Abstract

Construction and demolition wastes represent a primary source of new alternative materials which, if properly recovered, can be used to replace virgin raw materials partially or totally. The distrust of end-users in the use of recycled aggregates is mainly due to the environmental performance of these materials. In particular, the release of pollutants into the surrounding environment appears to be the aspect of greatest concern. This is because these materials are characterized by a strong heterogeneity which can sometimes lead to contaminant releases above the legal limits for recovery. In this context, an analysis of the leaching behaviour of both CDWs and RAs was conducted by applying a statistical analysis methodology. Subsequently, to evaluate the influence of the particle size and the volumetric reduction of the material on the release of contaminants, several experimental leaching tests were carried out according to the UNI EN 12457-2 and UNI EN 12457-4 standards. The results obtained show that chromium, mercury, and COD are the most critical parameters for both CDWs and RAs. Moreover, the material particle size generally affects the release of contaminants (i.e., finer particles showed higher releases), while the crushing process does not always involve higher releases than the sieving process.

1. Introduction

The construction sector is one of the main players involved in achieving environmental sustainability. This is due to the fact that it is primarily responsible for the exploitation of non-renewable natural resources, land use, energy consumption, and production of construction and demolition wastes (CDWs). According to Eurostat data [1], in 2018, 838.900 million tons of CDWs were produced in the 27 Member States of the European Union (EU-27). In the same year, 60.5 million tons of CDWs were produced in Italy, equal to 42.5% of all special waste produced in the nation [2]. In 2019, the CDW production increased to 69.6 million tons, accounting for around 50% of all special waste produced.

These large quantities of wastes represent a primary source of new alternative materials which, if properly recovered, can be used to replace virgin raw materials partially or totally. In this context, the Directive (EU) 2018/851 (amending Directive 2008/98/EC on waste) imposed a recovery rate for CDWs equal to 70% by weight by 2020. In particular, by 31 December 2024, the Commission will evaluate the feasibility of setting new targets on the preparation for reuse and recycling of CDWs.

Within this framework, in 2018, Italy recovered 35.5 million tons of CDWs, corresponding to 77.4% of all CDWs produced annually [2]. In 2019, this recovery rate increased further to 78.1%. At the national level, this percentage of recovery is sometimes not confirmed by other sources [3]. In particular, the most prominent and widespread environmental association in Italy, “Legambiente”, states that 77% generally represents CDWs only treated and recovered in treatment plants which are subsequently stored without any actual reuse in the economic market. This is mainly due the fact that end-users still prefer to use natural aggregates rather than recycled aggregates (RAs) because, to date, they are still cost-effective resources and are considered more reliable in terms of technical and environmental performance. In particular, the possible release of contaminants into the surrounding environment by the RAs is one of the main reasons for distrust in the use of these materials in the construction sector. This is mainly due to the high heterogeneity rate of both CDWs and RAs linked to the different origin of the materials contained (e.g., bricks, concrete, gypsum, wood, masonry, plastics, metals, and more) [4]. As highlighted and confirmed by Cabrera et al. [5] and Silva et al. [6], these materials may contain environmentally hazardous compounds that can potentially filter and contaminate the underlying soil as well as surface and groundwater [7,8]. Generally, concrete and masonry are usually the prevailing material fraction in CDWs, especially in Mediterranean countries [9]. Concrete derives from foundations, load-bearing structures, pavements, road structures, or sidewalk [10], while masonry and ceramic materials come from covering elements, such as roof tiles and brickworks [11]. Minor fractions of plastics, metals, gypsum, and wood may also be found depending on the source segregation level and the recovery technology adopted [12].

In the last few decades, several research studies have investigated the leaching of organic and inorganic compounds by CDWs and RAs [12,13,14,15,16,17,18,19,20]. Generally, CDW and RA eluates have alkaline pH (pH > 7) [17,21]. As stated by Delay et al. [22], pH values of concrete and mixed CDWs—as well as of the respective RAs produced—is strongly alkaline with pH values around 12.5 or even higher [23]. As stated by Park et al. [24] and Moreno et al. [25], this alkalinity is due to high content of cement paste and mortar in concrete. These compounds are mainly composed of portlandite and calcium-silicate-aluminate (C-S-H) which are hydrated in an aqueous solution to produce Ca(OH)2 with high alkalinity [26]. Conversely, the pH values of brick CDW leachates are neutral or slightly alkaline (pH ranging from 7 to 8.5) [27].

In this context, Engelsen [12] investigated the leaching performance of recycled concrete aggregates (RCAs) and reported that the pH of the concrete material, although strongly alkaline, gradually decreases over time due to carbonation, which is a natural well-known aging process that occurs when the hardened concrete comes in contact with atmospheric carbon dioxide and wetting-drying cycles [23,28]. In particular, in the case of recycled materials, carbonation occurs when the RAs (specifically the RCAs) are crushed and stored in heaps before being used in the desired applications. The crushing process, in fact, leads to a substantial increase in the specific surface of the crushed concrete and accelerates the carbonation process [29]. Based on this, the aging process can change the RCA pH from an alkaline pH of about 12–14 (reference for a fresh non-carbonated material) to a slightly basic pH of about 9–10 (reference for a fully-carbonated material) [12,16,27]. This is mainly due to the degradation of the alkaline hydrate phases by the reaction between the dissolved Ca(OH)2 and CO2 to form stable CaCO3 [30]. In reference to this, the authors Butera et al. [8] found and highlighted that the carbonation level of RCAs stored outdoor for several months is, however, partial and not total. The pH, in fact, decreases but is always higher than 9–10.

In addition to the crushing process and storage time, Engelsen et al. [31] stated that the RCA carbonation level is also related to the carbonation degree of the original concrete structure associated with its manufacturing year and its service life exposure. However, the authors Del Rey et al. [20] found small differences in the pH values of RCAs originated from concrete structures manufactured in 1960s and 1990s (pH of approximately 11.9) and those of RCAs originated from the demolition of new concrete samples (pH of approximately 12.9). Thus, despite the different manufacturing period, the RCAs were found to be partially carbonated (i.e., pH values higher than 10). As reported above, this may be due to the crushing of the old concrete that lead to the formation of new non-carbonated surfaces which come from the core of the concrete block and were not exposed throughout the lifetime of the building and never interacted with air or water [32].

Based on all these considerations, a high concrete carbonation degree or a high amount of ceramic materials (e.g., bricks, tiles) and soil in CDWs and RAs lead to lower pH values of the eluates [8,27]. As stated by Engelsen [12], these pH variations (i.e., more or less alkaline) affect the leachability of many chemical substances contained in both CDWs and RAs. Several studies, in fact, identified high releases of Cr, As, Zn, Se, Mo, and Sb at neutral or alkaline pH values [21,33,34]. In particular, the leaching of As, Se, and Cr is related to the degradation of hydrated attached mortar on the RA surface [33]. Del Rey and co-workers [20] also highlighted that at neutral or alkaline pH most of the total Cr is released as hexavalent chromium (Cr (VI)), which is harmful and can cause allergies, nasal lesions, bronchitis, and especially dermatitis [35]. Conversely, when the pH is less than 5, Cr is leached as Cr (III).

High releases of Cu, Ni, Pb, Cd, and Zn (metal cations) are instead detected at lower pH values (i.e., from pH 7 to pH 4) [36]. In particular, as stated by Nurhanim et al. [33], Zn is highly released in both acidic and alkaline environments. Obviously, as shown by previous research studies, the release of pollutants into the surrounding environment is also strictly related to the merceological fractions present in both CDWs and RAs. Nurhanim et al. [33] assessed the leaching behaviour of inorganic elements from concrete and gypsum CDWs. As compared with concrete CDWs, the highest concentration of inorganic pollutants was found in gypsum CDWs according to the order SO4 > Ca > CI > Mg > Zn > Cu > Fe. All these parameters showed concentrations below the regulatory limits of EU Landfill Directive (Directive 2003/33/EC), except for SO4. Specifically, the release of SO4 was due to the sulphur content contained in gypsum. These results have also been confirmed by other authors [8,20,37,38,39,40,41,42,43]. In particular, Agrela et al. [38] evaluated the leaching behaviour of mixed recycled aggregates (MRAs) in order to assess their compliance with the European landfill regulations and found that SO4 is the only critical parameter due to the presence of gypsum in the analysed samples. During the study, the authors also observed a relationship between the selective collection at the origin of CDWs, which reduces gypsum content, and the concentration of leached SO4.

In this context, Barbudo et al. [43] also investigated the correlation between sulphate content and leached SO4 in recycled aggregates with different contents of concrete, bituminous particles, ceramics, and gypsum. The results showed that high SO4 releases mainly occur in recycled aggregates with more than 30% by weight of ceramic particles (e.g., crushed bricks) or with more than 2% by weight of gypsum particles (from plaster, cardboard-plaster panels, stucco, etc.). Combined with this, the authors found that the SO4 in leaching processes comes also from other compounds of recycled aggregates such as concrete, mortar, and natural aggregates. In particular, the sulphate species from concrete and mortars originate by the additions of gypsum to the clinker in order to retard ‘‘fast setting’’. High SO4 releases in crushed granular concrete and adhered mortar samples were also detected by other authors [8,20,39,44]. In particular, Müllauer et al. [44] stated that SO4 release is controlled by the dissolution of portlandite.

As confirmed by Diotti et al. [13], Estokovà et al. [45], Vegas et al. [41], and Chen et al. [21], cement and concrete fractions also release high amounts of total Cr, As, Pb, and Se. In particular, the release of Pb can also be associated with lead-based painted plasters found mainly in older buildings [19], while the release of Cr can originate from raw materials and fuels used during cement production (e.g., clays, char, limestone, or iron-based ingredients) as well as from other sources, such as refractory bricks lining the kiln, mineral admixtures, and grinding media in the final finishing mills [45,46].

Based on past studies, Cr release is also associated with ceramic materials, such as bricks and tiles [20,42]. This finding was later corroborated by Galvin et al. [18] who evaluated the release of pollutant elements by compliance (EN 12457-3) and Dutch percolation leaching test (NEN 7343) from recycled aggregates with different ceramic particles and gypsum content. The results revealed that higher ceramic and gypsum content in the material caused higher levels of Cr release, above inert limits imposed by EU Landfill Directive.

Some studies have also demonstrated the correlation between the release of pollutants and the particle grain size, as well as the possible crushing of the material before being subjected to leaching tests [18,32,47]. Coudray et al. [32] investigated the leaching behaviour of RCAs with particle sizes of 0/6.3 mm, 6.3/20 mm, 20/40 mm, and >40 mm by applying two different leaching test methods: (1) the EN 12457-2 standard, in which each fraction was crushed to a 4 mm particle size before the leaching experiment (whatever the initial particle size of the sample) and (2) a non-standardised leaching test without any supplementary crushing (RAs only sieved), in order to show the effect of grain size on the leaching behaviour. The results of the tests performed on samples crushed to a 0–4 mm showed different concentration trends for the chemical elements analysed (Si, Al, Na, K, Ca, Mg, Fe, P, Cr, Ti, S). In particular, the smaller fraction (0–6 mm) concentrates trace elements (Cr, Cu, and Pb) and SO4 more often than the coarse fraction. The same behaviour was detected for RAs tested with the non-standardized method (i.e., only screened and not crushed). The results globally showed a decrease in the concentrations of K, SO4, Cl, Cr, and Cu as the grain size rises. Based on this, the study showed that smaller fractions generally leach more than the coarse fractions. Moreover, by comparing the two leaching test methods, the volumetric reduction involves a greater release of contaminants. In this context, the authors recommended the implementation of leaching tests on samples of different grain sizes without prior volumetric reduction. This finding was also corroborated by Mahedi and Cetin [48], who highlighted that leached concentrations of Ca, Ba, Cr, and SO4 decreased with an increase in RCA particle size, and by Bestgen et al. [49], who reported that leached metal concentrations increased when the particle size decreased.

Galvin et al. [18] also demonstrated the importance of evaluating the release of contaminants from RAs in their commercial particle size to simulate their actual on-site conditions. In particular, MRAs with 0–32 mm grain size distribution were tested by applying the Under Compaction Leaching Test (i.e., procedure that analyses the samples without any pre-crushing or alteration of the grain-size distribution). Compared with traditional leaching tests (UNE EN 12457-3 and NEN 7343) that predict a reduction in particle size (dmax < 4 mm), the results showed lower release levels.

Within the aforementioned context, most of the scientific studies [7,8,14,15,17,18,20,33,39,41,48,50,51,52] concerning the evaluation of the environmental properties of both CDWs and RAs are generally based on laboratory-scale research. Thus, one of the main purposes of this research was to evaluate the leaching behaviour of CDWs and RAs by adopting a statistical approach. In particular, several leaching test certificates related to CDWs and RAs were collected by two CDW treatment plants located in the Lombardy Region (northern Italy). The collected data were then statistically processed, and the leaching behaviour of both CDW and RAs was assessed in compliance with the limits defined by the Italian legislation for recovery of granular materials (Ministerial Decree 186/2006) [53]. Subsequently, in order to identify the sources of high release levels in both CDWs and RAs, the critical release of some contaminants was correlated with specific EWC codes (i.e., European Waste Code).

The second goal of this research was to investigate whether and how the RA grain size, as well as the crushing process before the leaching test, can affect the release of contaminants.

As reported above, the material crushing leads to higher pollutants release due to the increase of the contact surfaces between RAs and leaching agent, but, at the same time, sieving operations can also lead to greater fine fractions that cause high releases. Despite this, research studies that thoroughly evaluate these aspects are limited [18,32,48,54]. Thus, the main aim was to further investigate these conditions and support or integrate the data obtained from previous studies. In this context, different laboratory leaching tests were developed on RAs sampled from each of the two CDW treatment plants in order to evaluate the release of pollutants according to the EN 12457-2 (dmax < 4 mm) and EN 12457-4 (dmax < 10 mm) methods and, respectively, in conditions of simple sieving or crushing. As above, the release of pollutants was evaluated according to the limits imposed by Ministerial Decree 186/2006.

2. Materials and Methods

2.1. Construction and Demolition Wastes and Recycled Aggregates

Two CDW treatment plants located in the Province of Brescia (in Lombardy Region—northern Italy) were assumed as case studies. The managed CDWs are classified within Chapter 17 of the European Waste Code and are treated through consecutive operations of unwanted fraction separation (e.g., wood, plastic, glass, etc.), dry crushing, and iron removal and screening in order to obtain RAs with a selected granulometry. Specifically, the RAs produced are generally mixed recycled aggregates since about 80% of all the CDW managed by the analysed treatment plants are mixed CDWs, classified with EWC code 170904. This is due to the fact that, as for the national situation, the CDWs generally come from micro demolition operations [55]. Soil and rocks (EWC 170504), concrete (EWC 170101), and bituminous mixture (EWC 170302) are, instead, the other waste streams most managed by the plants. According to the Italian legislation, the RAs produced must comply with technical (EC marking) and environmental requirements. In particular, regarding the environmental properties, the recycled material must be subjected to leaching test according to the UNI EN 12457-2 and must comply with the limits imposed by the Ministerial Decree 186/2006.

2.2. Statistical Approach

A total number of 300 certificates of leaching tests performed on both CDWs and RAs were acquired from the databases of the two selected treatment plants. The collection period refers to 10 years. The collected data were subsequently elaborated using a statistical approach. Specifically, the “box-plot” methodology was applied to identify the variability of pollutant concentrations and the critical parameters according to the regulatory limits imposed by the M.D. 186/2006. In particular, this research methodology was applied using the IBM SPSS software.

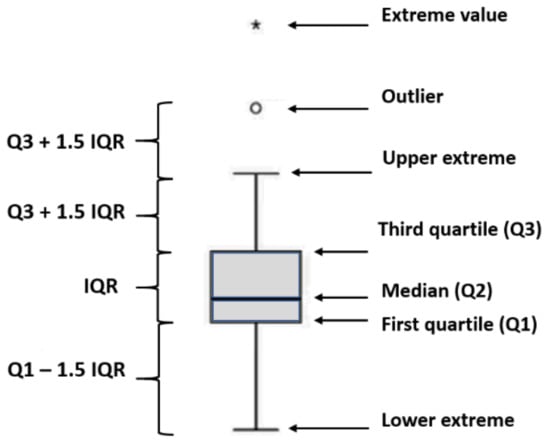

As shown in Figure 1, the box-plot graph visually shows the distribution of numerical data by means of five significant numbers:

Figure 1.

Scheme of the box-plot diagram.

- lower extreme: minimum value identified by a whisker. Points within a distance between Q1 and Q1 minus 1.5 times the interquartile range (IQR—the difference between Q3 and Q1).

- first quartile (Q1): 25% of the data values are less than or equal to this value;

- median (Q2): 50% of the data values are less than or equal to this value;

- third quartile (Q3): 75% of the data values are less than or equal to this value;

- upper extreme: maximum value identified by a whisker. Points within a distance between Q3 and Q3 plus 1.5 times the IQR.

The graph also shows the presence of anomalous values (i.e., outliers marked with circles and extreme values marked with asterisks) with respect to the majority of the observed data. These data are values that significantly differ from the general trend of the distribution and can be caused by errors (of transcription and measurement), exceptional circumstances, or contamination of data.

In this context, to better understand the behaviour of pollutants with respect to regulatory limits and to identify any critical parameters, the dispersion of concentrations in terms of IQR and whisker lengths was evaluated. In particular, the greatest criticality was identified when the box (i.e., IQR which contains 50% of all analysed data) exceeded the regulatory limit considered. By means of this methodology, the identified critical pollutant releases were then correlated with the merceological fractions (i.e., EWC code) present in the analysed material in order to identify possible correlations between the characteristics of RAs and those of the original CDWs. In particular, the analysis was developed with reference to the EWC codes most managed by the analysed treatment plants: EWC 170101 “cement”, EWC 170302 “bituminous mixtures”, EWC 170504 “soil and stones”, EWC 170904 “mixed construction and demolition wastes”.

2.3. Experimental Leaching Tests

In order to evaluate the influence of particle size and crushing conditions on the leaching behaviour of RAs, three RA samples were collected from the two selected CDW treatment plants (here called plant A and plant B) and subjected to experimental leaching tests. Specifically, based on the type of RA generally produced by the plants, a Mixed Recycled Aggregate (MRA) and a Concrete Recycled Aggregate (RCA) were gathered from plant A and a MRA was sampled from plant B, as shown in Table 1.

Table 1.

Origin, type, and dimension of the recycled aggregates sampled.

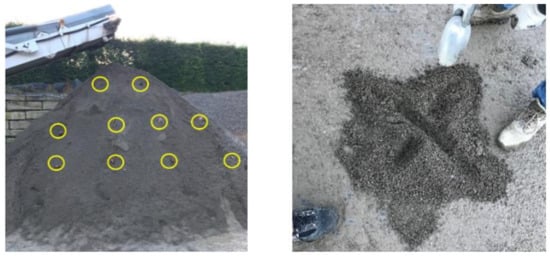

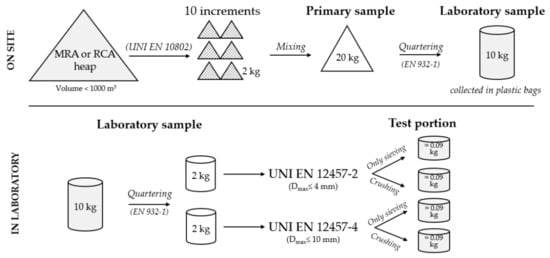

All the samples were collected according to the methodology provided by the standard UNI EN 10802. In particular, based on the RA heap volume (less than 1000 m3), 10 increments of mass 2 kg were sampled at different heap levels and carefully mixed to obtain a primary sample of about 20 kg. After that, the primary sample was reduced by quartering operations (EN 932-1) in order to obtain a laboratory sample of 10 kg (Figure 2). In laboratory, this sample was then further volumetrically reduced to 2 kg, and based on its moisture and dry matter content, the test portions for leaching were subsequently identified.

Figure 2.

RA sampling points and quartering operation.

On the three selected RAs two types of leaching test were performed (Table 2):

Table 2.

Comparison between the applied test methods (UNI EN 12457-2 and UNI EN 12457-4).

- batch leaching test according to UNI EN 12457-2 with particle size of at least 95% less than 4 mm;

- batch leaching test according to UNI EN 12457-4 with particle size of at least 95% less than 10 mm.

In particular, the UNI EN 12457-2 is the leaching test method adopted in Italy, while the UNI EN 12457-4 is the method applied by some EU countries which have already adopted End of Waste criteria (EoW) for CDWs (i.e., Austria, France). To date, in Italy there are no End of Waste criteria for CDWs. Thus, the purpose of performing new leaching tests taking as reference countries with more developed knowledge and policies could represent a basis for new knowledge to support standardization bodies that will adopt national EoW criteria.

As aforementioned, to evaluate the possible influence of size reduction and crushing conditions on the leaching behaviour, both tests were carried out, respectively, under conditions of (Table 3):

Table 3.

Battery of RA samples.

- simple sieving until the maximum diameter required by regulations (4 mm or 10 mm), and

- RA crushing until the maximum diameter required by regulations (4 mm or 10 mm).

Twelve parallel batch tests were stirred for 24 h at L/S ratio of 10 L/kg. The eluates sampled from all the tests were collected, filtered with a 0.45 µm membrane, and conserved for chemical analysis.

To allow discussion of the results, the concentration values below the Limit Of Detection (LOD) were assumed to be equal to the LOD. To identify potentially critical substances, all the leaching concentrations were compared with the legal limit established by the M.D. 186/2006 for recovery of granular materials.

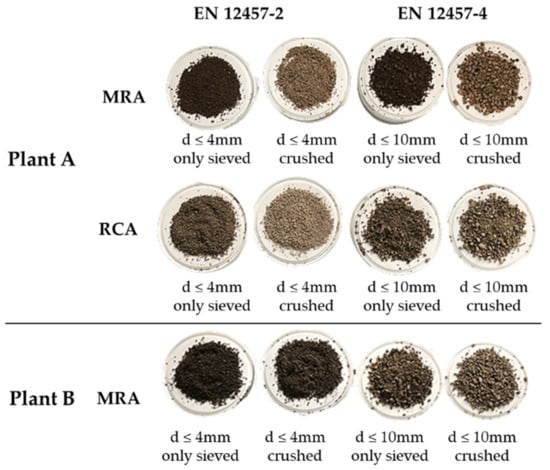

Finally, Figure 3 exemplifies the different stages implemented on-site and at the laboratory to obtain representative samples for each RAs analysed, while Figure 4 shows all the tested RA samples.

Figure 3.

Scheme of the RA sampling method adopted.

Figure 4.

Samples of RAs subjected to leaching tests according to EN 12457-2 and 4 standards.

3. Results

3.1. Statistical Evaluation of Leaching Behaviour of CDWs and RAs

The assessment of potential environmental impact of CDWs and RAs is a topic of great interest around the world, as the main goal of most countries is to achieve high recovery rates of these materials [31]. In this context, to ensure environmental protection and to evaluate the release of pollutants into the surrounding environment, these materials are subjected to leaching test during their recovery process. One of the main goals of the leaching test is to evaluate the potential pollution of a material by comparing the released contents of contaminants with the legal limits defined by national legislation [16].

In this study, the leaching behaviour of CDWs and RAs was evaluated according to the compliance test established by UNI EN 12457-2 and the release of pollutants was compared with the limits imposed by M.D. 186/2006. Table 4 reports the concentrations of released compounds in terms of minimum-maximum range and average value.

Table 4.

Leaching properties of CDWs and RAs (contaminant releases reported in the average and minimum–maximum range).

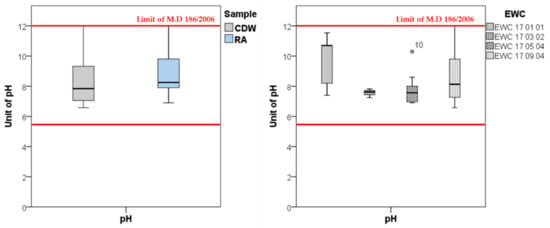

As research studies reported [14,40,48,52,56], the pH of both CDWs and RAs is generally alkaline with maximum values equal to the regulatory limit (i.e., pH 12) (Figure 5).

Figure 5.

pH values of CDWs and RAs (left) and pH values of different EWC codes (right).

Compared with the available regulatory limits, the average concentrations are generally lower except for mercury and COD in CDWs. Nitrates, fluorides, sulphates, chlorides, nickel, cadmium, and total chromium are also critical parameters for CDWs in terms of maximum concentrations. These results have also been confirmed by other authors [13,19,27,33]. Regarding RAs, critical maximum concentrations were detected for total chromium, lead, mercury, and COD.

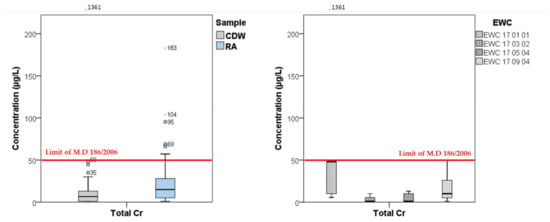

To identify the main sources of the most critical compounds for recovery (i.e., total chromium, mercury, and COD), the box-plot graphs resulting from the statistical analysis are shown in Figure 6, Figure 7 and Figure 8.

Figure 6.

Total chromium release in CDWs and RAs (left) and EWC code responsible for the highest release (right).

Figure 7.

Mercury release in CDWs and RAs (left) and EWC code responsible for the highest release (right).

Figure 8.

COD release in CDWs and RAs (left) and EWC code responsible for the highest release (right).

Figure 5 illustrates the variation of pH values in CDWs and RAs. Both materials are alkaline with 50% of the values ranging between 7 and 10, but values up to the regulatory limit (i.e., 12) were also detected. This alkalinity is mainly due to the cementitious fractions present in the CDWs and, consequently, in the produced RAs. In fact, EWC 170101 “cement” has the highest pH values, with a median value of approximately 11. Although to a lesser extent, mixed CDWs (EWC 170904) are also responsible for alkalinity, as they may contain concrete and cement fractions (median value of approximately 8), while CDWs with EWC 170504 (soil and stones) and EWC 170302 (bituminous mixtures) have significantly lower pH values (median values of about 7.5).

These results are confirmed by Chen and Zhou [14], Gupta et al. [52], and Butera et al. [8]. In particular, Butera et al. [8] highlighted that CDWs or RAs samples containing cement and concrete fractions have pH values between 11 and 13. Instead, mixed CDWs show slightly lower pH values due to the presence of ceramic and soil fractions. The results obtained also show that RAs generally have pH values higher than CDWs. This may be due to the fact that the RAs—subjected to crushing—present new non-carbonated surfaces coming from the core of the concretes that have higher pH values [32].

As previously stated, total chromium is one of the most conflictive elements for CDW recovery and RA use. As shown in Figure 6, the greatest criticality was found in RAs as part of the samples analysed (i.e., upper whisker) show total chromium concentrations higher than the regulatory limit of 50 µg/L. From the analysis developed, the main source of chromium are cementitious materials (EWC 170101), in which 50% of the total concentrations are close to the regulatory limit. This is mainly due to the presence of Portland cement [41] and the mortar adhered to the original natural aggregate [21].

The results are generally aligned well with the existing literature. In fact, as confirmed by several authors [45,46,57,58,59], total chromium is one of the parameters most released by cement when subjected to leaching test. This is mainly due to the raw materials and fuels used during its production [57]. Several studies have also demonstrated that total Cr is one the most leachable and unstable metal even in crushed granular concrete samples [44,60]. According to Galvin et al. [18], Del Rey et al. [20], and Butera et al. [8], also mixed CDWs (EWC 170904) containing ceramic fractions, bricks, tiles, and more can be a source of total chromium.

Figure 7 shows the mercury concentrations in both CDWs and RAs. The results showed mercury releases close to the regulatory limit of 1 µg/L in both CDWs and RAs. In particular, the greatest criticality was identified in RAs, in which 25% of all concentrations exceed the limit for recovery. These results confirm the considerations presented by the authors Puthussery et al. [61] and Engelsen et al. [62]. In particular, based on both compliance and availability test, the authors Puthussery et al. [61] found mercury concentrations higher than those reported by other studies [36,42] and above the permissible limits prescribed for inert waste landfills.

In this context, as highlighted in the graph, the main sources of mercury are the soil and rocks fractions (EWC 170504) contained in the CDWs, confirming the results obtained by [63].

Finally, COD was found as one of the most critical parameters, especially in CDWs in which more than 10% of the detected concentrations exceed the regulatory limit of 30 mg/L. Maximum concentrations up to 443 mg/L were also recorded.

The main sources responsible for high COD release are cement and concrete fractions (EWC 170101) and soil and stones (EWC 170504), according to the results reported by Mikami et al. [64] and Diotti et al. [13]. In particular, high levels of COD are mainly attributable to the degraded organic matter contained in the analysed materials [65].

3.2. Influence of Particle Grain Size and Crushing Conditions on the Leaching Behaviour of RAs

Table 5 shows the results obtained from the leaching tests carried out on the selected 12 RAs, according to the limits imposed by the M.D 186/2006.

Table 5.

Leaching behaviour of MRAs and RCAs tested according to the EN 12457-2 (d≤ 4 mm) and EN 12457-4 (d ≤ 10 mm) methods, under conditions of only sieving and crushing.

As previously mentioned, in order to evaluate the influence of the particle size and the volumetric reduction by crushing on the release of contaminants, the leaching tests were performed according to the UNI EN 12457-2 (dmax ≤ 4 mm) and UNI EN 12457-4 (dmax ≤ 10 mm) standards and in conditions of only sieving or crushing of the material. In particular, the pollutant concentrations that exceed the regulatory limits for recovery are marked in grey and bold.

Generally, the pollutant concentrations comply with the regulatory limits imposed by the M.D. 186/2006, except for total chromium and COD. In particular, total chromium was identified as critical for a crushed RCA, while COD for all the tested MRAs.

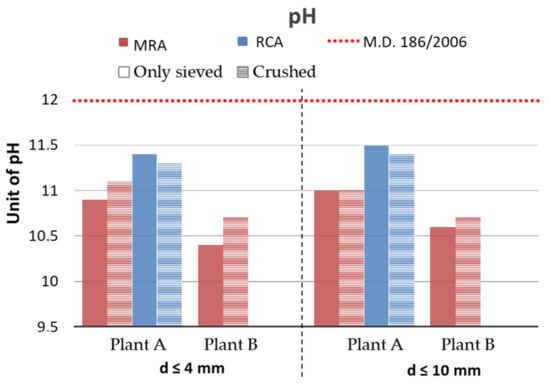

Figure 9 shows the pH values recorded in plants A and B in relation to the type of RA (RCA or MRA), particle sizes, and test conditions (i.e., material only sieved or crushed).

Figure 9.

Trend of pH values in relation to the type of RA (RCA or MRA), particle sizes, and test conditions (i.e., material only sieved or crushed).

As shown, the pH is always alkaline (pH > 10) for both MRAs and RCAs and below the regulatory limit of 12. Compared with MRAs, RCAs have higher pH values according to the results reported by several authors [8,27,52].

For both MRAs and RCAs, the particle size of the material (dmax less than 4 mm or 10 mm) does not significantly affect the pH values. Only slightly lower pH values are recorded for recycled aggregates with a maximum particle diameter equal to 4 mm. On the contrary, the crushing process greatly affects the pH values of MRAs produced by both treatment plants. In particular, regarding the MRAs produced by plant A, the pH of the only sieved material varies between 10.9 (dmax ≤ 4 mm) and 11 (dmax ≤ 10 mm), while the pH of the crushed material varies between 11 (dmax ≤ 10 mm) and 11.1 (dmax ≤ 4 mm).

Similarly, the MRAs produced by treatment plant 2 show pH values of the sieved material equal to 10.4 (dmax ≤ 4 mm) and 10.6 (dmax ≤ 10 mm), while equal to 10.7 (dmax ≤ 4 mm and 10 mm) for the crushed material.

The influence of the crushing process is not, however, evident in the RCA eluates. For these samples, in fact, the sieving process contributes to higher pH values (11.4 for dmax ≤ 4 mm and 11.5 for dmax ≤ 10 mm) than those of crushed samples (11.3 for dmax ≤ 4 mm and 11.4 for dmax ≤ 10 mm).

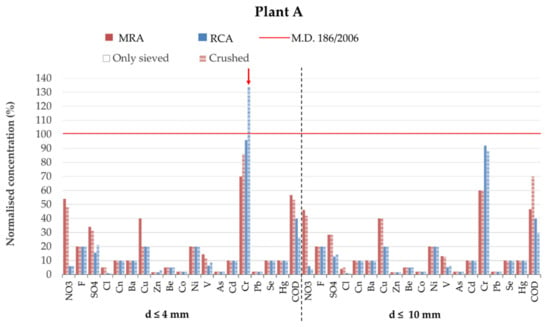

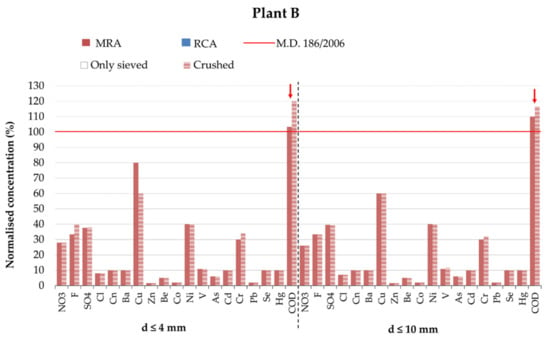

Figure 10 and Figure 11 show the pollutant concentrations normalized to their respective regulatory limits for recovery (M.D. 186/2006).

Figure 10.

Plant A: trend of pollutant concentrations in relation to the type of RA (RCA or MRA), particle sizes, and test conditions (i.e., material only sieved or crushed).

Figure 11.

Plant B: trend of pollutant concentrations in relation to the type of RA (RCA or MRA), particle sizes, and test conditions (i.e., material only sieved or crushed).

As for pH, Figure 10 shows the release of contaminants from MRAs and RCAs produced by plant A in terms of particle grain size and test conditions (i.e., sieving or crushing). As shown, the only critical parameter for recovery is total chromium released by the crushed RCA (dmax ≤ 4 mm) which, with a concentration of 67 µg/L, exceeds the regulatory limit of 50 µg/L. Generally, the results clearly show that the greatest concentration of chromium comes from RCAs, confirming the results obtained by other authors [13,21,41,45].

Overall, for both MRAs and RCAs, the coarser fraction (dmax ≤ 10 mm) releases lower pollutant concentrations than the finer fraction (dmax ≤ 4 mm), except for copper and COD. These results confirm the data observed by Mahedi and Cetin [48], Coudray et al. [32], and Bestgen et al. [49]. In particular, as stated by Bestgen et al. [49], this high release of contaminants from fine particles is due to their larger specific surface area, which allows a greater interaction between the aqueous solution and the recycled aggregate. In fact, as highlighted by Schmukat et al. [66], the available specific surface area exhibit a direct correlation with the release of contaminants.

Regarding the test conditions, the results obtained in plant A show that, compared with the crushing process, the sieving procedure generally involves a higher release of pollutants both in MRAs and RCAs, except for total chromium (in samples with dmax ≤ 4mm) and COD (in the MRA with dmax ≤ 10 mm). For these samples, the highest concentrations of pollutants were recorded under condition of volumetric reduction.

As for plant A, Figure 11 shows the release of contaminants from MRAs produced by plant B in terms of particle grain size and test conditions.

From the results obtained, COD is the only critical parameter for both the fraction with dmax ≤ 4 mm and dmax ≤ 10 mm. In particular, with respect to the regulatory limit, the concentration of COD increases from 3% to 20%. As compared with the MRAs of plant A that did not show critical issues in terms of COD release, the higher release of COD in the MRAs of plant B can be attributed to the greater presence of organic vegetable substances [65]. Additionally, in this case the finer fraction (d max ≤ 4 mm) releases higher concentrations of pollutants than the coarser fraction (d max ≤ 10 mm), except for COD.

According to Coudray et al. [32], the results obtained also highlight the influence of crushing condition on the release of several analysed compounds, especially for fluorides, sulphates, total chromium, and COD. On the other hand, copper is the only parameter that shows higher release in sieving conditions.

4. Conclusions

In this study, the leaching behaviour of CDWs and RAs was evaluated by means of a statistical analysis, and the possible influence of grain size and volumetric reduction on the release of contaminants from MRAs and RCAs sampled from two CDW treatment plants was evaluated by applying the UNI EN 12457-2 (dmax ≤ 4 mm) and UNI EN 12457-4 (dmax ≤ 10 mm) leaching test methods.

The analysed recycled aggregates were also tested in conditions of simple sieving and crushing, and the release of pollutants was compared to the legal limits imposed by the Ministerial Decree 186/2006.

According to the results obtained from the statistical analysis performed, the following conclusions are drawn:

- The pH of both CDWs and RAs is generally alkaline, with maximum values up to the legal limit of 12. This alkalinity is mainly due to the presence of cementitious fractions (EWC 170101) which show median values equal to 11. Instead, mixed CDWs (EWC 170904), soil and rocks (EWC 170504), and bituminous mixtures (EWC 170302) showed lower pH values (median values equal to about 7.5–8), and this is due to the presence of ceramic and soil fractions [8].

- In terms of release of contaminants, total chromium, mercury, and COD are the most critical parameters for the recovery of CDWs and RAs. In particular, total chromium is mainly released by cementitious materials (EWC 170101) due to the presence of cement and adhered mortar. Specifically, the main sources of chromium in cement are the raw materials and fuels used during its production process [57]. Instead, lower chromium release comes from mixed CDWs (EWC 170904).

- High mercury releases were detected in soil and rocks fractions (EWC 170504), while high releases of COD are mainly associated with both cementitious and soil and stone fractions. In particular, this is due to the presence of decomposable organic matter.

- Finally, maximum concentrations of nitrates, fluorides, sulphates, chlorides, nickel, and cadmium above the regulatory limits were detected in CDWs, while maximum concentrations of Pb were found in RAs.

The results obtained from the experimental leaching tests carried out on MRAs and RCAs produced by two CDW treatment plants led to the following conclusions:

- In line with the results obtained from the statistical analysis, the pH is always alkaline (pH > 10) for both MRAs and RCAs. In particular, compared with MRAs, RCAs show higher pH values.

- Total chromium and COD are the most critical parameters for recovery, as they showed concentrations above the regulatory limits of 50 µg/L and 30 mg/L, respectively. In particular, higher chromium concentrations were detected in RCAs, while COD in MRAs.

- The grain size of the tested recycled aggregates (i.e., dmax less than 4 or 10 mm) does not significantly affect the pH values for both MRAs and RCAs. Conversely, in terms of release of contaminants, the finer particles (dmax ≤ 4 mm) generally tend to release higher pollutant concentrations in the eluate than the coarse fractions (dmax ≤ 10 mm). This is mainly due to the larger specific surface area of the fine particles, which favours a greater interaction between the leaching agent and the solid matrix.

- Different from some findings available in the literature [32], in this study the crushing of the material before being subjected to leaching tests does not always influence the release of contaminants into the surrounding environment. In particular, from the results obtained in plant A, the sieving process contributes to a greater release of contaminants. Conversely, regarding plant B, the material crushing results in a higher release of pollutants (especially for fluorides, sulphates, chromium, and COD).

In conclusion, about this last aspect, the authors believe that the results obtained should be further investigated with additional experiments. In fact, as stated in the introduction, the research studies that address and evaluate the influence of the RA crushing process on the release of contaminants are still limited. These new analyses would help confirm whether the obtained considerations were precise and could produce a more meaningful analytical data database for future studies.

Author Contributions

Conceptualization, S.S. and A.D.; methodology, S.S. and A.D.; software, A.D.; investigation, A.D.; data curation, A.D. and S.S.; writing—original draft preparation, A.D.; writing—review and editing, A.D., S.S. and G.P.; supervision, S.S. and G.P.; project administration, S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

This work was developed within the Ph.D. project “Environmental and technical characterization of construction and demolition wastes and recycled aggregates for their use in concrete, road construction and geotechnical applications”, financed by the companies Gruppo Gatti S.p.A, Esse Emme S.r.l., and Fasanini S.r.l., located in Brescia, Italy. The authors would like to thank these companies for their selfless contribution of data and materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Eurostat. Generation of Waste by Economic Activity. Available online: https://ec.europa.eu/eurostat/databrowser/view/ten00106/default/table?lang=en (accessed on 9 November 2020).

- ISPRA. Rapporto Rifiuti Speciali 2020; Istituto Superiore per la Protezione e la Ricerca: Rome, Italy, 2020.

- Legambiente. Rapporto Cave 2021; Legambiente: Rome, Italy, 2021. [Google Scholar]

- Vázquez, E. Recycled Aggregates for Concrete: Problems and Possible Solutions. Int. J. Earth Environ. Sci. 2016, 1. [Google Scholar] [CrossRef] [PubMed]

- Cabrera, M.; Galvín, A.P.; Agrela, F. Leaching issues in recycled aggregate concrete. In New Trends in Eco Effic. and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 329–356. ISBN 9780081024805. [Google Scholar]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- López-Uceda, A.; Galvín, A.P.; Ayuso, J.; Jiménez, J.R.; Vanwalleghem, T.; Peña, A. Risk assessment by percolation leaching tests of extensive green roofs with fine fraction of mixed recycled aggregates from construction and demolition waste. Environ. Sci. Pollut. Res. 2018, 25, 36024–36034. [Google Scholar] [CrossRef] [PubMed]

- Butera, S.; Christensen, T.H.; Astrup, T.F. Composition and leaching of construction and demolition waste: Inorganic elements and organic compounds. J. Hazard. Mater. 2014, 276, 302–311. [Google Scholar] [CrossRef]

- Villoria Sáez, P.; Osmani, M.; Saez, P.V.; Hengl, I. Recovery Technologies for Construction and Demolition Waste. 2018. Available online: https://www.minea-network.eu/upload/D11Report.pdf (accessed on 5 July 2021).

- Kijjanapanich, P.; Annachhatre, A.P.; Esposito, G.; Van Hullebusch, E.D.; Lens, P.N. Biological sulfate removal from gypsum contaminated construction and demolition debris. J. Environ. Manag. 2013, 131, 82–91. [Google Scholar] [CrossRef]

- Cilli, E.; Bruneaux, M.A.; Chateau, L.; Lucatelli, J.M.; Peyratout, C.; Smith, A. Cleanliness of Mixed Fired Clay Bricks Coming from Construction and Demolition Waste. Waste Biomass Valorization 2017, 8, 2177–2185. [Google Scholar] [CrossRef]

- Engelsen, C.J. Leaching performance of recycled aggregates. In Advances in Construction and Demolition Waste Recycling; Elsevier: Amsterdam, The Netherlands, 2020; pp. 439–451. [Google Scholar]

- Diotti, A.; Galvin, A.P.; Piccinali, A.; Plizzari, G.; Sorlini, S. Chemical and Leaching Behavior of Construction and Demolition Wastes and Recycled Aggregates. Sustainability 2020, 12, 326. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, Y. The contents and release behavior of heavy metals in construction and demolition waste used in freeway construction. Environ. Sci. Pollut. Res. 2019, 27, 1078–1086. [Google Scholar] [CrossRef] [PubMed]

- Głuchowski, A.; Sas, W.; Dzięcioł, J.; Soból, E.; Szymański, A. Permeability and Leaching Properties of Recycled Concrete Aggregate as an Emerging Material in Civil Engineering. Appl. Sci. 2018, 9, 81. [Google Scholar] [CrossRef]

- Maia, M.B.; De Brito, J.; Martins, I.M.; Silvestre, J.D. Toxicity of Recycled Concrete Aggregates: Review on Leaching Tests. Open Constr. Build. Technol. J. 2018, 12, 187–196. [Google Scholar] [CrossRef]

- Lidelöw, S.; Mácsik, J.; Carabante, I.; Kumpiene, J. Leaching behaviour of copper slag, construction and demolition waste and crushed rock used in a full-scale road construction. J. Environ. Manag. 2017, 204, 695–703. [Google Scholar] [CrossRef]

- Galvín, A.P.; Ayuso, J.; Barbudo, A.; Cabrera, M.; López-Uceda, A.; Rosales, J. Upscaling the pollutant emission from mixed recycled aggregates under compaction for civil applications. Environ. Sci. Pollut. Res. 2017, 25, 36014–36023. [Google Scholar] [CrossRef]

- Devia, Y.P.; Suryo, E.A. Leachate of Demolition Waste. MATEC Web Conf. 2017, 138. [Google Scholar] [CrossRef][Green Version]

- Del Rey, I.; Ayuso, J.; Galvín, A.; Jiménez, J.R.; López, M.; García-Garrido, M. Analysis of chromium and sulphate origins in construction recycled materials based on leaching test results. Waste Manag. 2015, 46, 278–286. [Google Scholar] [CrossRef]

- Chen, J.; Tinjum, J.M.; Edil, T.B. Leaching of Alkaline Substances and Heavy Metals from Recycled Concrete Aggregate Used as Unbound Base Course. Transp. Res. Rec. J. Transp. Res. Board 2013, 2349, 81–90. [Google Scholar] [CrossRef]

- DeLay, M.; Lager, T.; Schulz, H.D.; Frimmel, F.H. Comparison of leaching tests to determine and quantify the release of inorganic contaminants in demolition waste. Waste Manag. 2007, 27, 248–255. [Google Scholar] [CrossRef] [PubMed]

- Ng, S.; Engelsen, C.J. Construction and demolition wastes. In Waste and Supplementary Cementitious Materials in Concrete: Characterisation, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 229–255. ISBN 9780081021569. [Google Scholar]

- Park, J.; Lee, J.; Chung, C.-W.; Wang, S.; Lee, M. Accelerated Carbonation of Recycled Aggregates Using the Pressurized Supercritical Carbon Dioxide Sparging Process. Minerals 2020, 10, 486. [Google Scholar] [CrossRef]

- Moreno-Pérez, E.; Hernández-Ávila, J.; Rangel-Martínez, Y.; Cerecedo-Sáenz, E.; Arenas-Flores, A.; Reyes-Valderrama, M.I.; Salinas-Rodriguez, E. Chemical and Mineralogical Characterization of Recycled Aggregates from Construction and Demolition Waste from Mexico City. Minerals 2018, 8, 237. [Google Scholar] [CrossRef]

- Thai, H.N.; Kato, A.; Giang Nguyen, H.; Nguyen, T.D.; Tong, T.K.; Nguyen, V.T.; Uchimura, T.; Maki, T.; Kawamoto, K. Effects Of Particle Size And Type Of Aggregate On Mechanical Properties And Environmental Safety Of Unbound Road Base And Subbase Materials: A Literature Review. Int. J. Geomate 2021, 20, 148–157. [Google Scholar] [CrossRef]

- Saca, N.; Dimache, A.; Radu, L.R.; Iancu, I. Leaching behavior of some demolition wastes. J. Mater. Cycles Waste Manag. 2015, 19, 623–630. [Google Scholar] [CrossRef]

- Abbaspour, A.; Tanyu, B.F.; Cetin, B. Impact of aging on leaching characteristics of recycled concrete aggregate. Environ. Sci. Pollut. Res. 2016, 23, 20835–20852. [Google Scholar] [CrossRef] [PubMed]

- Rémond, S.; Mechling, J.M.; Trauchessec, R.; Garcia-Diaz, E.; Lavaud, R.; Cazacliu, B. Characterization of recycled concrete aggregates. In Concrete Recycling; CRC Press: Boca Raton, FL, USA, 2019; pp. 33–60. [Google Scholar]

- Engelsen, C.J.; van der Sloot, H.A.; Petkovic, G. Long-term leaching from recycled concrete aggregates applied as sub-base material in road construction. Sci. Total. Environ. 2017, 587–588, 94–101. [Google Scholar] [CrossRef]

- Engelsen, C.J.; van der Sloot, H.A.; Wibetoe, G.; Petkovic, G.; Stoltenberg-Hansson, E.; Lund, W. Release of major elements from recycled concrete aggregates and geochemical modelling. Cem. Concr. Res. 2009, 39, 446–459. [Google Scholar] [CrossRef]

- Coudray, C.; Amant, V.; Cantegrit, L.; Le Bocq, A.; Thery, F.; Denot, A.; Eisenlohr, L. Influence of Crushing Conditions on Recycled Concrete Aggregates (RCA) Leaching Behaviour. Waste Biomass Valorization 2017, 8, 2867–2880. [Google Scholar] [CrossRef]

- Nurhanim, A.A.; Norli, I.; Morad, N.; Khalil, H.P.S.A. Leaching Behavior of Construction and Demolition Waste (Concrete and Gypsum). Iran. J. Energy Environ. 2016, 7, 2079–2115. [Google Scholar] [CrossRef]

- Galvín, A.P.; Ayuso, J.; García, I.; Jiménez, J.R.; Gutiérrez, F. The effect of compaction on the leaching and pollutant emission time of recycled aggregates from construction and demolition waste. J. Clean. Prod. 2014, 83, 294–304. [Google Scholar] [CrossRef]

- Frías, M.; Sánchez De Rojas, M.I. Total and soluble chromium, nickel and cobalt content in the main materials used in the manufacturing of Spanish commercial cements. Cem. Concr. Res. 2002, 32, 435–440. [Google Scholar] [CrossRef]

- Galvín, A.; Agrela, F.; Ayuso, J.; Beltrán, M.; Barbudo, M.A. Leaching assessment of concrete made of recycled coarse aggregate: Physical and environmental characterisation of aggregates and hardened concrete. Waste Manag. 2014, 34, 1693–1704. [Google Scholar] [CrossRef] [PubMed]

- Reis, G.; Quattrone, M.; Ambrós, W.; Cazacliu, B.G.; Sampaio, C.H. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef]

- Agrela, F.; Díaz-López, J.; Rosales, J.; Cuenca-Moyano, G.; Cano, H.; Cabrera, M. Environmental assessment, mechanical behavior and new leaching impact proposal of mixed recycled aggregates to be used in road construction. J. Clean. Prod. 2021, 280, 124362. [Google Scholar] [CrossRef]

- López-Uceda, A.; Galvín, A.P.; Barbudo, A.; Ayuso, J. Long-term leaching and mechanical behaviour at recycled aggregate with different gypsum contents. Environ. Sci. Pollut. Res. 2019, 26, 35565–35573. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M. Use of Mixed Construction and Demolition Recycled Materials in Geosynthetic Reinforced Embankments. Indian Geotech. J. 2017, 48, 279–292. [Google Scholar] [CrossRef]

- Vegas, I.; Broos, K.; Nielsen, P.; Lambertz, O.; Lisbona, A. Upgrading the quality of mixed recycled aggregates from construction and demolition waste by using near-infrared sorting technology. Constr. Build. Mater. 2015, 75, 121–128. [Google Scholar] [CrossRef]

- Galvin, A.P.; Ayuso, J.; Agrela, F.; Barbudo, A.; Jiménez, J.R. Analysis of leaching procedures for environmental risk assessment of recycled aggregate use in unpaved roads. Constr. Build. Mater. 2013, 40, 1207–1214. [Google Scholar] [CrossRef]

- Barbudo, A.; Galvin, A.P.; Agrela, F.; Ayuso, J.; Jiménez, J.R. Correlation analysis between sulphate content and leaching of sulphates in recycled aggregates from construction and demolition wastes. Waste Manag. 2012, 32, 1229–1235. [Google Scholar] [CrossRef] [PubMed]

- Müllauer, W.; Beddoe, R.E.; Heinz, D. Leaching behaviour of major and trace elements from concrete: Effect of fly ash and GGBS. Cem. Concr. Compos. 2015, 58, 129–139. [Google Scholar] [CrossRef]

- Estokova, A.; Palaščáková, L.; Kanuchova, M. Study on Cr(VI) Leaching from Cement and Cement Composites. Int. J. Environ. Res. Public Health 2018, 15, 824. [Google Scholar] [CrossRef] [PubMed]

- Sinyoung, S.; Songsiriritthigul, P.; Asavapisit, S.; Kajitvichyanukul, P. Chromium behavior during cement-production processes: A clinkerization, hydration, and leaching study. J. Hazard. Mater. 2011, 191, 296–305. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, F.; Carvalho, M.T.; Evangelista, L.; de Brito, J. Physical-chemical and mineralogical characterization of fine aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2013, 52, 438–445. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B. Carbonation based leaching assessment of recycled concrete aggregates. Chemosphere 2020, 250, 126307. [Google Scholar] [CrossRef]

- Bestgen, J.O.; Hatipoglu, M.; Cetin, B.; Aydilek, A.H. Mechanical and Environmental Suitability of Recycled Concrete Aggregate as a Highway Base Material. J. Mater. Civ. Eng. 2016, 28, 04016067. [Google Scholar] [CrossRef]

- Bianchini, G.; Ristovski, I.; Milcov, I.; Zupac, A.; Natali, C.; Salani, G.M.; Marchina, C.; Brombin, V.; Ferraboschi, A. Chemical Characterisation of Construction and Demolition Waste in Skopje City and Its Surroundings (Republic of Macedonia). Sustainability 2020, 12, 2055. [Google Scholar] [CrossRef]

- Zhang, Y.-B.; Chen, J.-N.; Ginder-Vogol, M.; Edil, T.B. Effect of pH and Grain Size on the Leaching Mechanism of Elements from Recycled Concrete Aggregate. In Proceedings of the GeoShanghai 2018 International Conference: Geoenvironment and Geohazard, Shanghai, China, 27–30 May 2018; Springer: Singapore, 2018; pp. 325–334. [Google Scholar]

- Gupta, N.; Kluge, M.; Chadik, P.A.; Townsend, T.G. Recycled concrete aggregate as road base: Leaching constituents and neutralization by soil Interactions and dilution. Waste Manag. 2018, 72, 354–361. [Google Scholar] [CrossRef] [PubMed]

- Ministerial Decree 186/2006 Ministerial Decree 04/05/2006 n.186. Regolamento Recante Modifiche al Decreto Ministeriale 5 Febbraio 1998 “Individuazione dei Rifiuti Non Pericolosi Sottoposti alle Procedure Semplificate di Recupero, ai Sensi Degli Articoli 31 e 33 del Decreto Legislati. 2006. Available online: https://www.albonazionalegestoriambientali.it/Download/it/NormativaNazionale/015-DM186_05.04.2006.pdf (accessed on 5 July 2021).

- Bestgen, J.O.; Cetin, B.; Tanyu, B.F. Effects of extraction methods and factors on leaching of metals from recycled concrete aggregates. Environ. Sci. Pollut. Res. 2016, 23, 12983–13002. [Google Scholar] [CrossRef] [PubMed]

- Altamura, P. Costruire a Zero Rifiuti. Strategie e Strumenti per la Prevenzione e L’upcycling dei Materiali di Scarto In Edilizia; FrancoAngeli: Milan, Italy, 2015; ISBN 9788891725677. [Google Scholar]

- Chen, J.; Sanger, M.; Ritchey, R.; Edil, T.B.; Ginder-Vogel, M. Neutralization of high pH and alkalinity effluent from recycled concrete aggregate by common subgrade soil. J. Environ. Qual. 2020, 49, 172–183. [Google Scholar] [CrossRef]

- Vollpracht, A.; Brameshuber, W. Binding and leaching of trace elements in Portland cement pastes. Cem. Concr. Res. 2016, 79, 76–92. [Google Scholar] [CrossRef]

- Lu, H.; Wei, F.; Tang, J.; Giesy, J.P. Leaching of metals from cement under simulated environmental conditions. J. Environ. Manag. 2016, 169, 319–327. [Google Scholar] [CrossRef]

- Eštoková, A.; Palaščáková, L.; Singovszká, E.; Holub, M. Analysis of the chromium concentrations in cement materials. Procedia Eng. 2012, 42, 123–130. [Google Scholar] [CrossRef]

- Demars, S.; Benoit, G. Leaching of ANC and Chromium from Concrete: Effect of Aging Simulated by Sample Carbonation. Water Air Soil Pollut. 2019, 230, 159. [Google Scholar] [CrossRef]

- Puthussery, J.; Kumar, R.; Garg, A. Evaluation of recycled concrete aggregates for their suitability in construction activities: An experimental study. Waste Manag. 2017, 60, 270–276. [Google Scholar] [CrossRef]

- Engelsen, C.; Lund, O.; Breedveld, G.; Petkovic, G.; Håøya, A. Leaching Characteristic of Unbound Recycled Aggregates: Preliminary Study and Ongoing Research. 1998. Available online: https://www.vegvesen.no/siteassets/content/www.vegvesen.no/vedlegg-file/fag/fou/06-wascon-engelsen-preliminary-study-and-ongoing-research.pdf (accessed on 5 July 2021).

- Vu, Q.H. Modelling Pollutants Leaching from Recycled Construction Materials. Ph.D. Thesis, Queensland University of Technology, Brisbane, QLD, Canada, 2019. [Google Scholar]

- Jansen Mikami, R.; Carolina, A.; Kummer, B.; Magdalena, M.; Döll, R. Leaching of Pervious Concrete Produced Using Mixed Recycled Aggregates. Braz. Arch. Biol. Technol. 2020, 63, e20180408. [Google Scholar] [CrossRef]

- Melendez, B.A. A Study of Leachate Generated from Construction and Demolition Landfills. Master’s Thesis, Naval Postgraduate University, Monterey, CA, USA, 1996. [Google Scholar]

- Schmukat, A.; Duester, L.; Ecker, D.; Schmid, H.; Heil, C.; Heininger, P.; Ternes, T. Leaching of metal(loid)s from a construction material: Influence of the particle size, specific surface area and ionic strength. J. Hazard. Mater. 2012, 227–228, 257–264. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).