Subcooled Flow Boiling Heat Flux Enhancement Using High Porosity Sintered Fiber

Abstract

:1. Introduction

2. Experimental Setup and Procedure

2.1. Test Loop

2.2. Test Section

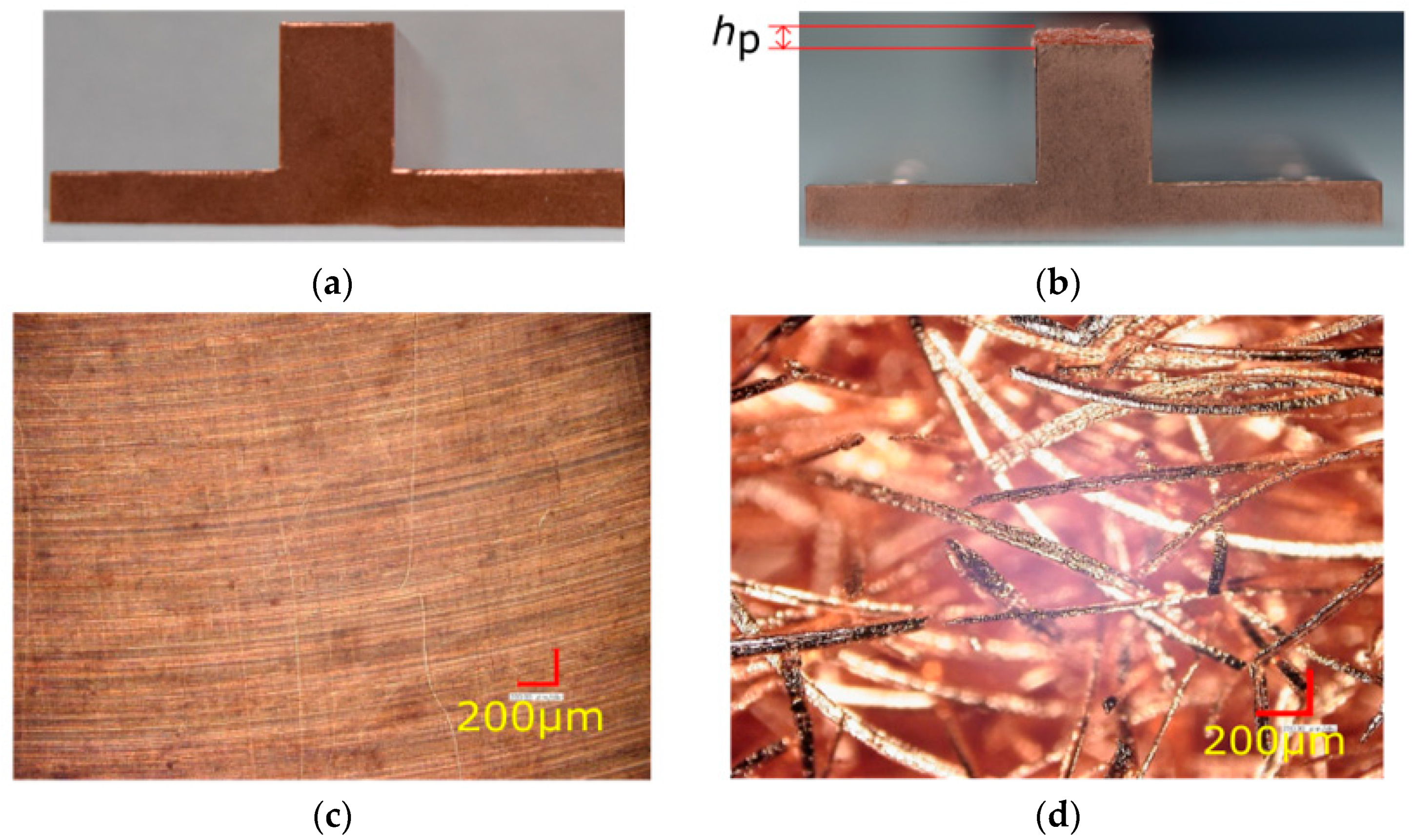

2.3. High Porosity Sintered Fiber

2.4. High Porosity Sintered Fiber

2.5. Uncertainly Analysis

3. Results

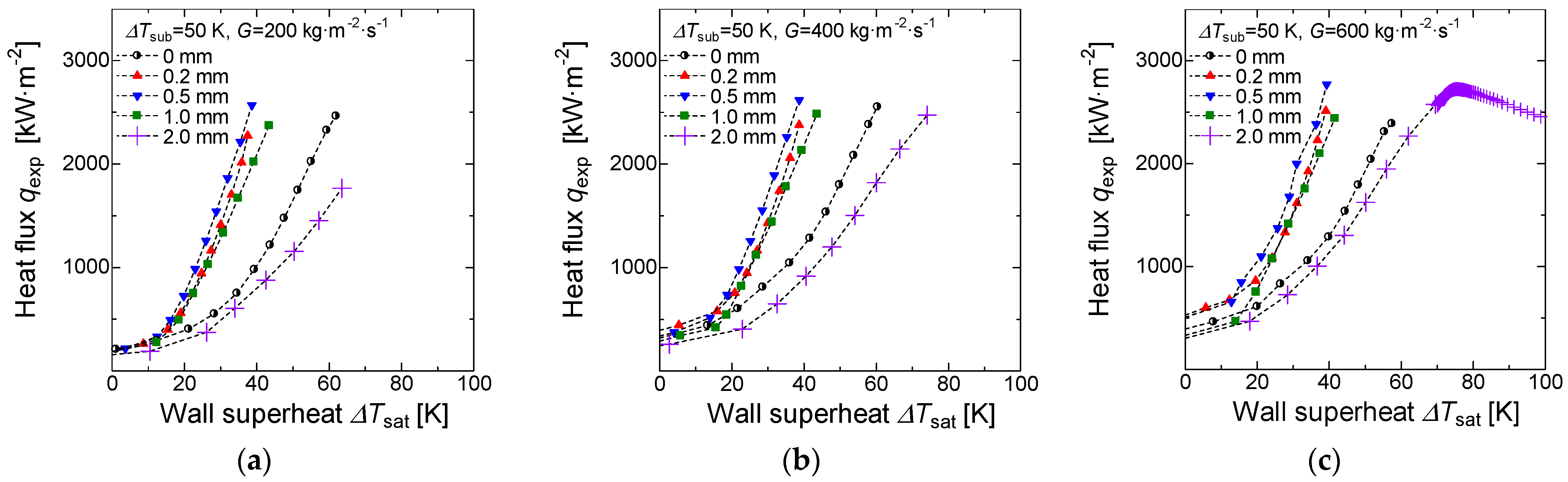

3.1. Boiling Curves under Different Flow Rates and Inlet Subcooling Temperature

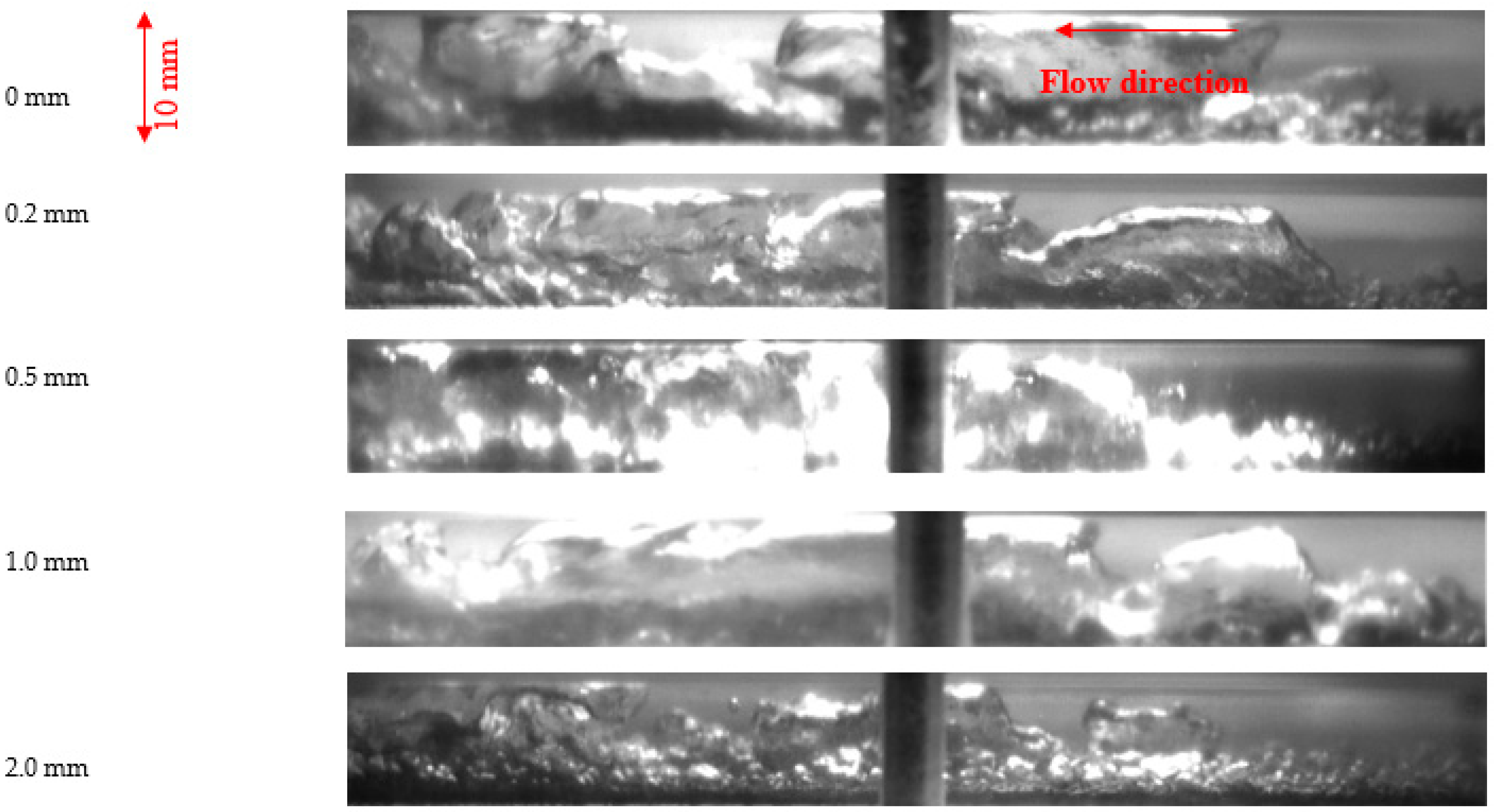

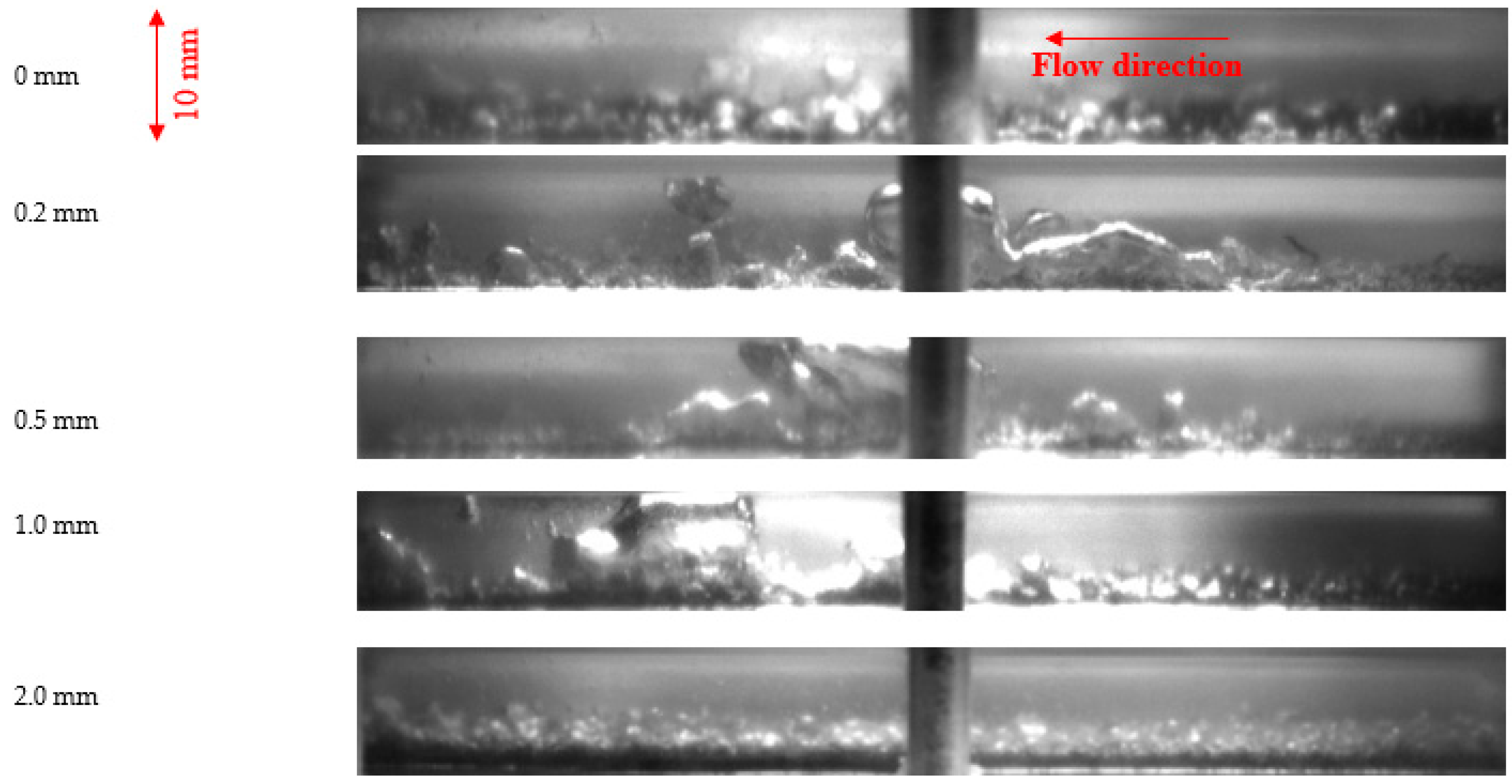

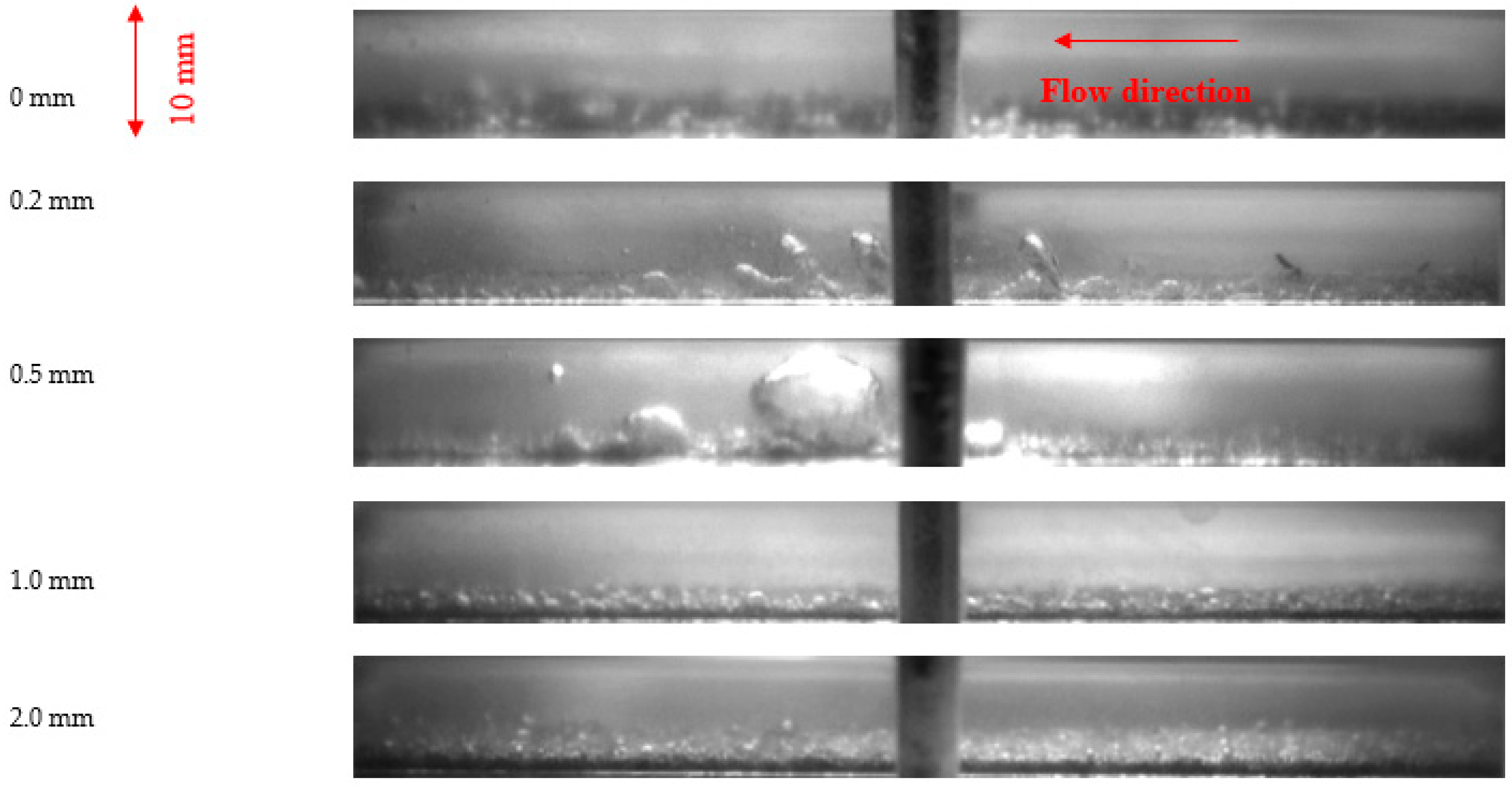

3.2. Flow and Bubble Pattern

4. Conclusions

- •

- Low porous thickness increases the heat flux at the same wall superheat temperature around two times, promoting bubble formation and increasing the bubble departure rate. Besides, the abrupt increment on the wall superheat can also be prevented, thus, the critical heat flux and film boiling are avoided.

- •

- The inlet subcooling temperature plays an important role to consider in the flow pattern and bubble formation. Higher inlet temperature condenses the small bubbles rapidly outside the porous body. However, inside the high thickness porous body, the vapor trap ability increases, thus a vapor blanket is formed.

- •

- The thickness of the porous body is an important parameter to consider 0.2, 0.5, and 1 mm porous body presented an enhancement in comparison with the 0 mm (bare surface). However, the 2 mm porous body presented a reduction in the heat flux at the same wall superheat temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zou, L. Experimental Study on Subcooled Flow Boiling on Heating Surfaces with Different Thermal Conductivities. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 2010. [Google Scholar]

- Jakob, M. Heat transfer in evaporation and condensation. Mech. Eng. Am. Soc. Mech. Eng. 1936, 58, 643–660. [Google Scholar]

- Dhir, V. Mechanistic prediction of nucleate boiling heat transfer–achievable or a hopeless task? J. Heat Transf. 2006, 128, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Kandlikar, S.G. Heat Transfer Characteristics in Partial Boiling, Fully Developed Boiling, and Significant Void Flow Regions of Subcooled Flow Boiling. J. Heat Transf. 1998, 120, 395–401. [Google Scholar] [CrossRef]

- Wang, G.; Cheng, P. Subcooled flow boiling and microbubble emission boiling phenomena in a partially heated microchannel. Int. J. Heat Mass Transf. 2009, 52, 79–91. [Google Scholar] [CrossRef]

- Lee, J.; Mudawar, I. Critical heat flux for subcooled flow boiling in micro-channel heat sinks. Int. J. Heat Mass Transf. 2009, 52, 3341–3352. [Google Scholar] [CrossRef]

- Maurus, R.; Sattelmayer, T. Bubble and boundary layer behaviour in subcooled flow boiling. Int. J. Therm. Sci. 2006, 45, 257–268. [Google Scholar] [CrossRef]

- Steiner, H.; Kobor, A.; Gebhard, L. A wall heat transfer model for subcooled boiling flow. Int. J. Heat Mass Transf. 2005, 48, 4161–4173. [Google Scholar] [CrossRef]

- Bar-Cohen, A.; Holloway, C.A. Thermal science and engineering from macro to nano in 200 years. In Proceedings of the 15th International Heat Transfer Conference, IHTC-15, Kyoto, Japan, 10–15 August 2014. [Google Scholar]

- Khan, S.A.; Atieh, M.A.; Koç, M. Micro-Nano Scale Surface Coating for Nucleate Boiling Heat Transfer: A Critical Review. Energies 2018, 11, 3189. [Google Scholar] [CrossRef] [Green Version]

- Manglick, R.M. Heat transfer Enhancement. In Heat Transfer Handbook; Bejan, A., Kraus, A.D., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; pp. 1029–1130. ISBN 0-471-39015-1. [Google Scholar]

- Jayaramu, P.; Gedupudi, S.; Das, S.K. An Experimental Investigation on the Influence of Copper Ageing on Flow Boiling in a Copper Microchannel. Heat Transf. Eng. 2020, 41, 333–350. [Google Scholar] [CrossRef]

- Fang, X.; Yuan, Y.; Xu, A.; Tian, L.; Wu, Q. Review of correlations for subcooled flow boiling heat transfer and assessment of their applicability to water. Fusion Eng. Des. 2017, 122, 52–63. [Google Scholar] [CrossRef]

- Wang, K.; Erkan, N.; Khan, A.R.; Gong, H.; Wang, L.; Okamoto, K. Comparison of pool boiling CHF of a polished copper block and carbon steel block on a declined slope. J. Nuclear Sci. Technol. 2018, 55, 1–14. [Google Scholar] [CrossRef]

- Vlachou, M.C.; Lioumbas, J.S.; David, K.; Chasapis, D.; Karapantsios, T. Effect of channel height and mass flux on highly subcooled horizontal flow boiling. Exp. Therm. Fluid Sci. 2017, 83, 157–168. [Google Scholar] [CrossRef]

- Wang, L.; Khan, A.R.; Erkan, N.; Gong, H.; Okamoto, K. Critical heat flux enhancement on a downward face using porous honeycomb plate in saturated flow boiling. Int. J. Heat Mass Transf. 2017, 109, 454–461. [Google Scholar] [CrossRef]

- Dewangan, A.K.; Kumar, A.; Kumar, R. Nucleate boiling of pure and quasi-azeotropic refrigerants from copper coated surfaces. Appl. Eng. 2016, 94, 395–403. [Google Scholar] [CrossRef]

- Sarangi, S.; Weibel, J.A.; Garimella, S.V. Effect of particle size on surface-coating enhancement of pool boiling heat transfer. Int. J. Heat Mass Transf. 2015, 81, 103–113. [Google Scholar] [CrossRef] [Green Version]

- Alam, T.; Lee, P.S.; Yap, C.R. Effects of surface roughness on flow boiling in silicon microgap heat sinks. Int. J. Heat Mass Transf. 2013, 64, 28–41. [Google Scholar] [CrossRef]

- Sahu, R.P.; Sinha-Ray, S.; Sinha-Ray, S.; Yarin, A.L. Pool boiling of Novec 7300 and self-rewetting fluids on electrically-assisted supersonically solution-blown, copper-plated nanofibers. Int. J. Heat Mass Transf. 2016, 95, 83–93. [Google Scholar] [CrossRef]

- Pialago, E.J.T.; Kwon, O.K.; Jin, J.S.; Park, C.W. Nucleate pool boiling of R134a on cold sprayed Cu-CNT SiC and Cu-CNT-AIN composite coatings. Appl. Therm. Eng. 2016, 103, 648–694. [Google Scholar] [CrossRef]

- El-Genk, M.S. Nucleate Boiling Enhancements on Porous Graphite and Microporous and Macro–Finned Copper Surfaces. Heat Transf. Eng. 2012, 33, 175–204. [Google Scholar] [CrossRef]

- Furberg, R.; Palm, B. Boiling heat transfer on a dendritic and micro-porous surface in R134a and FC-72. Appl. Eng. 2011, 31, 3595–3603. [Google Scholar] [CrossRef] [Green Version]

- Jarayumu, P.; Gedupudi, S.; Das, S.K. Influence of heating surface characteristics on flow boiling in a copper microchannel: Experimental investigation and assessment of correlations. Int. J. Heat Mass Transf. 2019, 128, 290–318. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, C.; Zhang, S.; Sun, Y.; Zeng, J.; Yuan, W.; Li, Z. Effects of structural parameter on flow boiling performance of interconnected microchannel net. Appl. Therm. Eng. 2017, 112, 164–173. [Google Scholar] [CrossRef]

- Manetti, L.L.; Moita, A.S.O.H.; De Souza, R.R.; Cardoso, E.M. Effect of copper foam thickness on pool boiling heat transfer of HFE-7100. Int. J. Heat Mass Transf. 2020, 152, 119547. [Google Scholar] [CrossRef]

- Otomo, Y.; Santiago Galicia, E.; Enoki, K. Enhancement of Subcooled Flow Boiling Heat Transfer with High Porosity Sintered Fiber Metal. Appl. Sci. 2021, 11, 1237. [Google Scholar] [CrossRef]

| Mass Flux | G [kg·m−2·s−1] | 200, 400, 600 |

|---|---|---|

| Inlet subcooling temperature | ΔTsub [K] | 70, 50, 30 |

| Porous thickness | Hp [mm] | 0, 0.2, 0.5, 1.0, 2.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galicia, E.S.; Otomo, Y.; Saiwai, T.; Takita, K.; Orito, K.; Enoki, K. Subcooled Flow Boiling Heat Flux Enhancement Using High Porosity Sintered Fiber. Appl. Sci. 2021, 11, 5883. https://doi.org/10.3390/app11135883

Galicia ES, Otomo Y, Saiwai T, Takita K, Orito K, Enoki K. Subcooled Flow Boiling Heat Flux Enhancement Using High Porosity Sintered Fiber. Applied Sciences. 2021; 11(13):5883. https://doi.org/10.3390/app11135883

Chicago/Turabian StyleGalicia, Edgar Santiago, Yusuke Otomo, Toshihiko Saiwai, Kenji Takita, Kenji Orito, and Koji Enoki. 2021. "Subcooled Flow Boiling Heat Flux Enhancement Using High Porosity Sintered Fiber" Applied Sciences 11, no. 13: 5883. https://doi.org/10.3390/app11135883

APA StyleGalicia, E. S., Otomo, Y., Saiwai, T., Takita, K., Orito, K., & Enoki, K. (2021). Subcooled Flow Boiling Heat Flux Enhancement Using High Porosity Sintered Fiber. Applied Sciences, 11(13), 5883. https://doi.org/10.3390/app11135883