Analytical Investigation on Torque of Three-Degree-of-Freedom Electromagnetic Actuator for Image Stabilization

Abstract

:Featured Application

Abstract

1. Introduction

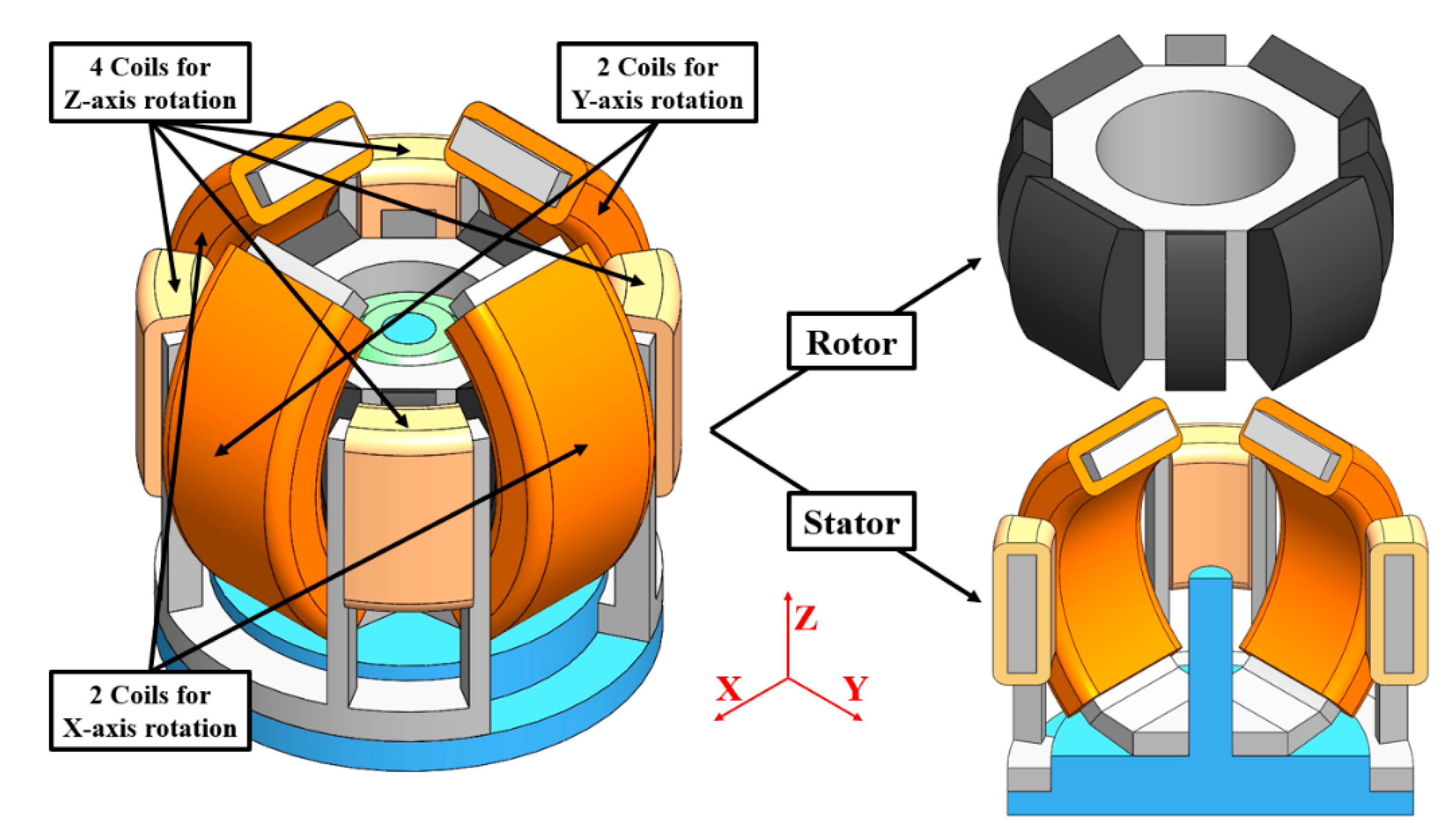

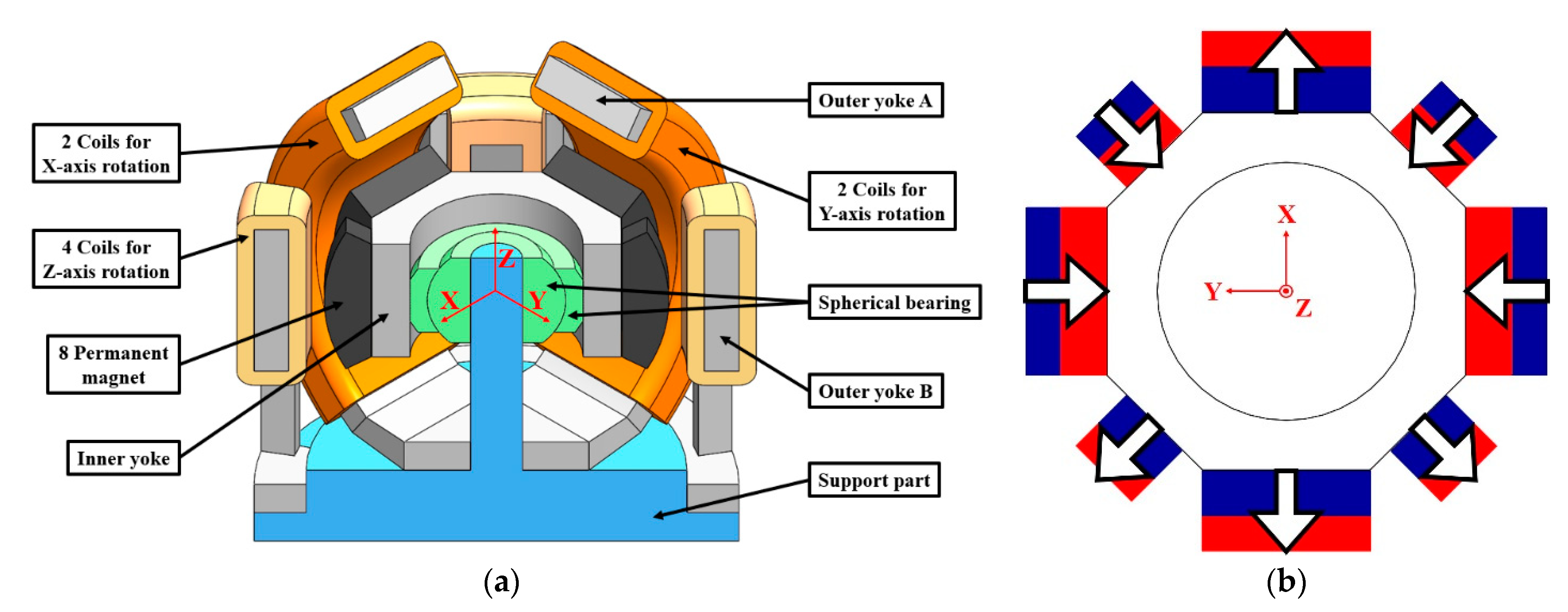

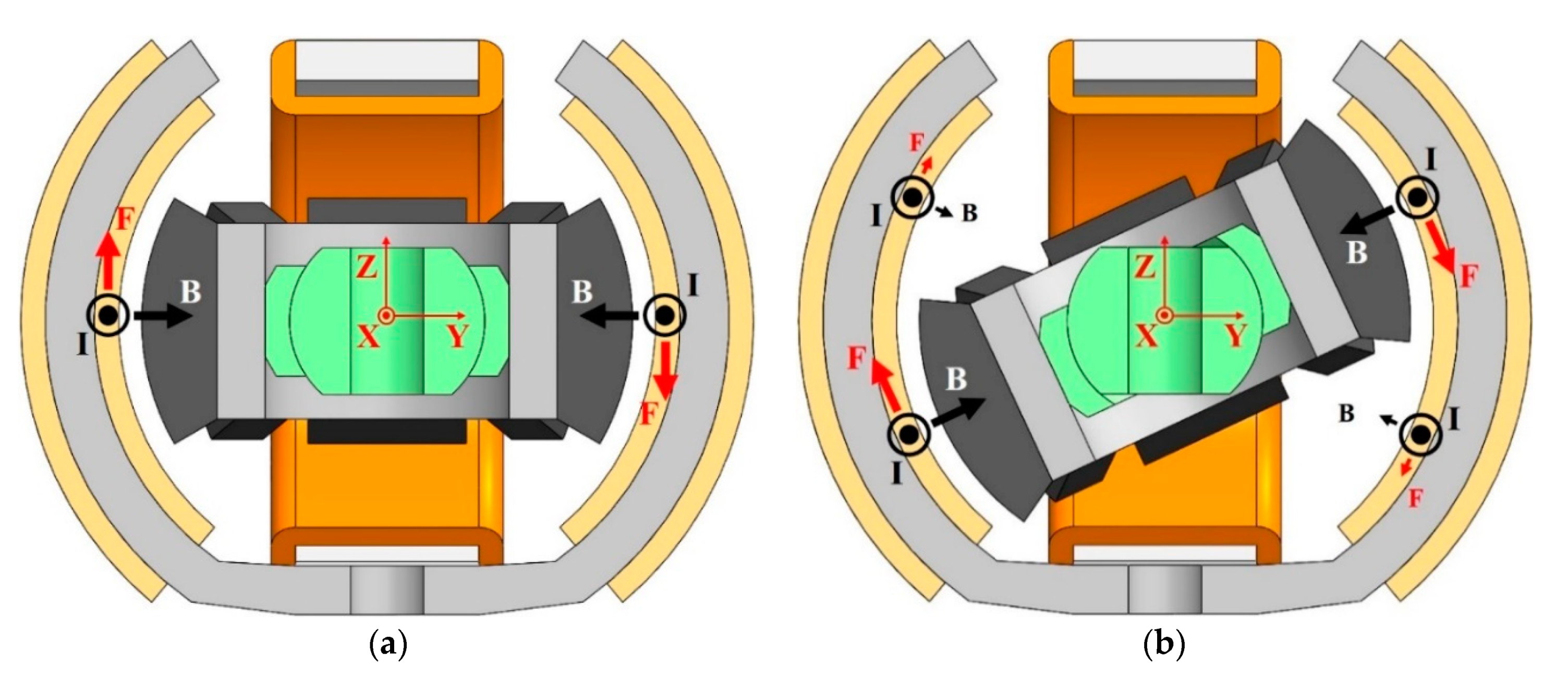

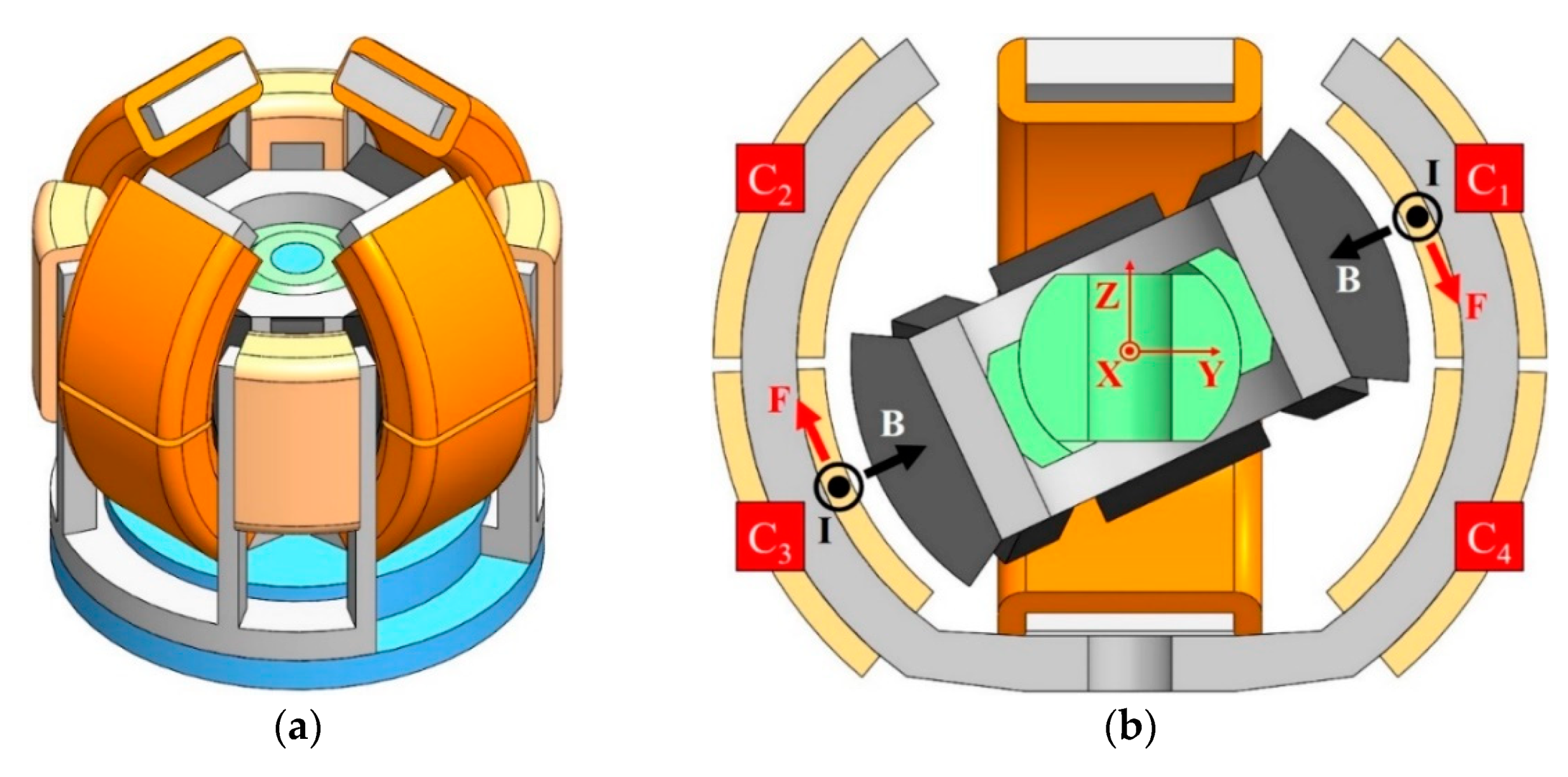

2. Design of Original 3-DOF Spherical Motor

3. Design of Proposed 3-DOF Spherical Motor

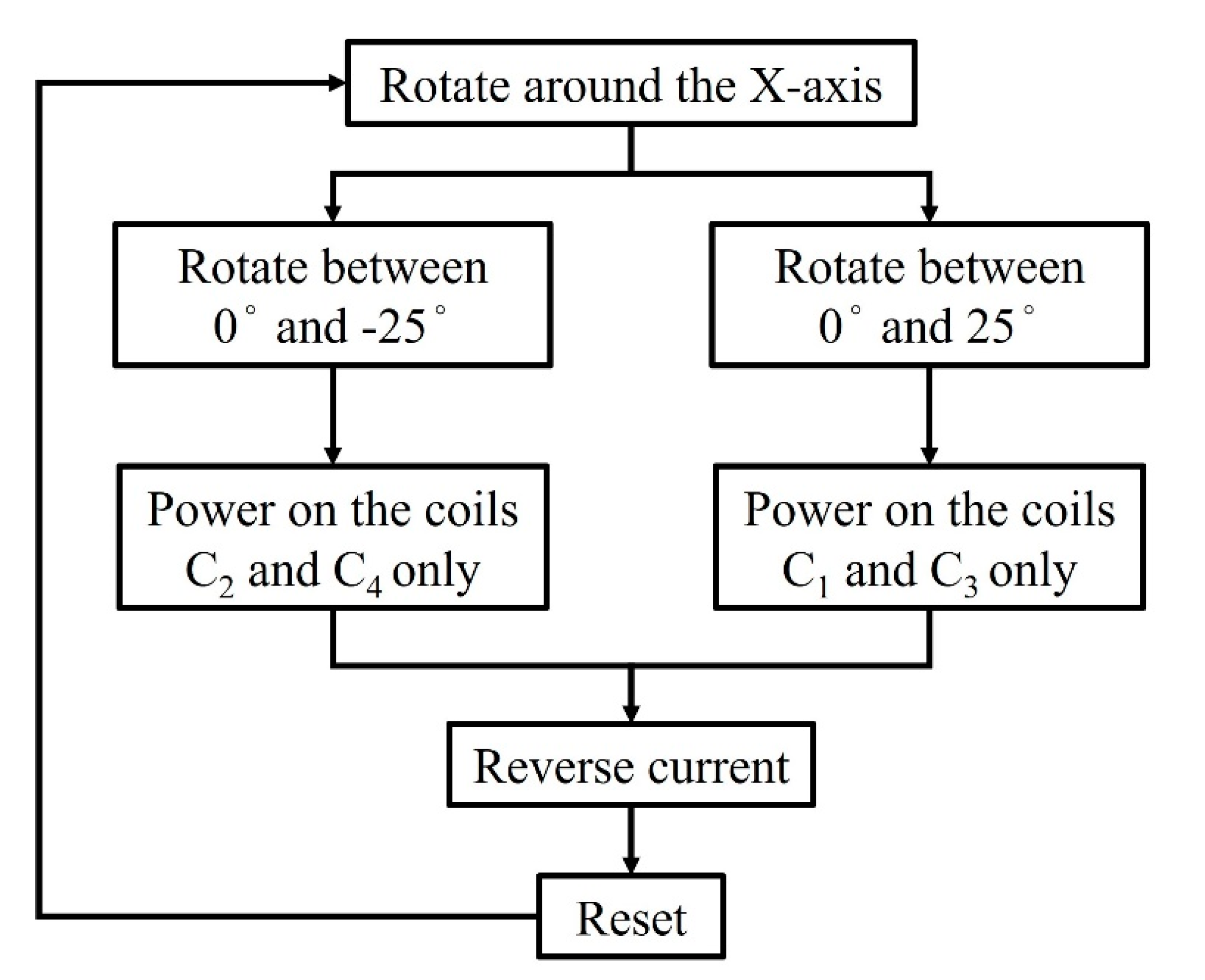

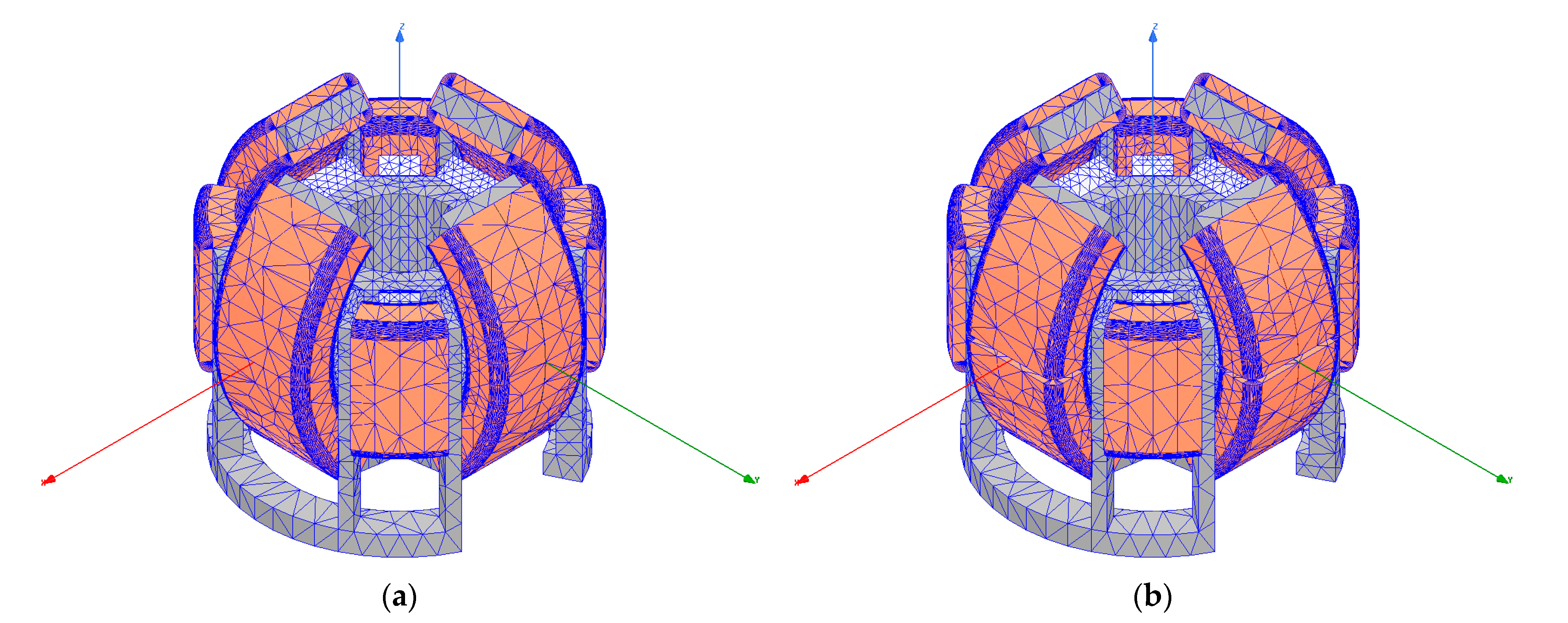

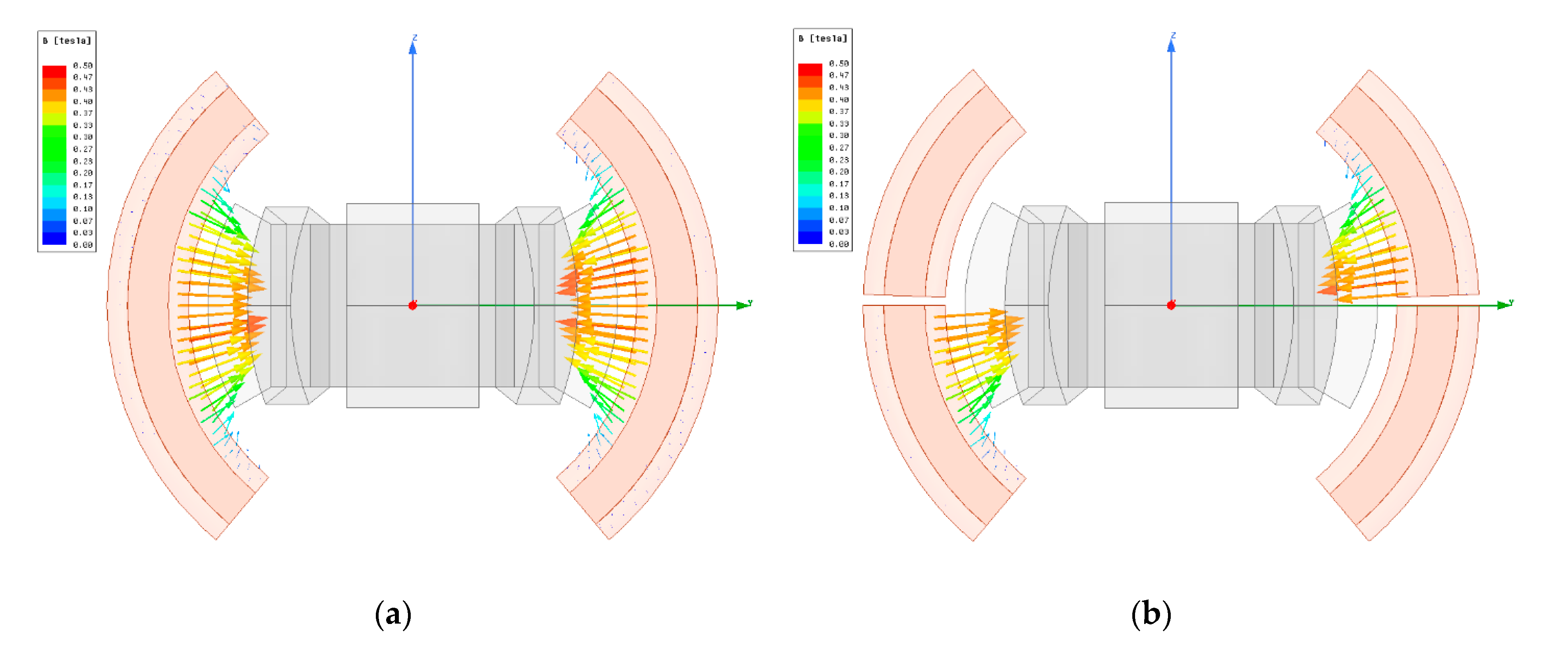

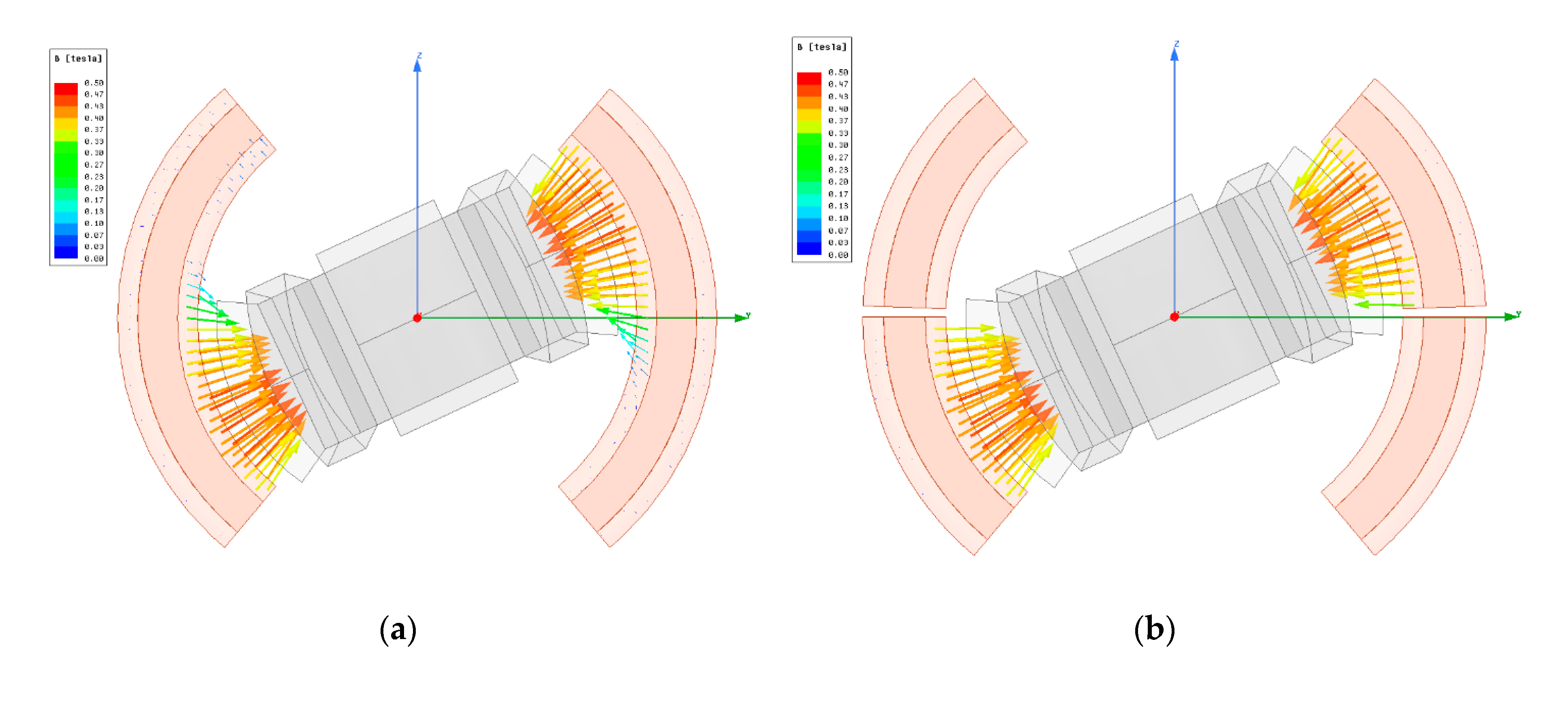

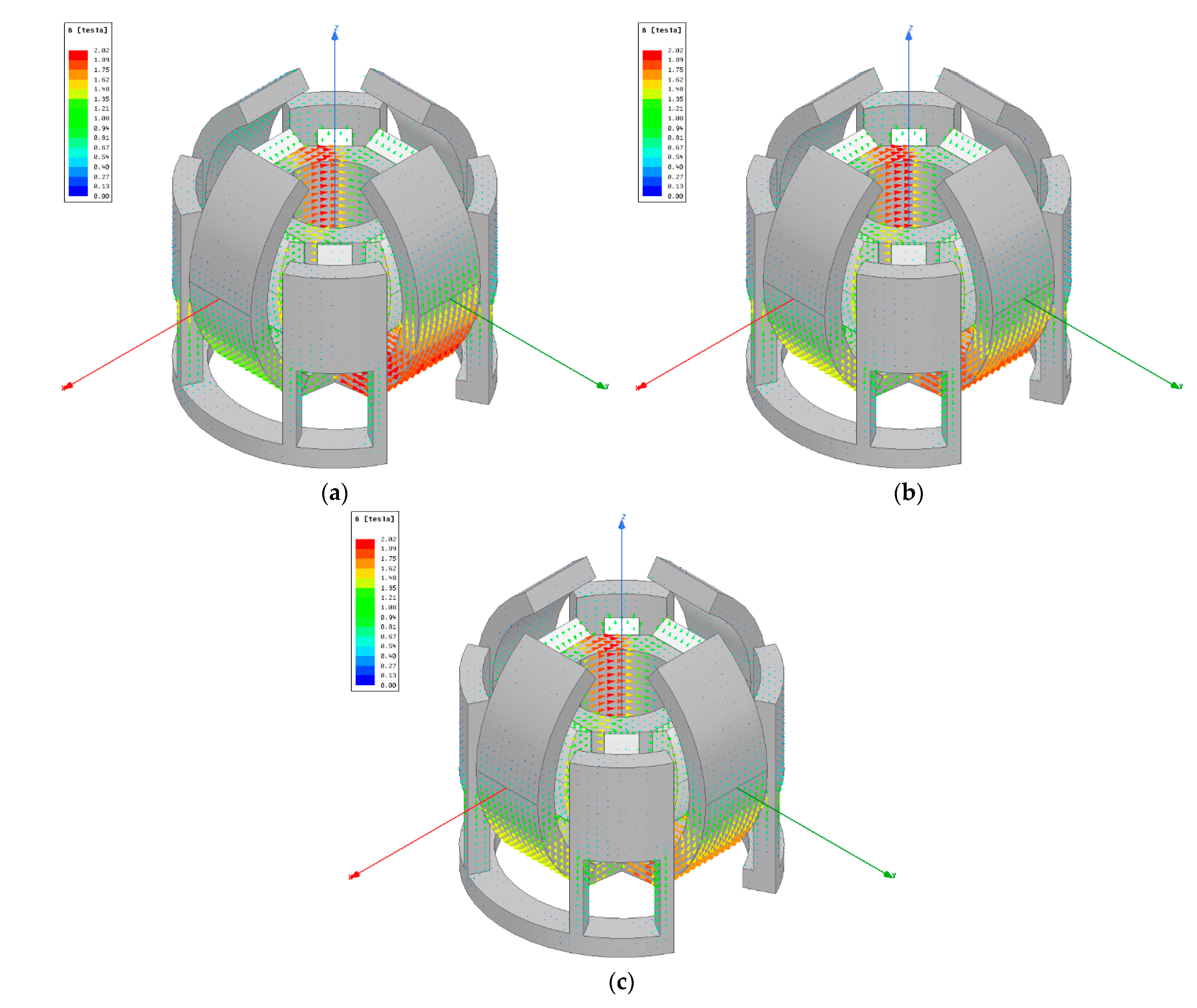

4. 3D FEM Simulation

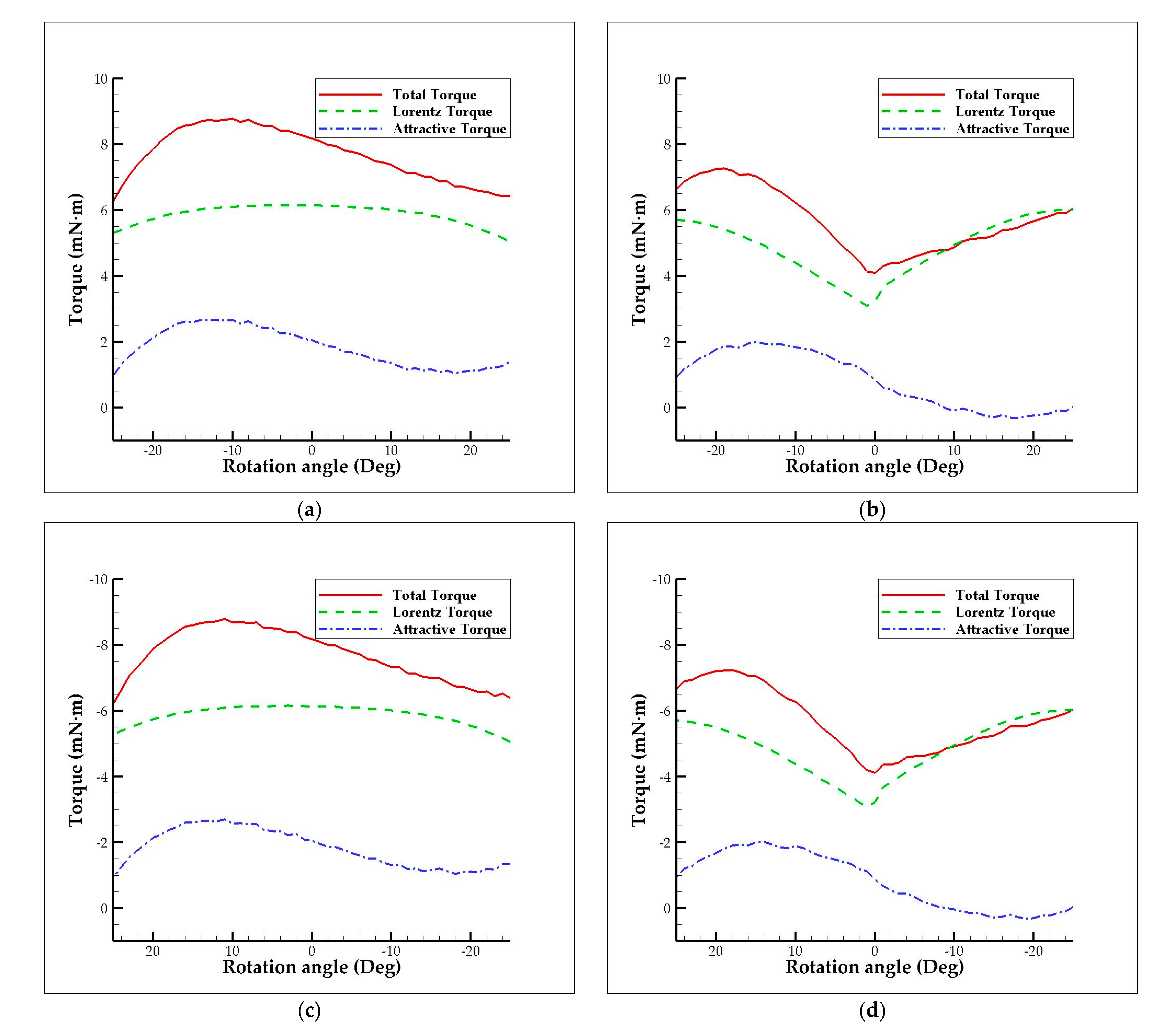

5. Numerical Results of 3D FEM and Discussion

6. Conclusions

7. Patents

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, J.; Wang, Q.; Li, G.; Zhou, R.; Wen, Y.; Ju, L.; Zhou, S. Sensorless Posture Detection of Reluctance Spherical Motor Based on Mutual Inductance Voltage. Appl. Sci. 2021, 11, 3515. [Google Scholar] [CrossRef]

- Cho, S.; Lim, J.; Oh, Y.J.; Jeong, G.; Kang, D.; Lee, J. A Study on Output Characteristics of the Spherical Multi-DOF Motor According to the Number of Phases and Pole Pitch Angles. IEEE Trans. Magn. 2018, 54, 8205005. [Google Scholar] [CrossRef]

- Hong, M.B.; Jo, Y.-H. Design of a novel 4-DOF wrist-type surgical instrument with enhanced rigidity and dexterity. IEEE/ASME Trans. Mechatron. 2014, 19, 500–511. [Google Scholar] [CrossRef]

- Palpacelli, M.C.; Carbonari, L.; Palmieri, G.; Callegari, M. Analysis and design of a reconfigurable 3-DoF parallel manipulator for multimodal tasks. IEEE/ASME Trans. Mechatron. 2015, 20, 1975–1985. [Google Scholar] [CrossRef]

- Jūrėnas, V.; Kazokaitis, G.; Mažeika, D. Design of Unimorph Type 3DOF Ultrasonic Motor. Appl. Sci. 2020, 10, 5605. [Google Scholar] [CrossRef]

- Jūrėnas, V.; Kazokaitis, G.; Mažeika, D. 3DOF Ultrasonic Motor with Two Piezoelectric Rings. Sensors 2020, 20, 834. [Google Scholar] [CrossRef] [Green Version]

- Dehez, B.; Galary, G.; Grenier, D.; Raucent, B. Development of a spherical induction motor with two degrees of freedom. IEEE Trans. Magn. 2006, 42, 2077–2089. [Google Scholar] [CrossRef]

- Song, M.G.; Hur, Y.J.; Park, N.C.; Park, K.S.; Park, Y.P.; Lim, S.C.; Park, J.H. Design of a voice-coil actuator for optical image stabilization based on genetic algorithm. IEEE Trans. Magn. 2009, 45, 4558–4561. [Google Scholar] [CrossRef]

- Song, M.G.; Baek, H.W.; Park, N.C.; Park, K.S.; Yoon, T.; Park, Y.P.; Lim, S.C. Development of small sized actuator with compliant mechanism for optical image stabilization. IEEE Trans. Magn. 2010, 46, 2369–2372. [Google Scholar] [CrossRef]

- Sakaidani, Y.; Hirata, K.; Maeda, S.; Niguchi, N. Feedback control of the 2-DOF actuator specialized for 2-axes rotation. IEEE Trans. Magn. 2013, 49, 2245–2248. [Google Scholar] [CrossRef]

- Hsieh, C.L.; Wang, H.Y.; Chang, Y.H.; Liu, C.S. Design of VCM actuator with the chamfered edge magnet for cellphone. Microsyst. Technol. 2017, 23, 5293–5302. [Google Scholar] [CrossRef]

- Hsieh, C.L.; Chang, Y.H.; Chen, Y.T.; Liu, C.S. Design of VCM actuator with L-shape coil for smartphone cameras. Microsyst. Technol. 2018, 24, 1033–1040. [Google Scholar] [CrossRef]

- Kwon, T.H.; Ro, J.S. Analysis and Optimal Design of a Novel Actuator System for a Camera Module. IEEE Access 2020, 9, 3441–3450. [Google Scholar] [CrossRef]

- Li, Z.; Lun, Q.; Xing, D.; Gao, P. Analysis and implementation of a 3-DOF deflection-type PM motor. IEEE Trans. Magn. 2015, 51, 8207304. [Google Scholar] [CrossRef]

- Chang, Y.H.; Lu, C.J.; Liu, C.S.; Liu, D.S.; Chen, S.H.; Liao, T.W.; Peng, W.Y.; Lin, C.H. Design of miniaturized optical image stabilization and autofocusing camera module for cellphones. Sens. Mater. 2017, 29, 989–995. [Google Scholar]

- Heya, A.; Hirata, K.; Matsushita, T.; Kono, Y. Design and Analysis of a Three-Degree-of-Freedom Linear Oscillatory Actuator. IEEE Trans. Magn. 2020, 56, 6701404. [Google Scholar] [CrossRef]

- Chang, Y.H.; Hao, G.; Liu, C.S. Design and characterisation of a compact 4-degree-of-freedom fast steering mirror system based on double Porro prisms for laser beam stabilization. Sens. Actuators A Phys. 2021, 322, 112639. [Google Scholar] [CrossRef]

- Hsieh, C.L.; Liu, C.S.; Cheng, C.C. Design of a 5 degree of freedom–voice coil motor actuator for smartphone camera modules. Sens. Actuators A Phys. 2020, 309, 112014. [Google Scholar] [CrossRef]

- Son, H.; Lee, K.M. Open-loop controller Design and Dynamic Characteristics of A Spherical Wheel motor. IEEE Trans. Ind. Electron. 2010, 57, 3475–3482. [Google Scholar] [CrossRef]

- Wang, J.; Jewell, G.W.; Howe, D. A Novel Spherical Actuator: Design and Control. IEEE Trans. Magn. 1997, 33, 4209–4211. [Google Scholar] [CrossRef]

- Wang, J.; Jewell, G.W.; Howe, D. Analysis, Design and Control of A Novel Spherical Permanent-magnet Actuator. IEEE Proc. Electr. Power Appl. 1998, 145, 61–71. [Google Scholar] [CrossRef]

- Fusayasu, H.; Masuyama, Y.; Hirata, K.; Niguchi, N.; Takahara, K. Analysis Accuracy in Positioning Calculation for Three-Degree-of-Freedom Spherical Actuator. IEEE Trans. Magn. 2021, 57, 8204104. [Google Scholar] [CrossRef]

- Yang, L.; Chen, I.-M.; Yang, G.; Lee, K.-M. Analytical and experimental investigation on the magnetic field and torque of a permanent magnet spherical actuator. IEEE Trans. Mechatron. 2006, 11, 409–419. [Google Scholar] [CrossRef]

- Heya, A.; Hirata, K.; Ezaki, S.; Ota, T. Dynamic Analysis of a new three-degree-of-freedom actuator for image stabilization. IEEE Trans. Magn. 2017, 53, 2706942. [Google Scholar] [CrossRef]

- Heya, A.; Hirata, K.; Niguchi, N. Dynamic modeling and control of three-degree-of-freedom electromagnetic actuator for image stabilization. IEEE Trans. Magn. 2018, 54, 8207905. [Google Scholar] [CrossRef]

- Heya, A.; Hirata, K. Experimental verification of three-degree-of-freedom electromagnetic actuator for image stabilization. Sensors 2020, 20, 2485. [Google Scholar] [CrossRef]

- Lin, Y.H.; Liu, C.S.; Yeh, C.N. Design and Simulation of Novel 3-DOF Spherical Voice Coil Motor. Actuators 2021, 10, 155. [Google Scholar] [CrossRef]

| Type | Voice Coil Motor Type | Stepping Motor Type | Induction Motor Type | Synchronous Motor Type | Reluctance Motor Type |

|---|---|---|---|---|---|

| Control | Simple | Complex | Complex | Complex | Medium |

| Structure | Simple | Complex | Complex | Complex | Simple |

| Response | High | Medium | Medium | Medium | Low |

| Positioning accuracy | High | Low | Low | High | Low |

| Force/Torque | Low | Medium | High | Medium | High |

| Cogging effect | No | Yes | No | Yes | No |

| Symbol | Corresponding Parameter | Value |

|---|---|---|

| DO1, DO2 | Outermost diameter | 28.0 (mm) |

| tO1, tO2 | Outer yoke thickness | 2.0 (mm) |

| tg1 | Air gap length | 2.0 (mm) |

| tg2 | 2.1 (mm) | |

| tm1 | Permanent magnet thickness | 3.1 (mm) |

| tm2 | 2.7 (mm) | |

| ti | Inner yoke thickness | 8.0 (mm) |

| θm1, θm2 | Permanent magnet angle | 60.0 (deg) |

| θO1, θO2 | Outer yoke angle | 70.0 (deg) |

| wO1 | Outer yoke width | 7.5 (mm) |

| wO2 | 10.0 (mm) | |

| wm1 | Permanent magnet width | 6.5 (mm) |

| wm2 | 3.0 (mm) | |

| wi1 | Inner yoke width | 13.9 (mm) |

| wi2 | 14.4 (mm) |

| Rotation Angle (Deg) | Total Torque Output (mN·m) | Lorentz Torque Output (mN·m) | Attractive Torque Output (mN·m) | Ratio of Lorentz and Attractive Torque Output |

|---|---|---|---|---|

| Rotate from −25° to +25° in a counter-clockwise direction | ||||

| −25 | 6.29 | 5.31 | 0.99 | 5.38 |

| −20 | 7.86 | 5.73 | 2.13 | 2.69 |

| −15 | 8.60 | 5.99 | 2.61 | 2.30 |

| −10 | 8.78 | 6.10 | 2.67 | 2.28 |

| −5 | 8.56 | 6.15 | 2.41 | 2.56 |

| 0 | 8.18 | 6.14 | 2.04 | 3.01 |

| 5 | 7.78 | 6.09 | 1.69 | 3.60 |

| 10 | 7.38 | 6.02 | 1.36 | 4.45 |

| 15 | 7.02 | 5.84 | 1.18 | 4.94 |

| 20 | 6.65 | 5.54 | 1.12 | 4.95 |

| 25 | 6.43 | 5.02 | 1.41 | 3.56 |

| Rotate from +25° to −25° in a clockwise direction | ||||

| 25 | −6.23 | −5.29 | −0.94 | 5.65 |

| 20 | −7.89 | −5.74 | −2.15 | 2.67 |

| 15 | −8.60 | −6.00 | −2.60 | 2.30 |

| 10 | −8.68 | −6.11 | −2.57 | 2.38 |

| 5 | −8.50 | −6.15 | −2.35 | 2.62 |

| 0 | −8.17 | −6.13 | −2.04 | 3.01 |

| −5 | −7.79 | −6.10 | −1.68 | 3.63 |

| −10 | −7.33 | −6.01 | −1.32 | 4.56 |

| −15 | −7.00 | −5.84 | −1.16 | 5.04 |

| −20 | −6.65 | −5.54 | −1.11 | 4.98 |

| −25 | −6.38 | −5.04 | −1.34 | 3.76 |

| Rotation Angle (Deg) | Total Torque Output (mN·m) | Lorentz Torque Output (mN·m) | Attractive Torque Output (mN·m) | Ratio of Lorentz and Attractive Torque Output |

|---|---|---|---|---|

| Rotate from −25° to +25° in a counter-clockwise direction | ||||

| −25 | 6.64 | 5.72 | 0.93 | 6.18 |

| −20 | 7.26 | 5.49 | 1.77 | 3.11 |

| −15 | 7.03 | 5.03 | 2.00 | 2.52 |

| −10 | 6.22 | 4.39 | 1.84 | 2.38 |

| −5 | 5.13 | 3.69 | 1.45 | 2.55 |

| 0 | 4.09 | 3.23 | 0.86 | 3.77 |

| 5 | 4.58 | 4.27 | 0.31 | 13.66 |

| 10 | 4.87 | 4.95 | −0.08 | −61.36 |

| 15 | 5.24 | 5.52 | −0.29 | −19.33 |

| 20 | 5.66 | 5.90 | −0.24 | −24.94 |

| 25 | 6.07 | 6.02 | 0.05 | 123.17 |

| Rotate from +25° to −25° in a clockwise direction | ||||

| 25 | −6.67 | −5.71 | −0.96 | 5.94 |

| 20 | −7.20 | −5.51 | −1.69 | 3.25 |

| 15 | −7.04 | −5.02 | −2.02 | 2.49 |

| 10 | −6.27 | −4.38 | −1.89 | 2.32 |

| 5 | −5.16 | −3.68 | −1.48 | 2.49 |

| 0 | −4.11 | −3.23 | −0.87 | 3.71 |

| −5 | −4.62 | −4.28 | −0.35 | 12.39 |

| −10 | −4.92 | −4.95 | 0.03 | −162.85 |

| −15 | −5.25 | −5.53 | 0.28 | −20.01 |

| −20 | −5.60 | −5.90 | 0.30 | −19.54 |

| −25 | −6.04 | −6.01 | −0.04 | 170.21 |

| Rotation Angle (Deg) | Total Torque Output of Original Motor (mN·m) | Total Torque Output of Proposed Motor (mN·m) | Total Torque Density of Original Motor (kN·m/m3) | Total Torque Density of Proposed Motor (kN·m/m3) | Improvement Percentage (%) |

|---|---|---|---|---|---|

| Rotate from −25° to +25° in a counter-clockwise direction | |||||

| −25 | 6.29 | 9.01 | 0.55 | 0.78 | 43.13 |

| −20 | 7.86 | 9.72 | 0.68 | 0.85 | 23.56 |

| −15 | 8.60 | 9.38 | 0.75 | 0.82 | 8.99 |

| −10 | 8.78 | 8.34 | 0.76 | 0.73 | −4.95 |

| −5 | 8.56 | 6.98 | 0.74 | 0.61 | −18.49 |

| 0 | 8.18 | 5.76 | 0.71 | 0.50 | −29.64 |

| 5 | 7.78 | 6.69 | 0.68 | 0.58 | −14.06 |

| 10 | 7.38 | 7.28 | 0.64 | 0.63 | −1.34 |

| 15 | 7.02 | 7.88 | 0.61 | 0.69 | 12.22 |

| 20 | 6.65 | 8.44 | 0.58 | 0.73 | 26.87 |

| 25 | 6.43 | 8.86 | 0.56 | 0.77 | 37.68 |

| Rotate from +25° to −25° in a clockwise direction | |||||

| 25 | −6.23 | −9.08 | −0.54 | −0.79 | 45.88 |

| 20 | −7.89 | −9.64 | −0.69 | −0.84 | 22.19 |

| 15 | −8.60 | −9.38 | −0.75 | −0.82 | 9.14 |

| 10 | −8.68 | −8.40 | −0.76 | −0.73 | −3.30 |

| 5 | −8.50 | −6.99 | −0.74 | −0.61 | −17.76 |

| 0 | −8.17 | −5.78 | −0.71 | −0.50 | −29.30 |

| −5 | −7.79 | −6.74 | −0.68 | −0.59 | −13.50 |

| −10 | −7.33 | −7.32 | −0.64 | −0.64 | −0.17 |

| −15 | −7.00 | −7.91 | −0.61 | −0.69 | 12.95 |

| −20 | −6.65 | −8.38 | −0.58 | −0.73 | 25.97 |

| −25 | −6.38 | −8.81 | −0.55 | −0.77 | 38.24 |

| Average (Magnitude) | 7.69 | 7.98 | 0.67 | 0.69 | 5.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.-S.; Lin, Y.-H.; Yeh, C.-N. Analytical Investigation on Torque of Three-Degree-of-Freedom Electromagnetic Actuator for Image Stabilization. Appl. Sci. 2021, 11, 6872. https://doi.org/10.3390/app11156872

Liu C-S, Lin Y-H, Yeh C-N. Analytical Investigation on Torque of Three-Degree-of-Freedom Electromagnetic Actuator for Image Stabilization. Applied Sciences. 2021; 11(15):6872. https://doi.org/10.3390/app11156872

Chicago/Turabian StyleLiu, Chien-Sheng, Yi-Hsuan Lin, and Chiu-Nung Yeh. 2021. "Analytical Investigation on Torque of Three-Degree-of-Freedom Electromagnetic Actuator for Image Stabilization" Applied Sciences 11, no. 15: 6872. https://doi.org/10.3390/app11156872

APA StyleLiu, C.-S., Lin, Y.-H., & Yeh, C.-N. (2021). Analytical Investigation on Torque of Three-Degree-of-Freedom Electromagnetic Actuator for Image Stabilization. Applied Sciences, 11(15), 6872. https://doi.org/10.3390/app11156872