Advisory and Knowledge Transfer Tool for Ammonia Emission Mitigation on Pig Farms in Hungary

Abstract

:1. Introduction

2. Materials and Methods

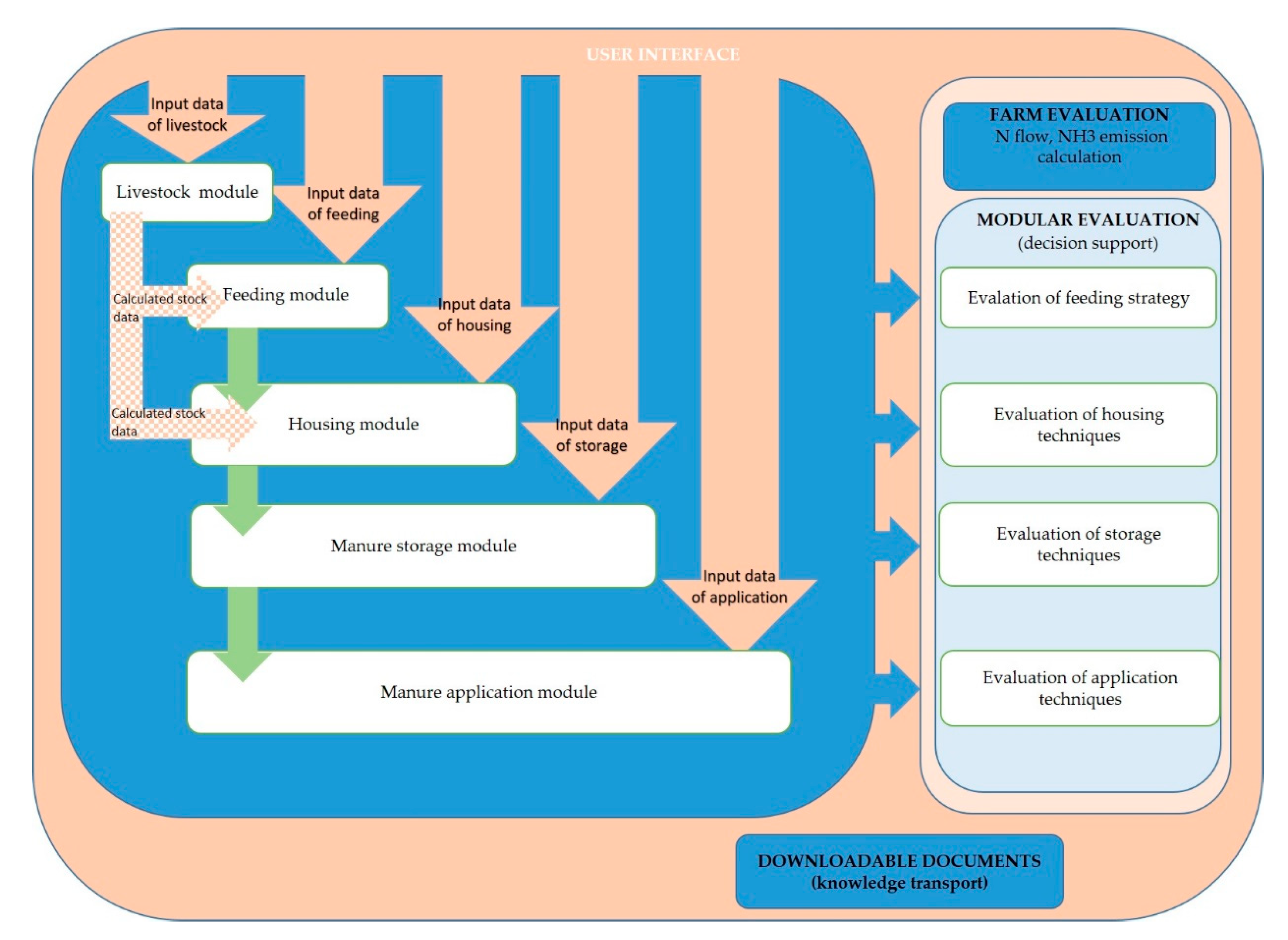

2.1. The System Architecture

2.2. Scientific Background of Data Requirement and Modules of AGEM-S

2.2.1. Input Data—Natural Indicators of Pig Livestock

2.2.2. Nutrition Module

2.2.3. Housing Module

2.2.4. Manure Storage Module

2.2.5. Manure Application Module

3. Results

3.1. The Data Structure and Functionality of AGEM-S

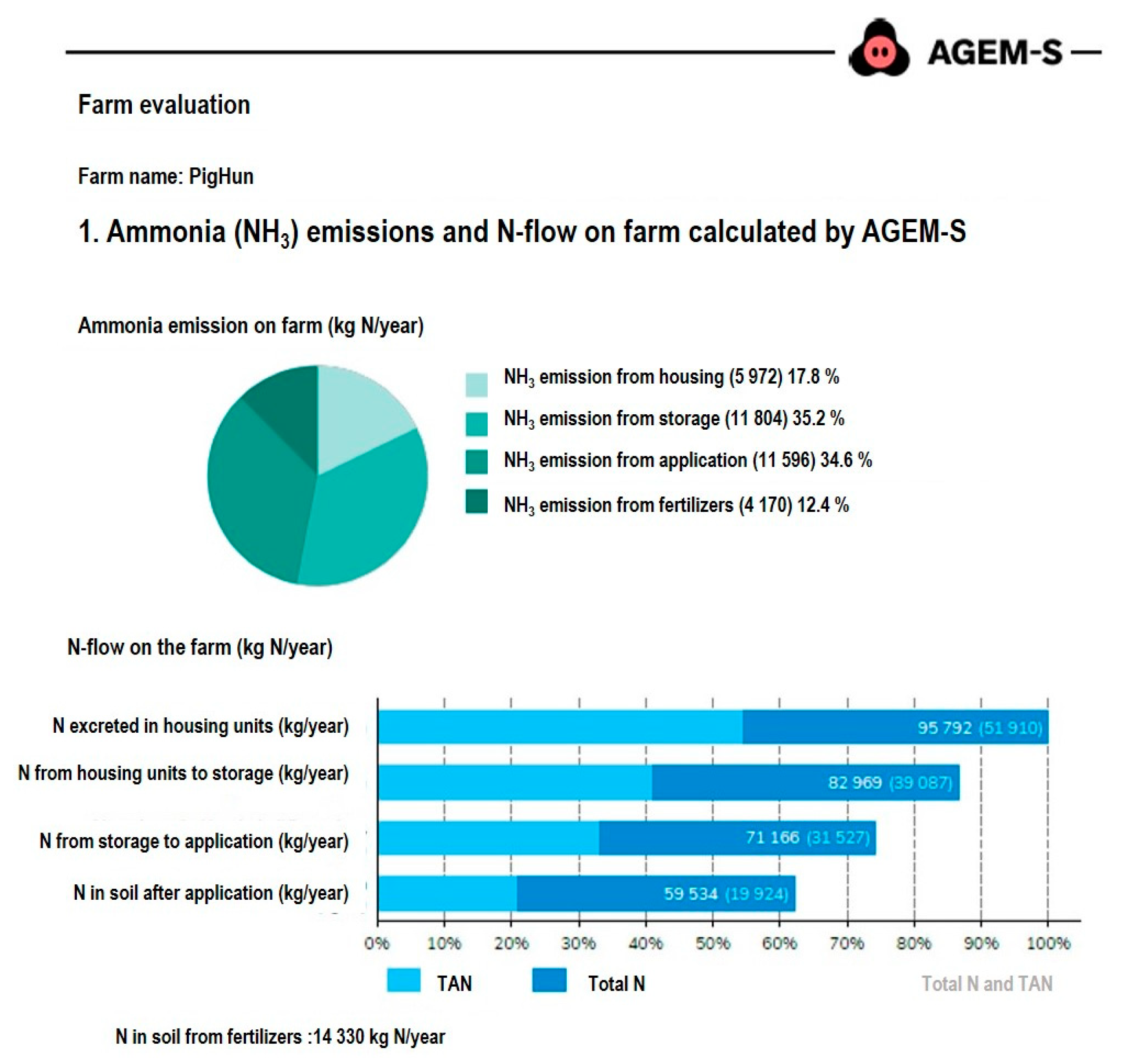

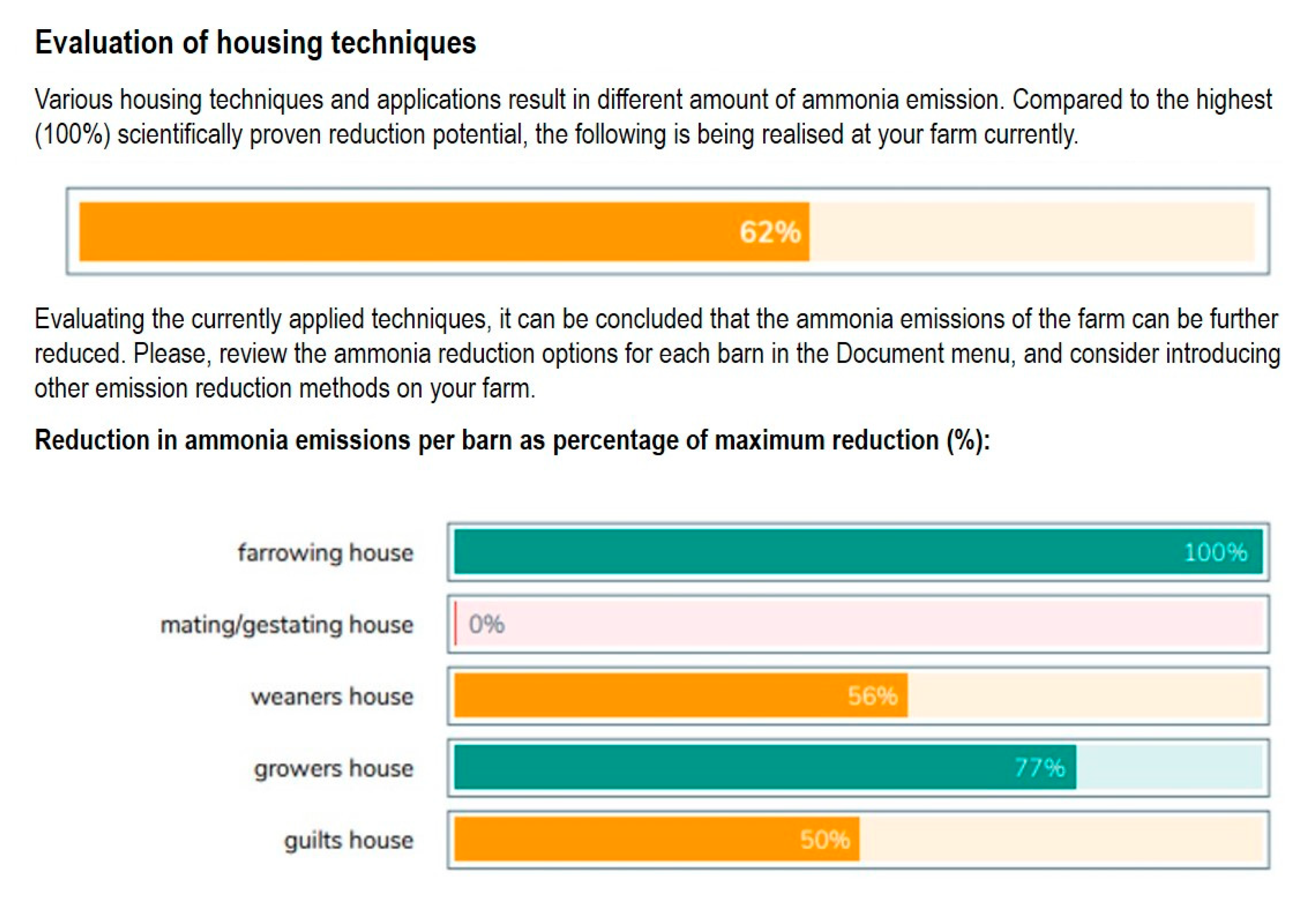

3.2. Farm Scale Evaluations as the Outputs of the AGEM-S

3.3. Using AGEM-S Decision Support and Knowledge Transfer Functionality in Practice

- (1)

- Guiding vision: ensuring needs within the capacity of the biosphere to sustain the potential of future generations. The principle is indirect, as it focuses on the possibilities of reducing ammonia emissions from pig farming, with reference to legal (NEC Directive) [9] requirements.

- (2)

- Consideration of the underlying social, economic and environmental system; the multiple dimensions of sustainability; current trends; and drivers of change, risks, uncertainties, and implications for decision making. The planning process was preceded by a preliminary study of the pig sector and analysis of trends in the European context, but an assessment of uncertainties and possible implications for decision making was not carried out.

- (3)

- Appropriate time horizon and geographical scope: the factors used for the estimation are only partly country specific (nutrition), while the typical technologies take into account local specificities. The time scale of the model is one year, and improvements can be tracked using the copy/modify function.

- (4)

- Framework and indicators: AGEM-S is a well-defined framework, in terms of the input data, the emissions and correction factors used for the calculation, the influencing factors included in the calculation, and the assessment methodology.

- (5)

- Transparency: full transparency of the development is partially achieved. A detailed report documenting the design of the system has been submitted to the supporting Ministry of Agriculture, but no peer-reviewed publications have been published to date. The operation of the system is also documented in detail for the users.

- (6)

- Effective communication: AGEM-S satisfies this principle. It uses easy-to-understand language to communicate the results and presents them in a comprehensive, graphical way, thus enabling users to better understand the processes affecting farm-level ammonia emissions and the effects of their changes.

- (7)

- Extensive participation in the development: during the development of AGEM-S, the experts for each module were selected from the respective disciplines. The IT tasks were carried out by IT specialists and the Hungarian Pig Breeding Association (MSTSZ) ensured effective communication between farmers and developers through its field representatives and were involved in the preliminary surveys, the definition of the input data set, and the testing of the system.

- (8)

- Continuity and capacity: AGEM-S is capable of producing re-estimates on an annual basis. The estimation system can be used to track the annual variation in farm ammonia emissions. The potential for improving the system through the incorporation of new scientific results (factors, techniques) is a targeted and obvious goal.

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bittman, S.; Dedina, M.; Howard, C.M.; Oenema, O.; Sutton, M.A. (Eds.) Options for Ammonia Mitigation: Guidance from the UNECE Task Force on Reactive Nitrogen; Centre for Ecology and Hydrology: Edinburgh, UK, 2014; Available online: http://www.clrtap-tfrn.org/ (accessed on 15 April 2021).

- Krupa, S. Effects of atmospheric ammonia (NH3) on terrestrial vegetation: A review. Environ. Pollut. 2003, 124, 179–221. [Google Scholar] [CrossRef]

- Sutton, M.; Howard, C.; Erisman, J.W. The European Nitrogen Assessment: Sources, Effects and Policy Perspectives; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- Wu, Y.; Gu, B.; Erisman, J.W.; Reis, S.; Fang, Y.; Lu, X.; Zhang, X. PM2.5 pollution is substantially affected by ammonia emissions in China. Environ. Pollut. 2016, 218, 86–94. [Google Scholar] [CrossRef] [Green Version]

- Giannakis, E.; Kushta, J.; Bruggeman, A.; Lelieveld, J. Costs and benefits of agricultural ammonia emission abatement options for compliance with European air quality regulations. Environ. Sci. Eur. 2019, 31, 93. [Google Scholar] [CrossRef] [Green Version]

- World Health Organization (WHO). Health Effects of Particulate Matter. Policy Implications for Countries in Eastern Europe, Caucasus and Central Asia, World Health Organization. 2013. Available online: http://www.euro.who.int/__data/assets/pdf_file/0006/189051/Health-effects-of-particulate-matter-final-Eng.pdf (accessed on 14 April 2021).

- Schraufnagel, D.; Balmes, J.; De Matteis, S.; Hoffman, B.; Kim, W.J.; Perez-Padilla, R.; Rice, M.; Sood, A.; Vanker, A.; Wuebbles, D. Health Benefits of Air Pollution Reduction. Ann. Am. Thorac. Soc. 2019, 16, 1478–1487. [Google Scholar] [CrossRef]

- IIR. Hungary Informative Inventory Report 1990–2019. 2021. Available online: https://www.ceip.at/status-of-reporting-and-review-results/2021-submission (accessed on 15 May 2021).

- EP (2016). Directive (EU) 2016/2284 of the European Parliament and of the Council of 14 December 2016 on the Reduction of National Emissions of Certain Atmospheric Pollutants, Amending Directive 2003/35/EC and Repealing Directive 2001/81/EC. Brussels: European Council. Off. J. Eur. Union 2016, 344, 1–34. Available online: http://data.europa.eu/eli/dir/2016/2284/oj (accessed on 16 April 2021).

- Murphy, P.; Crosson, P.; O’Brien, D.; Schulte, R.P.O. The Carbon Navigator: A decision support tool to reduce greenhouse gas emissions from livestock production systems. Animal 2013, 7, 427–436. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- NAK 2018: Nemzeti Agrárgazdasági Kamara: Erősödő agrár- és Élelmiszergazdaság, Jólétében Gyarapodó Vidék. 2018. Available online: https://www.nak.hu/kiadvanyok/kiadvanyok/2301-erosodo-agrar-es-elelmiszer-gazdasag-joleteben-gyarapodo-videk/file (accessed on 15 May 2021).

- EMEP/EEA Air Pollutant Emission Inventory Guidebook: Technical Guidance to Prepare National Emission Inventories; European Environment Agency: Copenhagen, Denmark, 2019. [CrossRef]

- Oudendag, D.A.; Luesink, H.H. The Manure Model: Manure, minerals (N, P and K), ammonia emission, heavy metals and the use of fertiliser in Dutch agriculture. Environ. Pollut. 1998, 102, 241–246. [Google Scholar] [CrossRef]

- Menzi, H.; Ruttimann, L.; Reidy, B. DYNAMO: A new calculation model for dynamic emission inventories for ammonia. In International Symposium on Gaseous and Odour Emission from Animal Production Facilities; Horsens, Denmark; pp. 378–381.

- Webb, J.; Misselbrook, T.H. A mass-flow model of ammonia emissions from UK livestock production. Atmos. Environ. 2004, 38, 2163–2175. [Google Scholar] [CrossRef]

- Webb, J.; Sommer, S.G.; Kupper, T.; Groenestein, K.; Hutchings, N.J.; Eurich-Menden, B.; Rodhe, L.; Misselbrook, T.H.; Amon, B. Gaseous emissions during the management of solid manures. Sustain. Agric. Rev. 2012, 8, 67–107. [Google Scholar]

- Zhang, Y.; Collins, A.L.; Gooday, R.D. Application of the FARMSCOPER tool for assessing agricultural diffuse pollution mitigation methods across the Hampshire Avon Demonstration Test Catchment, UK. Environ. Sci. 2012, 24, 120–131. [Google Scholar] [CrossRef]

- Velthof, G.L.; van Bruggen, C.; Groenestein, C.M.; de Haan, B.J.; Hoogeveen, M.W.; Huijsmans, J.F.M. A model for inventory of ammonia emissions from agriculture in the Netherlands. Atmos. Environ. 2012, 46, 248–255. [Google Scholar] [CrossRef]

- Pinder, R.W.; Anderson, N.J.; Strader, R.; Davidson, C.I.; Adams, P.J. Ammonia Emissions from Dairy Farms: Development of a Farm Model and Estimation of Emissions from the United States. In Proceedings of the 12th International Emission Inventory Conference-”Emission Inventories-Applying New Technologies”, San Diego, CA, USA, 29 April–1 May 2003; Available online: https://www3.epa.gov/ttnchie1/conference/ei12/part/pinder.pdf (accessed on 15 April 2021).

- Deike, S.; Pallut, B.; Christen, O. Investigations on the energy efficiency of organic and integrated farming with specific emphasis on pesticide use intensity. Eur. J. Agron. 2008, 28, 461–470. [Google Scholar] [CrossRef]

- Küstermann, B.; Kainz, M.; Hülsbergen, K.J. Modelling carbon cycles and estimation of greenhouse gas emissions from organic and conventional farming systems. Renew. Agric. Food Syst. 2008, 23, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Küstermann, B.; Christen, O.; Hülsbergen, K.J. Modelling nitrogen cycles of farming systems as basis of site- and farm-specific nitrogen management. Agric. Ecosyst. Environ. 2010, 135, 70–80. [Google Scholar] [CrossRef]

- Rücknagel, J.; Hofmann, B.; Paul, R.; Christen, O.; Hülsbergen, K.-J. Estimating precompression stress of structured soils on the basis of aggregate density and dry bulk density. Soil Tillage Res. 2007, 92, 213–220. [Google Scholar] [CrossRef]

- Neufeldt, H.; Schäfer, M. Mitigation strategies for greenhouse gas emissions from agriculture using a regional economic-ecosystem model. Ecosyst. Environ. 2008, 123, 305–316. [Google Scholar] [CrossRef]

- Reidy, B.; Dammgen, U.; Dohler, H.; Eurich-Menden, B.; van Evert, F.K.; Hutchings, N.J.; Luesink, H.H.; Menzi, H.; Misselbrook, T.H.; Monteny, G.-J.; et al. Comparison of models used for national agricultural ammonia emission inventories in Europe: Liquid manure systems. Atmos. Environ. 2008, 42, 3452–3464. [Google Scholar] [CrossRef]

- Available online: https://www.agrammon.ch/ (accessed on 15 April 2021).

- Available online: https://www.ars.usda.gov/northeast-area/up-pa/pswmru/docs/dairygem-download-instructions/ (accessed on 15 April 2021).

- Available online: https://www.ars.usda.gov/northeast-area/up-pa/pswmru/docs/dairy-gas-emissions-model/ (accessed on 15 April 2021).

- Li, C.; Salas, W.; Zhang, R.; Krauter, C.; Rotz, A.; Mitloehner, F. Manure-DNDC: A biogeochemical process model for quantifying greenhouse gas and ammonia emissions from livestock manure systems . Nutr. Cycl. Agroecosyst. 2012, 93, 163–200. [Google Scholar] [CrossRef]

- Kupper, T.; Bonjour, C.; Zaucker, F.; Achermann, B.; Menzi, H. Agrammon: An internet based model for the estimation of ammonia emissions. In 14th RAMIRAN International Conference; Cordovil, C., Ferreira, L., Eds.; RAMIRAN: Lisboa, Portugal, 2010; pp. 334–337. Available online: http://ramiran.uvlf.sk/ramiran2010/docs/Ramiran2010_0167_final.pdf (accessed on 15 April 2021).

- Kupper, T. Dokumentation Technische Parameter Modell Agrammon (Stand 2018). 2018. Available online: https://agrammon.ch/assets/Documents/Dokumentation-Technische-Parameter-20180925.pdf (accessed on 15 April 2021).

- Schinckel, A.P.; de Lange, C.F.M. Characterization of growth parameters needed as inputs for pig growth models. J. Anim. Sci. 1996, 74, 2021–2036. [Google Scholar] [CrossRef]

- Aarnink, A.J.A.; Verstegen, M.W.A. Nutrition, key factor to reduce environmental load from pig production. Livest. Sci. 2007, 109, 194–203. [Google Scholar] [CrossRef]

- Aarnink, A.J.A.; Canh, T.T.; Mroz, Z. Reduction of ammonia volatilization by housing and feeding in fattening piggeries. In Ammonia and Odour Control from Animal Production Facilities; Voermans, J.A.M., Monteney, G.J., Eds.; NVTL: Rosmalon, NL, USA, 1997; pp. 283–2911. [Google Scholar]

- Van Faassen, H.G.; Van Dijk, H. Manure as a source of nitrogen and phosphorus in soils. In Animal Manure on Grassland and Fodder Crops. Fertilizer or Waste? Van Der Meer, H.G., Unwin, R.J., Van Dijk, T.A., Ennik, G.C., Eds.; Developments in Plant and Soil Sciences; Springer: Dordrecht, The Netherlands, 1987; Volume 30. [Google Scholar] [CrossRef]

- Hutchings, N.J.; Sørensen, P.; Cordovil, C.M.; Leip, A.; Amon, B. Measures to increase the nitrogen use efficiency of European agricultural production. Glob. Food Secur. 2020, 26, 100381. [Google Scholar] [CrossRef]

- Koltay, I.A.; Benedek, Z.; Hegedűsné Baranyai, N.; Kovács, Á.; Valásek, S.; Such, N.; Farkas, V.; Török, N.; Farkas, L.; Wágner, L.; et al. The Effects of Genotype and Age on the Nitrogen Excretion of Young Pigs. 18. BOKU-Symposium Animal Nutrion, Wien. 2019, pp. 202–205. Available online: https://boku.ac.at/fileadmin/data/H03000/H97000/H97600/Symptagungsbaende/Tagungsband_2019_Internet_low.pdf (accessed on 16 April 2021).

- Informative Inventory Report (2015): Informative Inventory Report—Hungary 1990–2013; Agriculture (NFR Sector 3); Compiled by the Hungarian Meteorological Service, Unit of National Emissions Inventories: Budapest, Hungary, 2015; pp. 121–143. Available online: ceip.at (accessed on 16 June 2016).

- Mroz, Z.; Jongbloed, A.W.; Partanen, K.H.; Vreman, K.; Kemme, P.A.; Jogut, J. The effects of calcium benzoate in diets with or without organic acids on dietary buffering capacity, apparent digestibility, retention of nutrients and manure characteristics in swine. J. Anim. Sci. 2011, 78, 2622–2632. [Google Scholar] [CrossRef]

- Canh, T.T.; Aarnink, A.J.A.; Mroz, Z.; Jongbloed, W.; Schrama, J.W.; Verstegen, M.W.A. Influence of electrolyte balance and acidifying calcium salts in the diet of growing finishing pigs on urinary pH, slurry pH, and ammonia volatilisation from slurry. Livest. Prod. Sci. 1998, 56, 1–13. [Google Scholar] [CrossRef]

- Seradj, A.R.; Balcells, J.; Morazan, H.; Alvarez-Rodriguez, J.; Babot, D.; de la Fuente, G. The impact of reducing dietary crude protein and increasing total dietary fiber on hindgut fermentation, the methanogen community and gas emission in growing pigs. Anim. Feed Sci. Technol. 2018, 245, 54–66. [Google Scholar] [CrossRef] [Green Version]

- Aarnink, A.J.A.; Hoeksma, P.; van Ouwerkerk, E.N.J. Factors affecting ammonium concentration in slurry from fattening pigs. In Nitrogen flow in Pig Production and Environmental Consequences; Verstegen, M.W.A., den Hartog, L.A., van Kempen, G.J.M., Metz, J.H.M., Eds.; EAAP-Publication: Roma, Italy, 1993; Volume 69, pp. 413–420. [Google Scholar]

- Sutton, A.L.; Kephart, K.B.; Verstegen, M.W.A.; Canh, T.T.; Hobbs, P.J. Potential for reduction of odorous compounds in swine manure through diet modification. J. Anim. Sci. 1998, 77, 430–439. [Google Scholar] [CrossRef]

- Santonja, G.G.; Goergitzikis, K.; Scalet, B.M.; Montobbio, P.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Intensive Rearing of Poultry or Pigs; JRC Science for Policy Report; EUR 28674 EN; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar] [CrossRef]

- Muck, R.E.; Steenhuis, T.S. Nitrogen losses in free stall dairy barns. In Livestock Waste: A Renewable Resource; American Society of Agricultural Engineers: Amerillo, TX, USA, 1981; pp. 406–409. [Google Scholar]

- Aarnink, A.J.A. Ammonia Emission from Houses for Growing Pigs as Affected by Pen Design, Indoor Climate and Behaviour. Ph.D. Thesis, Wageningen University, Wageningen, NL, USA, 1997; p. 175. Available online: https://research.wur.nl/en/publications/ammonia-emission-from-houses-for-growing-pigs-as-affected-by-pen- (accessed on 16 April 2021).

- Elzing, A.; Monteny, G.J. Modeling and experimental determination of ammonia emissions rates from a scale model dairy-cow house. Trans. Am. Soc. Agric. Eng. 1997, 40, 721–726. [Google Scholar] [CrossRef]

- Monteny, G.J. Modelling of Ammonia Emissions from Dairy Cow Houses. Ph.D. Thesis, Wageningen University, Wageningen, NL, USA, 2000; p. 156. Available online: https://library.wur.nl/WebQuery/wurpubs/65624 (accessed on 16 April 2021).

- Groenestein, C.M.; Hendriks, M.M.W.B.; den Hartog, L.A. Effect of feeding schedule on ammonia emission from individual and group-housing systems for sows. Biosyst. Eng. 2003, 85, 79–85. [Google Scholar] [CrossRef]

- Harper, L.A. Ammonia: Measurement Issues Micrometeorology in Agricultural Systems (2005) Agronomy Monograph no. 47: 345–379. Available online: https://digitalcommons.unl.edu/usdaarsfacpub/1339 (accessed on 15 April 2021).

- Ni, J.Q.; Vinckier, C.; Coenegrachts, J.; Hendriks, J. Effect of manure on ammonia emission from a fattening pig house with partly slatted floor. Livest. Prod. Sci. 1999, 59, 25–31. [Google Scholar] [CrossRef]

- Kai, P.; Kaspers, B.; van Kempen, T. Modeling Sources of Gaseous Emissions in a Pig House with Recharge Pit. Trans. ASABE 2006, 49, 1479–1485. [Google Scholar] [CrossRef]

- Feilberg, A.; Sommer, S.G. Ammonia and Malodorous Gases: Sources and Abatement Technologies. In Animal Manure Recycling: Treatment and Management; Sommer, S.G., Christensen, M.L., Schmidt, T., Jensen, L.S., Eds.; John Wiley and Sons Ltd.: Chichester, UK, 2013; pp. 153–173. [Google Scholar]

- Philippe, F.X.; Cabaraux, J.F.; Baudouin, N. Ammonia emissions from pig houses:Influencing factors and mitigation techniques. Agric. Ecosyst. Environ. 2011, 141, 245–260. [Google Scholar] [CrossRef]

- Aarnink, A.J.A.; Elzing, A. Dynamic model for ammonia volatilization in housing with partially slatted floors, for fattening pigs. Livest. Prod. Sci. 1998, 53, 153–169. [Google Scholar] [CrossRef]

- Webb, J.; Sommer, S.G.; Kupper, T.; Groenestein, K.; Hutchings, N.J.; Eurich-Menden, B.; Rodhe, L.; Misselbrook, T.H.; Amon, B. Emissions of Ammonia, Nitrous Oxide and Methane During the Management of Solid Manures. Agroecol. Strateg. Clim. Chang. 2012, 67–107. [Google Scholar] [CrossRef]

- Cabaraux, J.F.; Philippe, F.X.; Laitat, M.; Canart, B.; Vandenheede, M.; Nicks, B. Gaseous emissions from weaned pigs raised on different floor systems. Agric. Ecosyst. Environ. 2009, 130, 86–92. [Google Scholar] [CrossRef]

- Philippe, F.X.; Laitat, M.; Canart, B.; Vandenheede, M.; Nicks, B. Comparison of ammonia and greenhouse gas emissions during the fattening of pigs, kept either on fully slatted floor or on deep litter. Livest. Sci. 2007, 111, 144–152. [Google Scholar] [CrossRef]

- Chadwick, D.R. Emissions of ammonia, nitrous oxide and methane from cattle manure heaps: Effect of compaction and covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Hansen, M.N.; Henriksen, K.; Sommer, S.G. Observations of production and emission of greenhouse gases and ammonia during storage of solids separated from pig slurry: Effects of covering. Atmos. Environ. 2006, 40, 4172–4181. [Google Scholar] [CrossRef] [Green Version]

- Amon, B.; Kryvoruchko, V.; Amon, T.; Zechmeister-Boltenstern, S. Methane, nitrous oxide and ammonia emissions during storage and after application of dairy cattle slurry and influence of slurry treatment. Agric. Ecosyst. Environ. 2006, 153–162. [Google Scholar] [CrossRef]

- Misselbrook, T.; Hunt, J.; Perazzolo, F.; Provolo, G. Greenhouse Gas and Ammonia Emissions from Slurry Storage: Impacts of Temperature and Potential Mitigation through Covering (Pig Slurry) or Acidification (Cattle Slurry). J. Environ. Qual. 2016, 45, 1520–1530. [Google Scholar] [CrossRef]

- Berg, W.; Brunsch, R.; Pazsiczki, I. Greenhouse gas emissions from covered slurry compared with uncovered during storage. Agric. Ecosyst. Environ. 2006, 112, 129–134. [Google Scholar] [CrossRef]

- Sommer, S.G.; Hutchings, N.J. Ammonia emission from field applied manure and its reduction-invited paper. Eur. J. Agron. 2001, 15, 1–15. [Google Scholar] [CrossRef]

- Sommer, S.G.; Schjoerring, J.K.; Denmead, O.T. Ammonia emission from mineral fertilizers and fertilized crops. Adv. Agron. 2004, 557–622. [Google Scholar] [CrossRef]

- Pintér, L.; Hardi, P.; Martinuzzi, A.; Hall, J. Bellagio STAMP: Principles for sustainability assessment and measurement. Ecol. Indicat. 2012, 17, 20–28. [Google Scholar] [CrossRef]

- Arulnathan, V.; Heidari, M.D.; Doyon, M.; Li, E.; Pelletier, N. Farm-level decision support tools: A review of methodological choices and their consistency with principles of sustainability assessment. J. Clean. Prod. 2020, 256, 120410. [Google Scholar] [CrossRef]

- EU 2017/302 Best Available Techniques (BAT) Conclusions, under Directive 2010/75/EU of the European Parliament and of the Council, for the Intensive Rearing of Poultry or Pigs. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2017.043.01.0231.01.ENG (accessed on 14 April 2021).

- BAT 2020. Útmutató az Elérhető Legjobb Technika Meghatározásához az Intenzív Sertéstartási Tevékenység Engedélyeztetése Során (Guideline for Determining the Best Available Techniques in the Process of Authorisation of Intensive Rearing of Pigs); Hermann Ottó Intézet: Budapest, Hungary, 2020; p. 212. Available online: http://www.hermanottointezet.hu/docs/BAT_utmutato_az_intenziv_sertestenyeszteshez_2020.pdf (accessed on 15 April 2020).

- Csótó, M. Analysis of smallholder farmers’s ICT-adoption and use through their personal information space. J. Agric. Inform. 2017, 8, 1–12. [Google Scholar] [CrossRef]

- Piwowar, A. Farming Practices for Reducing Ammonia Emissions in Polish Agriculture. Atmosphere 2020, 11, 1353. [Google Scholar] [CrossRef]

- Triste, L.; Marchand, F.; Debruyne, L.; Meul, M.; Lauwers, L. Reflection on the development process of a sustainability assessment tool: Learning from a Flemish case. Ecol. Soc. 2014, 19, 47. [Google Scholar] [CrossRef] [Green Version]

| Livestock Data | Comments |

|---|---|

| Average number of sows | Yearly average |

| Total number of farrowing per year | |

| Culling rate of sows (%) | Culling and death of breeding sows |

| Litter size at farrowing (piglets) | Average number of live born piglets in one litter |

| Lactation length (days) | Time of weaning in days |

| Mortality rate in nursery (%) | Mortality from farrowing to weaning |

| Average weight at weaning (kg/piglet) | Starting weight of growing if there is no farrowing and weaning on the farm. |

| Starting number of weaners (pigs/year) | Should be zero if there is farrowing and weaning at the farm. The date should be other than zero if there is no farrowing and weaning at the farm. |

| Length of growing (days) | |

| Mortality rate during growing (%) | |

| Average final weight at growing (kg/pig) | If there is no growing phase at the farm, but fatteners are purchased, the average starting weight of fatteners should be given. |

| Total number of sold growers (pigs/year) | |

| Starting number of fatteners (pigs) | The date should be zero if own pigs are fattened. The date should be other than zero if there is no growing phase at the farm. |

| Length of fattening (days) | |

| Mortality rate during fattening (%) | |

| Average slaughter weight of pigs (kg/pig) | |

| Total number of sold slaughters (pigs/year) | |

| Average number of gilts from own stock (gilts/year) | |

| Average number of purchased gilts (pigs/year) | |

| Starting age of gilt rearing (days) | |

| Age of gilts at first mating (days) | |

| Average number of breeding boars (pigs/year) |

| Dry matter content of the diet (%) | |

| Number of dietary phases in the fattening period | (1–4) |

| Crude protein content of the diets (%) | |

| Daily feed intake (g) | |

| Crystalline amino acid supplements | |

| Lysine | yes/not |

| Methionine | yes/not |

| Threonine | yes/not |

| Tryptophan | yes/not |

| Benzoic acid supplementation of the diets | yes/not |

| Name of the stable | |

| Place for pigs in stable | |

| Function of the stable | nursery |

| mating and gestating unit | |

| weaner unit | |

| grower/finisher unit | |

| replacing gilt unit | |

| Days in free range (optional) | |

| Housing techniques | typical housing techniques in Hungary: outdoor; litter-based housing: daily manure removal or deep litter; slurry-based housing: fully or partly slatted floor, concrete floor with manure channel |

| Mitigation techniques The most effective emission reduction technology used in the stable | frequent manure removal with vacuum, flushing gutters, cooling manure surface, feeding stalls and manure pit with slanted walls, floating balls on manure surface, water and manure channels, manure pan underneath, partially slatted floor with reduced pit, partially slatted floors and flushing gutters, partially slatted floor and collection in acidified liquid, partially slatted floor and cooling manure surface, partially slatted floor and manure channel with slanted walls, air scrubbing techniques (according to Bittman et al. [1]) |

| Amount of manure produced (tons/year) |

| Amount of manure sold (tons/year) |

| Amount of manure stored in covered storage (tons/year) |

| Amount of manure stored in uncovered storage (tons/year) |

| Amount of liquid manure produced (m3/year) | ||

| Amount of liquid manure sold (m3/year) | ||

| Amount of liquid manure stored in covered storage (m3/year) | Options | Input data |

| storage bag, tight roof, tent structure, floating covers, low technology floating covers, natural crust, tall open tanks | surface (m2) | |

| Amount of liquid manure stored in uncovered storage (m3/year) | store with no cover or crust | surface (m2) |

| Techniques of liquid manure application (distribution %) | Spreading |

| Trailing hose | |

| Trailing shoe | |

| Shallow injection | |

| Deep injection | |

| Time of incorporation after slurry/manure application (distribution %) | Incorporation within 1 h by ploughing |

| Incorporation within 1 h by non-inversion cultivation | |

| Within 4 h | |

| Within 24 h | |

| Within 72 h | |

| Over 72 h | |

| No incorporation | |

| Seasonal distribution of slurry/manure application (%) | Application in summer time (April to September) |

| Application in winter time (October, February, March) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magyar, M.; Pirkó, B.; Seenger, J.K.; Baranyai, N.H.; Dublecz, K.; Vojtela, T.; Rák, R.; Borka, G.; Szabó, A.; Benedek, Z. Advisory and Knowledge Transfer Tool for Ammonia Emission Mitigation on Pig Farms in Hungary. Appl. Sci. 2021, 11, 5970. https://doi.org/10.3390/app11135970

Magyar M, Pirkó B, Seenger JK, Baranyai NH, Dublecz K, Vojtela T, Rák R, Borka G, Szabó A, Benedek Z. Advisory and Knowledge Transfer Tool for Ammonia Emission Mitigation on Pig Farms in Hungary. Applied Sciences. 2021; 11(13):5970. https://doi.org/10.3390/app11135970

Chicago/Turabian StyleMagyar, Marianna, Béla Pirkó, Julianna Kótiné Seenger, Nóra Hegedűsné Baranyai, Károly Dublecz, Tibor Vojtela, Renáta Rák, György Borka, Anita Szabó, and Zsuzsanna Benedek. 2021. "Advisory and Knowledge Transfer Tool for Ammonia Emission Mitigation on Pig Farms in Hungary" Applied Sciences 11, no. 13: 5970. https://doi.org/10.3390/app11135970

APA StyleMagyar, M., Pirkó, B., Seenger, J. K., Baranyai, N. H., Dublecz, K., Vojtela, T., Rák, R., Borka, G., Szabó, A., & Benedek, Z. (2021). Advisory and Knowledge Transfer Tool for Ammonia Emission Mitigation on Pig Farms in Hungary. Applied Sciences, 11(13), 5970. https://doi.org/10.3390/app11135970