Heat Transfer Correlations for Star-Shaped Fins

Abstract

1. Introduction

1.1. Influence of Fin Spacing

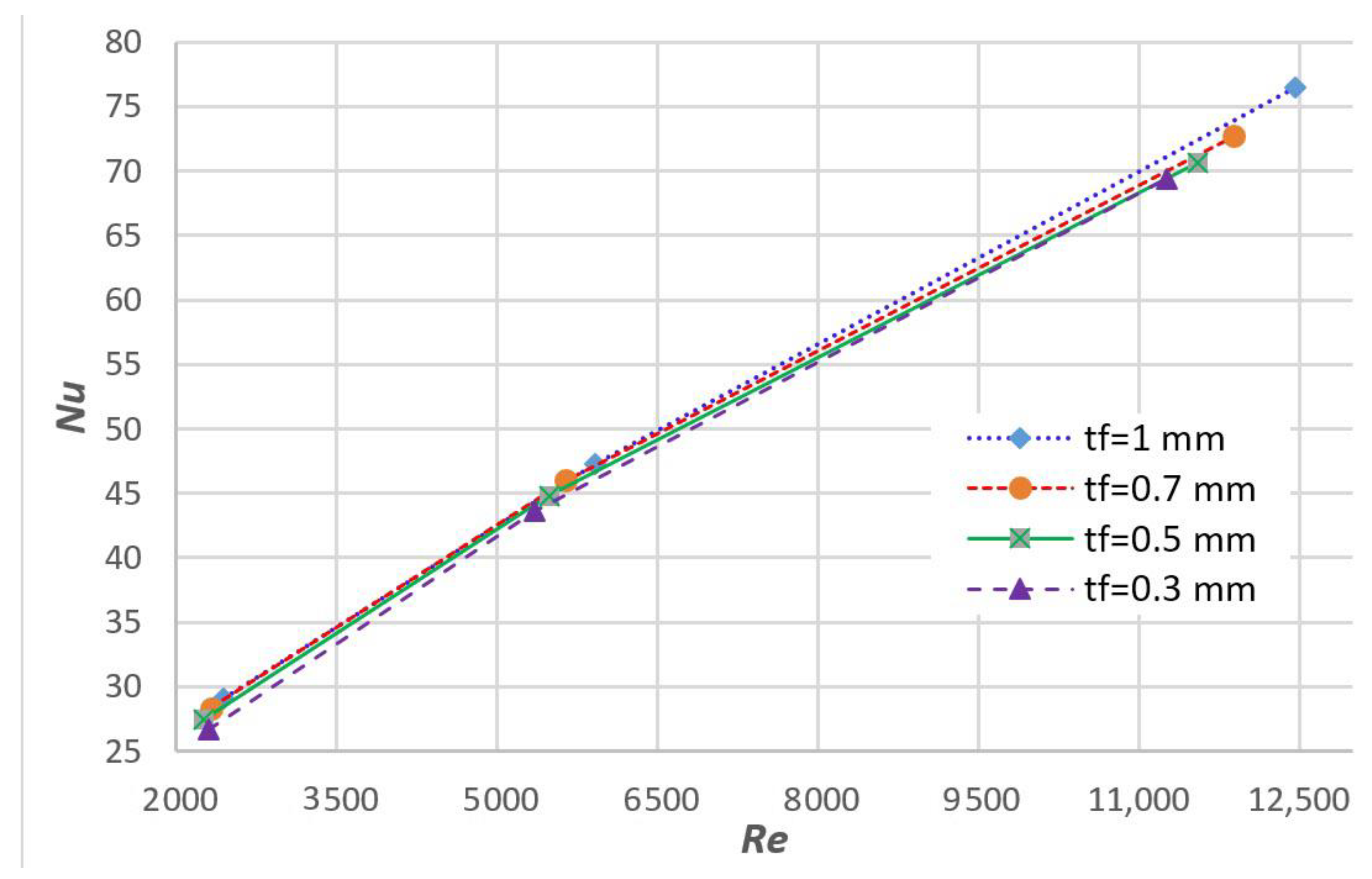

1.2. Influence of Fin Thickness

1.3. Influence of Outside Tube Diameter

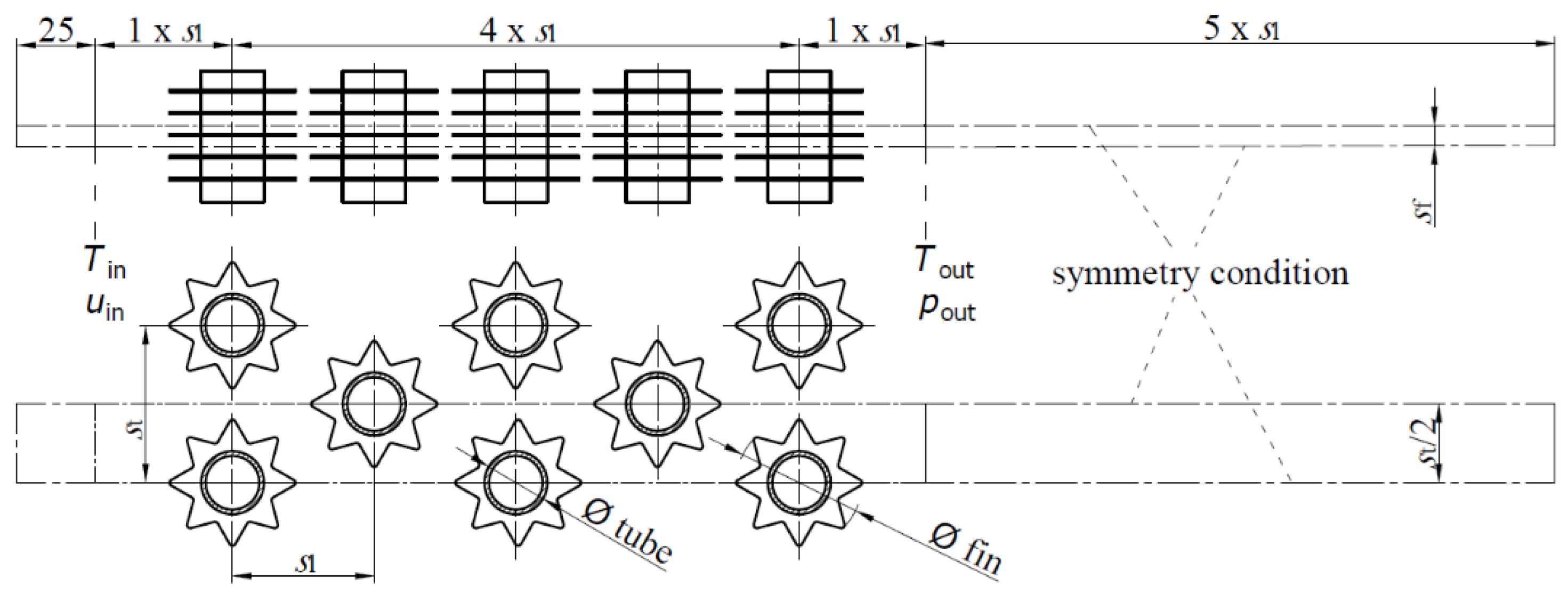

2. Materials and Methods

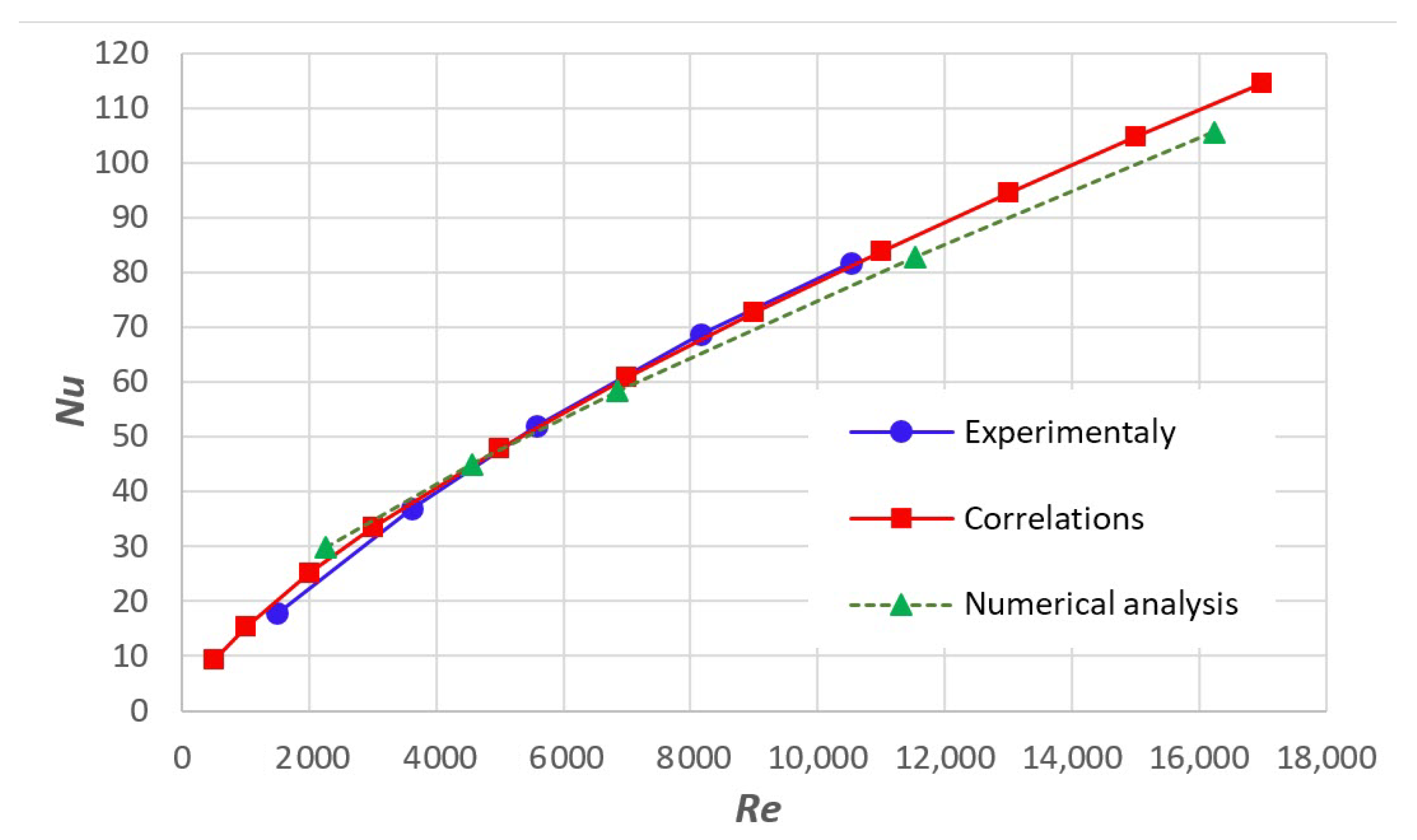

3. Results and Discussion

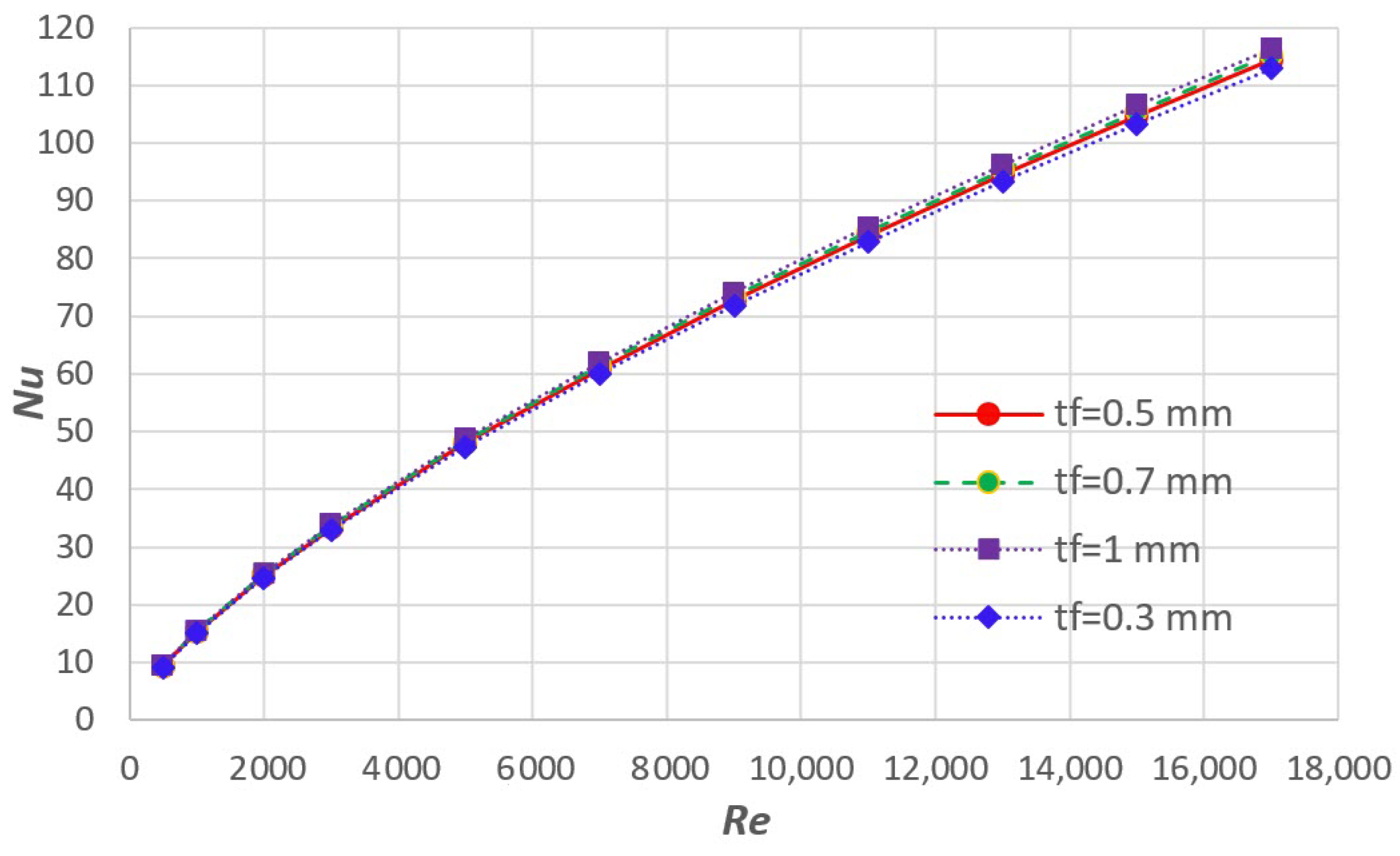

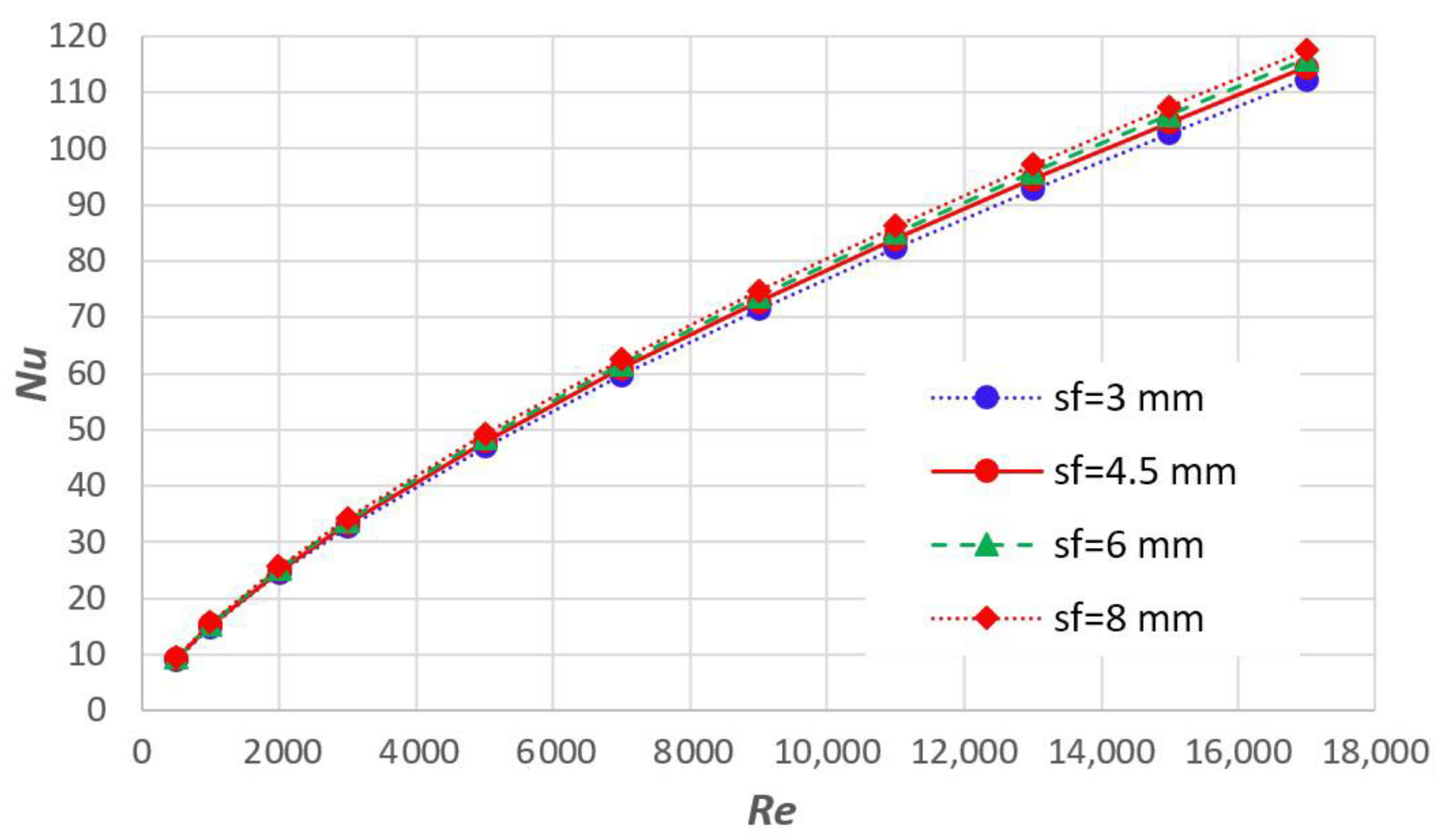

3.1. Determination of Correlation for Nu Number

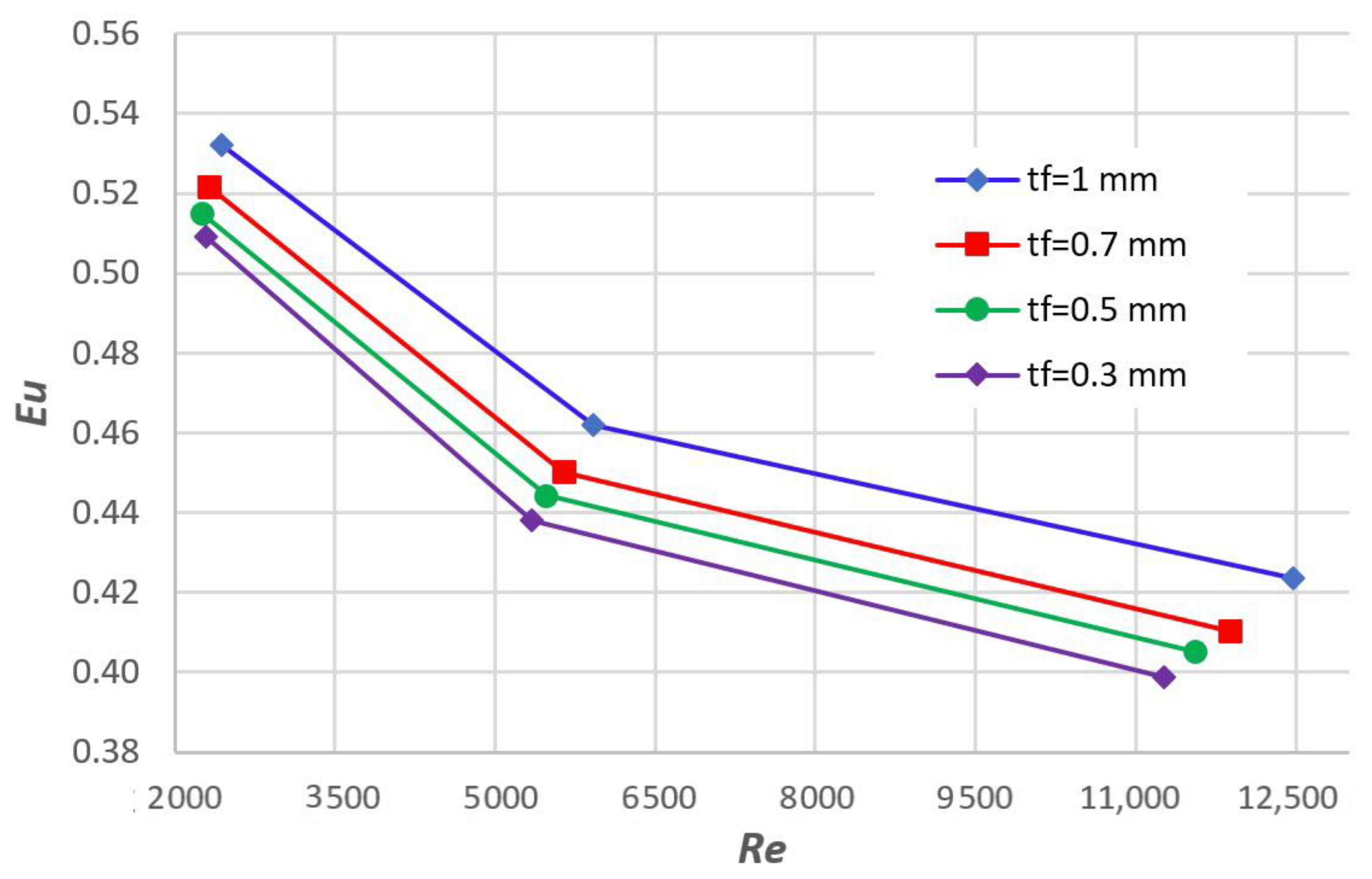

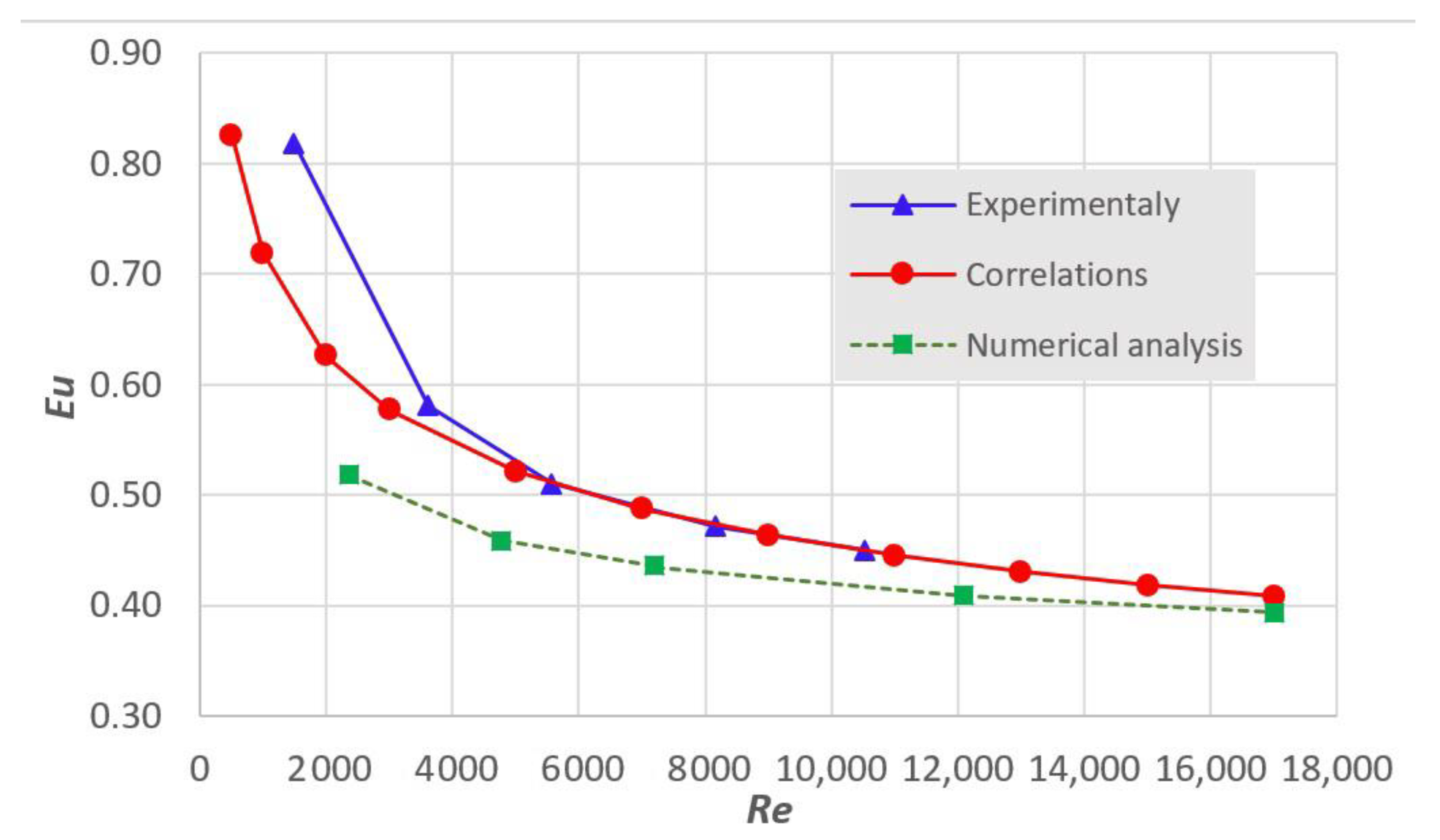

3.2. Determination of Correlation for the Eu Number

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Antuf’ev, V.M.; Gusev, E.K. Intensification of Heat Transfer of Cross-Flow Finned Surfaces. Teploenergetika 1968, 15, 31–34. [Google Scholar]

- Brauer, H. Wärme- und strömungstechnische Untersuchungen an quer angeströmten Rippenrohrbündeln, Teil 2, Einfluß der Rippen- und der Rohranordung. Chem. Ing. Tech. 1961, 33, 431–438. [Google Scholar] [CrossRef]

- Brauer, H. Wärme- und strömungstechnische Untersuchungen an quer angeströmten Rippenrohrbündeln, Teil 1, Versuchsanlagen und Meßergebnisse bei höheren Drucken. Chem. Ing. Tech. 1961, 33, 327–335. [Google Scholar] [CrossRef]

- Rabas, T.J.; Eckels, P.W.; Sabatino, R.A. The Effect of Fin Density on the Heat Transfer and Pressure Drop Performance of Low-Finned Tube Banks. Chem. Eng. Commun. 1981, 10, 127–147. [Google Scholar] [CrossRef]

- Rabas, T.J.; Taborek, J. Survey of Turbulent Forced-Convection Heat Transfer and Pressure Drop Characteristics of Low-Finned Tube Banks in Cross-Flow. Heat Transf. Eng. 1987, 8, 49–62. [Google Scholar] [CrossRef]

- Yudin, V.F.; Tokhtarova, L.S.; Lokshin, V.; Tulin, S.N. Correlation of Experimental Data on Convective Heat Transfer in Cross Flow Over Bundles with Transverse Spiral and Circumferential Fins. Tr. TsKTI 1968, 82. [Google Scholar]

- Žukauskas, A.A. Investigation of Heat Transfer in Different Arrangements of Heat Exchanger Surfaces. Teploenergetika 1974, 21, 40–46. [Google Scholar]

- Jameson, S.L. Tube Spacing in Finned Tube Banks. ASME Trans. 1945, 67, 633–642. [Google Scholar]

- Watel, B.; Harmand, S.; Desmet, B. Influence of Flow Velocity and Fin Spacing on the Forced Convective Heat Transfer from an Annular-Finned Tube. JSME Int. J. 1999, 42, 56–64. [Google Scholar] [CrossRef]

- Watel, B.; Harmand, S.; Desmet, B. Experimental Study of Convective Heat Transfer from a Rotating Finned Tube in Transverse Air Flow. Exp. Fluids 2000, 29, 79–90. [Google Scholar] [CrossRef]

- Briggs, D.E.; Young, E.H. Convection Heat Transfer and Pressure Drop of Air Flowing Across Triangular Pitch Banks of Finned Tubes. Chem. Eng. Prog. Symp. 1963, 59, 1–10. [Google Scholar]

- Kuntysh, V.B.; Iokhvedov, F.M. Heat Transfer. Sov. Res. 1971, 3, 50–61. [Google Scholar]

- Gianolio, E.; Cuti, F. Heat Transfer Coefficients and Pressure Drops for Air Coolers Under Induced and Forced Draft. Heat Transf. Eng. 1981, 3, 38–48. [Google Scholar] [CrossRef]

- Schmidt, E.T. Der Wärmeübergang an Rippenrohre und die Berechnung von Rohrbündle-Wärmeaustauschern. Kältetechnik 1963, 15, 98–102, 370–378. [Google Scholar]

- Lee, M.; Kang, T.; Kim, Y. Air-side heat transfer characteristics of spiral-type circular fin-and tube heat exchangers. Int. J. Refrig. 2010, 33, 313–320. [Google Scholar] [CrossRef]

- Pongsoi, P.; Wongwises, S. Determination of fin pitches for maximum performance index of L-footed spiral fin-and-tube heat exchangers. J. Therm. Eng. 2015, 1, 251–262. [Google Scholar]

- Mon, M.S.; Gross, U. Numerical study of fin-spacing effects in annular-finned tube heat exchangers. Int. J. Heat Mass Transf. 2004, 47, 1953–1964. [Google Scholar] [CrossRef]

- Kawaguchi, K.; Okui, K.; Asai, T.; Yutaka, H. Effects of serrated fin and fin pitch on pressure drop of the finned tube banks. Turbomachinery 2004, 32, 551–559. [Google Scholar]

- Naess, E. Experimental investigation of heat transfer and pressure drop in serrated-fin tube bundles with staggered tube layouts. Appl. Therm. Eng. 2010, 30, 1531–1537. [Google Scholar] [CrossRef]

- Ward, D.J.; Young, E.H. Heat Transfer and Pressure Drop of Air in Forced Convection Across Triangular Pitch Banks of Finned Tubes. Chem. Eng. Prog. Symp. Ser. 1959, 55, 37–44. [Google Scholar]

- Stasiulevičius, J.; Skrinska, A. Heat Transfer of Finned Tube Bundles in Crossflow; Hemisphere Publishing: London, UK, 1988; ISBN 3-540-18211-x. [Google Scholar]

- Mirkovic, Z. Heat Transfer and Flow Resistance Correlation for Helically Finned and Staggered Tube Banks in Cross Flow. Heat Exchangers: Design and Theory Source Book; Afgan, N.H., Schlünder, E.U., Eds.; Hemisphere: Washington, DC, USA, 1974; pp. 559–584. [Google Scholar]

- Torikoshi, K.; Xi, G. A Numerical Study of Flow and Thermal Fields in Finned Tube Heat Exchangers (Effect of the Tube Diameter). In Proceedings of the ASME Heat Transfer Division, HTD, San Francisco, CA, USA, 12–17 November 1995; Volume 317-1, pp. 453–457. [Google Scholar]

- Pongsoi, P.; Pikulkajorn, S.; Wongwises, S. Heat transfer and flow characteristics of spiral fin-and-tube heat exchangers: A review. Int. J. Heat Mass Transf. 2014, 79, 417–431. [Google Scholar] [CrossRef]

- FaJiang, H.; Wei Wu, C.; Ping, Y. Experimental investigation of heat transfer and flowing resistance for air flow cross over spiral finned tube heat exchanger. Energy Procedia 2012, 17, 741–749. [Google Scholar] [CrossRef]

- Unger, S.; Beyer, M.; Pietruske, H.; Szalinski, L.; Hampel, U. Air-side heat transfer and flow characteristics of additively manufactured finned tubes in staggered arrangement. Int. J. Therm. Sci. 2021, 161, 106752. [Google Scholar] [CrossRef]

- Kim, N.H. Air-side heat transfer and pressure drop of the fin-and-tube heat exchangers having oval tubes under wet condition. Heat Mass Transf. 2021. [Google Scholar] [CrossRef]

- Adhikari, R.; Wood, D.; Pahlevani, M. An experimental and numerical study of forced convection heat transfer from rectangular fins at low Reynolds numbers. Int. J. Heat Mass Transf. 2020, 163, 120418. [Google Scholar] [CrossRef]

- Anoop, B.; Balaji, C.; Velusamy, K. A characteristic correlation for heat transfer over serrated finned tubes. Anal. Nucl. Energy 2015, 85, 1052–1065. [Google Scholar] [CrossRef]

- Robinson, K.K.; Briggs, D.E. Pressure drop of air flowing across triangular pitch banks of finned tubes. AlChE Chem. Eng. Progr. Symp 1966, 62, 177–184. [Google Scholar]

- Bošnjaković, M.; Čikić, A.; Muhič, S.; Stojkov, M. Development of a new type of finned heat exchanger. Tech. Gaz. 2017, 24, 1785–1796. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Muhić, S.; Čikić, A. Experimental testing of the heat exchanger with star-shaped fins. Int. J. Heat Mass Transf. 2020, 149, 119190. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Muhić, S.; Čikić, A.; Živić, M. How Big Is an Error in the Analytical Calculation of Annular Fin Efficiency? Energies 2019, 12, 1787. [Google Scholar] [CrossRef]

- Gashim, S.L. New Correlation Equations for Finned Tube Heat Exchangers. J. Eng. Appl. Sci. 2019, 14, 1538–1548. [Google Scholar] [CrossRef][Green Version]

| Author | Correlation | |

|---|---|---|

| Briggs and Young [11] | (1) | |

| 1100 < Re < 18 × 103 1.01 <(sf − tf)/tf < 6.62 | ||

| 11.1 < do < 40.9 0.09 < hf/do < 0.69 | ||

| 1.54 < st/do < 8.23 0.011 < tf/do < 0.15 | ||

| 0.13 < (sf − tf)/hf < 0.63 246 < fins/m < 768 | ||

| Ward and Young [20] | (2) | |

| 1000 < Re < 28 × 103 0.41 < tf < 0.56 | ||

| 11.13 < do < 29.13 23.81 < st < 61.91 | ||

| 1.42 < hf < 14.69 20.62 < sl < 53.62 | ||

| 0.89 < sf < 4.39 number of tube rows > 3 | ||

| df-outside tube diameter |

| Author | Correlation | |

|---|---|---|

| Robinson and Briggs [30] | (3) | |

| 2 × 103 < Re < 5 × 104 2.31 < sf < 2.82 | ||

| 18.64 < do < 40.89 42.85 < st < 114.3 | ||

| 39.68 < df < 69.85 37.11 < sl < 98.89 | ||

| 10.52 < (df − do) < 14.48 1.8 < st/do < 4.6 | ||

| St–transversal tube pitch Sl–longitudinal tube pitch | ||

| Ward and Young [20] | (4) | |

| 1000 < Re < 28 × 103 0.41 < tf < 0.56 | ||

| 11.13 < do < 29.13 23.81 < st < 61.91 | ||

| 1.42 < hf < 14.69 20.62 < sl < 53.62 | ||

| 0.89 < sf < 4.39 number of tube rows ≥ 6 |

| Sizes of Fins and Tubes | |||

|---|---|---|---|

| Material | stainless steel | ||

| Tube data | d0 | mm | 20 |

| - | - | staggered | |

| st | mm | 50 | |

| sl | mm | 40 | |

| Nl | - | 5 | |

| Boundary Condition | |||

|---|---|---|---|

| Air temperature at the inlet | Tin | K | 288 |

| Air velocity at the inlet | uin | m/s | 1, 24 and 5 |

| Wall temperature of the internal tube | Tw | K | 353 |

| Gauge air pressure at the outlet of HE | pout | Pa | 0 |

| Wall condition (airside) | Hydraulically smooth wall |

| Variant No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| Pitch | sf | mm | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 |

| Thickness | tf | mm | 1.0 | 1.0 | 1.0 | 0.7 | 0.7 | 0.7 | 0.5 | 0.5 | 0.5 | 0.3 | 0.3 |

| Airspeed | uin | m/s | 1.0 | 2.4 | 5.0 | 1.0 | 2.4 | 5.0 | 1.0 | 2.4 | 5.0 | 1.0 | 2.4 |

| Variant No. | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | |||

| Pitch | sf | mm | 4.5 | 3.0 | 3.0 | 3.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | |

| Thickness | tf | mm | 0.3 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Airspeed | uin | m/s | 5.0 | 1.0 | 2.4 | 5.0 | 1.0 | 2.4 | 5.0 | 1.0 | 2.4 | 5.0 | |

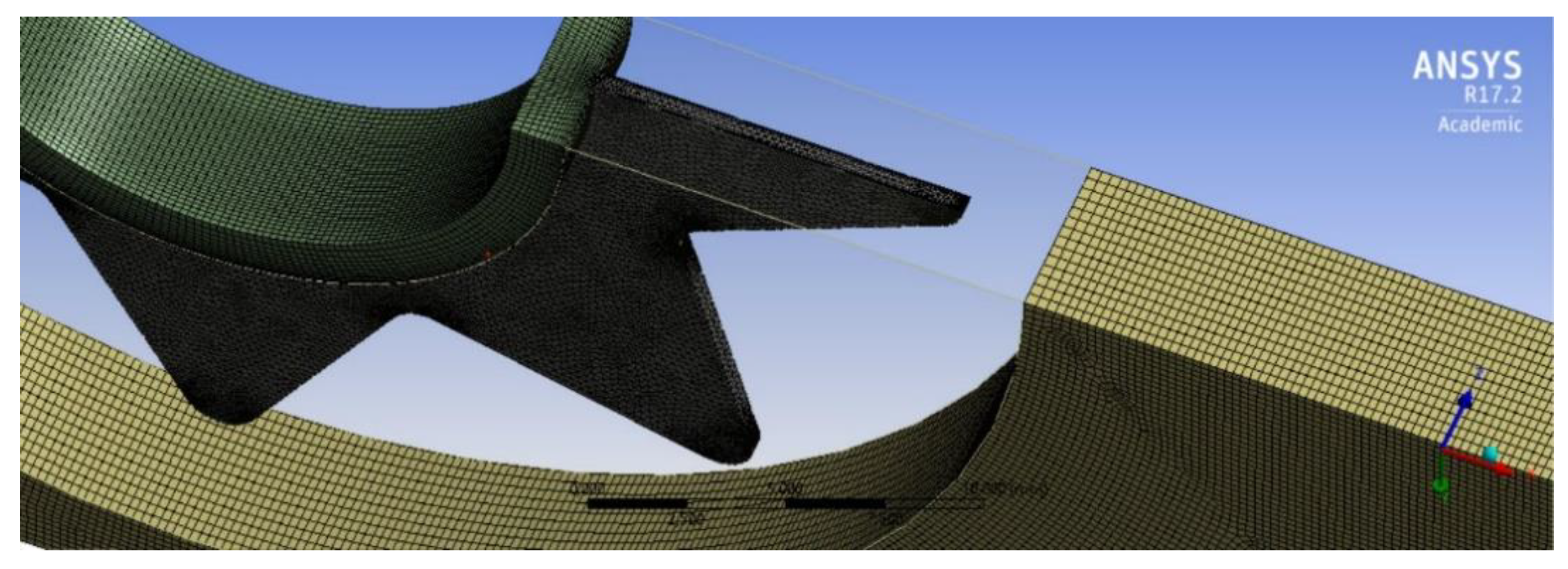

| Number of Finite Volumes (millions) | 5.8 | 8.2 | 10.8 | 15.0 |

|---|---|---|---|---|

| Nu | 54.7 | 51.4 | 51.3 | 51.4 |

| Eu | 0.34 | 0.38 | 0.41 | 0.41 |

| Fin Thickness (mm) | Fin Pitch (mm) | Skewness | Orthogonal Qual. | Aspect Ratio | Elements/Nodes |

|---|---|---|---|---|---|

| 1 | 4.5 | min. 1.3 × 10−10 max. 0.917 av. 0.24 | min. 0.1 max. 1 av. 0.86 | min. 1.07 max. 31.6 av. 2.7 | el. 11,334,069 nod. 3,161,411 |

| 0.7 | 4.5 | min. 1.3 × 10−10 max. 0.9 av. 0.24 | min. 0.111 max. 1 av. 0.85 | min. 1.07 max. 32.5 av. 2.74 | el. 11,062,274 nod. 3,060,684 |

| 0.3 | 4.5 | min. 1.3 × 10−10 max. 0.91 av. 0.24 | min. 8.8 × 10−2 max. 1 av. 0.85 | min. 1.07 max. 91.76 av. 2.87 | el. 10,736,408 nod. 2,935,164 |

| 0.5 | 3.0 | min. 1.3 × 10−10 max. 0.899 av. 0.25 | min. 0.14 max. 1 av. 0.85 | min. 1.04 max. 36.2 av. 3.0 | el. 8,042,694 nod. 2,366,694 |

| 0.5 | 6.0 | min. 1.3 max. 0.918 av. 0.23 | min. 0.1 max. 1 av. 0.86 | min. 1.0 max. 36.5 av. 2.6 | el. 13,742,299 nod. 3,664,919 |

| 0.5 | 8.0 | min. 1.3 max. 0.94 av. 0.22 | min. 0.1 max. 1 av. 0.86 | min. 1.0 max. 36.5 av. 2.45 | el. 17,402,882 nod. 4,535,607 |

| Variant | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| Tout | K | 325.76 | 314.74 | 307.66 | 323.84 | 312.89 | 305.81 | 321.8 | 311.1 | 304.3 | 318.8 | 308.49 |

| pin | Pa | 10.403 | 48.894 | 188.77 | 8.909 | 41.51 | 158.82 | 8.10 | 37.48 | 142.84 | 7.404 | 33.907 |

| pout | Pa | −2.11 | −12.4 | −52.47 | −2.139 | −12.33 | −52.36 | −2.10 | −12.28 | −52.52 | −2.044 | −12.14 |

| Variant | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | ||

| Tout | K | 302.32 | 328.27 | 316.28 | 308.46 | 317.4 | 307.67 | 301.89 | 313.46 | 304.98 | 300.0 | |

| pin | Pa | 128.49 | 11.197 | 49.427 | 183.38 | 6.756 | 32.356 | 125.19 | 5.808 | 28.70 | 112.66 | |

| pout | Pa | −52.28 | −2.132 | −12.38 | −53.19 | −2.067 | −12.06 | −51.39 | −2.131 | −11.73 | −49.89 | |

| Variant | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Pr | 0.7028 | 0.7038 | 0.7047 | 0.7031 | 0.7041 | 0.7050 | 0.7034 | 0.7044 | 0.7053 | 0.7039 | 0.7050 |

| Re | 2437 | 5918 | 12,470 | 2323 | 5644 | 11,892 | 2256 | 5484 | 11,555 | 2296 | 5349 |

| Nu | 29.07 | 47.25 | 76.45 | 28.34 | 46.0 | 72.7 | 27.47 | 44.81 | 70.64 | 26.65 | 43.59 |

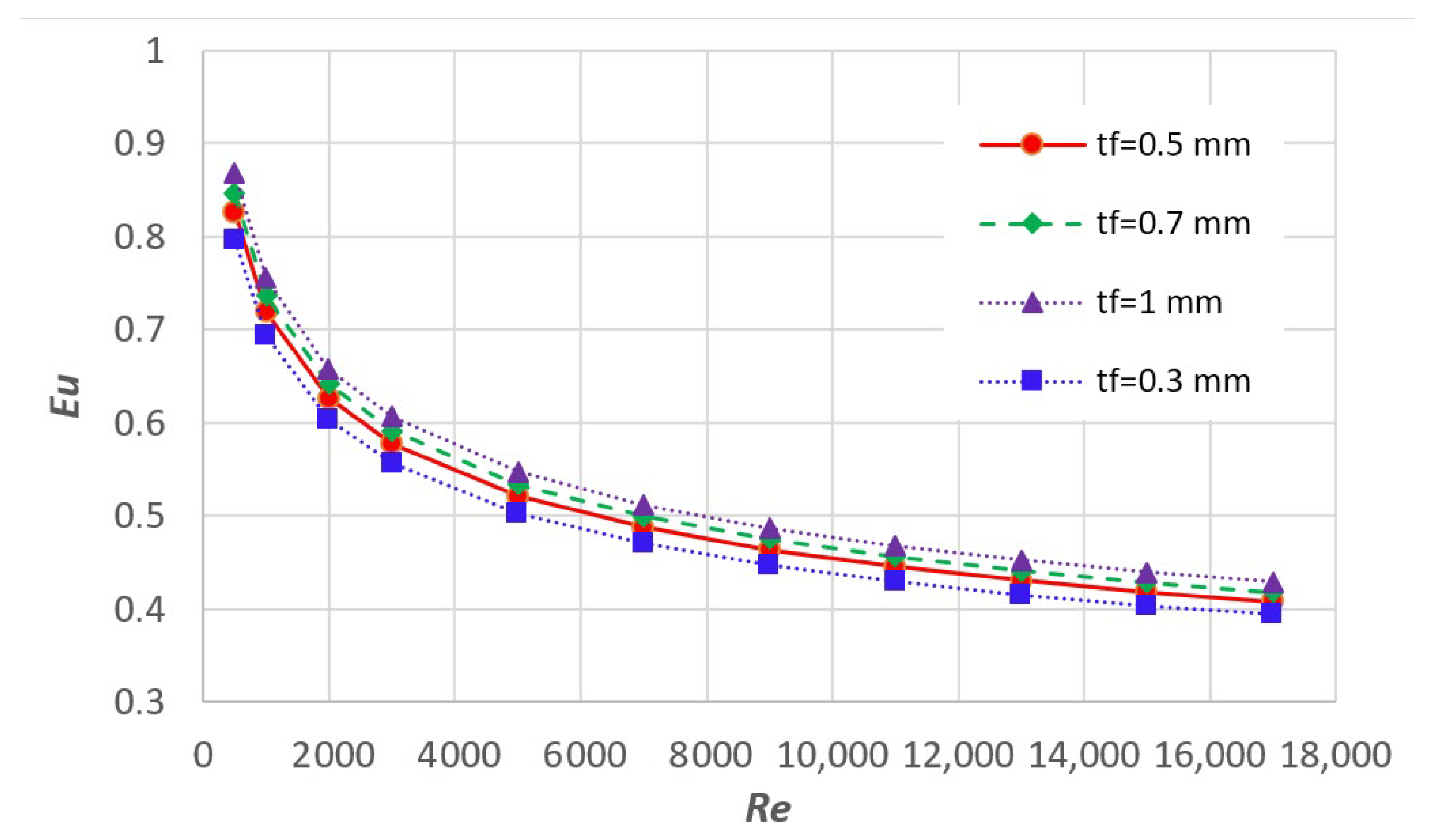

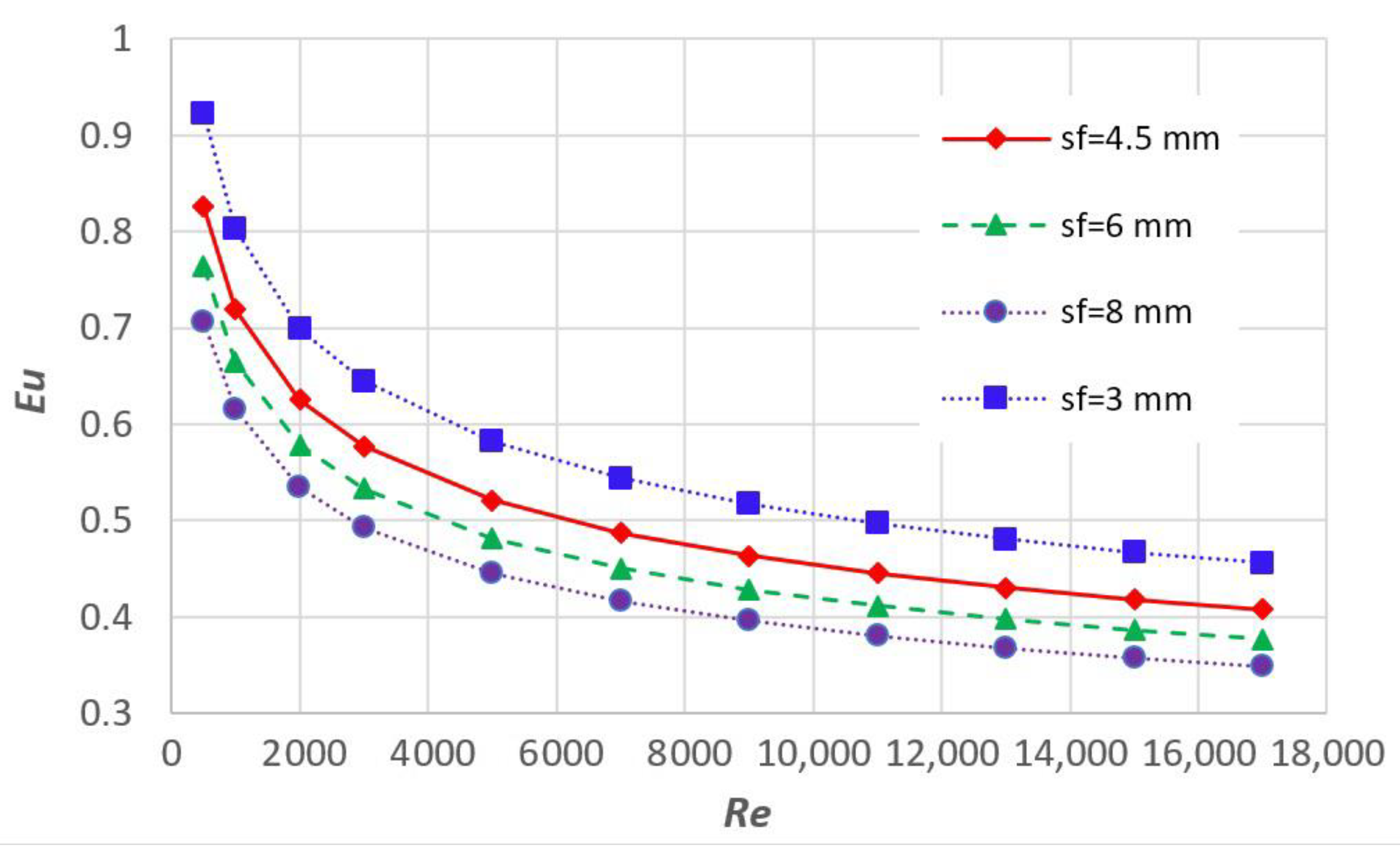

| Eu | 0.5321 | 0.4620 | 0.4226 | 0.5215 | 0.4501 | 0.4103 | 0.5150 | 0.4443 | 0.4051 | 0.5091 | 0.4380 |

| Variant | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | |

| Pr | 0.7059 | 0.7030 | 0.7042 | 0.7052 | 0.704 | 0.705 | 0.705 | 0.704 | 0.705 | 0.705 | |

| Re | 11,267 | 2340 | 5694 | 12,016 | 2217 | 5384 | 11,331 | 2189 | 5595 | 11,162 | |

| Nu | 69.41 | 26.20 | 42.68 | 69.54 | 27.63 | 44.48 | 70.18 | 27.40 | 44.45 | 69.80 | |

| Eu | 0.3987 | 0.6106 | 0.5021 | 0.4468 | 0.4685 | 0.4167 | 0.3840 | 0.4390 | 03938 | 0.3666 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bošnjaković, M.; Čikić, A.; Muhič, S.; Holik, M. Heat Transfer Correlations for Star-Shaped Fins. Appl. Sci. 2021, 11, 5912. https://doi.org/10.3390/app11135912

Bošnjaković M, Čikić A, Muhič S, Holik M. Heat Transfer Correlations for Star-Shaped Fins. Applied Sciences. 2021; 11(13):5912. https://doi.org/10.3390/app11135912

Chicago/Turabian StyleBošnjaković, Mladen, Ante Čikić, Simon Muhič, and Mario Holik. 2021. "Heat Transfer Correlations for Star-Shaped Fins" Applied Sciences 11, no. 13: 5912. https://doi.org/10.3390/app11135912

APA StyleBošnjaković, M., Čikić, A., Muhič, S., & Holik, M. (2021). Heat Transfer Correlations for Star-Shaped Fins. Applied Sciences, 11(13), 5912. https://doi.org/10.3390/app11135912