Industry 4.0 HUB: A Collaborative Knowledge Transfer Platform for Small and Medium-Sized Enterprises

Abstract

1. Introduction

- Analyze the existing KT initiatives and platforms supporting the Industry 4.0 transition within SMEs;

- Propose a new collaborative online platform to improve Industry 4.0 KT between SMEs.

2. Materials and Methods

- The first phase was a literature review conducted in 2019 and 2020 to evaluate current Industry 4.0 knowledge transfer initiatives and platforms. This will be described in Section 2.1.

- For the second phase, by the end of 2020, the collaborative online platform Industry 4.0 HUB for knowledge transfer for SMEs was developed. This phase will be explained in Section 2.2 and Section 2.3.

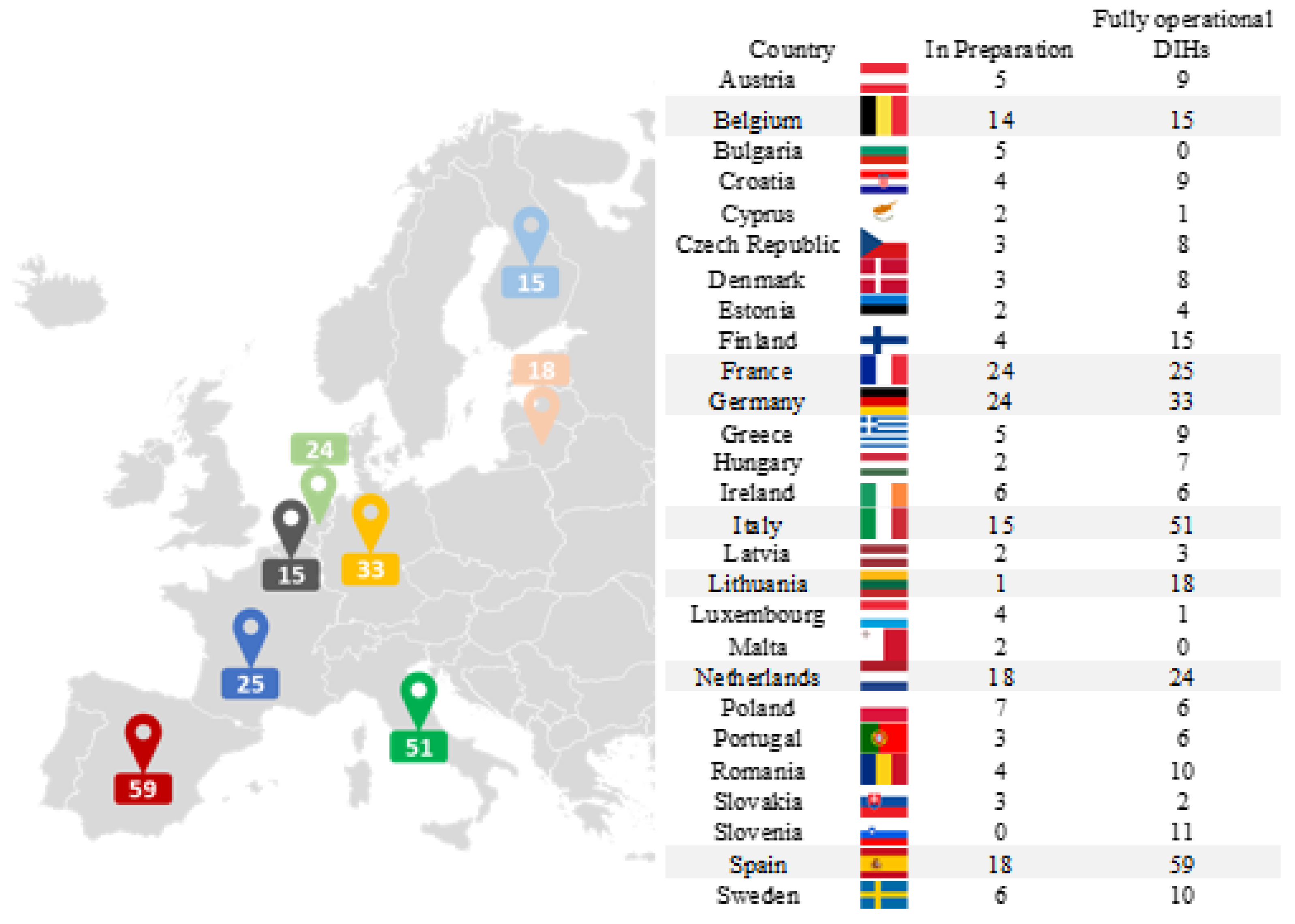

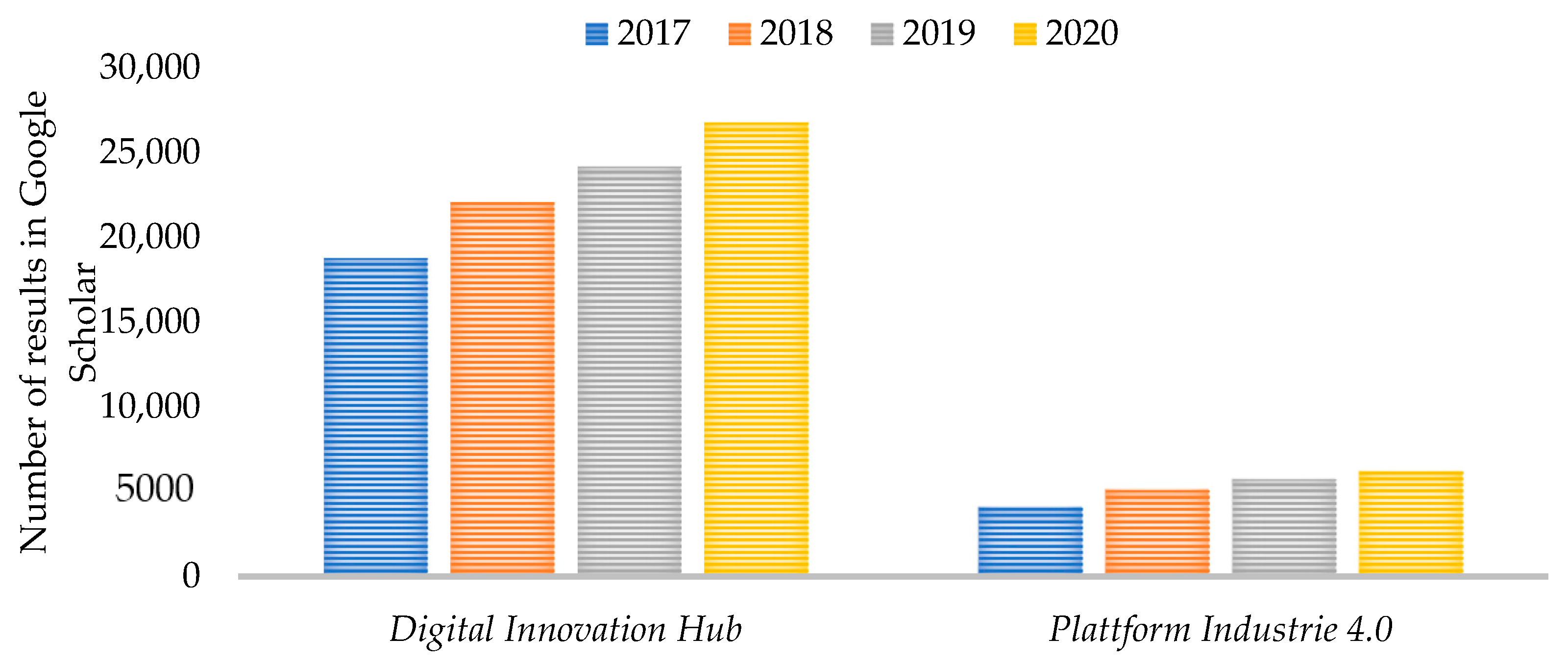

2.1. Literature Review

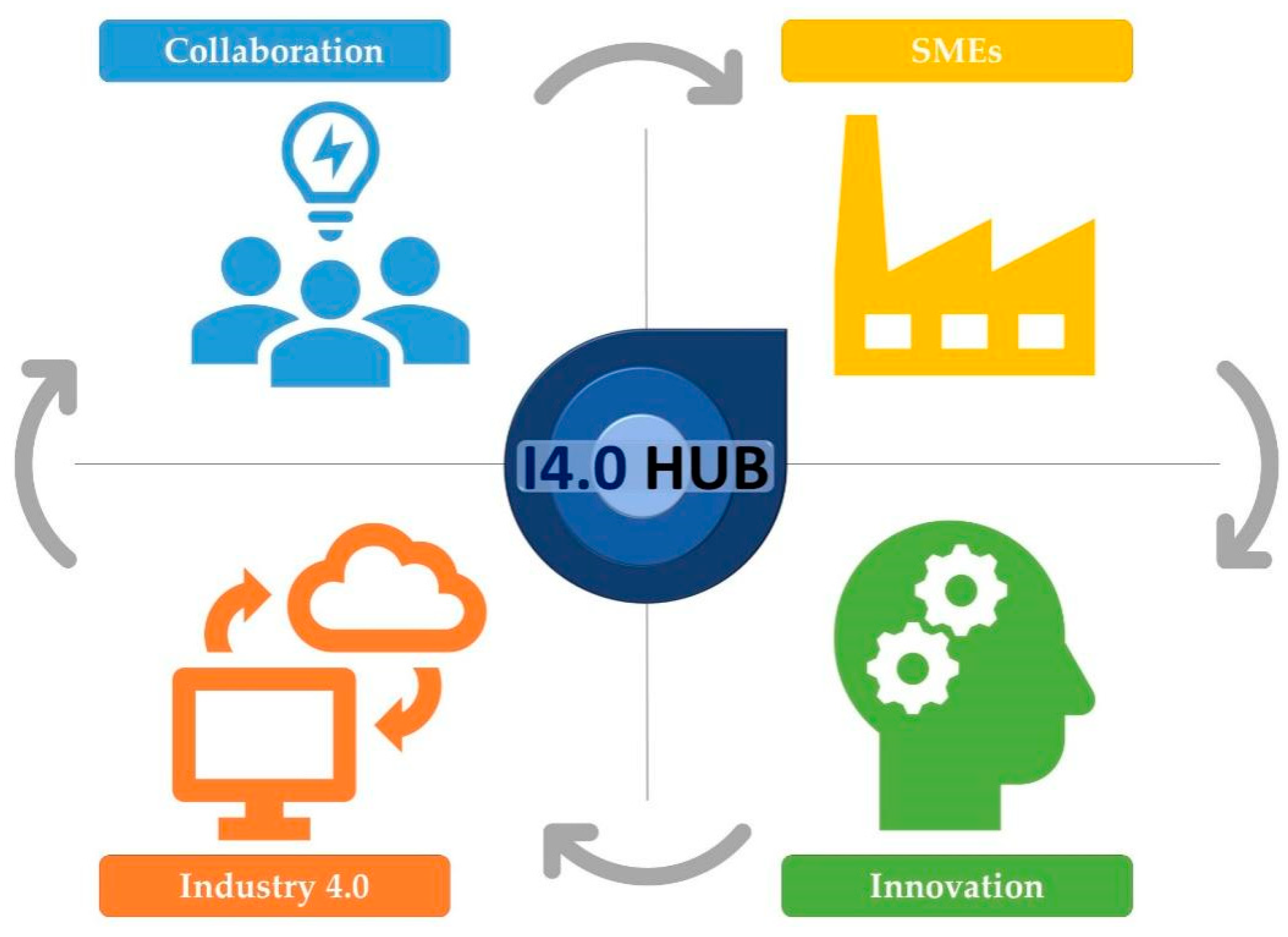

2.2. Industry 4.0 HUB

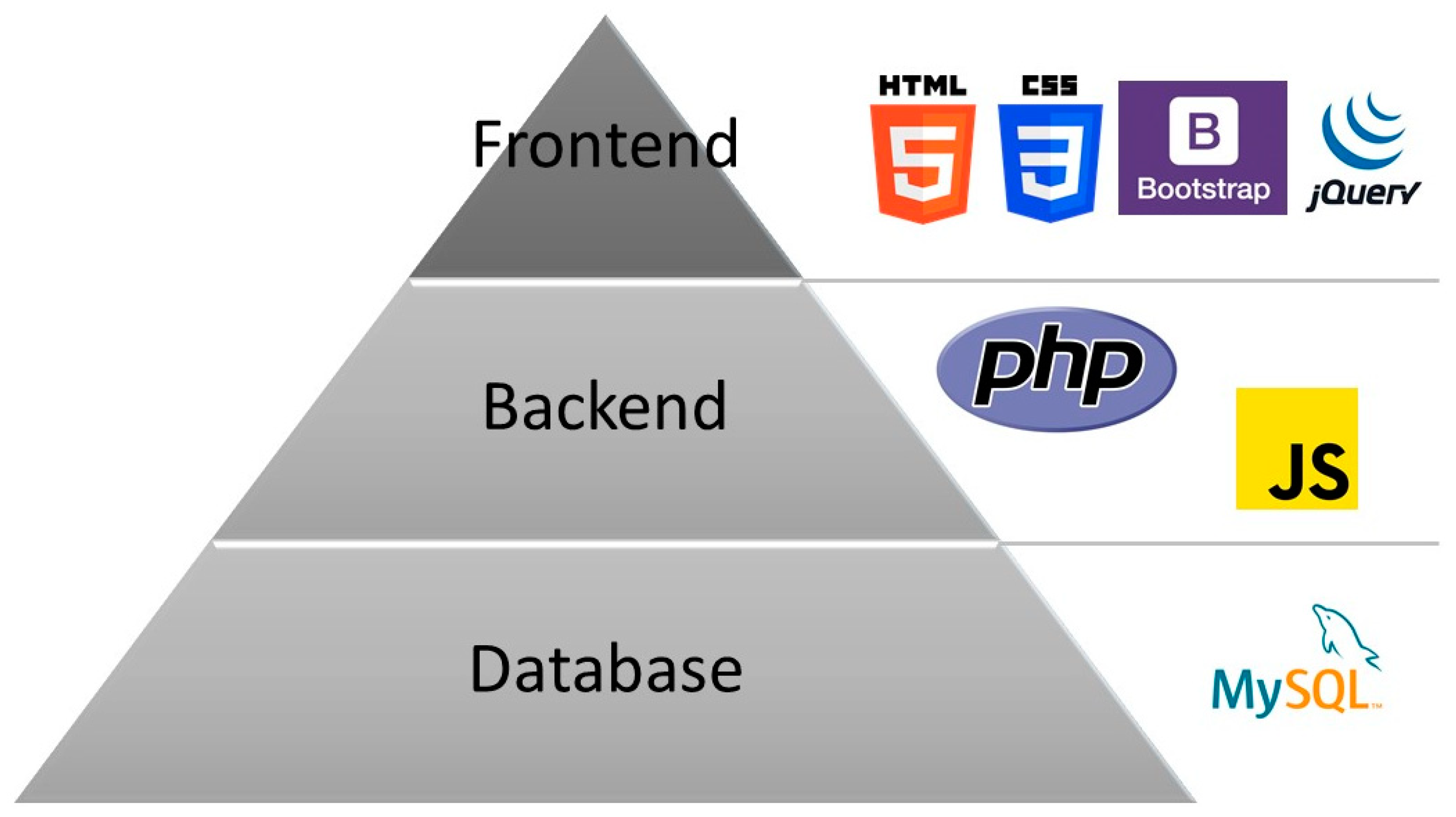

2.3. Development of the Industry 4.0 HUB

- HTML 5: the latest version of the markup language for web pages;

- CSS 3: a style sheet language used for describing the presentation of a document written in a markup language such as HTML;

- Bootstrap 4: HTML, CSS, and JavaScript framework for developing responsive web pages.

- PHP: a server scripting language and a powerful tool for making dynamic and interactive web pages;

- JavaScript: high-level and multi-paradigm programming language.

3. Results

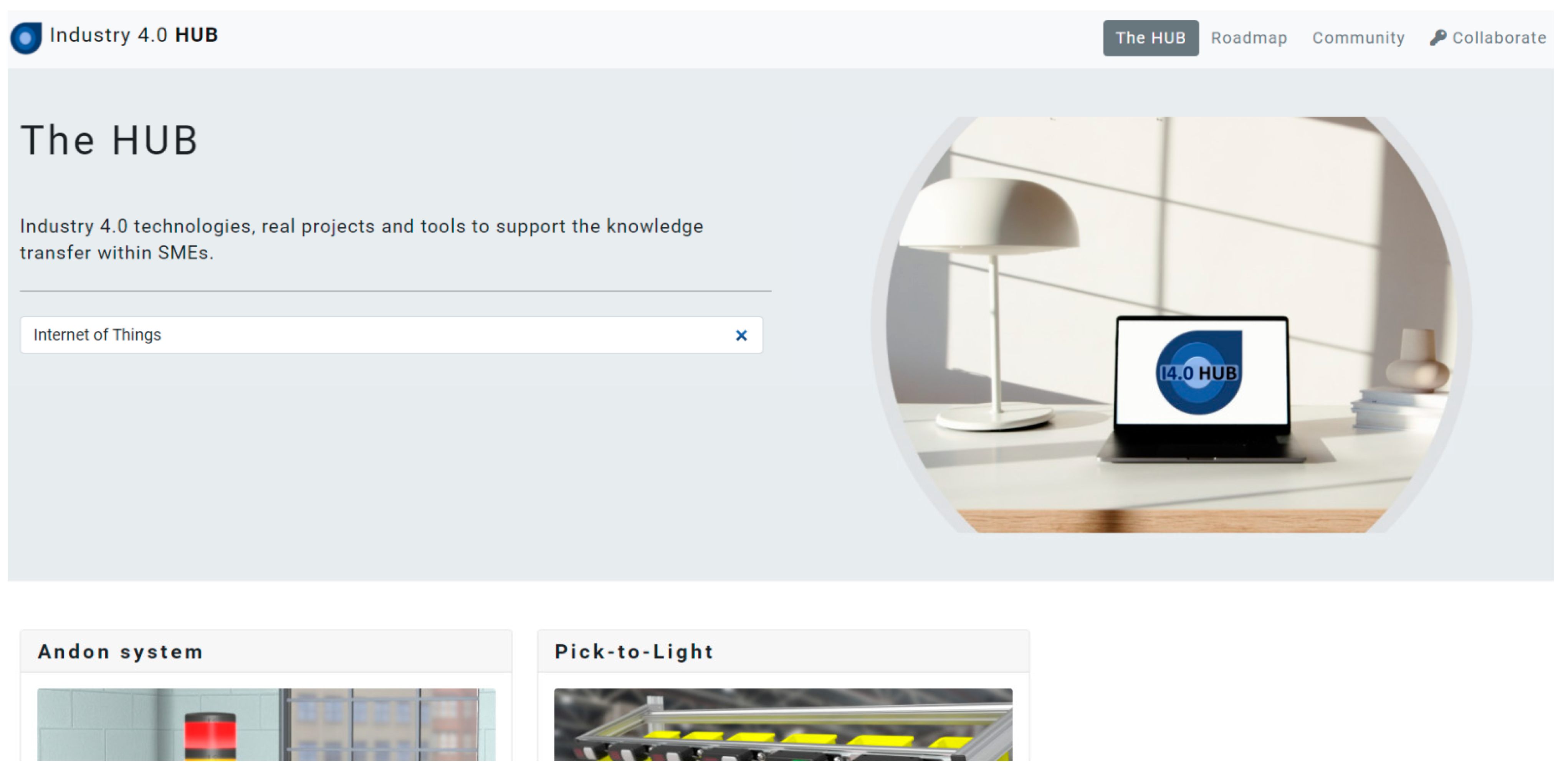

3.1. The HUB

3.2. Roadmap

3.3. Community

3.4. Collaborate

4. Discussion and Conclusions

- The Industry 4.0 HUB creates a single source for Industry 4.0 KT for SMEs. Every SME willing to implement Industry 4.0 technologies does not need to seek hundreds of papers, books, and platforms as everything is available in just one website, which covers the lack of knowledge highlighted in Section 1. Additionally, the resources needed to start the Fourth Industrial Revolution are minimized.

- The HUB provides real-time SME access to an immense collection of Industry 4.0 use cases.

- The Collaborate and Networking modules allow SMEs to enter use cases and share Industry 4.0 knowledge and resources, creating a collaborative network.

- The Roadmap module helps SMEs enter the new era of manufacturing using a simple process that does not require complex expertise or big teams.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Masooda, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 12. [Google Scholar] [CrossRef]

- Prause, M. Challenges of Industry 4.0 Technology Adoption for SMEs: The Case of Japan. Sustainability 2019, 11, 5807. [Google Scholar] [CrossRef]

- Ingaldi, M.; Ulewicz, R. Problems with the Implementation of Industry 4.0 in Enterprises from the SME Sector. Sustainability 2019, 12, 217. [Google Scholar] [CrossRef]

- Orzes, G.; Rauch, E.; Bednar, S.; Poklemba, R. Industry 4.0 Implementation Barriers in Small and Medium Sized Enterprises: A Focus Group Study. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Manage-ment (IEEM), Bangkok, Thailand, 16–19 December 2018. [Google Scholar]

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Issa, A.; Lucke, D.; Bauernhansl, T. Mobilizing SMEs Towards Industrie 4.0-enabled Smart Products. Procedia CIRP 2017, 63, 670–674. [Google Scholar] [CrossRef]

- Sommer, L. Industrial revolution—Industry 4.0: Are German manufacturing SMEs the first victims of this revolution? J. Ind. Eng. Manag. 2015, 8, 1512–1532. [Google Scholar] [CrossRef]

- ACotrino, A.; Sebastián, M.A.; González-Gaya, C. Industry 4.0 Roadmap: Implementation for Small and Medium-Sized Enterprises. Appl. Sci. 2020, 10, 8566. [Google Scholar] [CrossRef]

- Sufian, A.; Abdullah, B.; Ateeq, M.; Wah, R.; Clements, D. Six-Gear Roadmap towards the Smart Factory. Appl. Sci. 2021, 11, 3568. [Google Scholar] [CrossRef]

- Chonsawat, N.; Sopadang, A. Defining SMEs’ 4.0 Readiness Indicators. Appl. Sci. 2020, 10, 8998. [Google Scholar] [CrossRef]

- Matt, D.; Riedl, M.; Rauch, E. Knowledge Transfer and Introduction of Industry 4.0 in SMEs: A Five-Step Methodology to Introduce Industry 4.0. In Analyzing the Impacts of Industry 4.0 in Modern Business Environments; IGI Global: Hershey, PA, USA, 2018; p. 27. [Google Scholar]

- Schumacher, J. Knowledge is power—What get in the way of digitalization. Product. Manag. 2018, 23, 16–18. [Google Scholar]

- Girard, J.; Girard, J. Defining knowledge management: Toward an applied compendium. Online J. Appl. Knowl. Manag. 2015, 3, 20. [Google Scholar]

- Newman, B.D.; Conrad, K.W. A Framework for Characterizing Knowledge Management Methods, Practices, and Technologies. In Proceedings of the PAKM 2000, Third International Conference on Practical Aspects of Knowledge Management, Basel, Switzerland, 30–31 October 2000. [Google Scholar]

- Wiig, K.M. Knowledge Management Methods: Practical Approaches to Managing Knowledge; Schema Press, Ltd.: Arlington, TX, USA, 1995. [Google Scholar]

- Massaro, M.; Moro, A.; Aschauer, E.; Fink, M. Trust, control and knowledge transfer in small business networks. Rev. Manag. Sci. 2017, 13, 267–301. [Google Scholar] [CrossRef]

- Durst, S.; Edvardsson, I.R. Knowledge management in SMEs: A literature review. J. Knowl. Manag. 2012, 16, 879–903. [Google Scholar] [CrossRef]

- Paulin, D.; Suneson, K. Knowledge Transfer, Knowledge Sharing and Knowledge sharing and knowledge barriers—Three blurry terms in KM. Electron. J. Knowl. Manag. 2012, 10, 11. [Google Scholar]

- Duan, Y.; Nie, W.; Coakes, E. Identifying key factors affecting transnational knowledge transfer. Inf. Manag. 2010, 47, 356–363. [Google Scholar] [CrossRef]

- Stachová, K.; Stacho, Z.; Cagáňová, D.; Stareček, A. Use of Digital Technologies for Intensifying Knowledge Sharing. Appl. Sci. 2020, 10, 4281. [Google Scholar] [CrossRef]

- Schmidt, D.M.; Böttcher, L.; Wilberg, J.; Kammerl, D.; Lindemann, U. Modeling Transfer of Knowledge in an Online Platform of a Cluster. Procedia CIRP 2016, 50, 348–353. [Google Scholar] [CrossRef][Green Version]

- Ulmer, D.; Birkenmeier, B. Development of a central Knowledge Transfer Platform in a highly decentralised environment. In Proceedings of the 6th International Conference on Current Research Information Systems, Kassel, Germany, 29–31 September 2002. [Google Scholar]

- Bundesministerium für Wirtschaft und Energie. Plattform Industrie 4.0. 2013. Available online: https://www.plattform-i40.de/PI40/Navigation/DE/Home/home.html (accessed on 15 April 2021).

- Anderl, R. Industrie 4.0—Advanced Engineering of Smart Products and Smart Production. In Proceedings of the Technological Innovations in the Product Development, Piracicaba, Brazil, 9 October 2014. [Google Scholar]

- Crupi, A.; Del Sarto, N.; Di Minin, A.; Gregori, G.L.; Lepore, D.; Marinelli, L.; Spigarelli, F. The digital transformation of SMEs—A new knowledge broker called the digital innovation hub. J. Knowl. Manag. 2020, 24, 1263–1288. [Google Scholar] [CrossRef]

- Hervas-Oliver, J.-L.; Gonzalez-Alcaide, G.; Rojas-Alvarado, R.; Monto-Mompo, S. Emerging regional innovation policies for industry 4.0: Analyzing the digital innovation hub program in European regions. Competitiveness Rev. 2021, 31, 106–129. [Google Scholar] [CrossRef]

- European Commission. Digital Innovation Hubs (DIHs) in Europe. Available online: https://ec.europa.eu/digital-single-market/en/digital-innovation-hubs (accessed on 24 November 2020).

- Goetheer, A.; Butter, M. Digital Innovation Hubs Catalogue; TNO, The Hague: The Hague, The Netherlands, 2017. [Google Scholar]

- Hub Agency. de hub. Available online: https://www.de-hub.de/ (accessed on 27 December 2020).

- European Commission. Digital Innovation Hubs. Available online: https://s3platform.jrc.ec.europa.eu/digital-innovation-hubs-tool (accessed on 6 January 2021).

- Rissola, G.; Sörvik, J. Digital Innovation Hubs in Smart Specialisation Strategies; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- European Commission. DIHNET.EU. Available online: https://dihnet.eu/ (accessed on 28 December 2020).

- Dodgson, M. Asia’s national innovation systems: Institutional adaptability and rigidity in the face of global innovation challenges. Asia Pac. J. Manag. 2008, 26, 589–609. [Google Scholar] [CrossRef]

- Hassink, R.; Isaksen, A.; Trippl, M. Towards a comprehensive understanding of new regional industrial path development. Reg. Stud. 2019, 53, 1636–1645. [Google Scholar] [CrossRef]

- Lundvall, B.-Å. National Innovation Systems—Analytical Concept and Development Tool. Ind. Innov. 2007, 14, 95–119. [Google Scholar] [CrossRef]

- Wernberg, J.; Miörner, J.; Kalpaka, A.; Sörvik, J. Exploring Heterogeneous Digital Innovation Hubs in Their Context; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Tayliyev, A. Choosing a Tech Stack for Full-Cycle Web Application Development. 2020. Available online: https://medium.com/front-end-weekly/choosing-a-tech-stack-for-full-cycle-web-application-development-db5b336c7997 (accessed on 4 November 2020).

- Stack Overflow. Stack Overflow Annual Developer Survey. 2020. Available online: https://insights.stackoverflow.com/survey/ (accessed on 12 July 2020).

- Fraunhofer-Gesellschaft. Trends in Industrie 4.0; Fraunhofer-Gesellschaft Communications: Munich, Germany, 2016. [Google Scholar]

- The Mechanical Engineering Industry Association (VDMA). Industrie 4.0 in Practice; VDMA Verlag: Frankfurt am Main, Germany, 2019. [Google Scholar]

- The Mechanical Engineering Industry Association (VDMA). Industrie 4.0 Guideline: Guiding Principles for the Implementation of Industrie 4.0 in Small and Medium Sized Businesses; VDMA Verlag: Frankfurt am Main, Germany, 2016. [Google Scholar]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

| Field | Description |

|---|---|

| Name of the Industry 4.0 Project | Unique identification of the Industry 4.0 use case, which is used as a key for the SQL database. |

| Industry 4.0 Technology | The literature about technologies related to Industry 4.0 is extensive [39,40,41,42]. Considering the large number of technologies related to Industry 4.0, the authors have selected six of these technologies to classify the use cases: Internet of Things, machine learning, automation, big data, cloud computing, augmented reality, and other. |

| Description | Short introduction of the Industry 4.0 solution, including the use case of the project and the improvement achieved. With this information, other SMEs can gain a quick understanding of and easily and quickly comprehend the key usage of the solution and implement it in their organizations. |

| Budget | Several research works have highlighted that SMEs do not have the economic resources to implement Industry 4.0 technologies [5,8]. For the Industry 4.0 HUB, the authors included this category so that microenterprises and small enterprises with turnover ranges between EUR 0.5 million and EUR 10 million can carefully select the solution based on the costs and the investment. |

| Picture | This allows the user to upload a picture of the use case to support rapid visual recognition. |

| Additional Information (Link) | This is a field to include links to provide additional information, such as the website of the vendor of the technologies used. |

| Platform | Scalability | Resources | Networking | Technical Expertise | Specialization |

|---|---|---|---|---|---|

| DIH |  |  |  |  |  |

| Plattform Industrie 4.0 |  |  |  |  |  |

| Industry 4.0 HUB |  |  |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cotrino, A.; Sebastián, M.A.; González-Gaya, C. Industry 4.0 HUB: A Collaborative Knowledge Transfer Platform for Small and Medium-Sized Enterprises. Appl. Sci. 2021, 11, 5548. https://doi.org/10.3390/app11125548

Cotrino A, Sebastián MA, González-Gaya C. Industry 4.0 HUB: A Collaborative Knowledge Transfer Platform for Small and Medium-Sized Enterprises. Applied Sciences. 2021; 11(12):5548. https://doi.org/10.3390/app11125548

Chicago/Turabian StyleCotrino, Alberto, Miguel A. Sebastián, and Cristina González-Gaya. 2021. "Industry 4.0 HUB: A Collaborative Knowledge Transfer Platform for Small and Medium-Sized Enterprises" Applied Sciences 11, no. 12: 5548. https://doi.org/10.3390/app11125548

APA StyleCotrino, A., Sebastián, M. A., & González-Gaya, C. (2021). Industry 4.0 HUB: A Collaborative Knowledge Transfer Platform for Small and Medium-Sized Enterprises. Applied Sciences, 11(12), 5548. https://doi.org/10.3390/app11125548