A Systematic Review of Technologies, Control Methods, and Optimization for Extended-Range Electric Vehicles

Abstract

1. Introduction

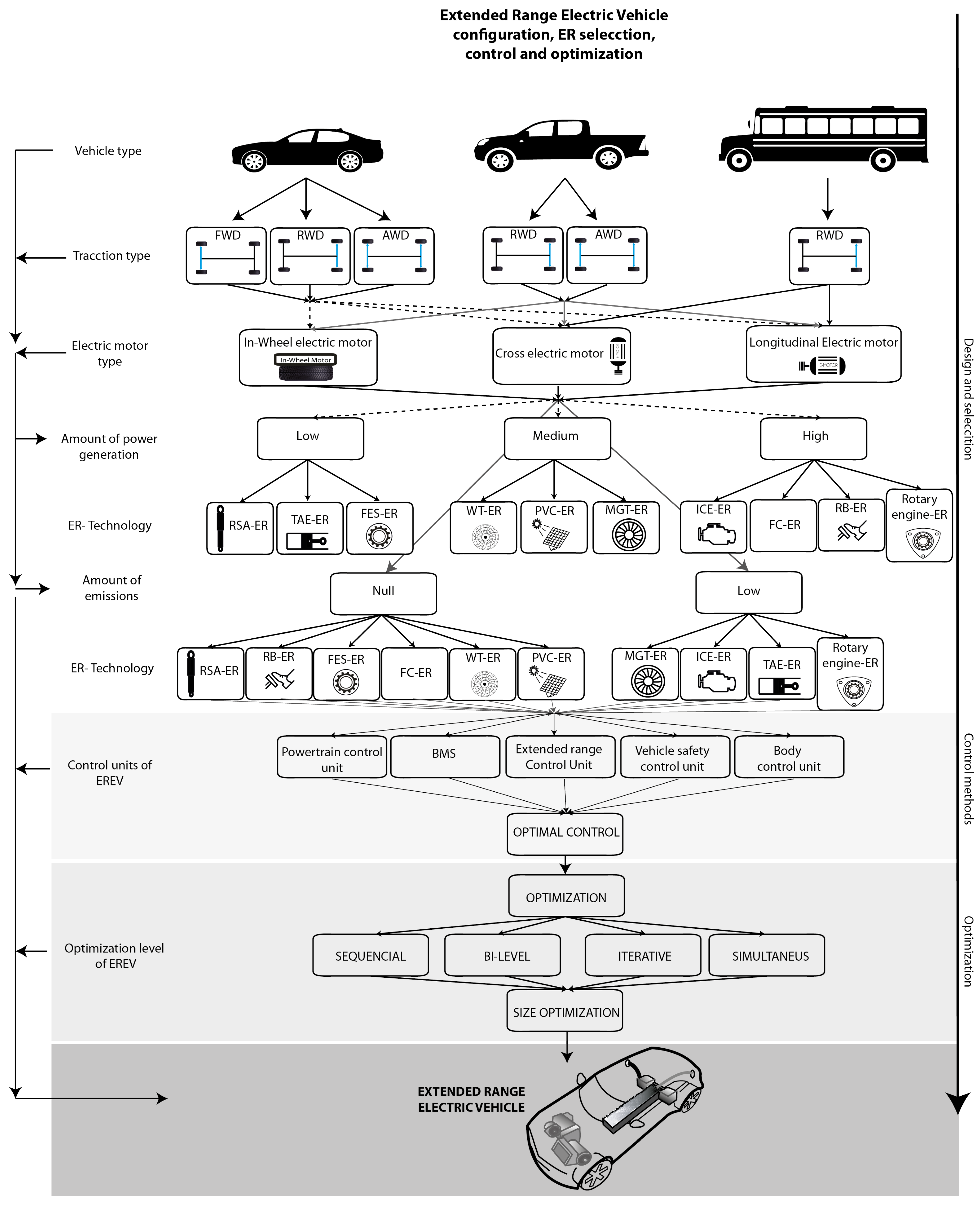

2. Extended Range Electric Vehicle Technology

2.1. Technological Classification of EREV

- High instant power and high power density.

- High torque at low speeds for starting and climbing, and high power at high speeds for cruising.

- An extensive speed range including constant-torque and constant-power regions. In this case, the APU, when it is on, needs to operate in the same regions.

- Fast torque response.

- High efficiency over a large speed and torque ranges.

- High reliability and robustness for various vehicle operating conditions.

- Reasonable cost.

2.1.1. Internal Combustion Engine Extended Range (ICE-ER)

2.1.2. Regenerative Shock Absorber Extended Range (RSA-ER)

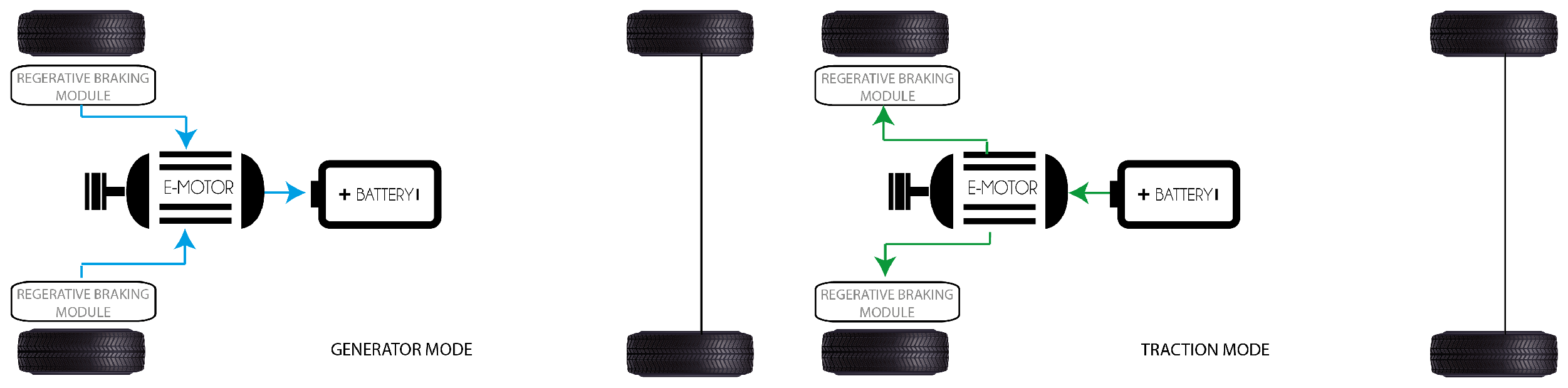

2.1.3. Regenerative Braking Extended Range RB-ER

2.1.4. Fuel Cell Extended Range (FC-ER)

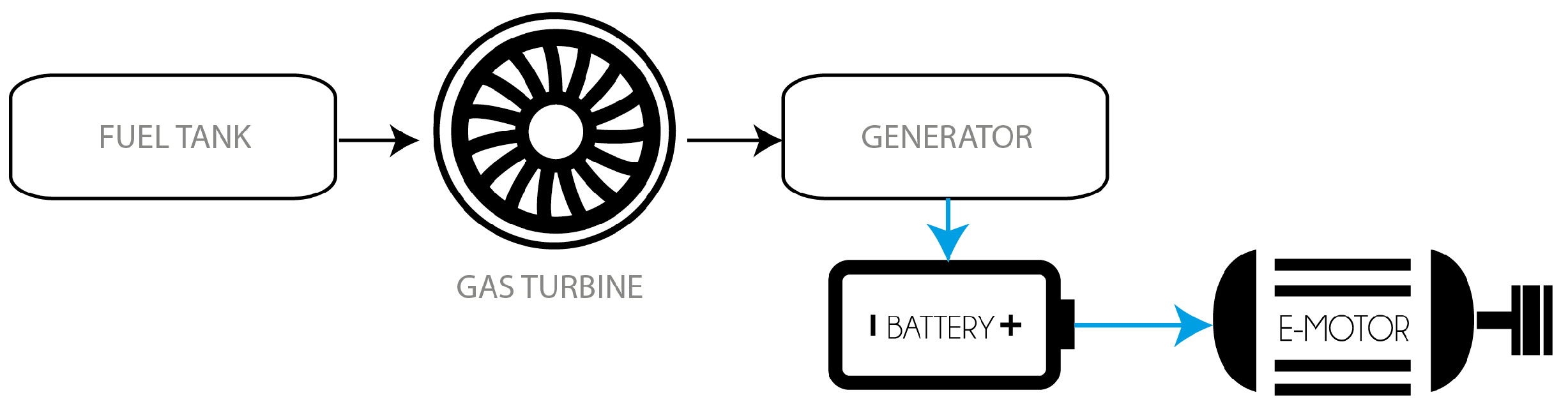

2.1.5. Micro Gas Turbine Extended Range (MGT-ER)

- A radial compressor compresses the inlet air.

- Air is pre-heated in the recuperator using heat from the turbine exhaust.

- Heated air from the recuperator is mixed with fuel in the combustion chamber and burned.

- Hot gas expands in turbine stages, and the gas’s energy is converted into mechanical energy to drive the air-compressor and the drive equipment (usually generator).

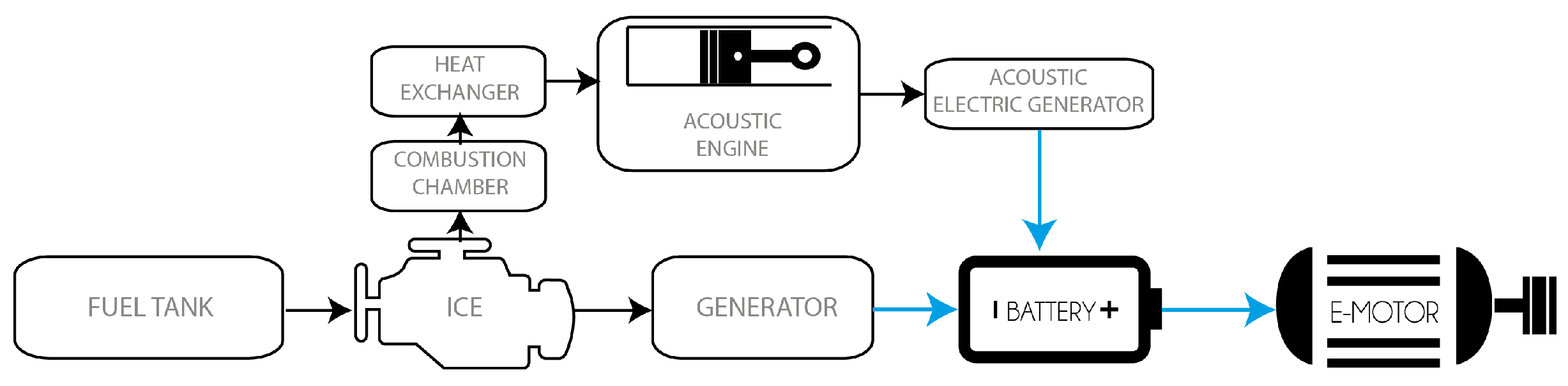

2.1.6. Thermoacoustic Engine Extended Range (TAE-ER)

- The exhaust heat is converted to acoustic energy (mechanical);

- The acoustic energy is converted to electrical energy [58].

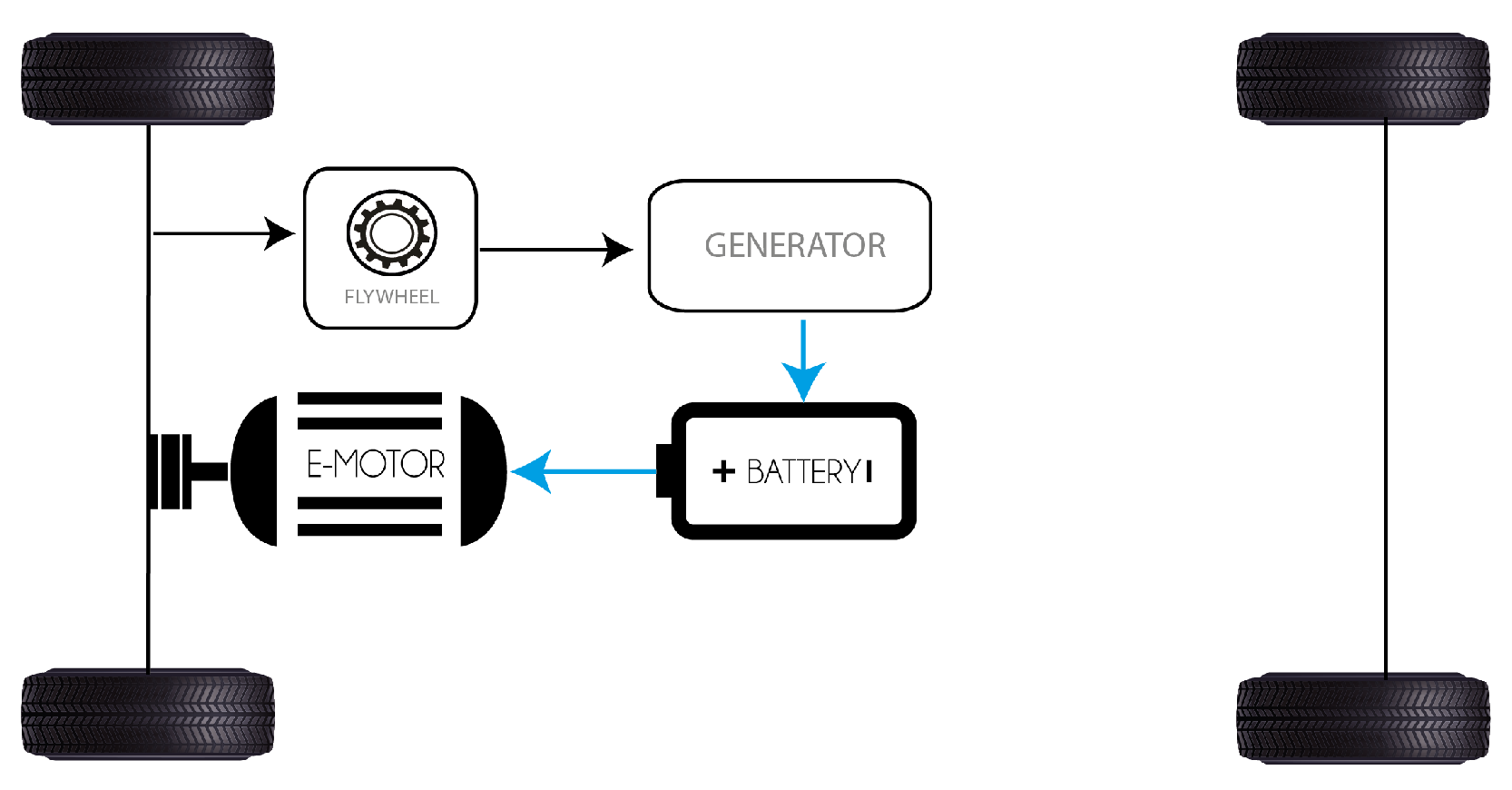

2.1.7. Flywheel Energy Storage Extended Range (FES-ER)

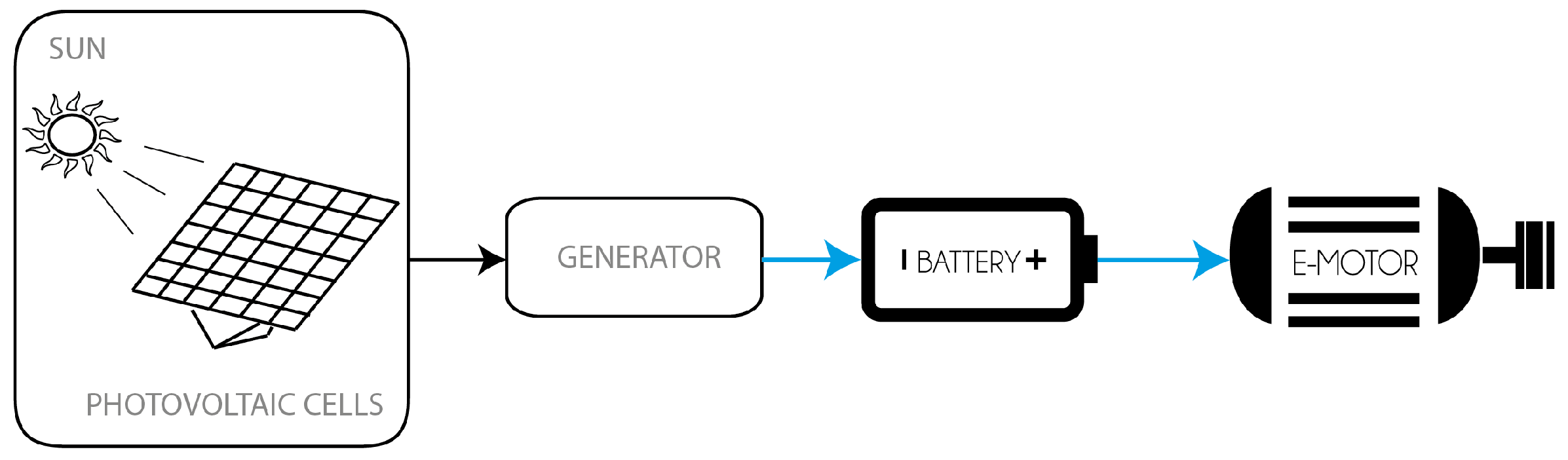

2.1.8. Solar Energy Storage Extended Range (SES-ER)

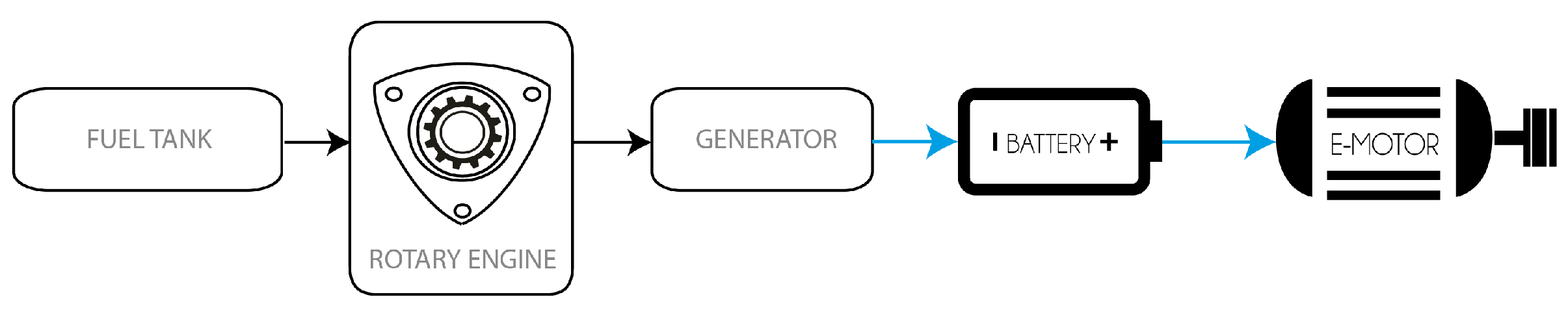

2.1.9. Rotatory Engine Extended Range (RE-ER)

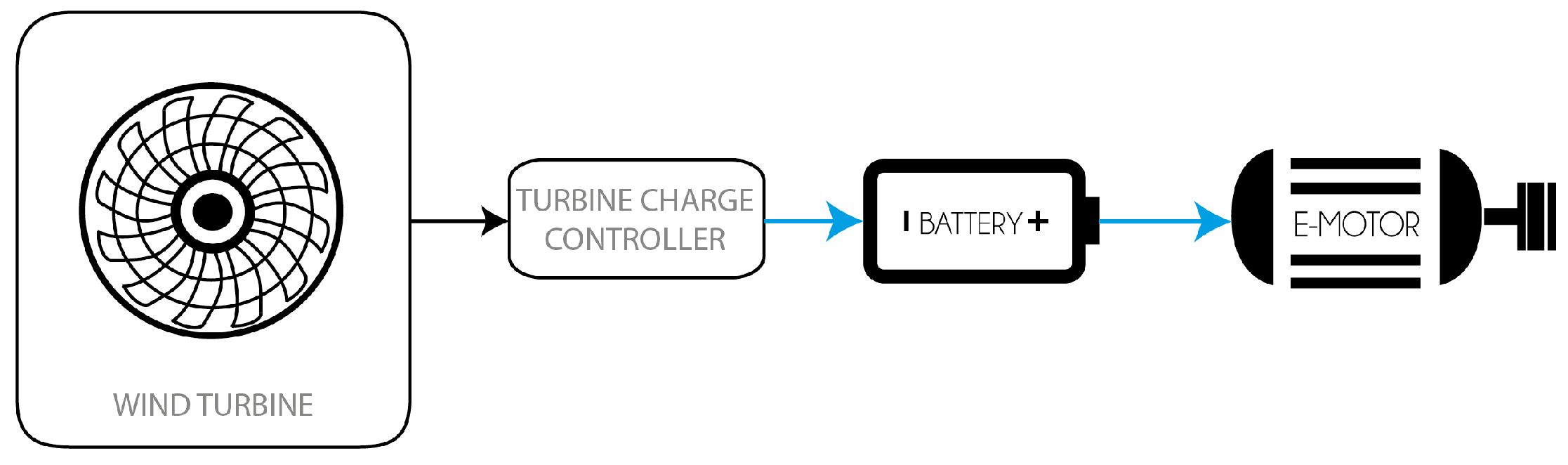

2.1.10. Wind Turbine Extended Range (WT-ER)

3. A Comparison of the Technology Used in EREVs

- System power;

- Amount of extra range;

- Global system efficiency;

- Emissions.

| Extended Range System | System Power | Extra Range | Efficiency | Emissions |

|---|---|---|---|---|

| ICE-ER | 30 kW [12] 35 kW [14] 5.5 kW [35] 111 kW [72] | 232.79% [7] 430 km [12] 51–139 km [35] 380 km [73] 330 km [74] 676 [72] | 20–40% [75,76] 31% [12] | Low |

| Fuel cell-ER | 20 kW [77] 85–83 kW [78] 1200 W [47] 25 kW [79] 128 kW [80] | 500 km [77] 650 km [80] 665 km [81] 594 km [81] 1500 km [82] | 70% [77] 63.6–72.4% [83] 43% [47] 55.21% [79] | No |

| Rotary engine-ER | 3.8 kW [84] 20 kW [85] | 80 km [85] 321 km [86] | 73% [87] 78% [84] 77% [85] | Low |

| RB-ER | 14.8 kW [88] 55.75–82.66 kJ [89] 298.75 kJ [90] | 32.1–47.7% of the total recoverable energy [89] 1.18% SOC improve [90] | 79–94% [88] 30–60% [26] 47% [89] | No |

| MGT-ER | 32 kW [91] 100 kW [92] 63.3 kW [93] | 370 km [94] | 47.2% [95] 28% [91] 30% [92] 35% [94] 38% [93] | Low |

| PVC-ER | 68.2–300 W [96] | 19.6 km [96] | 91.2% [96] 20.2–23% [96] | No |

| WT-ER | 2.64 kW [97] 0.1–1.1 kW [70] | add up to 10% [98] 7.27 km [97] | 75% [97] 75–90% [70] | Low |

| FES-ER | 40 kW to 1.6 MW [99] 60–101 kW [100] 1–20 kW [101] | 50% milage over [100] 1.17% milage over [102] | 60% [100] 90–95% [103] 70–90% [104] | No |

| TAE-ER | 710 W [105] 1029 W [106] 58 W [107] 1.5 kW [108] | 80% fuel consumtion savings [59] | 33.8–38.7% [60] 30% [105] 5.4% [106] 18% [78] 16% [108] | Low |

| RSA-ER | 8–40 W [100] 0.74–0.78 kW [109] 19.2–67.5 W [110] 4.3 W [38] | Can power an 8 W lidar for 323 days or a 2 W camera for 1292 days [100] | 70–80% [100] 71–84% [111] 33–63% [110] 87% [38] 16% [38] | No |

3.1. EREV Configuration

- The traction force, which can be forward, backward, or four-wheel drive.

- The position of the engine.

- If it has a gearbox and the type of differential, mechanical or electronic.

EREV Topological Configurations

3.2. Key Components of an EREV

4. Control and Management

- Optimize the system’s energy flow;

- Predict the remaining energy and hence the residual driving cycle;

- Turn on the APU to charge and improve the autonomy with a suitable control method;

- Suggest more efficient driving behavior;

- Direct energy regenerated from braking to receptive energy sources such as the batteries;

- Modulate temperature control as a response to external climate;

- Propose battery charging;

- Analyze the operation history of the energy source, especially the battery;

- Diagnose any incorrect behavior or defective components of the energy source, or malfunctions of any component.

| Control Methods/Strategy | Author | Controlled System | Technology | Purpose | Application |

|---|---|---|---|---|---|

| Constant power control strategy | [3] | BMS | ER-ICE | The lowest permissible level of SOC after the drive charge the vehicle | Charging Management Arterial Roads |

| A power follower control strategy | [3] | BMS | ER-ICE | The lowest permissible level of SOC after the drive charge the vehicle | Charging Management Express Way |

| Proportional resonant control strategy | [8] | Generator | ER-ICE | To maintain the efficient region of the generator | Generate more energy |

| Partial power following control strategy | [8] | ICE | ER-ICE | To maintain the efficient region to operate the ICE | Reduce fuel consumption |

| A control strategy based on Pontryagins Minimum Principle (PMP) | [9] | ICE | ER-ICE | Monitors the current SOC of the battery | Minimizes the energy consumed during driving |

| Predictive control-based energy management | [90] | Fuel Cells | ER-FC | Forecasted speed | Minimize hydrogen consumption |

| Regenerative Braking control strategy (RRBCS) | [28] | Regenerative braking | ER-RB | The better capacity of the regenerative braking energy consider slip ratio of the tire | Coordinate regenerative braking torque and mechanical friction to maximize energy recovery and to ensure the braking efficiency |

| A normal control strategy based on a state of charge (SOC) | [12] | ICE | ER-ICE | Monitors the battery state of charge (SOC) | Reduce CO2 emissions |

| Automatic Mechanical Transmission (AMT) Shift control strategy | [43] | Regenerative braking | ER-RB | Identify the braking intention and transmission shifts correctly | Improve the braking energy recovery rate, and ensure the braking safety a stability |

| Start-stop control strategy | [33] | ICE- Generator | ER-ICE | Reduce the start-stop times and running time | Fuel economy |

| Adaptive power management strategy PMS | [18] | ICE | ER-ICE | Asses the battery SOC and vehicle speed | Improve energy savings, the fuel, and electrical consumption |

| Method of quantitative estimation | [120] | Generator | ER-ICE | Optimize the design parameters aiming at the maximum efficiency in the continuos rated | Find maximum torque per ampere |

| Charge-deplete-charge- sustain (CDCS) strategy | [15] | ICE- Generator | ER-ICE | Asses the battery SOC and vehicle speed | Energy efficiency, reduce energy consumption and reduce costs of operation |

| Thermal management system to battery cooling strategy | [22] | Battery | ER-ICE | Quantify the heat generation sources and accurately predicting cell temperatures | Improve longevity, safety, and overall performance |

| A data driving behavior predictive control strategy | [23] | Driving behavior | ER-ICE | Predict the EV power requests and optimize their control inputs | Improving the driving range and battery life while maintaining thermal comfort for the passengers |

| Mixed-integer convex program | [37] | Powertrain | ER-ICE | Formulate an economic optimization | All the quantities to minimize are expressed as a monetary variable |

| The convex optimal control problem | [36] | Powertrain | ER-ICE | Optimization over the entire driving cycle is computed offline | Achieve the best possible energy consumption. |

| The optimal operation curve control strategy | [29] | ICE | ER-ICE | Research and control the vehicle required torque | Control the power allocation of APU and batteries to reduce fuel consumption and obtain good fuel economy |

| Multi-objective hierarchical prediction energy management strategy | [52] | Fuel cells | ER-FC | Propose a Global state of charge rapid planning method based only on the expected driving distance | Achieve optimal fuel cell life economy and energy consumption economy |

| A novel energy-aware velocity planning | [32] | ICE | ER-ICE | Propose energy-aware velocity planning | Improve electric vehicle fuel efficiency |

| Pseudospectral optimal control | [34] | APU | ER-ICE | Maintain engine speed constant is better for the dynamic characteristics of APU | Different limits of the APU power changing rate significantly influence the fuel consumption |

| Model predictive control | [121,122] | Powertrain | ER-ICE | Propose a computationally tractable model prediction control (MPC) | Prediction horizon so that energy consumption is minimized |

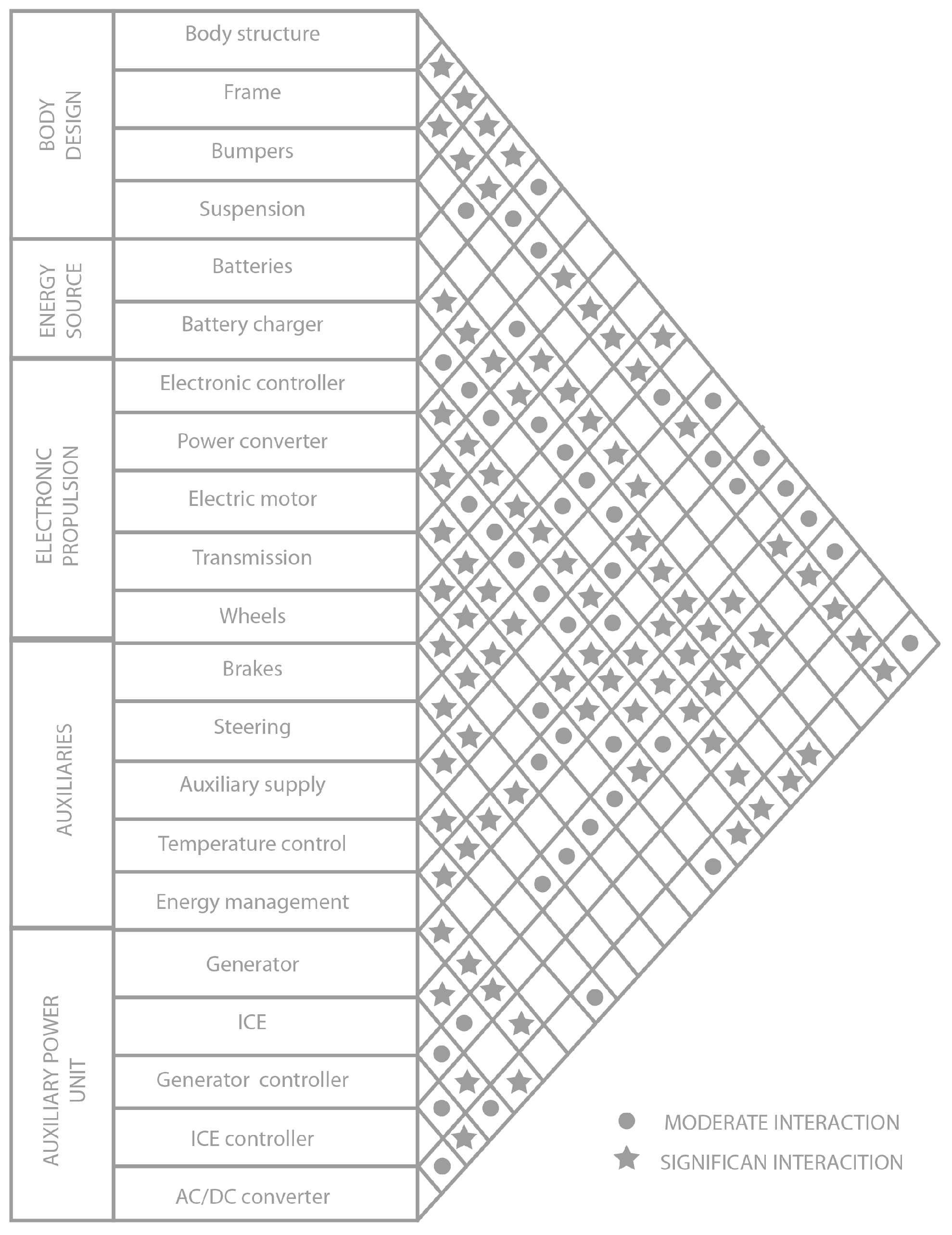

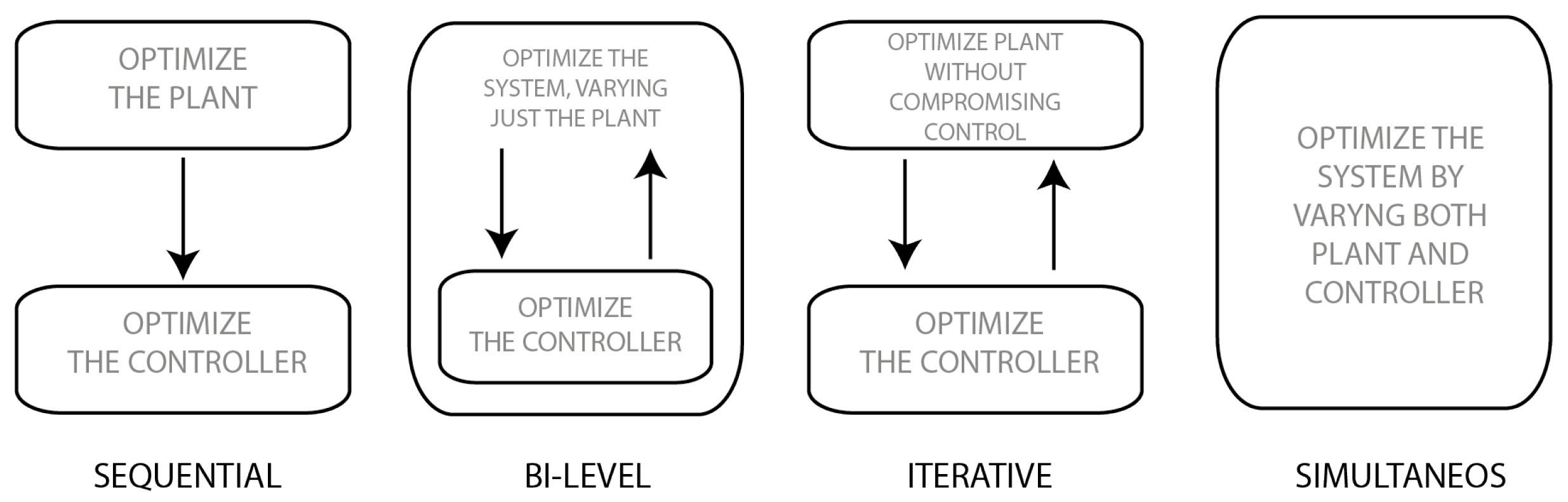

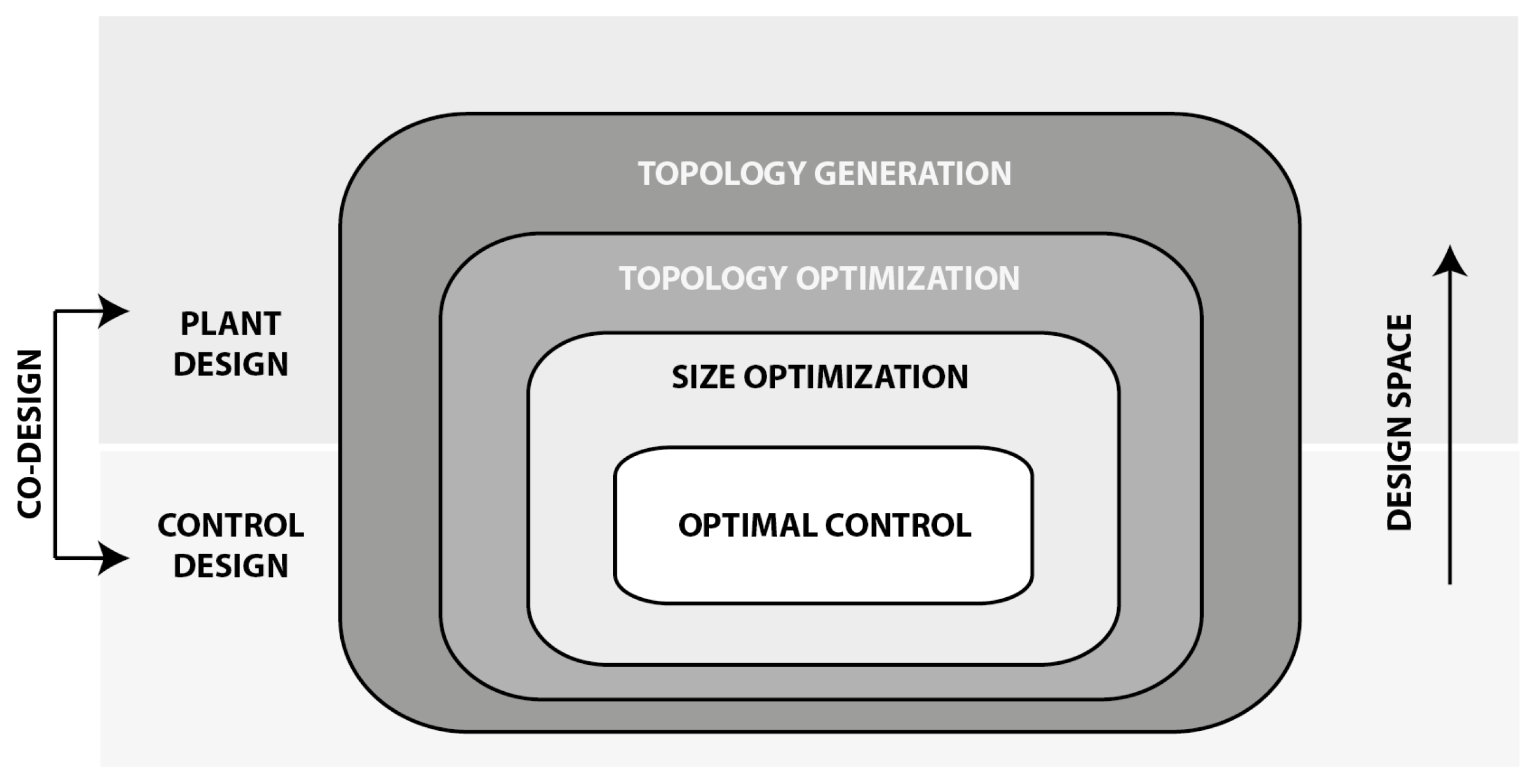

5. System Optimization

- As the interactions among various subsystems significantly affect the performances of EREVs, the significance of those interactions should be analyzed and taken into account.

- The model’s accuracy is usually correlated with the model’s complexity, but the latter may run counter to usability, tradeoffs among the accuracy, complexity, usability, and simulation time should be considered.

- The system voltage generally causes contradictory issues for EREV design. For example, the battery weight (higher voltage requires more battery modules in series, and hence more weight for the battery case). Similarly, motor drive voltage and current ratings, auxiliary power unit range, energy generated, acceleration performance, driving range, and safety should be optimized at the system level.

- The adoption of multiple energy sources helps to increase the driving range. For the EREV case, the APU should be optimized based on the vehicle’s performance and cost requirements.

5.1. Controller Optimization for Plant

5.2. Multidisciplinary Optimization

5.3. Optimal Control

5.4. Size Optimization

6. The Process of Designing an EREV

7. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EV | Electric vehicle |

| EREV | Extended range electric vehicle |

| APU | Auxiliary power unit |

| Series HEV | Series hybrid electric vehicles |

| RE | Range extender |

| ICEV | Internal combustion engine vehicle |

| SOC | State of charge |

| PHEV | Plug-in hybrid electric vehicle |

| FWD | Forward wheel drive |

| RWD | Rear-wheel drive |

| AWD | All wheel drive |

| ICE | Internal combustion engine |

| ICE-ER | Internal combustion engine extended range |

| RSA-ER | Regenerative shock absorber extended range |

| RB-ER | Regenerative braking extended range |

| RBS | Regenerative braking system |

| RRBCS | Revised regenerative braking control strategy |

| AMT | Automatic mechanical transmission |

| FC | Fuel cell |

| FC-ER | Fuel cell extended range |

| MGT | Micro gas turbine |

| MGT-ER | Micro gas turbine extended range |

| TAE | Thermoacoustic engine |

| TAE-ER | Thermoacoustic engine extended range |

| TAC | Thermoacoustic converter |

| FES | Flywheel energy storage |

| FES-ER | Flywheel energy storage extended range |

| PVC | Photovoltaic cell |

| SES | Solar energy storage |

| RE | Rotary engine |

| RE-ER | Rotary engine extended range |

| WT | Wind turbine |

| WT-ER | Wind turbine extended range |

| GHG | Greenhouse gases |

| EMS | Energy management system |

| BMS | Battery management system |

| OEM | Original equipment manufacturer |

| CAGR | Compound annual growth rate |

References

- İnci, M.; Büyük, M.; Demir, M.H.; İlbey, G. A review and research on fuel cell electric vehicles: Topologies, power electronic converters, energy management methods, technical challenges, marketing and future aspects. Renew. Sustain. Energy Rev. 2021, 137, 110648. [Google Scholar] [CrossRef]

- Lou, G.; Ma, H.; Fan, T.; Chan, H.K. Impact of the dual-credit policy on improvements in fuel economy and the production of internal combustion engine vehicles. Resour. Conserv. Recycl. 2020, 156, 104712. [Google Scholar] [CrossRef]

- Song, W.; Zhang, X.; Tian, Y.; Xi, L.h. A charging management-based intelligent control strategy for extended-range electric vehicles. J. Zhejiang Univ. Sci. A 2016, 17, 903–910. [Google Scholar] [CrossRef]

- Tate, E.D.; Harpster, M.O.; Savagian, P.J. The Electrification of the Automobile: From Conventional Hybrid, to Plug-in Hybrids, to Extended-Range Electric Vehicles. SAE Int. J. Passeng. Cars-Electron. Electr. Syst. 2008, 1, 2008-01-0458. [Google Scholar] [CrossRef]

- Song, K.; Zhang, J.; Zhang, T. Design and Development of a pluggable PEMFC extended Range Electric Vehicle. In Proceedings of the 2011 Second International Conference on Mechanic Automation and Control Engineering, Inner Mongolia, China, 15–17 July 2011; pp. 1144–1147. [Google Scholar] [CrossRef]

- Xian, T.F.; Soon, C.M.; Rajoo, S.; Romagnoli, A. A parametric study: The impact of components sizing on range extended electric vehicle’s driving range. In Proceedings of the 2016 Asian Conference on Energy, Power and Transportation Electrification (ACEPT), Singapore, 25–27 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Wahono, B.; Nur, A.; Santoso, W.B.; Praptijanto, A. A comparison study of range-extended engines for electric vehicle based on vehicle simulator. J. Mech. Eng. Sci. 2016, 10, 1803–1816. [Google Scholar] [CrossRef]

- Wang, X.; Lv, H.; Sun, Q.; Mi, Y.; Gao, P. A Proportional Resonant Control Strategy for Efficiency Improvement in Extended Range Electric Vehicles. Energies 2017, 10, 204. [Google Scholar] [CrossRef]

- Lee, W.; Jeoung, H.; Park, D.; Kim, N. An Adaptive Concept of PMP-Based Control for Saving Operating Costs of Extended-Range Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 11505–11512. [Google Scholar] [CrossRef]

- Tang, T.Q.; Chen, L.; Yang, S.C.; Shang, H.Y. An extended car-following model with consideration of the electric vehicle’s driving range. Phys. A Stat. Mech. Appl. 2015, 430, 148–155. [Google Scholar] [CrossRef]

- Xu, X.; Lv, M.; Chen, Z.; Ji, W.; Gao, R. Analysis of electric vehicle extended range misalignment based on rigid-flexible dynamics. IOP Conf. Ser. Earth Environ. Sci. 2017, 61, 012018. [Google Scholar] [CrossRef]

- Hall, J.; Marlok, H.; Bassett, M.; Warth, M. Analysis of Real World Data from a Range Extended Electric Vehicle Demonstrator. SAE Int. J. Altern. Powertrains 2014, 4, 2887. [Google Scholar] [CrossRef]

- Dost, P.; Spichartz, P.; Sourkounis, C. Charging behaviour of users utilising battery electric vehicles and extended range electric vehicles within the scope of a field test. In Proceedings of the 2015 International Conference on Renewable Energy Research and Applications (ICRERA), Palermo, Italy, 22–25 November 2015; Volume 54, pp. 1162–1167. [Google Scholar] [CrossRef]

- Figueroa-García, J.; López-Santana, E.; Villa-Ramírez, J.; Ferro-Escobar, R. Applied Computer Sciences in Engineering. Commun. Comput. Inf. Sci. 2017, 742, 65–71. [Google Scholar] [CrossRef]

- Du, J.; Chen, J.; Song, Z.; Gao, M.; Ouyang, M. Design method of a power management strategy for variable battery capacities range-extended electric vehicles to improve energy efficiency and cost-effectiveness. Energy 2017, 121, 32–42. [Google Scholar] [CrossRef]

- Guan, J.C.; Chen, B.C.; Wu, Y.Y. Design of an Adaptive Power Management Strategy for Range Extended Electric Vehicles. Energies 2019, 12, 1610. [Google Scholar] [CrossRef]

- Shi, L.; Guo, Y.; Xiao, D.; Han, Z.; Zhou, X. Design, optimization, and study of a rare-earth permanent-magnet generator with new consequent-pole rotor for extended-range electric vehicle. IEEJ Trans. Electr. Electron. Eng. 2019, 14, 917–923. [Google Scholar] [CrossRef]

- Du, J.; Chen, J.; Gao, M.; Wang, J. Energy Efficiency Oriented Design Method of Power Management Strategy for Range-Extended Electric Vehicles. Math. Probl. Eng. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Sneha Angeline, P.; Newlin Rajkumar, M. Evolution of electric vehicle and its future scope. Mater. Today Proc. 2020, 33, 3930–3936. [Google Scholar] [CrossRef]

- Lijewski, P.; Kozak, M.; Fuć, P.; Rymaniak, Ł.; Ziółkowski, A. Exhaust emissions generated under actual operating conditions from a hybrid vehicle and an electric one fitted with a range extender. Transp. Res. Part D Transp. Environ. 2020, 78, 102183. [Google Scholar] [CrossRef]

- Guo, R.; Cao, C.; Mi, Y.; Huang, Y. Experimental investigation of the noise, vibration and harshness performances of a range-extended electric vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230, 650–663. [Google Scholar] [CrossRef]

- Ramotar, L.; Rohrauer, G.L.; Filion, R.; MacDonald, K. Experimental verification of a thermal equivalent circuit dynamic model on an extended range electric vehicle battery pack. J. Power Sources 2017, 343, 383–394. [Google Scholar] [CrossRef]

- Vatanparvar, K.; Faezi, S.; Burago, I.; Levorato, M.; Al Faruque, M.A. Extended Range Electric Vehicle with Driving Behavior Estimation in Energy Management. IEEE Trans. Smart Grid 2019, 10, 2959–2968. [Google Scholar] [CrossRef]

- Yan, X.; Fleming, J.; Lot, R. Extending the range of Plug-in Hybrid Electric Vehicles by CVT transmission optimal management. Energy Procedia 2018, 151, 17–22. [Google Scholar] [CrossRef]

- Kim, T.Y.; Lee, S.H. Combustion and emission characteristics of wood pyrolysis oil-butanol blended fuels in a DI diesel engine. Int. J. Automot. Technol. 2015, 16, 903–912. [Google Scholar] [CrossRef]

- Wu, D.; Feng, L. On-Off Control of Range Extender in Extended-Range Electric Vehicle using Bird Swarm Intelligence. Electronics 2019, 8, 1223. [Google Scholar] [CrossRef]

- Lee, G.S.; Kim, D.H.; Han, J.H.; Hwang, M.H.; Cha, H.R. Optimal Operating Point Determination Method Design for Range-Extended Electric Vehicles Based on Real Driving Tests. Energies 2019, 12, 845. [Google Scholar] [CrossRef]

- Liu, H.; Lei, Y.; Fu, Y.; Li, X. Parameter matching and optimization for power system of range-extended electric vehicle based on requirements. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 3316–3328. [Google Scholar] [CrossRef]

- Jiang, Y. Parameters Optimization for Extended-range Electric Vehicle Based on Improved Chaotic Particle Swarm Optimization. Int. J. Grid Distrib. Comput. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Kopczyński, A.; Krawczyk, P.; Lasocki, J. Parameters selection of extended-range electric vehicle supplied with alternative fuel. E3S Web Conf. 2018, 44, 00073. [Google Scholar] [CrossRef]

- Ren, G.; Shan, S.; Ma, G.; Shang, X.; Zhu, S.; Zhang, Q.; Yang, T. Review of energy storage technologies for extended range electric vehicle. J. Appl. Sci. Eng. 2019, 22, 69–82. [Google Scholar] [CrossRef]

- Baek, D.; Chang, N. Runtime Power Management of Battery Electric Vehicles for Extended Range With Consideration of Driving Time. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2019, 27, 549–559. [Google Scholar] [CrossRef]

- Zhao, J.b.; Han, B.y.; Bei, S.y. Start-Stop Moment Optimization of Range Extender and Control Strategy Design for Extended -Range Electric Vehicle. IOP Conf. Ser. Mater. Sci. Eng. 2017, 241, 012025. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Chen, J.; Zhang, X. Study on energy management strategy and dynamic modeling for auxiliary power units in range-extended electric vehicles. Appl. Energy 2017, 194, 363–375. [Google Scholar] [CrossRef]

- Chambon, P.; Curran, S.; Huff, S.; Love, L.; Post, B.; Wagner, R.; Jackson, R.; Green, J. Development of a range-extended electric vehicle powertrain for an integrated energy systems research printed utility vehicle. Appl. Energy 2017, 191, 99–110. [Google Scholar] [CrossRef]

- Pozzato, G.; Formentin, S.; Panzani, G.; Savaresi, S. Least Costly Energy Management for Extended-Range Electric Vehicles with Noise Emissions Characterization. IFAC-PapersOnLine 2019, 52, 586–591. [Google Scholar] [CrossRef]

- Pozzato, G.; Formentin, S.; Panzani, G.; Savaresi, S.M. Least costly energy management for extended-range electric vehicles: An economic optimization framework. Eur. J. Control 2020, 56, 218–230. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, X.; Chen, W.; Rasim, Y.; Salman, W.; Pan, H.; Yuan, Y.; Wang, C. A high-efficiency energy regenerative shock absorber using supercapacitors for renewable energy applications in range extended electric vehicle. Appl. Energy 2016, 178, 177–188, Corrigendum in 2019, 254, 113634. [Google Scholar] [CrossRef]

- Satpute, N.V.; Singh, S.; Sawant, S.M. Energy Harvesting Shock Absorber with Electromagnetic and Fluid Damping. Adv. Mech. Eng. 2015, 6, 693592. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Zhan, M.; Guo, K.; Zhao, F.; Liu, Z. Study on a novel hydraulic pumping regenerative suspension for vehicles. J. Frankl. Inst. 2015, 352, 485–499. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, G.; Meng, M.; Shen, Y. A novel control strategy of regenerative braking system for electric vehicles under safety critical driving situations. Energy 2018, 149, 329–340. [Google Scholar] [CrossRef]

- Liu, H.; Lei, Y.; Fu, Y.; Li, X. An Optimal Slip Ratio-Based Revised Regenerative Braking Control Strategy of Range-Extended Electric Vehicle. Energies 2020, 13, 1526. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, S.; Ye, Y.; Yu, M.; Wang, G. Composite braking AMT shift strategy for extended-range heavy commercial electric vehicle based on LHMM/ANFIS braking intention identification. Clust. Comput. 2019, 22, 8513–8528. [Google Scholar] [CrossRef]

- Aygen, M.S.; İnci, M. Zero-sequence current injection based power flow control strategy for grid inverter interfaced renewable energy systems. Energy Sources Part Recover. Util. Environ. Eff. 2020, 1–22. [Google Scholar] [CrossRef]

- Ozden, A.; Shahgaldi, S.; Li, X.; Hamdullahpur, F. A review of gas diffusion layers for proton exchange membrane fuel cells—With a focus on characteristics, characterization techniques, materials and designs. Prog. Energy Combust. Sci. 2019, 74, 50–102. [Google Scholar] [CrossRef]

- İnci, M. Active/reactive energy control scheme for grid-connected fuel cell system with local inductive loads. Energy 2020, 197, 117191. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H.; Ravey, A.; Péra, M.C. An integrated predictive energy management for light-duty range-extended plug-in fuel cell electric vehicle. J. Power Sources 2020, 451, 227780. [Google Scholar] [CrossRef]

- Chu, Y.; Wu, Y.; Chen, J.; Zheng, S.; Wang, Z. Design of energy and materials for ammonia-based extended-range electric vehicles. Energy Procedia 2019, 158, 3064–3069. [Google Scholar] [CrossRef]

- Dimitrova, Z.; Maréchal, F. Environomic design for electric vehicles with an integrated solid oxide fuel cell (SOFC) unit as a range extender. Renew. Energy 2017, 112, 124–142. [Google Scholar] [CrossRef]

- Wu, X.L.; Xu, Y.W.; Zhao, D.Q.; Zhong, X.B.; Li, D.; Jiang, J.; Deng, Z.; Fu, X.; Li, X. Extended-range electric vehicle-oriented thermoelectric surge control of a solid oxide fuel cell system. Appl. Energy 2020, 263, 114628. [Google Scholar] [CrossRef]

- Karaoğlan, M.U.; Kuralay, N.S.; Colpan, C.O. Investigation of the effects of battery types and power management algorithms on drive cycle simulation for a range-extended electric vehicle powertrain. Int. J. Green Energy 2019, 16, 1–11. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Chen, Z.; Qin, D.; Zhang, Y. Research on a multi-objective hierarchical prediction energy management strategy for range extended fuel cell vehicles. J. Power Sources 2019, 429, 55–66. [Google Scholar] [CrossRef]

- Geng, C.; Jin, X.; Zhang, X. Simulation research on a novel control strategy for fuel cell extended-range vehicles. Int. J. Hydrogen Energy 2019, 44, 408–420. [Google Scholar] [CrossRef]

- Almasi, A. Bright future of micro-turbines: Nuclear emergency cooling and miniature generator. Aust. J. Mech. Eng. 2013, 11, 169–175. [Google Scholar] [CrossRef]

- Karvountzis-Kontakiotis, A.; Andwari, A.M.; Pesyridis, A.; Russo, S.; Tuccillo, R.; Esfahanian, V. Application of Micro Gas Turbine in Range-Extended Electric Vehicles. Energy 2018, 147, 351–361. [Google Scholar] [CrossRef]

- Bou Nader, W.S.; Mansour, C.J.; Nemer, M.G. Optimization of a Brayton external combustion gas-turbine system for extended range electric vehicles. Energy 2018, 150, 745–758. [Google Scholar] [CrossRef]

- Reine, A.; Bou Nader, W. Fuel consumption potential of different external combustion gas-turbine thermodynamic configurations for extended range electric vehicles. Energy 2019, 175, 900–913. [Google Scholar] [CrossRef]

- Sahoo, D.; Kotrba, A.; Steiner, T.; Swift, G. Waste Heat Recovery for Light-Duty Truck Application Using ThermoAcoustic Converter Technology. SAE Int. J. Engines 2017, 10, 0153. [Google Scholar] [CrossRef]

- Nader, W.B.; Chamoun, J.; Dumand, C. Optimization of the thermodynamic configurations of a thermoacoustic engine auxiliary power unit for range extended hybrid electric vehicles. Energy 2020, 195. [Google Scholar] [CrossRef]

- Bou Nader, W.; Chamoun, J.; Dumand, C. Thermoacoustic engine as waste heat recovery system on extended range hybrid electric vehicles. Energy Convers. Manag. 2020, 215, 112912. [Google Scholar] [CrossRef]

- Arani, A.K.; Karami, H.; Gharehpetian, G.; Hejazi, M. Review of Flywheel Energy Storage Systems structures and applications in power systems and microgrids. Renew. Sustain. Energy Rev. 2017, 69, 9–18. [Google Scholar] [CrossRef]

- Itani, K.; De Bernardinis, A.; Khatir, Z.; Jammal, A. Comparative analysis of two hybrid energy storage systems used in a two front wheel driven electric vehicle during extreme start-up and regenerative braking operations. Energy Convers. Manag. 2017, 144, 69–87. [Google Scholar] [CrossRef]

- ElNozahy, M.; Salama, M. Studying the feasibility of charging plug-in hybrid electric vehicles using photovoltaic electricity in residential distribution systems. Electr. Power Syst. Res. 2014, 110, 133–143. [Google Scholar] [CrossRef]

- Keshri, R.; Bertoluzzo, M.; Buja, G. Integration of a Photovoltaic Panel with an Electric City Car. Electr. Power Compon. Syst. 2014, 42, 481–495. [Google Scholar] [CrossRef]

- Ezzat, M.; Dincer, I. Development, analysis and assessment of a fuel cell and solar photovoltaic system powered vehicle. Energy Convers. Manag. 2016, 129, 284–292. [Google Scholar] [CrossRef]

- Zahir Hussain, M.; Anbalagan, R.; Jayabalakrishnan, D.; Naga Muruga, D.; Prabhahar, M.; Bhaskar, K.; Sendilvelan, S. Charging of car battery in electric vehicle by using wind energy. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- King, P. The Development of the Szorenyi Four-Chamber Rotary Engine. In Proceedings of the SAE International Powertrains, Fuels and Lubricants Meeting, Heidelberg, Germany, 17–19 September 2018. [Google Scholar] [CrossRef]

- Zambalov, S.D.; Yakovlev, I.A.; Maznoy, A.S. Effect of multiple fuel injection strategies on mixture formation and combustion in a hydrogen-fueled rotary range extender for battery electric vehicles. Energy Convers. Manag. 2020, 220, 113097. [Google Scholar] [CrossRef]

- Ferdous, S.; Bin Khaled, W.; Ahmed, B.; Salehin, S.; Ghani Ovy, E. Electric Vehicle with Charging Facility in Motion using Wind Energy. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; Volume 57, pp. 3629–3636. [Google Scholar] [CrossRef]

- Goushcha, O.; Felicissimo, R.; Danesh-Yazdi, A.H.; Andreopoulos, Y. Exploring harnessing wind power in moving reference frames with application to vehicles. Adv. Mech. Eng. 2019, 11, 168781401986568. [Google Scholar] [CrossRef]

- Hossain, M.F.; Fara, N. Integration of wind into running vehicles to meet its total energy demand. Energy Ecol. Environ. 2017, 2, 35–48. [Google Scholar] [CrossRef][Green Version]

- General Motors. 2019 Chevrolet Volt Brochure. Available online: https://www.chevrolet.ca/content/dam/chevrolet/na/canada/english/index/download-a-brochure/02-pdfs/my19-cdn-volt-brochure-en.pdf (accessed on 1 December 2020).

- BMW. BMW i3s REX Sport 2020. Available online: https://www.guideautoweb.com/en/makes/bmw/i3/2020/specifications/s-rex/ (accessed on 1 December 2020).

- BMW i3 (94 Ah) REX Dynamic Eléctrico 2017. Available online: https://www.bmw.com.mx/content/dam/bmw/marketMX/bmw_com_mx/Descargas/Fichas-Tecnicas-2018/i3/FichaTécnicaBMWi3(94Ah)REXDynamic2017.pdf (accessed on 1 December 2020).

- Leach, F.; Kalghatgi, G.; Stone, R.; Miles, P. The scope for improving the efficiency and environmental impact of internal combustion engines. Transp. Eng. 2020, 1, 100005. [Google Scholar] [CrossRef]

- Menzel, G.; Hennings Och, S.; Cocco Mariani, V.; Mauro Moura, L.; Domingues, E. Multi-objective optimization of the volumetric and thermal efficiencies applied to a multi-cylinder internal combustion engine. Energy Convers. Manag. 2020, 216, 112930. [Google Scholar] [CrossRef]

- Ouyang, T.; Zhao, Z.; Wang, Z.; Zhang, M.; Liu, B. A high-efficiency scheme for waste heat harvesting of solid oxide fuel cell integrated homogeneous charge compression ignition engine. Energy 2021, 229, 120720. [Google Scholar] [CrossRef]

- Hahn, S.; Braun, J.; Kemmer, H.; Reuss, H.C. Optimization of the efficiency and degradation rate of an automotive fuel cell system. Int. J. Hydrogen Energy 2021. [Google Scholar] [CrossRef]

- Hoeflinger, J.; Hofmann, P. Air mass flow and pressure optimisation of a PEM fuel cell range extender system. Int. J. Hydrogen Energy 2020, 45, 29246–29258. [Google Scholar] [CrossRef]

- Toyota. Second Generation Toyota Mirai. Still Zero Emissions. Available online: https://www.toyota-europe.com/world-of-toyota/articles-news-events/2019/new-mirai-concept (accessed on 1 December 2020).

- Hyundai NEXO de pila de combustible|Hyundai|Hyundai Motor España. Available online: https://www.hyundai.com/es/modelos/nexo.html (accessed on 1 December 2020).

- Nikola Two. Available online: https://nikolamotor.com/two (accessed on 1 December 2020).

- Taner, T. The novel and innovative design with using H2 fuel of PEM fuel cell: Efficiency of thermodynamic analyze. Fuel 2021, 302, 121109. [Google Scholar] [CrossRef]

- Ji, C.; Wang, H.; Shi, C.; Wang, S.; Yang, J. Multi-objective optimization of operating parameters for a gasoline Wankel rotary engine by hydrogen enrichment. Energy Convers. Manag. 2021, 229, 113732. [Google Scholar] [CrossRef]

- Sadiq, G.A.; Al-Dadah, R.; Mahmoud, S. Development of rotary Wankel devices for hybrid automotive applications. Energy Convers. Manag. 2019, 202, 112159. [Google Scholar] [CrossRef]

- Mazda 2 RE Range-Extender: Return of the Rotary-News-Car and Driver. Available online: https://www.caranddriver.com/news/a15366035/mazda-2-re-range-extender-return-of-the-rotary/ (accessed on 1 November 2020).

- Martins, J.J.; Uzuneanu, K.; Ribeiro, B.S.; Jasasky, O. Thermodynamic Analysis of an Over-Expanded Engine. SAE Tech. Pap. 2004, 113, 476–490. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, Y.; Zhang, Z.; Wang, S.; Wang, S. Optimization and matching for range-extenders of electric vehicles with artificial neural network and genetic algorithm. Energy Convers. Manag. 2019, 184, 709–725. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Lv, C.; Yuan, Y. New regenerative braking control strategy for rear-driven electrified minivans. Energy Convers. Manag. 2014, 82, 135–145. [Google Scholar] [CrossRef]

- Yang, Y.; He, Q.; Chen, Y.; Fu, C. Efficiency Optimization and Control Strategy of Regenerative Braking System with Dual Motor. Energies 2020, 13, 711. [Google Scholar] [CrossRef]

- Duan, J.; Fan, S.; An, Q.; Sun, L.; Wang, G. A comparison of micro gas turbine operation modes for optimal efficiency based on a nonlinear model. Energy 2017, 134, 400–411. [Google Scholar] [CrossRef]

- Nicolosi, F.F.; Renzi, M. Effect of the Regenerator Efficiency on the Performance of a Micro Gas Turbine Fed with Alternative Fuels. Energy Procedia 2018, 148, 687–694. [Google Scholar] [CrossRef]

- Ezzat, M.F.; Dincer, I. Development and exergetic assessment of a new hybrid vehicle incorporating gas turbine as powering option. Energy 2019, 170, 112–119. [Google Scholar] [CrossRef]

- Ji, F.; Zhang, X.; Du, F.; Ding, S.; Zhao, Y.; Xu, Z.; Wang, Y.; Zhou, Y. Experimental and numerical investigation on micro gas turbine as a range extender for electric vehicle. Appl. Therm. Eng. 2020, 173, 115236. [Google Scholar] [CrossRef]

- Barakat, A.A.; Diab, J.H.; Badawi, N.S.; Bou Nader, W.S.; Mansour, C.J. Combined cycle gas turbine system optimization for extended range electric vehicles. Energy Convers. Manag. 2020, 226, 113538. [Google Scholar] [CrossRef]

- Fathabadi, H. Utilizing solar and wind energy in plug-in hybrid electric vehicles. Energy Convers. Manag. 2018, 156, 317–328. [Google Scholar] [CrossRef]

- Fathabadi, H. Recovering waste vibration energy of an automobile using shock absorbers included magnet moving-coil mechanism and adding to overall efficiency using wind turbine. Energy 2019, 189, 116274. [Google Scholar] [CrossRef]

- de Dios Javier Roldán, I.C.M. Meet Eolo, A Wind-Powered EV From Colombia. Available online: https://www.iamrenew.com/green-transportation/meet-eolo-wind-powered-ev-colombia/#:~:text=The%20Eolo%2C%20Colombia’s%20only%20homegrown,it%20is%20powered%20by%20wind (accessed on 1 January 2021).

- Boyes, J.D.; Clark, N.H. Technologies for energy storage flywheels and super conducting magnetic energy storage. In Proceedings of the 2000 Power Engineering Society Summer Meeting (Cat. No. 00CH37134), Seattle, WA, USA, 16–20 July 2000; Volume 3, pp. 1548–1550. [Google Scholar] [CrossRef]

- Li, J.; Zhao, J. Energy recovery for hybrid hydraulic excavators: Flywheel-based solutions. Autom. Constr. 2021, 125, 103648. [Google Scholar] [CrossRef]

- Erdemir, D.; Dincer, I. Assessment of Renewable Energy-Driven and Flywheel Integrated Fast-Charging Station for Electric Buses: A Case Study. J. Energy Storage 2020, 30, 101576. [Google Scholar] [CrossRef]

- Wang, W.; Li, Y.; Shi, M.; Song, Y. Optimization and control of battery-flywheel compound energy storage system during an electric vehicle braking. Energy 2021, 226, 120404. [Google Scholar] [CrossRef]

- Vazquez, S.; Lukic, S.M.; Galvan, E.; Franquelo, L.G.; Carrasco, J.M. Energy storage systems for transport and grid applications. IEEE Trans. Ind. Electron. 2010, 57, 3881–3895. [Google Scholar] [CrossRef]

- Puddu, P.; Paderi, M. Hydro-pneumatic accumulators for vehicles kinetic energy storage: Influence of gas compressibility and thermal losses on storage capability. Energy 2013, 57, 326–335. [Google Scholar] [CrossRef]

- Chen, B.; Yousif, A.A.; Riley, P.H.; Hann, D.B. Development and Assessment of Thermoacoustic Generators Operating by Waste Heat from Cooking Stove. Engineering 2012, 04, 894–902. [Google Scholar] [CrossRef]

- Backhaus, S.; Swift, G.W. A thermoacoustic-Stirling heat engine: Detailed study. J. Acoust. Soc. Am. 2000, 107, 3148–3166. [Google Scholar] [CrossRef]

- Mumith, J.A.; Makatsoris, C.; Karayiannis, T.G. Design of a thermoacoustic heat engine for low temperature waste heat recovery in food manufacturing: A thermoacoustic device for heat recovery. Appl. Therm. Eng. 2014, 65, 588–596. [Google Scholar] [CrossRef]

- Blanc-benon, P.; Jondeau, E.; Comte-Bellot, G. Analysis of the acoustic field in a thermoacoustic system using time-resolved particle image velocimetry and constant-voltage anemometry. In Proceedings of the 3rd International Workshop on Thermoacoustics, Enschede, The Netherlands, 26–27 October 2015. [Google Scholar]

- Khoshnoud, F.; Zhang, Y.; Shimura, R.; Shahba, A.; Jin, G.; Pissanidis, G.; Chen, Y.K.; De Silva, C.W. Energy Regeneration from Suspension Dynamic Modes and Self-Powered Actuation. IEEE/ASME Trans. Mechatron. 2015, 20, 2513–2524. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Luhrs, G.; Lin, L.; Qin, Y.X. Electromagnetic energy-harvesting shock absorbers: Design, modeling, and road tests. IEEE Trans. Veh. Technol. 2013, 62, 1065–1074. [Google Scholar] [CrossRef]

- Maravandi, A.; Moallem, M. Regenerative shock absorber using a two-leg motion conversion mechanism. IEEE/ASME Trans. Mechatron. 2015, 20, 2853–2861. [Google Scholar] [CrossRef]

- Electric Vehicle Range Extender Market Forecast Report, 2018–2025. Available online: https://www.marketsandmarkets.com/Market-Reports/electric-vehicle-range-extender-market-208131566.html (accessed on 1 July 2021).

- Electric Vehicle (EV) Range Extender Market Statistics, Trends, Demand, Size by 2026. Available online: https://www.alliedmarketresearch.com/electric-vehicle-range-extender-market-A06026 (accessed on 1 July 2021).

- Electric Vehicle Range Extender Market to Witness 10.2% CAGR By 2025 Owing to Rising Usage of Commercial & Fully Electric Passenger Vehicles to Lower CO2 Emissions|Million Insights. Available online: https://www.prnewswire.com/news-releases/electric-vehicle-range-extender-market-to-witness-10-2-cagr-by-2025-owing-to-rising-usage-of-commercial--fully-electricpassenger-vehicles-to-lower-co2-emissions--million-insights-301220939.html (accessed on 1 July 2021).

- 2021 Honda Clarity Plug-In Hybrid—The Versatile Hybrid|Honda. Available online: https://automobiles.honda.com/clarity-plug-in-hybrid (accessed on 1 July 2021).

- Mack Trucks to Evaluate Wrightspeed Route Powertrain in Mack LR Model|Mack Trucks. Available online: https://www.macktrucks.com/mack-news/2016/mack-trucks-to-evaluate-wrightspeed-route-powertrain-in-mack-lr-model/ (accessed on 1 July 2021).

- Rover, L. Quarterly Light-Vehicle—Q1 2021. 2021. Available online: https://www.coxautoinc.com/wp-content/uploads/2021/04/Q1.Kelley-Blue-Book-Electrfication-Deck-2021.revised-4.26.pdf (accessed on 1 July 2021).

- Sales, Q.; Ev, B. Electrified-Vehicle 2021. pp. 1–5. Available online: https://www.coxautoinc.com/wp-content/uploads/2021/01/Kelley-Blue-Book-Salesand-Data-Report-for-2020-Q4.pdf (accessed on 1 July 2021).

- Masclans Abelló, P.; Medina Iglesias, V.; de los Santos López, M.A.; Álvarez-Flórez, J. Real drive cycles analysis by ordered power methodology applied to fuel consumption, CO2, NOx and PM emissions estimation. Front. Environ. Sci. Eng. 2021, 15, 4. [Google Scholar] [CrossRef]

- Lee, D.; Park, G.; Son, B.; Jung, H. Efficiency improvement of IPMSG in the electric power generating system of a range-extended electric vehicle. IET Electr. Power Appl. 2019, 13, 943–950. [Google Scholar] [CrossRef]

- Han, K.; Nguyen, T.W.; Nam, K. Battery energy management of autonomous electric vehicles using computationally inexpensive model predictive control. Electronics 2020, 9, 1277. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, X.; Tang, X.; Lin, X. Model predictive control of hybrid electric vehicles for fuel economy, emission reductions, and inter-vehicle safety in car-following scenarios. Energy 2020, 196, 117101. [Google Scholar] [CrossRef]

- Fathy, H.; Reyer, J.; Papalambros, P.; Ulsov, A. On the coupling between the plant and controller optimization problems. In Proceedings of the 2001 American Control Conference. (Cat. No.01CH37148), Arlington, VA, USA, 25–27 June 2001; Volume 3, pp. 1864–1869. [Google Scholar] [CrossRef]

- Silvas, E.; Hofman, T.; Murgovski, N.; Etman, P.; Steinbuch, M. Review of Optimization Strategies for System-Level Design in Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2016, 66. [Google Scholar] [CrossRef]

- Allison, J.T.; Herber, D.R. Special Section on Multidisciplinary Design Optimization: Multidisciplinary Design Optimization of Dynamic Engineering Systems. AIAA J. 2014, 52, 691–710. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puma-Benavides, D.S.; Izquierdo-Reyes, J.; Calderon-Najera, J.d.D.; Ramirez-Mendoza, R.A. A Systematic Review of Technologies, Control Methods, and Optimization for Extended-Range Electric Vehicles. Appl. Sci. 2021, 11, 7095. https://doi.org/10.3390/app11157095

Puma-Benavides DS, Izquierdo-Reyes J, Calderon-Najera JdD, Ramirez-Mendoza RA. A Systematic Review of Technologies, Control Methods, and Optimization for Extended-Range Electric Vehicles. Applied Sciences. 2021; 11(15):7095. https://doi.org/10.3390/app11157095

Chicago/Turabian StylePuma-Benavides, David Sebastian, Javier Izquierdo-Reyes, Juan de Dios Calderon-Najera, and Ricardo A. Ramirez-Mendoza. 2021. "A Systematic Review of Technologies, Control Methods, and Optimization for Extended-Range Electric Vehicles" Applied Sciences 11, no. 15: 7095. https://doi.org/10.3390/app11157095

APA StylePuma-Benavides, D. S., Izquierdo-Reyes, J., Calderon-Najera, J. d. D., & Ramirez-Mendoza, R. A. (2021). A Systematic Review of Technologies, Control Methods, and Optimization for Extended-Range Electric Vehicles. Applied Sciences, 11(15), 7095. https://doi.org/10.3390/app11157095