1. Introduction

Lever mechanisms have been used to amplify force or displacement for a mechanical advantage since time immemorial. Based on the conservation of energy, the amount of amplification a lever provides can be calculated as the ratio of the distance from the pivot point to the effort point and that from the pivot point to the load point. Numerous mechanical mechanisms and devices have been developed successfully with proper lever mechanisms [

1,

2,

3,

4,

5,

6]. H. Lin and W. Feng proposed a torque generator-driven lever mechanism for a torsional mirror. In the mechanism, a lever was exploited to enlarge traveling distance in limited design space [

1]. Woude et al. developed a new design for a lever-propelled wheelchair [

2]. K. Li and M. Gohnert suggested a lever mechanism for improving vibration isolation performance. In their study, damping force was conveyed to the mass through the lever [

3]. Several researchers have developed gripper mechanisms for microelectromechanical systems (MEMS) using lever mechanisms. C. Shi et al. proposed a microgripper with a large magnification ratio. In this mechanism, the lever successfully amplified the limited output displacement of a lead zirconate titanate (PZT) actuator for the desired displacement of the gripper [

4]. K. Kwon et al. developed a linear motor using a lever mechanism to improve the position accuracy. Unlike this mechanism of a microgripper, the lever mechanism in a linear motor had the role of reducing the displacement [

5]. M. French and M. Widden developed a static balancing mechanism using a spring and lever. In this mechanism, the lever amplified the spring force and achieved a lightweight static balancer for a lamp [

6].

In recent years, lever mechanisms with variable amplification ratios have frequently been applied in robot mechanisms, particularly variable stiffness actuators [

7,

8,

9,

10,

11,

12]. A. Jafari et al. [

7] and N. Tsagarakis [

8] et al. proposed adjustable stiffness actuators with class 1 levers for ankle assistance mechanisms. Sun et al. [

10], Groothuis et al. [

11] and Barrett et al. [

12] also developed a class 1 lever-based actuator to achieve variable stiffness. To adjust the stiffness, the lever position was varied using an additional motor. B. Kim and J. Song also developed a variable stiffness actuator with a lever mechanism. When the class 2 lever mechanism was applied, the position of the lever’s load point varied to change the actuator’s stiffness [

9]. Although the lever mechanisms with a variable amplification ratio achieved the desired function successfully, the shape for the levers was a straight line. Moreover, due to the simplicity of the straight lever, the above-mentioned studies did not propose a lever contour design methodology.

However, when a lever had an additional required function beyond amplification such as preventing intervention between design spaces or maximizing the variable range of amplification ratio, the lever was required to have a shape other than a simple straight line. J. Kim et al. developed a compact variable gravity compensation mechanism with a non-straight lever shape. An angled lever was devised to achieve the amplification of the spring force and also to satisfy the circular design space, [

13]. M. Dezman and A. Gams suggested an arc-shaped lever-based compliant actuator to satisfy both force amplification and energy-efficient stiffness variation functions [

14]. Although these studies showed a non-straight lever shape, the geometries of the levers’ contours were still simple and did not require any particular contour design methodology.

J. Kim et al. [

15] proposed a curved lever design to improve the performance of a variable gravity compensation mechanism. In this method, the curved lever was mathematically modeled based on B-spline representation and optimized using a genetic algorithm. Although the research suggested a curved lever design methodology, there was a limitation that the lever contour was represented as a unitary curve. This approach is suitable for a nonfunctional lever contour. However, when a multifunctional lever contour is designed using a unitary curve model and optimization approach, the complexity of the design problem could worsen due to the difficulties of determining the design vector and constructing a multivariable objective function with weighting factors.

Recently, we proposed a new version of a compact variable gravity compensator with a multifunctional lever [

16]. In this study, first, we proposed the early concept of divide-and-conquer design methodology for a curved lever contour. Although the lever contour, on the paper, showed the potential of the divide-and-conquer design methodology, one of the lever contours still had a curve representation for two assigned functions. When the lever contour was optimized for two variable objective functions, design variables that maximize each function could not be selected.

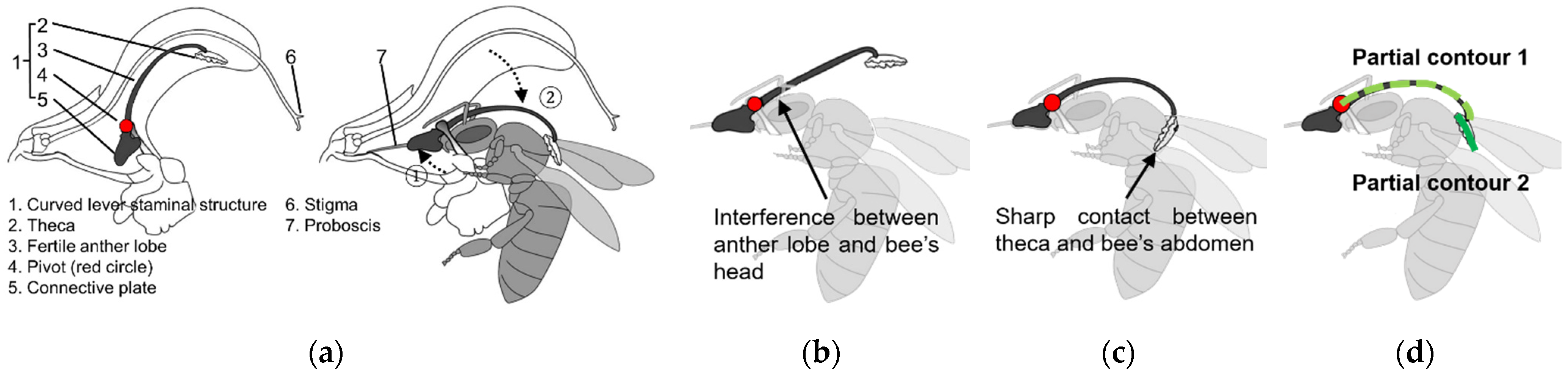

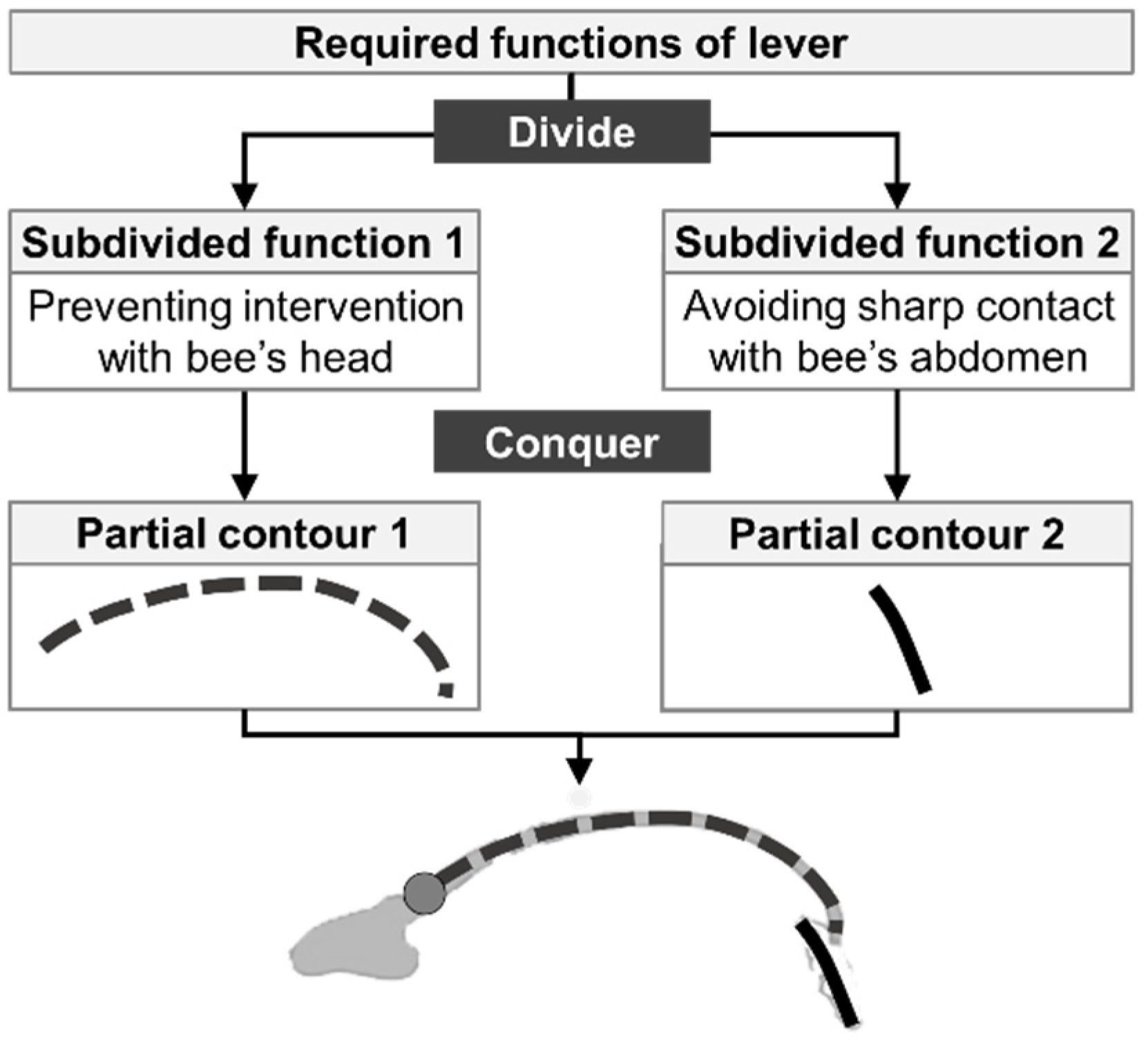

To overcome the limitation of the above-mentioned lever contour design methods, in this study, we proposed a bioinspired divide-and-conquer design methodology for multifunctional lever contours. Salvia pratensis flowers have a curved lever mechanism in the staminal lobe as an effective pollen dispensing system. The staminal lever curve can be subdivided into a contour to prevent interference with bees’ heads and a contour for applying pollen to bees’ abdomens. From this morphological insight, we subdivided all required functions into subfunctions that were assigned to the design goal of each partial contour. Each contour was represented by a mathematical curve model suitable for achieving the assigned function and was determined through an appropriate method. The design methodology provides a design tool for the designer to generate a multifunctional lever contour.

To convey the usage of the methodology, we determined the compact variable gravity compensation (CVGC) mechanism as a design case study. Four subfunctions were assigned to the curved lever, which included: (1) minimizing the required force for the torque variation, (2) maximizing the variable range of the compensation torque, (3) preventing interference with cam structure, and (4) connecting between contours with C1 continuity. The experiments showed that the derived lever contour successfully achieved all subfunctions simultaneously. Moreover, the lever contour showed a 1.3 times wider variable range as compared with the lever in [

16]. This paper is organized as follows: In

Section 2, we explain the bioinspired insight from

Salvia pratensis flowers and the concept of the lever contour design methodology in detail; in

Section 3, we describe the operating concept of CVGC and the required functions for the curve lever mechanism; in

Section 4, we discuss the detailed design processes for the lever contour; in

Section 5, we show the experimental results of the designed curved lever contour; and finally, in

Section 6, we present our conclusions.

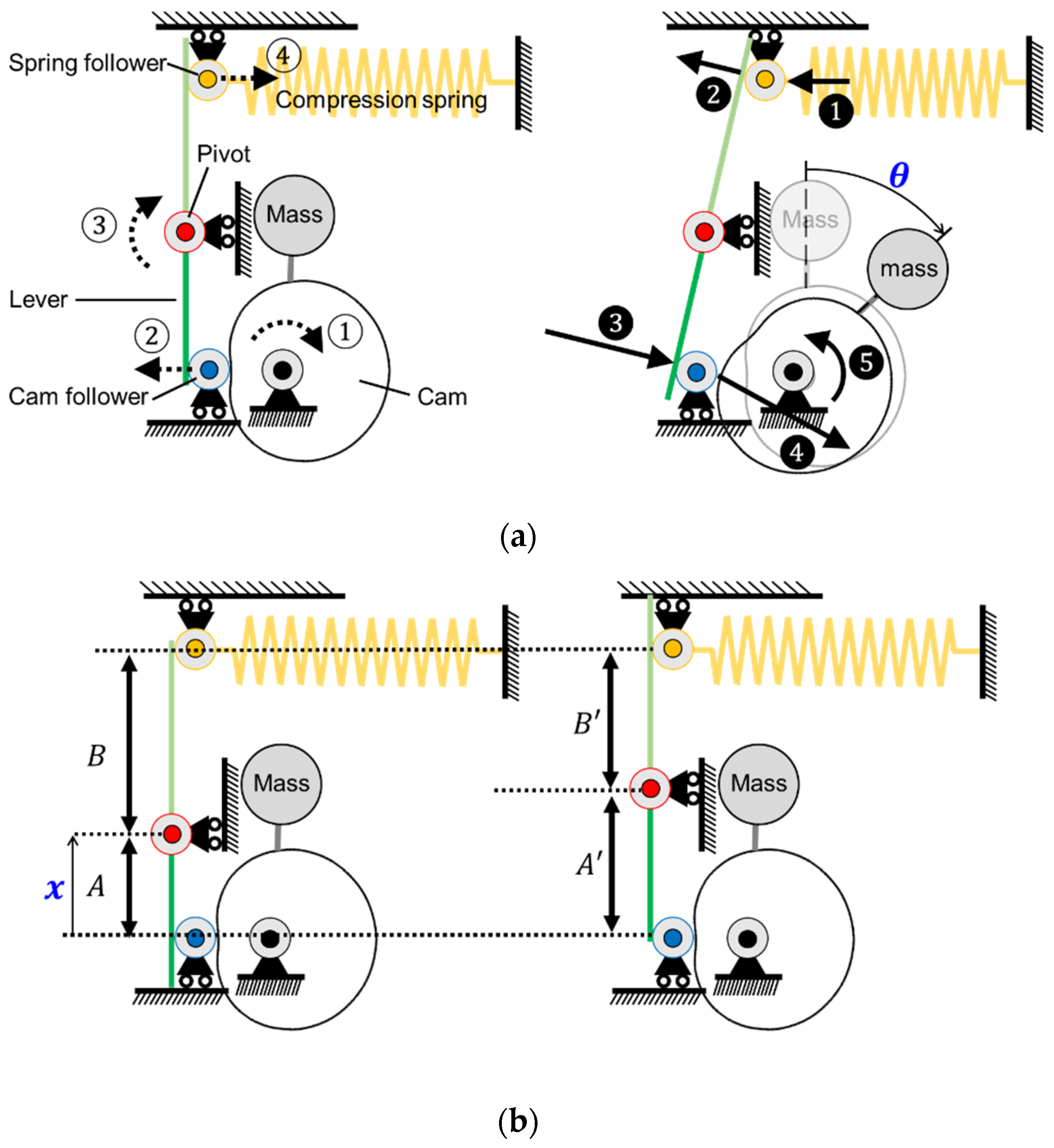

4. Curved Lever Contour Design

To design the lever contour to achieve the multifunctionality mentioned in

Section 3.2, the divide-and-conquer design methodology is applied. Through this method, each subfunction is assigned to the design goal of each partial contour. Partial contours are separately designed to satisfy their individual goals, and then combined as a final lever contour.

The geometrical design parameters of other mechanical components such as the cam profile, cam follower guides, and spring follower are given as geometrical constraints that those should not be able to pass through. The shape of the lever can be divided into the cam follower side and spring follower based on the pivot. In this section, it is assumed that the lever contour of the cam follower side is predetermined as a straight line and aims to design only the contour on the spring follower side.

4.1. Partial Contour 1 (PC1): Minimizing the Required Force for Torque Variation

The PC1 should not change the position of the spring follower when the pivot position varies along the pivot guide. The CVGC varies the compensation torque when the rotation angle of the cam is zero. Since the cam follower side of the lever always contacts the cam follower, the translation and rotation of the lever occur simultaneously when the pivot position changes, as illustrated in

Figure 5a.

In a global coordinate system, the contour design is complex due to the changes of relative angles and distances between the lever and the spring follower. However, the positions of points that determine the rigid lever shape do not change in the lever coordinate system. Therefore, the lever design problem can become easier when in a lever coordinate system.

To calculate the coordinate transformation, representative pivot positions are determined by dividing the pivot guidelines equally into n sections. Nine representative pivot positions were selected, including the top and bottom pivot positions. The unit length for a section and the rotation angles at each pivot position can be determined using (2) and (3) as follows:

where

and

indicate the position of the

pivot in the global coordinates;

and

are the

x and

y components of the unit length, respectively;

is the radius of the cam follower. Then, the translation and transformation matrices at the

selected pivot positions can be calculated using (4) and (5), respectively, as follows:

where the left subscript

G in (4) is the lever and global coordinate system, the left subscript

G and the superscript

L represent the global coordinates and lever coordinates, respectively, and

C and

S are the cosine and sine, respectively.

Using the transformation matrices, the fixed spring follower positions are transformed into a lever coordinate system and nine circles are generated, as shown in

Figure 5b. The PC1 should be designed to have a shape that makes contact with all nine circles at the same time. For the next step, the common circumferential lines and points between adjacent circles are computed to find contact points between the lever and circles. Except for the first and last circles, the

circle has two common circumferential lines and contact points between the

and

circles of spring followers. To assign one tangential line and point to a circle, the line and contact point between the

circle are selected. As a result, each of the nine circles has a corresponding contact point and slope of the tangential line at that point, as illustrated in

Figure 5c.

For the last step, piecewise curves connecting to the adjacent contact points with a satisfactory slope are generated based on the third order Hermite spline. Consequently, the PC1 is formed by connecting the eight piecewise curves that enable tangential contact with the spring follower at each pivot position, thereby achieving subfunction 1 as shown in

Figure 5d.

4.2. Partial Contour 2 (PC2): Maximizing the Variable Range of the Compensation Torque

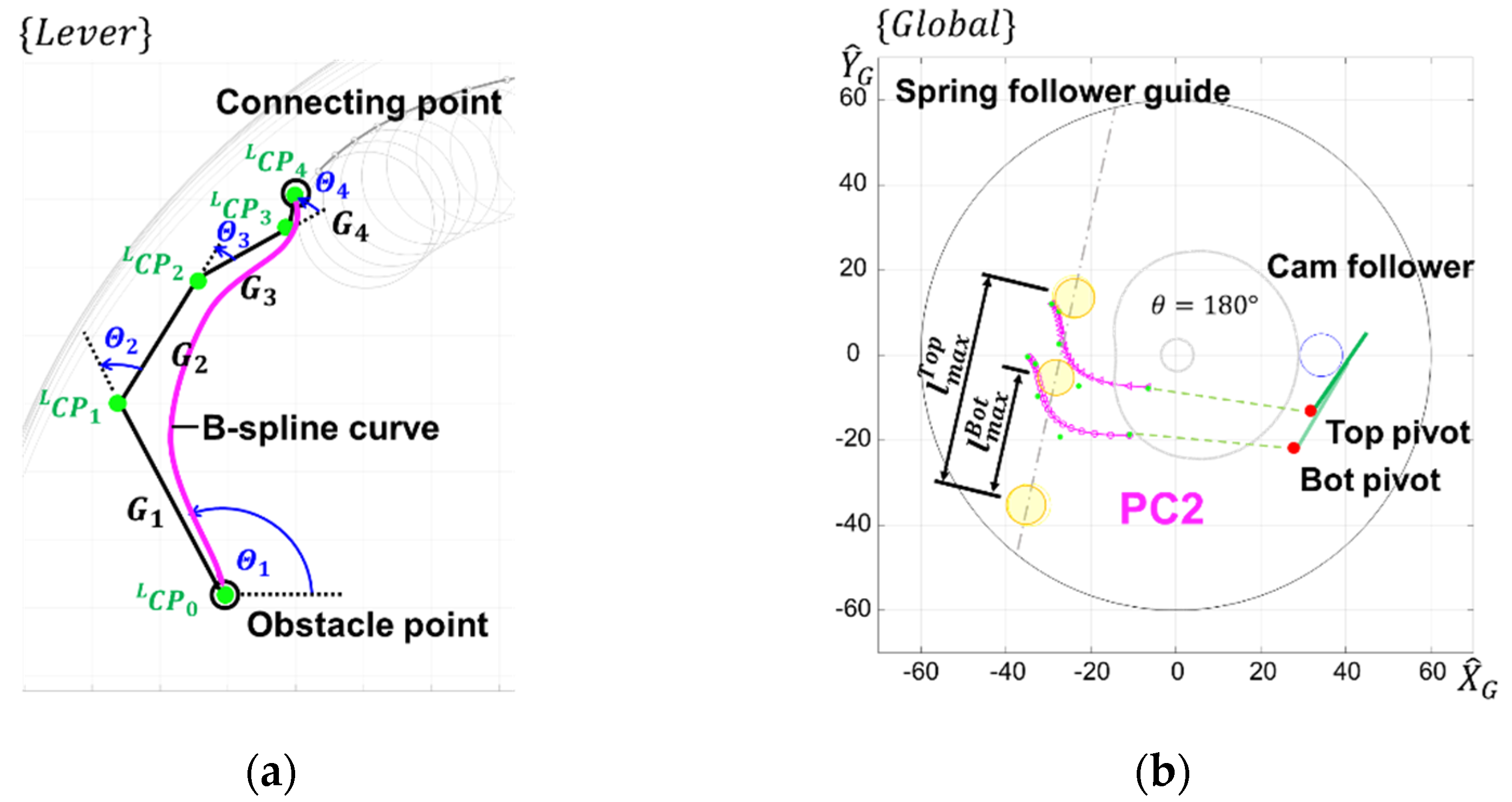

A B-spline curve representation and optimization approach is adopted to generate a PC2 that satisfies the subfunction. As illustrated in

Figure 6a, five control points are placed in the lever coordinates system to form a B-spline curve of PC2. The start and end points among the five control points are determined by an obstacle point and a connecting point, respectively, as explained in detail later. A serial link representation is used to avoid the cusp issue [

15] as in (6)–(15) as follows:

where

is the length of the

link and

is the relative angle between the

and

link.

The objective function for optimizing the B-spline is defined to maximize the variable range of the compensation torque as follows:

are the maximum deformation of the spring when the pivot is placed at the top and bottom positions, respectively, as shown in

Figure 6b. The denominator of the objective function increases as the deformation of the spring at the bottom pivot position decreases, which is related to the lowest compensation torque. The numerator increases when the deformation of the spring at the top pivot position increases, which is related to the highest compensation torque. The case in which the deformation by the PC2 exceeds the allowable deformation of the spring is excluded as a constraint condition. Therefore, the larger the objective function, the larger the variable range of the compensation torque that can be acquired.

Since

can be calculated by the geometrical relation between the B-spline curve and the spring follower guideline, the lever contour defined in the lever coordinate system should be transformed to the global coordinate system. Consequently, the optimization problem is as follows:

Table 1 shows the optimization result computed by the genetic algorithm in the global optimization toolbox of MATLAB (MATLAB R2019b, MathWorks, United States). The optimal PC2 generates 50.4 mm and 29.8 mm as the maximum compression lengthx of the spring at the top and bottom pivot positions, respectively.

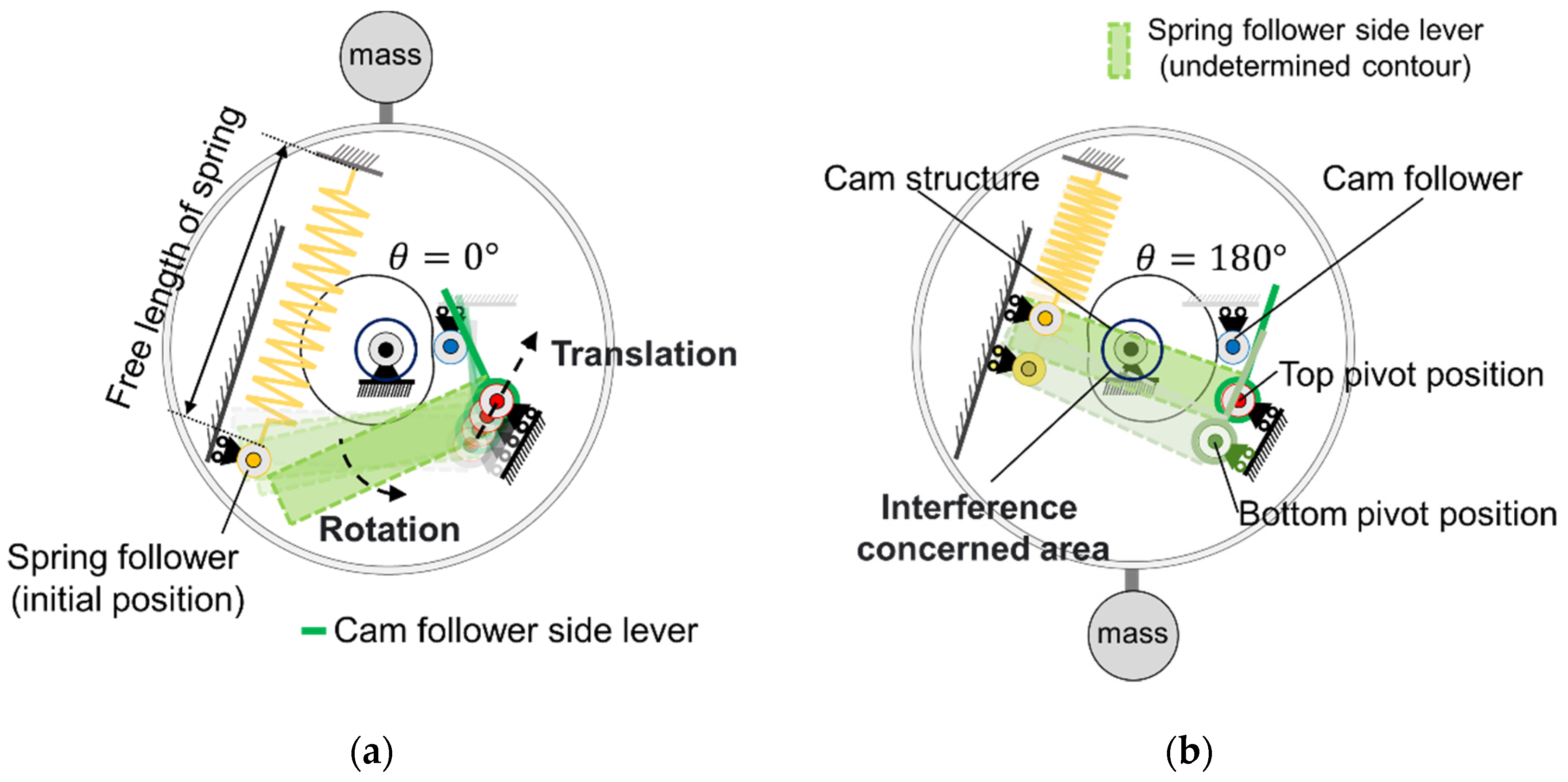

4.3. Partial Contour 3 (PC3): Preventing Interference with the Cam Structure

As shown in

Figure 4B, the PC3 should be designed to avoid interference with the cam structure only when the cam rotates to 180° at the top pivot position. As illustrated in

Figure 7, in the global coordinate system, the common circumferential line and points between the circle of the cam structure and the highest spring follower can be calculated.

The common point on the circle of the cam structure is the obstacle point that is used to design PC2. The obstacle points allow PC2 to avoid interference with the cam structure. Considering that the mass of the lever is proportional to its length, PC3 is determined using the simplest straight line and arc, as illustrated in

Figure 7a.

4.4. Partial Contour 4 (PC4): Connecting PC1 and PC2 with C1 Continuity

As a final step of the divide-and-conquer design methodology, combining the derived partial contours with proper continuity condition is important to generate the final contour. The connection between PC2 and PC3 is the area in which the spring follower does not contact with the spring follower. Therefore, the C0 continuity is sufficient to combine the PC2 and PC3. However, the area between the PC1 and PC2 makes contact with the spring follower, so the connection should satisfy the C1 continuity to ensure the smooth motion of the spring follower.

To achieve the connection with C1 continuity, PC4 is designed as follows: On the PC1 side, the starting point and slope at that point are already determined, as described in

Section 4.1.

The starting point of PC1 extends by distance ε in the direction of the slope to make the connecting point. The connecting point is used as the fifth control point of PC2, as described in

Section 4.2. Using the partial derivatives of PC2, the slope at the connecting point can also be calculated. Finally, based on the Hermite spline representation, PC4 can be determined, as illustrated in

Figure 7b. A pseudo code of the algorithm for the design of partial contours is attached in

Supplementary Materials.

5. Experiments and Results

The detail design of the lever contour made by combining PC1, PC2, PC3, and PC4 is as presented in

Figure 7c. To verify that the lever achieves the desired multifunctions, experiments are separately conducted on each partial contours. As shown in

Figure 7d, the lever used in the experiments was manufactured with a 3D-printer (Mark Two, Markforged, MA, US) with carbon-fiber materials that have sufficient strength for experimental verifications. According to the visual measurement method, the experiments successfully checked that each partial contour satisfied the geometrical conditions to achieve a given subfunction.

Figure 8 illustrates the manufactured CVGC mechanism with the designed lever contour.

To verify the subfunction of PC1, the position of the spring follower was measured by marker tracking when the position of the pivot changed. Although a minor position. change of the spring follower occurred, PC1 successfully minimized the movement, as shown in

Figure 9.

The position change of the spring follower had 0.4 mm as its maximum value. The reason for the design error of PC1 is the lack of a number of representative pivot points; therefore, this error can be mitigated by increasing the number of representative pivot points and piecewise curve segments of PC1.

Next, each position of the spring follower was measured at the top and bottom pivot positions to verify the function achievement of PC2. As presented in

Figure 10 and

Table 2, the amounts of spring deformation at each pivot condition are 29.5 and 50.5 mm, which is well-matched with the designed values. The errors of deformation length between simulation and experiment are 1.0% and 0.1% at the bottom (bot) and top pivot conditions, respectively. The absolute errors are 0.7 and 0.1 mm at the bot and top pivot positions, respectively. We expect the position error of marker installation is the main reason for the errors between simulation and experiment.

Finally, to verify the interference avoidance in the lever and cam structure, which is a function of PC3, the lever was observed at the top pivot position and at 180° cam rotation. As shown on the right side of

Figure 10, the lever pushed the spring follower without any interferences. Therefore, PC3 successfully achieves its subfunction.

6. Conclusions

In this study, we propose a contour design methodology for achieving a multifunctional lever based on the morphological principle of the Salvia pratensis flower. In this methodology, multiple functions were subdivided into subfunctions. Each subfunction was assigned to a partial contour as a design goal. The final lever contour was determined by combining the partial contours that could achieve the given subfunctions. Through this methodology, a designer can simplify complex and multifunctional curve design problems. Moreover, the most suitable modeling and parameters to determine the method can be selected for each partial contour.

This methodology was specifically explained by a design case study of CVGC, in which the lever should achieve three subfunctions. To achieve the first function, PC1 was modeled using a Hermite spline and was directly calculated to find the design parameters. For the second subfunction, PC2 was determined by B-spline model-based optimization. To satisfy the third subfunction, PC3 was derived simply by using an arc and straight line model. In addition, the PC4 based on Hermite spline was designed to generate a smooth rolling contact with the spring follower.

Finally, through marker tracking-based visual verification, it was verified that, for the derived lever contour, each partial contour could successfully achieve subfunctions. PC1 did not change the position of the spring follower and did not generate deformation of the compression spring. The difference between the maximum deformation of the spring was increased 1.3 times by PC2 when the pivot was placed in the top and bottom (bot) positions as compared with the previously derived lever in [

16]. As mentioned in

Section 4.2, this difference is directly related to the variable range of compensation torque. PC3 did not prevent any intervention between the lever and cam structure. PC4 achieved C1 continuity between C1 and C2. As future research goals, we plan to install the derived lever into CVGC and measure the performances of the variable gravity compensation torque. In addition, we are developing various versions of CVGC with different sizes and compensation torques. Therefore, we will actively utilize this methodology to design various versions of levers.