1. Introduction

Friction acts as a resistance to relative motion, which can, for example, help human beings walk and create desired sounds from instruments such as the violin [

1]. However, friction can lead to energy dissipation and be harmful to machine elements and biomedical implants due to, for example, material loss (wear) and degradation, affecting their performance and lifetime [

2]. Implant-bearing wear due to friction also is believed to play a notable role in the failure of artificial human joints [

3]. Moreover, friction can contribute to aseptic loosening of implants due to wear, shear forces, and high frictional torque, leading to bone fracture, instability and falls [

4,

5]. Friction also influences the relative motion of knee components significantly, which has several important implications. Excessive anterior-posterior displacements or internal-external rotations lead to the contact occurrence at the edges of the plastic body [

6], which can be especially damaging to the knee prosthesis, as is reported in retrieval studies [

7,

8]. Inadequate sliding motion can also impair human body function by increasing the likelihood of flexion contracture, reducing the range of flexion-extension and internal-external rotations, and the over-tensing of the soft tissues [

9,

10]. Furthermore, artificial human joints can undergo three-dimensional vibration due to friction, leading to an oscillating movement on top of the gross motion of joint components [

11]. Such an oscillating phenomenon can influence both the sliding distance and polyethylene wear, which can eventually cause prostheses to wear excessively, consistent with clinical reports. Friction-induced vibration can also lead to squeaking in biomedical joints [

11]. In addition, when ultra-high molecular weight polyethylene (UHMWPE) slides against a metallic counterface, changes in the orientation of molecular chains occur. They preferentially become oriented along a specific path, called principal molecular orientation (PMO), owing to friction while resulting in an orientation softening in the perpendicular direction of the PMO. They both contribute to a directional dependency of wear resistance of the polyethylene while depending on the joint trajectory [

12,

13,

14,

15]. The relative motion of the knee components can also influence the creep deformation as it is dependent on the applied load and under-force duration, both of which can change due to friction [

16,

17,

18].

Friction is a force developing and acting against the relative motion of solid surfaces and fluid layers that slides against one another. The origin of the word “friction” comes from the Latin verb “fricare” meaning “to rub”. It is worth noting that friction is not a fundamental force because it is reducible to underlying phenomena and forces such as atomic force and electromagnetic attraction between particles of in-contact surfaces. In addition, the friction coefficient is not a material property but a means of describing a friction system. In general, the friction coefficient depends on contact stress, relative tangential speed, surface roughness, the material property of contacting pair, surface contamination, temperature, among others [

19]. The scientific study of friction was pioneered by Leonardo da Vinci (1452–1519) who developed the basic friction laws in 1493 but did not document them [

20]. The first two classical friction laws were rediscovered and recorded in written form by Amontons (1663–1705) in 1699 [

21,

22]. He established that the friction force is directly proportional to the applied load but independent of the apparent contact area. Later, Leonhard Euler (1707–1783), through several experimental tests, clarified the distinctions between static and kinematic frictions [

23]. It is worth noting that the first who used the Greek symbol mu (μ) for the friction coefficient was Euler. The first mathematical relationship to computing friction force was formulated by a French engineer, Charles Augustin Coulomb (1736–1806), stating that friction is independent of the magnitude of relative velocity between sliding bodies [

21]. In his formulation, the friction force is set equal to the applied load multiplied by a coefficient that is the so-called Coulomb coefficient, still being used by both academia and industrial engineers. However, such a model cannot address some underlying physics associated with the friction phenomenon.

In the last decades, a great deal of research has been devoted to advancing phenomenological friction models. Such models have aimed at addressing the distinction between the static and kinematic friction, friction phases (stick, stick-slip, and pure slip), velocity-dependent property of friction, break-away force (pre-sliding displacement), and frictional lag [

24,

25]. In addition to the variety of friction models that address the above phenomena, the friction of UHMWPE, of which the tibial insert of total knee arthroplasty is made, demonstrates a dependency on contact pressure. In 2001, Wang et al., performed a series of experimental tests using a ball-and-socket test rig and found that friction decreases with increasing contact stress [

26]. Following their work, Saikko in 2006 reported the same finding while performing pin-on-disc friction tests [

27]. Both the above research studies found a significant correlation of the friction coefficient to the maximum contact pressure and reported associated empirical friction equations. In 2017, Barcenas-Sanchez et al., used a ball-on-disc test setup to obtain the friction coefficient of total knee arthroplasty during a walking gait cycle. Subsequently, they proposed a regression model to represent experimental data mathematically [

28]. In 2018, Garcia-Garcia et al., continued their research work while conducting a series of experiments to develop prediction models of the friction coefficient between the metallic ball and UHMWPE disk lubricated with diluted bovine serum [

29]. Regression parameters for a suggested model that fits well in experimental data were determined for the stance and swing phases separately. They later successfully proposed a formulation that represents the experimental data well to address the behavior of the friction coefficient over the transition from the mixed to the full-film lubrication regime during a walking gait cycle [

30]. The fitted model relates the friction coefficient to both contact stress and relative velocity. As the frictional events occur at the atomic level and are of multi-physics nature owing to interactions of chemical, electromagnetic, and mechanical processes, some frictional phenomena are yet to be understood and mathematically formulated despite great achievements so far [

19,

31].

Friction models are to be integrated into algorithms responsible for modeling dynamics of the knee joint. Sathasivam and Walker (1997) investigated the dynamics of total knee replacement under multiple friction coefficients while they used the Coulomb law to compute friction forces [

32]. Much of other research work studying the tribology of TKA commonly assumed a fixed friction coefficient, i.e., 0.04, for the whole numerical simulation. Fisher and Dowson reported that the friction coefficient in artificial human joints is in the range of 0.03–0.10 [

33]. However, other studies obtained higher ranges of the friction coefficient for artificial human joints, for example, 0.05–0.33 [

27], 0.06–0.25 [

26], and 0.06–0.17 [

28,

29]. Focusing on the dynamic modeling of total knee arthroplasty (TKA), some investigations have aimed at developing anatomy-based dynamic models to consider the kinetic and kinematic behavior of TKAs like quasi-static models [

34,

35,

36,

37,

38,

39,

40,

41], 2D dynamic approaches [

42,

43,

44,

45,

46,

47,

48], and sophisticated 3D mathematical dynamic solutions [

49,

50,

51]. One of the very first successful attempts to determine the 3D dynamic solution of the knee joint was carried out by Abdel-Rahman and Hefzy [

49]. Their model did not account for the deformation of the articular surfaces and the real geometry of the tibial insert. Later, Caruntu and Hefzy improved that model to include deformable contacts at the articular surfaces [

50]. Although much of the available knee joint dynamic models focused on the joint itself rather than whole-body simulation, Piazza and Delp utilized a full-body dynamic model [

52]. The drawback of their approach was to employ the rigid-contact theory to simulate the knee joint, incapable of calculating contact stresses. Recently, Askari and Andersen developed a 3D anatomy-based dynamic approach that links an in-detail forward dynamic methodology of the knee articulation with a deformable contact model to a musculoskeletal system. The latter is responsible for determining physiological forces and moments from surrounding tissues, like muscles and hip-joint reaction forces [

40].

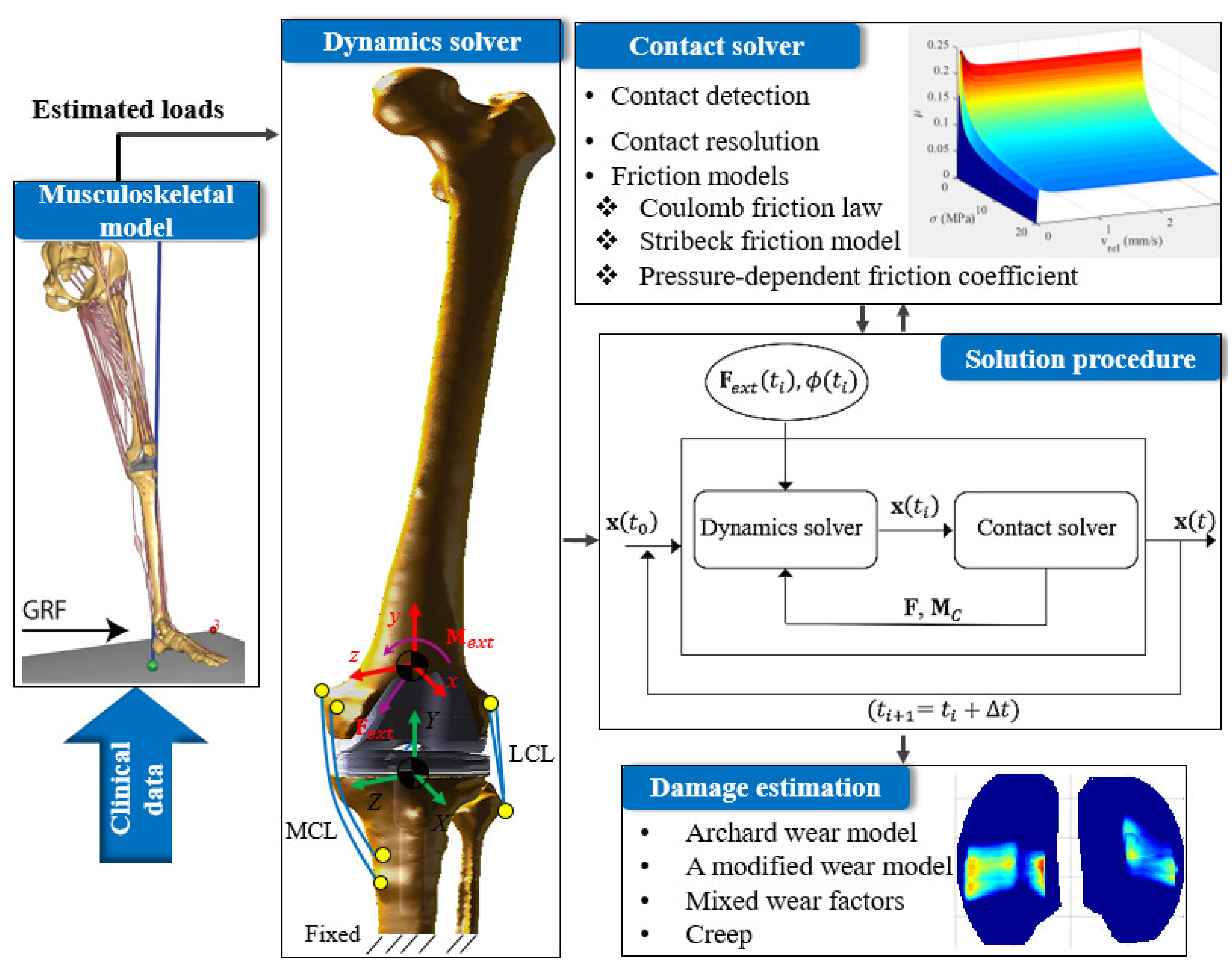

Given the state of the art in this field, the effects of friction on the TKA’s kinematics are yet unclear and remain to be investigated. Therefore, this research work aims at studying friction effects on the joint motion, friction-induced vibration, and the damage of TKAs. Moreover, this research work carries out a comparative study on several phenomenological and empirical friction models integrated into the algorithms accounting for the dynamics of TKA. The computational framework developed in this study also is observable in

Figure 1.

2. An Overview on Friction Models

Friction is generally described as the resistance to motion when two surfaces slide against each other. Friction between solid bodies is an extremely complicated physical phenomenon encompassing elastic and plastic deformations of the articulating bodies, chemical reactions, interactions with wear particles, micro-fractures and cracks, excitation of electrons, and the transfer of particles from one body to another. However, it is possible to represent this complex phenomenon using either simple friction laws with a couple of friction parameters or more sophisticated friction models that commonly require determining a larger number of parameters experimentally. One of the first and simplest friction laws is the Coulomb friction law. Coulomb (1736–1806) determined that the frictional force between two bodies pressed together with normal force

can be calculated by multiplying the normal force and friction coefficient that can be computed empirically [

21]. The relation between the applied load and relative velocity has the following mathematical form:

where

F is the friction force,

the tangential sliding speed,

is the Coulomb friction coefficient, and finally

is external, tangential force. Using this model to deal with friction in dynamic systems leads to a computational burden due to the discontinuity at zero velocity. The friction force can reach any value between

and

due to a sudden alteration in the velocity direction at zero speed. From a physical viewpoint, knowing the external force, imposed on the sliding bodies, can resolve this issue as the friction load is set equal to the externally applied force according to Newton’s first law. Although obtaining the external load is experimentally possible at zero velocity, this is not straightforward to determine in numerical simulations. It is worth noting that the Coulomb friction model only needs one input parameter, i.e.,

, which is why both academic and industrial communities commonly use this model for systems that do not require very precise quantifications.

Another issue with the Coulomb friction law is that it does not capture the distinction between static and kinematic friction. It is well-known that the external force required to make bodies in contact move from their rest status is higher than that when they are in relative motion. Therefore, the Coulomb friction law is modified by replacing the Coulomb coefficient in Equation (1) with a static friction coefficient, i.e.,

(

), which is sometimes called Coulomb friction with stiction.

The discontinuity issue at zero velocity is still present in this model, making it hard to detect stick and stick-slip phases of friction between bodies in contact. Moreover, the transition from the stick friction phase to the slip one is not smooth and continuous. To resolve these issues, smooth and continuous Coulomb friction models were developed to prevent the computational burden caused by the force discontinuity by introducing a smooth curve around zero velocity. To this end, several continuous functions have been adopted in the literature, like linear, exponential, and trigonometric function types. One such model is considered here that can be obtained by multiplying the hyperbolic tangent function of velocity to the Coulomb friction model, Equation (1) [

53]. This modification, which lets the new model be valid for all

from a computational viewpoint, is given by

in which

k is a coefficient that determines how fast the hyperbolic tangent function changes from near 0 to near +1, which can also be represented by

where

depicts a chosen velocity at which one expects the tanh function to take a value close to its maximum. Another model uses a linear friction−velocity relationship at the proximity of zero velocity to smooth out the discontinuity, which can be expressed as follows [

53]:

in which

is the slope of linear function between zero velocity and

to eliminate the difficulty in determining the friction force at zero sliding speed. Obviously, the friction force at zero relative velocity between the interacting bodies is not zero and is equal to the tangential applied force. Hence, the main drawback of the modified Coulomb friction laws explained above is that they assume zero friction at zero relative velocity, which does not make sense from a physics viewpoint.

With the study of lubrication by Rayleigh and Stokes, and the classical paper on theoretical modeling of fluid-film lubrication, which Osborne Reynolds published [

54], the following expression for the viscous friction can be written

in which

is the viscous coefficient. In full-film contacts, the viscous model can be assumed a good representation of behavior of the system. Moreover, the model can act well enough in other contact conditions provided that the viscous coefficient is tuned. Sometimes a better fit to experimental data can be achieved by assuming a nonlinear term of velocity in Equation (5). As such, Equation (5) can be recast as follows [

24]:

where the power

depends on the geometry of bodies in relative motion. The viscous friction term can be superimposed on the other friction models such as the Coulomb friction [

53], which results in, for example, the following formulation.

The Coulomb friction law, and its modified versions, do not explain the negative damping characteristic of friction [

11], which was observed by Stribeck as a continuous nonlinear velocity-dependent phenomenon called the Stribeck effect [

55].This dependency of friction on the relative sliding velocity was also observed by Panovko and Gubanova [

56] and Ibrahim [

57] experimentally. The general form of the Stribeck friction model can be written as follows:

where

is a friction coefficient function for which multiple formulations are available in the literature [

58] and one of the common forms of which is given below.

Here,

is the Stribeck velocity, and

is an exponent that depends on the geometry of the application. It is worth noting that

depicts both the Coulomb friction coefficient and kinetic friction coefficient in this paper while being recognizable according to the context. Friction parameters in Equation (9) can be obtained by performing the friction test for motions with constant velocity. Although the Stribeck friction model is velocity-dependent, this model can be considered a steady friction model. Moreover, the reason for decreasing friction with increasing speed in dry sliding metallic bodies was experimentally investigated and was found to be due to the material softening as a result of high temperatures generated at the contact surfaces [

59,

60]. Moreover, the friction in a lubricated contact decreases with increasing the relative velocity due to a decrease in the number of surface asperities being in contact until full-film lubrication is obtained. Afterward, the friction can gain a value, and either be constant, increase, or decrease with increasing the sliding speed due to viscous and thermal effects. In the case of an increase in friction when full-film lubrication is built, one can add the viscous friction presented in Equation (5) to the relationship Equation (9) to mimic the intuitive physics. The Stribeck model can provide a good representation of the friction between sliding surfaces. The discontinuity problem of the Coulomb friction model is a problem also observed in the Stribeck model. To cope with this issue, the same procedures taken for the Coulomb friction, like using a hyperbolic tangent function, are applicable here as well. Bengisu and Akay suggested a formulation, Equation (10), which is quite different from that in Equation (9), while resolving the aforementioned discontinuity issue [

61].

The first part of the above friction coefficient function uses a near-zero continuous curve to avoid divergence of the numerical model. The second term is the Stribeck friction relation. In addition,

is the negative slope of the sliding state [

62]. After the friction coefficient starts from zero, it increases to peak friction, which Bengisu and Akay [

61] referred to as the static friction coefficient,

. The friction coefficient then reduces with increasing tangential velocity until the friction finally reaches a steady state, i.e.,

.

As was discussed previously, the aforementioned models are not efficient to determine friction magnitude when the velocity is zero nor to manage the stiction phenomenon. Karnopp introduced a concept of the dead-velocity band of the zero proximity, i.e.,

, to cope with the difficulties encountered to detect zero velocity and prevent switching between multi-state relationships to transit between stick, stick-slip and pure slip phases of the friction [

63]. Within the abovementioned velocity interval, the speed is assumed to be null. The friction phase also is stiction, where the friction force can be equal to either tangential external force or static friction. For the velocities outside of that dead band, the friction force can get the form of Coulomb friction, Stibeck friction, and so forth. The following equation can express this idea.

However, the concept Karnopp used to introduce this friction model does not comply with friction physics. Moreover, this model requires the external load as an input, which is often not available explicitly and is an internal state of the dynamical system.

In addition to the phenomenological friction models, there are empirical friction models proposed for UHMWPE in the literature. Wang et al. [

26] reported the following formula derived from experimental data, showing a significant correlation to the contact stress. However, the Coulomb friction model and its modified versions cannot address changes in friction coefficient due to contact stress:

in which

stands for the friction coefficient and

is the contact stress with a unit of MPa. Furthermore, another empirical formulation was suggested by Saikko to relate the friction coefficient to the contact stress as follows [

27]:

where

is a reference pressure (1.1 MPa). The above relationship is correct for

and below this pressure, the coefficient of friction increases with increasing the contact pressure. Recently, several empirical friction models for tibiofemoral joints were developed by a research group in Mexico [

28,

29]. Montes-Seguedo et al. [

30] proposed a power-law model from which the friction coefficient can be estimated in both mixed lubrication regime and full-film lubrication regime as a function of the maximum pressure (

), entrainment velocity (

) in mm/s, and sliding-to-rolling ratio (

SRR), which is written as follows.

Models discussed above are not able to capture dynamic friction characteristics such as pre-sliding and frictional lag. Dynamic friction models such as the Dahl approach and LuGre model can address such phenomena. The discussion associated with the dynamic friction models stands out of the scope of the present study. Interested readers are referred to the following references [

24,

64,

65,

66,

67] for further information

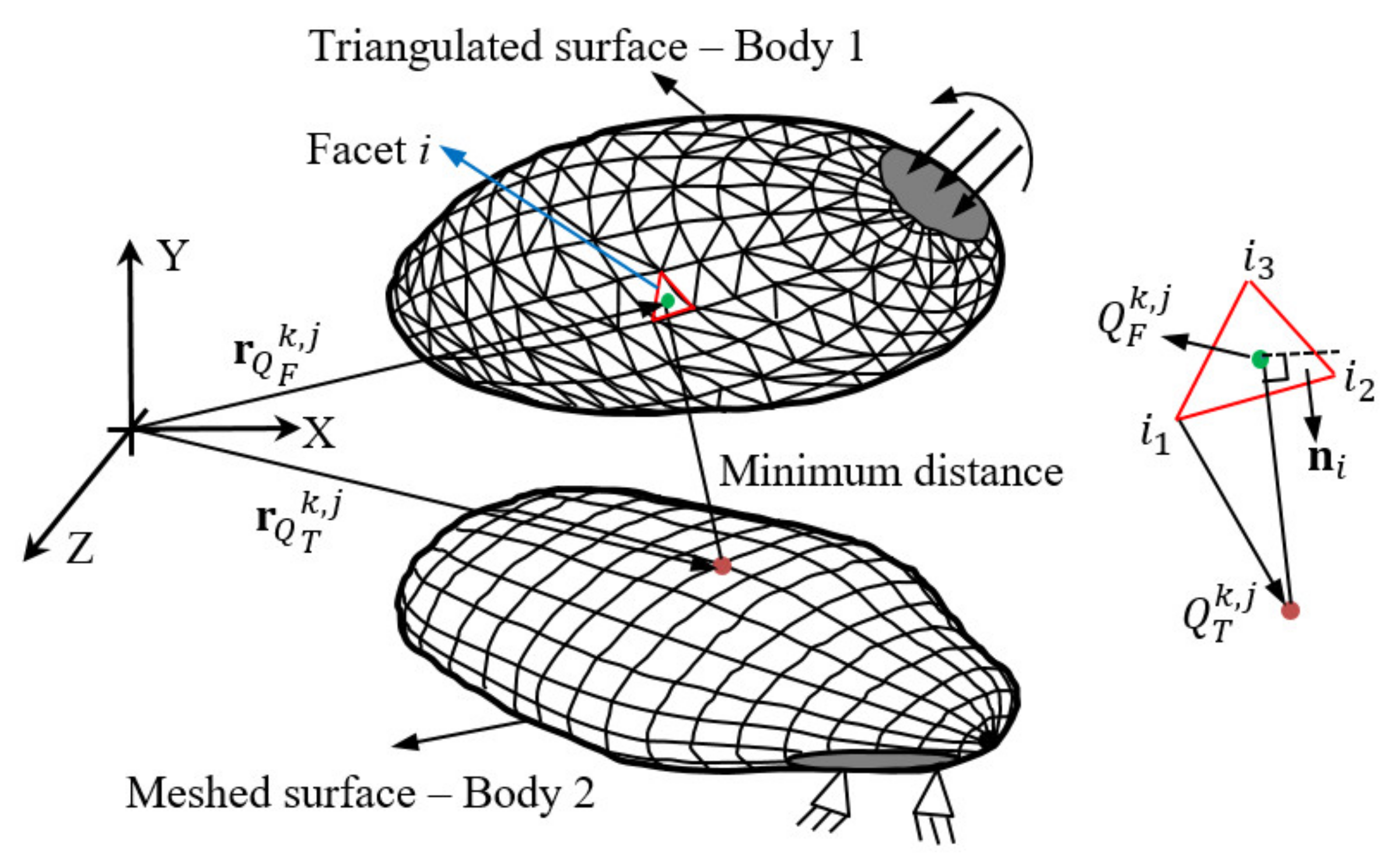

3. Contact Solver: Tangential Friction and Normal Contact Forces

As was discussed before, when two surfaces enter into a contact phase and tend to slide against each other, friction develops and acts as a resistance to the relative motion. In this study, the friction forces are taken into account employing several friction models, listed in

Table 1, that are: (A

1) a modified Coulomb friction model with a constant friction coefficient; (A

2) a modified Coulomb friction model with a pressure-dependent friction coefficient extracted from Wang et al.’s formulation; (A

3) a modified Coulomb friction model with a pressure-dependent friction coefficient extracted from Saikko’s formulation; (B

1) a Stribeck friction approach with constant friction coefficients; (B

2) a Stribeck friction approach with pressure-dependent friction coefficients extracted from Wang et al.’s formulation; (B

3) a Stribeck friction approach with pressure-dependent friction coefficients extracted from Saikko’s formulation; and (C

1) Montes-Seguedo et al.’s empirical friction model. The tangential friction force at a node of the femoral part, e.g.,

, is computed using the following formulation:

where

is the tangential relative velocity of the node

in contact as the tibial insert is assumed stationary, and

is the friction coefficient at the contacting node, which can be considered as a function of either relative velocity or contact pressure and can be substituted from each of the modified Coulomb friction and Stribeck friction models, outlined in

Table 1. Moreover, static and dynamic friction coefficients can be dependent upon the contact stress based on empirical models reported by Wang et al. [

26] and Saikko [

27]. Eventually, seven case scenarios are defined in

Table 1, each of which is considered in this study to study kinematics and tribology of TKAs.

In

Table 1,

is a constant value that takes a value greater than one. Moreover, the pressure-dependent friction coefficient is used in the models A

2 and B

2, illustrated in

Figure 2, to show the difference between such models. As can be seen, the friction coefficient is a function of both relative velocity and pressure when model B

2 is employed, while it varies merely with contact pressure in model A

2. It is worth adding that both models use the pressure-dependent friction relationship Wang et al., proposed in [

26]. However, such a relationship is integrated into the Coulomb friction formula for model A

2 and the Stribeck one for model B

2. It is worth noting that the empirical model Wang et al. [

26] suggested does not address the friction coefficient once the contact stress approaches zero. Therefore, the strategy considered here is to prevent the friction coefficient to exceed the value 0.25 that corresponds to the contact stress of 0.37 MPa. In addition, the models A

3 and B

3 are written based on the relationship recommended by Saikko. His empirical mathematical formulation is valid for the contact stress equal or greater than 1.1 MPa. According to the plot that shows the relationship between the contact stress and friction coefficient in his paper, it can be concluded that the friction coefficient decreases once the contact stress diminishes below 1.1 MPa until it gains an average value of 0.25 once the contact stress reaches zero value. Therefore, a quadratic function is fitted to the data while outliers are removed to address the value of friction once the contact stress gains a value less than 1.1 MPa. The model C

1 is the one developed by Montes-Seguedo et al. [

30], in which

is the velocity of the femoral part at the contact point, which is calculated according to the radius of the functional flexion-extension axis, multiplied by the respective angular velocity and

the speed of the tibial insert at the tibial plateau surface. The latter is computed as the summation of the anterior-posterior linear velocity and the multiplication of the radial distance from the tibial axis to the bottom of the tibial plateau and the internal-external angular velocity. For further information on how to determine these velocity terms, the reader is referred to the reference [

28].

At this stage, a short description of the joint kinematic is presented to determine the velocity of master nodes, including their tangential speed. The relative velocity of a master node like

with respect to its corresponding slave node

locating on body 2, i.e., the tibial insert, can be determined as follows:

where

is the velocity vector of the point

with respect to

,

and

depict the translational velocity of the local coordinate system and the angular velocity of body 1, respectively,

depicts the coordinate vector of the point

and

is the location of the origin of the local coordinate of body 1, i.e., the femoral body, at time

tn is the vector normal to the femoral body at the point

at time

tn. and

and

also are the normal and tangential relative velocities of the point

. As body 2 is assumed stationary, the components of the angular velocity vector resolved in the fixed basis could be evaluated based on Euler angles as follows [

68]:

where

in which

are Euler angles and

depict their time derivatives.

Eventually, the friction force at each element on the femoral components is evaluated knowing the tangential sliding velocities, Equation (18) at all element nodes, the normal load applied to the element, and contact pressure, which are addressed later in this paper. Finally, the resultant friction force tangentially applied to the femoral component can be obtained from the following integration that is performed over the contact area:

where

depicts the contact area,

is friction force at each element and

depicts the size of element area.

The present study implements a concept proposed in [

69] to evaluate contact stresses, but it is impossible to derive a closed-form mathematical formulation for the contact problem at hand. Askari obtained nonlinear and promising contact models while resolving the discontinuity issue with the Kelvin-Voigt model at both the beginning and end of the contact process [

69]. To this end, he simulated the contact by using a set of independent springs and dashpots, which represent the stiffness and viscous damping of the contact between articulating bodies, respectively. Readers interested are referred to the reference [

69,

70,

71,

72] and references therein for further information about the model employed in this study. Such a contact model does not put any kinematic constraints on the dynamical system. It is well-known that the Kelvin-Voigt model suffers from a discontinuity at both the beginning and end of the contact process due to the form of the damping term in its formulation [

73,

74]. The concept proposed in the reference [

69] showed that simulating a soft contact using a set of independent Kelvin-Voigt elements spread all over the contact surfaces instead of just one spring-damper element as is used in the Kelvin-Voigt contact model can resolve the above discontinuity. The penetration depth at each node on the polyethylene surface,

, is known from the minimum distance technique discussed later in the present paper (see

Section 5.3). Its time derivative

is also obtained from the normal velocity term given in Equation (17). Therefore, the normal contact pressure, i.e.,

, at any node of

can be determined based on the following Kelvin−Voigt contact relationship:

in which

is the contact stiffness and

the relaxation time,

is obtained from

where

and

is the tibia thickness [

40],

E and

are Young’s modulus and Poisson’s ratio of the polyethylene that are, respectively, 463 MPa and 0.46 as are reported in [

75,

76,

77]. Such a contact model belongs to the category of the penalty non-adhesive contact approaches and penalizes the indentation of the master body into the slave one. As independent Kelvin−Voigt elements are spread all over the contact area, the normal contact force applied to the femoral components should be computed by performing the following integration over the contact area:

where

is the normal unit vector of an element with the area

on the femur-bearing surface. It is worth noting that the following criterion is used to assess whether a node is in contact or not.

The resultant contact area can also be obtained according to the summation of the area associated with all elements engaged in contact area having nodes with non-zero contact pressure.

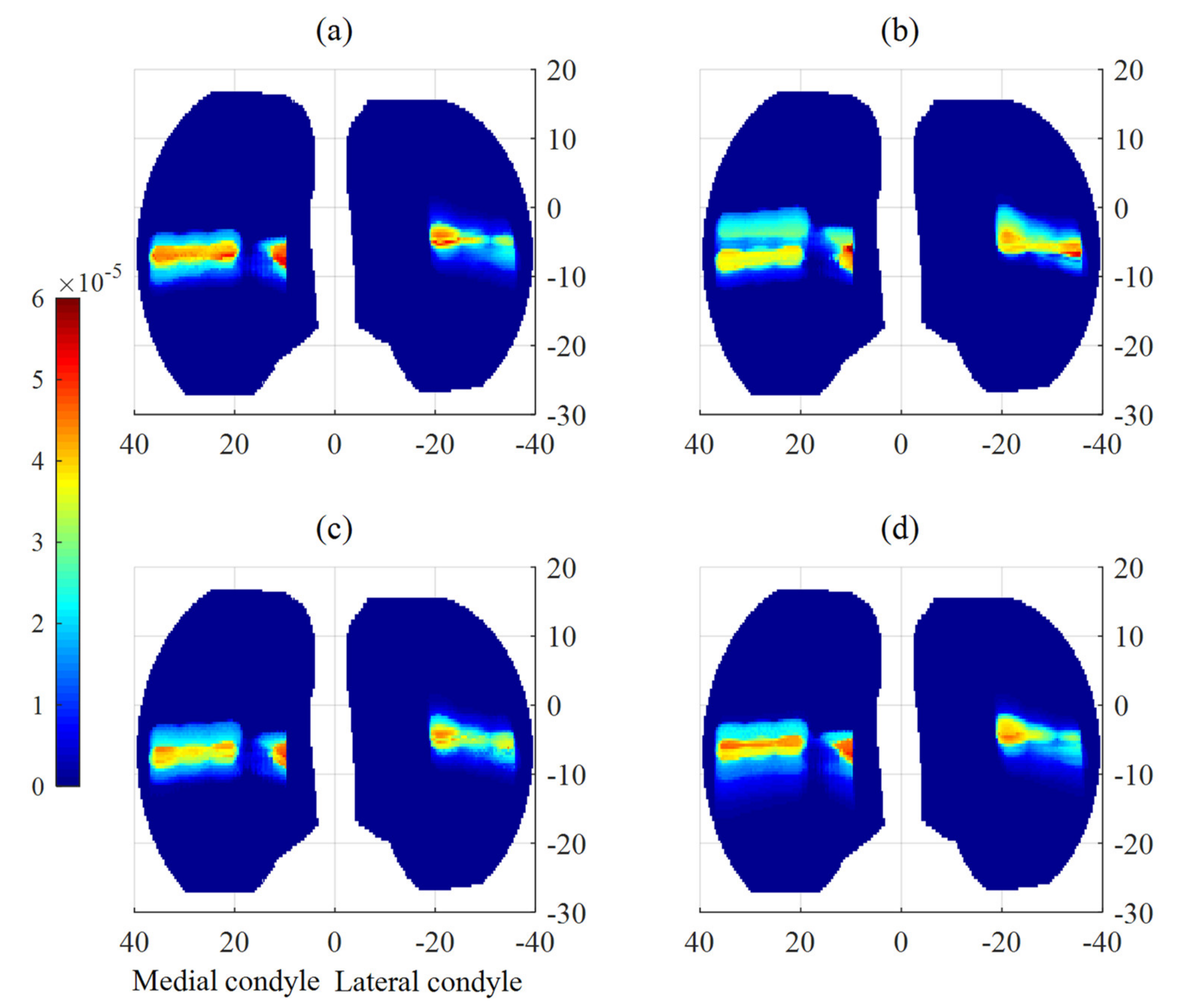

6. Damage Formulation

Now that the dynamic model is ready to be used, the tribology of TKA is formulated to predict wear. Archard wear model is commonly used by the tribology community to describe adhesive and abrasive wear mechanisms, although it is often adopted for a wide range of applications as a result of its efficiency and simplicity [

36]. Employing Archard wear law, the linear wear rate can be computed using the following expression [

91,

92]:

in which the wear depth and sliding distance are presented by

h and

s, respectively. The parameter

kW stands for the wear factor that has the following unit mm

3N

−1m

−1. Although the wear factor has been considered constant by several research studies, Equation (37), Kang et al., observed from experimental data that the wear factor is dependent on the contact pressure and cross-shear ratio. Therefore, they suggested a new formulation for the wear factor that varies with not only the cross-shear ratio,

, but also the contact pressure. They proposed a relationship to compute the wear factor of the UHMWPE tibial insert [

93] accounting for such dependencies given in Equation (38) in which the average contact stress, i.e.,

, for a given element is computed by averaging contact pressure over one gait cycle, and the definition of the cross-shear ratio and the procedure to compute it is well-described in [

93].The described wear techniques listed in

Table 2 are used in this study to estimate wear in total knee arthroplasties

Wear factor given in Equation (38) is dependent on the contact pressure and is not easily implemented into computational wear modeling. Abdelgaied et al. [

77] developed a wear model based on the idea that volumetric wear (

W) is proportional to the contact area (

A) and sliding distance (

S) and a non-dimensional wear coefficient (

C) determined experimentally to complete the wear formulation, Equation (39). The cross-shear ratio is

CS, and parameters

a,

b and

c are constant and determined from the experimental measurements of a multi-directional pin-on-disk wear test [

77] as

a = 8.5173e-65,

b = 9.3652e-60, and

c = −6.7454.

6.1. Cross-Shear Ratio

Under the sliding motion of a metallic part on ultra-high molecular weight polyethylene, the polymeric chains align in the direction of the maximum frictional work according to the experimental findings [

15,

94], which is the so-called principal molecular orientation (PMO) [

12,

15]. The cross-shear ratio can be quantified as the quotient of the frictional work done perpendicular to the PMO direction (

) to the total frictional work (

) as is formulated below [

95,

96,

97].

The frictional work can be calculated based on

where

is the incremental sliding distance that can be computed by

at each element. The direction (

) of incremental motion along the contact point trajectory is calculated to determine the vector of the incremental sliding distance,

. Moreover, considering a test PMO direction (axis) with an angle

, frictional force and incremental sliding distance components parallel to and perpendicular to that axis can be calculated for each increment [

12,

95,

96]. Assuming that the friction coefficient does not vary during a cycle, the cross-shear can be formulated as follows.

The dynamic model developed in the previous sections obtains the sliding distance and contact force with time, which allows calculating Equation (41) for each angle , from 0 to π, until the principal molecular orientation, , is reached where the cross-shear ratio is minimized.

6.2. Creep Estimation

In addition to the wear phenomenon, creep deformation contributes to the surface damage of the UHMWPE tibial insert due to the viscoelasticity of UHMWPE, where deformation under a constant load varies with time. Performing experimental creep tests, Lee and Pienkowski [

16] presented a nice formulation to compute the creep deformation, which is a function of both pressure and a logarithmic timescale as follows [

92]:

where

is the linear damage at an element (

k,

j) due to creep,

N is the total number of cycles in service,

is the thickness of element (

k,

j) of the acetabular cup and

associated with an element (

k,

j) of the cup surface is non-zero just when the corresponding

i is in the set of time values where the contact stress is non-zero. The unit of time and pressure are minute and MPa, respectively, according to Lee and Pienkowski experiment.

9. Conclusions and Future Research Directions

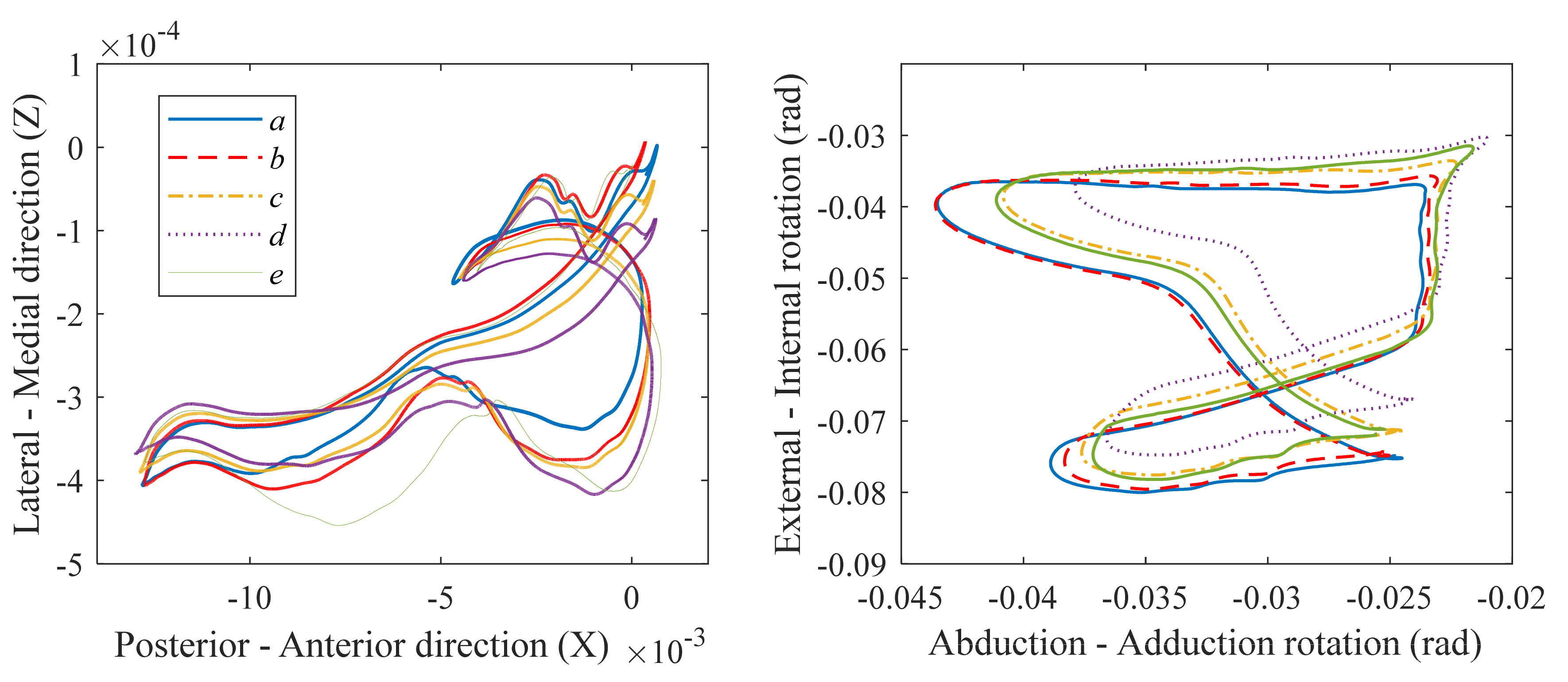

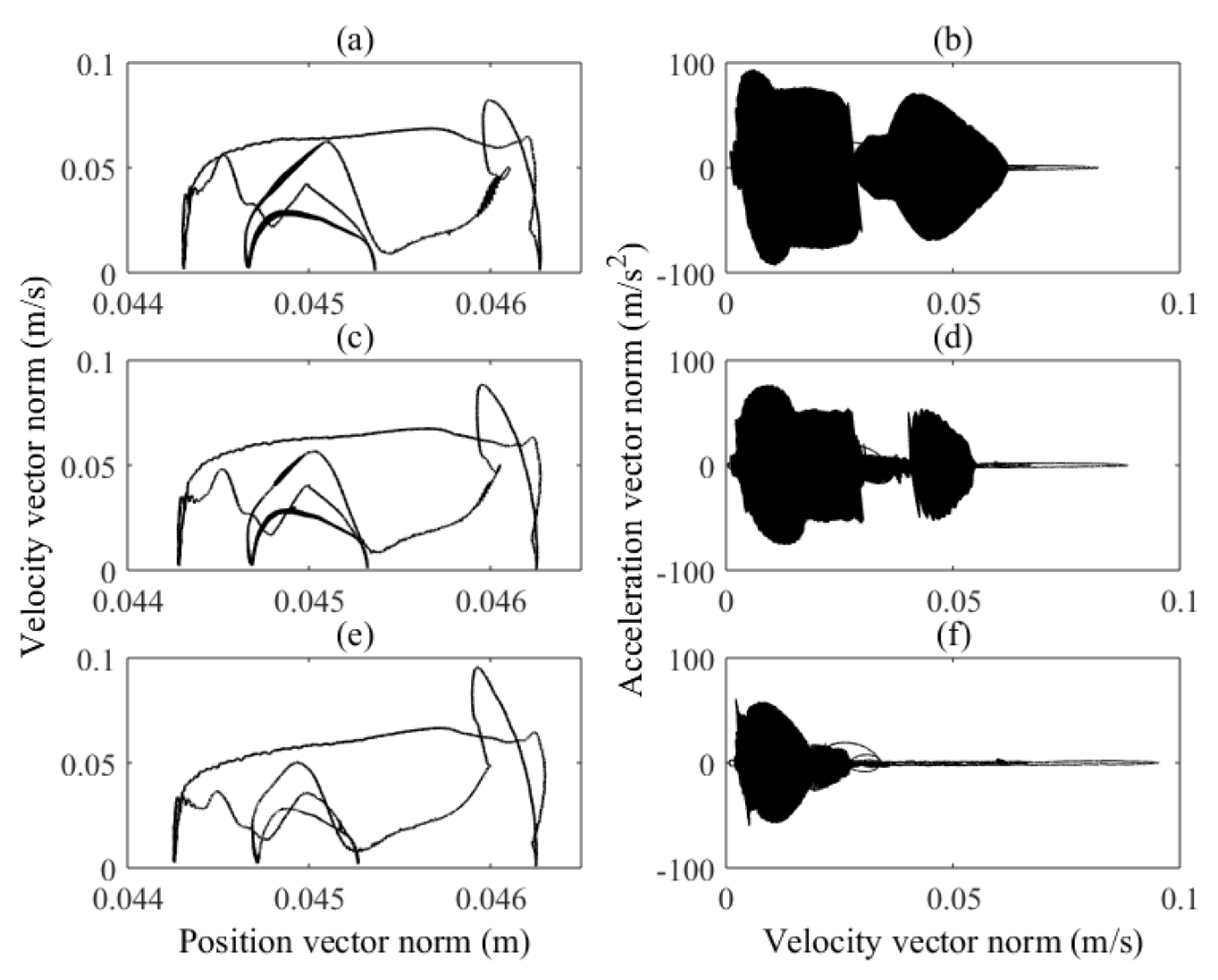

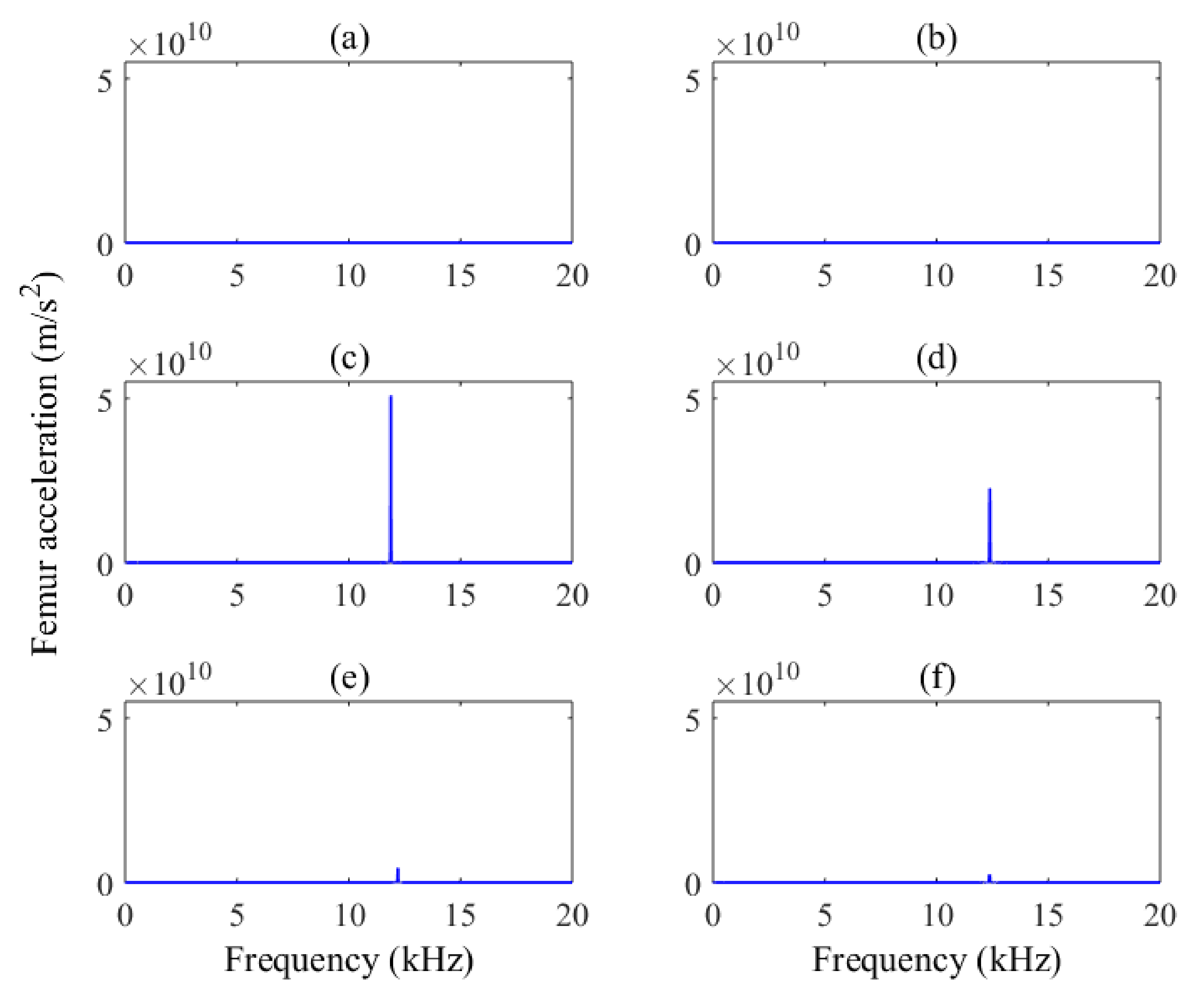

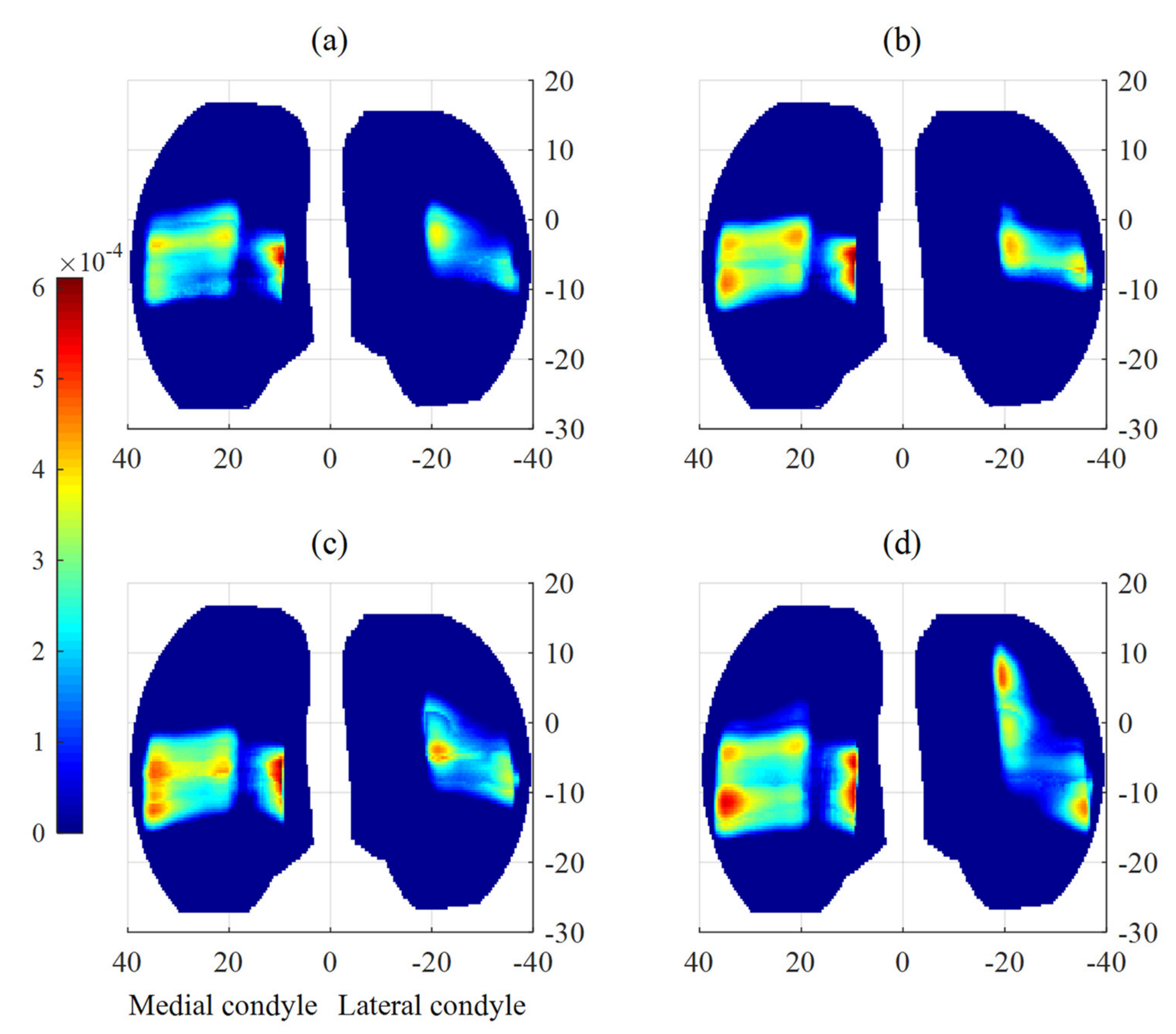

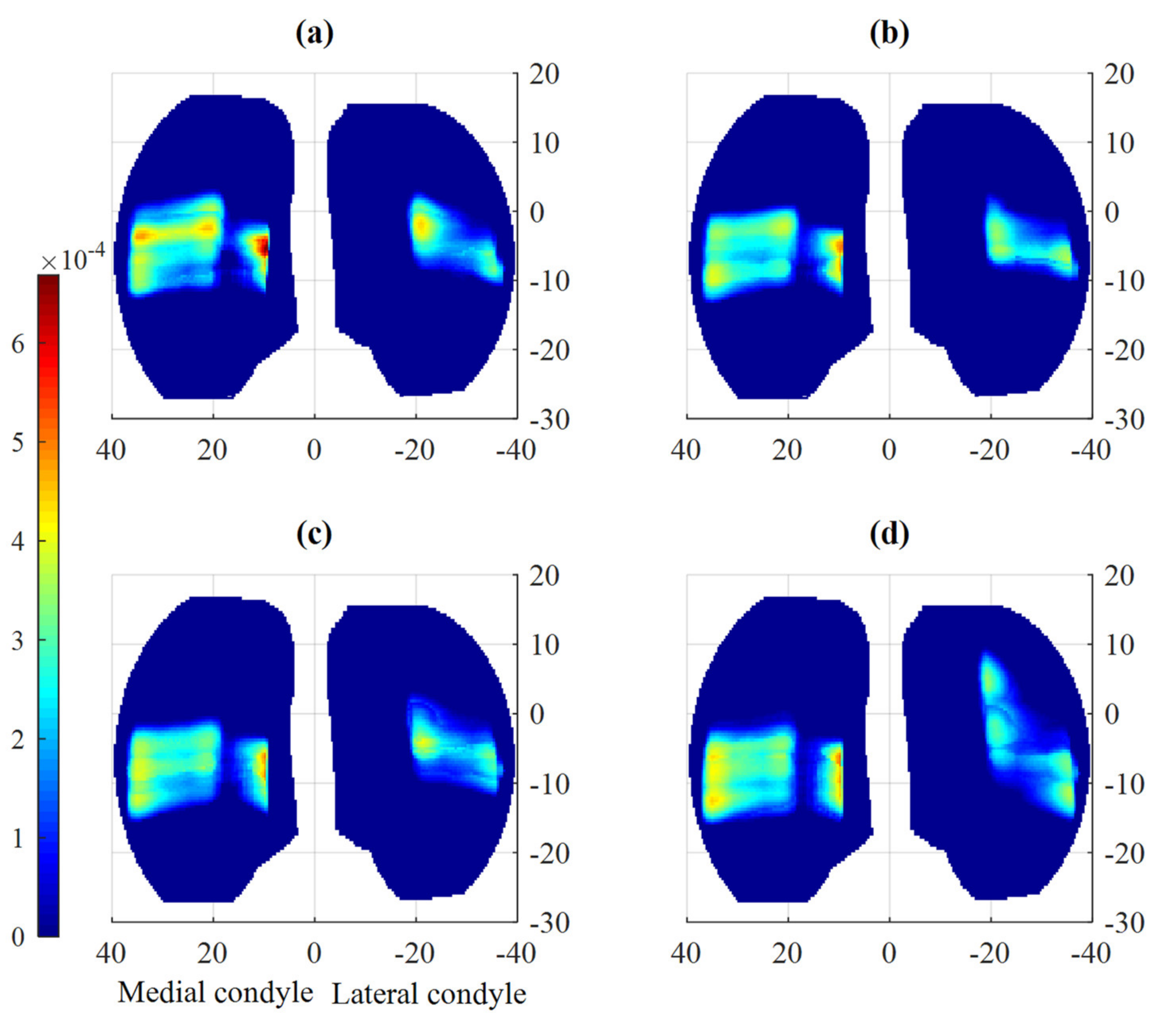

This study developed a spatial dynamic methodology to investigate the effect of friction on nonlinear dynamics, vibration, wear, and creep of tibiofemoral joints. A mesh density analysis was performed to end up with a fine mesh size that guarantees the accuracy of obtained outcomes. Comparing acquired results to those available in the literature also made it possible to evaluate the developed model. In conclusion, friction can considerably influence the motion and damage of TKAs. From the phase portrait diagrams, chaotic behaviors were observed in the tibiofemoral movement. It was also inferred that friction-induced vibration takes place when the friction coefficient increases. Moreover, using an empirical friction model resulted in vibration occurrence. Making any changes in the magnitudes of parameters in the Stribeck friction model led to the alteration of wear rates on both condyles. Furthermore, it cannot be expected that increasing the friction coefficient can always cause wear to rise owing to the strong nonlinearities of the wear mechanism. The three wear models employed in this study to predict the wear of TKAs also produced outcomes with significant differences, which should be taken into account by designers and engineers in their designing process. Eventually, it was illustrated that friction models influenced both translational and rotational loci of tibiofemoral motion, and consequently, the damage distribution.

As future research directions, the proposed model can be extended to account for the dynamics of the patella-femoral joint in addition to the tibiofemoral joint as well as to take fluid lubrication into account while handling fluid–structure interaction [

105,

106,

107]. Moreover, the suggested approach can be utilized to optimize the design and material properties of TKAs to improve their lifetime and tribology performance, using optimization approaches such as genetic algorithm (GA) and particle swarm optimization (PSO) algorithms [

108]. The friction models considered in this article are not able to capture dynamic characteristics of the friction phenomenon, e.g., pre-sliding and frictional lag. The dynamic-based friction approaches like Dahl and LuGre are to be employed accounting for these characteristics, which can lead to much more precise outcomes than those obtained in our study. As was illustrated, increasing friction leads to friction-induced vibration that should be considered in more detail experimentally as well. In addition, the viscoelasticity of polyethylene tibial insert can be considered using more sophisticated models, namely the generalized Maxwell model, Wagner model, and Prony series [

109].

The present study assumed that the geometry evolution of the polyethylene tibia owing to material loss and creep deformation does not affect the contact stresses and knee trajectory, whereby the wear magnitude varies linearly during the wear analysis. Surface evolution leads to a reduction in contact stresses over time, resulting in decreasing wear rates and creep deformation [

36]. Therefore, it can be deduced that the present study overestimated linear wear rates and creep deformation, both of which are dependent on contact pressure. The presented methodology can be extended to include the surface variations of the plastic tibial insert due to the wear and creep phenomena. The improved model will address the effect of the geometry update on both contact stresses and contact point trajectory, and eventually, wear and creep. Furthermore, damage distribution was found to vary with changes in the friction coefficient of knee components. Therefore, a greater area of the polyethylene tibia can get damaged when friction increases. A future direction of this research is to consider how any alteration in the damage map can influence the performance and lifetime of TKAs. The knowledge gained through such a study can contribute to the design and material development of TKAs.