1. Introduction

Underwater vehicles, such as submarines and torpedoes, normally have a limited speed because the resistance to their movement rapidly increases at high speeds owing to the large skin friction drag. The maximum speed of conventional underwater vehicles is generally considered to be approximately 75 knots; however, generally, it does not exceed half of this value [

1]. To overcome this underwater speed limit, it is essential to reduce the frictional drag. Supercavitation technology, which can considerably reduce the viscous drag by enclosing an underwater vehicle entirely in a low-density gas bubble, is considered the most promising among various drag reduction technologies.

Innovative, high-speed torpedoes using supercavitation technology have altered the nature of naval warfare and are crucial in the battlefield, as they do not provide sufficient time for enemies to react. The first successful application of supercavitation technology was the well-known Russian supercavitating torpedo named “Shkval”, which was developed in 1977. Shkval achieved an underwater speed of 200 knots, which was remarkably high compared with the existing technology. German engineers also developed a supercavitating torpedo named “Barracuda” in the 2000s and successfully demonstrated high-speed underwater motion faster than 200 knots [

2]. In the United States, a wide range of basic research and exploratory development programs sponsored by the US Navy were conducted to address the physics and engineering of a high-speed supercavitating torpedo named “Supercav” [

3].

The key technical areas for high-speed supercavitating torpedoes can be generally divided into cavitator, ventilation, guidance, control, and propulsion [

4]. The detailed sub-technologies could be different depending on the operational concept of the torpedo: for example, an unguided straight-running torpedo such as Shkval or a guided homing torpedo such as Barracuda. This study mainly focuses on the cavitator design for a straight-running torpedo. A cavitator, mounted on the nose of the supercavitating torpedo, is required to initiate and maintain a supercavity with the aid of ventilation. However, because a cavitator is in continuous contact with water during supercavity generation, the hydrodynamic drag on the cavitator accounts for the largest portion of the overall drag of the torpedo and thus can significantly affect the torpedo performance, such as the maximum operating range. A cavitator is also closely associated with controlling the motion of the torpedo. As a supercavitating torpedo is unavoidably accompanied by negative buoyancy, the cavitator should produce sufficient hydrodynamic forces to compensate for the weight of the torpedo and stabilize the torpedo motion for underwater level flight [

5,

6].

The cavitator design is crucial in developing a supercavitating torpedo because it is closely linked to the torpedo performance. The cavitator must be designed not only to create the supercavity required to minimize the overall drag of the torpedo in high-speed motion but also to provide the hydrodynamic forces required for straight and level flight while maintaining basic motion stability [

6,

7]. Most previous works on cavitator design, however, focused only on shape optimization, in which drag is minimized without considering motion stability [

8,

9,

10]. Alyanak et al. [

11] studied the optimal design of a supercavitating torpedo from a structural viewpoint and presented a method to determine the optimal configuration that satisfied the design requirements, in which the torpedo should operate inside the most stable portion of the cavity and be fitted in a torpedo tube. However, the hydrodynamic forces on the cavitator, required to stabilize the torpedo motion, were not explicitly considered in the design requirements. In contrast, Ahn [

5] discussed the optimal design of supercavitating vehicles and developed an integrated design method based on a 6-DOF dynamic model of a supercavitating vehicle, in order to optimize the vehicle configuration in terms of maximizing the range and turn rate in level flight; although the work provided a significant performance improvement, the application of this method was limited to natural supercavitating vehicles using disk-type cavitators. In this study, a cavitator design method was developed for application in ventilated supercavitating vehicles because a supercavitating torpedo is generally equipped with both a ventilation system for supercavity generation and a cavitator. Unlike the case of natural supercavitating vehicles, in the case of ventilated supercavitating vehicles, the design cavitation number cannot be determined only by the given operational speed and depth because it depends considerably on the amount of ventilation. Therefore, the procedure for determining the design cavitation number has been included in the developed cavitator design method, and a practical way to determine the design cavitation number is proposed in this study. Additionally, the proposed method has been developed to be applicable to the designs of both cone- and disk-type cavitators.

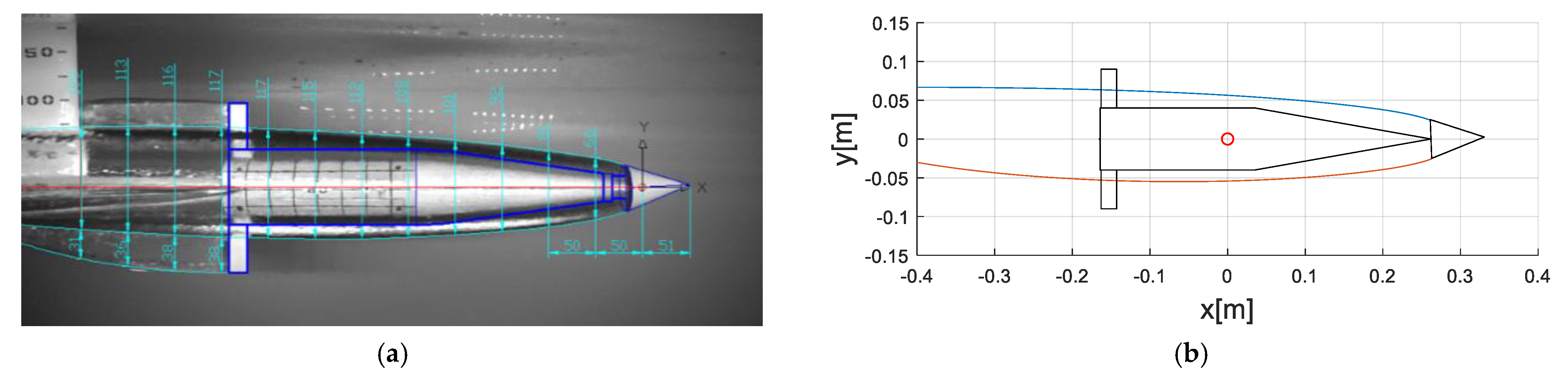

This study aims to develop a cavitator design method for a straight-running-type supercavitating torpedo for practical applications. The method would identify the optimum cavitator that fulfills the aforementioned design requirements for a specific supercavitating vehicle configuration. The design procedure involves determining the design cavitation number and cavitator type for obtaining the optimal cavitator that minimizes the overall drag in straight level flight. The equations of force and moment equilibrium were solved by varying parameters such as the size and inclination angle of the cavitator and trim angle of the vehicle. To solve the equations, cavity shapes and hydrodynamic forces were determined using existing mathematical models, which were verified for practical use through specially devised model experiments on a small-scale supercavitating vehicle. A preliminary design was also implemented using the developed design method for a realistic supercavitating vehicle.

Section 2 introduces the cavitator design procedure, and detailed methods for design implementation are explained. In

Section 3, the mathematical models are verified, and the stabilization of motion associated with disk- and cone-type cavitators is investigated. In

Section 4, a preliminary design trial for a realistic supercavitating vehicle using the proposed design method is presented. Finally,

Section 5 concludes this paper.

2. Cavitator Design Procedure

The cavitator design procedure was established based on operational concepts and design requirements. A straight-running supercavitating torpedo such as “Shkval” is known to operate in such a way that it rapidly accelerates up to the supercavitating speed immediately after being discharged from the launching tube and moves straight at a constant speed and depth corresponding to operational conditions. The torpedo was designed to fit the launching tube, and the design was implemented according to the operational conditions. The first step of cavitator design is to determine the design cavitation number defined as follows:

where

represents the fluid density,

is the operational speed, and

and

are the ambient pressure at the operational depth and cavity pressure, respectively.

If there is no ventilation system in the torpedo, the design cavitation number is determined only by the given operational speed and depth. However, when a ventilation system is used for supercavity generation, the designer may have multiple choices for the design cavitation number by adjusting the amount of ventilated gas. Generally, the cavitation number decreases with the increase in the ventilation flow rate, and a larger supercavity can be generated for a given cavitator. From a design perspective, it is advantageous to minimize the design cavitation number, allowing for a smaller cavitator to produce lower drag while maintaining the supercavity size. However, the minimum cavitation number achieved by ventilation is limited by the excessive ventilation rate, causing instability of the ventilated cavity [

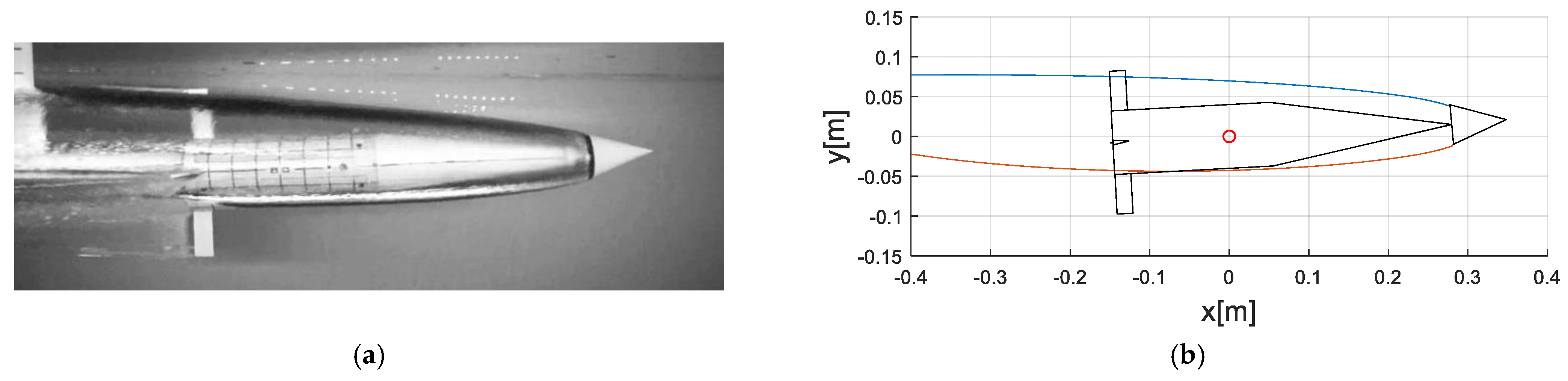

12]. This so-called “cavity pulsation” phenomenon, as shown in

Figure 1, must be avoided because the motion stability of the torpedo might deteriorate considerably owing to this phenomenon, and the torpedo might become out of control under such a circumstance.

Using a stability parameter

, where

represents the natural cavitation number and

the vapor pressure), Paryshev [

13] developed a theory on the stability of ventilated supercavities and proposed a criterion for its dynamic stability, in which the supercavities are stable in the range of

and unstable at

[

12]. The range of the design cavitation number is accordingly determined as follows:

Kirschner and Arzoumanian [

14] implemented Paryshev’s model of cavity dynamics and predicted the critical value

(≈2.703) close to Paryshev’s value for the cavitator alone. They also investigated the stability of ventilated supercavities when the body of a supercavitating vehicle existed and found that the presence of the body within the supercavity can result in a lower critical value of the stability parameter than that of the cavitator alone. Therefore, in practical design, it is desirable to adopt a design cavitation number sufficiently larger than its minimum value.

Once the design cavitation number is determined, the next step is to identify an optimum cavitator that fulfills the design requirements mentioned in

Section 1. First, the cavitator type should be determined. Disk- and cone-type cavitators are the most suitable for supercavitating vehicles. The designer must choose the better one of these two considering the operational concept of a supercavitating torpedo. For example, in the case of a long-range straight-running torpedo with a water-breathing ramjet propulsion system, the disk-type cavitator is more suitable because it facilitates the installation of a water intake system and has better static stability [

15]. In the case of a short-range homing torpedo with a sonar system, the cone-type cavitator may be a good choice because it is much easier to accommodate the sonar system.

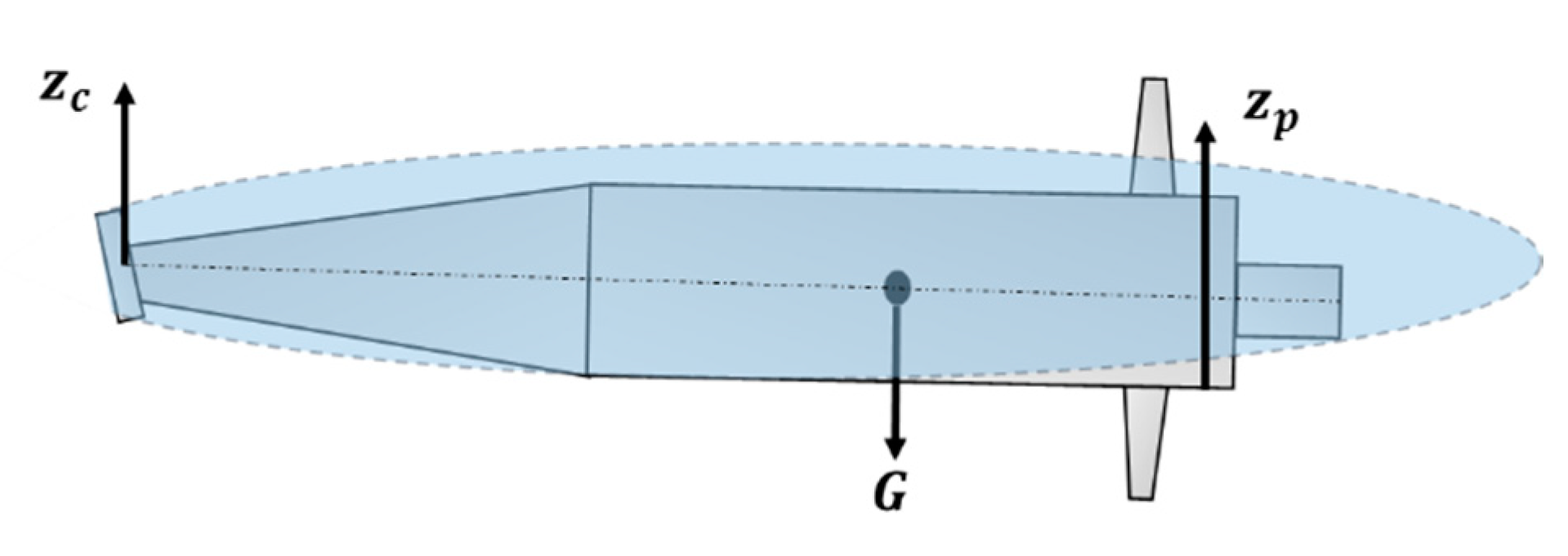

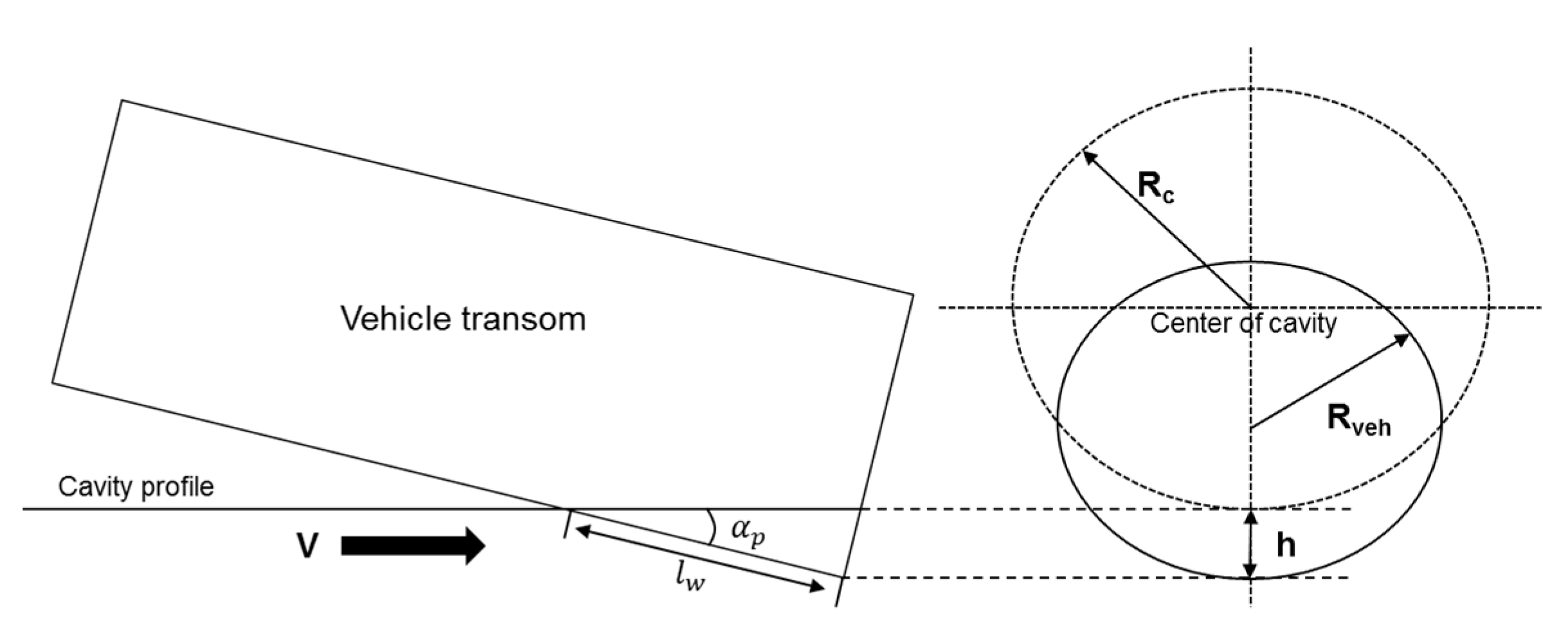

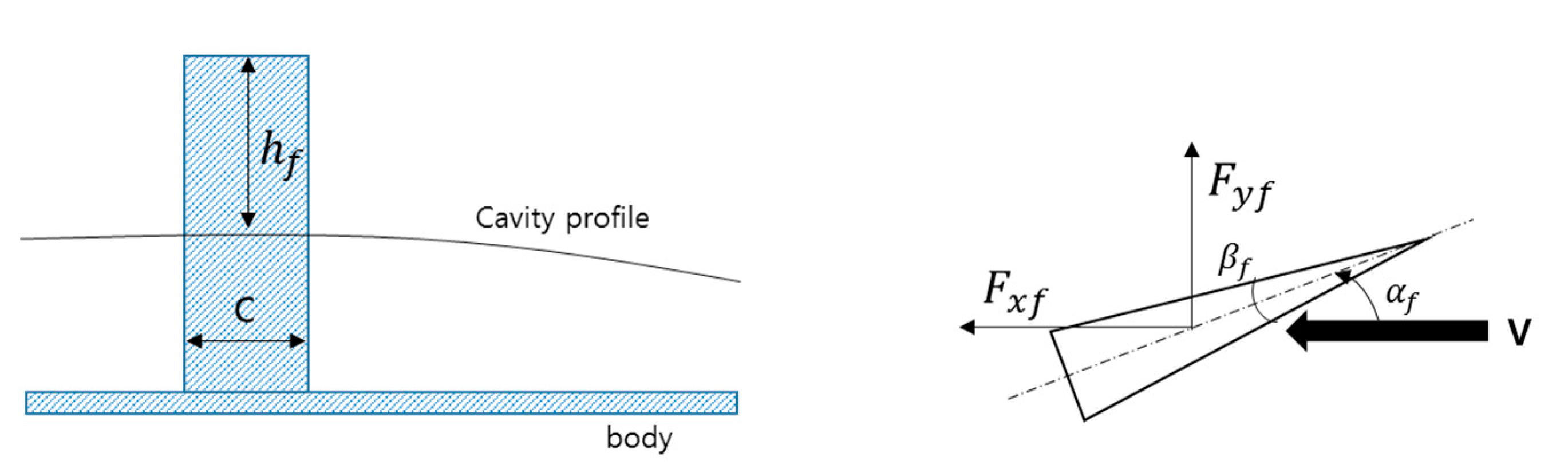

After the cavitator type is determined, the optimal cavitator size that can ensure the minimum overall drag and basic motion stability of the torpedo should be determined. An algorithm was developed to determine the conditions of straight level flight with variation in the cavitator size and to calculate the overall drag of the torpedo in straight level flight. In this study, the motion scheme of stationary planing along the lower internal cavity surface was considered for straight level flight, as depicted in

Figure 2, because the lowest hydrodynamic drag occurs with this scheme owing to the smallest wetted part [

7]. During this motion, it is assumed that there are no roll and yaw motions owing to the vertical fins and an automatic feedback control system, and the horizontal fins are supposed to be retracted into the vehicle to minimize the hydrodynamic drag and interference with the supercavity. Therefore, only the longitudinal vertical plane motion of the vehicle was considered on the basis of these assumptions.

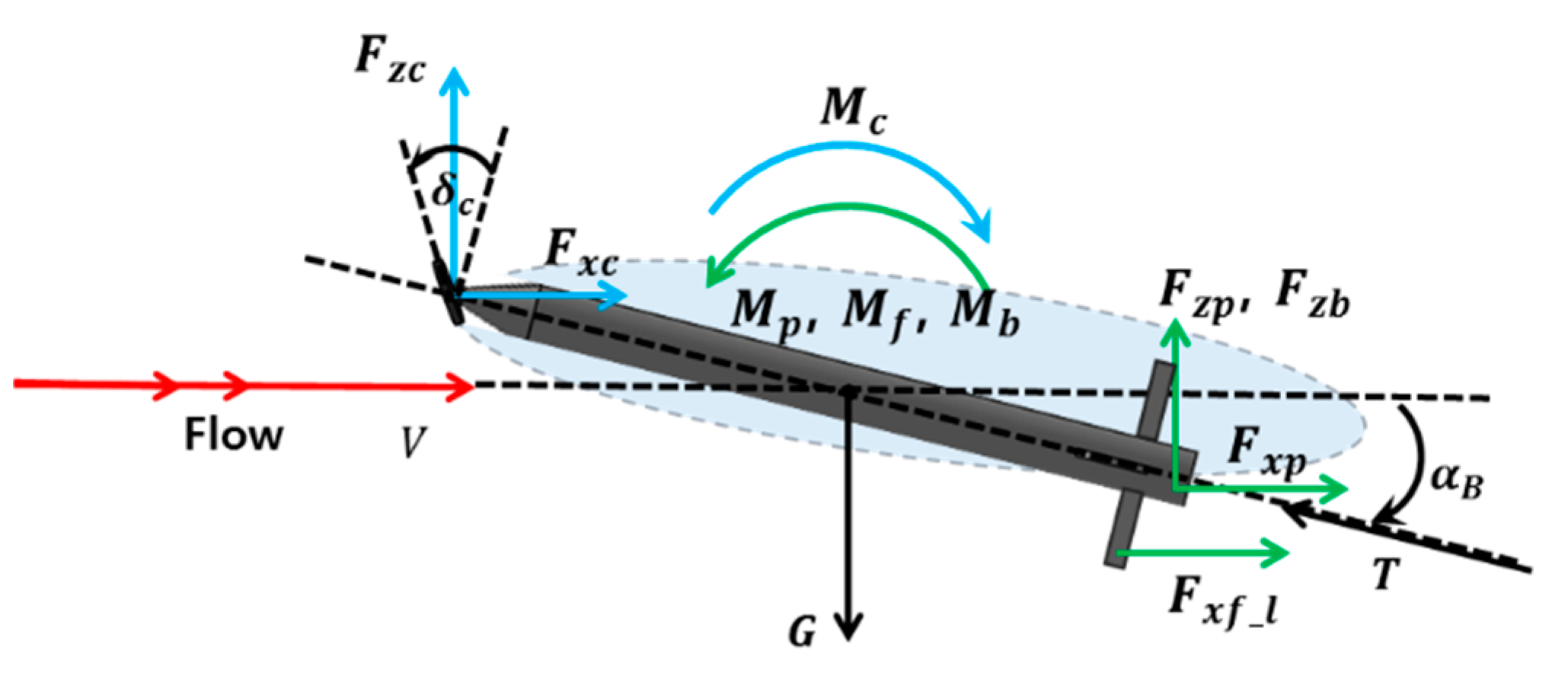

A free-body diagram of a supercavitating vehicle in a longitudinal vertical plane is shown in

Figure 3. The equations of force and moment equilibrium for straight level flight can be expressed as

where

,

, and

represent the hydrodynamic drag, lift, and the sum of their moments acting on the cavitator, respectively.

,

, and

represent the hydrodynamic drag, lift, and the sum of their moments on the wetted part of the vehicle by planing, respectively.

and

represent the hydrostatic buoyancy force and its moment on the wetted part, respectively.

,

, and

represent the hydrodynamic drag force and the sum of their moments acting on the upper and lower vertical fins, respectively.

represents the vehicle weight,

is the thrust (which equals the overall drag of the vehicle),

is the trim angle of the vehicle, and

is the inclination angle of the cavitator.

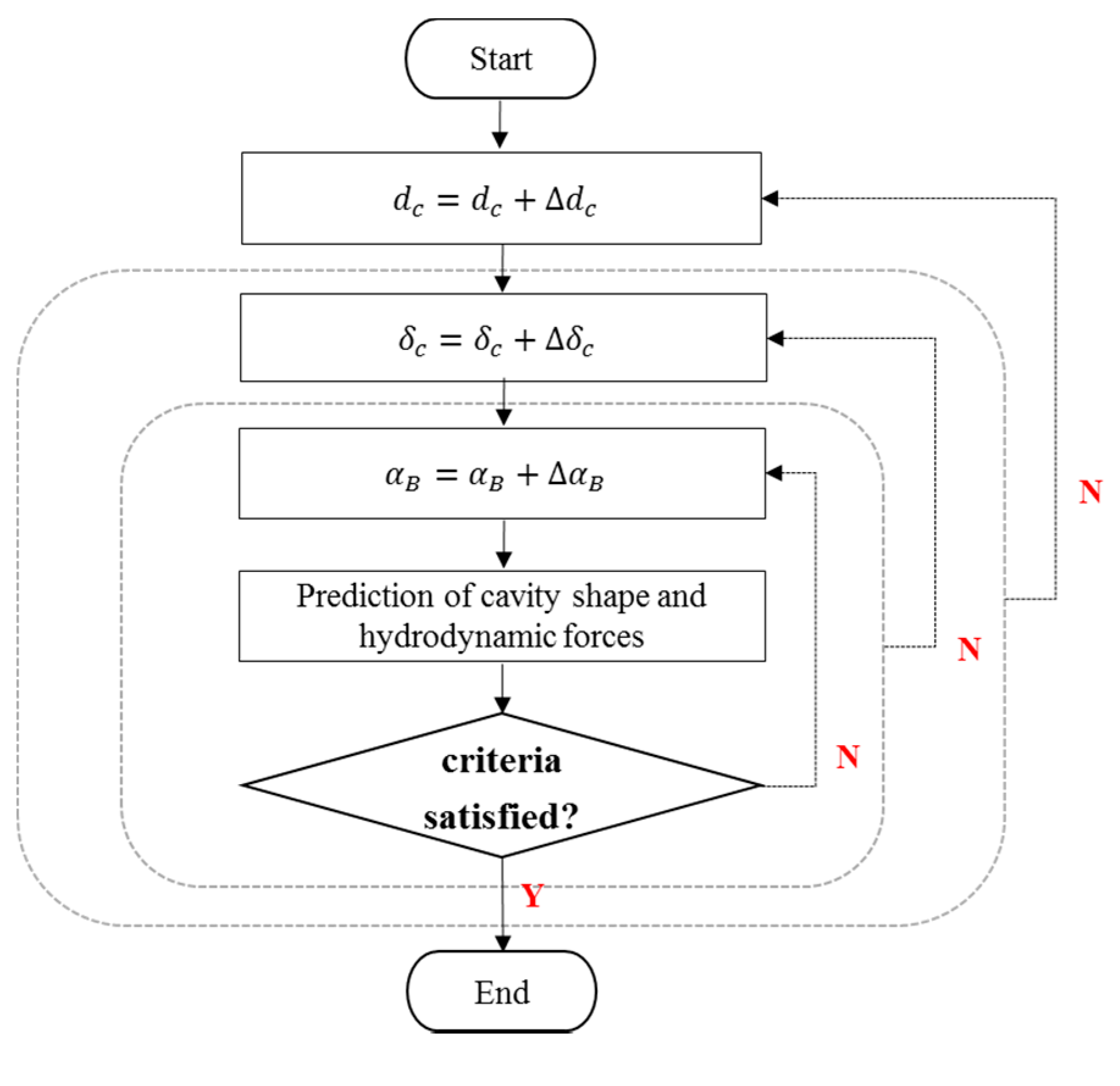

To determine the conditions of straight level flight, the equations of force and moment equilibrium were solved iteratively until the following practical convergence criteria were satisfied by varying the diameter of the cavitator (

, its angle of inclination (

), and the trim angle of the vehicle (

):

where

and

represent the difference between the total lift force of the vehicle and its weight, and that between the total moment on the cavitator and the total moment on the wetted part of the vehicle, respectively.

A flowchart of the iteration process is shown in

Figure 4. To solve the equations of force and moment equilibrium, the cavity shapes and hydrodynamic forces were predicted using existing mathematical models, which are described in the following section.

After the conditions of straight level flight were determined, the optimal cavitator size that minimizes the overall drag of the vehicle was finally determined by comparing the overall drag calculated under each straight level flight condition.

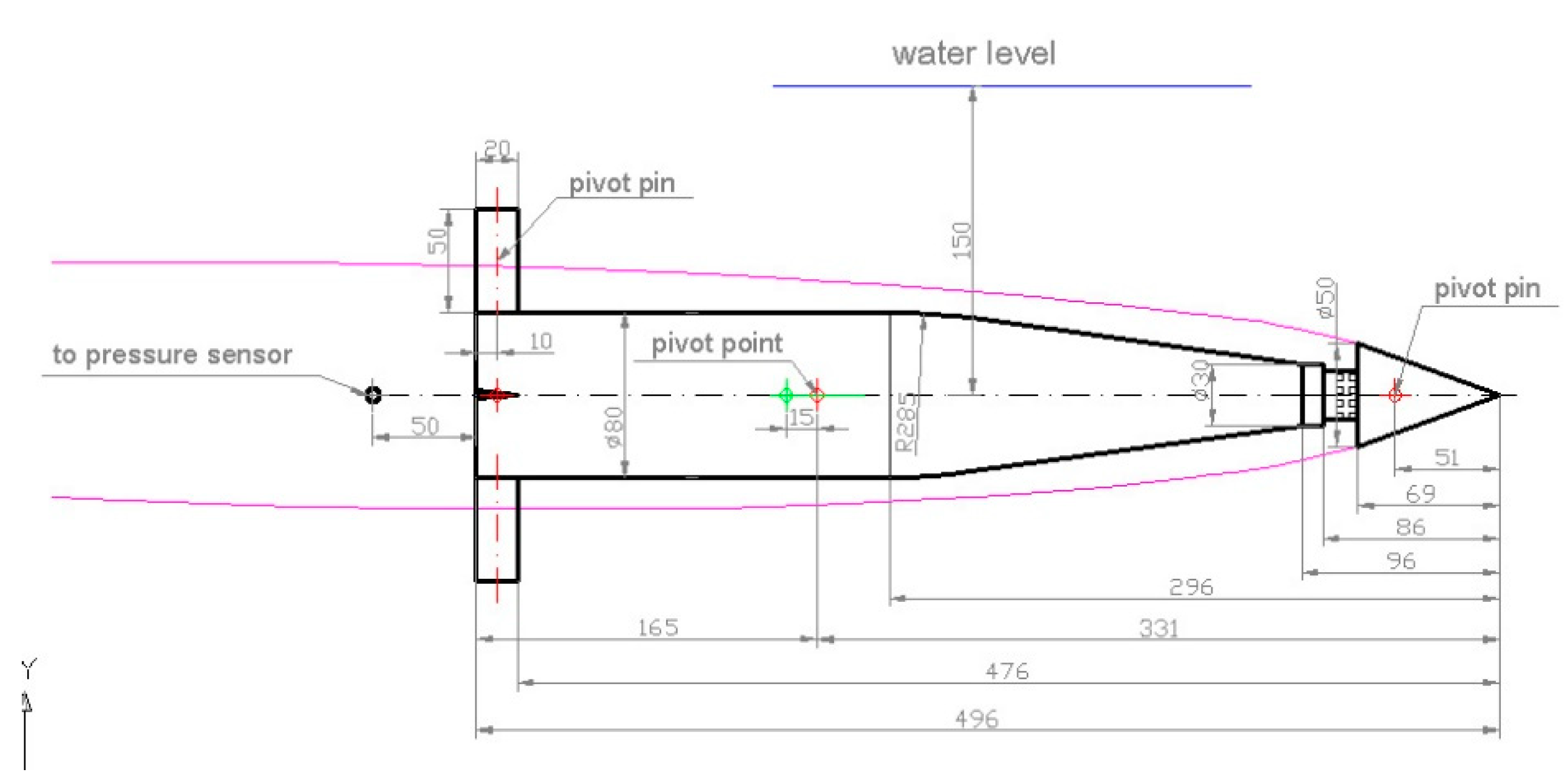

4. Preliminary Design for a Realistic Supercavitating Vehicle

A preliminary design was performed for a realistic supercavitating vehicle using the developed design method. Detailed information on the vehicle used in the design is presented in

Table 2.

According to the design procedure, the design cavitation number was first determined to satisfy the stability condition of the ventilated supercavity

described in

Section 2. As mentioned before, the critical value of the stability parameter

becomes lower in the presence of the vehicle inside the supercavity, and the simulation performed by Kirschner and Arzoumanian [

14] indicated that

in such a case. However, this body effect has not been sufficiently addressed, and further studies with various body shapes and operating conditions that may affect the critical value of the stability parameter are required. Therefore, it is reasonable to determine the design cavitation number with a sufficient margin, and a moderate value of

was selected to determine the design cavitation number for this particular design trial. Accordingly, the corresponding design cavitation number is

. This design cavitation number has to be changed if it is not available from the ventilation system of the vehicle. In that case, the design procedure has to be re-performed with a new design cavitation number.

Regarding the cavitator type, the disk-type cavitator was chosen because it is more suitable for a straight-running-type supercavitating vehicle. For the iteration to determine the optimal cavitator that minimizes the overall drag of the vehicle in straight level flight, the upper and lower bounds and increments of varying parameters were set as listed in

Table 3. The upper bound of the cavitator inclination angle is the maximum allowable inclination of the cavitator. The lower bound of the cavitator diameter and the upper bound of the vehicle trim angle were determined by pre-examining the conditions for the planing motion scheme. Below the lower bound of the cavitator diameter, only partial cavities are generated on the vehicle; over the upper bound of the vehicle trim angle, the lower surface of the cavity collides with the conical part of the vehicle such that the cavity can no longer grow into the supercavity.

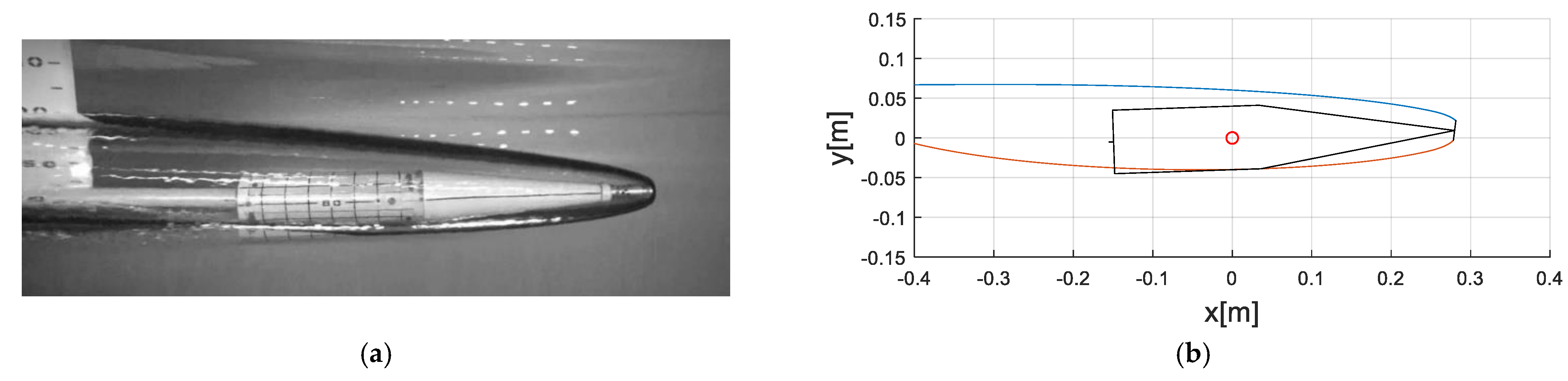

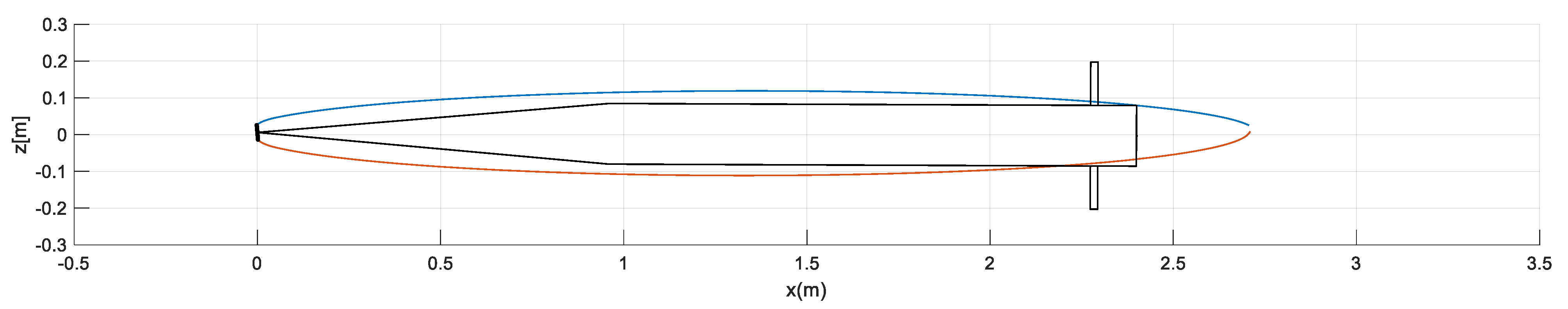

From the iteration, a disk-type cavitator with a diameter of

m was determined to be the optimal one, producing the lowest overall drag of the vehicle in straight level flight. It was confirmed that the cavitator inclination angle and vehicle trim angle for straight level flight were

and

, respectively.

Figure 11 shows the straight level flight conditions with the predicted supercavity shape. The figure indicates that, except for a very small planing area of the vehicle transom, the supercavity created by the optimal cavitator tightly envelops the vehicle, resulting in minimum overall drag. It is noteworthy that the motion stability of the vehicle may be affected when the vehicle transom is considerably close to a cavity closure region featuring a highly unsteady flow behavior. If the designers want to ensure the torpedo operates inside the forward stable region of the supercavity, sufficiently away from the closure region, the minimum size of the supercavity can be imposed as a constraint in the design process.