Design for Additive Manufacturing and for Machining in the Automotive Field

Abstract

:1. Introduction

2. Materials and Methods

2.1. Definition of Functions and Requirements

- Increasing the stiffness under two assigned static load cases as described in Section 2.2;

- Leaving the weight unincreased;

- Fitting the design space (DS) limits;

- Allowing for a structural safety factor, Sf, not lower than 2, where Sf is the ratio between maximum applied stress, σmax, and tensile strength, Rm;

- Meeting dimensional and geometrical tolerances.

2.2. Topology Optimization and Finite Element Analysis

2.3. Industrialization

2.4. Process Simulation

- (1)

- A layer of Voxel elements is introduced, and a uniform heat flow is applied on the exposed surface of the layer to simulate the melting phase;

- (2)

- Appropriate conditions of conductive, convective and radiative thermal exchange are applied to the areas of the model that require them, depending for example, on the contact with loose powder or with solid supports;

- (3)

- The recoating phase is simulated by adding a new Voxel layer while maintaining the boundary conditions of the previous step; during this step, no heat flow is applied to the new layer under construction.

2.5. Building and Post-Process Finishing Operations

2.6. Dimensional Control

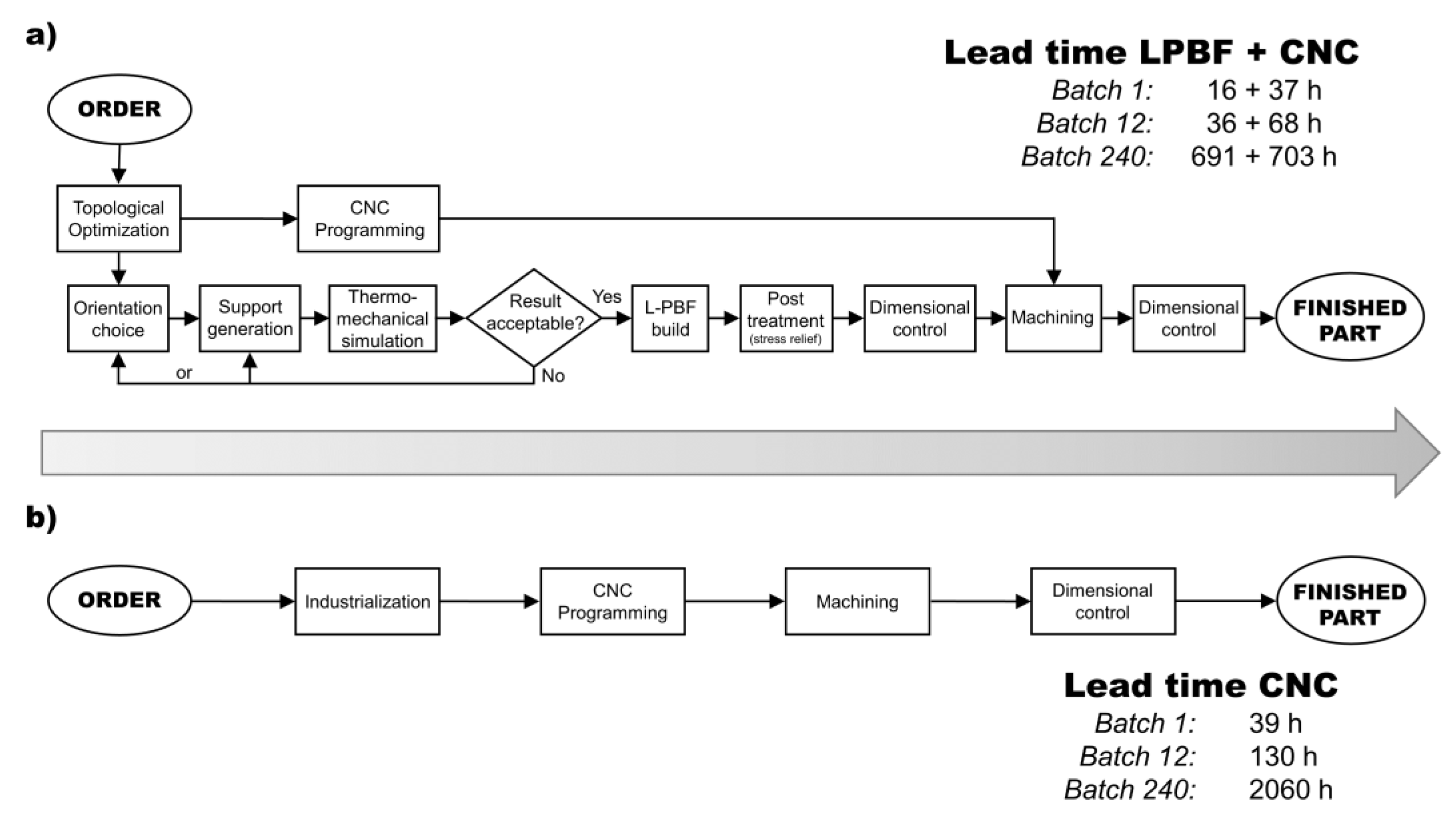

2.7. Time and Cost Comparison between LPBF and CNC

3. Results

3.1. Topology Optimization and FEA

3.2. Industrialization and Process Simulation

3.3. Industrialization and Process Simulation

3.4. Time and Cost Comparison between LPBF and CNC

4. Discussion and Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Mantovani, S.; Campo, G.A.; Ferrari, A.; Cavazzuti, M. Optimization Methodology for Automotive Chassis Design by Truss Frame: A Preliminary Investigation Using the Lattice Approach. In Proceedings of the 25th ISPE Inc. International Conference on Transdisciplinary Engineering, Modena, Italy, 3–6 July 2018; IOS Press BV: Amsterdam, The Netherlands, 2018; pp. 984–992. [Google Scholar]

- Murr, L.E. Frontiers of 3D Printing/Additive Manufacturing: From Human Organs to Aircraft Fabrication†. J. Mater. Sci. Technol. 2016, 32, 987–995. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology optimization approaches. A comparative review. Struct. Multidisc. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Zegard, T.; Paulino, G.H. Bridging topology optimization and additive manufacturing. Struct. Multidiscip. Optim. 2016, 53, 175–192. [Google Scholar] [CrossRef]

- Zhai, Y.; Lados, D.A.; Lagoy, J.L. Additive Manufacturing: Making Imagination the Major Limitation. JOM 2014, 66, 808–816. [Google Scholar] [CrossRef] [Green Version]

- Alsalla, H.H.; Smith, C.; Hao, L. Effect of build orientation on the surface quality, microstructure and mechanical properties of selective laser melting 316L stainless steel. Rapid Prototyp. J. 2018, 24, 9–17. [Google Scholar] [CrossRef]

- Król, M.; Dobrzański, L.A.; Reimann, Ł.; Czaja, I. Surface quality in selective laser melting of metal powders. Arch. Mater. Sci. 2013, 60, 87–92. [Google Scholar]

- Griffiths, V.; Scanlan, J.P.; Eres, M.H.; Martinez-Sykora, A.; Chinchapatnam, P. Cost-driven build orientation and bin packing of parts in Selective Laser Melting (SLM). Eur. J. Oper. Res. 2019, 273, 334–352. [Google Scholar] [CrossRef] [Green Version]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Wiberg, A.; Persson, J.; Ölvander, J. Design for additive manufacturing – a review of available design methods and software. Rapid Prototyp. J. 2019, 25, 1080–1094. [Google Scholar] [CrossRef] [Green Version]

- Leutenecker-Twelsiek, B.; Klahn, C.; Meboldt, M. Considering Part Orientation in Design for Additive Manufacturing. Procedia CIRP 2016, 50, 408–413. [Google Scholar] [CrossRef] [Green Version]

- Brika, S.; Zhao, Y.F.; Brochu, M.; Mezzetta, J. Multi-Objective Build Orientation Optimization for Powder Bed Fusion by Laser. Ind. Eng. Manag. 2017, 6, 1–9. [Google Scholar] [CrossRef]

- Morgan, H.D.; Cherry, J.A.; Jonnalagadda, S.; Ewing, D.; Sienz, J. Part orientation optimisation for the additive layer manufacture of metal components. Int. J. Adv. Manuf. Technol. 2016, 86, 1679–1687. [Google Scholar] [CrossRef] [Green Version]

- Foroozmehr, A.; Badrossamay, M.; Foroozmehr, E.; Golabi, S. Finite Element Simulation of Selective Laser Melting process considering Optical Penetration Depth of laser in powder bed. Mater. Des. 2016, 89, 255–263. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.; Dalgarno, K. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Gatto, A.; Bassoli, E.; Denti, L.; Sola, A.; Tognoli, E.; Comin, A.; Porro, J.A.; Cordovilla, F.; Angulo, I.; Ocaña, J.L. Effect of Three Different Finishing Processes on the Surface Morphology and Fatigue Life of A357.0 Parts Produced by Laser-Based Powder Bed Fusion. Adv. Eng. Mater. 2019, 21, 1801357. [Google Scholar] [CrossRef]

- Jamal, M.; Morgan, M.N. Design Process Control for Improved Surface Finish of Metal Additive Manufactured Parts of Complex Build Geometry. Inventions 2017, 2, 36. [Google Scholar] [CrossRef] [Green Version]

- Salmi, A.; Calignano, F.; Galati, M.; Atzeni, E. An integrated design methodology for components produced by laser powder bed fusion (L-PBF) process. Virtual Phys. Prototyp. 2018, 13, 191–202. [Google Scholar] [CrossRef]

- Ning, Y.; Wong, Y.; Fuh, J.; Loh, H. An approach to minimize build errors in direct metal laser sintering. IEEE Trans. Autom. Sci. Eng. 2006, 3, 73–80. [Google Scholar] [CrossRef]

- Senck, S.; Happl, M.; Reiter, M.; Scheerer, M.; Kendel, M.; Glinz, J.; Kastner, J. Additive manufacturing and non-destructive testing of topology-optimised aluminium components. Nondestruct. Test. Evaluation 2020, 35, 315–327. [Google Scholar] [CrossRef]

- Duarte, V.R.; Rodrigues, T.A.; Machado, M.A.; Pragana, J.P.; Pombinha, P.; Coutinho, L.; Silva, C.M.; Miranda, R.M.; Goodwin, C.; Huber, D.E.; et al. Benchmarking of Nondestructive Testing for Additive Manufacturing. 3D Print. Addit. Manuf. 2021, 8, 263–270. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1-4, 64–76. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Orme, M.E.; Gschweitl, M.; Ferrari, M.; Madera, I.; Mouriaux, F. Designing for Additive Manufacturing: Lightweighting Through Topology Optimization Enables Lunar Spacecraft. J. Mech. Des. 2017, 139, 100905. [Google Scholar] [CrossRef]

- Rindi, A.; Meli, E.; Boccini, E.; Iurisci, G.; Corbò, S.; Falomi, S. Static and Modal Topology Optimization of Turbomachinery Components. J. Eng. Gas Turbines Power 2016, 138, 112602. [Google Scholar] [CrossRef]

- Saadlaoui, Y.; Milan, J.-L.; Rossi, J.-M.; Chabrand, P. Topology optimization and additive manufacturing: Comparison of conception methods using industrial codes. J. Manuf. Syst. 2017, 43, 178–186. [Google Scholar] [CrossRef]

- Hodge, N.E.; Ferencz, R.; Solberg, J.M. Implementation of a thermomechanical model for the simulation of selective laser melting. Comput. Mech. 2014, 54, 33–51. [Google Scholar] [CrossRef]

- Mani, M.; Lane, B.; Donmez, A.; Feng, S.; Moylan, S.; Fesperman, R. Measurement Science Needs for Real-Time Control of Additive Manufacturing Powder Bed Fusion Processes. National Institute of Standards and Technology, NISTIR 8036. 2015. Available online: http://dx.doi.org/10.6028/NIST.IR.8036 (accessed on 1 May 2021).

- Salmi, M.; Ituarte, I.F.; Chekurov, S.; Huotilainen, E. Effect of build orientation in 3D printing production for material extrusion, material jetting, binder jetting, sheet object lamination, vat photopolymerisation, and powder bed fusion. Int. J. Collab. Enterp. 2016, 5, 218. [Google Scholar] [CrossRef]

- Klahn, C.; Leutenecker, B.; Meboldt, M. Design Strategies for the Process of Additive Manufacturing. Procedia CIRP 2015, 36, 230–235. [Google Scholar] [CrossRef] [Green Version]

| Original Bracket | TO Bracket | |

|---|---|---|

| displacements |  |  |

| Von Mises stresses |  |  |

| Details of Building Job from Industrialization | |

|---|---|

| Build time (12 parts + 3 specimens) | 26 h |

| Powder waste | ≈500 g |

| Supports volume | 72,500 mm3 |

| Part volume | 477,000 mm3 |

| Supports type | 90% Block; 7% cones; 3% Lines |

| Machine | SLM 280 Twin HL (double laser) |

| Original | LPBF + CNC | CNC Alone | |

|---|---|---|---|

|  |  | |

| Mass [g] | 88 | 85 | 114 |

| Max displacement [mm] | 0.34 | 0.33 | 0.37 |

| Max Von Mises stress [MPa] | 464 | 297 | 351 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bassoli, E.; Defanti, S.; Tognoli, E.; Vincenzi, N.; Degli Esposti, L. Design for Additive Manufacturing and for Machining in the Automotive Field. Appl. Sci. 2021, 11, 7559. https://doi.org/10.3390/app11167559

Bassoli E, Defanti S, Tognoli E, Vincenzi N, Degli Esposti L. Design for Additive Manufacturing and for Machining in the Automotive Field. Applied Sciences. 2021; 11(16):7559. https://doi.org/10.3390/app11167559

Chicago/Turabian StyleBassoli, Elena, Silvio Defanti, Emanuele Tognoli, Nicolò Vincenzi, and Lorenzo Degli Esposti. 2021. "Design for Additive Manufacturing and for Machining in the Automotive Field" Applied Sciences 11, no. 16: 7559. https://doi.org/10.3390/app11167559

APA StyleBassoli, E., Defanti, S., Tognoli, E., Vincenzi, N., & Degli Esposti, L. (2021). Design for Additive Manufacturing and for Machining in the Automotive Field. Applied Sciences, 11(16), 7559. https://doi.org/10.3390/app11167559