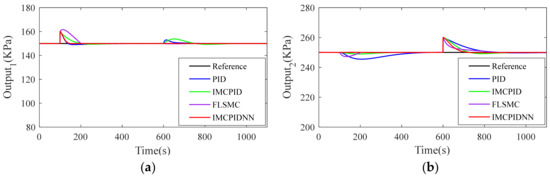

Figure 6 shows that the dynamic output of each loop meets the desired set point. The dynamic tracking performances obtained by PID, IMCPID, FLSMC and IMCPIDNN controllers for the two-input and two-output nonlinear system were compared. The process of starting the system from the shutdown state is imitated, where the set-points of the first output and the second output change from 0 kPa to 120 kPa and 220 kPa at moment t = 0 synchronously. Obviously, IMCPIDNN has the shortest settle time and the smallest overshoot, and it performs the best among the four algorithms while PID performs worst.

Figure 6.

Comparison of step responses with concurrent changes in set-points: (a) Output1; (b) Output2.

Table 3 presents the best control performance indices obtained by each controller. What stands out in the table is all the performance indices of the IMCPIDNN controller are optimal in the closed-loop step response. The value of the settle time of the step responses for the two loops are: 61.91 s and 146.78 s, respectively. They are smaller than those obtained by the other three algorithms. The IAE, ITAE, ISE and ITSE values obtained with the proposed algorithm for loop 1 are: 2.62, 1.98, 0.42 and 1.96, and for loop 2: 10.60, 14.05, 4.01 and 31.14. Compared with the PID controller, IMCPID controller and FLSMC controller, the proposed IMCPIDNN controller performs better in terms of set-point tracking.

Table 3.

Performance comparison of the four algorithms used for concurrent step responses.

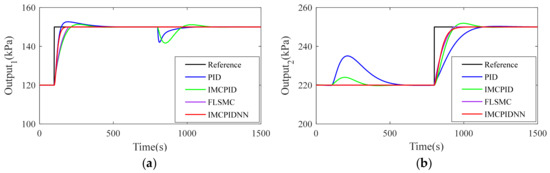

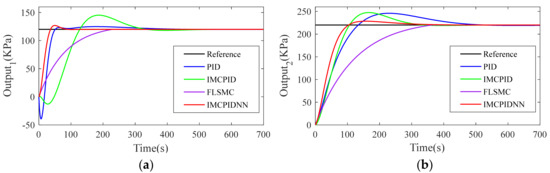

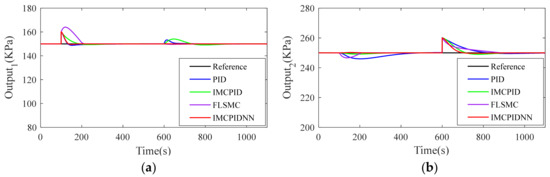

At the moments t = 100 and t = 800, the set-point value is changed sequentially in the two loops. The simulation result in Figure 7 shows the step response and control effect obtained by the proposed IMCPIDNN controller. It is relevant to note that the performance of the PID and IMDPID controllers are not satisfied, and this is expected because of the strong interactions. The common problem of the two controllers is that they cannot eliminate the system coupling problem. For example, the step change at moment t = 100 in the set-point of the first input caused a negative effect on the second output, which is undesirable. It indicates that the system coupling is serious with no decoupling method. The FLSMC controller eliminates the coupling of the system by nonlinear method, but its performance in step response is not as good as that of the IMCPIDNN controller. Compared with the other three controllers, the proposed IMCPIDNN controller performs better in set-point tracking. Neither the first step change nor the second step change has a large effect on the other loop.

Figure 7.

Comparison of step responses with sequential changes in set-points: (a) Output1; (b) Output2.

The performance comparison of the four algorithms used for sequential step responses are presented in Table 4. For loop 1 and 2, the settle times obtained using the proposed controller are 61.91 s and 146.78 s respectively, and the overshoots are both zero. Meanwhile, the results of the smallest four error evaluation indexes obtained by the IMCPIDNN controller can ensure the set-point tracking accuracy. Obviously, the IMCPIDNN controller performs better in terms of facing the interactions.

Table 4.

Performance comparison of the four algorithms used for sequential step responses.

4.2. Anti-Interference and Robustness Test

To illustrate the stability of the proposed IMCPIDNN controller, some anti-interference and robustness tests had been done. We want to know how the control effect changes when the values of the transfer function time constant and gain are mismatched with the actual system and how these controllers perform when the control process encounters external disturbance.

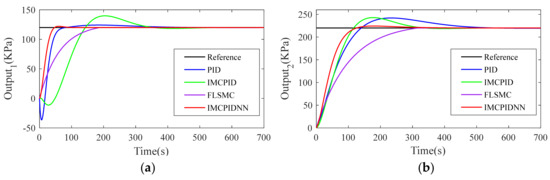

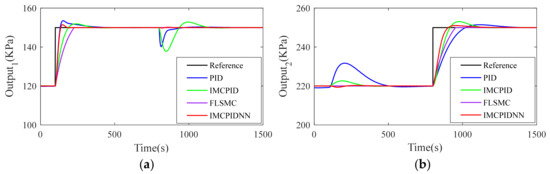

Figure 8 and Figure 9 present the step response with +40% variation on time constant and gains. We can see that the proposed IMCNNPID controller is very stable to the changes of model parameters. Figure 8 shows that the overshoot of PID, IMCPID, FLSM and IMCPIDNN in the face of model mismatch is 3.60%, 16.59%, 0% and 1.79%, respectively. Additionally, it can be seen that the IMCPIDNN controller has a faster adjustment speed than the other three controllers. Figure 9 shows the process outputs when the model mismatch increases to +40%. The most interesting aspect of these two figures is that the overshoot obtained by the IMCPIDNN controller is slightly larger than Figure 10 and Figure 11, but it is acceptable because it is still small enough. Obviously, the proposed IMCPIDNN controller is effective and superior to other three controllers for the varied system errors.

Figure 8.

Comparison of concurrent step responses with +20% variation on time constant and gains: (a) Output1; (b) Output2.

Figure 9.

Comparison of sequential step responses with +20% variation on time constant and gains: (a) Output1; (b) Output2.

Figure 10.

Comparison of concurrent step responses with +40% variation on time constant and gains: (a) Output1; (b) Output2.

Figure 11.

Comparison of sequential step responses with +40% variation on time constant and gains: (a) Output1; (b) Output2.

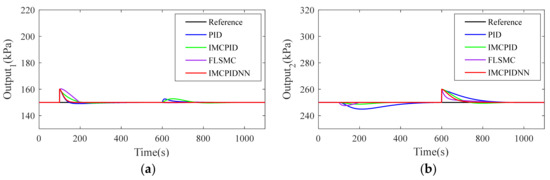

Next, 20 kPa of external disturbance was added to output 1 and output 2 at t = 100 s and t = 600 s, respectively. The simulation results are shown in Figure 12, Figure 13, Figure 14. Compared with the PID, IMCPID and FLSMC controllers, the settle time and overshoot of the proposed IMCPIDNN controller performed better, obviously. Under the action of the IMCPIDNN controller, the output can return to the set-point faster and more steadily, and the other loop is not interfered. This is meaningful for a stepless flow control system as it can ensure that the system runs more safely in the presence of external interference and reduce the failure rate of the equipment.

Figure 12.

Comparison of closed-loop responses to external disturbance with matching model: (a) Output1; (b) Output2.

Figure 13.

Comparison of closed-loop responses to external disturbance with +20% variation on time constant and gains: (a) Output1; (b) Output2.

Figure 14.

Comparison of closed-loop responses to external disturbance with +40% variation on time constant and gains: (a) Output1; (b) Output2.

5. Conclusions

In this paper, an IMCPIDNN controller based on IMCPID and a neural network optimization algorithm is proposed to optimize the control effect of MIMO processes such as stepless flow control of reciprocating compressors. The main contributions of this paper are the stepless flow process model with dynamic parameters as well as an IMCPIDNN controller, which inherits the main structure of a PID controller. In order to adjust the control parameters more efficiently, an adaptive algorithm based on a BP neural network is constructed. In terms of efficiently adjusting control parameters, the BP neural network algorithm with dynamically adjustable parameters has played a key role. Numerical experiments show that the proposed IMCPIDNN controller has good setpoint tracking performance and adaptability to a system model mismatch. Compared with PID, IMCPID and FLSMC controllers under the same conditions, the proposed IMCPIDNN controller performs best in terms of settle time, overshoot, robustness and anti-interference ability. More importantly, the process of the proposed IMCPIDNN controller to adjust the control parameters is the simplest because of the fewest adjustable parameters, which will provide great convenience for actual industrial applications. Finally, the proposed controller can be applied to any linear or non-linear MIMO system. We will continue to study process modeling, stability analysis, system convergence and robustness analysis to achieve better control effects.

Author Contributions

Conceptualization, H.H. and Z.J.; methodology, H.H., W.M., W.X. and J.Z.; software, H.H., W.M. and W.L.; validation, H.H. and Y.W.; formal analysis, H.H. and W.X.; investigation, Y.W.; resources, W.L.; data curation, H.H.; writing—original draft preparation, H.H.; writing—review and editing, H.H. and Z.J.; visualization, J.Z.; supervision, Z.J.; project administration, Z.J.; funding acquisition, Z.J., W.M. and J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by State Key Laboratory of Compressor Technology under Grant SKL-YSJ201911, Fundamental Research Funds for the Central Universities under Grant ZY2016, Double First-rate Construction Special Funds under Grant ZD1601 and the Fundamental Research Funds for the Central Universities under Grant JD2107.

Institutional Review Board Statement

This study did not involve humans or animals.

Informed Consent Statement

This study did not involve humans.

Data Availability Statement

This study did not report any data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, Y.; Jiang, Z.; Zhang, J.; Zhou, C.; Liu, W. Performance analysis and optimization of reciprocating compressor with stepless capacity control system under variable load conditions. Int. J. Refrig. 2018, 94, 174–185. [Google Scholar] [CrossRef]

- Bin, T.; Yuanyang, Z.; Liansheng, L.; Guangbin, L.; Le, W.; Qichao, Y.; Haiping, X.; Feng, Z.; Wenhui, M. Thermal performance analysis of reciprocating compressor with stepless capacity control system. Appl. Therm. Eng. 2013, 54, 380–386. [Google Scholar] [CrossRef]

- Li, D.; Wu, H.; Gao, J. Experimental study on stepless capacity regulation for reciprocating compressor based on novel rotary control valve. Int. J. Refrig. 2013, 36, 1701–1715. [Google Scholar] [CrossRef]

- Astuti, D.W.; Juwari, J.; Handogo, R. Mp Tuning for Internal Model Control 2×2 Multi Input Multi Output (MIMO) System. IPTEK J. Proc. Ser. 2015, 1, 467–473. [Google Scholar] [CrossRef]

- Chekari, T.; Mansouri, R.; Bettayeb, M. IMC-PID Fractional Order Filter Multi-loop Controller Design for Multivariable Systems Based on Two Degrees of Freedom Control Scheme. Int. J.Control. Autom. Syst. 2018, 16, 689–701. [Google Scholar] [CrossRef]

- Li, P.; Zhu, G. IMC-based PID control of servo motors with extended state observer. Mechatronics 2019, 62, 102252. [Google Scholar] [CrossRef]

- Ziegler, J.G.; Nichols, N.B. Optimum settings for automatic controllers. Trans. ASME 1942, 64, 759–765. [Google Scholar] [CrossRef]

- Goncalves, E.N.; Palhares, R.M.; Takahashi, R.H.C. A novel approach for H-2/H-infinity robust PID synthesis for uncertain systems. J. Process. Control. 2008, 18, 19–26. [Google Scholar] [CrossRef]

- Rivera, D.E.; Morari, M.; Skogestad, S. Internal model control: PID controller design. Ind. Eng. Chem. Res. 1986, 25, 2163. [Google Scholar] [CrossRef]

- Chen, S.-Y.; Lin, F.-J. Decentralized PID neural network control for five degree-of-freedom active magneticbearing. Eng. Appl. Artif. Intell. 2013, 26, 962–973. [Google Scholar] [CrossRef]

- Li, S.; Gu, H. Fuzzy Adaptive Internal Model Control Schemes for PMSM Speed-Regulation System. IEEE Trans. Ind. Inform. 2012, 8, 767–779. [Google Scholar] [CrossRef]

- Saxena, S.; Hote, Y.V. Internal model control based PID tuning using first-order filter. Int. J.Control. Autom. Syst. 2016, 15, 149–159. [Google Scholar] [CrossRef]

- Isaksson, A.J.; Graebe, S.F. Analytical PID parameter expressions for higher order systems. Automatica 1999, 35, 1121–1130. [Google Scholar] [CrossRef]

- Wang, Q.G.; Hang, C.C.; Yang, X.P. Single-loop controller design via IMC principles. Automatica 2001, 37, 2041–2048. [Google Scholar] [CrossRef]

- Skogestad, S. Simple analytic rules for model reduction and PID controller tuning. J. Process. Control. 2004, 13, 291–309. [Google Scholar] [CrossRef] [Green Version]

- Lennartson, B.; Kristiansson, B. Evaluation and tuning of robust PID controllers. IET Control. Theory Appl. 2009, 3, 294–302. [Google Scholar] [CrossRef] [Green Version]

- Sutikno, J.P.; Aziz, B.A.; Yee, C.S.; Mamat, R. A New Tuning Method for Two-Degree-of-Freedom Internal Model Control under Parametric Uncertainty. Chin. J. Chem. Eng. 2013, 21, 1030–1037. [Google Scholar] [CrossRef]

- Efe, M.Ö. Neural Network Assisted Computationally Simple PIλDμ Control of a Quadrotor UAV. IEEE Trans. Ind. Inform. 2011, 7, 354–361. [Google Scholar] [CrossRef]

- Han, G.; Fu, W.; Wang, W.; Wu, Z. The Lateral Tracking Control for the Intelligent Vehicle Based on Adaptive PID Neural Network. Sensors 2017, 17, 1244. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, D.; Wei, B. A review on model reference adaptive control of robotic manipulators. Annu. Rev. Control. 2017, 43, 188–198. [Google Scholar] [CrossRef]

- Gu, J.; Shen, L.; Zhang, L. Application of internal model and self-adaptive PSD controller in the main steam temperature system. In Proceedings of the 2005 International Conference on Machine Learning and Cybernetics, Guangzhou, China, 18–21 August 2005; pp. 570–573. [Google Scholar]

- Zhao, Z.; Zhang, J.; Hou, M. An adaptive IMC-PID control scheme based on neural network. In Proceedings of the 2009 WRI Global Congress on Intelligent Systems, Xiamen, China, 19–21 May 2009; pp. 31–35. [Google Scholar]

- Fang, M.; Zhuo, Y.; Lee, Z. The application of the self-tuning neural network PID controller on the ship roll reduction in random waves. Ocean. Eng. 2010, 37, 529–538. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Wang, C.; Wu, X. Coupling Analysis on Current Control at Low Switching Frequency for the Three-Phase PWM Converter Based on RGA and a Novel Output Feedback Decoupling Method. IEEE Trans. Ind. Electron. 2016, 63, 6684–6694. [Google Scholar] [CrossRef]

- Mu, S.; Tanaka, K.; Takahashi, K.; Sasaki, M. Position control of ultrasonic motor using PID-IMC combined with neural network based on probability. Int. J. Appl. Electromagn. Mech. 2013, 41, 59–71. [Google Scholar] [CrossRef]

- Kang, J.; Meng, W.; Abraham, A.; Liu, H. An adaptive PID neural network for complex nonlinear system control. Neurocomputing 2014, 135, 79–85. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, Z.; Wang, Y.; Zhou, C.; Sun, X.; Zhang, J. Performance Degradation Analysis and Optimization of the Stepless Capacity Regulation System for Reciprocating Compressors. Appl. Sci. 2020, 10, 704. [Google Scholar] [CrossRef] [Green Version]

- Wenhua, L.; Zhinong, J.; Tianyu, Z.; Yao, W.; Jinjie, Z. Optimization Technology of Capacity Control Method for Reciprocating Compressor. Control. Eng. China 2019, 7, 1365–1371. [Google Scholar]

- Ye, H.-T.; Li, Z.-Q. PID Neural Network Decoupling Control Based on Hybrid Particle Swarm Optimization and Differential Evolution. Int. J. Autom. Comput. 2015, 17, 867–872. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, H.; Gao, Y. Analysis of a neural-network-based adaptive controller for deep-space formation flying. Adv. Space Res. 2021, 68, 54–70. [Google Scholar] [CrossRef]

- Ren, H.; Hou, B.; Zhou, G.; Shen, L.; Wei, C.; Li, Q. Variable Pitch Active Disturbance Rejection Control of Wind Turbines Based on BP Neural Network PID. IEEE Access 2020, 8, 71782–71797. [Google Scholar] [CrossRef]

- Zeng, G.; Xie, X.; Chen, M.; Weng, J. Adaptive population extremal optimization-based PID neural network for multivariable nonlinear control systems. Swarm Evol. Comput. 2019, 44, 320–334. [Google Scholar] [CrossRef]

- Ali, E.S. Speed control of DC series motor supplied by photovoltaic system via firefly algorithm. Neural Comput. Appl. 2014, 26, 1321–1332. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).