Abstract

This study aimed to evaluate the effect of the adhesive application method on the durability of the enamel bond and the thickness of the adhesive layer. A new-generation two-step universal adhesive system, G2-Bond Universal, and two conventional two-step adhesive systems were utilized. The shear bond strength to bovine enamel was measured after thermal cycling in both etch-and-rinse and self-etch modes. Fifteen specimens were divided into three groups as follows: Group I, wherein a strong air stream was applied over the bonding agent for 5 s; Group II, wherein a gentle air stream was applied over the bonding agent for 5 s; and Group III, which was prepared as in Group II, followed by the application of a second layer of the bonding agent and a gentle air stream for 5 s. The durability of the enamel bond and thickness of the tested adhesives were influenced by the application method in both etching modes. The application method used in Group II appeared to be most suitable in terms of the bonding of the adhesives to the enamel. The new-generation two-step self-etch adhesive, comprising a universal adhesive-derived primer and a hydrophobic bonding agent, showed superior bond performance to the conventional two-step adhesive systems.

1. Introduction

The methods used to apply adhesives can considerably influence the clinical outcomes, regardless of the adhesive system utilized [1,2]. Previous studies investigated the bond effectiveness of various adhesive systems using different adhesive application methods and concluded that bond performance and morphological features in the vicinity of the resin–tooth interface were strongly influenced by the adhesive application method [3,4,5,6]. For instance, a warm air blow technique [1], the etching mode [4], an active application technique [5,6], and double-layer application [7,8,9] have been reported to improve the bonding performance of universal adhesives. Some of these techniques also influence the morphological features at the interface between the adhesive layer and the tooth substrate and the thickness of the adhesive layer [7,8,9].

The configuration of the tooth cavity is highly variable—depending on the location, depth, and size of the lesion, and the defects of the tooth substrate—and can influence not only the contraction stress of the resin composite but also the methods of adhesive application, air blowing, and filling [10,11]. The thickness of the adhesive layer might vary within the cavity. Furthermore, the thickness of the adhesive layer depends on the viscosity of the adhesive, the method used to apply the adhesive, and the strength of the air blow stream [7,8,9]. When comparing the thickness of the adhesive layer between multiple-step adhesive systems and single-step self-etch adhesive systems, including universal adhesive systems, the adhesive layers in the three-step etch-and-rinse and two-step self-etch adhesive systems were approximately five times thicker than those in the single-step self-etch adhesives [12]. A thicker adhesive layer is thought to improve the bond performance because it reduces the concentration of local stress, suppresses crack propagation, and decreases the relative thickness of the oxygen inhibited layer [7,8,9]. Hashimoto et al. [13] investigated the effect of consecutive coatings of the three-step adhesive system on the dentin microtensile bond strength and concluded that the bond strengths increased with each coating, up to four coats; no increase in bond strength was observed after more than four coats. However, the optimal thickness of the adhesive layer remains controversial and may vary among the different adhesive systems and tooth substrates. Phosphoric acid pre-etching has profound effects on the immediate and long-term bond durability because of the creation of a strong mechanical interlocking between the adhesive layer and the enamel substrate [14].

A recently introduced two-step adhesive system comprises a 2-hydroxyethyl methacrylate (HEMA)-free universal adhesive-derived primer and a hydrophobic bonding agent without any solvents or functional monomers. This adhesive system showed superior bond durability under thermal stress and long-term water storage when compared with conventional two-step self-etch adhesives, regardless of the tooth substrate or etching mode used [15]. Moreover, Tamura et al. [16] showed that the enamel and dentin bond durability achieved under fatigue stress by the new two-step adhesive system was equivalent to that attained by a gold standard two-step self-etch adhesive, Clearfil SE Bond. Thus, this new adhesive system might be able to achieve a durable bond performance and can be used in the clinical setting owing to the presence of a universal adhesive-derived primer. However, there is little information regarding the bond performance of this two-step adhesive system when applied using different methods.

This study aimed to investigate the effect of the adhesive application method on the durability of the enamel bond and the thickness of the adhesive layer using the new two-step adhesive system and compare it with those of the conventional two-step self-etch adhesive systems. The null hypotheses were as follows: (i) the enamel bond durability of the universal adhesive-derived two-step adhesive system (under thermal stress) would vary with the different application methods used, and (ii) the trend of enamel bond durability based on the different application methods used would not differ from those observed using the tested conventional two-step adhesive systems.

2. Materials and Methods

2.1. Study Materials

Table 1 lists the two-step adhesive systems used in this study. An adhesive system utilizing a universal adhesive-derived primer, G2-Bond Universal (GU, GC, Tokyo, Japan), was used. Additionally, two conventional two-step adhesive systems, Clearfil SE Bond 2 (CS, Kuraray Noritake Dental, Tokyo, Japan) and OptiBond eXTRa (OX, Kerr, Brea, CA, USA), were used for comparison. The phosphoric acid etching agent Ultra-Etch was obtained from Ultradent Products (South Jordan, UT, USA), and the resin composite Clearfil AP-X was obtained from Kuraray Noritake Dental. A light-emitting diode curing unit with an internal tip diameter of 10 mm (Valo; Ultradent Products) was used, and a light irradiance of 1000 mW/cm2 (standard mode) was maintained during the course of the experiment.

Table 1.

Materials used in this study.

2.2. Specimen Preparation

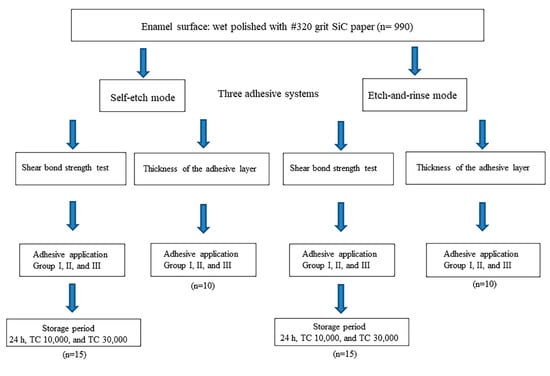

Bovine teeth were used as a substitute for human teeth. Approximately two-thirds of the apical root of each tooth was removed using a diamond-impregnated disk in a precision sectioning saw (IsoMet 1000 Precision Sectioning Saw; Buehler, Lake Bluff, IL, USA). The labial surfaces were subjected to mechanical grinding/polishing (Ecomet 4; Buehler) with a wet #180-grit silicon carbide (SiC) paper (Fuji Star Type DDC; Sankyo Rikagaku, Saitama, Japan) to create a flat enamel surface, approximately 8 mm in diameter. The prepared tooth was then inserted in self-curing acrylic resin (Tray Resin II; Shofu, Kyoto, Japan) to expose the flattened enamel surface. The adherent enamel bonding surfaces were wet polished using #240-grit SiC paper followed by #320-grit SiC paper (Fuji Star Type DDC). We used 810 bovine teeth for SBS tests and 180 teeth for adhesive layer thickness measurements (Figure 1).

Figure 1.

Flow diagram of this study.

2.3. Adhesive Application Protocol and Thermal Cycling

As part of the design process for this study, we assumed that variations in clinical bonding procedures might result in the creation of different adhesive layer thicknesses. Such variation may occur in clinical situations due to misunderstanding of bonding procedures, cavity configuration, or errors in handling. We therefore designed protocols to generate adhesive layers of different thicknesses. Table 2 shows the adhesive application protocols for the adhesives. Fifteen specimens were prepared to determine the shear bond strength (SBS) to enamel in the self-etch mode (SE mode, without phosphoric acid pre-etching) and etch-and-rinse mode (ER mode, phosphoric acid pre-etching for 15 s). The bonded area was standardized as the center of the labial surface. For the ER mode, 35% phosphoric acid was applied to the enamel surface for 15 s, before applying the primer, and rinsed with water spray from a dental syringe for 15 s. For both etching modes, the primers were applied to the adherent surface following the manufacturers’ instructions. The 15 specimens were divided into three groups on the basis of the application method as follows:

Table 2.

Application protocols for pre-etching and two-step adhesive systems.

Group I: a strong stream of air was applied over the bonding agent for 5 s;

Group II: a gentle stream of air was applied over the bonding agent for 5 s (the strength of the air blow was similar to that recommended by each manufacturers’ instructions);

Group III: prepared as in Group II followed by the application of a second layer of the bonding agent and a gentle air blow for 5 s.

The bonding agent-treated enamel surfaces were light irradiated for 10 s. The bonded specimens were created by clamping the plastic molds (height, 2.0 mm; internal diameter, 2.38 mm; Ultradent Products) in a fixture against the adherent surfaces. The resin composite was condensed into the mold and light irradiated for 20 s. All steps in the bonding procedures were conducted by a single operator over the course of the whole experiment. After removing the excessive bonding agent with a sharp scalpel, we subjected the bonded specimens to thermal cycling (TC) after storage in 37 °C distilled water for 24 h. The specimens were subjected to either 10,000 or 30,000 TCs between 5 °C and 55 °C, with a dwell time of 30 s, before the SBS test [6]. Baseline specimens were stored in distilled water at 37 °C for 24 h before the SBS test (24 h groups).

2.4. SBS Tests

Notched-edge SBS tests were conducted in accordance with ISO 29022 [17]. The bonded specimens were fixed with an Ultradent shearing fixture and loaded to failure at a crosshead speed of 1.0 mm per min using a universal testing machine (Type 5500R; Instron, Norwood, MA, USA). The SBS values (MPa) were calculated by dividing the peak load at failure by the area of the bonded enamel. The debonded sites on the enamel surfaces and the debonded resin composite rods were observed using an optical microscope (SZH-131; Olympus, Tokyo, Japan) to evaluate the failure mode. When more than 80% of the adherent area was occupied by the adhesive, resin composite, or enamel substrate, the failure mode was classified as an adhesive failure, cohesive failure in resin, or cohesive failure in enamel, respectively. Other failure patterns, such as partially adhesive and partially cohesive, were classified as mixed failures [8].

2.5. Thickness of the Adhesive Layer

To determine the thickness of the adhesive layer in each group, we observed the resin/enamel interfaces using a confocal laser scanning microscope (CLSM, VK-8700; Keyence, Osaka, Japan). Ten bonded specimens per group were made, as described earlier, and embedded in epoxy resin (Epon 812; Nisshin EM, Tokyo, Japan). The embedded specimens were longitudinally sectioned with a precision sectioning saw (IsoMet 1000 Precision Sectioning Saw). The sectioned surfaces were wet polished using #4000-grit SiC paper and a sequence of carbide polishing papers (Struers, Cleveland, OH, USA). The resin/enamel interfaces of all the specimens were observed under the CLSM, and the thickness of the adhesive layer was measured using the software supplied with the CLSM. Profilometric measurements were conducted in three regions, at the center and two further points located one-quarter of the interface length from the center of the specimen, and the mean values were calculated for each group.

2.6. Scanning Electron Microscopy Observations

Representative adhesive treated enamel surfaces and resin/enamel interfaces were observed using scanning electron microscopy (SEM; ERA-8800FE; Elionix, Tokyo, Japan). The enamel surfaces were treated, following the manufacturers’ instructions, and rinsed with acetone and water. Additionally, the prepared specimen with #320-grit SiC paper, with and without 35% phosphoric acid pre-etching for 15 s, but not rinsed with acetone, were evaluated (baseline) to compare the morphological changes after adhesive treatment.

Bonded specimens stored in 37 °C distilled water for 24 h were embedded in the epoxy resin (Epon 812) and longitudinally sectioned with a precision sectioning saw. The sectioned surfaces of the resin/enamel interfaces were polished to a high gloss using abrasive disks (Fuji Star Type DDC) followed by diamond pastes (DP-Paste; Struers, Ballerup, Denmark) down to a particle size of 0.25 μm, followed by ultrasonic cleaning for 20 min. The specimens were dehydrated in a graded series of tert-butyl alcohol (50% for 20 min, 75% for 20 min, 95% for 20 min, and 100% for 2 h) and transferred from the final 100% bath to a freeze dryer (Model ID-3; Elionix) for 30 min. The specimens with the resin/enamel interfaces were then subjected to argon–ion beam etching (EIS-200ER; Elionix) for 45 s with the ion beam (accelerating voltage, 1.0 kV; ion current density, 0.4 mA/cm2) directed perpendicular to the polished surface [12]. Finally, all the specimens were coated with a thin film of gold using a sputter coater (Quick Coater Type SC-701; Sanyu Electron, Tokyo, Japan). Further observations were performed under a field emission SEM at an operating voltage of 10 kV.

2.7. Statistical Analysis

A statistical power analysis (G Power calculator) indicated that at least 13 specimens were required to effectively measure the SBS in each group and 9.4 measurements of the thickness of the adhesive layer were required per group. The parameters used were as follows: f = 0.25, α = 0.05, β = 0.2, and power = 0.8. Hence, the experiments were performed using 15 specimens for the SBS test and 10 specimens for the thickness measurements. Post hoc power tests were performed on the gathered data, and the sample size was found to be adequate.

The homogeneity of variance (Bartlett’s test) and distribution of normality (Shapiro–Wilk test) were confirmed before analysis of variance (ANOVA) was performed. In the case of the SBS data, the groups that underwent the SE and ER modes were analyzed separately, and three-way ANOVA followed by Tukey’s honest significant difference (HSD) test (α = 0.05) was used to analyze each data set. The following factors were used: adhesive application method, TC period, and adhesive system. One-way ANOVA, followed by Tukey’s HSD test (α = 0.05), was used for comparisons within subsets.

In the case of the thickness measurements, three-way ANOVA, followed by Tukey’s HSD test (α = 0.05), was used to analyze the full data set using the following factors: etching mode, adhesive application method, and adhesive system. The statistical analyses were performed using a statistical analysis software system (Sigma Plot 13; SPSS, Chicago, IL, USA).

3. Results

3.1. SBS in SE Mode

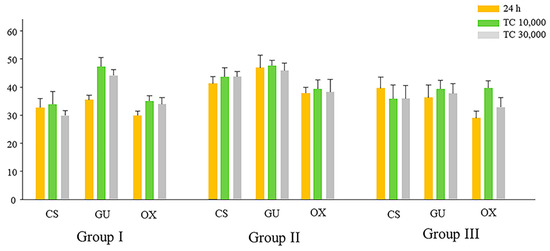

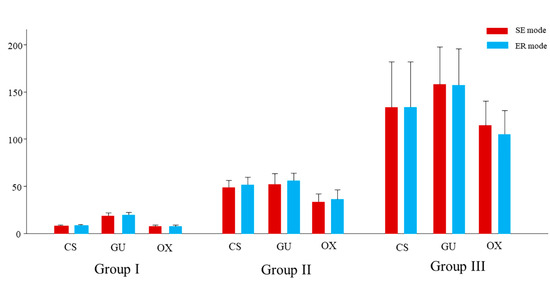

The SBS values of the enamel under TC in the SE mode are presented in Table 3 and Figure 2. Three-way ANOVA showed that all the factors significantly influenced the values and that all interactions were significant (p < 0.001).

Table 3.

Influence of application method on enamel bond strength (SE mode).

Figure 2.

Influence of application method on enamel SBS (SE mode).

The mean SBS values in the SE mode ranged from 29.9 to 43.8 MPa in CS, 35.5 to 47.7 MPa in GU, and 29.0 to 39.7 MPa in OX. Considering the trends of SBS in the different application groups, we found that all the adhesives showed higher SBS values in Group II than in Groups I and III, regardless of the storage period. All adhesives in Group II showed significantly higher SBS values than those at 24 h in Group I and at TC 30,000 in Group III. In Group I, although no significant differences in SBS values were observed among the storage periods in the CS subgroup, GU and OX presented with significantly higher SBS values at TC 10,000 and TC 30,000 than at 24 h (Table 3). In Group II, no significant differences were observed among the storage periods for all three adhesives, whereas in Group III, although no significant differences in the SBS values were observed among the various storage periods for CS and GU, OX presented with a significantly higher value at TC 10,000 in comparison with those at the other storage periods. Furthermore, GU showed higher SBS values than the other adhesives, regardless of the storage period or application group. In particular, GU presented with significantly higher SBS values than the other adhesives at all storage periods in Group I and at 24 h and TC 10,000 in Group II.

3.2. SBS in ER Mode

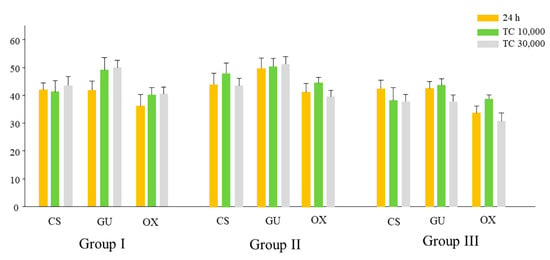

Table 4 and Figure 3 present the enamel SBS values in the ER mode under TC. Three-way ANOVA showed that all the factors significantly influenced the values and that all interactions were significant (p < 0.001).

Table 4.

Influence of application method on enamel bond strength (ER mode).

Figure 3.

Influence of application method on enamel SBS (ER mode).

The mean SBS values in the SE mode ranged from 38.4 to 48.3 MPa in CS, 38.0 to 51.6 MPa in GU, and 30.9 to 44.9 MPa in OX. All the adhesives showed higher SBS values in Group II than in Groups I and III, regardless of the storage period (Table 4). In particular, the SBS values of all three adhesives at TC 10,000 in Group II were significantly higher than at the other storage periods in Groups I and III, except for GU at TC 10,000 and TC 30,000 in Group I. In Group I, although no significant differences in SBS values were observed among the storage periods in the case of CS, GU and OX presented with significantly higher values after TC than at 24 h (Table 4). In Group II, no significant differences among the storage periods were observed in the cases of CS and GU. Similarly, no significant differences among the storage periods were observed in the case of CS in Group III; however, GU and OX presented with significantly lower SBS values at TC 30,000 than at the other storage periods. The SBS values in OX were significantly lower than in the other adhesives during most of the storage periods, regardless of the application group (Table 4). Furthermore, GU and OX showed significantly higher SBS values in the ER mode at 24 h than in the SE mode. However, no significant differences in the SBS values of the three adhesives were observed between the SE and ER modes at TC 30,000 in Group III.

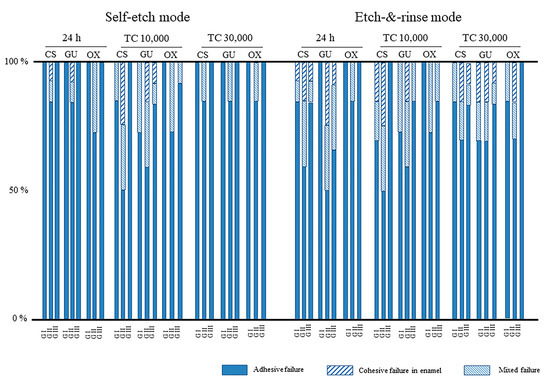

3.3. Failure Mode Analysis of Debonded Specimens after SBS

Figure 4 shows the frequencies of the failure modes in the tested adhesive systems. In the SE mode, all the adhesive systems in the 24 h and TC 30,000 groups predominantly presented with adhesive failure, regardless of the application method. The proportion of mixed or cohesive failure in the enamel was markedly higher in Group II at TC 10,000 than the other groups. In the ER mode, the frequencies of mixed and cohesive failure in enamel were higher than those in the SE mode. In particular, CS and GU showed higher frequencies of these failure modes in Group II at 24 h and TC 10,000 than in the other groups.

Figure 4.

Failure mode analysis of the debonded enamel specimens. CS: Clearfil SE Bond 2, GU: G2-Bond Universal, OX: OptiBond eXTRa, TC: thermal cycle, G I/II/III: Group I/II/III.

3.4. Thickness of the Adhesive Layer

Table 5 and Figure 5 present the thicknesses of the adhesive layer in the different adhesive systems under different application methods. Three-way ANOVA revealed that although the application method and adhesive systems used significantly influenced the thickness of the adhesive layer (p < 0.001), the etching mode did not have any influence (p = 0.974). The three-way interaction between the etching mode, application method, and type of adhesive system was not significant (p = 0.987). Although the two-way interaction between the application method and type of adhesive system used was significant (p < 0.05), other interactions, such as those between the etching mode and application method and etching mode and type of adhesive system used, were not significant (p = 0.697 and p = 0.873, respectively).

Table 5.

Thickness of adhesive layer in different application methods in different adhesive systems.

Figure 5.

Thickness of adhesive layer in different application methods in different adhesive systems.

The mean adhesive thickness ranged from 8.2 to 20.2 μm in Group I, 34.4 to 56.9 μm in Group II, and 105.9 to 158.7 μm in Group III (Table 5). In Group I, GU showed a significantly thicker adhesive layer than the other adhesive systems in both etching modes. In Group II, although no significant differences were observed between GU and CS, OX showed a significantly thinner adhesive layer than the other adhesive systems in both etching modes. In Group III, GU showed a significantly thicker adhesive layer than OX in both etching modes. The coefficient of variation (CV) was obtained from the mean adhesive thickness and standard deviation. The CV ranged from 7.6% to 15.9% in Group I, 13.5% to 26.8% in Group II, and 22.5% to 35.8% in Group III. The CV tended to increase with the increase in thickness of the adhesive thickness (Group I < Group II < Group III), regardless of the adhesive system.

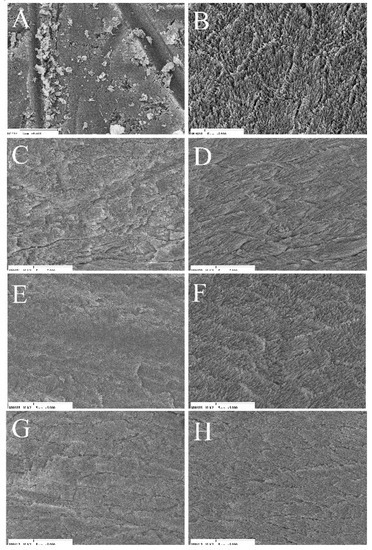

3.5. SEM Observations

Representative SEM images of treated and baseline enamel surfaces are shown in Figure 6. The baseline specimen ground with SiC papers exhibited scratch marks from the carbide polishing paper; additionally, the smear layer along with some enamel fragments was observed (Figure 6A). In the baseline specimen treated with phosphoric acid, the smear layer was completely removed, and a typical etching pattern was observed (Figure 6B). All the adhesive systems had a similar morphological appearance in the SE mode; most of the smear layer was dissolved, and a shallow etching pattern was observed. Particularly, the enamel rods were more clearly observed in OX than in the other adhesive systems (Figure 6G). Conversely, in the ER mode, although the adhesive systems showed similar morphological appearances to those of the baseline specimen treated with phosphoric acid, the spicular etching pattern appeared to be collapsed in OX (Figure 6H).

Figure 6.

Representative SEM images of the treated enamel surface. (A) Ground with SiC paper #320 (×5000). (B) Phosphoric acid etching for 15 s (×5000). (C) CS in SE mode (×5000). (D) CS in ER mode (×5000). (E) GU in SE mode (×5000). (F) GU in ER mode (×5000). (G) OX in SE mode (×5000). (H) OX in ER mode (×5000).

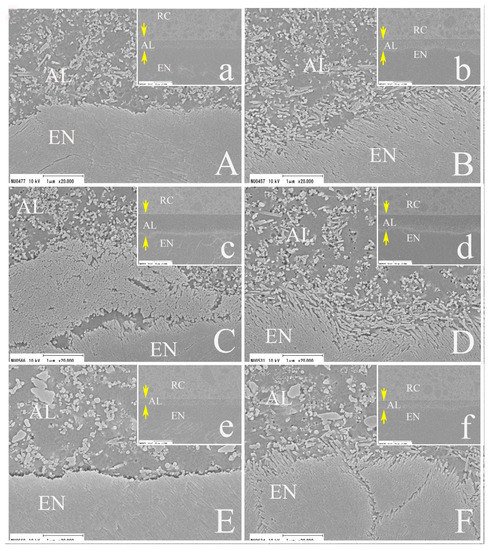

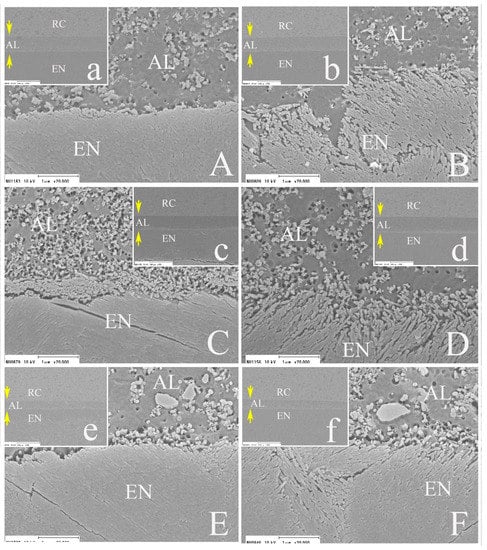

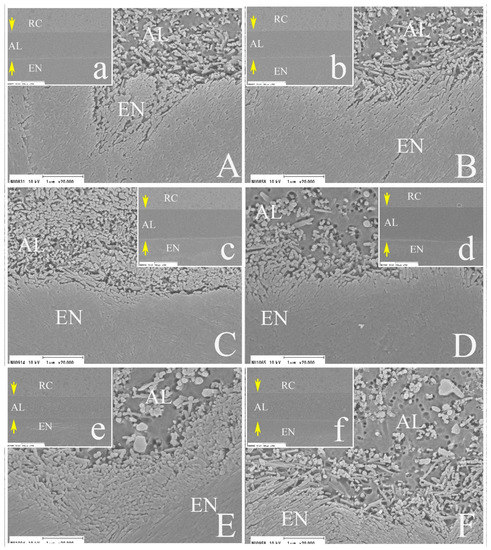

Figure 7, Figure 8 and Figure 9 show representative resin/enamel interfaces. All the adhesive systems showed excellent adaptation between the adhesive layer and the decalcified enamel substrate in both etching modes. No clear differences were observed in the thickness of the adhesive layer in the different etching modes, regardless of the adhesive system or application method used. In Group I (Figure 7), the thickness of the adhesive layers in CS and OX were similar (approximately 10 μm), but GU presented with twice the thickness of the other adhesive systems. In Groups II and III (Figure 8 and Figure 9), the thickness of the adhesive layers in CS and GU were similar and higher than that in OX. In the ER mode, the smear layer was completely dissolved, and adhesive interpenetration with enamel as resin tags was clearly observed, regardless of the adhesive system or application method used. On the contrary, enamel resin tags were not clearly seen in the SE mode, regardless of the adhesive system or application used. Part of the smear layer remained on the treated surface and created a hybrid layer (Figure 7C, Figure 8C and Figure 9A,C,E), which was infiltrated by the resin monomers in some instances. The ultrastructure of the adhesive layer was dependent on the adhesive system used. Unlike CS and GU, somewhat larger irregular fillers (approximately 0.1–0.5 μm in size) and nano-sized fillers were observed in OX. The thickness of the adhesive layer differed with the different adhesive systems and application methods used.

Figure 7.

Representative SEM images of resin/enamel interfaces (Group I). (A) CS in SE mode (×20,000, ×1000). (B) CS in ER mode (×20,000, ×1000). (C) GU in SE mode (×20,000, ×1000). (D) GU in ER mode (×20,000, ×1000). (E) OX in SE mode (×20,000, ×1000). (F) OX in ER mode (×20,000, ×1000). AL: adhesive layer, EN: enamel, RC: resin composite. The yellow arrows indicate the adhesive layer.

Figure 8.

Representative SEM images of resin/enamel interfaces (Group II). (A) CS in SE mode (×20,000, ×1000). (B) CS in ER mode (×20,000, ×1000). (C) GU in SE mode (×20,000, ×1000). (D) GU in ER mode (×20,000, ×1000). (E) OX in SE mode (×20,000, ×1000). (F) OX in ER mode (×20,000, ×1000). AL: adhesive layer, EN: enamel, RC: resin composite. The yellow arrows indicate the adhesive layer.

Figure 9.

Representative SEM images of resin/enamel interfaces (Group III). (A) CS in SE mode (×20,000, ×1000). (B) CS in ER mode (×20,000, ×1000). (C) GU in SE mode (×20,000, ×1000). (D) GU in ER mode (×20,000, ×1000). (E) OX in SE mode (×20,000, ×1000). (F) OX in ER mode (×20,000, ×1000). AL: adhesive layer, EN: enamel, RC: resin composite. The yellow arrows indicate the adhesive layer.

4. Discussion

This study aimed to determine the influence of the thickness of the adhesive layer formed by different application modes on the immediate enamel bond performance and bond durability of a new-generation two-step adhesive system and to compare it with those of conventional two-step SE adhesive systems. A major concern regarding the experimental protocol was the standardization and reproduction of an adhesive layer of similar thickness with each bonded specimen. It is practically difficult to reproduce the same thickness with a limited error range of a few micrometers, and the adhesive thickness cannot be monitored in each bonded specimen during the SBS test. The different application methods used in this study produced adhesive layers of different thicknesses within a certain range, which were clinically accepted bonding procedures. Although the CV was dependent on the method of application, significant differences in film thickness were observed among the three groups. GU showed thicker films than the other adhesive systems; additionally, a significant difference in thickness was observed between GU and the other adhesives in Group I. This can be explained by the components of the primer and bonding agent in GU. The primer contains nanofillers and functional monomers that resemble universal adhesives. On the other hand, the bonding agent in GU does not contain any functional monomers, solvent, or HEMA. These factors might influence the viscosity of the primer and bonding agent and the polymerization performance of the resin monomer. In particular, the nanofillers in the primer in GU remained on the enamel surface and increased the thickness of the adhesive layer even when a strong stream of air was applied in Group I [16]. Therefore, the adhesive layer of GU in Group I might have been thicker than those in the other adhesive systems.

The bond performances of all the tested adhesive systems were dependent on the application method used. Therefore, the first null hypothesis, that the enamel bond durability of the new two-step adhesive system under thermal stress would not differ with the different application methods used, was rejected. All the adhesives in Group II showed superior immediate and durable bond performances to those in Groups I and III, regardless of the etching mode. Therefore, the optimal adhesive thickness for the effectiveness of the enamel bond in the tested two-step adhesive systems might be similar to that seen in Group II (approximately 40 to 60 μm).

In the 24 h group, all the adhesives showed significantly lower SBS values in Group I when compared to those in Group II in both etching modes. A thicker adhesive layer might act as an elastic buffer zone during the polymerization process of the resin composite [18,19]. Additionally, the stress distribution at the interface might be better, owing to the increase in the size of the plastic zone and the improved elasticity [20,21]. During bond strength testing, load stress might generate cracks and create plastic deformation zones near the ends of these cracks. Crack propagation and fracture are thought to be related to the size of the plastic deformation zone [20,21]. Therefore, the thicker adhesive layer in Group II allows for a plastic deformation zone that is larger than that in Group I; thus, the stress distribution at the interface might be more dispersed. Furthermore, the thickness of the adhesive in the oxygen inhibition layer in Group I is much higher than those in the other groups; thus, the thinner oxygen layer might prove to be weak under load stress [22].

There are only a few studies on the effect of the thickness of the adhesive layer on the enamel bond performance, in contrast to similar work on the dentin. Moreover, the efficacy of the double-layer technique and an extra layer of hydrophobic resin on the enamel bond performances of two-step adhesive systems is still controversial. Albuquerque et al. [19] reported that double application and the placement of an additional hydrophobic resin layer had a negative impact on the μ-TBS of the enamel when using Clearfil SE Bond. On the other hand, Hirokane et al. [8] found no significant difference in the SBS between the single and double-layer application methods when using Clearfil SE Bond. Fujiwara et al. [7] reported no significant change in the SBS between the single- and double-layer application methods with OptiBond XTR. In the present study, although CS did not show any significant differences between groups II and III in SBS regardless of etching mode, the other adhesives showed lower SBS values in group III than group II. Additionally, the proportion of adhesive failure was higher in all the adhesives in Group III when compared to those in Group II. Thus, it can be inferred that an excessively thick adhesive layer might be more prone to defects and voids leading to increased residual stress after polymerization [23]. This might have a negative impact on the mechanical-physical properties of the resin composite restoration when using the two-step adhesive system [24].

In Group I, although no significant differences were observed between the TC groups and the 24 h Group in CS, GU and OX presented with significantly higher SBS values in the TC groups in both etching modes. In particular, a drastic increase in SBS after TC was observed in GU when compared to those in the other adhesives. This might be attributed to a possible delay in the post-polymerization reaction in the adhesive layer in Group I when compared to those in Groups II and III. In the case of GU in Group I, the remnant water and solvent derived from the primer might inhibit the polymerization of the bonding agent during the early phase. Thus, the second null hypothesis that the trend in the durability of the enamel bond during the different application methods was similar among the tested two-step adhesive systems was rejected.

Most of the application groups and adhesive systems demonstrated significantly higher SBS values in the ER mode than in the SE mode. This was in line with previous studies, which showed that phosphoric acid pre-etching before the application of a primer contributes to enhanced immediate and durable enamel bond performance [25,26]. However, none of the adhesives in Group III after TC showed any significant differences in SBS between the ER and SE modes, apart from GU at TC 10,000. For all the adhesives in Group III, the proportion of adhesive failure tended to increase after TC, even in those subjected to the ER mode. This finding suggested that although a strong mechanical interlocking between the etched enamel substrate and the adhesive layer might have been achieved in Group III, the deterioration of the adhesive layer might have been accelerated by both thermal stress and hydrolytic degradation during TC. Additionally, the stress distribution might be different because of the different mechanical properties of each adhesive layer. In particular, the HEMA-, solvent-, and functional monomer-free bonding agent in GU is thought to create a hydrophobic adhesive layer, which might have higher mechanical properties than those formed in the other adhesives [15,16]. This might explain why GU was the only adhesive to show a significantly higher SBS in the ER mode than that in the SE mode at TC 10,000 in Group III.

Among the tested adhesive systems, the new-generation two-step adhesive GU, which utilizes a universal adhesive-derived primer, showed SBS values equal to or higher than the other conventional two-step adhesive systems, regardless of the application mode, etching mode, or bonded specimen storage period. In particular, GU in Group II (similar to the manufacturer’s recommended bonding procedures) showed superior immediate and durable enamel bond performances to the other adhesives. Alternatively, GU did not demonstrate any significant differences in SBS under TC between Groups I and II. Hence, although an excessively thick adhesive layer appeared to have a negative impact on the immediate and durable bond performance in all the adhesives, GU appeared to be more tolerant of a thin adhesive layer than did the other materials, regardless of the etching mode.

In clinical situations, a thicker adhesive layer at the enamel margin can cause discoloration and gap formation in resin composite restorations. Additionally, it is likely to form the thicker adhesive layer at the corner of cavities. Thus, it is important to limit the thickness of the bonding agent when using a two-step adhesive system.

5. Conclusions

From the results of this study, we can draw the following conclusions.

- All the factors (adhesive application method, TC period, and adhesive system) significantly influenced the SBS values in SE mode (p < 0.001).

- All the factors (adhesive application method, TC period, and adhesive system) significantly influenced the SBS values in ER mode (p < 0.001).

- Although the application method and adhesive systems significantly influenced the thickness of the adhesive layer (p < 0.001), the etching mode did not have any influence (p = 0.974).

- Although GU and OX showed significantly higher SBS values in ER mode than in SE mode at 24 h, no significant differences in the SBS values of the three adhesives were observed between the SE and ER modes at TC 30,000 in Group III.

- The application method in Group II, which conformed to the manufacturers’ recommendations, resulted in an adhesive layer that was approximately 40–60 μm in thickness and appeared to be optimal for effective enamel bonding, regardless of the type of adhesive system or etching mode.

- Within the limitations of this study, the new-generation two-step SE adhesive, which adopts a universal adhesive-derived primer and a hydrophobic bonding agent, showed superior bond performance to the conventional two-step adhesive systems.

Author Contributions

T.T. and M.M. conceived and designed the experiments; M.Y., K.S. and A.T. conducted the experiments; S.S. analyzed the data; T.T. wrote the paper; M.A.L. and W.W.B. proofread the manuscript and contributed to the discussion. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by Grants-in-Aid for Scientific Research, Nos. 19K10158, 21K16975, 21K16977, and 21K09900 from the Japan Society for the Promotion of Science. This project was also supported in part by the Sato Fund (2021) and by a grant from the Dental Research Center of the Nihon University School of Dentistry (2021), Japan.

Conflicts of Interest

The authors of this manuscript certify that they have no proprietary, financial, or other personal interest of any nature or kind in any product, service, and/or company that is presented in this article.

References

- Perdigão, J.; Muñoz, M.A.; Sezinando, A.; Luque-Martinez, I.V.; Staichak, R.; Reis, A.; Loguercio, A.D. Immediate adhesive properties to dentin and enamel of a universal adhesive associated with a hydrophobic resin coat. Oper. Dent. 2014, 39, 489–499. [Google Scholar] [CrossRef] [PubMed]

- Saikaew, P.; Chowdhury, A.F.M.A.; Fukuyama, M.; Kakuda, S.; Carvalho, R.M.; Sano, H. The effect of dentine surface preparation and reduced application time of adhesive on bonding strength. J. Dent. 2016, 47, 63–70. [Google Scholar] [CrossRef]

- Shiratsuchi, K.; Tsujimoto, A.; Takamizawa, T.; Furuichi, T.; Tsubota, K.; Kurokawa, H.; Miyazaki, M. Influence of warm air-drying on enamel bond strength and surface free-energy of self-etch adhesives. Eur. J. Oral. Sci. 2013, 121, 370–376. [Google Scholar] [CrossRef]

- Takamizawa, T.; Barkmeier, W.W.; Tsujimoto, A.; Scheidel, D.D.; Erickson, R.L.; Latta, M.A.; Miyazaki, M. Effect of phosphoric acid pre-etching on fatigue limits of self-etching adhesives. Oper. Dent. 2015, 40, 379–395. [Google Scholar] [CrossRef]

- Imai, A.; Takamizawa, T.; Sai, K.; Tsujimoto, A.; Nojiri, K.; Endo, H.; Barkmeier, W.W.; Latta, M.A.; Miyazaki, M. Influence of application method on surface free energy and bond strength of universal adhesive systems to enamel. Eur. J. Oral Sci. 2017, 125, 385–395. [Google Scholar] [CrossRef]

- Moritake, N.; Takamizawa, T.; Ishii, R.; Tsujimoto, A.; Barkmeier, W.W.; Latta, M.A.; Miyazaki, M. Effect of active application on bond durability of universal adhesives. Oper. Dent. 2019, 44, 188–199. [Google Scholar] [CrossRef]

- Fujiwara, S.; Takamizawa, T.; Barkmeier, W.W.; Tsujimoto, A.; Imai, A.; Watanabe, H.; Erickson, R.L.; Latta, M.A.; Nakatsuka, T.; Miyazaki, M. Effect of double-layer application on bond quality of adhesive systems. J. Mech. Behav. Biomed. Mater. 2018, 77, 501–509. [Google Scholar] [CrossRef]

- Hirokane, E.; Takamizawa, T.; Kasahara, Y.; Ishii, R.; Tsujimoto, A.; Barkmeier, W.W.; Latta, M.A.; Miyazaki, M. Effect of double-layer application on the early enamel bond strength of universal adhesives. Clin. Oral. Investig. 2021, 25, 907–921. [Google Scholar] [CrossRef]

- Yokoyama, M.; Takamizawa, T.; Tamura, T.; Namura, Y.; Tsujimoto, A.; Barkmeier, W.W.; Latta, M.A.; Miyazaki, M. Influence of different application methods on the bonding effectiveness of universal adhesives to the dentin in the early phase. J. Adhes. Dent. 2021, in press. [Google Scholar]

- Shirai, K.; De Munk, J.; Yoshida, Y.; Inoue, S.; Lambrechts, P.; Suzuki, K.; Shintani, H.; Van Meerbeek, B. Effect of cavity configuration and aging on the bonding effectiveness of six adhesives to dentin. Dent. Mater. 2005, 21, 110–124. [Google Scholar] [CrossRef]

- Cunha, L.G.; Alonso, R.C.B.; Pfeifer, C.S.C.; Correr-Sobrinho, L.; Ferracane, J.L.; Shihoreti, M.A.C. Contraction stress and physical properties development of a resin-based composite irradiated using modulated curing methods at two C-factor levels. Dent. Mater. 2008, 24, 392–398. [Google Scholar] [CrossRef]

- Takamizawa, T.; Imai, A.; Hirokane, E.; Tsujimoto, A.; Barkmeier, W.W.; Erickson, R.L.; Latta, M.A.; Miyazaki, M. SEM observation of novel characteristic of the dentin bond interfaces of universal adhesives. Dent. Mater. 2019, 35, 1791–1804. [Google Scholar] [CrossRef]

- Hashimoto, M.; Sano, H.; Yoshida, E.; Hori, M.; Kaga, M.; Oguchi, H.; Pashely, D.H. Effects of multiple adhesive coatings on dentin bonding. Oper. Dent. 2004, 29, 416–423. [Google Scholar]

- Takamizawa, T.; Barkmeier, W.W.; Tsujimoto, A.; Endo, H.; Tsuchiya, K.; Erickson, R.L.; Latta, M.A.; Miyazaki, M. Influence of pre-etching times on fatigue strength of self-etch adhesives to enamel. J. Adhes. Dent. 2016, 18, 501–511. [Google Scholar] [CrossRef]

- Yamanaka, A.; Mine, A.; Matsumoto, M.; Hagino, R.; Yumitate, M.; Ban, S.; Ishida, M.; Miura, J.; Van Meerbeek, B.; Yatani, H. Back to the multi-step adhesive system: A next-generation two-step system with hydrophobic bonding agent improves bonding effectiveness. Dent. Mater. J. 2021. [Google Scholar] [CrossRef]

- Tamura, T.; Takamizawa, T.; Ishii, R.; Hirokane, E.; Tsujimoto, A.; Barkmeier, W.W.; Latta, M.A.; Miyazaki, M. Influence of a primer resembling universal adhesive on the bonding effectiveness of an experimental two-step self-etch adhesive. J. Adhes. Dent. 2020, 22, 635–646. [Google Scholar] [CrossRef]

- International Organization for Standardization. Dentistry—Adhesion—Notched-Edge Shear Bond Strength Test; ISO 29022 TR: Geneva, Switzerland, 2013. [Google Scholar]

- Ausiello, P.; Apicella, A.; Davidson, C.L. Effect of adhesive layer properties on stress distribution in composite restorations-a 3D finite element analysis. Dent. Mater. 2002, 18, 295–303. [Google Scholar] [CrossRef]

- Albuquerque, M.; Pegoraro, M.; Mattei, G.; Loguercio, A.D. Effect of double-application or the application of a hydrophobic layer for improved efficacy of one-step self-etch systems in enamel and dentin. Oper. Dent. 2008, 33, 564–570. [Google Scholar] [CrossRef]

- Wakasa, K.; Yamaki, M.; Matsui, A. Calculation models for average stress and plastic deformation zone size of bonding area in dentine bonding systems. Dent. Mater. J. 1995, 14, 152–165. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, A.F.M.A.; Saikaew, P.; Alam, A.; Sun, J.; Carvalho, R.M.; Sano, H. Effects of double application of contemporary self-etch adhesives on their bonding performance to dentin with clinically relevant smear layers. J. Adhes. Dent. 2019, 21, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Osorio, R.; Osorio, E.; Aguilera, F.S.; Tay, F.R.; Pinto, A.; Toledano, M. Influence of application parameters on bond strength of an “all in one” water-based self-etching primer/adhesive after 6 and 12 months of water aging. Odontology 2010, 98, 117–125. [Google Scholar] [CrossRef]

- De Neves, A.A.; Coutinho, E.; Poitevin, A.; Van der Sloten, J.; Van Meerbeek, B.; Van Oostereyck, H. Influence of joint component mechanical properties and adhesive layer thickness on stress distribution in micro-tensile bond strength specimens. Dent. Mater. 2009, 25, 4–12. [Google Scholar] [CrossRef]

- D’Arcangelo, C.; Vanini, L.; Prosperi, G.D.; Di Bussolo, G.; De Angelis, F.; D’Amario, M.; Caputi, S. The influence of adhesive thickness on the microtensile bond strength of three adhesive systems. J. Adhes. Dent. 2009, 11, 109–115. [Google Scholar] [CrossRef]

- Ermis, R.B.; Temel, U.B.; Cellik, E.U.; Kam, O. Clinical performance of a two-step self-etch adhesive with additional enamel etching in Class III cavities. Oper. Dent. 2010, 35, 147–155. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Takamizawa, T.; Hirokane, E.; Ishii, R.; Tsujimoto, A.; Barkmeier, W.W.; Latta, M.A.; Miyazaki, M. Bond durability of universal adhesives to intact enamel surface in different etching modes. Eur. J. Oral. Sci. 2021, 129, e12768. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).