STEP-NC Compliant Intelligent CNC Milling Machine with an Open Architecture Controller

Abstract

:1. Introduction

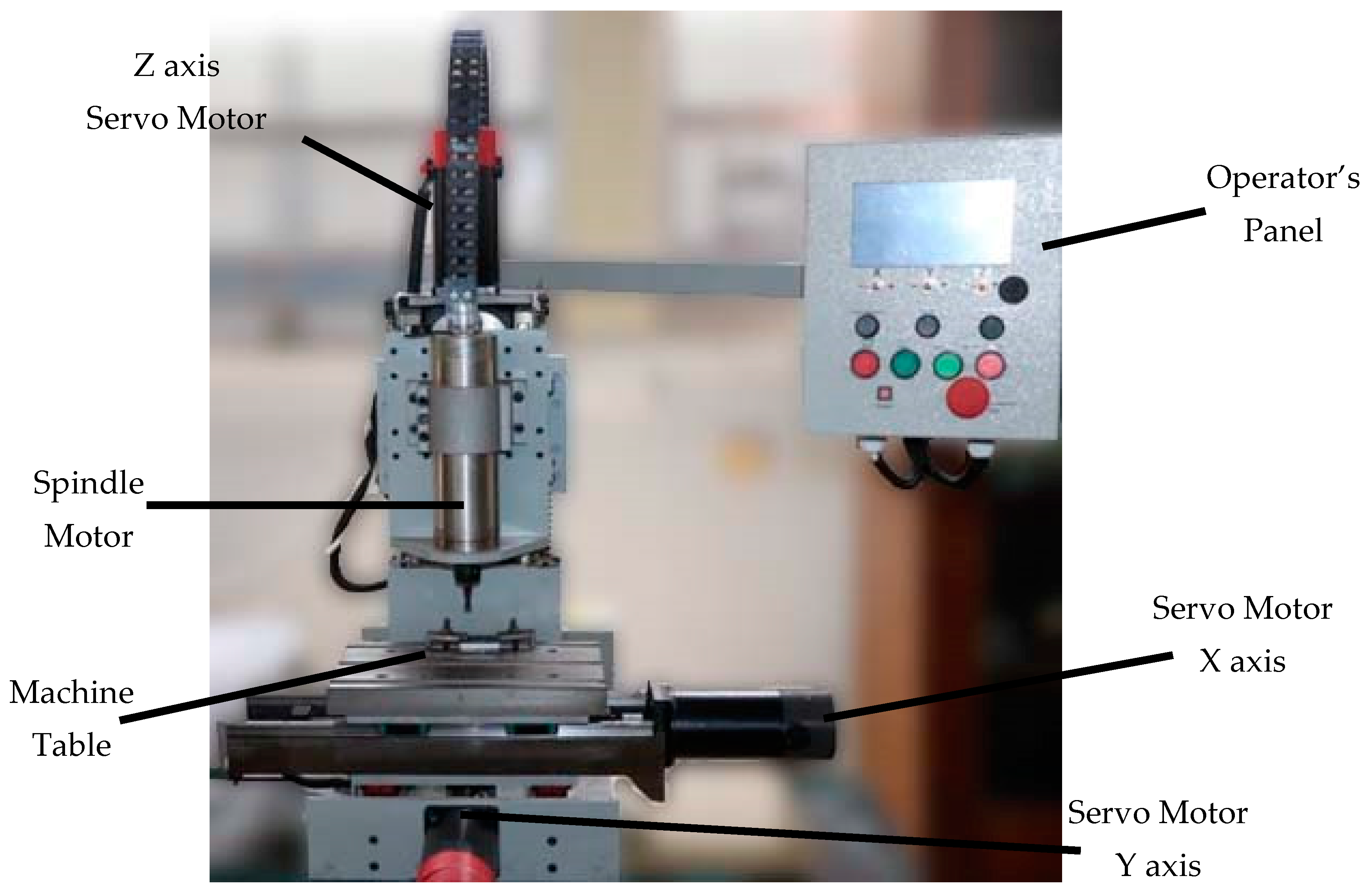

2. Hardware Development

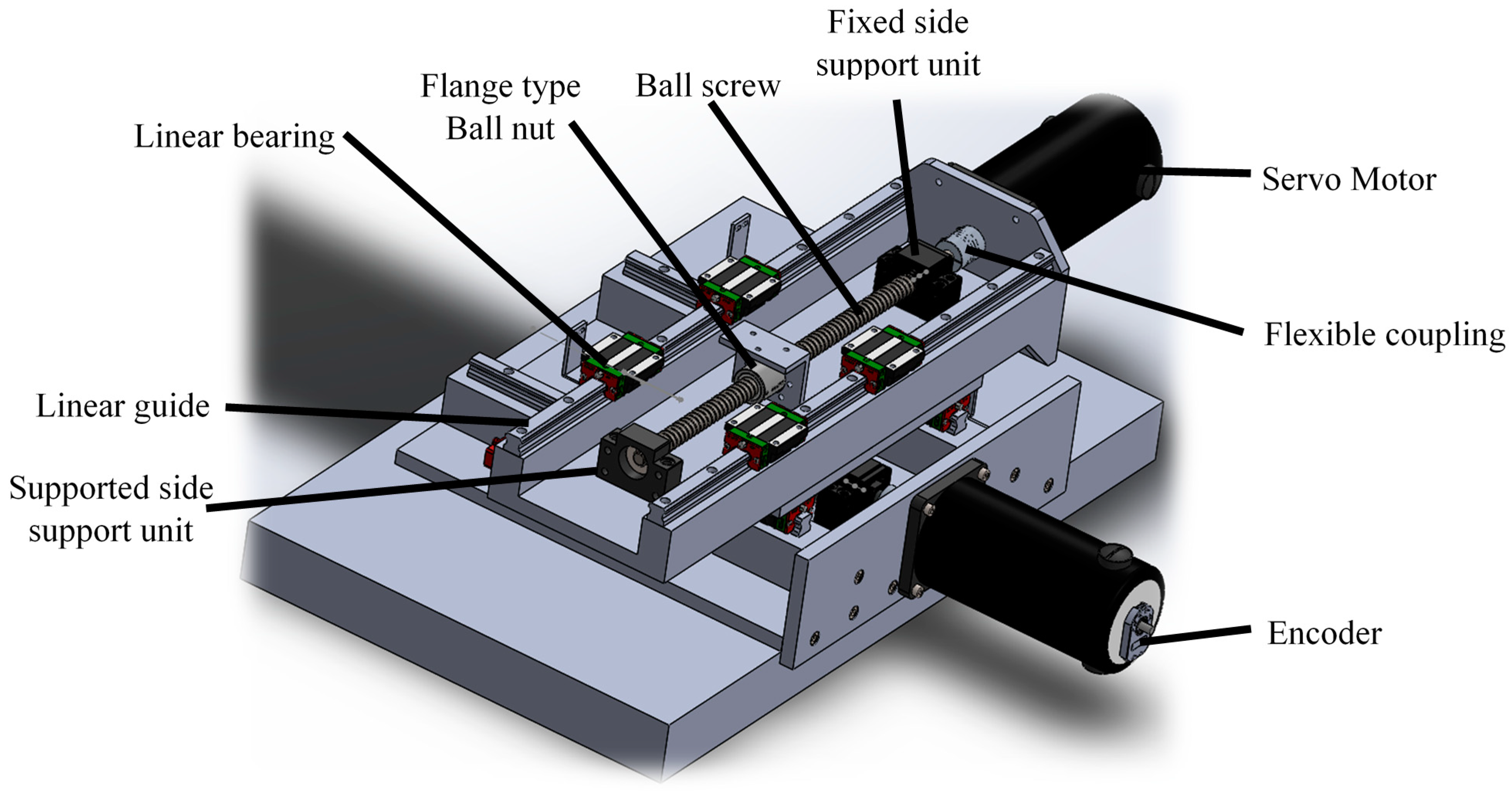

2.1. Mechanical System

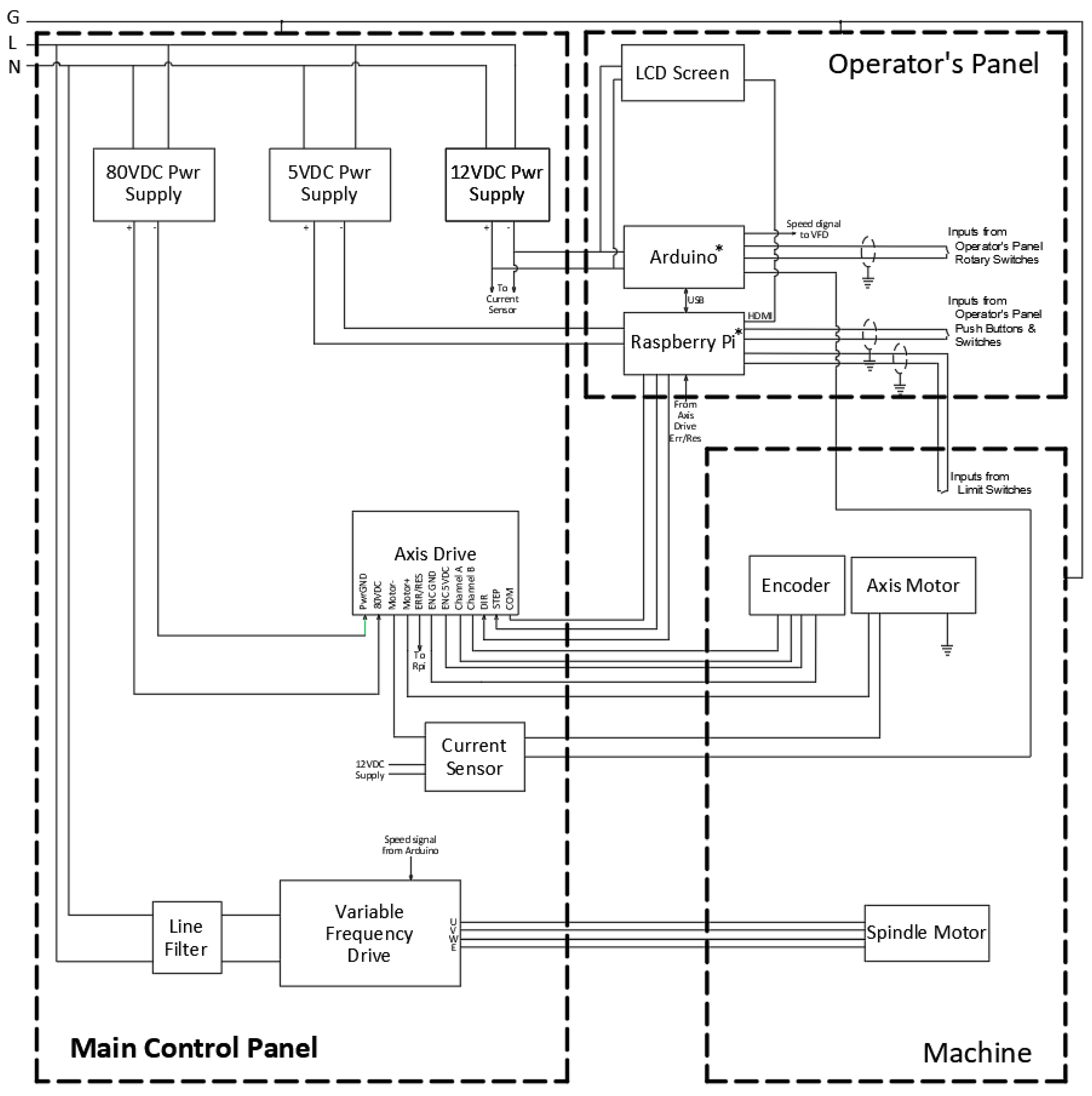

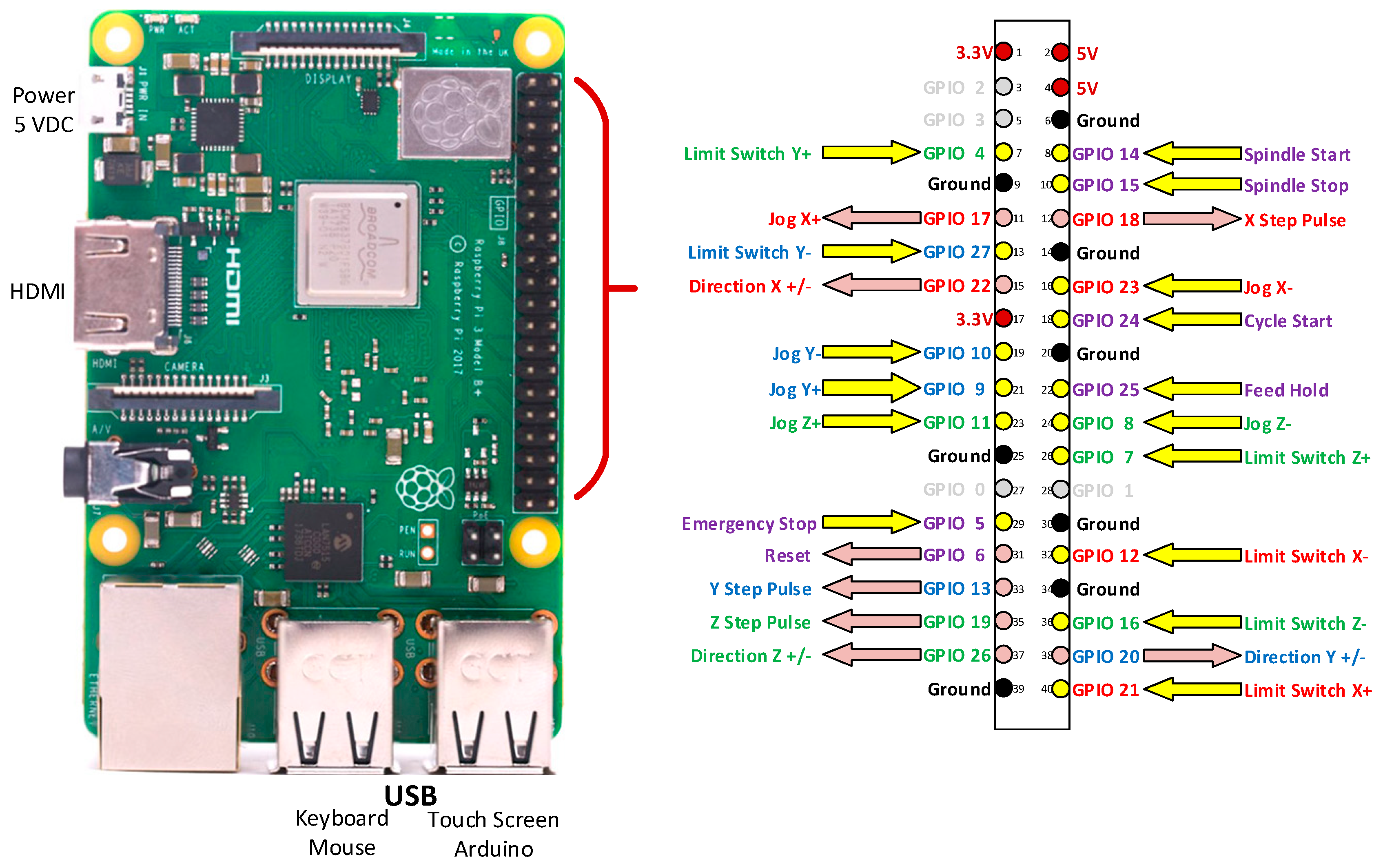

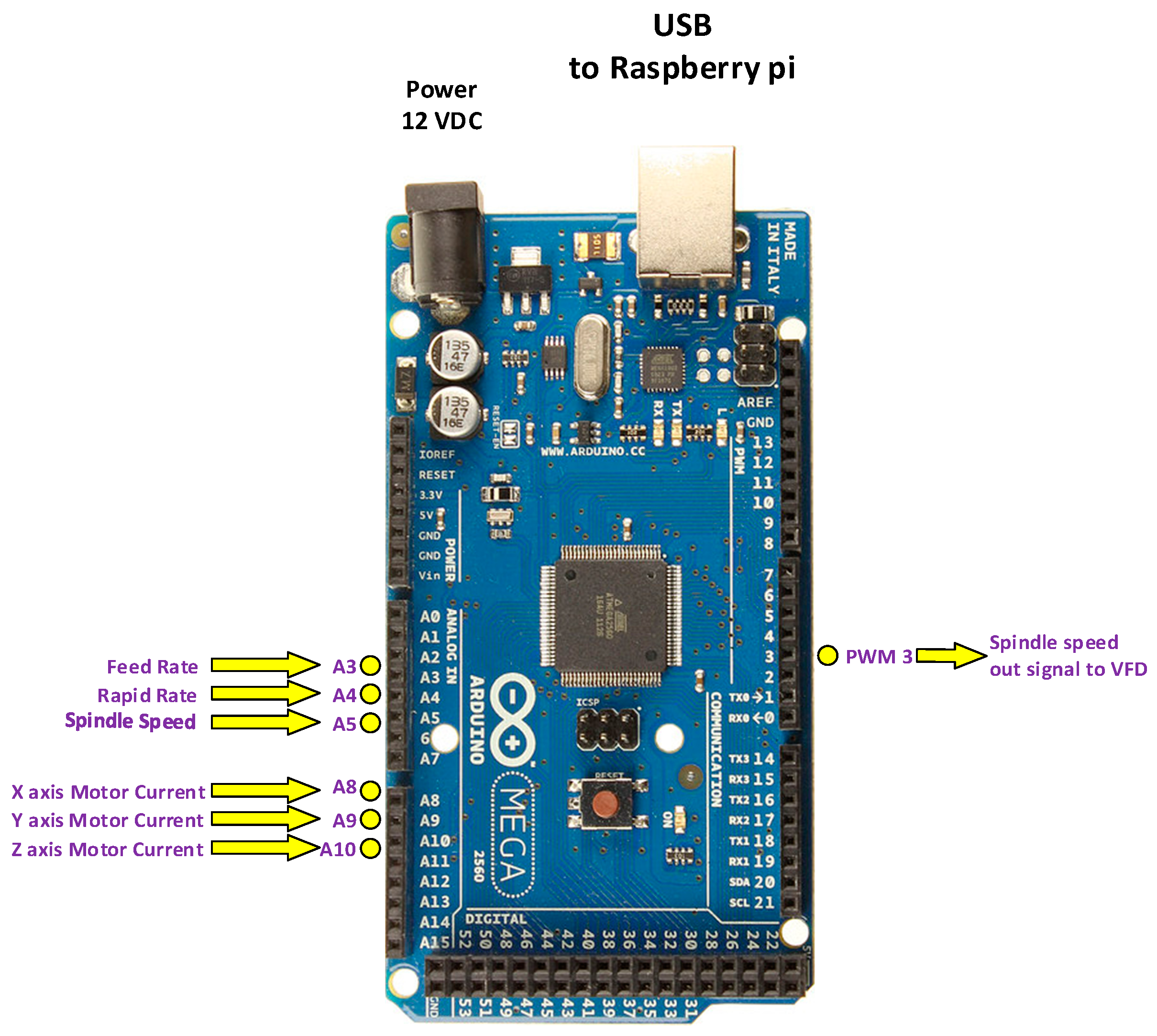

2.2. Electrical System

2.2.1. Operator’s Panel

2.2.2. Main Control Panel

2.2.3. Servo Motor and Encoder

2.2.4. Spindle Motor Control

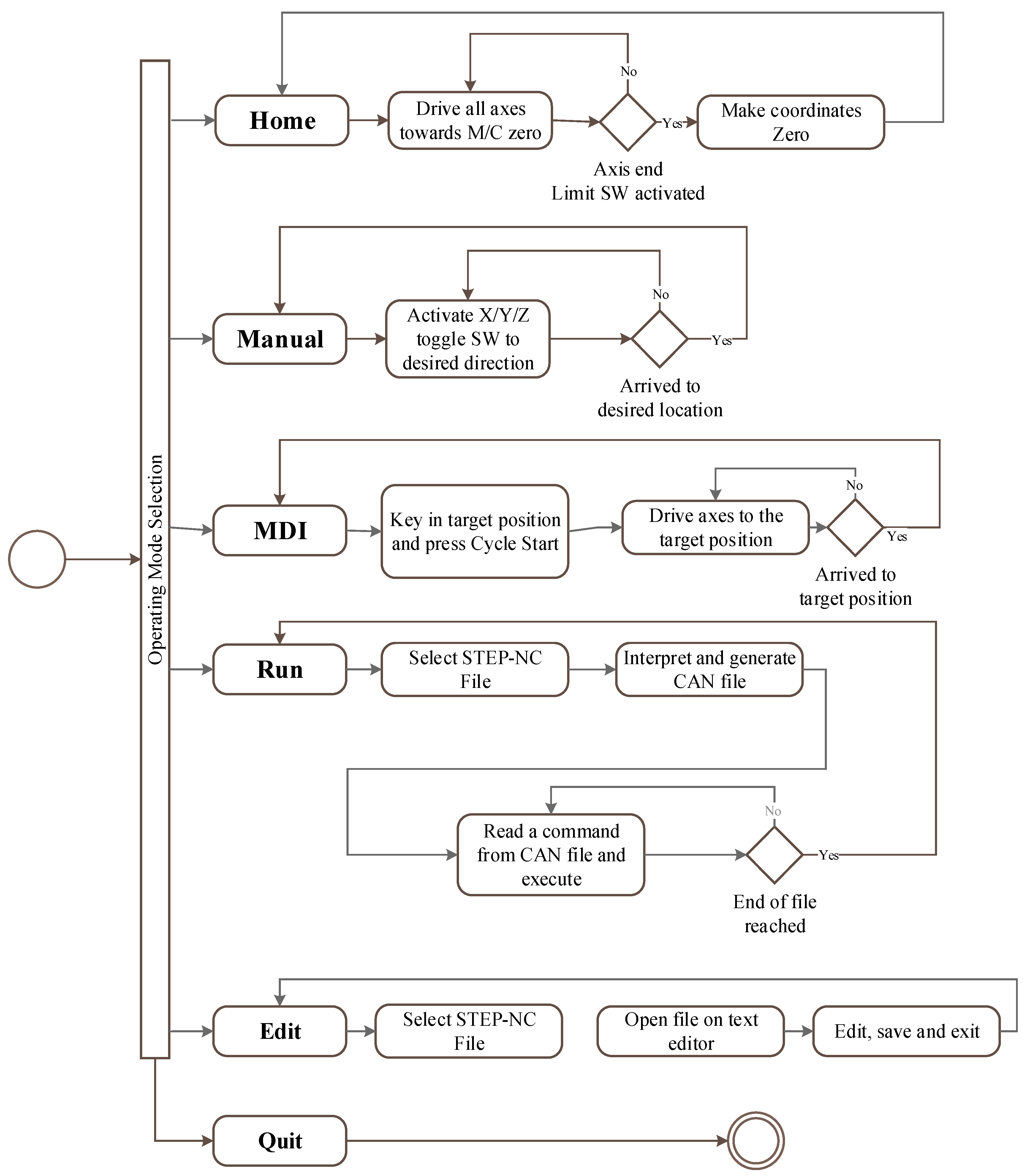

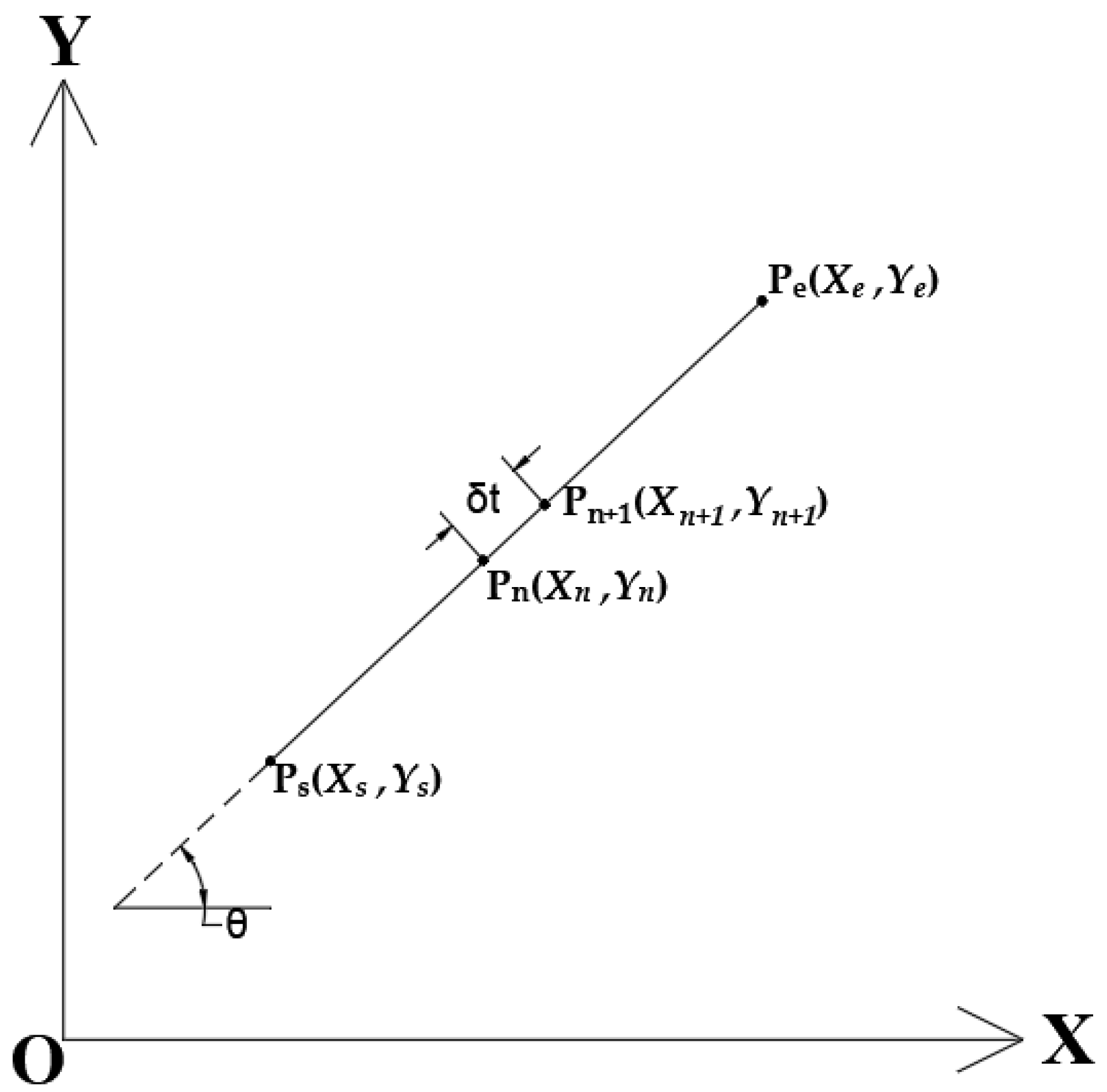

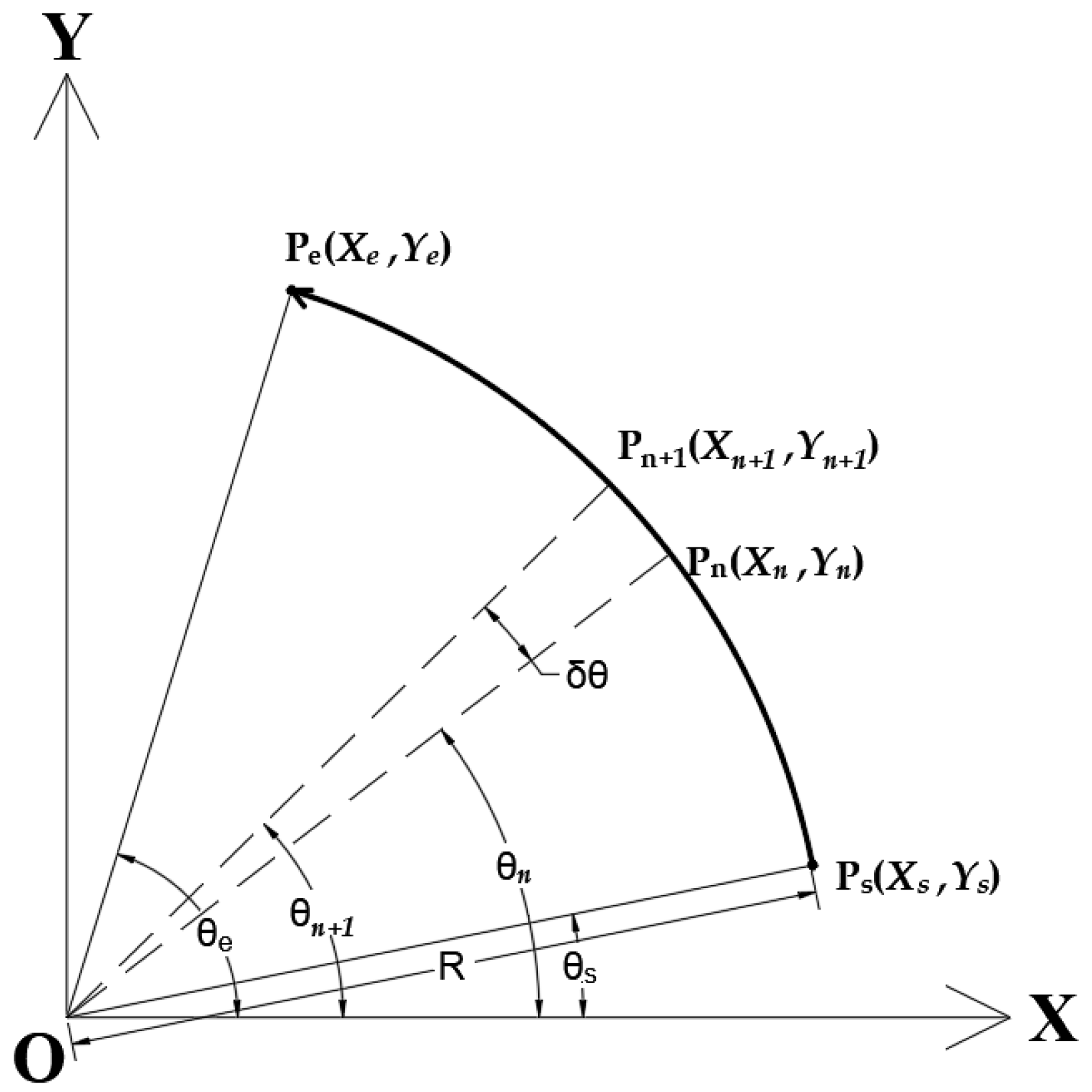

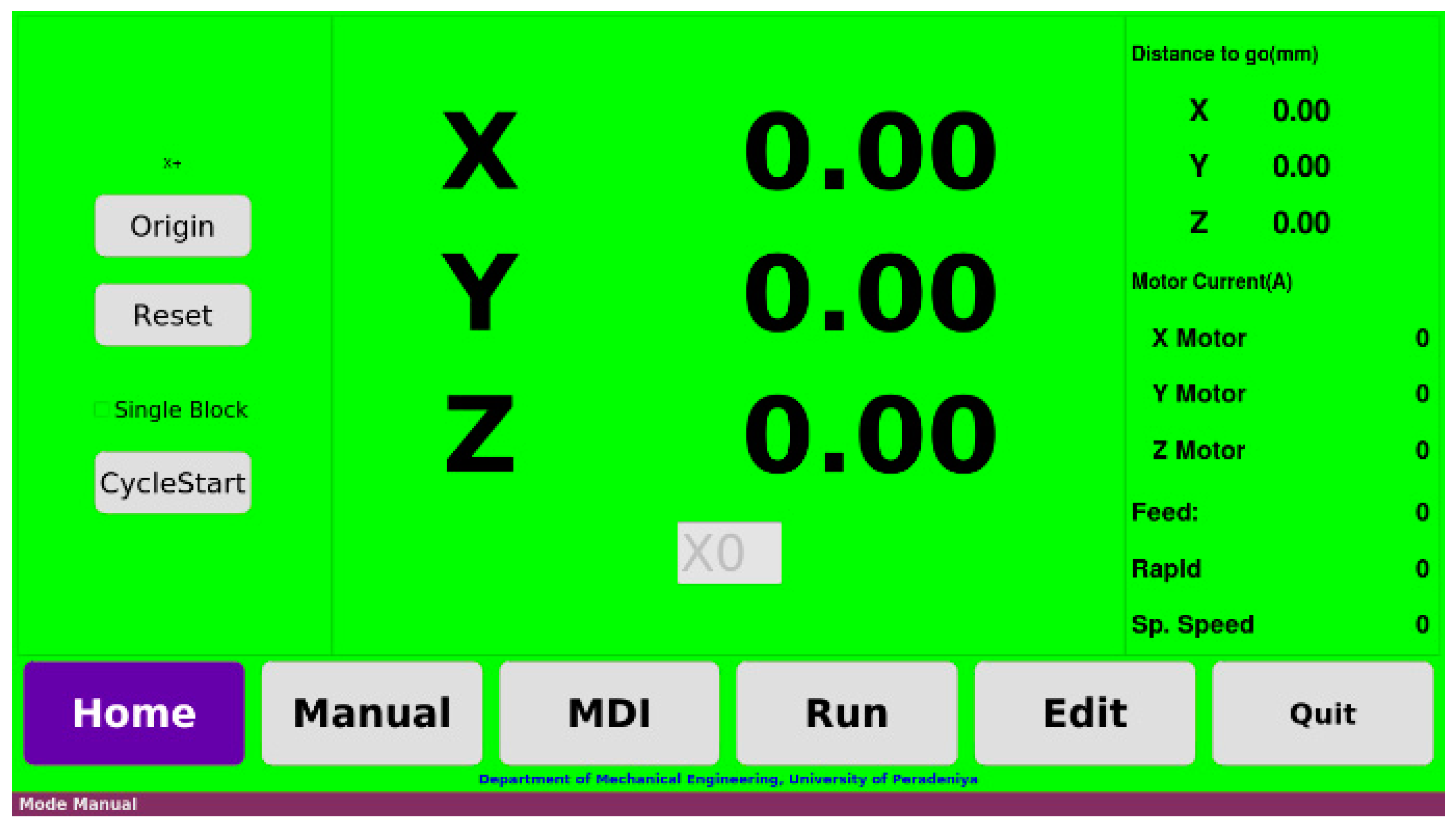

3. Software Development

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Organization for Standardization. ISO 6983-1:2009 Automation Systems and Integration—Numerical Control of Machines—Program Format and Definitions of Address Words—Part 1: Data Format for Positioning, Line Motion and Contouring Control Systems; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Latif, K.; Yusof, Y.; Nassehi, A.; Latif, Q.B.A.I. Development of a feature-based open soft-CNC system. Int. J. Adv. Manuf. Technol. 2016, 89, 1013–1024. [Google Scholar] [CrossRef] [Green Version]

- Othman, M.; Minhat, M.; Jamaludin, Z. An overview on STEP-NC compliant controller development. IOP Conf. Ser. Mater. Sci. Eng. 2017, 257, 12048. [Google Scholar] [CrossRef] [Green Version]

- International Organization for Standardization. ISO 14649-11:2004 Industrial Automation Systems and Integration—Physical Device Control—Data Model for Computerized Numerical Controllers—Part 11: Process Data for Milling; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Xu, X.; Newman, S. Making CNC machine tools more open, interoperable and intelligent—A review of the technologies. Comput. Ind. 2006, 57, 141–152. [Google Scholar] [CrossRef]

- Ma, X.-B.; Han, Z.-Y.; Wang, Y.-Z.; Fu, H.-Y. Development of a PC-based Open Architecture Software-CNC System. Chin. J. Aeronaut. 2007, 20, 272–281. [Google Scholar] [CrossRef] [Green Version]

- Brecher, C.; Verl, A.; Lechler, A.; Servos, M. Open control systems: State of the art. Prod. Eng. 2010, 4, 247–254. [Google Scholar] [CrossRef]

- Pritschow, G.; Altintas, Y.; Jovane, F.; Koren, Y.; Mitsuishi, M.; Takata, S.; Van Brussel, H.; Weck, M.; Yamazaki, K. Open Controller Architecture–Past, Present and Future. CIRP Ann. 2001, 50, 463–470. [Google Scholar] [CrossRef]

- Katz, R.; Min, B. Open architecture control technology trends. ERC/RMS Rep. 2000, 35, 1–29. [Google Scholar]

- Asato, O.L.; Kato, E.R.R.; Inamasu, R.Y.; Porto, A.J.V. Analysis of open CNC architecture for machine tools. J. Braz. Soc. Mech. Sci. 2002, 24, 208–212. [Google Scholar] [CrossRef]

- Yusof, Y.; Latif, K. New technique for the interpretation of ISO 14649 and 6983 based on open CNC technology. Int. J. Comput. Integr. Manuf. 2015, 29, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Elias, D.; Yusof, Y.; Minhat, M. An Open STEP-NC Controller via LabVIEW Platform. Appl. Mech. Mater. 2014, 660, 873–877. [Google Scholar] [CrossRef] [Green Version]

- Yusof, Y.; Latif, K. Frame Work of LV-UTHM: AN I S 0 14649 Based Open Control System for CNC Milling Machine. Appl. Mech. Mater. 2013, 330, 619–624. [Google Scholar] [CrossRef] [Green Version]

- Latif, K.; Yusof, Y. New Method for the Development of Sustainable STEP-Compliant Open CNC System. Procedia CIRP 2016, 40, 230–235. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.S.; Bang, Y.B. Development of ISO14649 Compliant CNC Milling Machine Operated by STEP-NC in XML Format. Int. J. KSPE 2009, 5, 5–7. [Google Scholar]

- Calabrese, F.; Celentano, G. Design and realization of a STEP-NC compliant CNC embedded controller. In Proceedings of the 2007 IEEE Conference on Emerging Technologies & Factory Automation (EFTA 2007), Patras, Greece, 25–28 September 2007. [Google Scholar]

- Xu, X.-M.; Li, Y.; Sun, J.-H.; Wang, S.-G. Research and Development of Open CNC System Based on PC and Motion Controller. Procedia Eng. 2012, 29, 1845–1850. [Google Scholar] [CrossRef] [Green Version]

- Elias, D.; Yusof, Y.; Minhat, M. CNC machine system via STEP-NC data model and LabVIEW platform for Milling operation. In Proceedings of the 2013 IEEE Conference on Open Systems (ICOS), Kuching, Malaysia, 2–4 December 2013; pp. 27–31. [Google Scholar]

- Narayanan, A.; Kanyuck, A.; Gupta, S.K.; Rachuri, S. Machine Condition Detection for Milling Operations Using Low Cost Ambient Sensors. In Proceedings of the International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016. [Google Scholar]

- Downey, J.; O’Sullivan, D.; Nejmen, M.; Bombiński, S.; O’Leary, P.; Raghavendra, R.; Jemielniak, K. Real Time Monitoring of the CNC Process in a Production Environment- the Data Collection & Analysis Phase. Procedia CIRP 2016, 41, 920–926. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Lu, X.; Wang, S.; Wang, W.; Li, W. A multi-sensor based online tool condition monitoring system for milling process. Procedia CIRP 2018, 72, 1136–1141. [Google Scholar] [CrossRef]

- Mikolajczyk, T. Numerical Control System of Conventional Milling Machine. Appl. Mech. Mater. 2016, 841, 179–183. [Google Scholar] [CrossRef]

- Wazir, S.; Mujahid, U.; Imran, H.A.; Bilal, M.; Latif, U. Single Board Computers (SBC): The Future of Next Generation Pedagogies in Pakistan. arXiv 2020, arXiv:2008.06576. [Google Scholar]

- Grigoriev, S.N.; Martinov, G. An ARM-based Multi-channel CNC Solution for Multi-tasking Turning and Milling Machines. Procedia CIRP 2016, 46, 525–528. [Google Scholar] [CrossRef] [Green Version]

- Wagner, C. Raspberry Pi CNC Controller. Available online: https://www.youtube.com/watch?v=qL530kJUmII&t=26s (accessed on 10 May 2021).

- Winegarner, T. Raspberry Pi CNC Controller. Available online: https://www.youtube.com/watch?app=desktop&v=u35L0jGCqFc (accessed on 10 May 2021).

- Ballard, R. Raspberry Pi CNC Build. Available online: https://www.youtube.com/watch?v=a7UodK7AxeQ (accessed on 10 May 2021).

- Uriarte, L.; Azcárate, S.; Herrero, A.; Lamikiz, A.; De Lacalle, L.N.L. Mechanistic modelling of the micro end milling operation. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 23–33. [Google Scholar] [CrossRef]

- Lamikiz, A.; De Lacalle, L.N.L.; Sanchez, J.A.; Salgado, M.A. Cutting force integration at the CAM stage in the high-speed milling of complex surfaces. Int. J. Comput. Integr. Manuf. 2005, 18, 586–600. [Google Scholar] [CrossRef]

- Díaz-Tena, E.; Ugalde, U.; De Lacalle, L.N.L.; De La Iglesia, A.; Calleja-Ochoa, A.; Campa, F.J. Propagation of assembly errors in multitasking machines by the homogenous matrix method. Int. J. Adv. Manuf. Technol. 2013, 68, 149–164. [Google Scholar] [CrossRef]

- Gomez-Acedo, E.; Olarra, A.; de la Calle, L.N.L. A method for thermal characterization and modeling of large gantry-type machine tools. Int. J. Adv. Manuf. Technol. 2012, 62, 875–886. [Google Scholar] [CrossRef]

- Dhayaneswaran, Y.; Murthy, K.V.; Balamurugan, R. Review on Influence of Electrical Noise on Field Elements. In Proceedings of the 2011 International Conference on Process Automation, Control and Computing, Coimbatore, India, 20–22 July 2011; pp. 1–5. [Google Scholar]

- Morinec, A.G. Power quality considerations for CNC machines: Grounding. In Proceedings of the Annual Meeting Industrial and Commercial Power Systems Technical Conference, Clearwater, FL, USA, 7–11 May 2000; pp. 7–14. [Google Scholar]

- Zhao, Y.F.; Habeeb, S.; Xu, X. Research into integrated design and manufacturing based on STEP. Int. J. Adv. Manuf. Technol. 2009, 44, 606–624. [Google Scholar] [CrossRef]

- Xú, S.; Anwer, N.; Lavernhe, S. Conversion of G-Code Programs for Milling into STEP-NC. In Proceedings of the International Joint Conference on Mechanics, Design Engineering and Advanced Manufacturing, Toulouse, France, 2–4 June 2014. [Google Scholar]

- Suh, S.H.; Kang, S.K.; Chung, D.H.; Stroud, I. Theory and Design of CNC System; Springer Science & Business Media: New York, NY, USA, 2008. [Google Scholar]

- Tsai, M.C.; Cheng, M.C.; Lin, K.U.; Tsai, N.C. On acceleration/deceleration before interpolation for CNC motion control. In Proceedings of the IEEE International Conference on Mechatronics, Taipei, Taiwan, 10–12 July 2005; pp. 382–387. [Google Scholar]

- Altintas, Y. Manufacturing Automation; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Pollefliet, J. Current -, Angular Position -, Speed Transducers. Power Electron. 2018, 18.1–18.34. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 230-2:2014 Test Code for Machine Tools—Part 2: Determination of Accuracy and Repeatability of Positioning of Numerically Controlled Axes; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Lamikiz, A.; Muñoa, J.; Sanchez, J.A. The CAM as the centre of gravity of the five-axis high speed milling of complex parts. Int. J. Prod. Res. 2005, 43, 1983–1999. [Google Scholar] [CrossRef]

- de Lacalle, L.L.; Lamikiz, A.; Muñoa, J.; Salgado, M.; Sanchez, J.A. Improving the high-speed finishing of forming tools for advanced high-strength steels (AHSS). Int. J. Adv. Manuf. Technol. 2006, 29, 49–63. [Google Scholar] [CrossRef]

- Lakner, T.; Hardt, M. A Novel Experimental Test Bench to Investigate the Effects of Cutting Fluids on the Frictional Conditions in Metal Cutting. J. Manuf. Mater. Process. 2020, 4, 45. [Google Scholar] [CrossRef]

| Item | Details |

|---|---|

| Main controller | Raspberry Pi 3B |

| Slave I/O module | Arduino Mega 2560 |

| Axis drive motor | DC servo, 1.6 Nm |

| x axis travel | 180 mm |

| y axis travel | 70 mm |

| z axis travel | 65 mm |

| Programmable feed rate | 0–600 mm/min |

| Worktable size | 220 × 320 mm |

| T-slot (Pitch × width × No.) | 65 mm × 10 mm × 3 mm |

| Programmable spindle speed | 60–12,000 rpm (continuously variable) |

| Spindle collet size | ER20 |

| Spindle motor | 2.2 kW AC induction, water cooled |

| Component | Details |

|---|---|

| Servo Motor | Brushed DC motor, KL34-180-90 |

| Axis Drive | Gecko Drive G320X |

| Encoder | CUI AMT102 |

| Power supply | 80VDC |

| Controller | Raspberry Pi 3 Model B+ |

| I/O Board | Arduino Mega 2560 |

| Spindle Motor | Three Phase, 2.2 kW, AC Induction Motor, RTM-80 |

| VFD | NowforEver E100 |

| Current Sensor | CZH-LABS D-1020 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dharmawardhana, M.; Ratnaweera, A.; Oancea, G. STEP-NC Compliant Intelligent CNC Milling Machine with an Open Architecture Controller. Appl. Sci. 2021, 11, 6223. https://doi.org/10.3390/app11136223

Dharmawardhana M, Ratnaweera A, Oancea G. STEP-NC Compliant Intelligent CNC Milling Machine with an Open Architecture Controller. Applied Sciences. 2021; 11(13):6223. https://doi.org/10.3390/app11136223

Chicago/Turabian StyleDharmawardhana, Mahanama, Asanga Ratnaweera, and Gheorghe Oancea. 2021. "STEP-NC Compliant Intelligent CNC Milling Machine with an Open Architecture Controller" Applied Sciences 11, no. 13: 6223. https://doi.org/10.3390/app11136223

APA StyleDharmawardhana, M., Ratnaweera, A., & Oancea, G. (2021). STEP-NC Compliant Intelligent CNC Milling Machine with an Open Architecture Controller. Applied Sciences, 11(13), 6223. https://doi.org/10.3390/app11136223