Effect of Design Parameters on Compressive and Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate: An Overview

Abstract

:1. Introduction

Research Significance

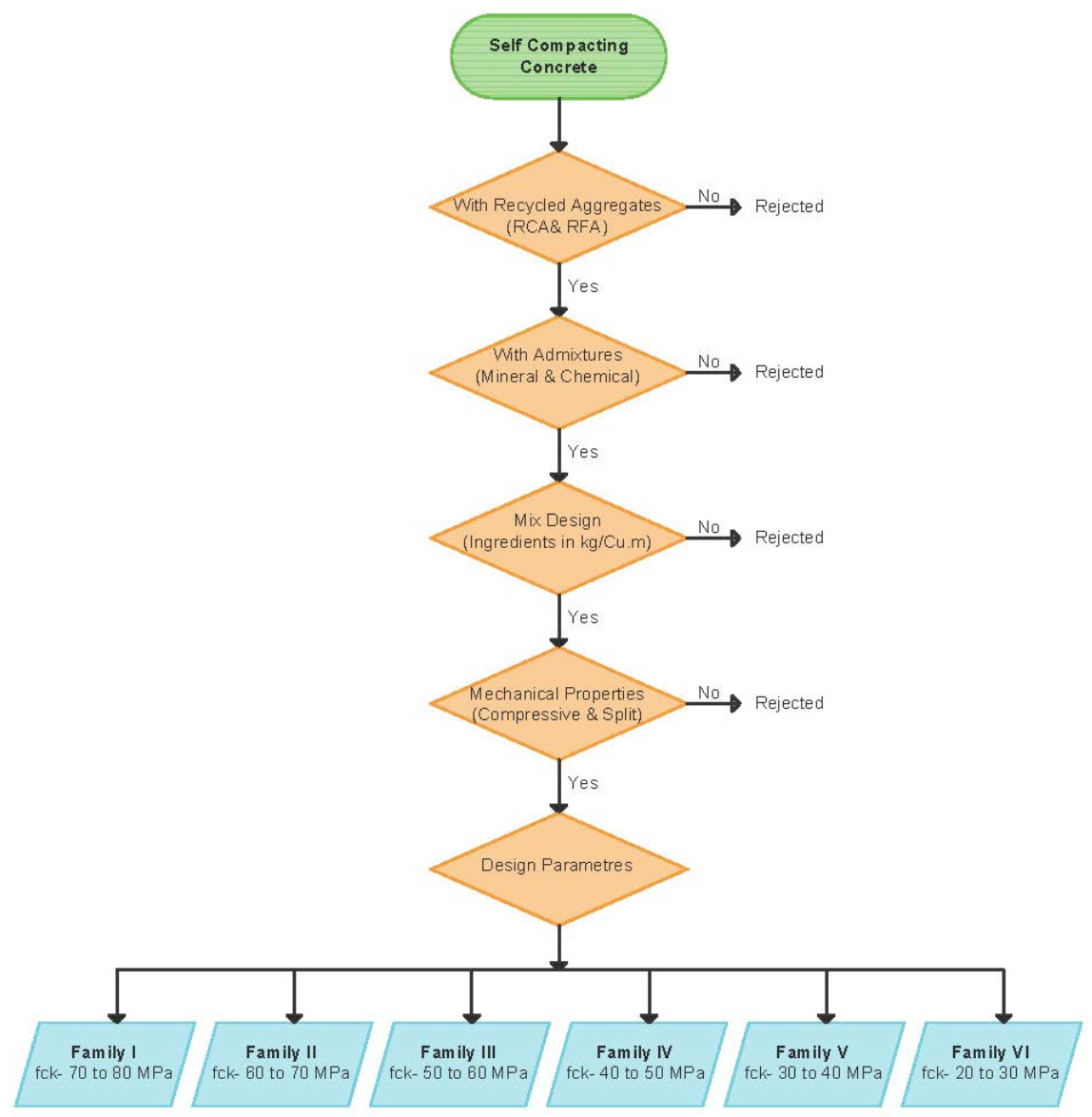

2. Review Methodology

2.1. Search Strategies

2.2. Data Extraction

3. Design Parameters from Literature

4. Effect of Design Parameters on Strength

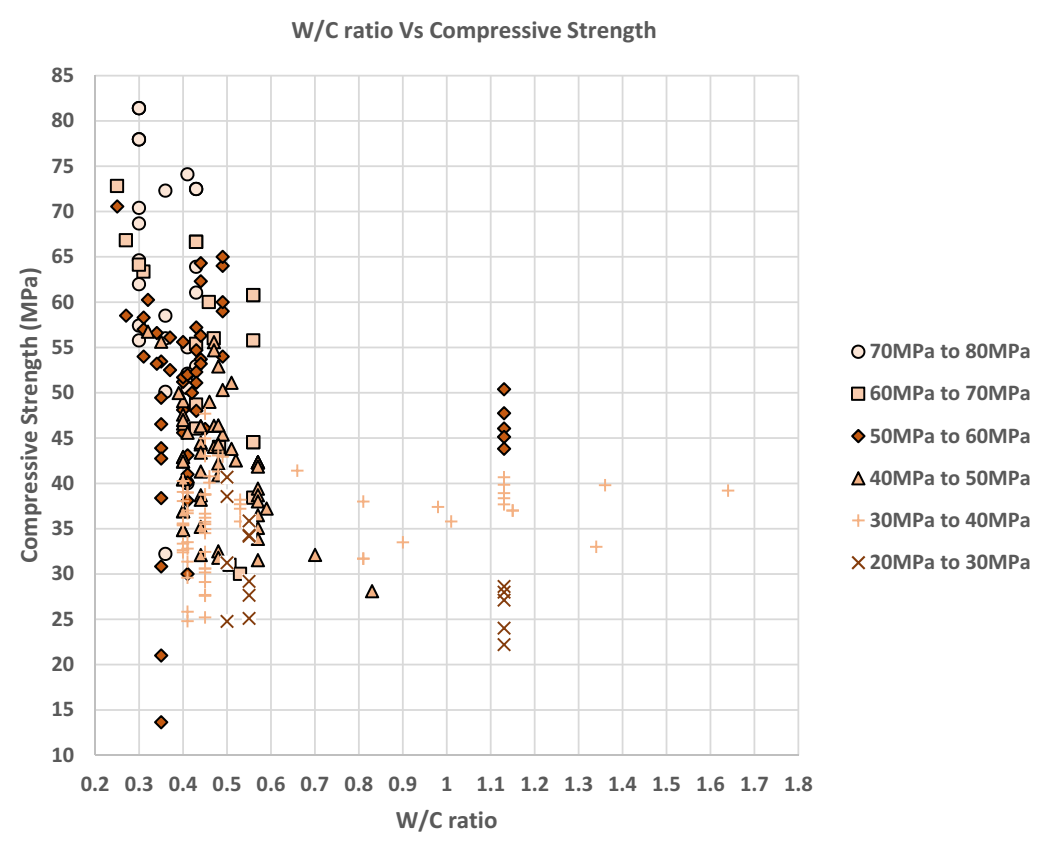

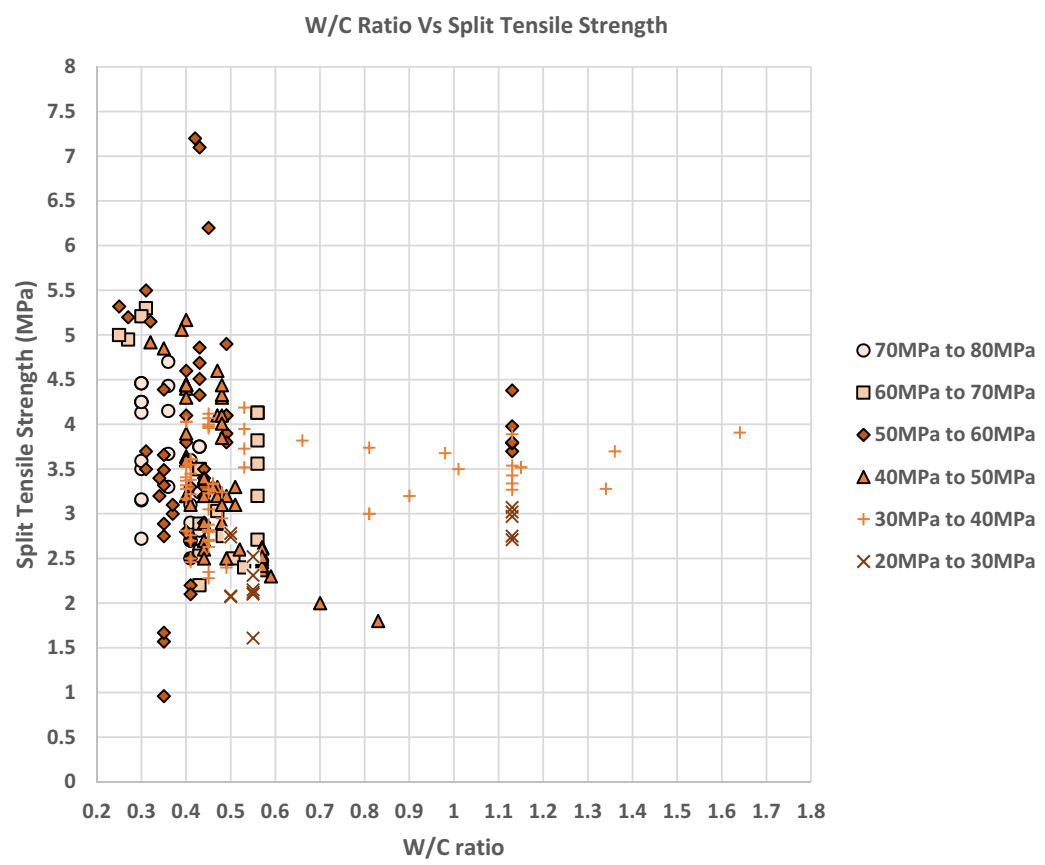

4.1. Effect of W/C Ratio on Compressive Strength and Split Tensile Strength

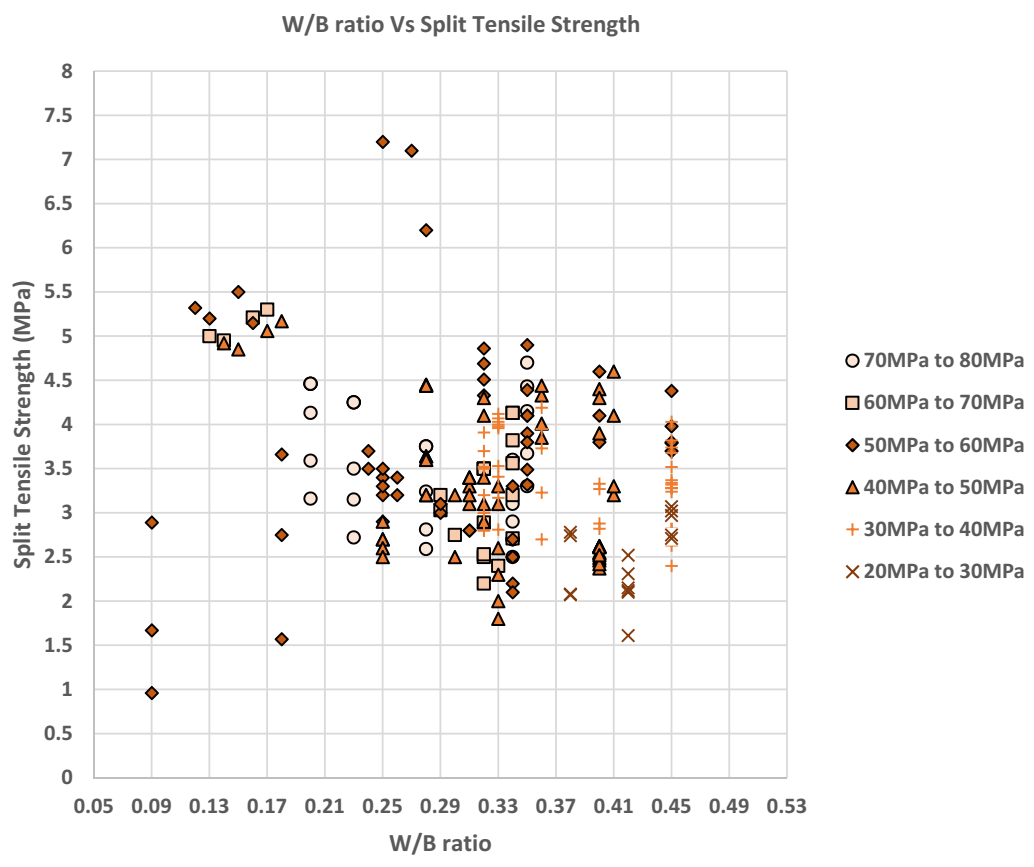

4.2. Effect of W/B Ratio on Compressive Strength and Split Tensile Strength

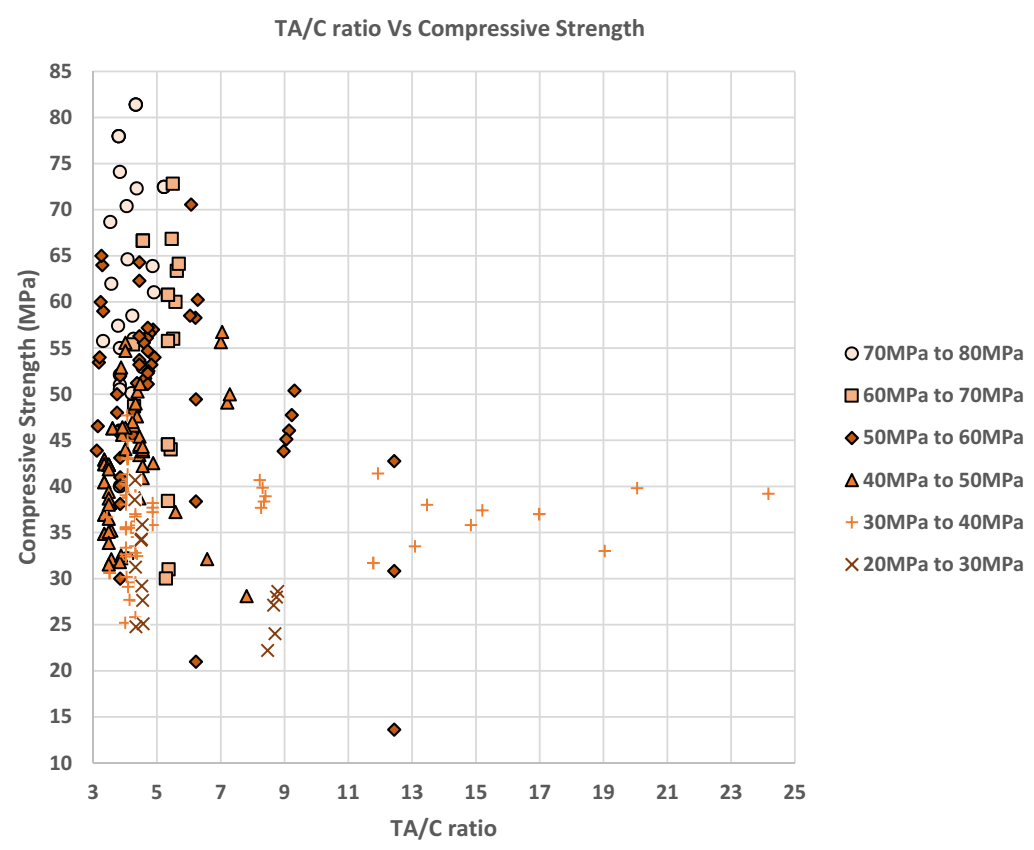

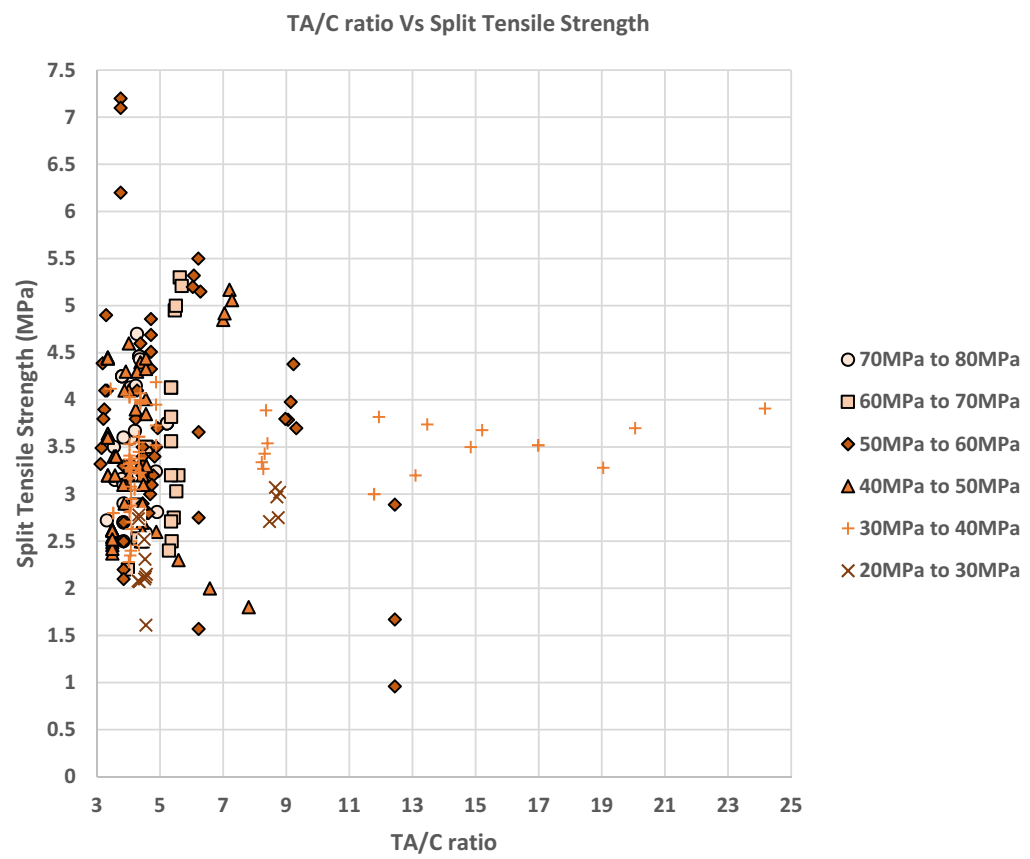

4.3. Effect of TA/C Ratio on Compressive Strength and Split Tensile Strength

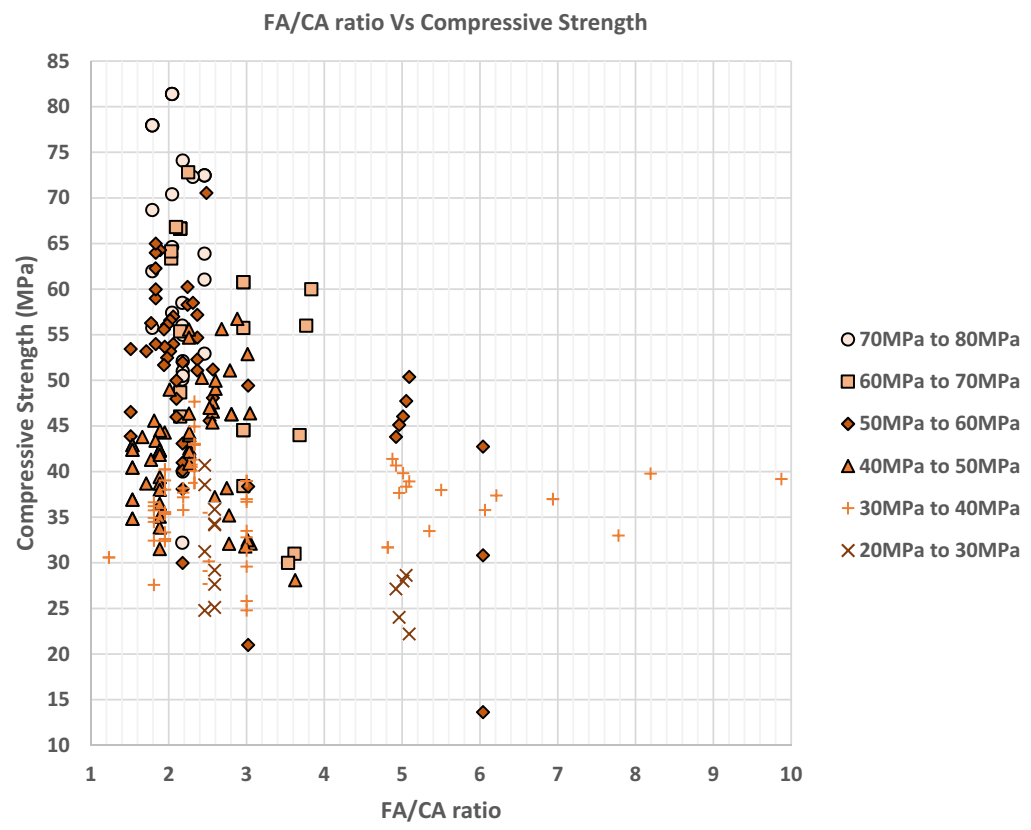

4.4. Effect of FA/CA Ratio on Compressive Strength and Split Tensile Strength

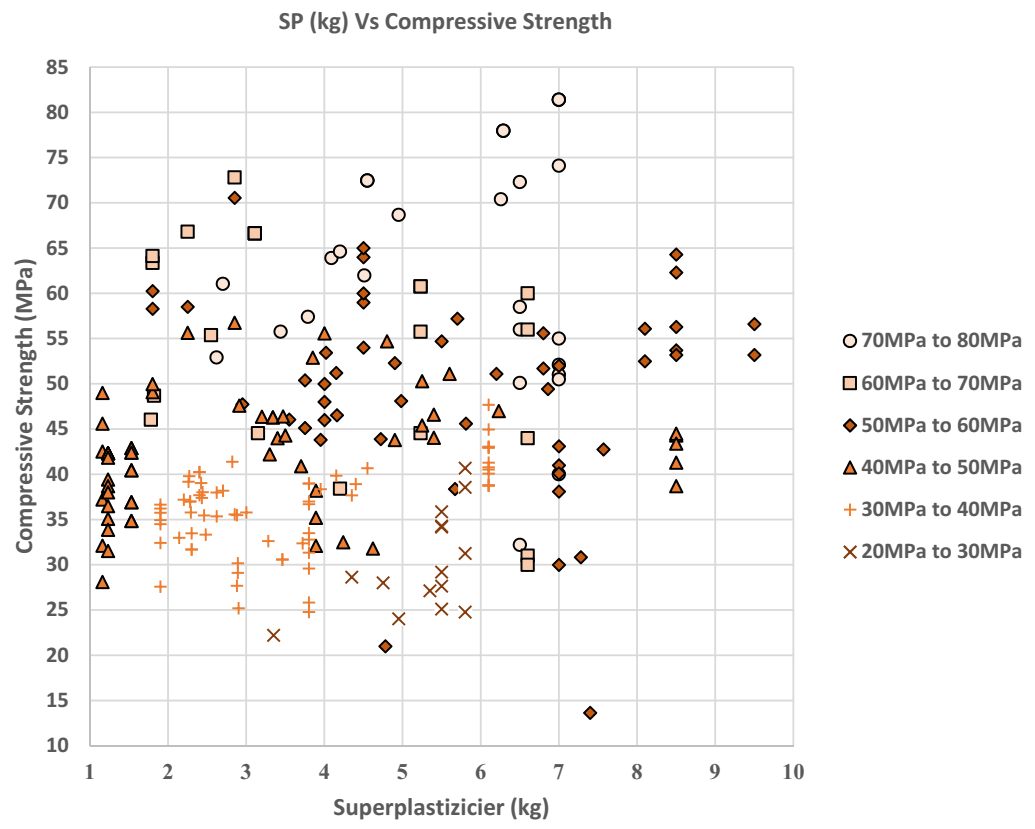

4.5. Effect of Superplasticizer Weight on Compressive Strength and Split Tensile Strength

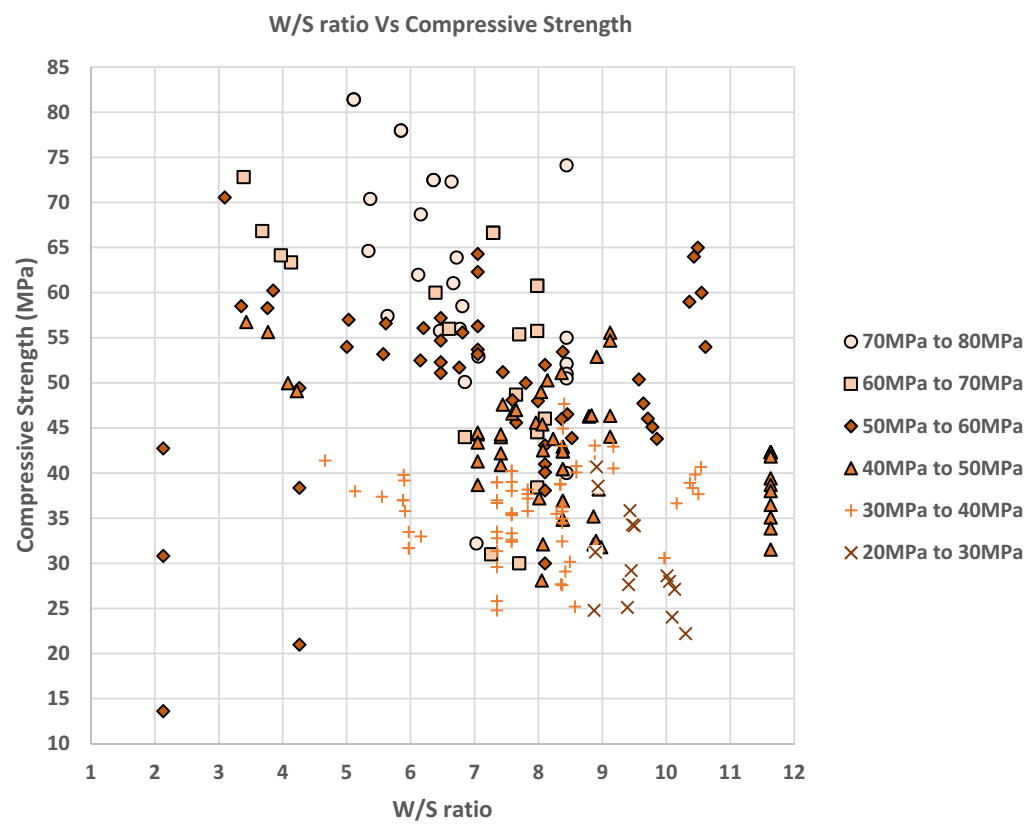

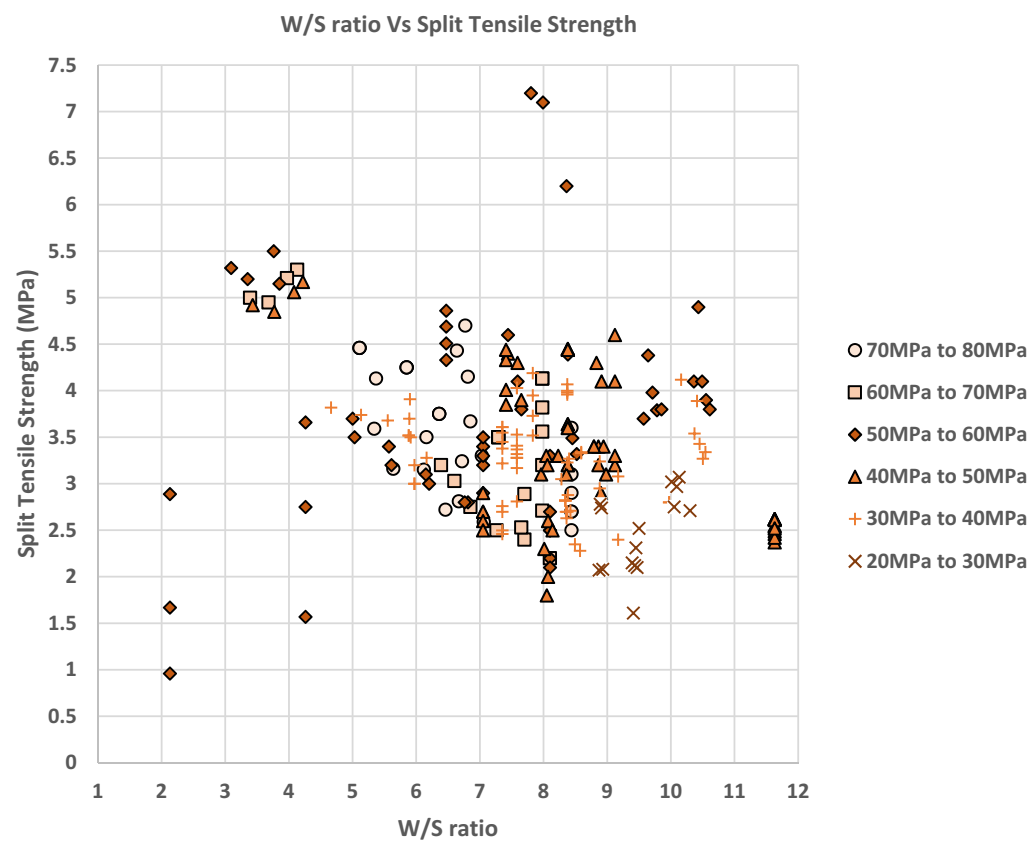

4.6. Effect of W/S on Compressive Strength and Split Tensile Strength

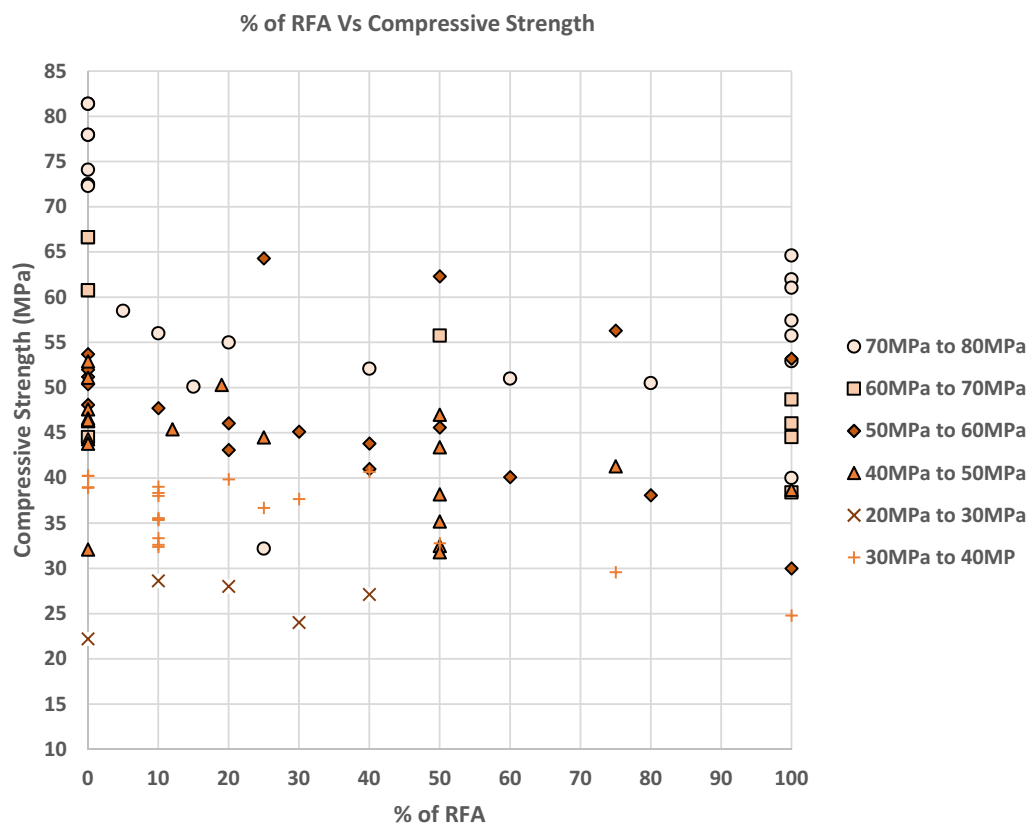

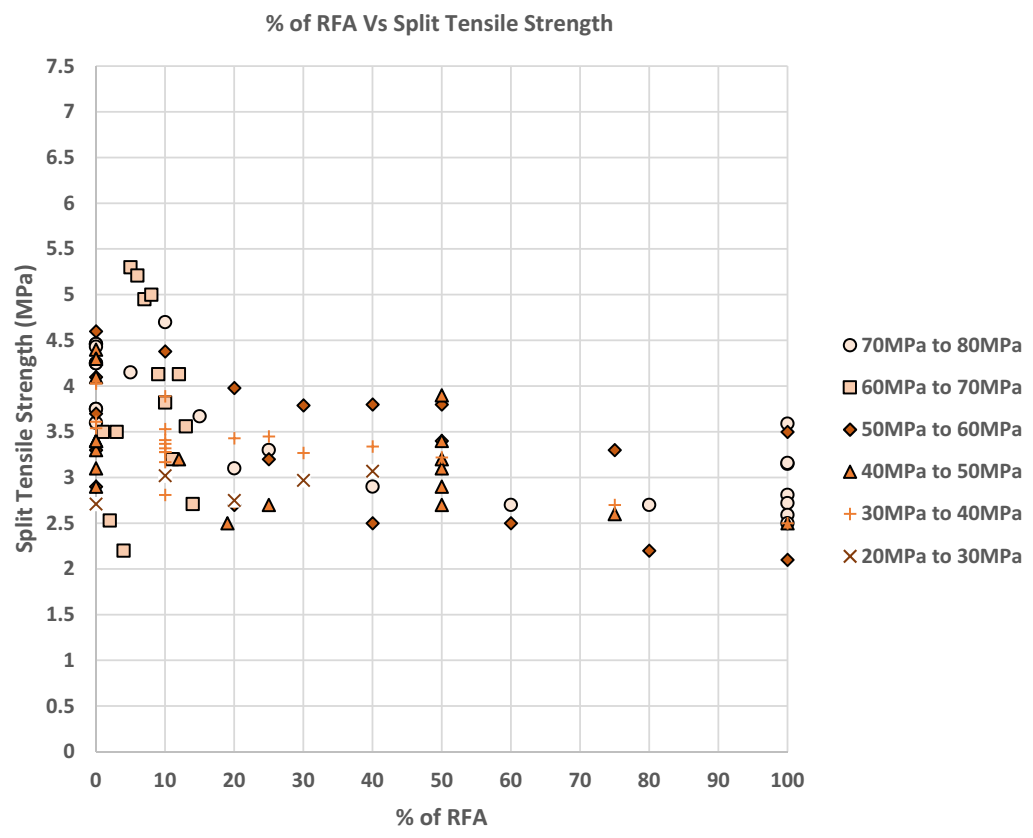

4.7. Effect of the Percentage of RFA on Compressive Strength and Split Tensile Strength

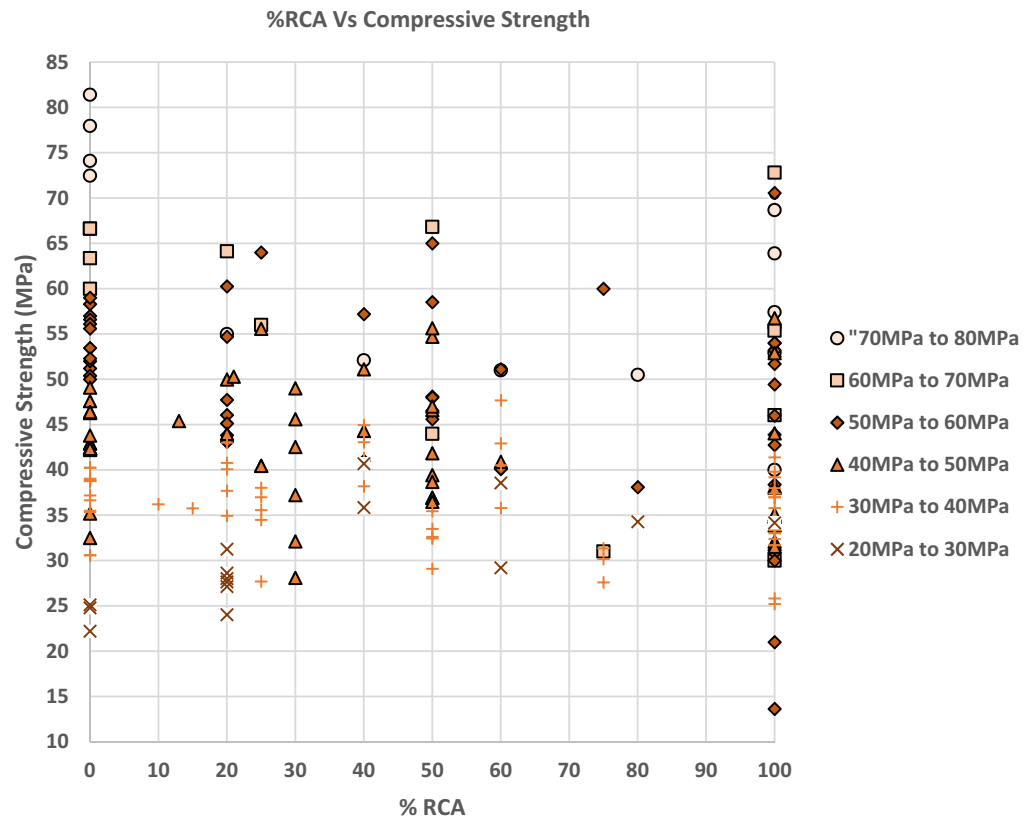

4.8. Effect of the Percentage of RCA on Compressive Strength and Split Tensile Strength

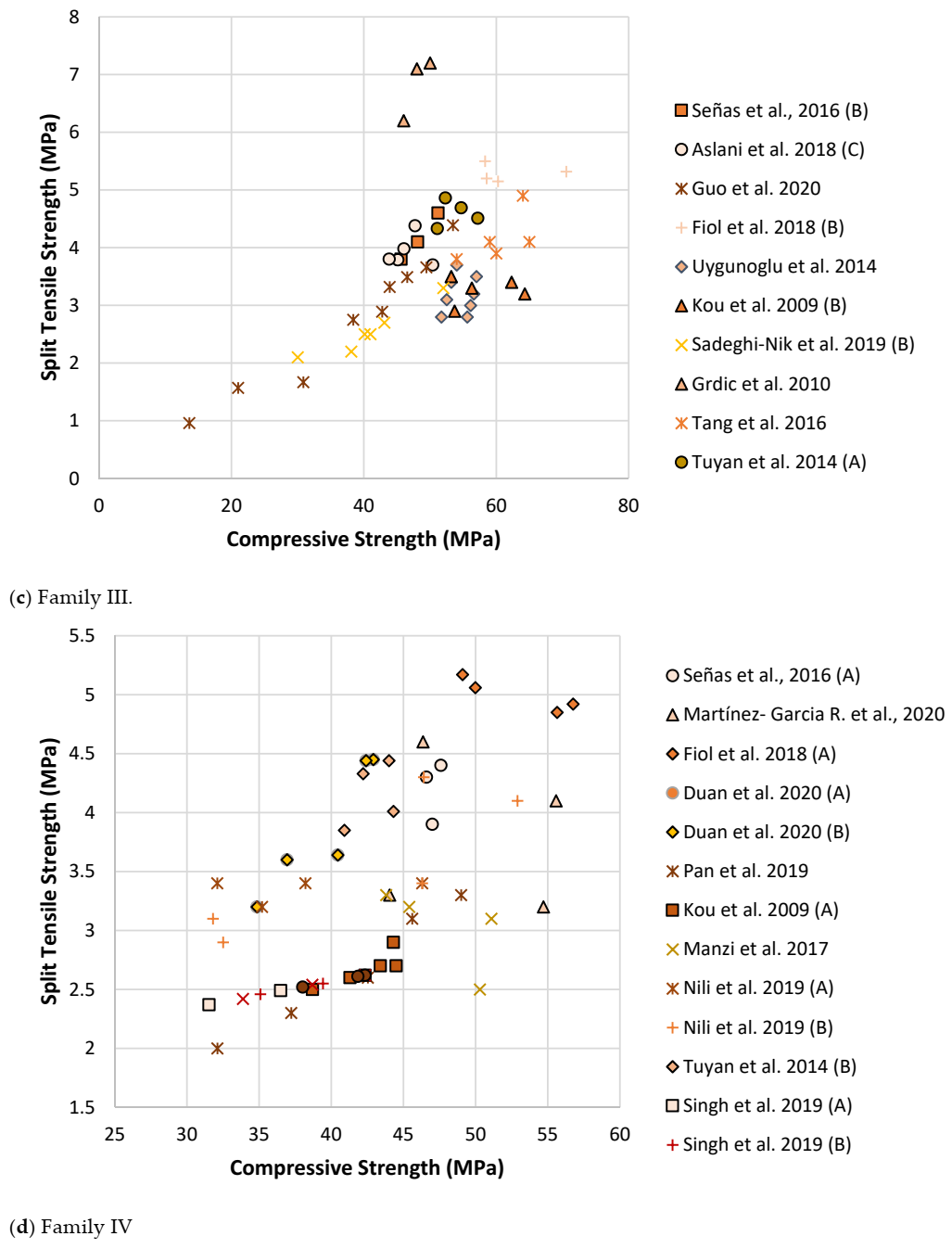

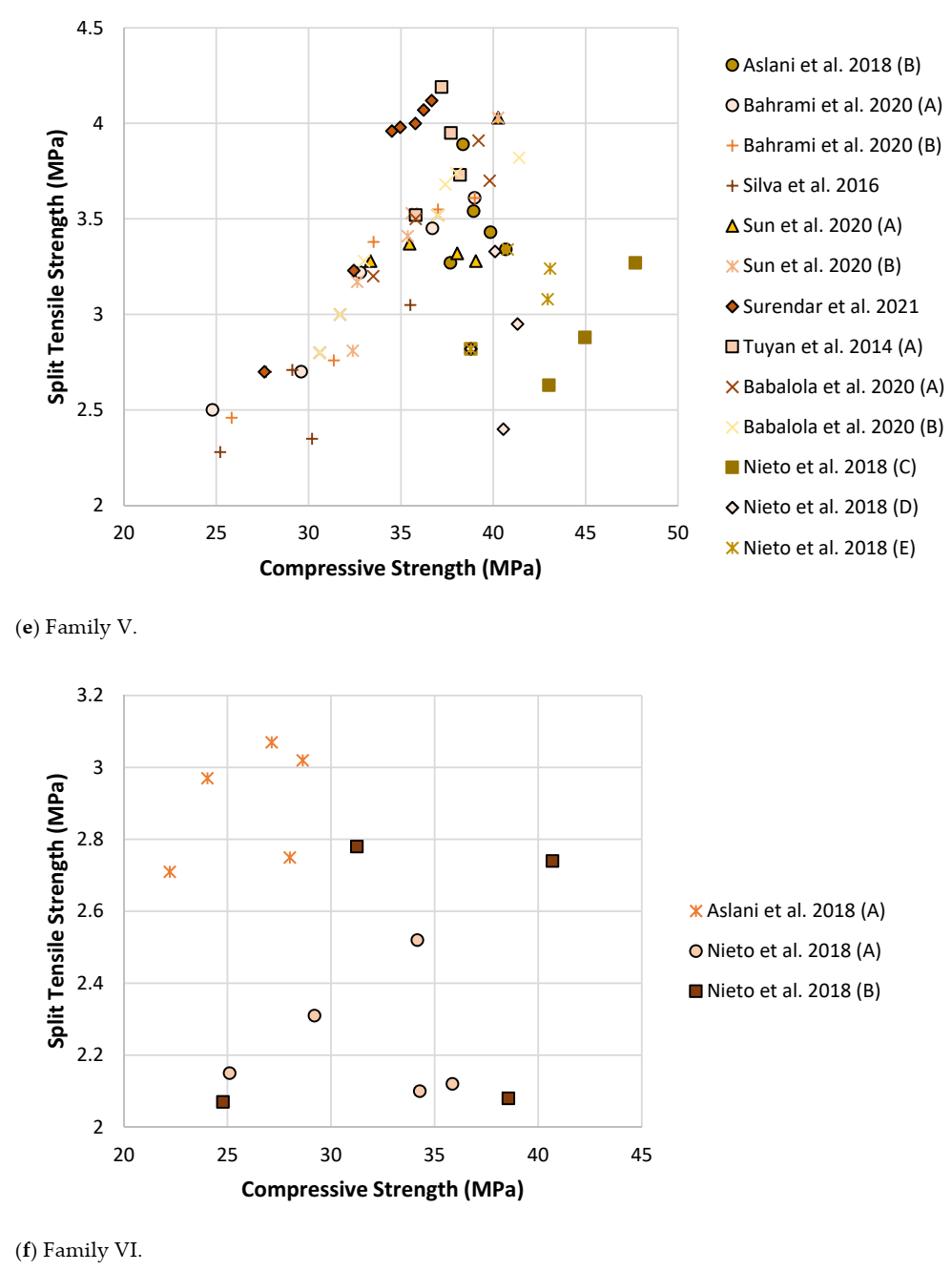

5. Relation between Compressive Strength and Split Tensile Strength

6. Conclusions

- Increase in W/C ratio results in a decrease in compressive strength and split tensile strength. A W/C ratio greater than 0.6 is observed for Family V and VI. Split tensile strength greater than 4.5 MPa is obtained for Family II, III, and IV with a lower W/C ratio.

- W/B ratio less than 0.30 produces higher compressive strength and, simultaneously, higher split tensile strength. Further increase in the W/B ratio results in a decrease in compressive strength and split tensile strength.

- The lower the TA/C ratio is, the higher the compressive strength will be. However, there is a controversial result observed with respect to split tensile strength. When the TA/C ratio decreases in compressive and split tensile strength, the optimum range for TA/C ratio with respect to compressive and split tensile strength is 3 to 9.

- For most of the literature, it was found that FA/CA ratio lies in the range of 1.5 to 3.0 for compressive and split tensile strength. There is no constant relationship between strength and FA/CA ratio but it plays a vital role in fresh concrete properties for SCC.

- There is no constant relationship between SP and strength for SCC.

- When the W/S ratio is lower, the compressive and split tensile strength becomes higher. Higher W/S ratio results in lower compressive and split tensile strength.

- Higher compressive and split tensile strength is obtained for the lower-level replacement of NFA by RFA. However, 100% replacement of NFA by RFA results in compressive strength in a range of 40 MPa to 65 MPa and split tensile strength in a range of 2.5 MPa to 3.5 MPa.

- Higher compressive strength is obtained for 100% replacement of NCA by RCA. Most researchers had used the replacement of NCA by RCA up to 60% relative to the obtained compressive strength of more than 35 MPa. The increase in replacement of NCA by RCA results in a decrease in split tensile strength.

- For several families, there is cluster formation in family III and V observed for compressive and split tensile strength. For family I, II, and IV, there is linear relationship and family VI demonstrates a non-linear relationship.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of Parent Concrete on the Properties of Recycled Aggregate Concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Singh, A.; Arora, S.; Sharma, V.; Bhardwaj, B. Workability Retention and Strength Development of Self-Compacting Recycled Aggregate Concrete Using Ultrafine Recycled Powders and Silica Fume. J. Hazardous Toxic Radioact. Waste 2019, 23, 04019016. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Suárez-Silgado, S.; Molina, J.D.A.; Mahecha, L.; Calderón, L. Diagnóstico y Propuestas Para La Gestión de Los Residuos de Construcción y Demolición En La Ciudad de Ibagué (Colombia). Gest. Ambient. 2018, 21, 9–21. [Google Scholar] [CrossRef]

- Albeiro, C.; Bustos, P.; Guillermo, L.; Pumarejo, F.; Humberto, É.; Cotte, S.; Alexander, H.; Quintana, R. Residuos de Construcción y Demolición (RCD), Una Perspectiva de Aprovechamiento Para La Ciudad de Barranquilla Desde Su Modelo de Gestión. Ing. Desarro. 2017, 35, 533–555. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R.; Lublóy, É. Performance of Self-Compacting High-Performance Concrete Produced with Waste Materials after Exposure to Elevated Temperature. J. Mater. Civ. Eng. 2020, 32, 05019004. [Google Scholar] [CrossRef]

- Thummarukudy, M. Disaster Waste Management: An Overview. Community Environ. Disaster Risk Manag. 2012, 9, 195–218. [Google Scholar] [CrossRef]

- UNEP. Report of the United Nations Environment Programme; UNEP: New York, NY, USA, 2015. [Google Scholar]

- Taller Regional: Instrumentos para la Implementación Efectiva y Coherente de la Dimensión Ambiental de la Agenda de Desarrollo|Evento|Comisión Económica para América Latina y el Caribe. Available online: https://www.cepal.org/es/eventos/taller-regional-instrumentos-la-implementacion-efectiva-coherente-la-dimension-ambiental-la (accessed on 1 May 2021).

- Eurostat. Available online: https://ec.europa.eu/eurostat/databrowser/view/env_wasgen/default/table?lang=en (accessed on 1 May 2021).

- Eurostat. Recovery Rate of Construction and Demolition Waste. Available online: https://ec.europa.eu/eurostat/cache/metadata/en/cei_wm040_esmsip2.htm (accessed on 1 May 2021).

- Robalo, K.; Costa, H.; do Carmo, R.; Júlio, E. Experimental Development of Low Cement Content and Recycled Construction and Demolition Waste Aggregates Concrete. Constr. Build. Mater. 2021, 273, 121680. [Google Scholar] [CrossRef]

- Vaishnavi Devi, S.; Gausikan, R.; Chithambaranathan, S.; Wilfred Jeffrey, J. Utilization of Recycled Aggregate of Construction and Demolition Waste as a Sustainable Material. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. High Tech Startup Creation for Energy Efficient Built Environment. Renewable and Sustainable Energy Reviews; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 618–629. [Google Scholar] [CrossRef] [Green Version]

- García González, J.; Juan Valdés, A.; Morán del Pozo, J.M.; De Belie, N. Concrete with Ceramic Mixed Construction and Demolition Waste: Optimization of Physical, Mechanical and Durability Properties by Aggregate Pre-Saturation, Use of Superplasticizers and Microbially Induced Carbonate Precipitation; Universidad de León: León, Spain, 2016. [Google Scholar]

- Mas, B.; Cladera, A.; del Olmo, T.; Pitarch, F. Influence of the Amount of Mixed Recycled Aggregates on the Properties of Concrete for Non-Structural Use. Constr. Build. Mater. 2012, 27, 612–622. [Google Scholar] [CrossRef]

- Cui, H.Z.; Shi, X.; Memon, S.A.; Xing, F.; Tang, W. Experimental Study on the Influence of Water Absorption of Recycled Coarse Aggregates on Properties of the Resulting Concretes. J. Mater. Civ. Eng. 2015, 27, 04014138. [Google Scholar] [CrossRef]

- Nagataki, S.; Gokce, A.; Saeki, T. Effects of Recycled Aggregate Characteristics on Performance Parameters of Recycled Aggregate Concrete. Spec. Publ. 2000, 192, 53–72. [Google Scholar] [CrossRef]

- Lee, G.; Ling, T.C.; Wong, Y.L.; Poon, C.S. Effects of Crushed Glass Cullet Sizes, Casting Methods and Pozzolanic Materials on ASR of Concrete Blocks. Constr. Build. Mater. 2011, 25, 2611–2618. [Google Scholar] [CrossRef]

- Taffese, W.Z. Suitability Investigation of Recycled Concrete Aggregates for Concrete Production: An Experimental Case Study. Adv. Civ. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Bandi, S.M.; Patel, Y.J.; Vyas, V.H. Study on Fresh and Hardened Properties of Self Compacted Concrete Using Recycled Concrete Aggregate. Int. J. Innov. Res. Sci. Eng. Technol. 2007, 3297. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Tam, C.T.; Zhang, M.H. Effects of the Parent Concrete Properties and Crushing Procedure on the Properties of Coarse Recycled Concrete Aggregates. J. Mater. Civ. Eng. 2013, 25, 1795–1802. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical Behaviour of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Enhancing the Durability Properties of Concrete Prepared with Coarse Recycled Aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical Properties of Recycled Aggregate Concrete under Uniaxial Loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of Recycled Concrete Aggregates on Strength Properties of Concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Butler, L.; West, J.S.; Tighe, S.L. Effect of Recycled Concrete Coarse Aggregate from Multiple Sources on the Hardened Properties of Concrete with Equivalent Compressive Strength. Constr. Build. Mater. 2013, 47, 1292–1301. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of Concrete Prepared with PVA-Impregnated Recycled Concrete Aggregates. Cem. Concr. Compos. 2010, 32, 649–654. [Google Scholar] [CrossRef]

- Lovato, P.S.; Possan, E.; Molin, D.C.C.D.; Masuero, Â.B.; Ribeiro, J.L.D. Modeling of Mechanical Properties and Durability of Recycled Aggregate Concretes. Constr. Build. Mater. 2012, 26, 437–447. [Google Scholar] [CrossRef]

- Rodríguez-Robles, D.; García-González, J.; Juan-Valdés, A.; Morán-del Pozo, J.M.; Guerra-Romero, M.I. Effect of Mixed Recycled Aggregates on Mechanical Properties of Recycled Concrete. Mag. Concr. Res. 2015, 67, 247–256. [Google Scholar] [CrossRef]

- Braga, M.; De Brito, J.; Veiga, R. Incorporation of Fine Concrete Aggregates in Mortars. Constr. Build. Mater. 2012, 36, 960–968. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Guan, R. Test Research on Mechanical Properties of Recycled Fine Aggregate Mortar. In Proceedings of the 2016 5th International Conference on Sustainable Energy and Environment Engineering (ICSEEE 2016), Zhuhai, China, 12–13 November 2016; Volume 63, pp. 733–739. [Google Scholar] [CrossRef] [Green Version]

- Mardani-Aghabaglou, A.; Beglarigale, A.; Yazıcı, H.; Ramyar, K. Microstructural Analyses of Recycled Aggregate-Bearing Mortar Mixture. ACI Mater. J. 2016, 113. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Xiao, J.; Zhong, P. A Method to Determine Water Absorption of Recycled Fine Aggregate in Paste for Design and Quality Control of Fresh Mortar. Constr. Build. Mater. 2019, 197, 30–41. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Martín-Pascual, J.; Martín-Morales, M.; Valverde-Palacios, I.; Zamorano, M. Effects of Water to Cement Ratio, Recycled Fine Aggregate and Air Entraining/Plasticizer Admixture on Masonry Mortar Properties. Constr. Build. Mater. 2020, 230, 116929. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Performance of Cementitious Renderings and Masonry Mortars Containing Recycled Aggregates from Construction and Demolition Wastes. Construction and Building Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; pp. 400–415. [Google Scholar] [CrossRef]

- Restuccia, L.; Spoto, C.; Ferro, G.A.; Tulliani, J.M. Recycled Mortars with C&D Waste. In Procedia Structural Integrity; Elsevier B.V.: Amsterdam, The Netherlands, 2016; Volume 2, pp. 2896–2904. [Google Scholar] [CrossRef] [Green Version]

- Gonçalves, T.; Silva, R.V.; de Brito, J.; Fernández, J.M.; Esquinas, A.R. Mechanical and Durability Performance of Mortars with Fine Recycled Concrete Aggregates and Reactive Magnesium Oxide as Partial Cement Replacement. Cem. Concr. Compos. 2020, 105, 103420. [Google Scholar] [CrossRef]

- Ledesma, E.F.; Jiménez, J.R.; Fernández, J.M.; Galvín, A.P.; Agrela, F.; Barbudo, A. Properties of Masonry Mortars Manufactured with Fine Recycled Concrete Aggregates. Comput. Chem. Eng. 2014, 71, 289–298. [Google Scholar] [CrossRef]

- Dapena, E.; Alaejos, P.; Lobet, A.; Pérez, D. Effect of Recycled Sand Content on Characteristics of Mortars and Concretes. J. Mater. Civ. Eng. 2011, 23, 414–422. [Google Scholar] [CrossRef]

- Neno, C.; De Brito, J.; Veiga, R. Using Fine Recycled Concrete Aggregate for Mortar Production. Mater. Res. 2014, 17, 168–177. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Hanif, A.; Usman, M.; Park, W. Influence of Bonded Mortar of Recycled Concrete Aggregates on Interfacial Characteristics—Porosity Assessment Based on Pore Segmentation from Backscattered Electron Image Analysis. Constr. Build. Mater. 2019, 212, 149–163. [Google Scholar] [CrossRef]

- Santha Kumar, G. Influence of Fluidity on Mechanical and Permeation Performances of Recycled Aggregate Mortar. Constr. Build. Mater. 2019, 213, 404–412. [Google Scholar] [CrossRef]

- Dhir, R.K.; de Brito, J.; Silva, R.V.; Lye, C.Q. Use of Recycled Aggregates in Mortar; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar] [CrossRef]

- de Oliveira Andrade, J.J.; Possan, E.; Squiavon, J.Z.; Ortolan, T.L.P. Evaluation of Mechanical Properties and Carbonation of Mortars Produced with Construction and Demolition Waste. Constr. Build. Mater. 2018, 161, 70–83. [Google Scholar] [CrossRef]

- Le, M.T.; Tribout, C.; Escadeillas, G. Durability of Mortars with Leftover Recycled Sand. Constr. Build. Mater. 2019, 215, 391–400. [Google Scholar] [CrossRef]

- Jochem, L.F.; Casagrande, C.A.; Rocha, J.C. Effect of Lead in Mortars with Recycled Aggregate and Lightweight Aggregate. Constr. Build. Mater. 2020, 239, 117702. [Google Scholar] [CrossRef]

- Zhao, Z.; Remond, S.; Damidot, D.; Xu, W. Influence of Fine Recycled Concrete Aggregates on the Properties of Mortars. Constr. Build. Mater. 2015, 81, 179–186. [Google Scholar] [CrossRef]

- Martínez-García, R.; de Rojas, M.I.S.; Pozo, J.M.M.; Fraile-Fernández, F.J.; Juan-Valdés, A. Evaluation of Mechanical Characteristics of Cement Mortar with Fine Recycled Concrete Aggregates (FRCA). Sustainability 2021, 13, 414. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the Influence of Attached Mortar Content on the Properties of Recycled Concrete Aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.P.; Singh, B.; Singh, P. Effect of Recycled Aggregates on Fresh and Hardened Properties of Self Compacting Concrete. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 32, pp. 600–607. [Google Scholar] [CrossRef]

- Fenollera, M.; Míguez, J.; Goicoechea, I.; Lorenzo, J. Experimental Study on Thermal Conductivity of Self-Compacting Concrete with Recycled Aggregate. Materials 2015, 8, 4457–4478. [Google Scholar] [CrossRef] [Green Version]

- Santos, S.A.; da Silva, P.R.; de Brito, J. Mechanical Performance Evaluation of Self-Compacting Concrete with Fine and Coarse Recycled Aggregates from the Precast Industry. Materials 2017, 10, 904. [Google Scholar] [CrossRef] [Green Version]

- Uysal, M.; Yilmaz, K. Effect of Mineral Admixtures on Properties of Self-Compacting Concrete. Cem. Concr. Compos. 2011, 33, 771–776. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; De Brito, J.; Martínez-Abella, F.; González-Taboada, I.; Silva, P. Study of the Rheology of Self-Compacting Concrete with Fine Recycled Concrete Aggregates. Constr. Build. Mater. 2015, 96, 491–501. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability Performance of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Li, L.; Zhan, B.J.; Lu, J.; Poon, C.S. Systematic Evaluation of the Effect of Replacing River Sand by Different Particle Size Ranges of Fine Recycled Concrete Aggregates (FRCA) in Cement Mortars. Constr. Build. Mater. 2019, 209, 147–155. [Google Scholar] [CrossRef]

- Djelloul, O.K.; Menadi, B.; Wardeh, G.; Kenai, S. Performance of Self-Compacting Concrete Made with Coarse and Fine Recycled Concrete Aggregates and Ground Granulated Blast-Furnace Slag. Adv. Concr. Constr. 2018, 6, 103–121. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; Martínez-Abella, F.; González-Taboada, I.; de Brito, J.; Varela-Puga, F. Proportioning, Fresh-State Properties and Rheology of Self-Compacting Concrete with Fine Recycled Aggregates. Hormig. Acero 2018, 69, 213–221. [Google Scholar] [CrossRef]

- Okamura, H.; Ozawa, K. Self-Compactable High-Performance Concrete in Japan. Spec. Publ. 1996, 159, 31–44. [Google Scholar] [CrossRef]

- Song, Q.; Yu, R.; Wang, X.; Rao, S.; Shui, Z. A Novel Self-Compacting Ultra-High Performance Fibre Reinforced Concrete (SCUHPFRC) Derived from Compounded High-Active Powders. Constr. Build. Mater. 2018, 158, 883–893. [Google Scholar] [CrossRef]

- Bahrami, N.; Zohrabi, M.; Mahmoudy, S.A.; Akbari, M. Optimum Recycled Concrete Aggregate and Micro-Silica Content in Self-Compacting Concrete: Rheological, Mechanical and Microstructural Properties. J. Build. Eng. 2020, 31, 101361. [Google Scholar] [CrossRef]

- Topçu, I.B.; Şengel, S. Properties of Concretes Produced with Waste Concrete Aggregate. Cem. Concr. Res. 2004, 34, 1307–1312. [Google Scholar] [CrossRef]

- Türkmen, I. Influence of Different Curing Conditions on the Physical and Mechanical Properties of Concretes with Admixtures of Silica Fume and Blast Furnace Slag. Mater. Lett. 2003, 57, 4560–4569. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Bahrami, N.; Vaezi, M.; Ozbakkaloglu, T. Optimum Rice Husk Ash Content and Bacterial Concentration in Self-Compacting Concrete. Constr. Build. Mater. 2019, 222, 796–813. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N. Microstructure, Strength, and Durability of Eco-Friendly Concretes Containing Sugarcane Bagasse Ash. Constr. Build. Mater. 2018, 184, 258–268. [Google Scholar] [CrossRef]

- Majeed Khan, R.; Amin, F.; Ahmad, M.; Professor, A. Comparison of Self Compacting Concrete Using Recycled Aggreagtes & Normal Aggregates. Int. J. Adv. Res. Sci. Eng. 2015, 4, 75–83. [Google Scholar]

- Corinaldesi, V.; Moriconi, G. The Role of Industrial By-Products in Self-Compacting Concrete. Constr. Build. Mater. 2011, 25, 3181–3186. [Google Scholar] [CrossRef]

- Şahmaran, M.; Christianto, H.A.; Yaman, I.Ö. The Effect of Chemical Admixtures and Mineral Additives on the Properties of Self-Compacting Mortars. Cem. Concr. Compos. 2006, 28, 432–440. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; De Brito, J. The Effect of Superplasticisers on the Workability and Compressive Strength of Concrete Made with Fine Recycled Concrete Aggregates. Constr. Build. Mater. 2012, 28, 722–729. [Google Scholar] [CrossRef] [Green Version]

- Duan, Z.; Singh, A.; Xiao, J.; Hou, S. Combined Use of Recycled Powder and Recycled Coarse Aggregate Derived from Construction and Demolition Waste in Self-Compacting Concrete. Constr. Build. Mater. 2020, 254, 119323. [Google Scholar] [CrossRef]

- Arafa, M.; Tayeh, B.A.; Alqedra, M.; Shihada, S.; Hanoona, H. Investigating the Effect of Sulfate Attack on Compressive Strength of Recycled Aggregate Concrete. J. Eng. Res. Technol. JERT 2017, 4, 137–143. [Google Scholar]

- Alaejos, P.; De Juan, M.S.; Rueda, J.; Drummond, R.; Valero, I. Quality Assurance of Recycled Aggregates. RILEM State Art Rep. 2013, 8, 229–273. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; Martínez-Abella, F.; González-Taboada, I.; De Brito, J.; Varela-Puga, F. Proportioning, Microstructure and Fresh Properties of Self-Compacting Concrete with Recycled Sand. In Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 171, pp. 645–657. [Google Scholar] [CrossRef]

- Tuyan, M.; Mardani-aghabaglou, A.; Ramyar, K. Freeze—Thaw Resistance, Mechanical and Transport Properties of Self-Consolidating Concrete Incorporating Coarse Recycled Concrete Aggregate. Mater. Des. 2014, 53, 983–991. [Google Scholar] [CrossRef]

- Panda, K.C.; Bal, P.K. Properties of Self Compacting Concrete Using Recycled Coarse Aggregate. In Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; Volume 51, pp. 159–164. [Google Scholar] [CrossRef] [Green Version]

- Manzi, S.; Mazzotti, C.; Bignozzi, M.C. Self-Compacting Concrete with Recycled Concrete Aggregate: Study of the Long-Term Properties. Constr. Build. Mater. 2017, 157, 582–590. [Google Scholar] [CrossRef]

- Mohammed, S.I.; Najim, K.B. Mechanical Strength, Flexural Behavior and Fracture Energy of Recycled Concrete Aggregate Self-Compacting Concrete. Structures 2020, 23, 34–43. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Öz, H.Ö.; Taha, I.; Yasemin, M.T. Failure Characteristics of Self-Compacting Concretes Made with Recycled Aggregates. Constr. Build. Mater. 2015, 98, 334–344. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Ma, Y.; Guo, S. Fresh and Mechanical Performance and Freeze-Thaw Durability of Steel Fiber-Reinforced Rubber Self-Compacting Concrete (SRSCC). J. Clean. Prod. 2020, 277, 123180. [Google Scholar] [CrossRef]

- Sadeghi-Nik, A.; Berenjian, J.; Alimohammadi, S.; Lotfi-Omran, O.; Sadeghi-Nik, A.; Karimaei, M. The Effect of Recycled Concrete Aggregates and Metakaolin on the Mechanical Properties of Self-Compacting Concrete Containing Nanoparticles. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 503–515. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Manso, J.M. Effect of Fine Recycled Concrete Aggregate on the Mechanical Behavior of Self-Compacting Concrete. Constr. Build. Mater. 2020, 263, 120671. [Google Scholar] [CrossRef]

- Fiol, F.; Thomas, C.; Muñoz, C.; Ortega-López, V.; Manso, J.M. The Influence of Recycled Aggregates from Precast Elements on the Mechanical Properties of Structural Self-Compacting Concrete. Constr. Build. Mater. 2018, 182, 309–323. [Google Scholar] [CrossRef]

- Behera, M.; Minocha, A.K.; Bhattacharyya, S.K. Flow Behavior, Microstructure, Strength and Shrinkage Properties of Self-Compacting Concrete Incorporating Recycled Fine Aggregate. Constr. Build. Mater. 2019, 228, 116819. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Yim Wan, D.L.; Muselin, G. Development of High-Performance Self-Compacting Concrete Using Waste Recycled Concrete Aggregates and Rubber Granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Señas, L.; Priano, C.; Marfil, S. Influence of Recycled Aggregates on Properties of Self-Consolidating Concretes. Constr. Build. Mater. 2016, 113, 498–505. [Google Scholar] [CrossRef] [Green Version]

- Guo, Z.; Jiang, T.; Zhang, J.; Kong, X.; Chen, C.; Lehman, D.E. Mechanical and Durability Properties of Sustainable Self-Compacting Concrete with Recycled Concrete Aggregate and Fly Ash, Slag and Silica Fume. Constr. Build. Mater. 2020, 231, 117115. [Google Scholar] [CrossRef]

- Uygunoğlu, T.; Topçu, I.B.; Çelik, A.G. Use of Waste Marble and Recycled Aggregates in Self-Compacting Concrete for Environmental Sustainability. J. Clean. Prod. 2014, 84, 691–700. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of Self-Compacting Concrete Prepared with Coarse and Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Grdic, Z.J.; Toplicic-Curcic, G.A.; Despotovic, I.M.; Ristic, N.S. Properties of Self-Compacting Concrete Prepared with Coarse Recycled Concrete Aggregate. Constr. Build. Mater. 2010, 24, 1129–1133. [Google Scholar] [CrossRef]

- Tang, W.C.; Ryan, P.C.; Cui, H.Z.; Liao, W. Properties of Self-Compacting Concrete with Recycled Coarse Aggregate. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef] [Green Version]

- Martínez-García, R.; Guerra-Romero, I.M.; Morán-del Pozo, J.M.; de Brito, J.; Juan-Valdés, A. Recycling Aggregates for Self-Compacting Concrete Production: A Feasible Option. Materials 2020, 13, 868. [Google Scholar] [CrossRef] [Green Version]

- Pan, Z.; Zhou, J.; Jiang, X.; Xu, Y.; Jin, R.; Ma, J.; Zhuang, Y.; Diao, Z.; Zhang, S.; Si, Q.; et al. Investigating the Effects of Steel Slag Powder on the Properties of Self-Compacting Concrete with Recycled Aggregates. Constr. Build. Mater. 2019, 200, 570–577. [Google Scholar] [CrossRef]

- Nili, M.; Sasanipour, H.; Aslani, F. The Effect of Fine and Coarse Recycled Aggregates on Fresh and Mechanical Properties of Self-Compacting Concrete. Materials 2019, 12, 1120. [Google Scholar] [CrossRef] [Green Version]

- Babalolaa, O.E.; Awoyera, P.O.; Tran, M.T.; Le, D.-H.; Olalusi, O.B.; Viloria, A.; Ovallos-Gazabon, D. Mechanical and Durability Properties of Recycled Aggregate Concrete with Ternary Binder System and Optimized Mix Proportion. J. Mater. Res. Technol. 2020, 9, 6521–6532. [Google Scholar] [CrossRef]

- Sun, C.; Chen, Q.; Xiao, J.; Liu, W. Resources, Conservation & Recycling Utilization of Waste Concrete Recycling Materials in Self-Compacting Concrete. Resour. Conserv. Recycl. 2020, 161, 104930. [Google Scholar] [CrossRef]

- Surendar, M.; Beulah Gnana Ananthi, G.; Sharaniya, M.; Deepak, M.S.; Soundarya, T.V. Mechanical Properties of Concrete with Recycled Aggregate and M−sand. Mater. Today Proc. 2021, 44, 1723–1730. [Google Scholar] [CrossRef]

- Silva, P.; de Brito, J. Experimental Study of the Mechanical Properties and Shrinkage of Self-Compacting Concrete with Binary and Ternary Mixes of Fly Ash and Limestone Filler. Eur. J. Environ. Civ. Eng. 2017, 21, 430–453. [Google Scholar] [CrossRef]

- Nieto, D.; Dapena, E.; Alaejos, P.; Olmedo, J.; Pérez, D. Properties of Self-Compacting Concrete Prepared with Coarse Recycled Concrete Aggregates and Different Water:Cement Ratios. J. Mater. Civ. Eng. 2019, 31, 04018376. [Google Scholar] [CrossRef]

- Akinpelu, M.A.; Odeyemi, S.O.; Olafusi, O.S.; Muhammed, F.Z. Evaluation of Splitting Tensile and Compressive Strength Relationship of Self-Compacting Concrete. J. King Saud Univ. Eng. Sci. 2019, 31, 19–25. [Google Scholar] [CrossRef]

| Authors | Design Parameters | Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | fc | fs | |

| Gesoglu et al., 2015 (A) [79] | 0.30 | 0.23 | 3.800 | 1.789 | 6.29 | 5.85 | - | 0 | 77.96 | 4.25 |

| 0.30 | 0.23 | 3.540 | 1.789 | 4.95 | 6.16 | - | 100 | 68.67 | 3.50 | |

| Gesoglu et al., 2015 (B) [79] | 0.30 | 0.20 | 4.340 | 2.044 | 7.00 | 5.11 | - | 0 | 81.40 | 4.46 |

| 0.30 | 0.20 | 4.050 | 2.044 | 6.26 | 5.37 | - | 100 | 70.39 | 4.13 | |

| Gesoglu et al., 2015 (D) [79] | 0.43 | 0.28 | 5.223 | 2.459 | 4.55 | 6.36 | - | 0 | 72.47 | 3.75 |

| 0.43 | 0.28 | 4.867 | 2.459 | 4.09 | 6.72 | - | 100 | 63.89 | 3.24 | |

| Gesoglu et al., 2015 (E) [79] | 0.30 | 0.23 | 3.800 | 1.789 | 6.29 | 5.85 | 0 | - | 77.96 | 4.25 |

| 0.30 | 0.23 | 3.571 | 1.789 | 4.51 | 6.12 | 100 | - | 61.97 | 3.15 | |

| Gesoglu et al., 2015 (F) [79] | 0.30 | 0.20 | 4.340 | 2.044 | 7.00 | 5.11 | 0 | - | 81.40 | 4.46 |

| 0.30 | 0.20 | 4.081 | 2.044 | 4.20 | 5.34 | 100 | - | 64.61 | 3.59 | |

| Gesoglu et al., 2015 (H) [79] | 0.43 | 0.28 | 5.223 | 2.459 | 4.55 | 6.36 | 0 | - | 72.47 | 3.75 |

| 0.43 | 0.28 | 4.908 | 2.459 | 2.70 | 6.67 | 100 | - | 61.04 | 2.81 | |

| Gesoglu et al., 2015 (I) [79] | 0.30 | 0.23 | 3.800 | 1.789 | 6.29 | 5.85 | 0 | 0 | 77.96 | 4.25 |

| 0.30 | 0.23 | 3.313 | 1.789 | 3.44 | 6.46 | 100 | 100 | 55.76 | 2.72 | |

| Gesoglu et al., 2015 (J) [79] | 0.30 | 0.20 | 4.340 | 2.044 | 7.00 | 5.11 | 0 | 0 | 81.40 | 4.46 |

| 0.30 | 0.20 | 3.785 | 2.044 | 3.79 | 5.64 | 100 | 100 | 57.41 | 3.16 | |

| Gesoglu et al., 2015 (L) [79] | 0.43 | 0.28 | 5.223 | 2.459 | 4.55 | 6.36 | 0 | 0 | 72.47 | 3.75 |

| 0.43 | 0.28 | 4.552 | 2.459 | 2.62 | 7.06 | 100 | 100 | 52.92 | 2.59 | |

| Wang et al., 2020 [80] | 0.36 | 0.35 | 4.366 | 2.309 | 6.50 | 6.64 | 0 | - | 72.30 | 4.43 |

| 0.36 | 0.35 | 4.232 | 2.174 | 6.50 | 6.81 | 5 | - | 58.50 | 4.15 | |

| 0.36 | 0.35 | 4.269 | 2.174 | 6.50 | 6.77 | 10 | - | 56.00 | 4.70 | |

| 0.36 | 0.35 | 4.202 | 2.174 | 6.50 | 6.85 | 15 | - | 50.10 | 3.67 | |

| 0.36 | 0.35 | 4.067 | 2.174 | 6.50 | 7.03 | 25 | - | 32.20 | 3.30 | |

| Sadeghi-Nik. et al., 2019 (B) [81] | 0.41 | 0.34 | 3.840 | 2.180 | 7.00 | 8.44 | 0 | 0 | 74.10 | 3.60 |

| 0.41 | 0.34 | 3.840 | 2.180 | 7.00 | 8.44 | 20 | 20 | 55.00 | 3.10 | |

| 0.41 | 0.34 | 3.840 | 2.180 | 7.00 | 8.44 | 40 | 40 | 52.10 | 2.90 | |

| 0.41 | 0.34 | 3.840 | 2.180 | 7.00 | 8.44 | 60 | 60 | 51.00 | 2.70 | |

| 0.41 | 0.34 | 3.840 | 2.180 | 7.00 | 8.44 | 80 | 80 | 50.50 | 2.70 | |

| 0.41 | 0.34 | 3.840 | 2.180 | 7.00 | 8.44 | 100 | 100 | 40.00 | 2.50 | |

| Authors | Design Parameters | Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | fc | fs | |

| Gesoglu et al., 2015 (C) [79] | 0.430 | 0.32 | 4.563 | 2.148 | 3.11 | 7.29 | - | 0 | 66.63 | 3.50 |

| 0.430 | 0.32 | 4.252 | 2.148 | 2.55 | 7.70 | - | 100 | 55.38 | 2.89 | |

| Gesoglu et al., 2015 (G) [79] | 0.430 | 0.32 | 4.563 | 2.148 | 3.11 | 7.29 | 0 | - | 66.63 | 3.50 |

| 0.430 | 0.32 | 4.288 | 2.148 | 1.82 | 7.65 | 100 | - | 48.69 | 2.53 | |

| Gesoglu et al., 2015 (K) [79] | 0.430 | 0.32 | 4.563 | 2.148 | 3.11 | 7.29 | 0 | 0 | 66.63 | 3.50 |

| 0.430 | 0.32 | 3.978 | 2.148 | 1.78 | 8.10 | 100 | 100 | 46.04 | 2.20 | |

| Revilla Cuesta et al., 2020 [82] | 0.459 | 0.29 | 5.583 | 3.833 | 6.60 | 6.39 | - | 0 | 60.00 | 3.20 |

| 0.470 | 0.29 | 5.516 | 3.767 | 6.60 | 6.60 | - | 25 | 56.00 | 3.03 | |

| 0.482 | 0.30 | 5.433 | 3.683 | 6.60 | 6.85 | - | 50 | 44.00 | 2.75 | |

| 0.506 | 0.32 | 5.367 | 3.617 | 6.60 | 7.26 | - | 75 | 31.00 | 2.50 | |

| 0.530 | 0.33 | 5.283 | 3.533 | 6.60 | 7.70 | - | 100 | 30.00 | 2.40 | |

| Fiol et al., 2018 (C) [83] | 0.310 | 0.17 | 5.625 | 2.031 | 1.80 | 4.13 | - | 0 | 63.36 | 5.30 |

| 0.300 | 0.16 | 5.688 | 2.031 | 1.80 | 3.97 | - | 20 | 64.13 | 5.21 | |

| 0.270 | 0.14 | 5.469 | 2.094 | 2.25 | 3.68 | - | 50 | 66.82 | 4.95 | |

| 0.250 | 0.13 | 5.500 | 2.250 | 2.85 | 3.39 | - | 100 | 72.81 | 5.00 | |

| Behera et al., 2019 (A) [84] | 0.560 | 0.34 | 5.350 | 2.960 | 5.23 | 7.98 | 0 | - | 60.76 | 4.13 |

| 0.560 | 0.34 | 5.350 | 2.960 | 5.23 | 7.98 | 50 | - | 55.76 | 3.82 | |

| 0.560 | 0.34 | 5.350 | 2.960 | 5.23 | 7.98 | 100 | - | 44.54 | 3.20 | |

| Behera et al., 2019 (B) [84] | 0.560 | 0.34 | 5.350 | 2.960 | 5.23 | 7.98 | 0 | - | 60.76 | 4.13 |

| 0.560 | 0.34 | 5.350 | 2.960 | 3.15 | 7.98 | 0 | - | 44.54 | 3.56 | |

| 0.560 | 0.34 | 5.350 | 2.960 | 4.20 | 7.98 | 100 | - | 38.41 | 2.71 | |

| Authors | Design Parameters | Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | fc | fs | |

| Señas et al., 2016 (B) [86] | 0.40 | 0.40 | 4.373 | 2.566 | 4.15 | 7.44 | 0 | 0 | 51.20 | 4.60 |

| 0.40 | 0.40 | 4.272 | 2.566 | 4.98 | 7.59 | 0 | 50 | 48.10 | 4.10 | |

| 0.40 | 0.40 | 4.229 | 2.523 | 5.81 | 7.65 | 50 | 50 | 45.60 | 3.80 | |

| Aslani et al., 2018 (C) [85] | 1.13 | 0.45 | 9.311 | 5.090 | 3.75 | 9.57 | 0 | 0 | 50.39 | 3.70 |

| 1.13 | 0.45 | 9.225 | 5.050 | 2.95 | 9.64 | 10 | 20 | 47.74 | 4.38 | |

| 1.13 | 0.45 | 9.139 | 5.010 | 3.55 | 9.71 | 20 | 20 | 46.06 | 3.98 | |

| 1.13 | 0.45 | 9.054 | 4.960 | 3.75 | 9.78 | 30 | 20 | 45.13 | 3.79 | |

| 1.13 | 0.45 | 8.968 | 4.920 | 3.95 | 9.85 | 40 | 20 | 43.82 | 3.80 | |

| Guo et al., 2020 [87] | 0.35 | 0.35 | 3.177 | 1.510 | 4.02 | 8.38 | - | 0 | 53.45 | 4.39 |

| 0.35 | 0.35 | 3.143 | 1.510 | 4.16 | 8.45 | - | 50 | 46.54 | 3.49 | |

| 0.35 | 0.35 | 3.110 | 1.510 | 4.72 | 8.52 | - | 100 | 43.89 | 3.32 | |

| 0.35 | 0.18 | 6.219 | 3.019 | 4.78 | 4.26 | - | 100 | 21.00 | 1.57 | |

| 0.35 | 0.18 | 6.219 | 3.019 | 5.67 | 4.26 | - | 100 | 38.38 | 2.75 | |

| 0.35 | 0.18 | 6.219 | 3.019 | 6.86 | 4.26 | - | 100 | 49.44 | 3.66 | |

| 0.35 | 0.09 | 12.438 | 6.038 | 7.40 | 2.13 | - | 100 | 13.64 | 0.96 | |

| 0.35 | 0.09 | 12.438 | 6.038 | 7.28 | 2.13 | - | 100 | 30.84 | 1.67 | |

| 0.35 | 0.09 | 12.438 | 6.038 | 7.57 | 2.13 | - | 100 | 42.75 | 2.89 | |

| Fiol et al., 2018 (B) [83] | 0.31 | 0.15 | 6.207 | 2.241 | 1.80 | 3.76 | - | 0 | 58.30 | 5.50 |

| 0.32 | 0.16 | 6.276 | 2.241 | 1.80 | 3.85 | - | 20 | 60.25 | 5.15 | |

| 0.27 | 0.13 | 6.034 | 2.310 | 2.25 | 3.35 | - | 50 | 58.52 | 5.20 | |

| 0.25 | 0.12 | 6.069 | 2.483 | 2.85 | 3.09 | - | 100 | 70.56 | 5.32 | |

| Uygunoglu et al., 2014 [88] | 0.31 | 0.24 | 4.874 | 2.057 | 10.80 | 5.03 | - | 0 | 57.00 | 3.50 |

| 0.31 | 0.24 | 4.920 | 2.057 | 10.80 | 5.00 | - | 100 | 54.00 | 3.70 | |

| 0.34 | 0.26 | 4.777 | 2.017 | 9.50 | 5.61 | - | 0 | 56.60 | 3.20 | |

| 0.34 | 0.26 | 4.823 | 2.017 | 9.50 | 5.57 | - | 100 | 53.20 | 3.40 | |

| 0.37 | 0.29 | 4.683 | 1.977 | 8.10 | 6.20 | - | 0 | 56.10 | 3.00 | |

| 0.37 | 0.29 | 4.729 | 1.977 | 8.10 | 6.15 | - | 100 | 52.50 | 3.10 | |

| 0.40 | 0.31 | 4.586 | 1.937 | 6.80 | 6.81 | - | 0 | 55.60 | 2.80 | |

| 0.40 | 0.31 | 4.631 | 1.937 | 6.80 | 6.76 | - | 100 | 51.70 | 2.80 | |

| Kou and Poon, 2009 [89] | 0.44 | 0.25 | 4.447 | 1.947 | 8.50 | 7.05 | 0 | - | 53.70 | 2.90 |

| 0.44 | 0.25 | 4.447 | 1.888 | 8.50 | 7.05 | 25 | - | 64.30 | 3.20 | |

| 0.44 | 0.25 | 4.447 | 1.829 | 8.50 | 7.05 | 50 | - | 62.30 | 3.40 | |

| 0.44 | 0.25 | 4.447 | 1.771 | 8.50 | 7.05 | 75 | - | 56.30 | 3.30 | |

| 0.44 | 0.25 | 4.447 | 1.709 | 8.50 | 7.05 | 100 | - | 53.20 | 3.50 | |

| Sadeghi-Nik., et al., 2019 (B) [81] | 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 0 | 0 | 52.00 | 3.30 |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 20 | 20 | 43.10 | 2.70 | |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 40 | 40 | 41.00 | 2.50 | |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 60 | 60 | 40.10 | 2.50 | |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 80 | 80 | 38.10 | 2.20 | |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 100 | 100 | 30.00 | 2.10 | |

| Grdic et al., 2010 [90] | 0.42 | 0.25 | 3.748 | 2.098 | 4.00 | 7.80 | - | 0 | 50.00 | 7.20 |

| 0.43 | 0.27 | 3.748 | 2.098 | 4.00 | 7.99 | - | 50 | 48.00 | 7.10 | |

| 0.45 | 0.28 | 3.748 | 2.098 | 4.00 | 8.36 | - | 100 | 46.00 | 6.20 | |

| Tang et al., 2016 [91] | 0.49 | 0.35 | 3.315 | 1.831 | 4.50 | 10.36 | - | 0 | 59.00 | 4.10 |

| 0.49 | 0.35 | 3.285 | 1.831 | 4.50 | 10.43 | - | 25 | 64.00 | 4.90 | |

| 0.49 | 0.35 | 3.258 | 1.831 | 4.50 | 10.49 | - | 50 | 65.00 | 4.10 | |

| 0.49 | 0.35 | 3.231 | 1.831 | 4.50 | 10.55 | - | 75 | 60.00 | 3.90 | |

| 0.49 | 0.35 | 3.202 | 1.831 | 4.50 | 10.61 | - | 100 | 54.00 | 3.80 | |

| Tuyan et al., 2014 (A) [74] | 0.43 | 0.32 | 4.708 | 2.365 | 4.90 | 6.47 | - | 0 | 52.30 | 4.86 |

| 0.43 | 0.32 | 4.708 | 2.365 | 5.50 | 6.47 | - | 20 | 54.70 | 4.69 | |

| 0.43 | 0.32 | 4.708 | 2.365 | 5.70 | 6.47 | - | 40 | 57.20 | 4.51 | |

| 0.43 | 0.32 | 4.708 | 2.365 | 6.20 | 6.47 | - | 60 | 51.10 | 4.33 | |

| Authors | Design Parameters | Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | fc | fs | |

| Señas et al., 2016 (A) [86] | 0.40 | 0.40 | 4.373 | 2.566 | 2.91 | 7.44 | - | - | 47.60 | 4.40 |

| 0.40 | 0.40 | 4.272 | 2.566 | 5.40 | 7.59 | - | 50 | 46.60 | 4.30 | |

| 0.40 | 0.40 | 4.229 | 2.523 | 6.23 | 7.65 | 50 | 50 | 47.00 | 3.90 | |

| Martínez-García et al., 2020 [92] | 0.47 | 0.41 | 4.010 | 2.260 | 3.20 | 9.12 | - | 0 | 46.36 | 4.60 |

| 0.47 | 0.41 | 4.010 | 2.260 | 4.00 | 9.12 | - | 25 | 55.58 | 4.10 | |

| 0.47 | 0.41 | 4.010 | 2.260 | 4.80 | 9.12 | - | 50 | 54.70 | 3.20 | |

| 0.47 | 0.41 | 4.010 | 2.260 | 5.40 | 9.12 | - | 100 | 44.04 | 3.30 | |

| Fiol et al., 2018 (A) [83] | 0.40 | 0.18 | 7.200 | 2.600 | 1.80 | 4.22 | - | 0 | 49.09 | 5.17 |

| 0.39 | 0.17 | 7.280 | 2.600 | 1.80 | 4.08 | - | 20 | 49.98 | 5.06 | |

| 0.35 | 0.15 | 7.000 | 2.680 | 2.25 | 3.77 | - | 50 | 55.64 | 4.85 | |

| 0.32 | 0.14 | 7.040 | 2.880 | 2.85 | 3.43 | - | 100 | 56.75 | 4.92 | |

| Duan et al., 2020 (A) [71] | 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 0 | 42.91 | 4.45 | |

| 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 0 | 42.41 | 4.44 | ||

| 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 25 | 40.45 | 3.64 | ||

| 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 50 | 36.93 | 3.60 | ||

| 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 100 | 34.85 | 3.20 | ||

| Duan et al., 2020 (B) [71] | 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 0 | 42.91 | 4.45 | |

| 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 0 | 41.25 | 3.89 | ||

| 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 25 | 40.73 | 3.63 | ||

| 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 50 | 35.97 | 3.34 | ||

| 0.40 | 0.28 | 3.345 | 1.533 | 1.53 | 8.38 | 100 | 34.43 | 2.89 | ||

| Pan et al., 2019 [93] | 0.41 | 0.33 | 3.904 | 1.812 | 1.16 | 7.96 | - | 30 | 45.60 | 3.10 |

| 0.46 | 0.33 | 4.331 | 2.010 | 1.16 | 8.04 | - | 30 | 49.00 | 3.30 | |

| 0.52 | 0.33 | 4.877 | 2.264 | 1.16 | 8.07 | - | 30 | 42.53 | 2.60 | |

| 0.59 | 0.33 | 5.581 | 2.591 | 1.16 | 8.01 | - | 30 | 37.22 | 2.30 | |

| 0.70 | 0.33 | 6.573 | 3.051 | 1.16 | 8.07 | - | 30 | 32.11 | 2.00 | |

| 0.83 | 0.33 | 7.808 | 3.624 | 1.16 | 8.05 | - | 30 | 28.10 | 1.80 | |

| Kou and Poon., 2009 [89] | 0.44 | 0.25 | 4.447 | 1.947 | 8.50 | 7.05 | 0 | - | 44.30 | 2.90 |

| 0.44 | 0.25 | 4.447 | 1.888 | 8.50 | 7.05 | 25 | - | 44.50 | 2.70 | |

| 0.44 | 0.25 | 4.447 | 1.829 | 8.50 | 7.05 | 50 | - | 43.40 | 2.70 | |

| 0.44 | 0.25 | 4.447 | 1.771 | 8.50 | 7.05 | 75 | - | 41.30 | 2.60 | |

| 0.44 | 0.25 | 4.447 | 1.709 | 8.50 | 7.05 | 100 | - | 38.70 | 2.50 | |

| Manzi et al., 2017 [77] | 0.51 | 0.31 | 4.566 | 1.660 | 4.90 | 8.23 | 0 | 0 | 43.80 | 3.30 |

| 0.49 | 0.30 | 4.451 | 2.560 | 5.25 | 8.06 | 12 | 13 | 45.40 | 3.20 | |

| 0.49 | 0.30 | 4.389 | 2.426 | 5.25 | 8.14 | 19 | 21 | 50.30 | 2.50 | |

| 0.51 | 0.31 | 4.469 | 2.786 | 5.60 | 8.36 | 0 | 40 | 51.10 | 3.10 | |

| Nili et al., 2019 (A) [94] | 0.44 | 0.31 | 3.605 | 2.804 | 3.34 | 8.79 | 0 | 0 | 46.30 | 3.40 |

| 0.44 | 0.31 | 3.567 | 2.775 | 3.89 | 8.86 | 0 | 100 | 32.10 | 3.40 | |

| 0.44 | 0.31 | 3.569 | 2.775 | 3.89 | 8.86 | 50 | 0 | 35.20 | 3.20 | |

| 0.44 | 0.32 | 3.531 | 2.746 | 3.89 | 8.94 | 50 | 100 | 38.20 | 3.40 | |

| Nili et al., 2019 (B) [94] | 0.44 | 0.31 | 3.605 | 2.804 | 3.34 | 8.79 | 0 | 0 | 46.30 | 3.40 |

| 0.48 | 0.32 | 3.914 | 3.044 | 3.47 | 8.83 | 0 | 0 | 46.40 | 4.30 | |

| 0.48 | 0.32 | 3.873 | 3.013 | 3.85 | 8.91 | 0 | 100 | 52.90 | 4.10 | |

| 0.48 | 0.32 | 3.875 | 3.013 | 4.24 | 8.90 | 50 | 0 | 32.50 | 2.90 | |

| 0.48 | 0.32 | 3.834 | 2.982 | 4.62 | 8.98 | 50 | 100 | 31.80 | 3.10 | |

| Tuyan et al., 2014 (B) [74] | 0.48 | 0.36 | 4.549 | 2.263 | 3.30 | 7.41 | - | 0 | 42.20 | 4.33 |

| 0.48 | 0.36 | 4.549 | 2.263 | 3.40 | 7.41 | - | 20 | 44.00 | 4.44 | |

| 0.48 | 0.36 | 4.549 | 2.263 | 3.50 | 7.41 | - | 40 | 44.30 | 4.01 | |

| 0.48 | 0.36 | 4.549 | 2.263 | 3.70 | 7.41 | - | 60 | 40.90 | 3.85 | |

| Singh et al., 2019 (A) [2] | 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 0 | 42.34 | 2.62 |

| 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 50 | 36.49 | 2.49 | |

| 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 100 | 31.53 | 2.37 | |

| Singh et al., 2019 (B) [2] | 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 0 | 42.34 | 2.62 |

| 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 50 | 39.42 | 2.55 | |

| 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 100 | 35.08 | 2.46 | |

| Singh et al., 2019 (C) [2] | 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 0 | 42.34 | 2.62 |

| 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 50 | 38.69 | 2.54 | |

| 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 100 | 33.88 | 2.42 | |

| Singh et al., 2019 (D) [2] | 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 0 | 42.34 | 2.62 |

| 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 50 | 41.85 | 2.61 | |

| 0.57 | 0.40 | 3.488 | 1.884 | 1.23 | 11.63 | - | 100 | 38.02 | 2.52 | |

| Authors | Design Parameters | Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | fc | fs | |

| Aslani et al., 2018 (B) [85] | 1.13 | 0.45 | 8.399 | 5.090 | 4.40 | 10.37 | 0 | 0 | 38.93 | 3.54 |

| 1.13 | 0.45 | 8.355 | 5.050 | 3.95 | 10.41 | 10 | 20 | 38.36 | 3.89 | |

| 1.13 | 0.45 | 8.310 | 5.010 | 4.15 | 10.45 | 20 | 20 | 39.85 | 3.43 | |

| 1.13 | 0.45 | 8.266 | 4.960 | 4.35 | 10.50 | 30 | 20 | 37.68 | 3.27 | |

| 1.13 | 0.45 | 8.221 | 4.920 | 4.55 | 10.54 | 40 | 20 | 40.68 | 3.34 | |

| Bahrami et al., 2020 (A) [62] | 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | - | - | 38.99 | 3.61 |

| 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | 25 | - | 36.70 | 3.45 | |

| 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | 50 | - | 32.80 | 3.22 | |

| 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | 75 | - | 29.60 | 2.70 | |

| 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | 100 | - | 24.80 | 2.50 | |

| Bahrami et al., 2020 (B) [62] | 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | - | - | 38.99 | 3.61 |

| 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | - | 25 | 37.00 | 3.55 | |

| 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | - | 50 | 33.51 | 3.38 | |

| 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | - | 75 | 31.36 | 2.76 | |

| 0.41 | 0.33 | 4.325 | 3.000 | 3.80 | 7.35 | - | 100 | 25.83 | 2.46 | |

| Silva et al., 2016 [98] | 0.45 | 0.36 | 4.188 | 2.513 | 2.88 | 8.28 | - | 0 | 35.50 | 3.05 |

| 0.45 | 0.36 | 4.141 | 2.513 | 2.88 | 8.35 | - | 25 | 27.69 | 2.70 | |

| 0.45 | 0.36 | 4.095 | 2.513 | 2.89 | 8.42 | - | 50 | 29.11 | 2.71 | |

| 0.45 | 0.36 | 4.049 | 2.513 | 2.89 | 8.49 | - | 75 | 30.18 | 2.35 | |

| 0.45 | 0.36 | 4.003 | 2.513 | 2.90 | 8.57 | - | 100 | 25.21 | 2.28 | |

| Sun et al., 2020 (A) [96] | 0.40 | 0.32 | 4.027 | 1.949 | 2.40 | 7.58 | 0 | 0 | 40.26 | 4.03 |

| 0.40 | 0.32 | 4.027 | 1.949 | 2.42 | 7.58 | 10 | 0 | 39.05 | 3.28 | |

| 0.40 | 0.32 | 4.027 | 1.949 | 2.44 | 7.58 | 10 | 25 | 38.04 | 3.32 | |

| 0.40 | 0.32 | 4.027 | 1.949 | 2.46 | 7.58 | 10 | 50 | 35.46 | 3.37 | |

| 0.40 | 0.32 | 4.027 | 1.949 | 2.48 | 7.58 | 10 | 100 | 33.35 | 3.28 | |

| Sun et al., 2020 (B) [96] | 0.40 | 0.32 | 4.027 | 1.949 | 2.40 | 7.58 | 0 | 0 | 40.26 | 4.03 |

| 0.40 | 0.32 | 4.027 | 1.949 | 2.62 | 7.58 | 10 | 0 | 35.36 | 3.41 | |

| 0.40 | 0.32 | 4.027 | 1.949 | 2.85 | 7.58 | 10 | 25 | 35.58 | 3.53 | |

| 0.40 | 0.32 | 4.027 | 1.949 | 3.28 | 7.58 | 10 | 50 | 32.63 | 3.17 | |

| 0.40 | 0.32 | 4.027 | 1.949 | 3.72 | 7.58 | 10 | 100 | 32.39 | 2.81 | |

| Surendar et al., 2021 [97] | 0.45 | 0.45 | 3.429 | 1.808 | 1.90 | 10.16 | - | 0 | 36.66 | 4.12 |

| 0.45 | 0.45 | 4.376 | 1.808 | 1.90 | 8.37 | - | 10 | 36.22 | 4.07 | |

| 0.45 | 0.45 | 4.376 | 1.808 | 1.90 | 8.37 | - | 15 | 35.77 | 4.00 | |

| 0.45 | 0.45 | 4.376 | 1.808 | 1.90 | 8.37 | - | 20 | 34.95 | 3.98 | |

| 0.45 | 0.45 | 4.376 | 1.808 | 1.90 | 8.37 | - | 25 | 34.50 | 3.96 | |

| 0.45 | 0.45 | 4.376 | 1.808 | 1.90 | 8.37 | - | 50 | 32.44 | 3.23 | |

| 0.45 | 0.45 | 4.376 | 1.808 | 1.90 | 8.37 | - | 75 | 27.60 | 2.70 | |

| Tuyan et al., 2014 (A) [74] | 0.53 | 0.4 | 4.867 | 2.184 | 2.20 | 7.83 | - | 0 | 37.20 | 4.19 |

| 0.53 | 0.4 | 4.867 | 2.184 | 2.40 | 7.83 | - | 20 | 37.70 | 3.95 | |

| 0.53 | 0.4 | 4.867 | 2.184 | 2.70 | 7.83 | - | 40 | 38.20 | 3.73 | |

| 0.53 | 0.4 | 4.867 | 2.184 | 3.00 | 7.83 | - | 60 | 35.80 | 3.52 | |

| Babaloa et al., 2020 (A) [95] | 0.45 | 0.45 | 3.515 | 1.229 | 3.46 | 9.97 | - | 0 | 30.60 | 2.80 |

| 0.81 | 0.45 | 11.781 | 4.813 | 2.30 | 5.97 | - | 100 | 31.70 | 3.00 | |

| 0.90 | 0.45 | 13.09 | 5.347 | 2.30 | 5.97 | - | 100 | 33.50 | 3.20 | |

| 1.01 | 0.45 | 14.843 | 6.063 | 2.29 | 5.91 | - | 100 | 35.80 | 3.50 | |

| 1.15 | 0.45 | 16.982 | 6.937 | 2.28 | 5.88 | - | 100 | 37.00 | 3.52 | |

| 1.36 | 0.45 | 20.053 | 8.191 | 2.27 | 5.89 | - | 100 | 39.80 | 3.70 | |

| 1.64 | 0.45 | 24.167 | 9.872 | 2.26 | 5.90 | - | 100 | 39.20 | 3.91 | |

| Babaloa et al., 2020 (B) [95] | 0.45 | 0.45 | 3.515 | 1.229 | 3.46 | 9.97 | - | 0 | 30.60 | 2.80 |

| 0.81 | 0.45 | 11.781 | 4.813 | 2.30 | 5.97 | - | 100 | 31.70 | 3.00 | |

| 0.66 | 0.37 | 11.930 | 4.873 | 2.82 | 4.66 | - | 100 | 41.40 | 3.82 | |

| 0.81 | 0.35 | 13.464 | 5.500 | 2.62 | 5.13 | - | 100 | 38.00 | 3.74 | |

| 0.98 | 0.40 | 15.202 | 6.210 | 2.43 | 5.55 | - | 100 | 37.40 | 3.68 | |

| 1.15 | 0.45 | 16.982 | 6.937 | 2.28 | 5.88 | - | 100 | 37.00 | 3.52 | |

| 1.34 | 0.50 | 19.040 | 7.778 | 2.14 | 6.16 | - | 100 | 33.00 | 3.28 | |

| Nieto et al., 2018 (C) [99] | 0.45 | 0.35 | 4.105 | 2.328 | 6.10 | 8.34 | - | 0 | 38.78 | 2.82 |

| 0.45 | 0.35 | 4.093 | 2.328 | 6.10 | 8.36 | - | 20 | 43.01 | 2.63 | |

| 0.45 | 0.35 | 4.081 | 2.328 | 6.10 | 8.38 | - | 40 | 44.96 | 2.88 | |

| 0.45 | 0.35 | 4.069 | 2.328 | 6.10 | 8.40 | - | 60 | 47.69 | 3.27 | |

| Nieto et al., 2018 (D) [99] | 0.45 | 0.35 | 4.105 | 2.328 | 6.10 | 8.34 | - | 0 | 38.78 | 2.82 |

| 0.46 | 0.36 | 4.093 | 2.328 | 6.10 | 8.59 | - | 20 | 40.09 | 3.33 | |

| 0.48 | 0.37 | 4.081 | 2.328 | 6.10 | 8.88 | - | 40 | 41.30 | 2.95 | |

| 0.49 | 0.38 | 4.069 | 2.328 | 6.10 | 9.17 | - | 60 | 40.54 | 2.40 | |

| Nieto et al., 2018 (E) [99] | 0.45 | 0.35 | 4.105 | 2.328 | 6.10 | 8.34 | - | 0 | 38.78 | 2.82 |

| 0.46 | 0.36 | 4.093 | 2.328 | 6.10 | 8.59 | - | 20 | 40.78 | 3.34 | |

| 0.48 | 0.37 | 4.081 | 2.328 | 6.10 | 8.88 | - | 40 | 43.07 | 3.24 | |

| 0.49 | 0.38 | 4.069 | 2.328 | 6.10 | 9.17 | - | 60 | 42.94 | 3.08 | |

| Authors | Design Parameters | Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | fc | fs | |

| Aslani et al., 2018 (A) [85] | 1.13 | 0.45 | 8.468 | 5.090 | 3.35 | 10.30 | 0 | 0 | 22.21 | 2.71 |

| 1.13 | 0.45 | 8.788 | 5.050 | 4.35 | 10.01 | 10 | 20 | 28.63 | 3.02 | |

| 1.13 | 0.45 | 8.743 | 5.010 | 4.75 | 10.05 | 20 | 20 | 28.01 | 2.75 | |

| 1.13 | 0.45 | 8.699 | 4.960 | 4.95 | 10.09 | 30 | 20 | 24.03 | 2.97 | |

| 1.13 | 0.45 | 8.654 | 4.920 | 5.35 | 10.13 | 40 | 20 | 27.13 | 3.07 | |

| Nieto et al., 2018 (A) [99] | 0.55 | 0.42 | 4.564 | 2.589 | 5.50 | 9.39 | - | 0 | 25.11 | 2.15 |

| 0.55 | 0.42 | 4.550 | 2.589 | 5.50 | 9.41 | - | 20 | 27.65 | 1.61 | |

| 0.55 | 0.42 | 4.537 | 2.589 | 5.50 | 9.43 | - | 40 | 35.86 | 2.12 | |

| 0.55 | 0.42 | 4.523 | 2.589 | 5.50 | 9.45 | - | 60 | 29.20 | 2.31 | |

| 0.55 | 0.42 | 4.510 | 2.589 | 5.50 | 9.47 | - | 80 | 34.29 | 2.10 | |

| 0.55 | 0.42 | 4.496 | 2.589 | 5.50 | 9.50 | - | 100 | 34.17 | 2.52 | |

| Nieto et al., 2018 (B) [99] | 0.50 | 0.38 | 4.339 | 2.461 | 5.80 | 8.87 | - | 0 | 24.78 | 2.07 |

| 0.50 | 0.38 | 4.326 | 2.461 | 5.80 | 8.89 | - | 20 | 31.25 | 2.78 | |

| 0.50 | 0.38 | 4.313 | 2.461 | 5.80 | 8.91 | - | 40 | 40.69 | 2.74 | |

| 0.50 | 0.38 | 4.301 | 2.461 | 5.80 | 8.93 | - | 60 | 38.56 | 2.08 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jagadesh, P.; Juan-Valdés, A.; Guerra-Romero, M.I.; Morán-del Pozo, J.M.; García-González, J.; Martínez-García, R. Effect of Design Parameters on Compressive and Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate: An Overview. Appl. Sci. 2021, 11, 6028. https://doi.org/10.3390/app11136028

Jagadesh P, Juan-Valdés A, Guerra-Romero MI, Morán-del Pozo JM, García-González J, Martínez-García R. Effect of Design Parameters on Compressive and Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate: An Overview. Applied Sciences. 2021; 11(13):6028. https://doi.org/10.3390/app11136028

Chicago/Turabian StyleJagadesh, P., Andrés Juan-Valdés, M. Ignacio Guerra-Romero, Julia M. Morán-del Pozo, Julia García-González, and Rebeca Martínez-García. 2021. "Effect of Design Parameters on Compressive and Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate: An Overview" Applied Sciences 11, no. 13: 6028. https://doi.org/10.3390/app11136028

APA StyleJagadesh, P., Juan-Valdés, A., Guerra-Romero, M. I., Morán-del Pozo, J. M., García-González, J., & Martínez-García, R. (2021). Effect of Design Parameters on Compressive and Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate: An Overview. Applied Sciences, 11(13), 6028. https://doi.org/10.3390/app11136028