Featured Application

This review provides guidance for the future studies of this new pavement technology, which may be of concern in many fields of road construction, such as heavy-duty pavement, perpetual pavement, reclaimed asphalt pavement, and new airport runway.

Abstract

Grouted Semi-flexible Pavement (GSP) is a novel pavement composed of open-graded asphalt concrete grouted with high-fluidity cement mortar. Due to its excellent load-bearing and anti-rutting performance, it has great potential as anti-rutting overlay and surface in road construction. However, the understanding of GSP performance remains limited and pertinent findings are inconsistent. This article aims to provide a systematic literature review for the articles which were published between 2000 and 2020 on GSP, explore the problems in the recent research, identify knowledge gaps, and deliver recommendations for future research. The influential factors and the relative evaluation methods of GSP performance are summarized and discussed in this article.

1. Introduction

Conventional flexible pavement, namely asphalt concrete (AC) pavement, suffers from many distresses including rutting, moisture damage, and fatigue failure after long-term operation, because of weather wearing and traffic volume growing worldwide [1,2]. With soaring demand of transportation, the costs of highway construction and pavement maintenance have increased dramatically over time. As a solution for these problems, Grouted Semi-flexible Pavement (GSP), as known as Resin-Modified Pavement, is a type of high-performance pavement that was derived in France in the 1950s. GSP consists of an open-graded matrix asphalt (OMA) mattress with a 20–35% void rate, grouted by high-fluidity cement mortar (HCM) [3,4,5,6,7,8]. GSP has great resistance to rutting, top-down cracking, oil corrosion, and fatigue damage, combining advantages of both asphalt and concrete [9,10,11]. It is cost-effective and has been used in many fields, which may be under unfavorable or complex traffic environments that are slow-speed, heavy-duty, or high-temperature, such as airport runways, factory field pavement, bus rapid transit lanes, and high-performance reclaimed asphalt pavement [12,13,14].

Construction of GSP is normally a two-phase operation. First, the OMA mattress is prepared and paved by equipment lighter than or equal to that used for AC. After the asphalt is cooled, HCM can be spread on the surface. Due to the good connectivity of voids in OMA, HCM penetrates the whole layer to obtain a very low residential void rate for GSP by rubber scrapers and light vibratory rollers. The GSP eventually forms the required strength for traffic through curing for a few days. The beneficial properties of this material rely on careful construction process control, and recent related challenges are problems for mechanical mechanism investigation and distress prevention, such as cracking.

In Europe, GSP was originally invented as a patent of heat-resistant pavement, namely “Salviacim”, by French company Jean Lefebvre at Cognac airport in 1954 [3,15]. In 1987, two companies, Densit and Phoenix, jointly developed and promoted the second generation of GSP, called “Densiphalt”, of which the residual void rate was reduced after being grouted to improve in-field performance [15,16,17]. In 1989, Roffe, the researcher belonging to the Jean Lefebvre Company in France, published a monograph on the “Salviacim”, which was still considered a special construction method by the public [3,18].

The U.S. Army issued a series of evaluation reports of GSP and practiced this technology on airport aprons and tank runways from 1976 [19,20,21]. The Departments of Transportation of states and the U.S. were also concerned for the performance of GSP and conducted many projects to prove its performance [22,23,24]. Consequently, the specification of GSP by the U.S. Army was established and applied in many fields, and were updated several times [25,26,27,28].

Wang et al., conducted a trial road of GSP on Huishen pavement in the Guangdong province in China in 1986 [29]. In 1995, Xu et al., introduced laboratory tests for GSP and presented the bending tensile strength as an indicator to control its quality [30]. Subsequently, Zhang and Pan adapted the Main Aggregate Filling (MAF) method and the orthogonal tests to design GSP in 2000 [31,32]. Further, Hao et al., proposed that the optimal asphalt content of OMA should be determined by the Cantabro test and the Schellenberg Binder Drainage test, while the low-temperature cracking of GSP was found to be the main problem affecting its operational life [4,5,6].

Although GSP was just used originally as a construction technique for special pavements such as airport aprons, it is now considered as a rather new technology because it is found to be strongly different from rigid pavement and flexible pavement for their working behaviors. With the theory of perpetual pavement arousing and traffic load increasing in the recent years, GSP has been welcomed into a rapidly developing period and has become a potential high-performance and cost-effective pavement which has a higher complex shear modulus than AC. However, standards of this technology are seldom published in the world. There are still many unsolved problems in GSP design, such as low-temperature cracking, unreasonable testing parameters, and undeveloped laboratory methods, etc., which need intensive research [6,33]. The poor understanding of these problems limited further development and application of GSP.

The objectives of this study are to summarize the findings in GSP over the past two decades and analyze the relationships of various factors and the methods of laboratory tests on the performance to identify knowledge gaps, promote this technology and deliver recommendations for future research. 143 papers have been selected and reviewed in total on three principles: first, the study should illustrate a qualitative and quantitative evaluation for GSP; second, the research should come from a new perspective for factors and properties of GSP; third, new findings and different conclusions are included for more discussion. Finally, relevant recommendations and future studies are proposed.

2. Influential Factors on the Performance of GSP

2.1. Microstructure

Raw materials and structures of GSP are the essential elements affecting laboratory performance and also yielding technical problems. In a microscopic view, the relationships among asphalt, aggregate, and cement particles build the macro-strength of GSP. Indeed, the micro-analysis method is most commonly used in laboratory tests to demonstrate the intuitive influential factors of micromorphology on the behavior of GSP.

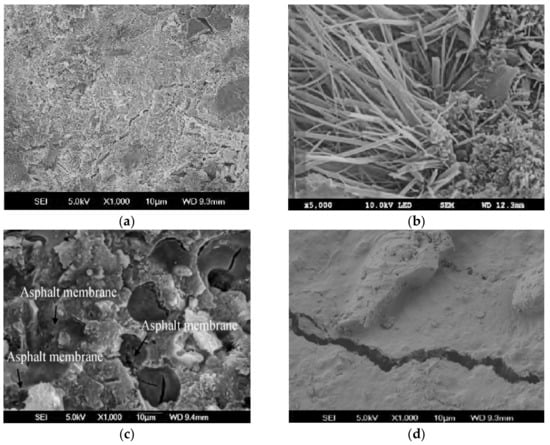

In recent years, resolution of micromorphology techniques, especially the Scanning Electron Microscope (SEM), has reached to the nanometer level, which can capture the microstructure views between different particles to analyze their relationships [34,35]. The GSP samples are observed in various instruments, resolutions, and observing ranges. The methods and results are shown in Table 1 and Figure 1.

Table 1.

Methods of microscopic observation for GSP.

Figure 1.

The GSP microscopic images observed by SEM: (a) Microstructure at 90-day age; (b) Interface and fibrous structures; (c) Wrapping phenomenon of asphalt film; (d) Generation of micro-cracking and bridging effect of the fiber-like network.

GSF has higher density and solidity than traditional AC, which contributes to great complex shear modulus and compressive strength [36]. The strength of GSP is reinforced with increase of age (at ages of 7 d, 28 d, and 90 d), and the inner hydrated cement forms a fibrous-like network that penetrates through asphalt films, as shown in Figure 1 [39]. This exclusive phenomenon, refered to as three-dimensional lattices or a mosaic spatial network, bridges asphalt and cement, which increases the thickness of interface transition zones and enhances the bonding force between asphalt and cement [36]. Meanwhile, the un-hydrated cement plays a role as mineral powder to strengthen the adhesion between asphalt and aggregate.

The propagation of micro-cracks in GSP can be also investigated by SEM (Figure 1). The observation results indicate cracking emerges from the bottoms of samples and expands along with the interface between asphalt and cement [38,40]. This reveals that the asphalt-cement interface is the weak interface existing through the whole depth of GSP structure, approved by the Heavy Vehicle Simulator test and the Dynamic Cone Penetrometer test [41,42]. Additionally, the reaction of internal among raw materials is mainly physical, because no chemical or asphalt aging processes are identified at the interfaces by the Fourier Infrared Spectrum Analyzer (FISA) (200SXVFT-IR) [37].

In general, these characteristics of micro-structure determine the macro properties of GSP, which has high rutting resistance and low cracking resistance. Moreover, the micro-analysis method can effectively and intuitively gain the relationships of each of these components and raw materials. On the other hand, this method is also limited, owing to the subjectivity of corresponding researchers and the complexity of GSP’s structure. For example, some different fibrous structures can be observed from GSP samples, but which has a better coherent strength between materials is unknown because it is hard to get quantitative analysis from SEM images.

2.2. Raw Materials and Admixtures

GSP is a complex composite, combining multiple materials, such as asphalt binder, aggregate, cement, and admixtures. Generally, the effects of them can be separated into two independent steps: intermediate mixes (OMA and HCM) and final grouted or combined mix (GSP). In other words, the properties and the formation of raw materials and admixtures can directly determine the performance of intermediate mixes, which further affects the quality of the following GSP.

OAC is an asphalt mattress with high void rate similar to the open grade friction course (OGFC). According to design principles of OGFC, aggregate gradation can contribute to the volume of void and binder is able to provide inner cohesive strength in OAC. Likewise, strength and fluidity are two main properties of HCM, and are controlled by two factors: formation and types of raw materials.

2.2.1. Aggregate Gradation

Open-grade aggregate is designed primarily as a skeleton of OAC for GSP. It mainly maintains compressive pressures from traffic loads and forms inter-air voids of OAC. Therefore, a good gradation can not only provide a good compressive strength but also construct an even and interconnective space of void.

An optimal gradation mostly can be realized by two design methods: an experiential method and a volumetric method called the main aggregate filling (MAF) method. The latter assumes coarse aggregate is supporting the main structure of OAC and can achieve the required void volume by filling fine aggregate and binder into the compacted coarse aggregate. Due to back-calculation of the void volume, this method is concise to control the final void rate of OMA [43,44]. However, interconnectivity of void is overlooked in this method, which is another important factor for permeability of OAC equally to void volume [45]. Therefore, factors affecting particle sizes and consecutiveness of aggregate gradation are considered to establish the relationships between the given characters above, illustrated in Figure 2, Table 2, Table 3 and Table 4.

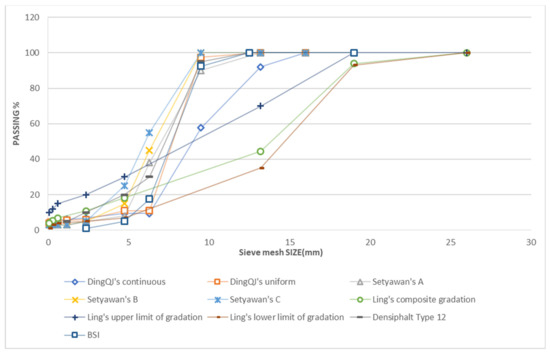

Figure 2.

Some used gradations with different particle sizes and proportions.

Table 2.

Effects of gradations on permeability of OAC [46,47].

Table 3.

Effects of gradations on physical properties of OAC [47].

Table 4.

Effects of gradations on physical properties of GSP [48,49].

The main coarse aggregate used in GSP normally falls in a range of 4.75 mm–13.2 mm particle size. Several combinations of different tiers in this range can form OMA with the requested void rate. Under the similar void rate, gradation with a large particle size will benefit the whole structure. Moreover, the water permeability of samples which have a large proportion in larger particles (14~10 mm) is significantly higher than that of average samples (Table 2) [46]. A lower residual void rate of GSP will be obtained after grouting [50,51]. Overall, a coarser aggregate gradation can be more conducive to forming a larger void space, which has better interconnection, to make the grouted cement mortar more easily able to penetrate the OMA mat [46,52]. Subsequently, flexural tensile strength and compressive strength of the following GSP are also be improved, which are positively linked with low-temperature performance and high-temperature performance, respectively [49]. On the contrary, some other properties may be slightly harmed with the increase of particle size. Cantabro loss rises to a certain value, which indicates that the cohesion between aggregate in GSP is weakened.

From a different perspective, Ding et al., proposed that uniform gradation could conduct smoother void spaces and less stress concentration than continuous gradation. He compared two types of gradations: uniform gradation (one tier: 10~5 mm) and continuous gradation (three tiers: 13~10 mm, 10~5 mm, and 5~3 mm) [53]. It was found that GSP with uniform gradation was superior to that with continuous gradation in the properties of Marshall stability, splitting strength, compressive resilience, and low-temperature bending capacity [53].

Saboo et al., evaluated seven types of gradations using the hierarchical ranking strategy considering parameters as void content, permeability, abrasion resistance, and tensile strength of OAC; BSI-4% and Densiphalt12-4.5% were selected as the optimal gradation which had a main tier of 4.75 mm~12.5 mm [47]. In general, gradation with the main particle sizes in the scope of 4.75 mm~12.5 mm is appropriate to improve the performance of GSP to form a better structure (Figure 2).

However, a conflict exists in previous hypotheses that mainly concerns coarse particles. For example, a given continuous gradation may also contain larger-tier aggregate. The reason may be that the influence of gravel morphology and fine aggregate is overlooked which needs further research [52]. In our opinion, the two viewpoints are all correct, though only the applying scope of these principles is different. The definitions for describing gradation types are difficult to quantify, due to the existence of few samples with untested properties, such as residual void rate and water permeability. Large particle size and uniform gradation can both contribute to the formation of evener and larger void space.

2.2.2. Asphalt Binder

The types of asphalt binder in OMA include base asphalt, rubber asphalt, SBS-modified asphalt, and high-viscosity modified asphalt. Due to various characteristics at different temperatures, the optimal type and content of asphalt binder as two factors varies in OMA design, as shown in Table 5. Orthogonal experiment uncovers the effects of binder on the relative OMA or GSP sample, as illustrated in Table 5 and Table 6.

Table 5.

Optimal binder and high-temperature performance of OMA.

Table 6.

Optimal binder and low temperature performance of OMA.

Asphalt binder with high viscosity and low penetration, such as 50-pen straight-run asphalt, SBS asphalt, rubber-asphalt, and high-viscosity asphalt, can increase strength and reduce Cantabro loss for OMA which will result in good high-temperature performance of GSP. However, binder types have little impact on void space structure in OMA, as well as strength and moisture resistance of GSP [46,54].

OMA samples using SBS asphalt as binder can obtain favorable water permeability. Setyawan et al., explained that modified asphalt protected OMA from drainage that caused void-blocking [46]. Therefore, the performance of following GSP samples was also enhanced, especially in low-temperature cracking resistance [46,54,55].

Rubber asphalt also promotes high-temperature performance of GSP. It is considered as a potential candidate due to its excellent cost-effectiveness and environment-friendliness [48].,High-viscosity asphalt also shows advantages of flexural tensile strain and stiffness modulus at a low temperature, which is associated with better anti-cracking performance [54].

Optimal binder content of OMA can be determined by three main parameters in orthogonal testing: compressive strength, tensile strength, and Cantabro loss. The value of it mostly falls in a range of 3%~5%, due to different test methods. However, it can be argued that a high content rate of binder in OMA can increase toughness of OMA, leading to good anti-cracking performance of GSP [57], because the Marshall stability of OMA continues to rise with the increase of the binder content rate, even up to 9% [58].

Besides these two factors: binder type and content in OMA, bonding force for the asphalt-cement interface is overlooked in steps of influential factors analysis, which can contribute to low-temperature performance of GSP. To achieve a criterion for AC (the flexural tensile strain in small beam bending test should exceed 2000 με at −10 °C [59]), the factors for anti-cracking characteristics of GSP should be considered of both OMA and HCM to bridge two materials in whole structure in design.

2.2.3. High-Fluidity Cement Mortar

High-fluidity cement mortar (HCM) is a specialized grouting material which can penetrate OMA due to its high fluidity to construct a fibrous-like network structure inside the asphalt mattress. Strength and shrinkage rate are the two main factors of HCM controlling the performance of GSP. Therefore, to investigate their effects, various formulas of raw materials and different additives are compared, as shown in Table 7.

Table 7.

Formulas of raw materials and performance of HCM.

The water-cement ratio is the critical factor affecting both fluidity and strength of cement mortar. The fluidity of HCM is positively associated with the water-cement ratio and negatively related to the sand-cement ratio [65]. However, an excess water-cement ratio or a short sand-cement ratio will lead to high dry shrinkage [60,61]. In addition, with the increase of water-cement ratio, the bleeding rate of HCM shows an upward trend, which may cause void-blocking and slurry leakage [66,67]. Therefore, Cheng et al., recommends that the water-cement ratio should be less than or equal to 0.55 for HCM, while Saboo et al., advises a ratio scope of 0.4~0.6 [45,66]. Additionally, 10~14 s is a recommended range for HCM fluidity [45,49,67].

The additive type is another factor in determining the performance of HCM. Superplasticizer and fly ash are commonly used to increase fluidity of HCM and minimize residual void after grouting. Some studies indicates that silica fume, mineral powder, and ultrafine sand also have good effects on fluidity [43,64,68,69]. Expansion agent UEA can reduce the shrinkage of HCM and furtherly enhance the anti-cracking ability of following GSP [60,61,62,63,70]. However, the strength of cement mortar is inevitably underestimated by fluidity improving in the methods above. Therefore, to achieve the balance design between fluidity and strength, a range of strength value is proposed as 10~30 Mpa, and furtherly narrowed to 20~25 Mpa for HCM [45,49]. Although other factors such as the shrinkage and flexural strength of HCM have important effects on the low-temperature performance of GSP, their values are not considered as parameters by recent studies comprehensively.

Cai et al., used ABAQUS software to simulate the shrinkage and expansion of cement mortar in GSP to estimate the inner stresses [71]. Index values of the deformation were calculated and determined to protect GSP from cracking that is caused by stress concentration of shrinkage, as shown in Table 8.

Table 8.

Recommended deformation indexes of cement mortar in GSP [71].

2.3. Admixtures

Admixtures for GSP refer to specific materials adding to OMA or HCM to improve workability or strength of following GSP. Resin is the admixture early used in GSP which can be traced back to 1976 in the U.S. Amy [72], and polymers have been used to enhance the anti-cracking performance of GSP from the 1980s on the Huishen highway, China [73]. Over the past 40 years, more and more types of admixtures have been developed into a big family for GSP.

According to different ingredients, GSP admixtures can be roughly classified into five categories: polymers, fibers, interface modifiers, emulsified asphalt, and other new functional admixtures. New functional admixtures have been recently explored for extension in road functions such as emission-reducing, water conservation, and weather cooling. In addition, two blending methods are usually used for admixtures of GSP: firstly, admixture is blended into cement mortar to reduce rigidity and dry shrinkage of HCM, which furtherly improve cracking resistance for following GSP; secondly, it is mixed within asphalt to enhance the strength of OMA, which achieves a high rutting resistance for the whole structure. Admixtures and their effects on GSP are illustrated in Table 9.

Table 9.

Admixtures and their effects on GSP.

2.3.1. Polymers

Polymers are the most traditional admixtures used in GSP, including latex, resin, SBS, styrene-butadiene rubber (SBR), and waste rubber [74,84]. Latex and resin are efficient to smooth the high rigidity of HCM and reinforce the tensile strength of the whole structure because of their hydrophilicity, which results in bonding at interfaces between materials [56,76]. However, they have little or no influence on the high-temperature performance of GSP. That is because adding polymers into cement mortar will impair the compressive strength of HCM.

In contrast, GSP with rubber as an admixture has little promotion to the low-temperature cracking resistance, due to the weak interface between rubber and cement [48,75], although the fatigue life of rubber-modified GSP is prolonged with the increase of rubber content [85]. In this category, waste rubber is thought to be a cost-effective and environmental-friendly admixture as a substitute to replace raw materials with a high blending ratio up to 20% [75]. Its weakness of insufficient strength can be enhanced by adding an interface modifier, which will be introduced later in this paper [86].

2.3.2. Fibers

Fiber plays a role in reinforcing tensile strength in GSP [87]. It can be blended into GSF in two ways: adding into OMA alone or into both OMA and HCM. However, the effect of fiber mainly works in OMA structure, as there is no obvious advantage showed by the latter method [78].

Nevertheless, it is possible that fiber may harm GSP. GSP samples with 0.3% loose cellulose fiber show a high abrasion loss, which is difficult to meet the requirement as a surface course [46]. Moreover, the tensile strength of fiber-modified GSP may decrease sometimes, even though the fatigue life was increased [83]. The reason is unknown.

2.3.3. Interface Modifiers

Interface modifier commonly refers to silane coupling agent (SCA) or other additives, which can enhance the cohesive strength of interfaces between asphalt and cement to protect weak interfaces from cracking [79]. With the increase of the dosage of SCA, all properties of GSP are improved, especially shear resistance [88,89].

However, SCA needs to be combined with other additives such as rubber or latex to loosen the inner stress in HCM, due to its high stiffness after reaction. It is found that the workability and fluidity of HCM modified by SCA are improved, while the dry shrinkage rate and bleeding rate are greatly alleviated. Therefore, the following GSP samples are strengthened in the cracking and rutting resistance [90].

2.3.4. Emulsified Asphalt

Anionic emulsified asphalt and cationic emulsified asphalt are two types of emulsified asphalt which are always blended with cement to produce cement asphalt (CA) as grouting material for GSP. Cationic CA efficiently increases the flexibility of grouting material, compared to anionic CA and average cement mortar [80]. In addition, CA (especially Cationic CA) has better cohesion with asphalt than average cement mortar, which can also act as a kind of interface modifier [76].

Despite advancement in anti-cracking resistance, CA-modified GSP will be inevitably sabotaged in both the compressive strength of grouting material and the rutting resistance of GSP. Accordingly, Xu et al., presents a method using SBS in OMA to offset the decrease in strength of CA-modified GSP [76].

2.3.5. Complex Admixtures

The purpose of complex admixtures for GSP is to combine advantages of different admixtures. However, some combinations are not always as expected, because of underlying contradictive influences of combined admixtures on GSP. Therefore, in its composition design, more factors and more procedures should be considered in a comprehensive way to achieve desired outcomes, comparing to the individual components [83].

2.3.6. New Functional Admixtures

Some novel admixtures are applied in GSP to extend functions of a road, such as environment conservation and road life extension. For example, water-retaining material is mixed into grouting material to produce water-retaining GSP. This pavement can cool down 8 °C–10 °C for eight hours for the surrounding area by evaporating the water absorbed from rain, while it maintains a high anti-rutting performance [91,92]. Phase-change material (PCM) is also added into GSP to adjust the ambient temperature. The PCM-modified GSP can be protected from the damage of temperature fluctuation by the thermal storage capacity of PCM. It is proved that GSP mixed with 5% PCM can relieve the temperature of pavement by 11.5 °C for 4 h [93,94].

3. Evaluation Methods of the Performance of GSP

3.1. Common Laboratory Testing Methods

Common traditional laboratory tests are used for the evaluation of GSP, including: the Marshall test and the rutting test to assess high-temperature performance, splitting test, semi-circular bending test, small beam bending test at −10 °C to measure low-temperature performance, and Immersion Marshall Residual Stability test to estimate moisture resistance, as shown in Table 10.

Table 10.

Traditional laboratory tests and performance of GSP.

3.1.1. High-Temperature Performance

The Marshall test is most commonly employed to evaluate high-temperature performance of GSP and then results can be easily compared by this index from different projects. GSP has greater Marshall stability and lower flow value than traditional AC, due to its enhanced strength and fewer residual voids by grouting cement mortar. Additionally, the compressive strength of GSP continues to improve with growth of the OMA void [6]. GSP containing reclaimed asphalt pavement (RAP) is also evaluated by the Marshall test, which shows a promising stability value of 53.9 kN [105].

The Rutting test is another popular method, and shows the great anti-rutting resistance of GSP. Average dynamic stability of GSP can be up to 15,000 times/mm, compared to the value of AC-16 at only 2000 times/mm [49,106]. GSP samples can keep their excellent function even at a high test-temperature of 70 °C [103]. Additionally, the Static Indentation Creep test is also adopted to illustrate these characteristics of GSP [107].

3.1.2. Low-Temperature Performance

Evaluation methods for the low-temperature performance of GSP include the small beam bending (SBB) test, splitting test, and semi-circular bending (SCB) test. Additionally, the creep test and indirect tensile strength (ITS) test are also employed at −10 °C to inspect the anti-cracking resistance of GSP [6,108].

Tensile strength of GSP can approximated to AC in the SBB test, while tensile strain is found lower than AC. This is because the excess stiffness of GSP limits the deformation of whole structure. However, admixtures can be efficient to accomplish a significant enhancement in tensile strength of GSP [38]. That is, the modified GSP shows improved low -temperature performance in the SCB test, creep test, and ITS test at −10 °C [108].

However, the laboratory behavior of GSP in splitting tests is far different from that in SBB tests, and both tensile strength and strain are significantly lower than AC’s [70]. Modifiers also had a mild effect on GSP in this test. Therefore, these methods need further investigation and selection to uncover properties of GSP concisely. Further, Ding et al., investigated recycled Semi-flexible Pavement material by splitting test at 20 °C, which indicated its anti-cracking resistance was positively linked with viscoelasticity of the binder [109].

3.1.3. Moisture Resistance

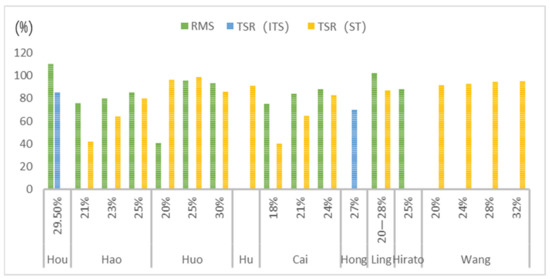

GSP is considered as a promising anti-moisture pavement as it prevents water permeation by its high density and low residual void. This property can be assessed by freeze-thaw test and Immersion Marshall test. The freeze-thaw test is divided into the freeze-thaw splitting test (ST) and freeze-thaw indirect tensile strength (ITS) test. Thus, the results of retained Marshall stability (RMS) and tensile strength ratios (TSR) are summarized and illustrated in Figure 3 [6,38,49,70,77,103,104,110,111].

Figure 3.

Moisture resistance of GSP.

Moisture resistance of GSP is significantly enhanced with high void rate OMA. The reason is that a high void rate can lead to void interconnection and saturated grouting [112]. From the figure, results of Immersion Marshall testing are commonly higher and easier to reach design requirement than those in freeze-thaw tests, because of the more rigorous experimental environment of the latter. There is another interesting phenomenon where some RMS results exceed 100%. This phenomenon may be triggered by further hydration of cement in GSP. Therefore, from this aspect, the freeze-thaw test may be more accurate than the RMS test in the evaluation of moisture resistance for GSP.

3.1.4. Oil Corrosion Resistance

GSP is made to possess an excellent oil corrosion resistance by its good density. Hao et al., adopted oil corrosion resistance test to assess GSP samples. Marshall samples were soaked in #90 gasoline for 24 h to test its retained Marshall stability (RMS), which was 88.5% twice bigger than AC [6]. Hirato et al., also immersed Marshall samples in kerosene for 48 h to attain RMS values, which exceeded 80% [111].

3.1.5. Impact Resistance

Impact resistance of GSP was just tested for some airport lanes by Split Hopkinson Pressure Bar equipment, which was raised by Kolsky to measure stress pulse propagation [113]. The peak stress and failure modes of samples were collected and analyzed by Dong-Hua Test Real-Time Data Measurement Analysis Software System under various air pressures and different OMA void rates. It was found that GSP with 25% void rate had the best impact resistance in the low-pressure areas (0.25 Mpa and 0.30 Mpa), and the 27%-GSP sample could resist the peak stress value of 19.67 Mpa in the high-pressure areas (0.35 Mpa and 0.4 Mpa) [113].

3.1.6. Anti-Weather-Exposure Ability

Anti-weather-exposure ability of GSP was tested by conserving samples in an exposing environment for 7 days, 90 days, 180 days, and 240 days. Its strength and fatigue life were shown no decline in Marshall stability test and cyclic wheel load test [114].

In addition, thermal cracking equipment was adopted to evaluate long-necked specimens at −5 °C. It was found the thermal resistance of GSP was positively related to the content and viscosity of binders [115].

3.2. Fatigue Life Performance

The fatigue life of GSP has raised more concern in recent years, because of its different fatigue life behavior from asphalt and concrete [116]. The results of fatigue life of GSP are summarized in characteristics and correction factors, which are attained by the Indirect Tensile Fatigue test (ITFT), Fatigue Bending test, Cyclic Wheel Load test, Proportion-scale Accelerated Road test, and Full-scale Accelerated Road test. Test methods and fatigue equations of these studies are also shown in Table 11.

Table 11.

Fatigue life behavior of GSP.

3.2.1. Characteristics of Fatigue Life of GSP

Raw materials have effects on the fatigue characteristics of GSP. To assess the fatigue life of GSP, the indirect tensile fatigue test (ITFT) and two-point bending test are commonly used under stress or strain control mode. Fatigue curves illustrate that modified asphalt (polymer asphalt or rubber asphalt) and low-shrinkage cement mortar dominate the fatigue life behavior, while binder content has a slight influence [123]. Moreover, cement may be the most effective material for fatigue life in GSP, compared with asphalt and aggregate [120]. The fatigue life also increases with the growth of the void rate in OMA, which means more cement mortar will be grouted in OMA [77]. Additionally, from the aspect of test conditions, the fatigue life decreases with the rising test temperature and cannot be changed with different loading frequencies [119,124].

The fatigue life of GSP has a linear relationship with stiffness modulus, of which the equation is expressed as below [125]:

α, β, γ are the regression parameters. is the stiffness parameter on the 100th cycle of the fatigue test according to the European standard, and R2 could reach 0.79.

In general, GSP shows a better fatigue life than traditional AC, especially in a low-stress level [120,125]. However, the fatigue life of GSP decreases more rapidly than that of AC and more slowly than that of semi-rigid material at the high-stress level. Due to this reason, GSP may be inferior to AC in anti-fatigue performance with a higher stress [38]. The cumulative fatigue life of GSP will be also shorter than that of AC based on MINER’s Linear Fatigue Damage Accumulation theory, according to the traditional fatigue failure standard (50% of initial stiffness) [126].

However, far different from the pattern of fatigue curves of AC, GSP does not have a sudden drop after loss of the 50% initial stiffness, and thus can still maintain its work capacity instead of failing with loading time [117]. Consequently, 10% residual stiffness is presented to be a new failure standard for GSP, and then the fatigue life of GSP is found to be greatly underestimated [127]. Therefore, failure standards are important and can lead to different results for the evaluation of fatigue life. Additionally, the strain control mode is recommended for fatigue life test of GSP due to its thin course structure applied in field, which shows a better fatigue life than the stress-control mode [123,128].

In 2015, Yang et al., adopted the Cyclic Wheel Loading test on GSP with different OMA void ratios (20%, 23%, 26%, and 30%) [121,122]. The failure standard was defined as a 20 mm crack on the surface. Finally, the repeated wheel loading times was derived, which was close to the actual fatigue life in the field [121].

3.2.2. Fatigue Correction Factor

The correction factor or shift factor of fatigue life is an experiential effective coefficient expressing the relationship between the fatigue life in test and that in field. According to complex test conditions including material types, test methods, loading mode, and testing temperatures, the shift factor is difficult to be unified and determined through different studies.

Ling et al., calculated the fatigue correction coefficient of GSP as follows [119]:

Specifically, the intermittent time coefficient was selected as 5; the stress-reduction multiple of the fatigue life was 3 times; the transverse distribution coefficient was adopted as 0.5; and the unfavorable season days was 60 [119].

Similarly, in another test, Ding et al., considered different factors from Ling: the intermittent time coefficient was 7; the crack propagation coefficient was 20; the Days number of the unfavorable season was 60; and the transverse distribution coefficient was 0.5. The result was expressed as follows [109]:

Olivia et al., indicated the fatigue life correction factor of GSP should be calculated based on ITFT data, considering the intermittent time and loading mode, as shown in Table 12 [117,118].

Table 12.

Fatigue Correction Coefficient of GSP [117,118].

Due to an additional factor of 1.1 for the lateral load distribution, 45 was finally determined as the correction factor [117,118]. However, this factor was still thought to be a conservative value, because the loading intermission in field was much longer than that in experiment.

3.3. Computationand Simulation Method

3.3.1. Finite Element Method under Various Contact Models

The Finite Element Method (FEM) is widely utilized in study of material engineering. FEM software such as ANSYS, ABAQUS, and BISAR are practiced in computation and simulation for GSP. Physical properties of GSP are calculated under various contact models according to different computational hypothesis and parameters from experience and tests, as shown in Table 13 and Table 14.

Table 13.

Computational parameters of GSP in FEM.

Table 14.

Results of FEM Calculation.

FEM can calculate load status of GSP structures using the Elastic Layered System model in three dimensions (3D) and two dimensions (2D). This model easily describes the relationship between the traffic load and the whole structure of GSP. It is found that the bonding of interlayers can reduce the shear stress, bottom tensile stress, and rebound deflection in GSP [133,134]. Thus, the structure shows a better anti-shear capability than AC, which results in a high rutting resistance [120,121,122,123,124,125,126,127,128,129,130,131]. This method also fits well and gains consistent conclusion in many circumstances, such as airports, which have different structures and requirements, [122,132].

The toughness of GSP is calculated using the Visco-Elastoplastic model as the contact model by the ABAQUS software. It is found that the toughness is affected by the OMA void: when it was 25%, GSP has the highest toughness of 11.358 kJ/m2, showing the best anti-cracking capacity [135].

A 2D sectional image model is established by a CCD digital camera and CAD software to analyze the position of cracking for GSP. OMA is assumed to be visco-elastoplastic, and cement mortar is defined as elastic in the computational process. Then, expansion force and contraction force in GSP are calculated by ABAQUS. The results show that expansion of cement mortar has little or no effect on GSP; but contraction can dramatically increase stress on asphalt-cement interfaces to lead to cracking [71]. In short, low-temperature shrinkage of cement mortar is the main reason causing cracking and asphalt-cement interfaces are the weak interfaces.

3.3.2. Compressive Strength Prediction Model

Compressive strength of GSP is assessed by Cube compressive strength test. The values have a linear relationship with that of grouted hydrated cement mortar [136]. The expression is shown as below:

is the compressive strength of cement mortar; is the compressive strength of GSP.

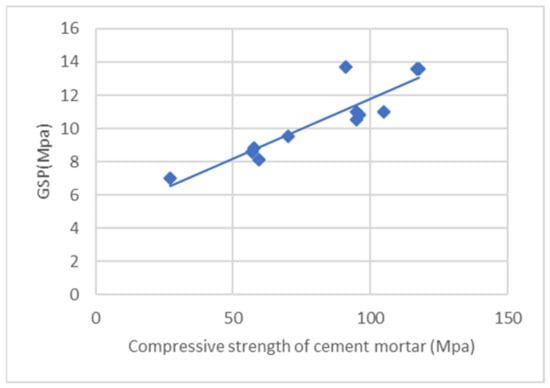

And the relationship can be illustrated in Figure 4:

Figure 4.

Relationship of compressive strength between cement mortar and GSP [136].

In addition, Wu et al., indicated that void rates of OMA and compressive strength of GSP had an empirical regression relationship as follows [137,138]:

was the void rate of OMA (20%~30%); was the resilient modulus of GSP.

3.3.3. 2S2P1D Model

Cai et al., evaluated the viscoelastic behavior of GSP according to the 2S2P1D model (composed of 2 spring units, 2 parabolic units, and 1 clay pot unit). It was found that the 2S2P1D model had a good correlation with the test results. The equation was expressed as follows [139]:

was the complex modulus; was the equilibrium modulus; was the glassy modulus; was the angular frequency; was a calibration constant; was the complex number; was the characteristic relaxation time; k and h were constant values defined as 0 < < < 1; and was a constant that depended on the viscosity of the dashpot.

The reinforcement effect of GSP is positively linked with the OMA void ratio, and the dynamic modulus is associated with the gradation [139]. In other words, cement can play a role to enhance the strength of GSP under high-temperature and low-frequency loads.

3.3.4. Weak Interlayer Model

A cracking model is specially introduced to calculate cohesion strength of interfaces to determine the position of cracking and explain the internal factors through a full-scale Heavy Vehicle Simulator test [42,140]. Then, the strain energy of distortion (SED) is defined as the response parameter to predict weak interlayers. A high SED value presents a higher vulnerability to to cracking at this position. The equation is illustrated as follows:

SED is the strain energy of distortion (N·m/m3); is the total strain energy per unit volume; is Young’s Modulus (Mpa); is Poison’s Ratio; was shear modulus (Mpa); is compressive or tensile stress; and is shear stress (Mpa).

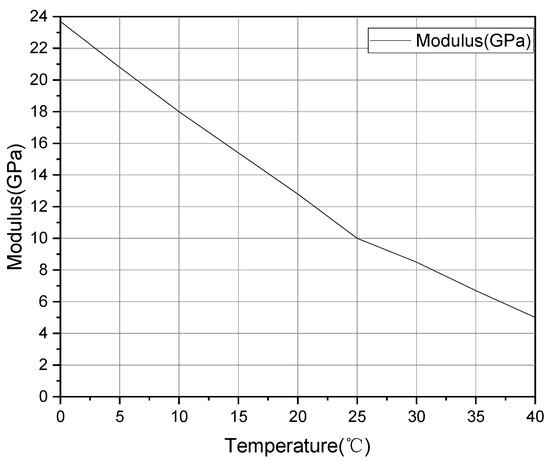

From the traditional perspective, thicknesses and Poisson’s ratios of GSP are selected from experiential values referring to traditional AC pavement, rather than the values from actually measuring. Therefore, though specialized parameters are adopted in tests for GSP, these values vary widely. For instance, the U.S. Air Force recommends that the elastic modulus of GSP should be 12,000 Mpa at 20 °C, following the given modulus-temperature correlation curve (Figure 5), and Poisson’s ratio should be 0.27 [27]. However, the design manual in the United Kingdom suggests the elastic modulus should be 8000 Mpa and Poisson’s Ratio should be 0.25, according to an Indirect Tensile Stiffness Modulus (ITSM) test at the frequency of 5 Hz and the temperature of 20 °C [118,141]. In contrast, Pożarycki et al., back-calculated the in-situ GSP modulus by a Falling Weight Deflectometer, of which the value reaches to 23,700 Mpa [142]. For this reason, the full-scale pavement test is suggested to obtain the more precise property parameters [140].

Figure 5.

GSP Resilient Modulus Versus Temperature Design Curve.

4. Conclusions

According to the influential factors and the evaluation methods, recent studies of GSP have been investigated over the last twenty years in this review article. It is concluded that:

- Microstructure can be analyzed by microscopic observation method in the study of influential factors. However, the result is generally subjective, because image capturing and judging mainly rely on personal experience. Thus, associating tests should be introduced to acquire results in qualitative and quantitative ways;

- Effects of raw materials such as asphalt content and fine aggregate on GSP are not clear enough, due to assumptions in GSP design. More conditions and parameters need to be revised and developed for the evaluation of GSP;

- Individual admixture cannot completely meet the requirement for the low-temperature performance of GSP, while the combination of admixtures cannot be designed reasonably. More effective modifiers should be developed to improve the cracking resistance of GSP;

- Some other characteristics of GSP including interface strength, skid resistance, and other properties are seldom studied, which should be explored to assess the performance of GSP;

- Models used in GSP simulation are based on assumptions of traditional AC. Therefore, these computations and predictions cannot be accurate, as they ignore the difference in behaviors and parameters between GSP and AC.

5. Future Studies

Based on the current literatures, some recommendations for future studies are provided, as follows:

- Advanced technologies like X-ray CT and AFM technology can be used for characterizing the micro-structure of GSP;

- More factors need to be considered and revised by laboratory tests, including binder content and fine aggregate;

- High-efficiency interface modifiers and combined admixtures need to be developed and evaluated;

- Full-scale accelerated test is recommended to assess the fatigue life and other properties of GSP;

- Models of GSP should be carefully considered according to the influential factors in simulation and computation.

Author Contributions

Conceptualization, X.G. and P.H.; methodology, X.G.; validation, X.G. and P.H.; formal analysis, X.G. and P.H.; investigation, X.G.; resources, X.G.; data curation, X.G.; writing—original draft preparation, X.G.; writing—review and editing, X.G.; visualization, X.G.; supervision, P.H.; project administration, P.H.; funding acquisition, P.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

This work was supported by the China Scholarship Council (Grant No.201906560026).

Conflicts of Interest

The authors declares no conflict of interest.

References

- Moghaddam, T.B.; Karim, M.R.; Abdelaziz, M. A review on fatigue and rutting performance of asphalt mixes. Int. J. Sci. Res. Essays 2011, 6, 670–682. [Google Scholar] [CrossRef]

- Aalborg. Densiphalt Handbook; Densit A/S: Glenview, IL, USA, 2000. [Google Scholar]

- Roffe, J.C. Salviacim–Introducing the Pavement; Jean Lafebvre Enterprise: Paris, France, 1989. [Google Scholar]

- Cheng, L.; Hao, P.-W. Design method of mother-asphalt-mixture with semi-flexible pavement based on the volume method. J. Xi’an Highw. Univ. 2002, 22, 1–3. [Google Scholar]

- Cheng, L.; Hao, P.-W. Mixture of cement slurry with semi-flexible pavement. J. Xi’an Highw. Univ. 2002, 22, 1–4. [Google Scholar]

- Hao, P.-W.; Cheng, L.; Lin, L. Pavement performance of semi-flexible pavement in laboratory. J. Chang. Univ. (Nat. Sci. Ed.) 2003, 23, 2. [Google Scholar]

- Goel, A.; Das, A. Emerging road materials and innovative applications. In Proceedings of the National Conference on Materials and Their Application in Civil Engg, Hamirpur, India, 26–27 August 2004; pp. 1–12. [Google Scholar]

- Ahlrich, R.C.; Anderton, G.L. Construction and Evaluation of Resin Modified Pavement; Army Engineer Waterways Experiment Station Vicksburg Ms Geotechnical Lab: Vicksburg, MS, USA, 1991. [Google Scholar]

- Svenson, K. Estimated lifetimes of road pavements in Sweden using time-to-event analysis. J. Transp. Eng. 2014, 140, 04014056. [Google Scholar] [CrossRef]

- Jacobsen, S. The Effectiveness of Grouted Macadam at Intersections: A Life-Cycle Cost Analysis. Stockholm, KTH School of Architecture and the Built Environment. 2012, p. 101. Available online: http://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-101813 (accessed on 14 July 2021).

- Du, Y.; Chen, J.; Han, Z.; Liu, W.J.C.; Materials, B. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.; Radziszewski, P.; Casado, R.; Blanco, V.; Pérez, D.; Viñas, V.M.; Brijsse, Y.; Frosch, M.; Le, D. Eco-friendly materials for a new concept of asphalt pavement. Transp. Res. Procedia 2016, 14, 3582–3591. [Google Scholar] [CrossRef]

- Pratelli, C.; Betti, G.; Giuffre, T.; Marradi, A. Preliminary In-Situ Evaluation of an Innovative, Semi-Flexible Pavement Wearing Course Mixture Using Fast Falling Weight Deflectometer. Materials 2018, 11, 611. [Google Scholar] [CrossRef]

- Zhao, M.; Shen, F.; Qiao, L.; Ding, Q. Recovery and utilization of waste asphalt materials (RAP) on semi-flexible pavement. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2014, 32, 3401–3408. [Google Scholar]

- Mayer, J.; Thau, M. Jointless pavements for heavy-duty airport application: The Semi-Flexible approach. Adv. Airfield Pavements 2001, 87–100. [Google Scholar] [CrossRef]

- Pelland, R.J.; Gould, J.S.; Mallick, R.B. Selecting a rut resistant hot mix asphalt for Boston-Logan International Airport. Airfield Pavements Chall. New Technol. 2004, 390–408. [Google Scholar] [CrossRef]

- Collop, A.; Elliott, R. Assessing the mechanical performance of Densiphalt. In Performance and Durability of Bituminous Materials and Hydraulic Stabilised Composites, Proceedings of the Third European Symposium, Leeds, UK, April 1999; Springer: Berlin/Heidelberg, Germany, 1999; pp. 343–357. [Google Scholar]

- Setyawan, A. Development of Semi-Flexible Heavy-Duty Pavements; University of Leeds: Leeds, UK, 2006. [Google Scholar]

- Rone, C.L.J.M.P.S. Evaluation of Salviacim; US Army Corps of Engineer Waterways Experiment Station: Vicsburg, MS, USA, 1976. [Google Scholar]

- Ahlrich, R.C.; Anderton, G.L. Evaluation of Resin-Modified Paving Process; Transportation Research Board: Washington, DC, USA, 1991; pp. 32–41. ISBN 030905155X. [Google Scholar]

- Emery, J. An evaluation of the performance of concrete blocks on aircraft pavements at Luton airport. In Proceedings of the 3rd International Conference on Concrete Block Paving, Rome, Italy, 17–19 May 1988. [Google Scholar]

- Anderton, G.L.; Ahlrich, R.C. Design, Construction and Performance of Resin Modified Pavement at Fort Campbell Army Airfield; Army Engineer Waterways Experiment Station Vicksburg Ms Geotechnical Lab: Vicksburg, MS, USA, 1994. [Google Scholar]

- Battey, R. Construction, Testing and Preliminary Performance Report on the Resin Modified Pavement Demonstration Project; Mississippi Department of Transportation: Grenada, MS, USA, 2004. Available online: https://rosap.ntl.bts.gov/view/dot/24140 (accessed on 14 July 2021).

- Battey, R.L.; Whittington, J.S. Construction, Testing and Performance Report on the Resin Modified Pavement Demonstration Project; Mississippi Department of Transportation: Washington, DC, USA, 2007. Available online: https://rosap.ntl.bts.gov/view/dot/24137 (accessed on 14 July 2021).

- Anderton, G.L. User’s Guide: Resin Modified Pavement; Army Engineer Waterways Experiment Station Vicksburg Ms Geotechnical Lab: Vicksburg, MS, USA, 1996. [Google Scholar]

- Anderton, G.L. Engineering Properties of Resin Modified Pavement (RMP) for Mechanistic Design; Army Engineer Waterways Experiment Station Vicksburg Ms Geotechnical Lab: Vicksburg, MS, USA, 2000. [Google Scholar]

- Department of the Air Force. Engineering Technical Letter (ETL) 01-8: Resin Modified Pavement (RMP) Design and Application Criteria; Department of the Air Force Headquarters Air Force Civil Engineer Support Agency: Tyndall AFB, FL, USA, 2001. [Google Scholar]

- Ahlrich, R.C.; Anderton, G.L. Resin modified pavement in airfield applications. In Proceedings of the Airport Pavement Innovations. Theory to Practice. Proceedings of Conference, Vicksburg, MS, USA, 8–10 September 1993; Available online: http://worldcat.org/isbn/0872629252 (accessed on 14 July 2021).

- Wang, S.Q.; Lin, X.X.; Lou, H.X. Study on special asphalt mixture, a new type of pavement composite material. J. East China Highw. 1989, 2, 76–81. [Google Scholar]

- Xu, P.H.; Wang, Z.K. Indoor test and research on poured semi-rigid pavement materials. J. Xi ’an Highw. Jiaotong Univ. 1995, 3, 22–25. [Google Scholar]

- Zhang, X.; Pan, D. Design method of Semi-flexible pavement base asphalt mixture. J. Highw. Eng. 2000, 25, 22–23. [Google Scholar]

- Zhang, X.; Pan, D. Preparation of Semi-flexible pavement cement slurry. J. Highw. Eng. 2000, 25, 6–7. [Google Scholar]

- Bonicelli, A.; Preciado, J.; Rueda, A.; Duarte, A. Semi-flexible material: A solution for high-performance pavement infrastructures. In Proceedings of the 3rd World Multidisciplinary Civil Engineering, Architecture, Urban Planning Symposium, WMCAUS 2018, Prague, Czech Republic, 18–22 June 2018. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Mazumder, M.; Ahmed, R.; Ali, A.W.; Lee, S.-J.J.C.; Materials, B. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build Mater. 2018, 186, 313–329. [Google Scholar] [CrossRef]

- Ling, T.Q.; Tang, Q.Q.; Luo, R. Microstructure analysis and strength theory of semi-flexible pavement materials. In Proceedings of the 4th International Road and Airport Pavement Technology Conference, Kunming, China, 23–25 April 2002. [Google Scholar]

- Huo, Y.Z.; Liang, Y.; Huang, B.T. Performance test and mechanism analysis of semi-flexible pavement. J. Highw. 2009, 2, 52–56. [Google Scholar]

- Hou, S.; Xu, T.; Huang, K. Investigation into engineering properties and strength mechanism of grouted macadam composite materials. Int. J. Pavement Eng. 2015, 17, 878–886. [Google Scholar] [CrossRef]

- Cheng, L. Research on Performance and Design Method of Semi-Flexible Pavement Mixture; Chang’an University: Xi’an, China, 2002. [Google Scholar]

- Setyawan, A.; Zoorob, S.E.; Hasan, K.E. Investigating and Comparing Traffic Induced and Restrained Temperature Stresses in a Conventional Rigid Pavement and Semi-Rigid Layers. Procedia Eng. 2013, 54, 875–884. [Google Scholar] [CrossRef][Green Version]

- Netterberg, F.; de Beer, M. Weak interlayers in flexible and semi-flexible road pavements: Part 1. J. S. Afr. Inst. Civ. Eng. 2012, 54, 32–42. [Google Scholar]

- De Beer, M. Weak interlayers found in flexible and semi-flexible road pavements. In Proceedings of the 8th RILEM International Conference on Mechanisms of Cracking and Debonding in Pavements, Nantes, France, 7–9 June 2016; pp. 425–430. [Google Scholar]

- Koting, S.; Karim, M.R.; Mahmud, H.B.; Abdul Hamid, N.A. Mechanical properties of cement-bitumen composites for semi-flexible pavement surfacing. Balt. J. Road Bridge Eng. 2014, 9, 191–199. [Google Scholar] [CrossRef]

- Yang, G.L.; Wu, K.H.; Wang, W.M.; Meng, F.B.; Li, Y.F.; Bao, X.N. Parent Asphalt Mixture Design of Semi-Flexible Pavement Based on Method of Main Mineral Aggregate Void Filling. Adv. Mater. Res. 2012, 446–449, 2599–2602. [Google Scholar] [CrossRef]

- Saboo, N.; Khalpada, V.; Sahu, P.K.; Radhakrishnan, R.; Gupta, A. Optimal proportioning of grout constituents using mathematical programming for semi flexible pavement. Int. J. Pavement Res. Technol. 2019, 12, 297–306. [Google Scholar] [CrossRef]

- Setiawan, A. Design and properties of hot mixture porous asphalt for semi-flexible pavement applications. J. Tek. Sipil. 2009, 5, 41–46. [Google Scholar]

- Saboo, N.; Ranjeesh, R.; Gupta, A.; Suresh, M. Development of hierarchical ranking strategy for the asphalt skeleton in semi-flexible pavement. Constr. Build. Mater. 2019, 201, 149–158. [Google Scholar] [CrossRef]

- Ling, T.Q.; Dong, Q.; Dong, Y.Y. Application of rubber asphalt in infilled semi-flexible pavement. J. Chang. Univ. (Nat. Sci. Ed.) 2009, 26, 24–27. [Google Scholar]

- Ling, T.-Q.; Zhaoz, Z.-J.; Xiong, C.-H.; Dong, Y.-Y.; Liu, Y.-Y.; Dong, Q. The Application of Semi-Flexible Pavement on Heavy Traffic Roads. Int. J. Pavement Res. Technol. 2009, 2, 211–217. [Google Scholar]

- Husain, N.M.; Mahmud, H.; Karim, M.R.; Hamid, N. Effects of aggregate gradations on properties of grouted Macadam composite pavement. In Proceedings of the 2010 2th International Conference on Chemical, Biological and Environmental Engineering, Cairo, Egypt, 2–4 November 2010; pp. 128–131. [Google Scholar]

- Husain, N.M.; Karim, M.R.; Mahmud, H.B.; Koting, S. Effects of Aggregate Gradation on the Physical Properties of Semiflexible Pavement. Adv. Mater. Sci. Eng. 2014, 2014, 8. [Google Scholar] [CrossRef]

- Hou, S.; Xu, T.; Huang, K. Aggregate gradation influence on grouting results and mix design of asphalt mixture skeleton for semi-flexible pavement. J. Test. Eval. 2017, 45, 591–600. [Google Scholar] [CrossRef]

- Ding, Q.J.; Sun, Z.; Shen, F.; Huang, S.L. The performance analysis of semi-flexible pavement by the volume parameter of matrix asphalt mixture. Adv. Mater. Res. 2011, 168–170, 351–356. [Google Scholar] [CrossRef]

- Zhao, G.Q.; Huang, C.; Deng, C. Research on the influence of asphalt type on the performance of semi-flexible pavement materials. J. Highw. Eng. 2017, 42, 199–201. [Google Scholar]

- Wang, W.M.; Gao, D.; Wu, K.H. Study on the properties of semi-flexible pavement materials. J. Highw. Eng. 2014, 1, 78–82. [Google Scholar]

- Luo, S.; Yang, X.; Zhong, K.; Yin, J. Open-graded asphalt concrete grouted by latex modified cement mortar. Road Mater. Pavement Des. 2018, 21, 1–17. [Google Scholar] [CrossRef]

- Plug, C.; de Bondt, A.; van der Woerd, B.; Steensma, G. Improved Performance Grouted Macadams–High Performance Applications of Grouted Macadam; Ooms Nederland Holding bv: Avenhorn, The Netherlands, 2006; Available online: http://www.materialedge.co.uk/docs/CP-AdB-Stabifalt(English)[1].pdf (accessed on 14 July 2021).

- Debbarma, C.; Debbarma, D.; Roy, A.; Zachariah, J.P.; Sarkar, P. A study on the effect of admixture in grouted macadam. In Proceedings of the AMIE Section A & B Summer Examination Commences wef 2nd, Agartala, India, 30 April 2018; p. 62. [Google Scholar]

- Liu, B. Specification for Design of Highway Asphalt Pavement; Ministry of Transport of the People’s Republic of China: Beijing, China, 2017. [Google Scholar]

- Hu, S.G.; Zhang, R.G.; Ding, Q.J. Semi-flexible pavement performance of grouting cement mortar research. J. Highw. 2009, 7, 1–6. [Google Scholar]

- Hu, S.; Huang, S.; Ding, Q.; Zhang, R. Study on the cementitious mortar for semi-flexible pavement. In Proceedings of the 1st International Conference on Microstructure Related Durability of Cementitious Composites, Nanjing, China, 13–15 October 2008; pp. 1237–1246. [Google Scholar]

- Pei, J.; Cai, J.; Zou, D.; Zhang, J.; Li, R.; Chen, X.; Jin, L. Design and performance validation of high-performance cement paste as a grouting material for semi-flexible pavement. Constr. Build. Mater. 2016, 126, 206–217. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, J.; Pei, J.; Li, R.; Chen, X. Formulation and performance comparison of grouting materials for semi-flexible pavement. Constr. Build. Mater. 2016, 115, 582–592. [Google Scholar] [CrossRef]

- Koting, S.; Karim, M.R.; Mahmud, H.; Mashaan, N.S.; Ibrahim, M.R.; Katman, H.; Husain, N.M. Effects of using silica fume and polycarboxylate-type superplasticizer on physical properties of cementitious grout mixtures for semiflexible pavement surfacing. Sci. World J. 2014, 2014, 596364. [Google Scholar] [CrossRef]

- Vijaya, S.S.A.; Karim, M.R.; Mahmud, H.; Ishak, N.F. Influence of superplasticiser on properties of cementitious grout used in semi-flexible pavement. In Proceedings of the 8th International Conference of Eastern Asia Society for Transportation Studies, Eastern Asia Society for Transportation Studies, Surabaya, Indonesia, 16–19 November 2009; p. 296. [Google Scholar] [CrossRef]

- Cheng, Z.Q.; Kong, F.S.; Jia, R.R. Study on bleeding performance of cement-based grout materials for semi-flexible pavement. J. China Foreign Highw. 2014, 36, 276–279. [Google Scholar]

- Gu, X.Y.; Li, L.X.; Cheng, Z.Q. Study on flow performance of cement-based grout materials for semi-flexible pavement. J. Highw. 2017, 62, 280–285. [Google Scholar]

- Wang, Y.J.; Guo, C.Y.; Tian, Y.F.; Wang, J.J. Design of Mix Proportion of Cement Mortar with High-performance Composite Semi-flexible Pavement. Adv. Mater. Res. Switz. 2013, 641–642. [Google Scholar] [CrossRef]

- Hassan, K.; Setyawan, A.; Zoorob, S. Effect of Cementitious Grouts on the Properties of Semi-Flexible Bituminous Pavements in Performance of Bituminous and Hydraulic Materials in Pavements; Routledge: London, UK, 2017; pp. 113–120. [Google Scholar]

- Cai, J.; Pei, J.; Luo, Q.; Zhang, J.; Li, R.; Chen, X. Comprehensive service properties evaluation of composite grouting materials with high-performance cement paste for semi-flexible pavement. Constr. Build. Mater. 2017, 153, 544–556. [Google Scholar] [CrossRef]

- CAI, X.; Zhang, S.X.; Li, K. Limit stress analysis of weak internal parts of Semi-flexible materials. J. Taiyuan Univ. Technol. 2017, 48, 652–656. [Google Scholar]

- Anderton, G.L. The Resin Modified Pavement System: A New Pavement Surfacing Technology. In Airport Facilities: Innovations for the Next Century, Proceedings of the 25th International Air Transportation Conference, Austin, TX, USA, 14–17 June 1998; American Society of Civil Engineers: Austin, TX, USA, 1998. [Google Scholar]

- Wang, S.; Lin, X.; Lou, H. Study on the composite material of new pavement-special asphalt mixture. J. East China Highw. 1989, 2, 15. [Google Scholar]

- Ling, T.; Zhou, J.; Zhao, Z.; Li, C.; Dong, Y.; Research, T. Study on Optimization of Polymer Modified Cement Slurry for Poured Semi-flexible Pavement. J. Highw. 2009, 6, 24–28. [Google Scholar]

- Huang, C.; Hong, J.X.; Lin, J.T.; Deng, C.; Li, L. Utilization of Waste Rubber Powder in Semi-Flexible Pavement. Key Eng. Mater. 2014, 599, 361–367. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, Y.; Xue, J.; Tong, X.; Cheng, Y.J.C. High-Performance Semi-Flexible Pavement Coating Material with the Microscopic Interface Optimization. Coatings 2020, 10, 268. [Google Scholar] [CrossRef]

- Wang, D.; Liang, X.; Jiang, C.; Pan, Y. Impact analysis of Carboxyl Latex on the performance of semi-flexible pavement using warm-mix technology. Constr. Build. Mater. 2018, 179, 566–575. [Google Scholar] [CrossRef]

- Cheng, Z.-Q.; Zhang, X.-Y.; Kong, F.-S. Research on Mechanism and Improving Low Temperature Performance of Semi Flexible Pavement Material by Use of PVA. J. Wuhan Univ. Technol. 2016, 38, 44–49. [Google Scholar]

- Yang, Y.; Huang, S.L.; Ding, Q.J.; Peng, X.Y. The Property Research on Interfacial Modificated Semi-Flexible Pavement Material. Appl. Mech. Mater. 2011, 71–78, 1090–1098. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Cheng, Z.Q.; Kong, F.S. Low Temperature Performance of Semi-flexible Pavement With CA Grouting Material. J. Beijing Univ. Technol. 2017, 43, 1205–1211. [Google Scholar] [CrossRef]

- Huang, C.; Liu, J.; Hong, J.; Liu, Z. Improvement on the crack resistance property of semi-flexible pavement by cement-emulsified asphalt mortar. In Proceedings of the 3rd Mainland, Taiwan and Hong Kong Conference on Green Building Materials, GBM 2011, Wuhan, China, 25–27 November 2011; pp. 26–32. [Google Scholar]

- Sun, Z.; Hou, X.X.; He, G.P. Research on the Crack Resistance at Low Temperature and the Mechanism of Semi-Flexible Pavement. Aer. Adv. Eng. Res. 2015, 22, 533–536. [Google Scholar]

- Gong, M.; Xiong, Z.; Chen, H.; Deng, C.; Chen, X.; Yang, J.; Zhu, H.; Hong, J. Evaluation on the cracking resistance of semi-flexible pavement mixture by laboratory research and field validation. Constr. Build. Mater. 2019, 207, 387–395. [Google Scholar] [CrossRef]

- Fang, B.; Xu, T.; Shi, S. Laboratory study on cement slurry formulation and its strength mechanism for semi-flexible pavement. J. Test. Eval. 2016, 44, 907–913. [Google Scholar] [CrossRef]

- Hamzani; Munirwansyah; Hasan, M.; Sugiarto, S. The influence of the using waste tire rubber and natural ziolite as Asphalt and Cement replacements to compressive strength of Semi-Flexible Pavement. In Proceedings of the 8th Annual International Conference 2018 on Science and Engineering, Aceh, Indonesia, 12–14 September 2018; IOP Publishing Ltd: Banda Aceh, Indonesia, 2018. [Google Scholar]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Yin, H. Study on the Performance of Semi-Flexible Pavement Mixed With Fiber; University Of South China: Hengyang, China, 2013. [Google Scholar]

- Hou, Q.Q.; Sun, Z. Study on the properties of semi-flexible pavement modified by water-based epoxy resin. J. Traffic Stand. 2013, 24, 81–84. [Google Scholar] [CrossRef]

- Kong, F.S. Study on the Performance of HIGH Performance Semi-Flexible Pavement Materials; Chang’an University: Xi’an, China, 2016. [Google Scholar]

- Li, Z.M. Study on Temperature Stability of Semi-Flexible Pavement Composites Filled with Rubber Powder; Guangxi University of Science and Technology: Liuzhou, China, 2013. [Google Scholar]

- Ling, T.-Q.; Zheng, X.-W.; Ling, M.; Xiong, C.-H.; Dong, Q. Research on performance of water-retention and temperature-fall semi-flexible pavement material. China J. Highw. Transp. 2010, 23, 7–11. [Google Scholar]

- Dong, Q.; Wang, C.; Xiong, C.; Li, X.; Wang, H.; Ling, T. Investigation on the Cooling and Evaporation Behavior of Semi-Flexible Water Retaining Pavement based on Laboratory Test and Thermal-Mass Coupling Analysis. Materials 2019, 12, 2546. [Google Scholar] [CrossRef]

- Liu, G.Y. Application of Phase Change Materials in Semi-Flexible Pavement; Chang’an University: Xi’an, China, 2013. [Google Scholar]

- Sha, S. Study on Preparation and Application of PEG/SiO2 Compound Phase Change Materials for Semi-flexible Pavement. Road Mach. Constr. Mech. 2016, 33, 63–66. [Google Scholar] [CrossRef]

- Xu, P. Experimental study on composite materials for semi-rigid road surface. J. Highw. Eng. 2002, 15, 7–10. [Google Scholar]

- Wu, G.X.; Zhang, Y.L.; Wang, A.M. Experimental study on high temperature stability of semi-flexible pavement. J. Chongqing Jiaotong Univ. 2007, 26, 52–55. [Google Scholar] [CrossRef]

- Zhang, D.K.; Cheng, C.Q.; Wu, G.X. Analysis of water stability and low temperature crack resistance of semi-flexible pavement. J. Chongqing Jiaotong Univ. 2007, 26, 55–57. [Google Scholar] [CrossRef]

- Dong, Y.Y. Research on Design Parameters and Construction Technology of High-Performance Semi-Flexible Pavement; Chongqing Jiaotong University: Chongqing, China, 2008. [Google Scholar]

- Zhang, R.K. Research and Application of High Performance Perfusion Semi-Flexible Pavement Materials; Wuhan University of Technology: Wuhan, China, 2009. [Google Scholar]

- Pang, C.Q.; Yang, Y.L. Research on Properties of Semi-Flexible Mixtures. J. Highw. 2004, 4, 108–110. [Google Scholar] [CrossRef]

- Pang, C.Q. Mixture design for grouting pavements. In Proceedings of the International Workshop on Energy and Environment in the Development of Sustainable Asphalt Pavements, Xi’an, China, 1 June 2010; pp. 262–265. [Google Scholar]

- Li, X.; Li, Y. Analysis of road performance of semi-flexible cement asphalt mixture. J. Shandong Agric. Univ. (Nat. Sci. Ed.) 2018, 49, 815–818. [Google Scholar]

- Hu, S.-G.; Huang, S.-L.; Liu, Z.-G.; Ding, Q.-J.; Wu, G.-X. Design and construction of the semi-flexible based permeable anti-sliding noise-reducing pavement. J. Wuhan Univ. Technol. 2008, 30, 27–31. [Google Scholar]

- Huo, Y.-Z.; Liang, Y.; Huang, B.-T.; Huang, F. Laboratory Test and Mechanism Analysis of Road Performance of SemiFlexible Pavement. Highway 2009, 11, 52–56. [Google Scholar]

- Afonso, M.L.; Dinis-Almeida, M.; Pereira-de-Oliveira, L.A.; Castro-Gomes, J.; Zoorob, S.E. Development of a semi-flexible heavy duty pavement surfacing incorporating recycled and waste aggregates—Preliminary study. Constr. Build. Mater. 2016, 102, 155–161. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Li, R. Laboratory study on performance of semi-flexible mixture. In Proceedings of the 4th International Conference on Civil, Architectural and Hydraulic Engineering, ICCAHE 2015, Guangzhou, China, 20–21 June 2015; pp. 989–994. [Google Scholar]

- Manikantha Raju, G.; Sita Rami Reddy, D.; Sudhakar Reddy, K. Performance evaluation of cement grouted bituminous mixes. In Proceedings of the 12th International Conference on Asphalt Pavements, ISAP 2014, Raleigh, NC, USA, 1–5 June 2014; pp. 1047–1056. [Google Scholar]

- Zhang, W.; Shen, S.; Goodwin, R.D.; Wang, D.; Zhong, J.J.M. Performance Characterization of Semi-Flexible Composite Mixture. Materials 2020, 13, 342. [Google Scholar] [CrossRef]

- Ding, Q.J.; Zhao, M.Y.; Shen, F.; Zhang, X.Q. Mechanical Behavior and Failure Mechanism of Recycled Semi-flexible Pavement Material. J. Wuhan Univ. Technol. 2015, 30, 981–988. [Google Scholar] [CrossRef]

- Hong, J.X.; Wang, K.J.; Xiong, Z.J.; Gong, M.H.; Deng, C.; Peng, G.; Zhu, H.R. Investigation into the freeze-thaw durability of semi-flexible pavement mixtures. Road Mater. Pavement Des. 2019, 21, 2198–2214. [Google Scholar] [CrossRef]

- Hirato, T.; Murayama, M.; Sasaki, H.J. Development of high stability hot mix asphalt concrete with hybrid binder. J. Traffic Transp. Eng. 2014, 1, 424–431. [Google Scholar] [CrossRef]

- Liu, Z.K. Experimental study on the properties of single gradation asphalt crushed stone with cement slurry filling hole. J. Highw. 2015, 60, 219–221. [Google Scholar]

- Li, Y.; Wang, J.W.; Zhang, Y. Study on impact resistance of perfusion semi-flexible pavement materials. J. Highw. Eng. 2016, 41, 55–59. [Google Scholar] [CrossRef]

- Karami, M. Application of the Cementitious Grouts on Stability and Durability of Semi Flexible Bituminous Mixtures. AIP Conf. Proc. 2017, 1903, 020012. [Google Scholar] [CrossRef]

- Oliveira, J.; Thom, N.; Zoorob, S. Fracture and Fatigue Strength of Grouted Macadams. Available online: http://hdl.handle.net/1822/7208 (accessed on 14 July 2021).

- Da Rios, G.; Agostinacchio, M.; Fiori, F. Performance and durability of grouted open grade asphalt concretes. In Proceedings of the 2021 5th International Conference on Maintenance and Rehabilitation of Pavements and Technological Control, MAIREPAV 2007, Park City, UT, USA, 8–10 August 2007; pp. 505–510. [Google Scholar]

- De Oliveira, J.R.M. Grouted Macadam: Material Characterisation for Pavement Design; University of Nottingham: Nottingham, UK, 2006. [Google Scholar]

- Oliveira, J.; Pais, J.C.; Thom, N.H.; Zoorob, S.E. The effect of using rest periods in 4PB tests on the fatigue life of grouted macadams. In Proceedings of the C-TAC International Conference Communications, Universidade do Minho, Guimarães, Portugal, 24–25 September 2009; pp. 277–283. [Google Scholar]

- Ling, T.Q.; Zhao, Z.J.; Wu, D. Experimental study on fatigue resistance of semi-flexible pavement materials. In Proceedings of the Annual Meeting of China Highway Society and Technical Seminar of Highway Construction in Mountainous Areas, Chongqing, China, 10 September 2009. [Google Scholar]

- Huang, C. Study on Volume Stability and Crack Resistance of Semi-Flexible Pavement Materials; Wuhan University of Technology: Wuhan, China, 2010. [Google Scholar]

- Yang, B.; Weng, X. The influence on the durability of semi-flexible airport pavement materials to cyclic wheel load test. Constr. Build. Mater. 2015, 98, 171–175. [Google Scholar] [CrossRef]

- Yang, B.; Weng, X.; Liu, J.; Jiang, L.; Zhang, J.; Liu, P.; Wen, X. The influence of on semi-flexible airport pavement material working performance by porosity. In Proceedings of the Advanced Materials and Structural Engineering: Proceedings of the International Conference on Advanced Materials and Engineering Structural Technology (ICAMEST 2015), Qingdao, China, 25–26 April 2015; p. 157. [Google Scholar]

- Oliveira, J.; Sangiorgi, C.; Fattorini, G.; Zoorob, S. Investigating the fatigue performance of grouted macadams. Proc. Inst. Civil Eng.-Transp. 2009, 162, 115–123. [Google Scholar] [CrossRef]

- Wu, D. Experimental Study on Fatigue Resistance of Semi-Flexible Pavement Materials; Chongqing Jiaotong University: Chongqing, China, 2009. [Google Scholar]

- Corradini, A.; Cerni, G.; D’Alessandro, A.; Ubertini, F.J.C.; Materials, B. Improved understanding of grouted mixture fatigue behavior under indirect tensile test configuration. Constr. Build Mater. 2017, 155, 910–918. [Google Scholar] [CrossRef]

- Oliveira, J.R.; Thom, N.H.; Zoorob, S. Design of pavements incorporating grouted macadams. J. Traffic Transp. Eng. 2008, 134, 7–14. [Google Scholar] [CrossRef]

- Oliveira, J.; Pais, J.C.; Thom, N.H.; Zoorob, S. A study of the fatigue properties of grouted macadams. Int. J. Pavements 2007, 6, 112–123. [Google Scholar]

- Oliveira, J.; Zoorob, S.; Thom, N.; Pereira, P.A. A simple approach to the design of pavements incorporating grouted macadams. Available online: http://hdl.handle.net/1822/8002 (accessed on 14 July 2021).

- Yu, Z.H. Study on the Structure and Performance of Semi-Flexible Asphalt Mixture Pavement; Hunan University: Changsha, China, 2007. [Google Scholar]

- Huang, F. Research on Structural Design Theory and Method of Semi-Flexible Composite Pavement; Chongqing Jiaotong University: Chongqing, China, 2008. [Google Scholar]

- Chen, C. Study on Semi-Flexible Structure of Highway Tunnel Pavement; Chongqing Jiaotong University: Chongqing, China, 2011. [Google Scholar]

- Xu, G.; Li, G.; Xu, W.; Li, C.; Li, Y. Mechanics Numerical Analysis of Semi-flexible Compound Pavement for Large Aircraft. J. Highw. Eng. 2015, 40, 122–126. [Google Scholar] [CrossRef]

- Wang, W.P. Research on Semi-Flexible Composite Pavement Material and Structure; Changsha University of Science and Technology: Changsha, China, 2012. [Google Scholar]

- Gao, J.H.; Wang, Z.L. The Analysis of Layer Cohesive Force of Semi-flexible Composite Pavement Based on the Software of BISAR. J. Highw. Eng. 2013, 38, 17–20. [Google Scholar]

- Wang, W.M.; Wu, K.H. Research on crack resistance of semi-flexible pavement material based on J integral. J. Highw. 2016, 61, 63–67. [Google Scholar]

- Setyawan, A. Asessing the Compressive Strength Properties of Semi-Flexible Pavements. Procedia Eng. 2013, 54, 863–874. [Google Scholar] [CrossRef]

- Huang, F.; Wu, G.-X.; Wang, Y.; Zhang, D. Study on Compacted Rebound Modulus of Semi-Flexible Pavement Compound Material. J. Chongqing Jiaotong Univ. 2008, 1, 65–68. [Google Scholar]

- Wu, G.-X.; Wang, Y.; Wang, R.-Y. A study of the strength mechanism of semi-flexible composite pavement material and a modified method for the determination of its compressive resilient modulus. In Integrated Transportation Systems: Green, Intelligent, Reliable, Proceedings of the 10th International Conference of Chinese Transportation Professionals, Beijing, China, 4–8 August 2010; American Society of Civil Engineers: Beijing, China, 2010; pp. 3055–3062. [Google Scholar]

- Cai, X.; Zhang, H.; Zhang, J.; Chen, X.; Yang, J.; Hong, J. Investigation on reinforcing mechanisms of semi-flexible pavement material through micromechanical model. Constr. Build. Mater. 2019, 198, 732–741. [Google Scholar] [CrossRef]

- De Beer, M.; Maina, J.W.; Netterberg, F. Mechanistic modelling of weak interlayers in flexible and semi-flexible road pavements: Part 2. J. S. Afr. Inst. Civ. Eng. 2012, 54, 43–54. [Google Scholar]

- Highways Agency. Design Manual for Roads and Bridges; HM Stationery Office: London, UK, 2006. [Google Scholar]

- Pożarycki, A.; Fengier, J.; Górnaś, P.; Wanatowski, D. Backcalculation of pavements incorporating Grouted Macadam technology. Road Mater. Pavement Des. 2017, 19, 1372–1388. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).