The Prediction of the Performance of a Twisted Rudder

Abstract

:1. Introduction

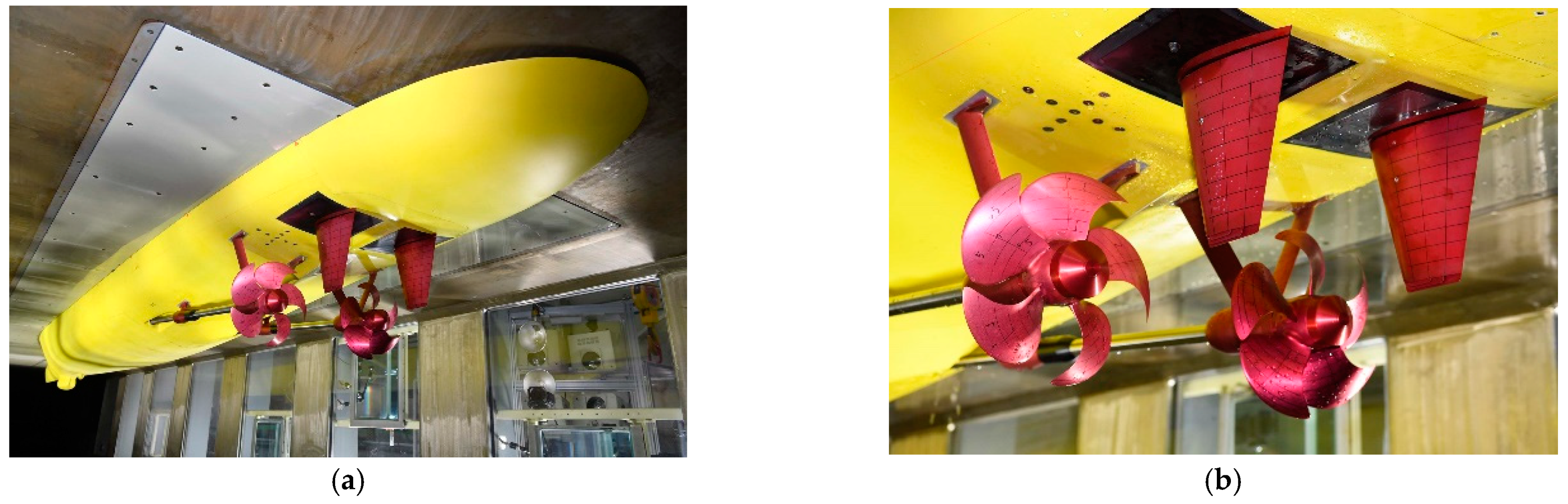

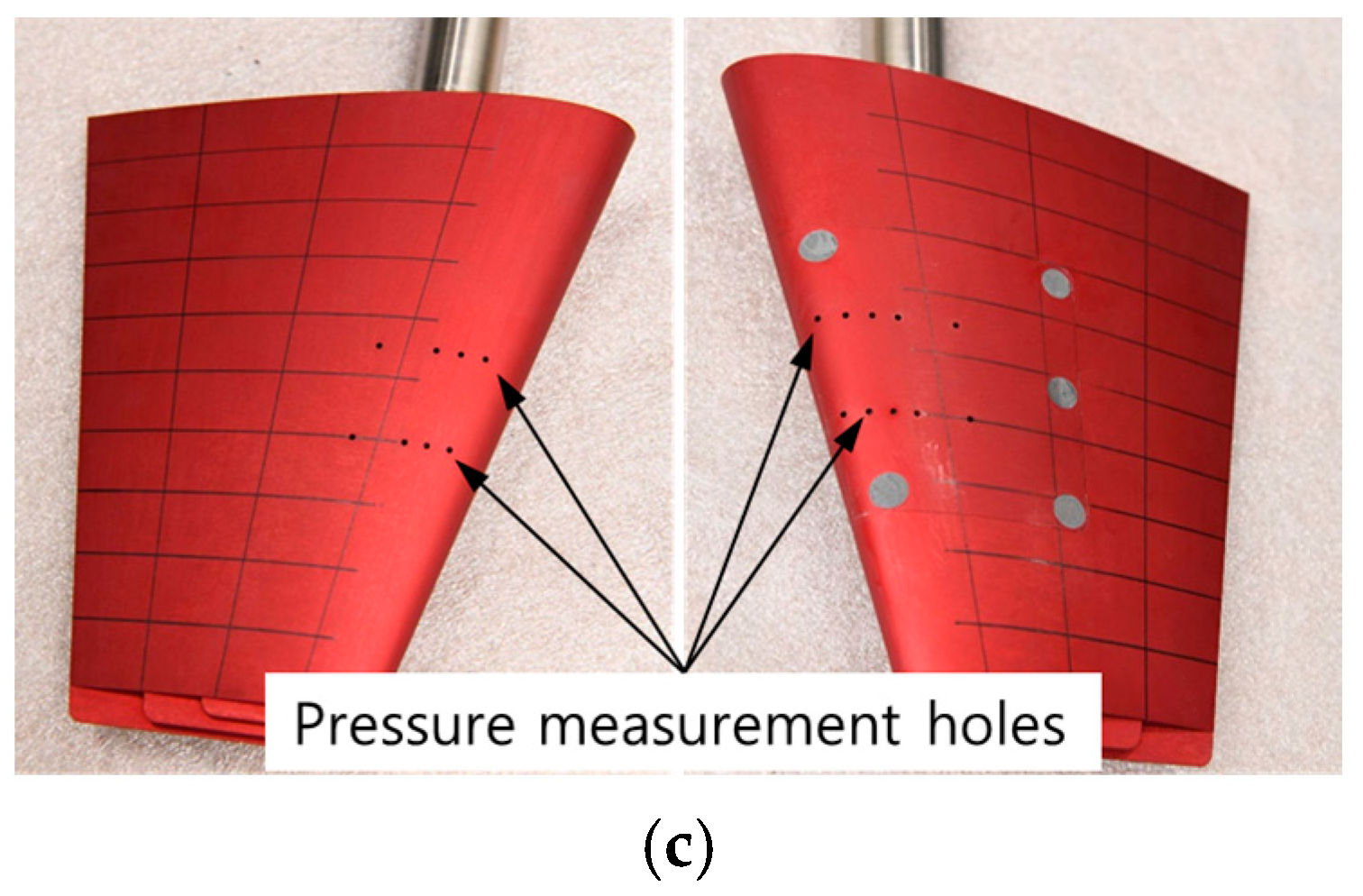

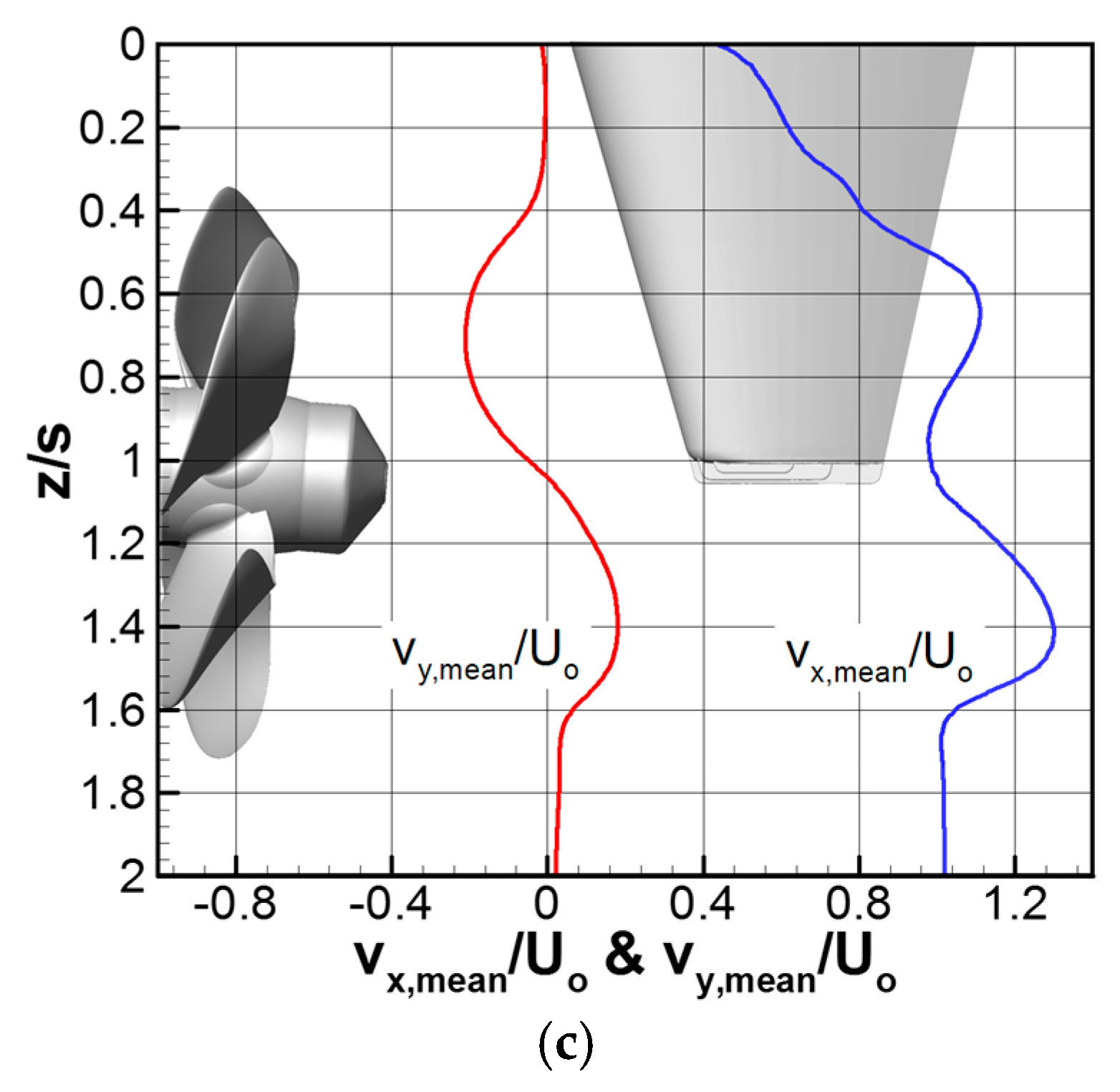

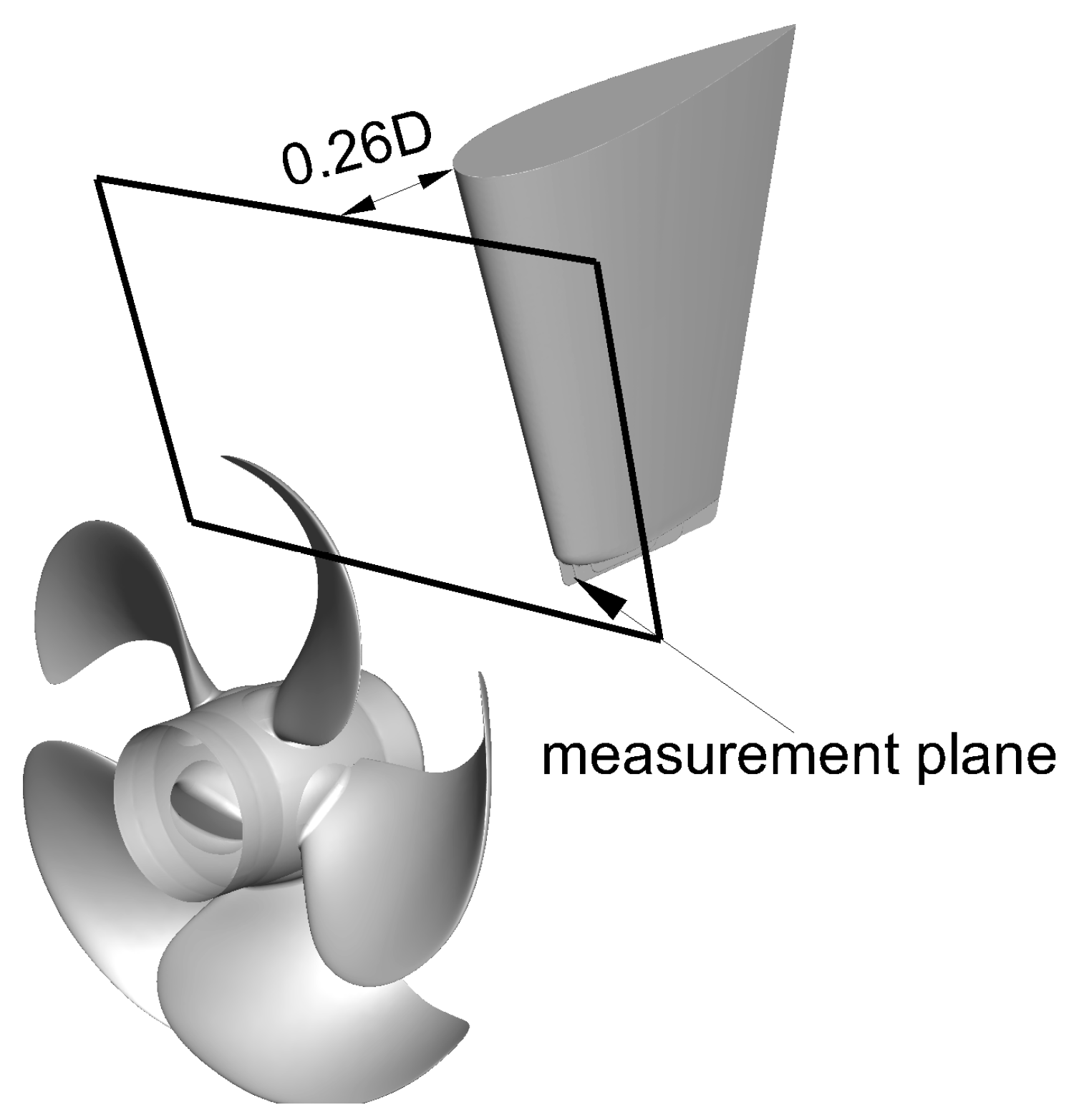

2. Experimental Approaches

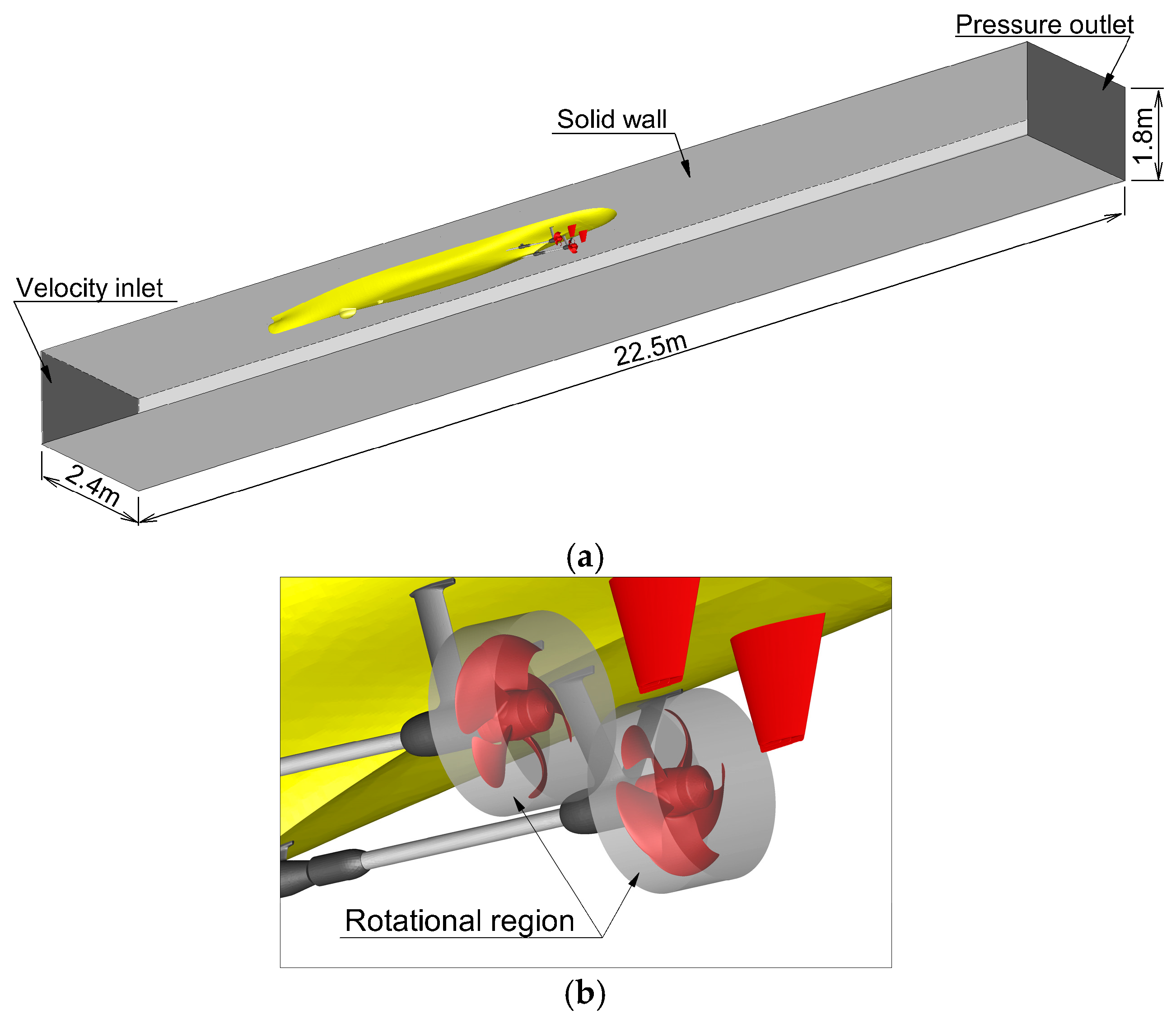

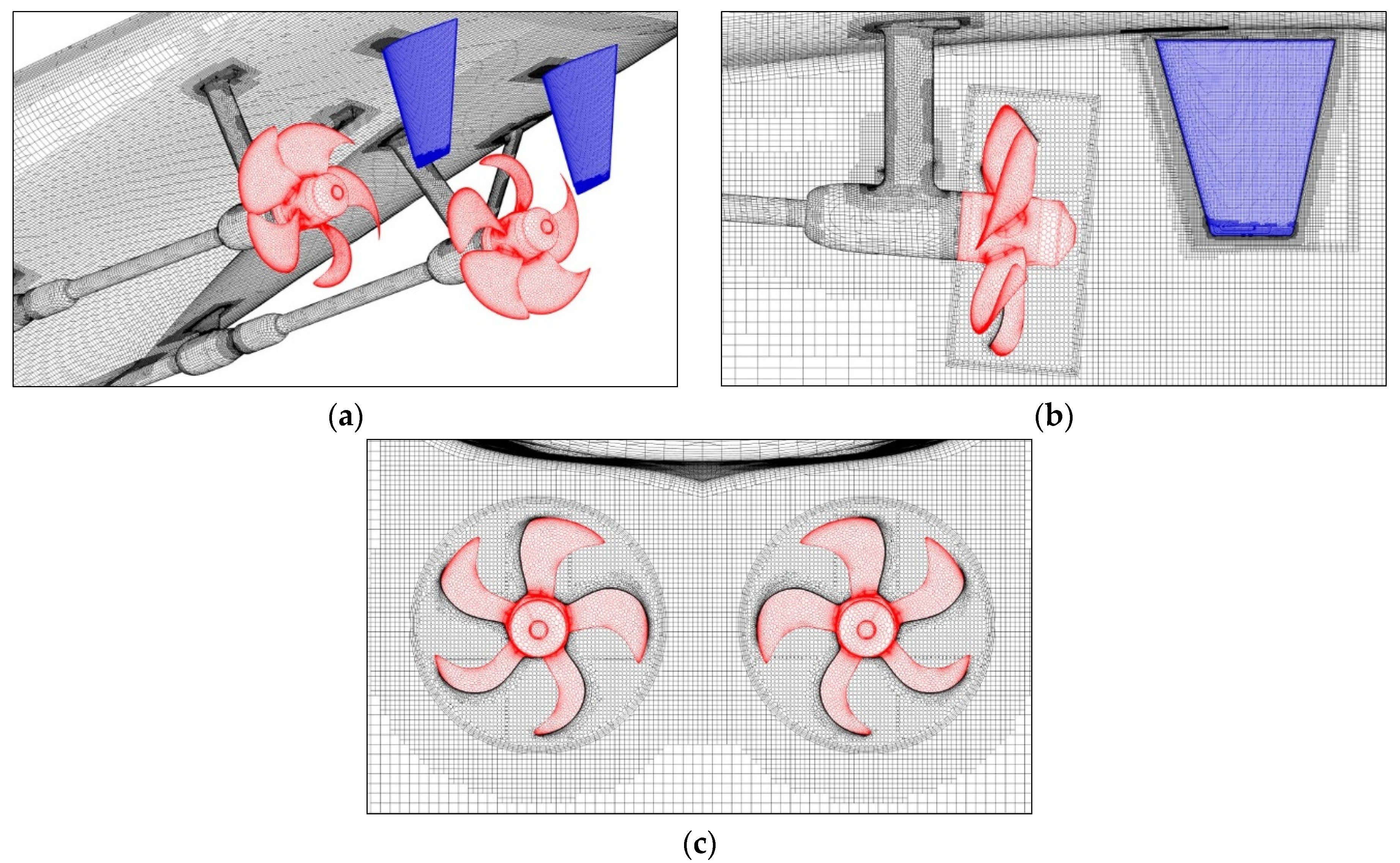

3. Numerical Approaches

3.1. Reynolds-Averaged Navier-Stokes Equations

3.2. Cavitation Model

3.3. Numerical Solution Procedure

4. Results and Discussions

4.1. Validation of the Flow around a Flat Rudder

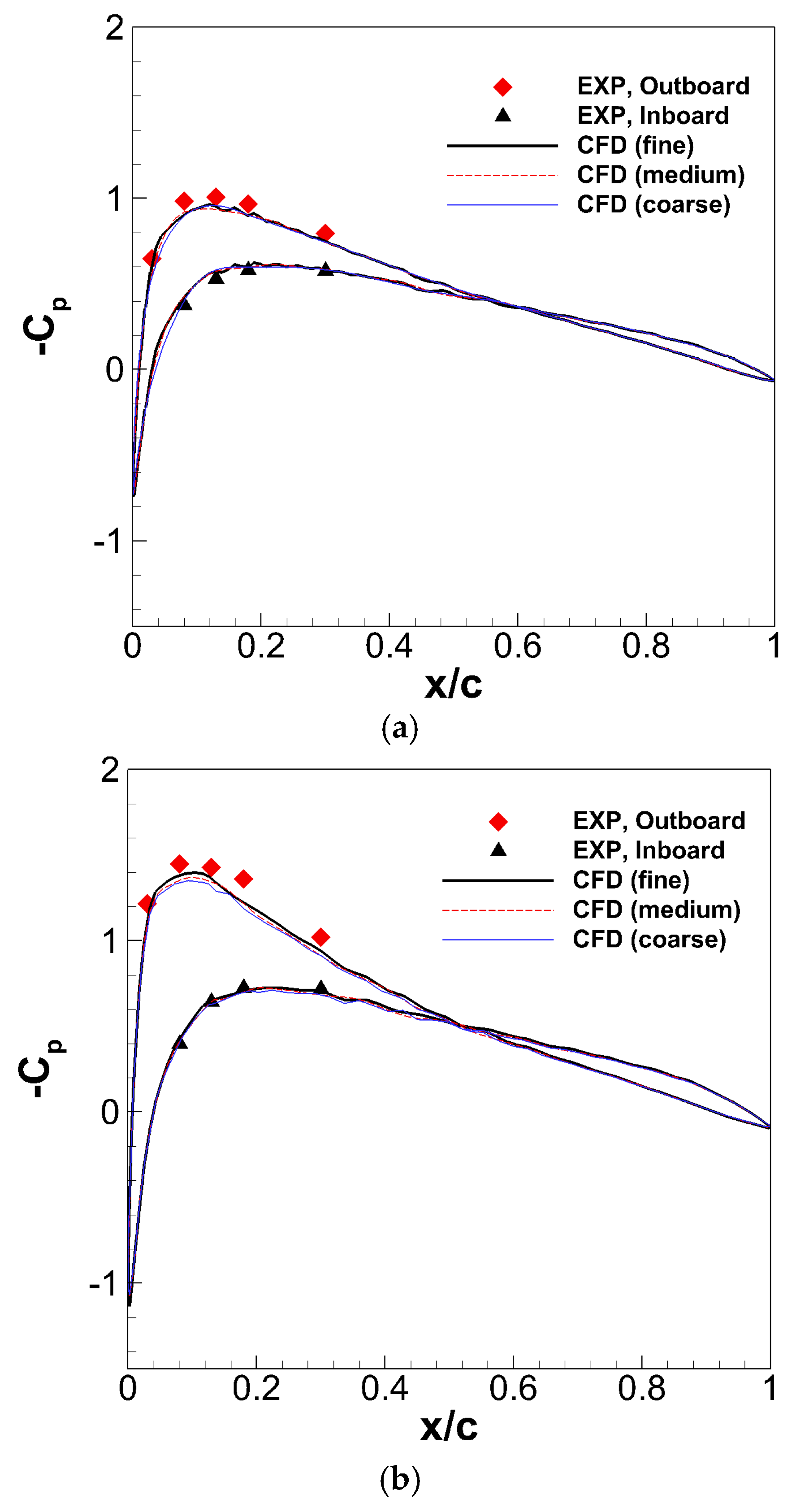

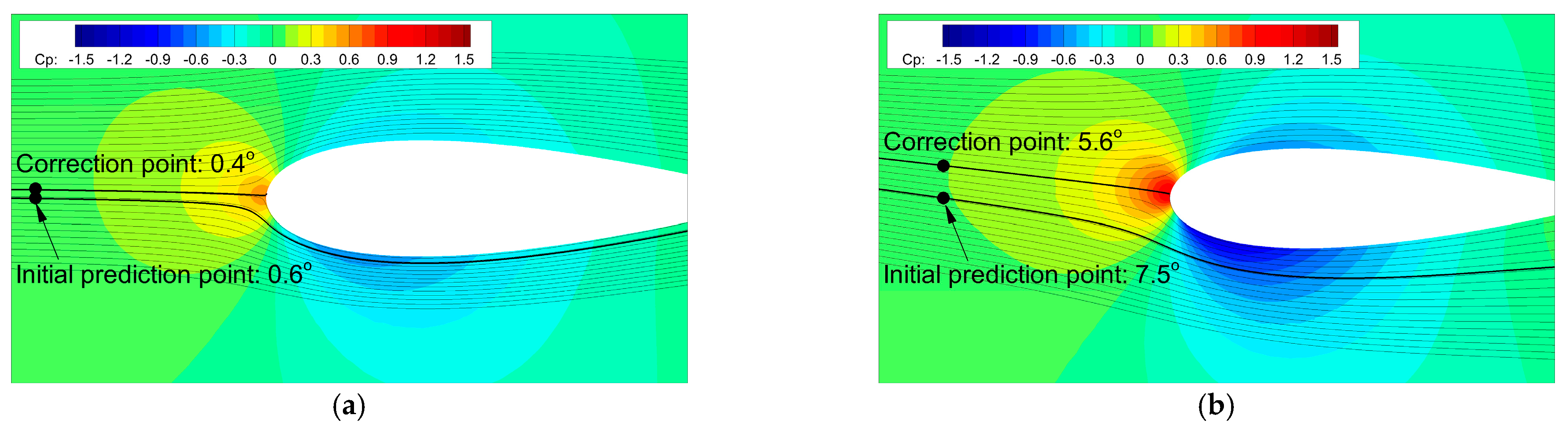

4.1.1. Pressure Distributions

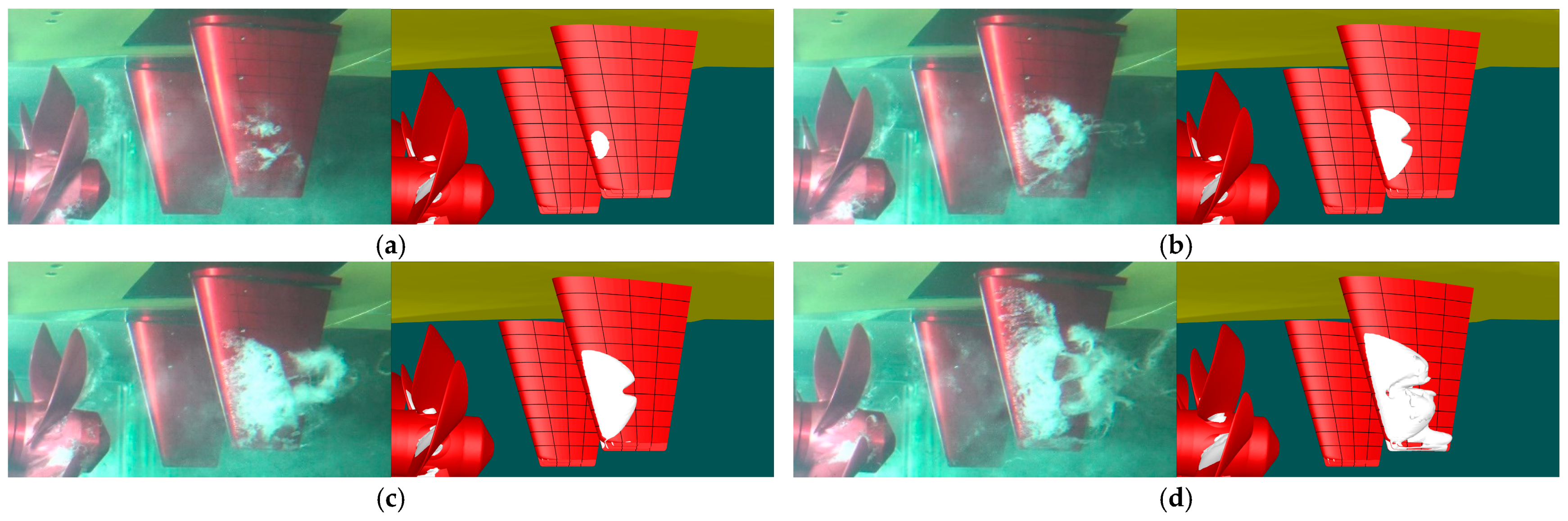

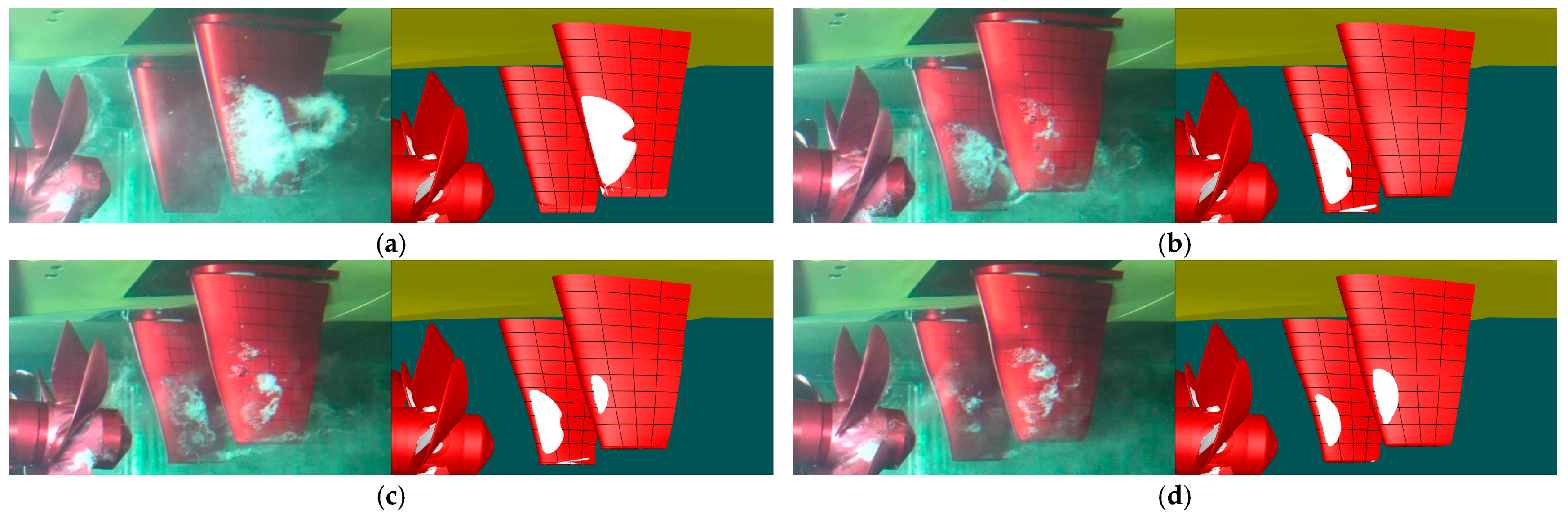

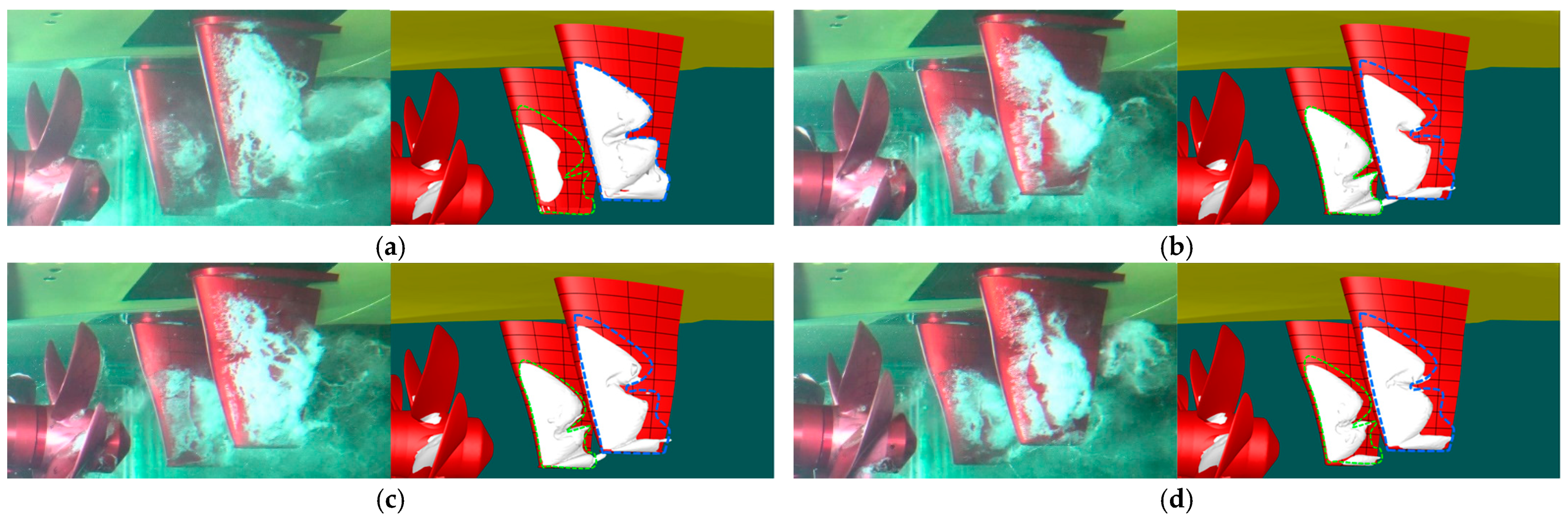

4.1.2. Surface Cavitation

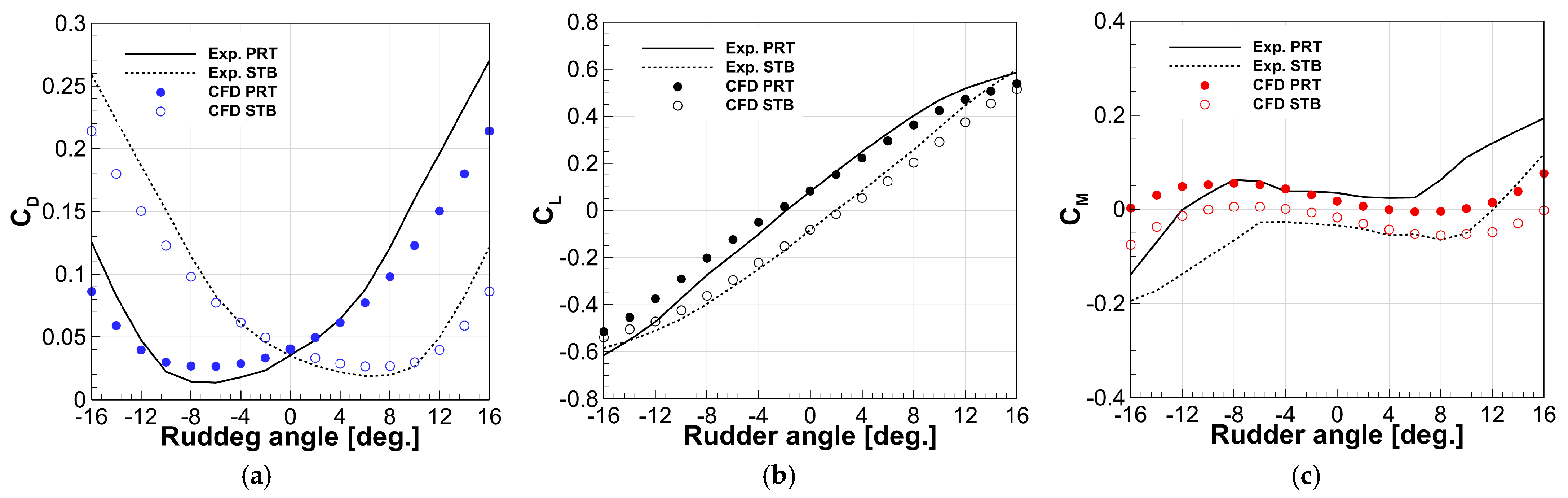

4.1.3. Forces and Moment

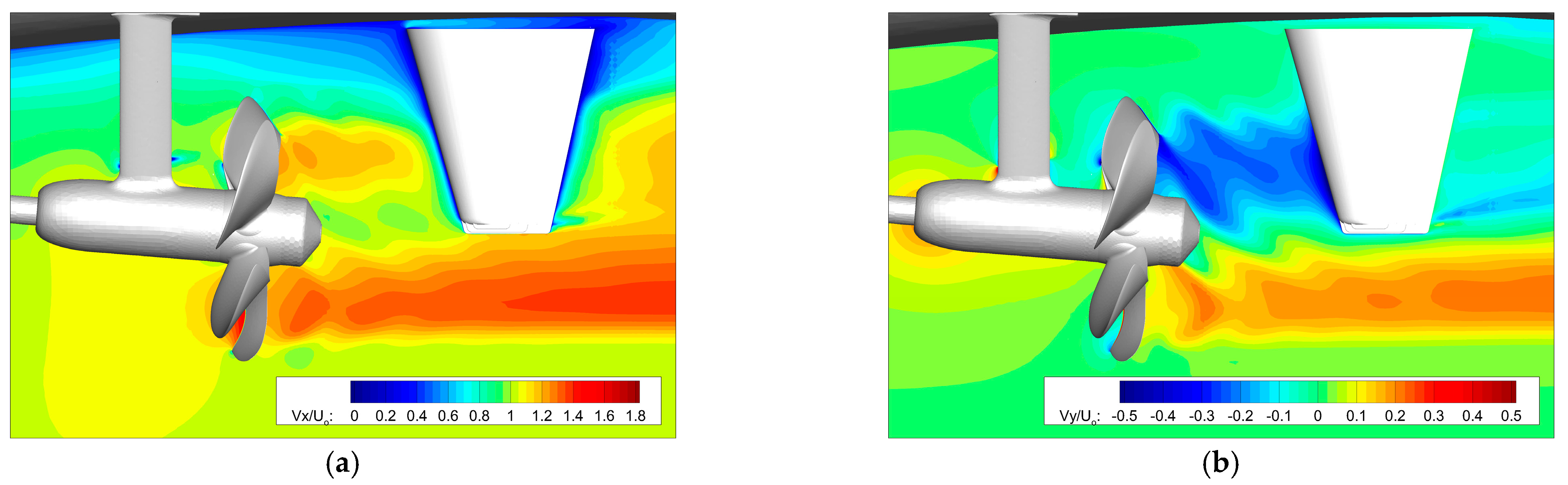

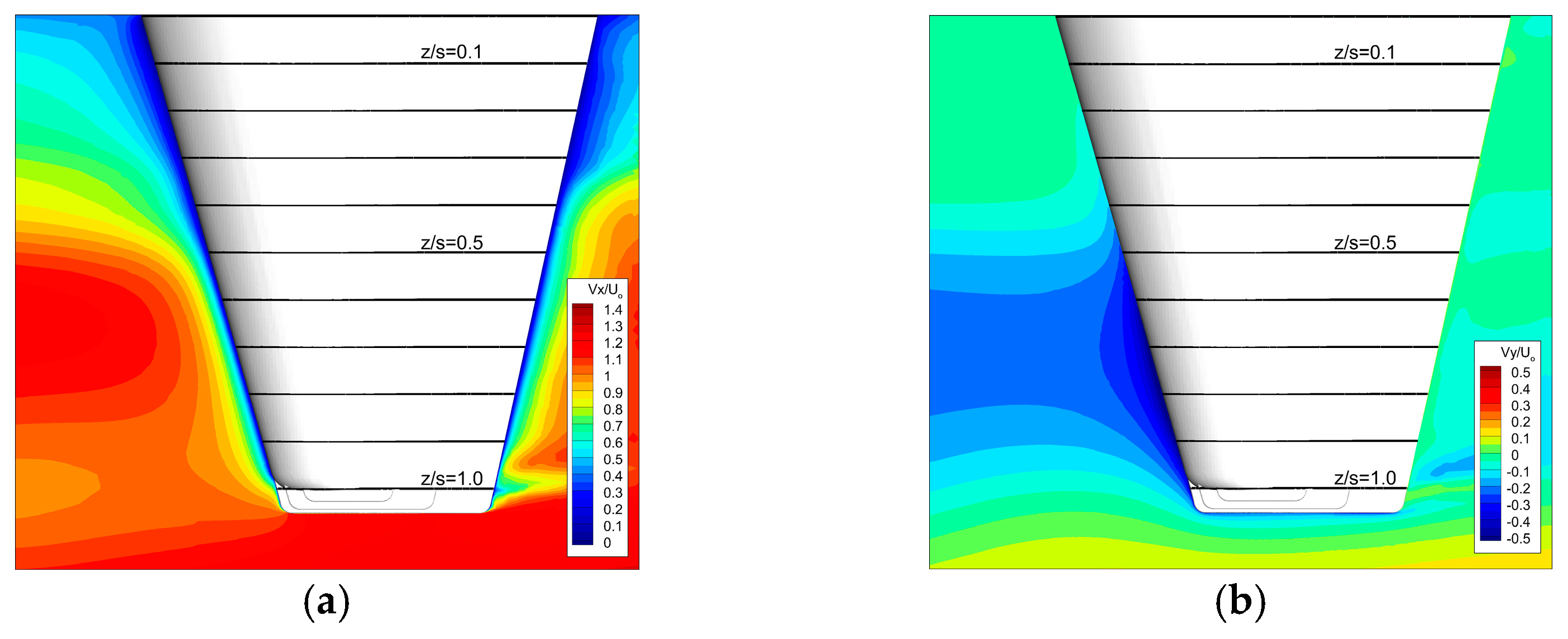

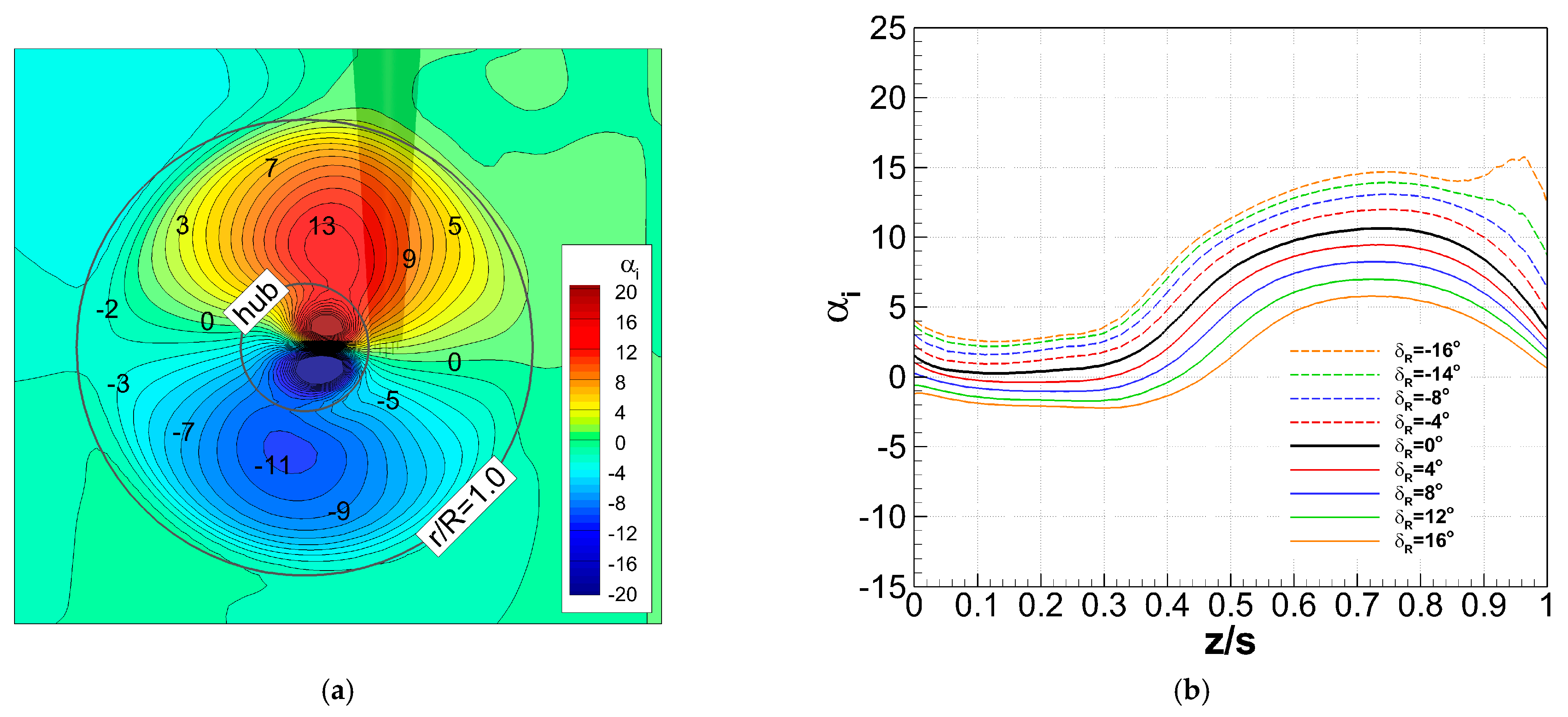

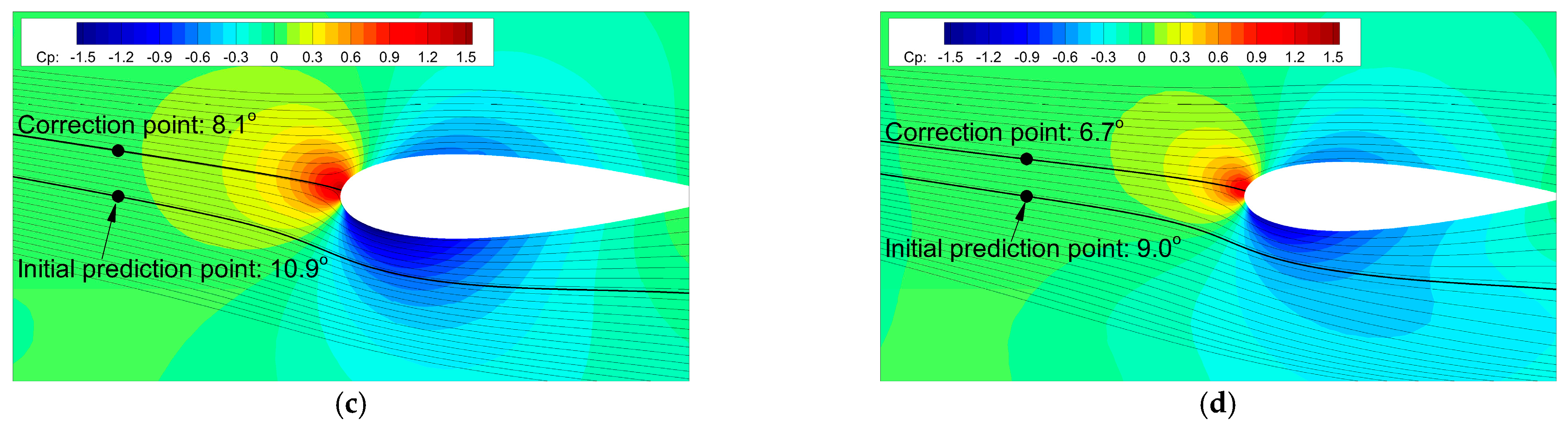

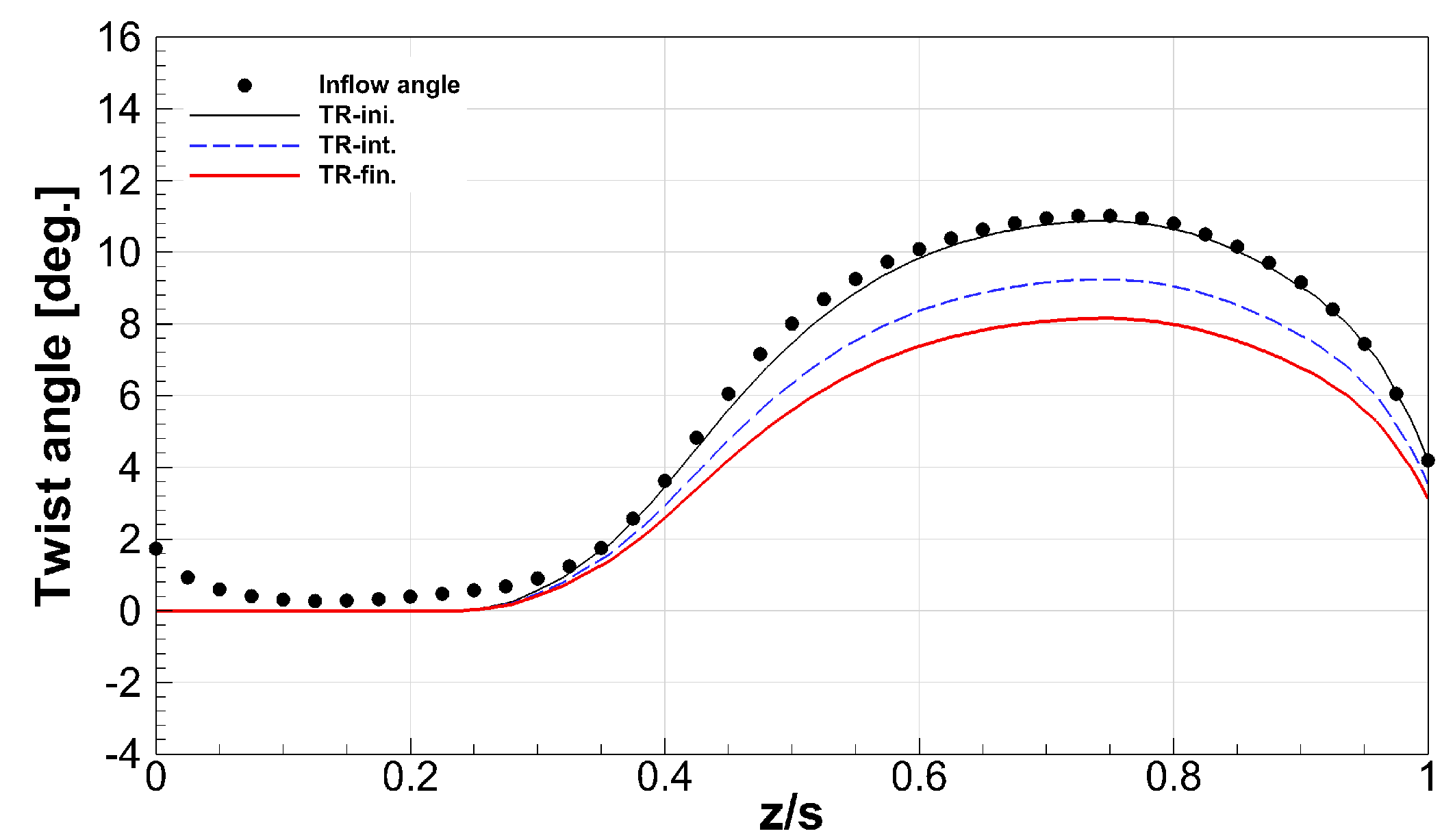

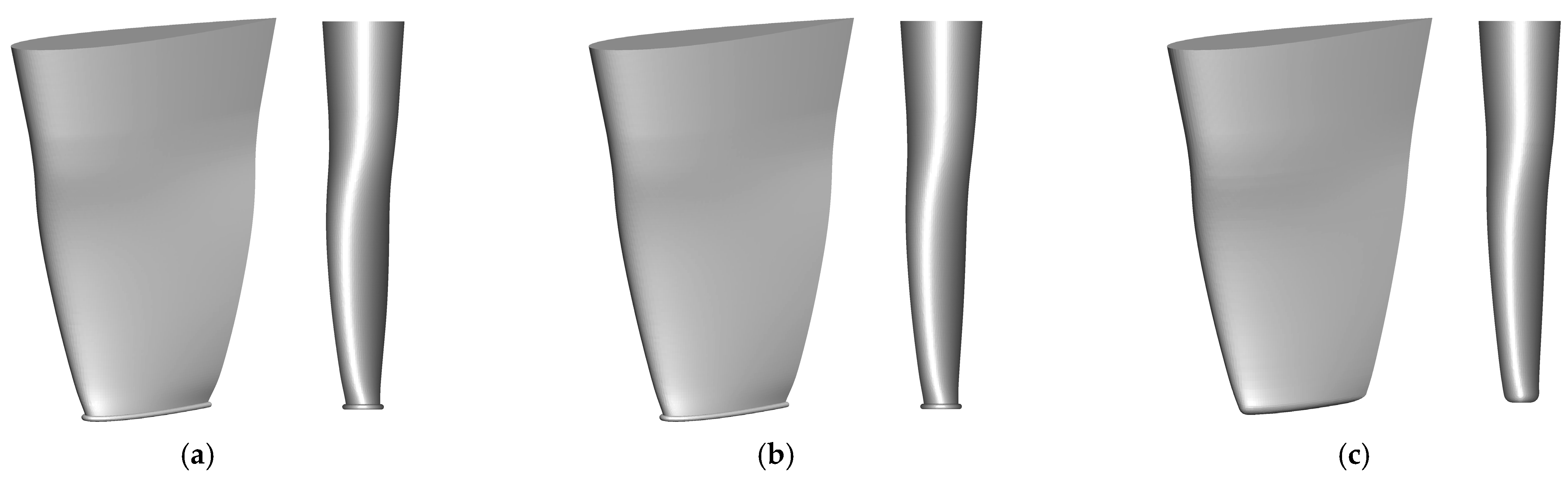

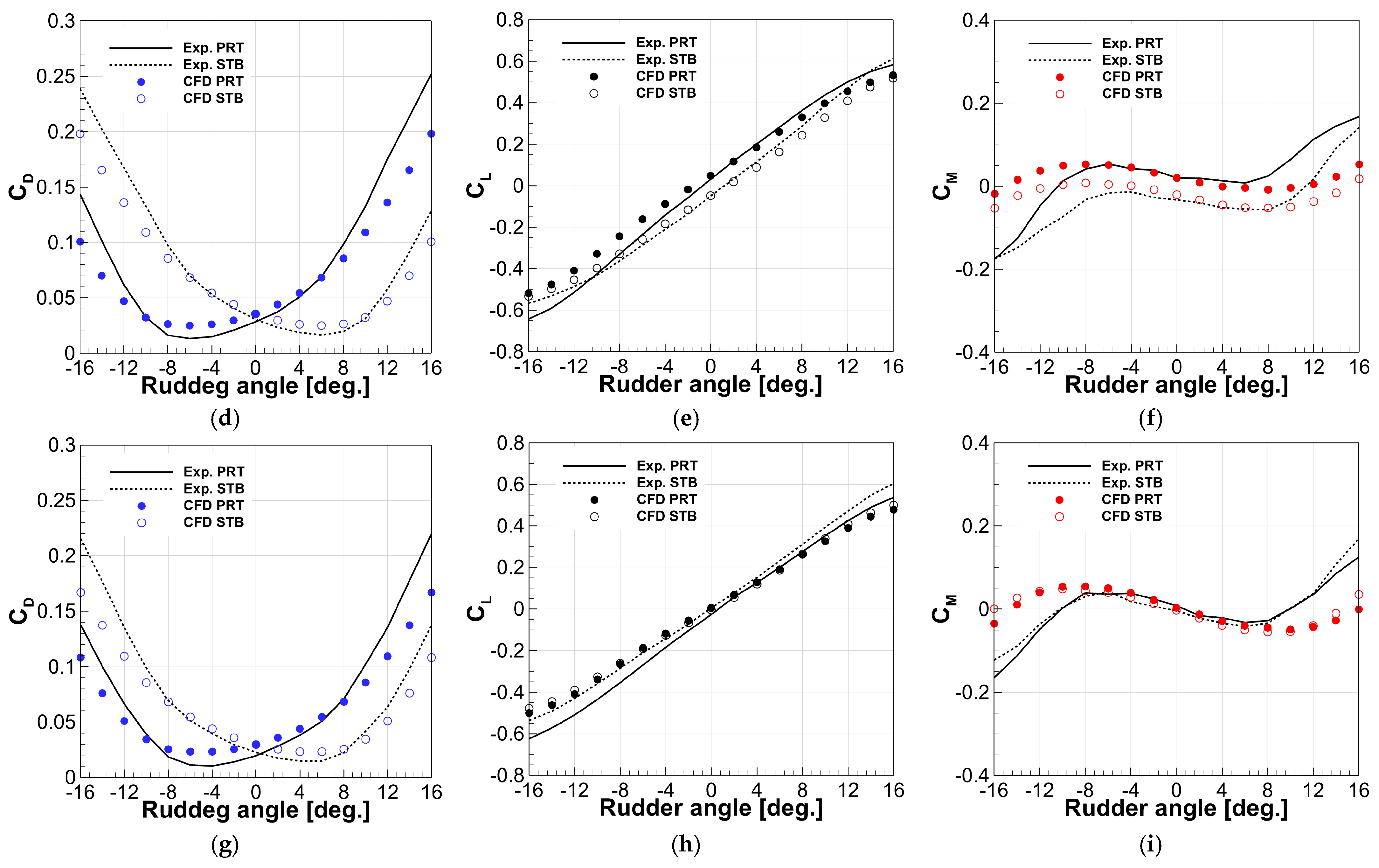

4.2. Prediction and Correction of Twist Angles

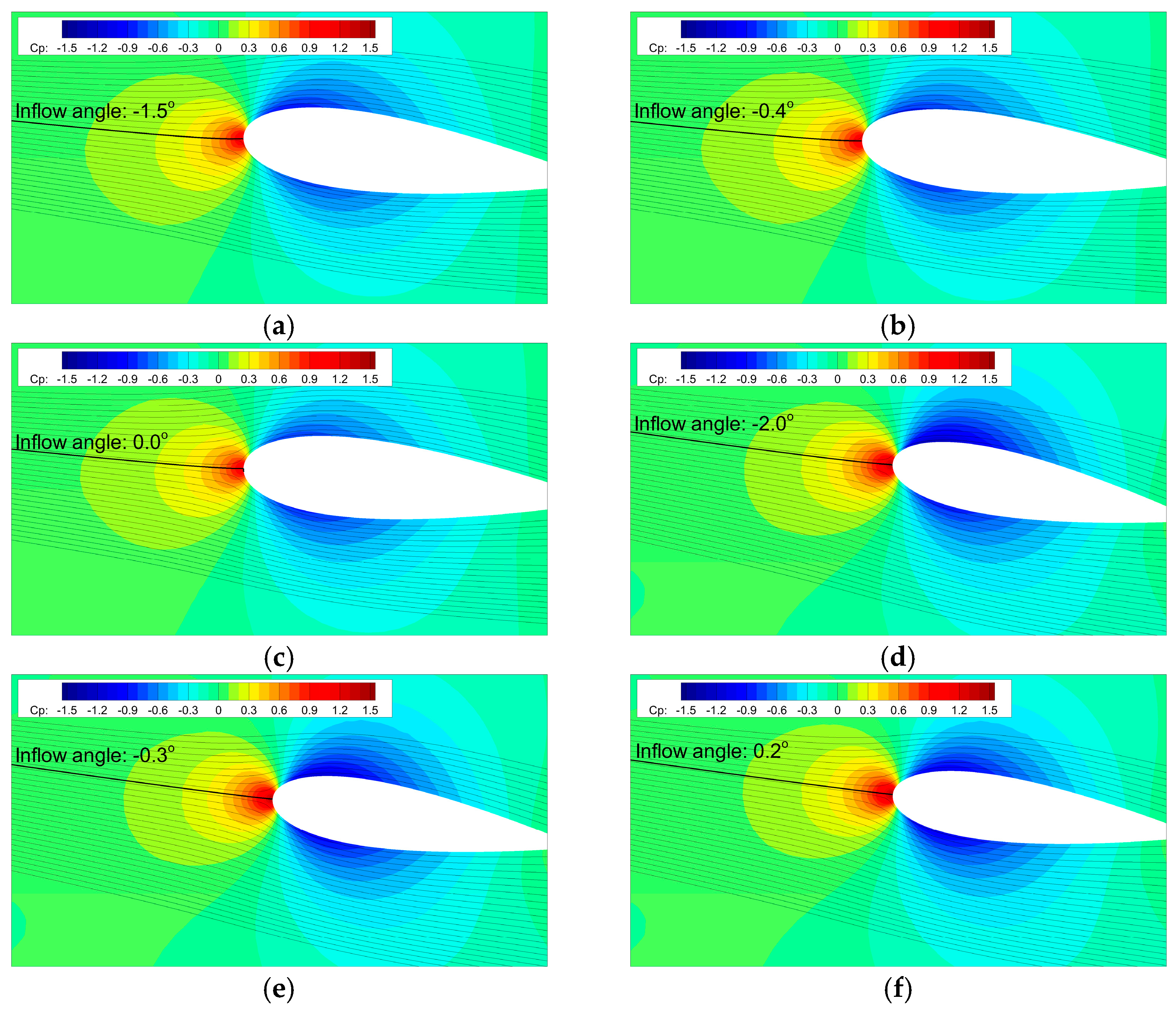

4.3. Hydrodynamic Performances of Twisted Rudders

4.4. Summary of Twisted Rudder Performances

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| c | rudder chord length |

| drag coefficient | |

| lift coefficient | |

| moment coefficient | |

| pressure coefficient | |

| propeller diameter | |

| rudder drag force | |

| turbulent kinetic energy | |

| propeller thrust coefficient | |

| rudder moment arm | |

| rudder lift force | |

| mass transfer rate | |

| rudder moment | |

| propeller rotational speed | |

| nuclei concentration | |

| number of cavitation bubbles | |

| rudder surface pressure | |

| free stream reference pressure | |

| static pressure in the LCT | |

| water vapor pressure | |

| time averaged pressure | |

| cavitation bubble radius | |

| propeller radius | |

| rudder span length | |

| lateral projected rudder area | |

| physical time | |

| propeller thrust | |

| velocity fluctuations | |

| time averaged velocities | |

| inflow velocity in the LCT test section | |

| ship speed | |

| fluid volume fraction | |

| inflow angle | |

| rudder angle | |

| turbulence dissipation rate | |

| cavitation number | |

| fluid dynamic viscosity | |

| turbulent eddy viscosity | |

| water dynamic viscosity | |

| fluid density | |

| water density |

References

- Grigoropoulos, G.J.; Chalkias, D.S. Hull-Form optimization in calm and rough water. Comput. Aided Des. 2010, 42, 977–984. [Google Scholar] [CrossRef]

- Calton, J.S. Marine Propellers and Propulsion, 3rd ed.; Butterworth Heinemann: London, UK, 2012; ISBN 978-008-097-124-7. [Google Scholar]

- Park, S.H.; Oh, G.H.; Rhee, S.H.; Koo, B.Y.; Lee, H.S. Full scale wake prediction of an energy saving device by using computational fluid dynamics. Ocean Eng. 2015, 101, 254–263. [Google Scholar] [CrossRef]

- Kim, J.H.; Choi, J.E.; Choi, B.J.; Chung, S.H.; Seo, H.W. Development of energy-saving devices for a full slow-speed ship through improving propulsion performance. Int. J. Nav. Archit. Ocean. Eng. 2015, 7, 390–398. [Google Scholar] [CrossRef] [Green Version]

- Mewis, F.; Hollenbach, U. Special Measures for Improving Propulsive Efficiency. HSVA NewsWave, Jan 2006. The newsletter from the Hamburg Ship Model Basin. Available online: https://www.hsva.de/files/newswave2006_1.pdf (accessed on 29 July 2021).

- Lucke, T.; Streckwall, H. Cavitation research on a very large semi spade rudder. In Proceedings of the First International Symposium on Marine Propulsors SMP’09, Trondheim, Norway, 22–24 June 2009. [Google Scholar]

- Sohn, K.H.; Lee, K.W. Study on the maneuvering characteristics of a ship with stern bulb. J. Soc. Nav. Archit. Korea 1994, 31, 65–78. [Google Scholar]

- Mewis, F.; Deichmann, F. Power and cost-savings for container vessel by hydrodynamic energy saving devices. In Proceedings of the 4th International Ship Efficiency Conference, Hamburg, Germany, 23–24 September 2013; pp. 153–155. [Google Scholar]

- Celik, F. A numerical study for effectiveness of a wake equalizing duct. Ocean Eng. 2007, 34, 2138–2145. [Google Scholar] [CrossRef]

- Chang, X.; Sun, S.; Zhi, Y.; Yuan, Y. Investigation of the effects of a fan-shaped Mewis duct before a propeller on propulsion performance. J. Mar. Sci. Technol. 2019, 24, 46–59. [Google Scholar] [CrossRef] [Green Version]

- Park, W.G.; Jung, Y.R.; Kim, C.K. Numerical flow analysis of single-stage ducted marine propulsor. Ocean Eng. 2005, 32, 1260–1277. [Google Scholar] [CrossRef]

- Chen, C.W.; Kang, D.D.; Leng, J.X.; Lin, H.T.; Wang, J.; Jiao, L. Numerical analysis on the wake field of fast container ship stern with novel propeller duct. In Proceedings of the 6th International Symposium on Fluid Machinery and Fluid Engineering, Wuhan, China, 22 October 2014. [Google Scholar]

- Çelik, F.; Güner, M. Energy saving device of stator for marine propellers. Ocean Eng. 2007, 34, 850–855. [Google Scholar] [CrossRef]

- Watson, D.G.M. Devices to improve propulsive efficiency. Pract. Ship Des. 1998, 1, 226–228. [Google Scholar]

- Lee, K.J.; Bae, J.H.; Kim, H.T.; Hoshino, T. A performance study on the energy recovering turbine behind a marine propeller. Ocean Eng. 2014, 91, 152–158. [Google Scholar] [CrossRef]

- Heinke, H.J.; Hellwing-Rieck, K. Investigation of scale effects on ships with a wake equalizing duct or with vortex generator fins. In Proceedings of the 2nd international Symposium on Marine Propulsors SMP’11, Hamburg, Germany, 15–17 June 2011. [Google Scholar]

- Chen, P.F.; Li, J.Y.; Chen, L.C. A study on the technology of energy saving 10% (ES-10) for container vessel. In Proceedings of the 11th International Symposium on Practical Design of Ships and Other Floating Structures, Rio de Janeiro, Brazil, 19–24 September 2010. [Google Scholar]

- Shen, H.L.; Enock, O.O.; Su, Y.M. Scale effects for rudder bulb and rudder thrust fin on propulsive efficiency based on computational fluid dynamics. Ocean Eng. 2016, 117, 1199–1209. [Google Scholar]

- Mori, M.; Yamasaki, T.; Fujino, R.; Ohtagake, Y. IHI A.T. Fin—1st report its principle and development. IHI Eng. Rev. 1984, 17, 1–7. [Google Scholar]

- Ohtagake, Y.; Arai, M.; Mizoguchi, S.; Muraoka, K.; Sasaki, T.; Mori, M. IHI A.T. Fine—2nd report performance in still water and in waves. IHI Eng. Rev. 1986, 19, 123–129. [Google Scholar]

- Okamoto, Y.; Masuda, S. Development of the Energy Saving Device (NKK-Venus); NKK Technical Report; NKK Technical: Tokyo, Japan, 1999; Volume 168, pp. 13–17. [Google Scholar]

- Liu, Y.B.; Su, Y.M.; Shen, H.L.; Ju, L. Study on energy-saving rudder bulb fin combination based on surface panel method. J. Shanghai Jiao Tong Univ. (Sci.) 2012, 46, 374–378. [Google Scholar]

- Kanemaru, T.; Yoshitake, A.; Ando, J. Development of new type low drag rudders in propeller slipstream. In Proceedings of the Fifth International Symposium on Marine Propulsors SMP’17, Espoo, Finland, 12–15 June 2017. [Google Scholar]

- Chen, W.C.; Lin, T.Y.; Chen, B.Y.; Kouh, J.S. Parametric design and optimization of a pivoting s-type rudder for containerships. J. Mar. Sci. Technol. 2018, 26, 749–763. [Google Scholar]

- Rhee, S.Y.; Oh, J.K.; Lee, C.M.; Lee, H.B. Experimental and computational analysis of rudder gap cavitation. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar]

- Paik, B.G.; Kim, K.Y.; Ahn, J.W.; Kim, Y.S.; Kim, S.P.; Park, J.J. Experimental study on the gap entrance profile affecting rudder gap cavitation. Ocean Eng. 2008, 35, 139–149. [Google Scholar] [CrossRef]

- Paik, B.G.; Kim, G.D.; Kim, K.S.; Kim, K.Y.; Suh, S.B. Measurements of the rudder inflow affecting the rudder cavitation. Ocean Eng. 2012, 48, 1–9. [Google Scholar] [CrossRef]

- Reichel, M. Influence of rudder location on propulsive characteristics of a single screw container ship. In Proceedings of the First International Symposium on Marine Propulsor, Trondheim, Norway, 22–24 June 2009. [Google Scholar]

- Krasilnikov, V.; Ponkratov, D.; Crepier, P. A numerical study on the characteristics of the system propeller and rudder at low-speed operation. In Proceedings of the Second International Symposium on Marine Propulsors, Hamburg, Germany, 15–17 June 2011. [Google Scholar]

- Mandel, P. Some hydrodynamical aspects of appendage design. Soc. Nav. Archit. Mar. Eng. Trans. 1953, 61, 464–515. [Google Scholar]

- Nishiyama, S. Experiment on rudder cavitation and its preventive measures. In Proceedings of the 14th ITTC, Ottawa, ON, Canada, 14 September 1975. [Google Scholar]

- Shen, Y.T.; Jiang, C.W.; Remmers, K.D. A Twisted Rudder for Reduced Cavitation. J. Ship Res. 1997, 41, 260–272. [Google Scholar] [CrossRef]

- Kim, I.W.; Kim, M.C.; Lee, J.H.; Chun, H.H.; Jung, U.H. Study on design of a twisted full-spade rudder for a large container ship by the genetic algorithm. J. Soc. Nav. Archit. Korea 2009, 46, 479–487. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.E.; Kim, J.H.; Lee, H.G.; Park, D.W. Hydrodynamic characteristics and speed performance of a full spade and a twisted rudder. J. Soc. Nav. Archit. Korea 2010, 47, 163–177. [Google Scholar] [CrossRef]

- Kim, J.H.; Choi, J.E.; Choi, B.J.; Chung, S.H. Twisted rudder for reducing fuel-oil consumption. Int. J. Nav. Archit. Ocean. Eng. 2014, 6, 715–722. [Google Scholar] [CrossRef] [Green Version]

- Ahn, K.S.; Choi, G.H.; Son, D.I.; Rhee, K.P. Hydrodynamic characteristics of X-Twisted rudder for large container carriers. Int. J. Nav. Archit. Ocean. Eng. 2012, 4, 322–334. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Su, Y.M.; Hu, H.Z. Experimental study and numerical simulation on hydrodynamic performance of a Twisted rudder. Mar. Technol. Soc. J. 2015, 49, 58–69. [Google Scholar] [CrossRef]

- Kim, H.J.; Choi, J.E.; Chun, H.W. Hull-form optimization using parametric modification functions and particle swarm optimization. J. Mar. Sci. Technol. 2016, 21, 129–144. [Google Scholar] [CrossRef]

- Shin, Y.J.; Kim, M.C.; Lee, J.H.; Song, M.S. A numerical and experimental study on the performance of a twisted rudder with wave configuration. Int. J. Nav. Archit. Ocean. Eng. 2019, 11, 131–142. [Google Scholar] [CrossRef]

- Shih, T.H.; Liou, W.W.; Shabir, A.; Zhu, J. A New ε Eddy Viscosity Model for High Reynolds Number Turbulent Flows-Model Development and Validation. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Schnerr, G.H.; Sauer, J. Physical and Numerical Modeling of Unsteady Cavitation Dynamics. In Proceedings of the 4th International Conference on Multiphase Flow, New Orleans, LA, USA, 27 May–1 June 2001. [Google Scholar]

- Siemense; STAR-CCM+ 11.04 User Guide. Available online: https://support.industrysoftware.automation.siemens.com/general/documentation.shtml (accessed on 1 January 2018).

| Ship | Length between perpendiculars | 7.067 m |

| Breath | 0.933 m | |

| Draft | 0.269 m | |

| Propeller | Propeller Diameter | 0.28 m |

| Number of blades | 5 | |

| Rotation Direction | Outward | |

| Rudder | Root chord length | 0.1967 m |

| Tip chord length | 0.0887 m | |

| Span length | 0.2147 m |

| n | ||||

|---|---|---|---|---|

| 30.0 kts | 0.1879 | 1.2485 | 9.0 m/s | 31.61 rps |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, I.; Paik, B.; Ahn, J.; Kim, J. The Prediction of the Performance of a Twisted Rudder. Appl. Sci. 2021, 11, 7098. https://doi.org/10.3390/app11157098

Park I, Paik B, Ahn J, Kim J. The Prediction of the Performance of a Twisted Rudder. Applied Sciences. 2021; 11(15):7098. https://doi.org/10.3390/app11157098

Chicago/Turabian StylePark, Ilryong, Bugeun Paik, Jongwoo Ahn, and Jein Kim. 2021. "The Prediction of the Performance of a Twisted Rudder" Applied Sciences 11, no. 15: 7098. https://doi.org/10.3390/app11157098

APA StylePark, I., Paik, B., Ahn, J., & Kim, J. (2021). The Prediction of the Performance of a Twisted Rudder. Applied Sciences, 11(15), 7098. https://doi.org/10.3390/app11157098