In this section, we first illustrate the Manhattan distance and present the objective function based on the Manhattan distance. Then, we apply a statistical approach to obtain the global minimizer for the continuous-space single-facility location problem, where several properties of the minimizer can be obtained. With these properties of the minimizer, we can drive optimization procedures in searching for the globally optimal facility locations.

3.2. Minimum Distance Approach

In this subsection, we provide the three-dimensional single-facility location methods for the Manhattan distance. With the objective function of

in (3), let

be the optimal facility location. Then, we have

The minimizer of

in (3), denoted by

, can be obtained by the following estimating equations that need to be solved for

,

, and

according to Section 1.3 of Hettmansperger and McKean [

57].

Then, the optimal values

,

, and

can be calculated separately. It is easily seen that they are the weighted medians of the

-axis,

-axis, and

-axis observations, which will be detailed later. Note that the weighted median was first suggested by Edgeworth [

58] and since then it has been widely used in many applications [

59]. As an illustration, we briefly introduce the conventional median first and then the weighted median. As the values

,

, and

can be obtained separately, we only consider the weighted median for the

-axis observations. Then, the weighted medians for the

-axis and

-axis observations are easily obtained using the same method.

Definition 1. Given a set of observations,, …, , the empirical cumulative distribution function is defined as

where

represents the indicator function defined as

Definition 2. Csorgo [60] defined the left sample quantile function (inverse cumulative distribution function) as below. Using this, the conventional median

is obtained as:

where

.

Definition 3. Wasserman [61]defined the right sample quantile function (inverse cumulative distribution function), which is given by Note that the definition by Wasserman [

61] is slightly different to that of Csorgo [

61]. It is easily seen that

Thus, the sample quantile by Csorgo [

60] is called the left quantile, while the sample quantile by Wasserman [

61] is the right quantile. Rychlik [

62] and Hosseini [

63] showed that

Based on the quantile function by Wasserman [

61], we have the corresponding median

, which is obtained as:

where

.

It is obvious that the difference between (13) and (15) is the case when with even . It is obvious that (13) takes the left bound value and (15) takes the right bound value. Moreover, both of them are the minimizers (medians) to the total Manhattan distance of the -axis observations.

The above definitions on the empirical distribution and the sample quantile do not consider the weights of the observations. Thus, the definitions with weights are given below.

Definition 4. Given a set of observations,, …, with corresponding positive weights ,

, …, such that , we have the empirical cumulative distribution function with weights, which is defined as

Note that the above

includes the conventional empirical cumulative distribution function

in (8), as a special case when

. Similar to the definition of the sample quantile function in Csorgo [

60], we define the sample quantile function with weights.

Definition 5. Given a set of observations,, …, with corresponding positive weights ,, …, such that , the sample left and right quantiles with weights are given by

Next, our goal is to obtain the minimizer of the

in (3). As the weighted medians for the

-axis,

-axis, and

-axis observations can be calculated separately, we only focus on the weighted median of

-axis observations, which are given by

where

is the weight for

.

According to the equations in (14) and (20), we can deduce the following equation. Then, we have

It is obvious that the above minimizes the weighted Manhattan distance. However, it is not a unique minimizer when there is a tied value at. Thus, we have two cases and both of them are the minimizers to the objective function:

- (i)

and

- (ii)

and

Because the minimizer of

, denoted by

,

, and

can be calculated separately. Based on the weighted median obtained in this subsection, the globally optimal location of the facility in a three-dimensional space is given by

In addition, the globally optimal location of the facility in a two-dimensional plane is easily obtained by (22) and (23). For the higher-dimensional () globally optimal facility location problem with Manhattan distance, the main task is to calculate each of the weighted medians for all the axes. Then, the optimal facility location in a higher-dimensional hyperspace can be obtained.

3.3. Properties of the Minimizer

Next, we derive the properties of the globally optimal locations for the continuous-space multi-facility location problem. As obtained of the minimizer for

, the globally optimal single-facility location is the weighted median of the axis observations. In the first case, there is only one minimizer

, whereas the second case contains an infinite number of minimizers between

and

. Suppose that we choose only one minimizer among

,

, (

)/2 for the second case, we can construct the candidate facility locations. To better observe the characteristic of the optimal single-facility location, we use four examples (i.e., Examples 1–4) to illustrate the property of the optimal facility location, and the datasets are provided in

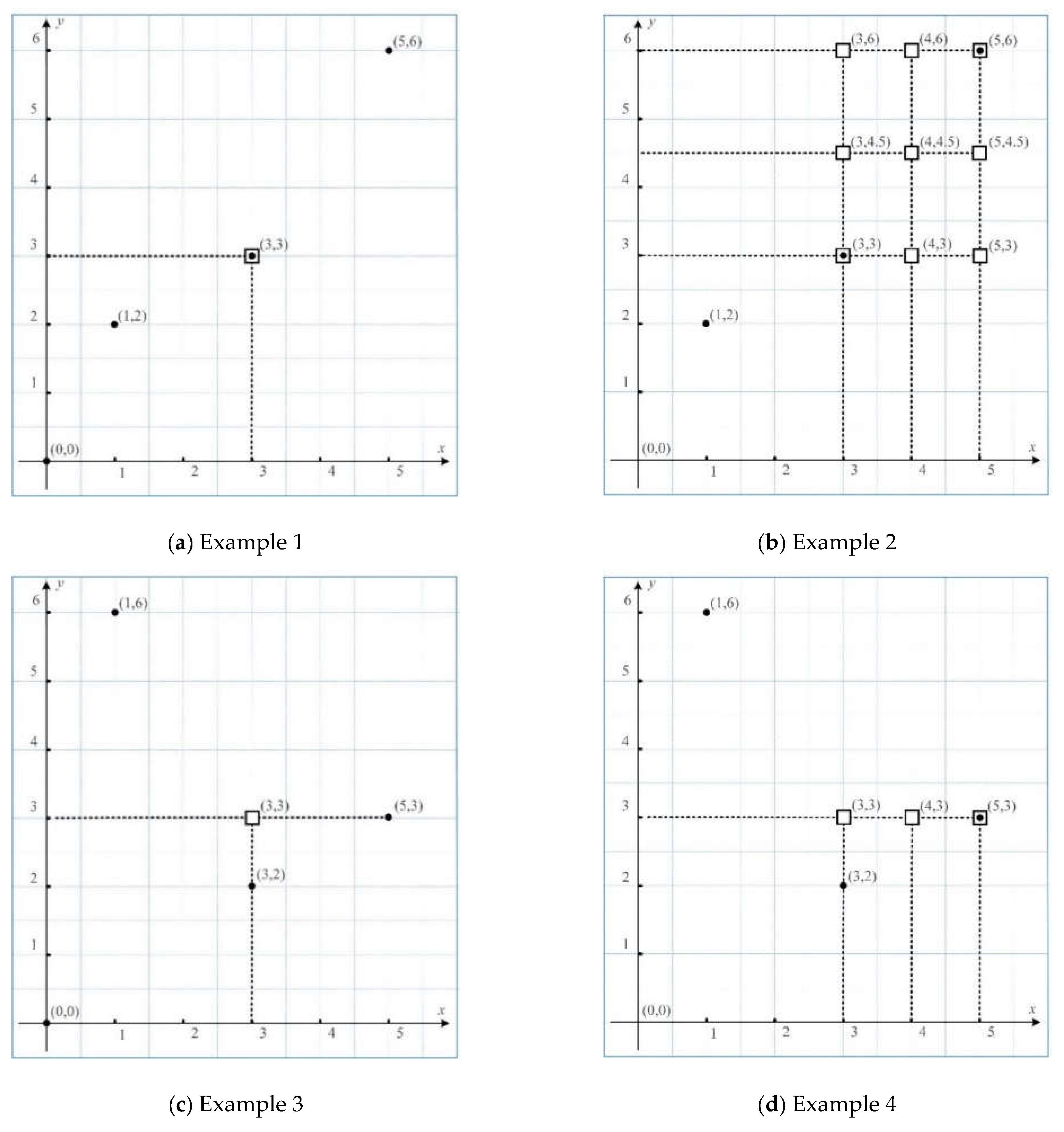

Table 2.

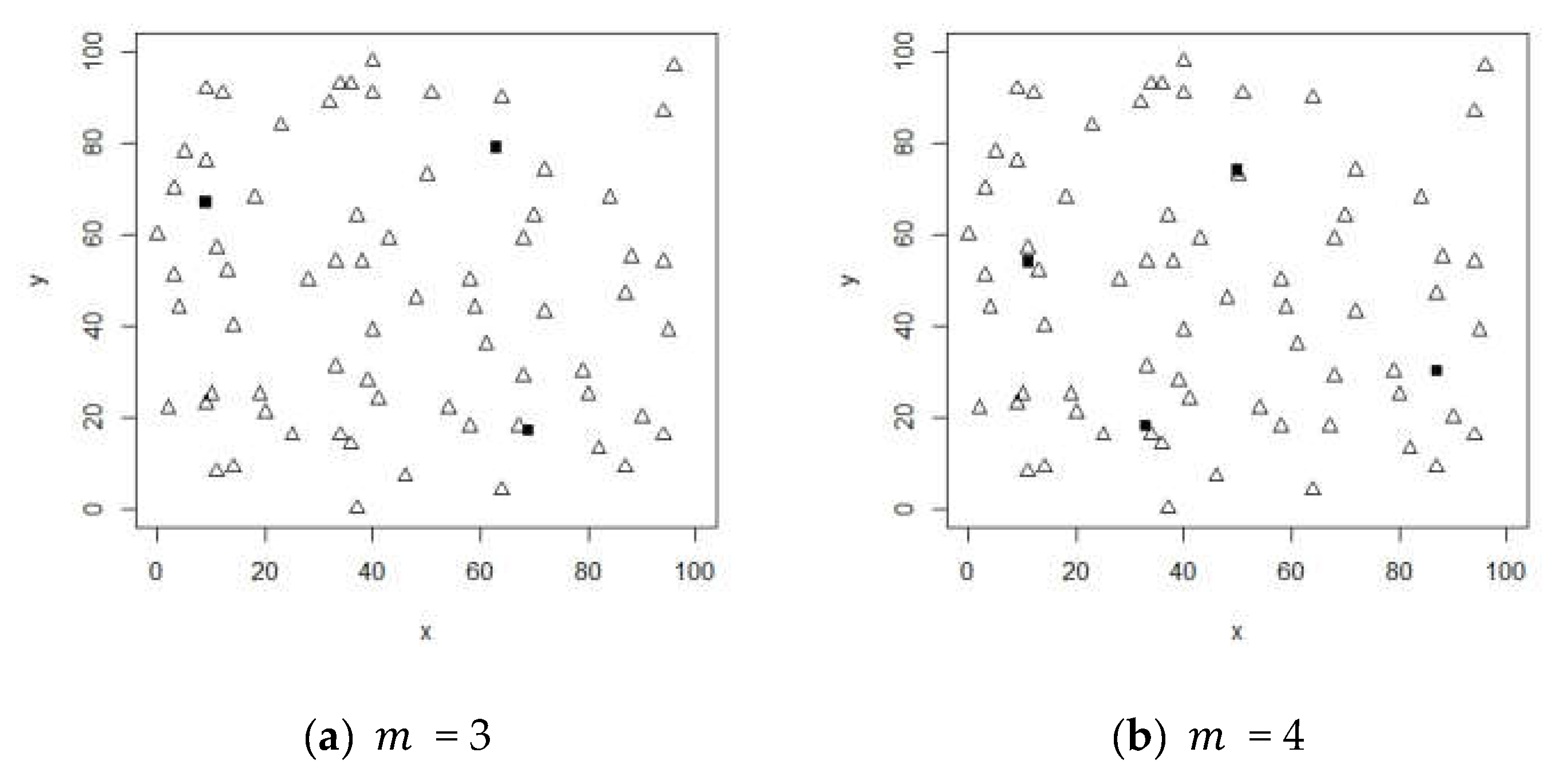

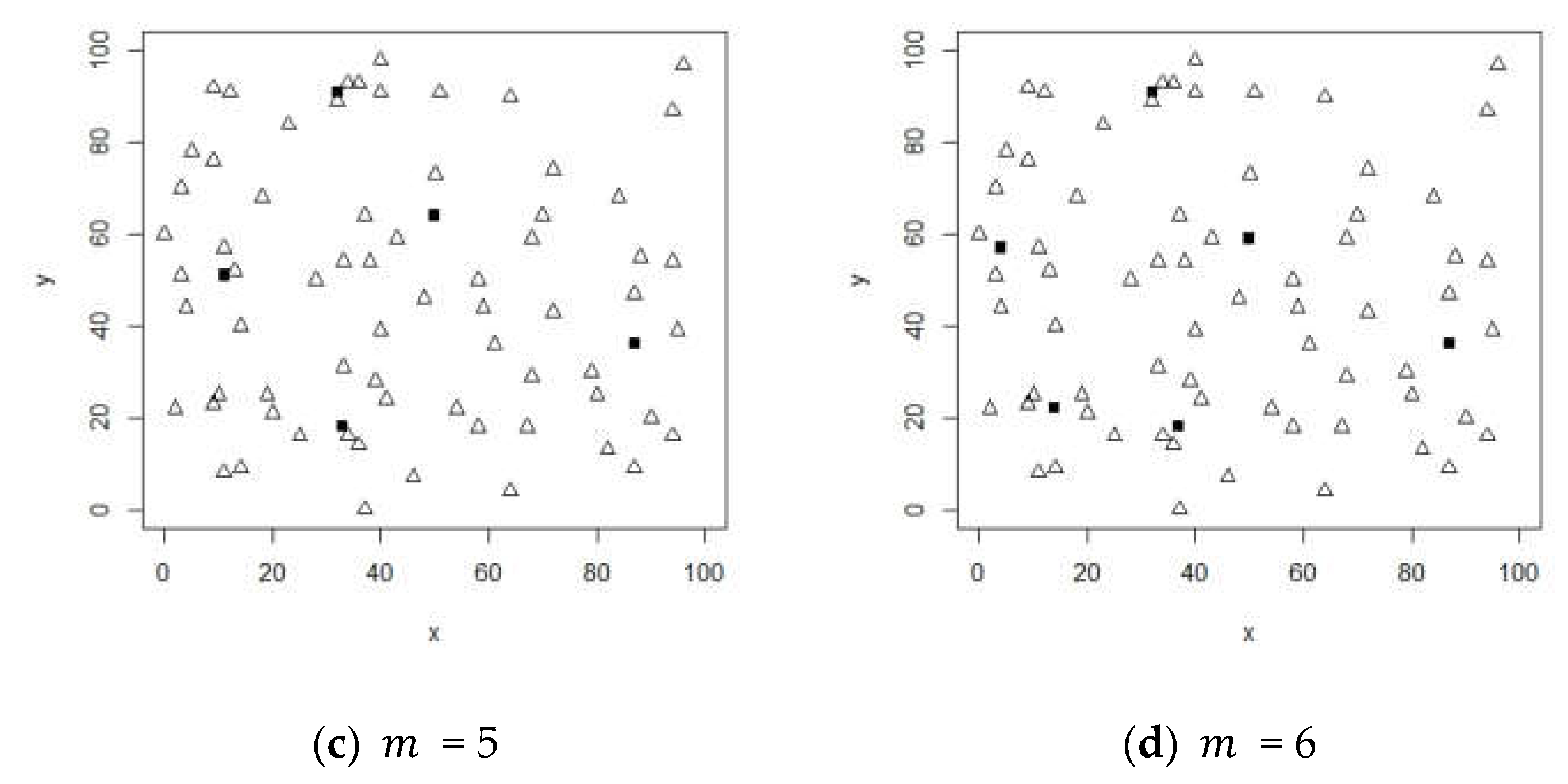

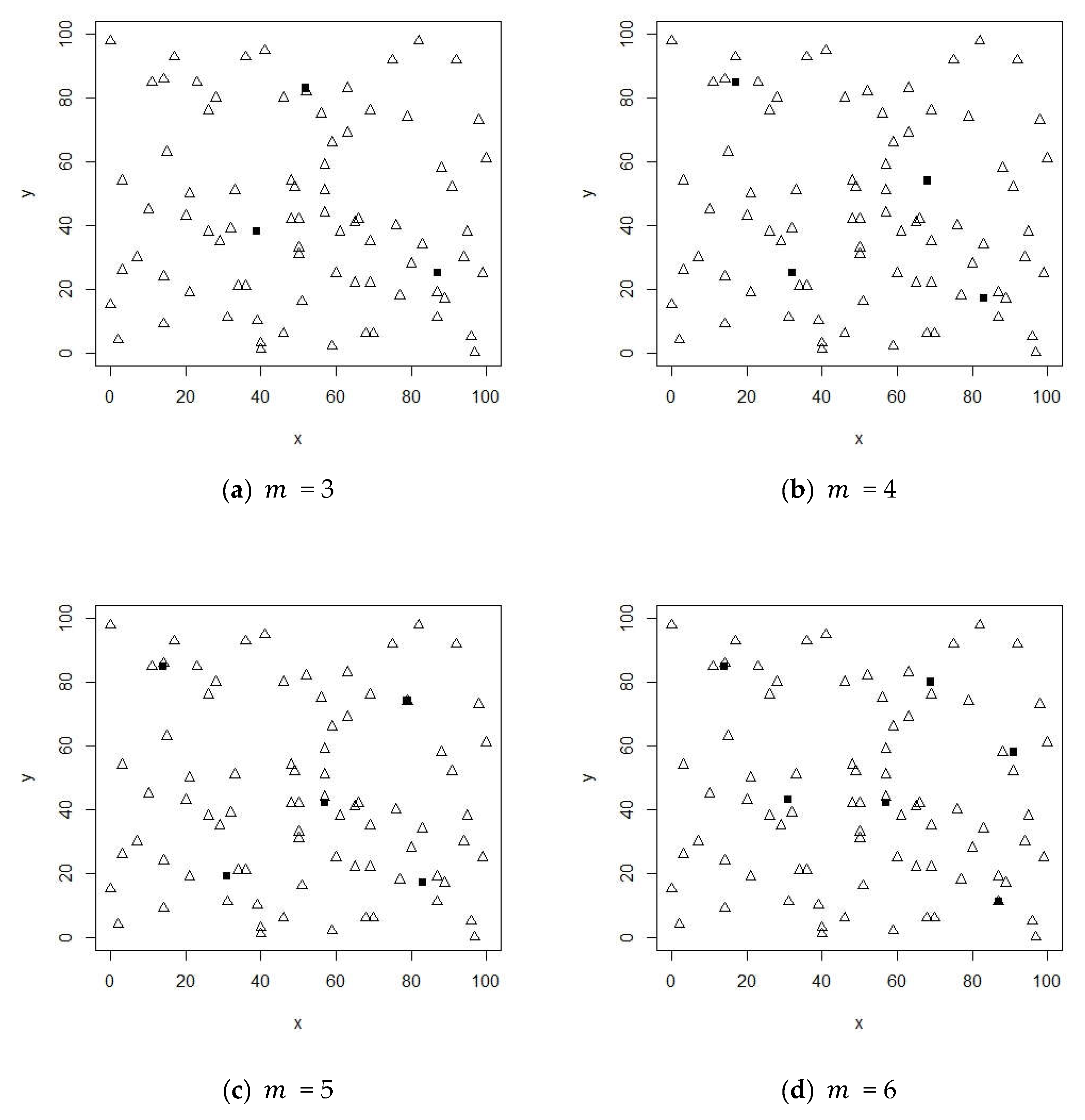

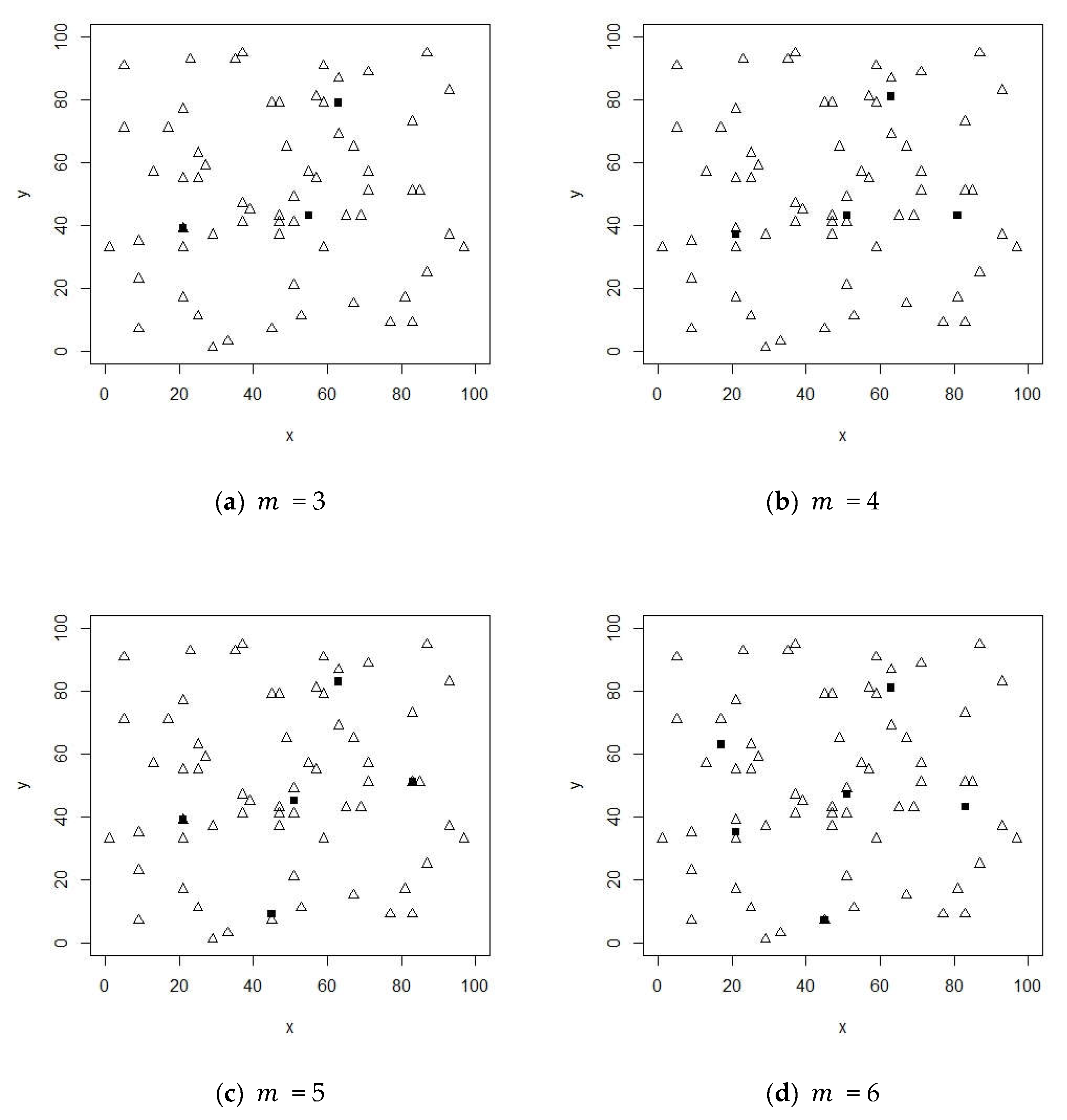

3.3.1. Example 1

As shown in

Figure 1, the black circles stand for the demand points and black hollow squares represent the optimal facility locations. In Example 1 (see

Figure 1a), the optimal facility location is located at the second demand point due to its coordinate values and weights, which are given by

3.3.2. Example 2

There are four optimal facility locations (black hollow squares) in Example 2 (see

Figure 1b) because of weight construction. Then, the weighted medians are given by

It is easy to obtain the optimal facility locations through permutation and combination of the weighted medians on different axes, which are (3, 3), (3, 6), (3, 4.5), (5, 3), (5, 6), (5, 4.5), (4, 3), (4, 6), and (4, 4.5). It is obvious that two of them, i.e., (3, 3) and (5, 6), are located at the demand points, but the others are not. As they have the same objective function value, any one among them can be considered as the location for the facility.

3.3.3. Example 3

As shown in

Figure 1c, there is only one specific location for the facility due to the singular weighted median on each of the axis. The optimal facility location does not locate at the demand point, which is given by

3.3.4. Example 4

In this case, the weighted median on the axes are given by

Thus, there are three black hollow squares in

Figure 1d, where any of them can be considered as the optimal location for the facility.

As presented in

Figure 1 for Examples 1–4, we can conclude that the globally optimal facility location is based on the coordinate values of the observations on different axes. After constructing the set of mesh points that are consist of the coordinate combinations, it is obvious that the optimal single-facility location is an element from the set of mesh points. Then, we have the following formula

Similarly, if we choose only one minimizer among

and

for the second case in (39), the optimal single-facility location is also an element from the other set of mesh points, which is given by

Note that the number of candidate locations in (34) is smaller than that in (33) but the objective function obtained through (34) is the same as that through (33). In this sense, the number of candidate locations in (34) is suggested in this study.

3.4. Identification of the Candidate Locations

As presented in (33), the globally optimal single-facility location is an element from the set of mesh points. Then, we investigate the candidate locations for the multi-facility location problem. In the multi-facility location problem, each demand point is assigned to its closest facility. Suppose that we have obtained the optimal facility locations, then the set of demand points served by the same facility is considered as a group, which is independent of other groups. In this sense, the optimal facility location is still one of the mesh points within this group. After considering the optimal facility locations for all groups, these optimal facility locations are from the mesh points that are constructed based on the observation coordinates. Then, we have

where

is the number of facilities, which is indexed by

.

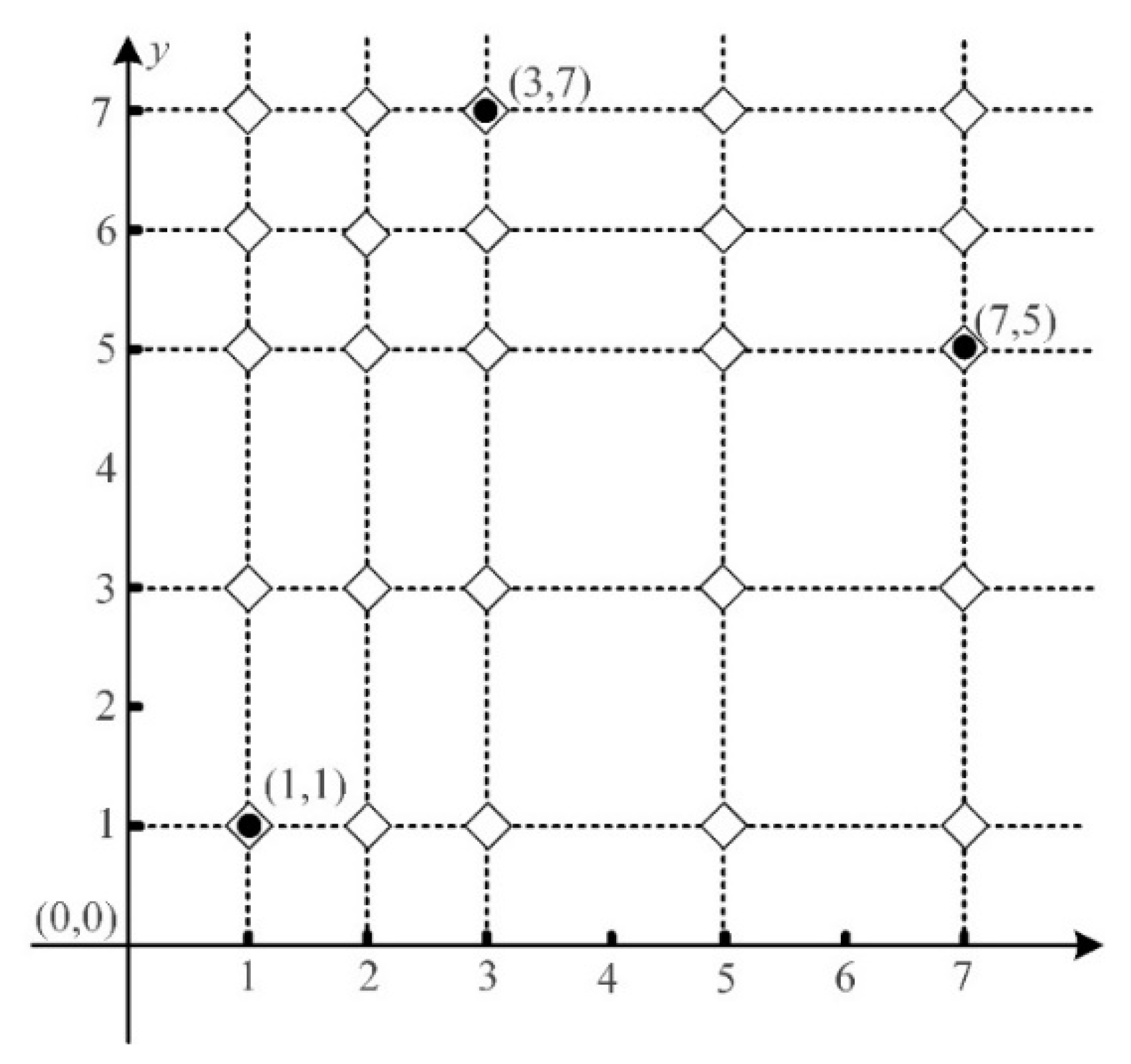

As an illustration, we provide an example to show the candidate locations (i.e., mesh points) for the facilities. In the example, we consider three demand points (see

Table 3). As shown in

Figure 2, we construct the mesh points based on these three demand-point coordinates. Accordingly, 25 mesh points are represented by black hollow rhombuses that also contain three demand points. These 25 mesh points are considered as the candidate facility locations. It is easy to conclude that the number of candidate facilities

is related to the number of demand points

, where the relationship between them is given by

When the demand points have the same coordinate value on one axis, the number of candidate facilities

can be smaller. Suppose that there are

(

) different

-axis values and

(

) different

-axis values, the number of candidate facilities

can be smaller, which is given by

Based on the conclusion about the number of the candidate locations for the two-dimensional multi-facility location problem, it is easy to deduce the number of candidate locations for the three-dimensional multi-facility location problem, which is given by

If we consider the minimizer from

and

for the second case presented in (39), the number of mesh points can be reduced and the number of candidate facilities

for the two- and three-dimensional multi-facility location problems are given below

Finally, we construct the candidate facility locations and transfer the continuous-space multi-facility location problem to the discrete-space multi-facility location problem. Next, our goal is to select the optimal locations from the mesh points, which is the global optimum solution to the problem.

3.5. Determination of the Globally Optimal Facility Locations

After the construction of the candidate locations for the facilities, what we need to do is to select the optimal facility locations from the mesh points. We formulate the mathematical model for the multi-facility location problem, which is also called the location-allocation problem. Besides, the construction of the candidate locations for the facilities makes it possible to determine the globally optimal locations for the capacitated facilities. Then, we present the different models for different facility location problems.

3.5.1. Model for the Uncapacitated Multi-Facility Problem

With the number of demand points

, we have

candidate facility locations. Let

be the set of demand points, which is indexed by

with

. Let

be the set of candidate facility locations, which is indexed by

with

. Then, the distance from the candidate facility location

to the demand point

is known, which is denoted by

. Given the number of facilities

, our goal is to select

locations among

candidate facility locations and allocate the demand points to these facilities to minimize the total cost. To formulate this problem, we need to define two more decision variables, which are given by

Then, we have the following mathematical model for the general multi-facility location-allocation problem:

The objective function in (41) minimizes the total weighted travel cost. Constraint in (42) means that we must locate exactly facilities. Constraint (43) states that a demand point can only be serviced by one facility. Constraint (44) indicates that the demand point can only be assigned to the opened facility.

3.5.2. Model for the Uncapacitated Multi-Facility Problem with Fixed Cost

In the above mathematical model, the fixed cost of opening a facility is not considered. However, in practice, the fixed cost of opening a facility is inevitable. Thus, the fixed cost, denoted by , needs to be considered in the multi-facility location-allocation problem. In this sense, the number of facilities is also a decision variable. Then, the mathematical model is given by

The objective function in (45) minimizes the total cost including the weighted travel cost and fixed cost. The first constraint in (46) means that the number of facilities cannot be more than . Constraints (47) and (48) are the same as the Constraints (43) and (44).

3.5.3. Model for the Capacitated Multi-Facility Problem with Fixed Cost

Generally, the clustering-based method is applied to solve the uncapacitated continuous-space multi-facility location problem. Even though some studies have applied the adjusted clustering-based algorithms to solve the capacitated multi-facility problem [

30,

31], it is still impossible to guarantee the global optimum of the solution. In this sense, obtaining the globally optimal locations for the facilities is warranted when the practical factor of the limited capacities is considered. Based on the constructed candidate locations for the facilities, the globally optimal locations for the capacitated facilities also can be selected from the mesh points. Let

be the quantity of demand at demand point

and

be the capacity of the facility

. Note that

can be considered as the weight of demand point

. Then, the capacitated continuous-space multi-facility problem can be formulated as the following mathematical model

.

The objective function in (49) minimizes the total cost including the travel cost and fixed cost. The first constraint in (50) guarantees the maximum number of facilities. Constraints (51) and (52) are the same as the Constraints (43) and (44). Constraint (53) restricts the facility capacity.