Comparative Analysis of Digital Models of Objects of Cultural Heritage Obtained by the “3D SLS” and “SfM” Methods

Abstract

1. Introduction

- Comparison of data acquisition procedures for artefacts of material cultural heritage in SfM and 3D SLS technologies.

- Generating 3D objects of museum artefacts in SfM and 3D SLS technology.

- Assessment of parameters and quality of 3D models obtained in SfM and 3D SLS technologies.

2. Background Study

3. Method and Materials

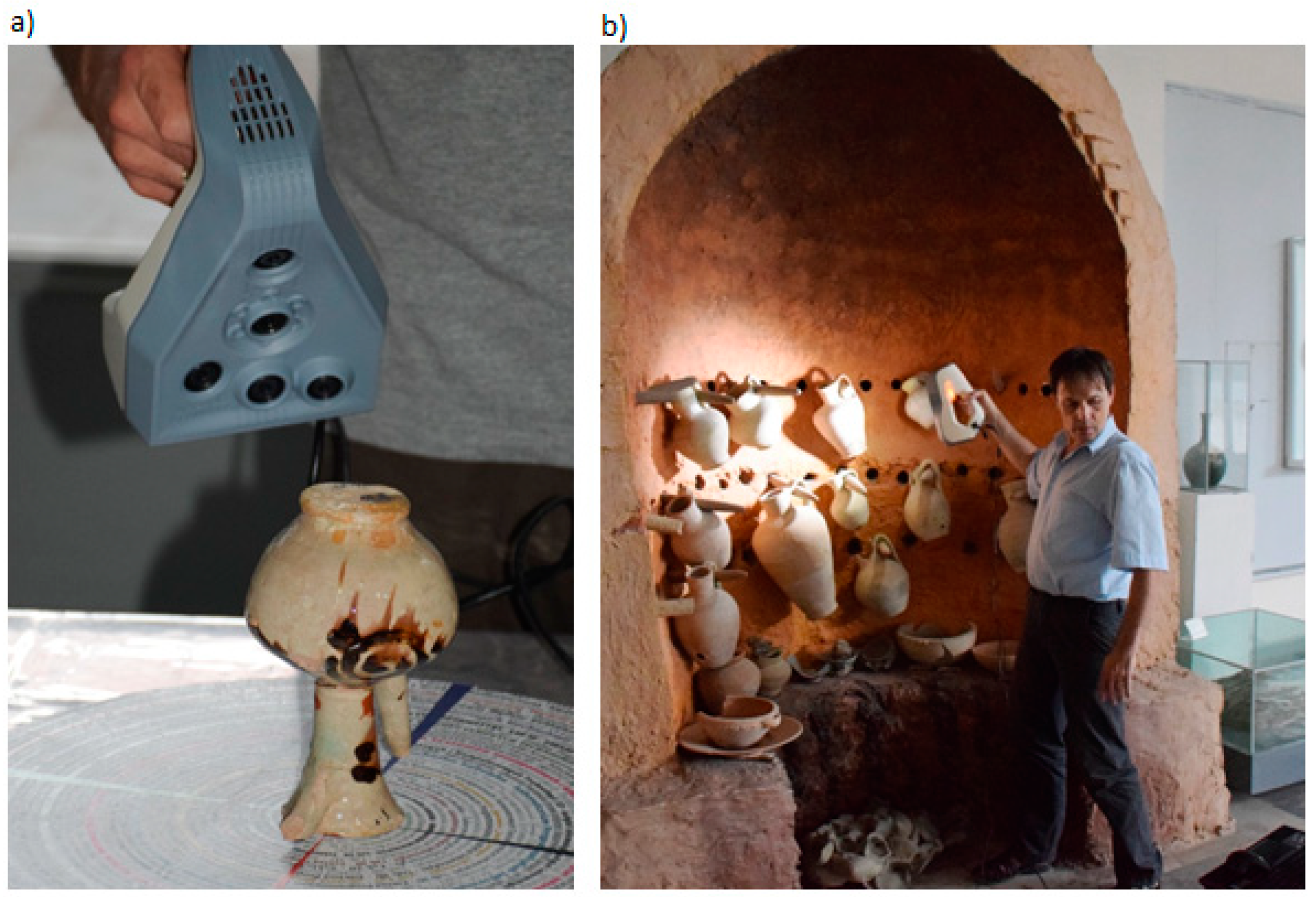

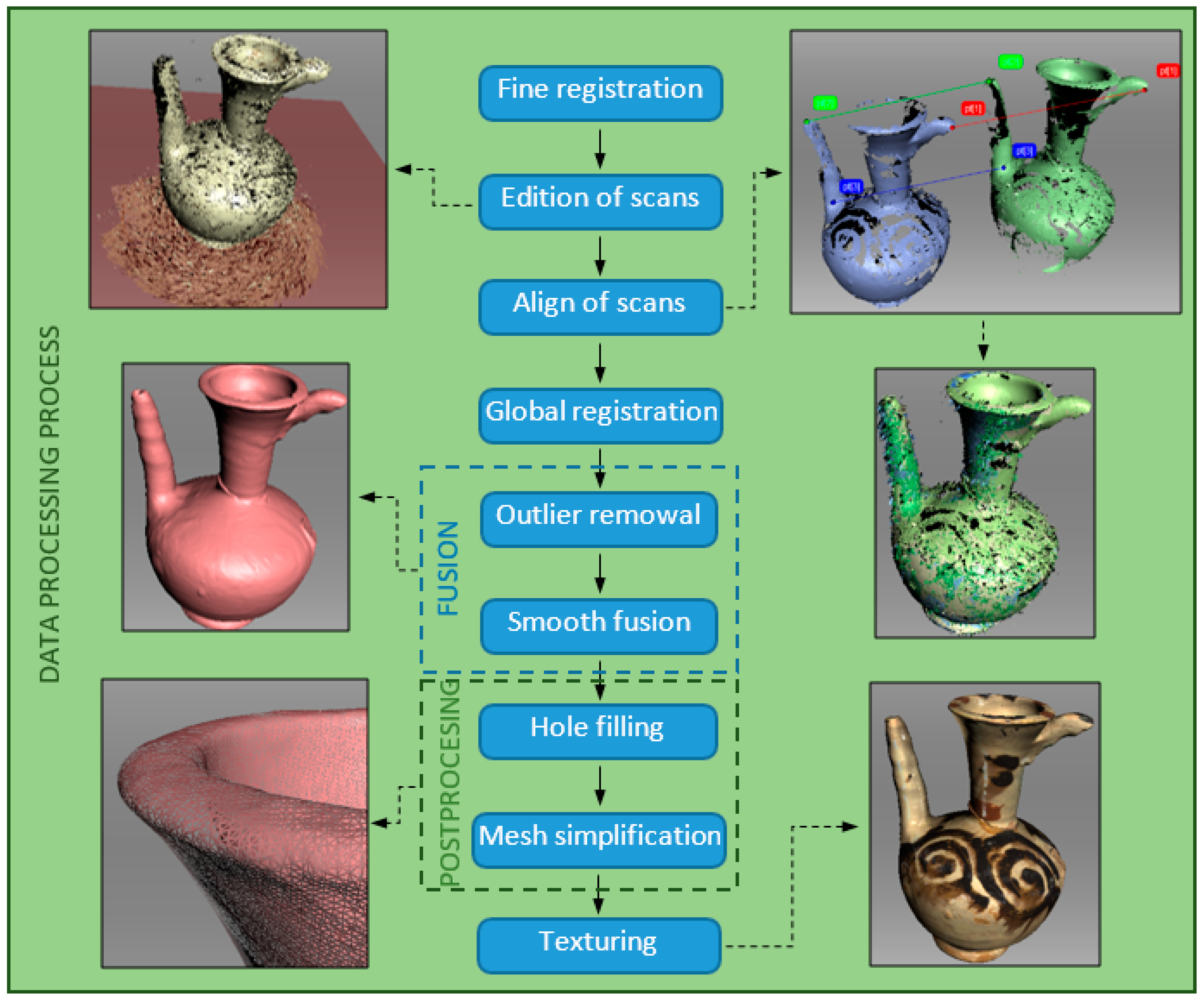

3.1. Structured-Light 3D Scanning

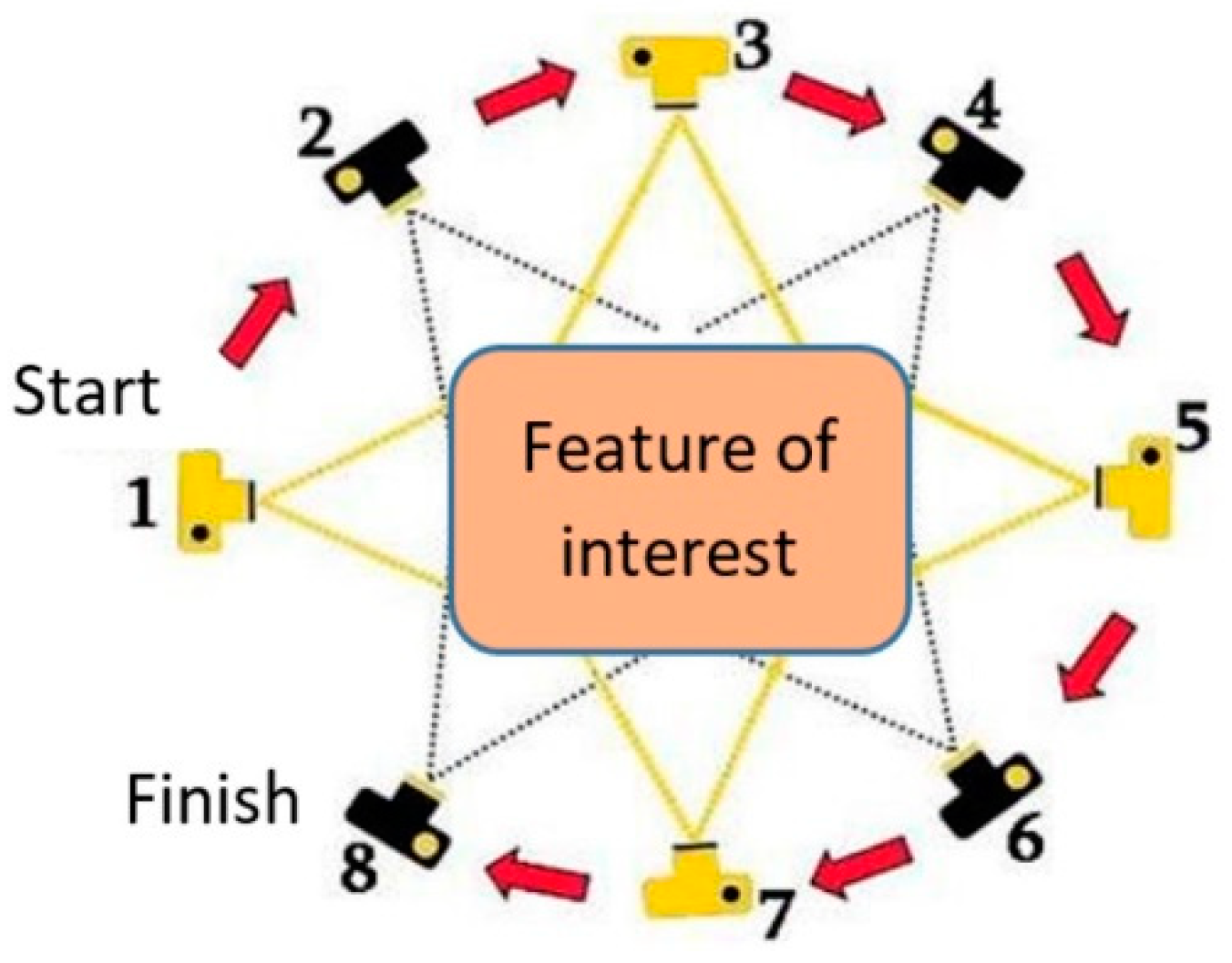

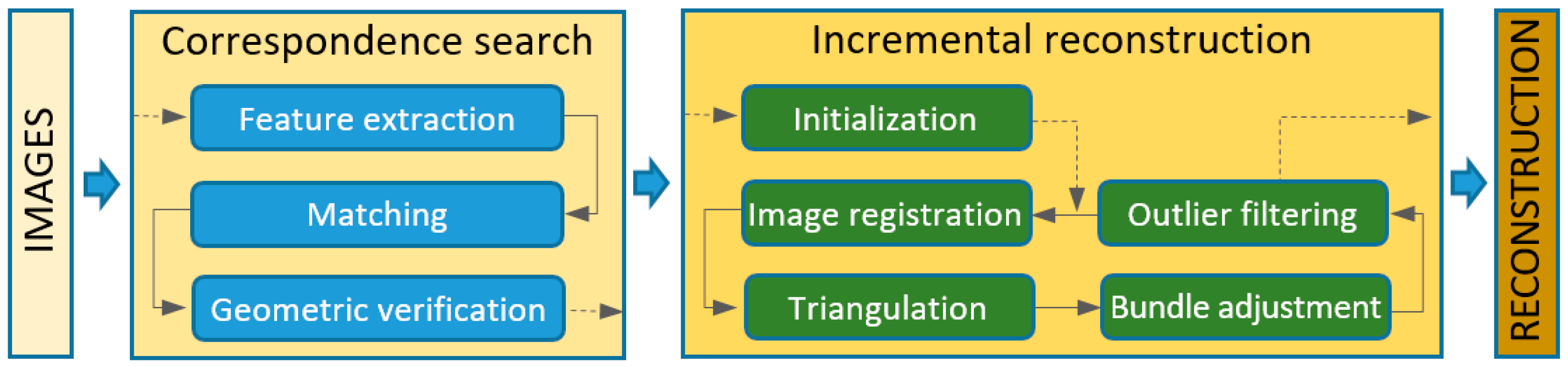

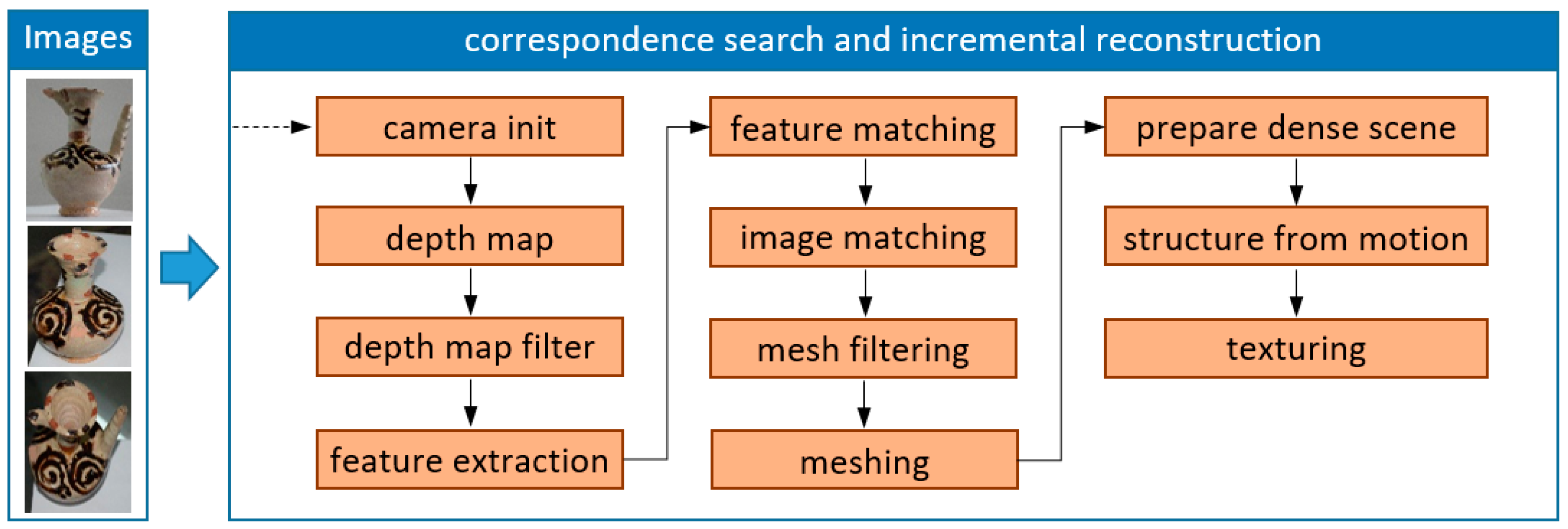

3.2. Structure from Motion

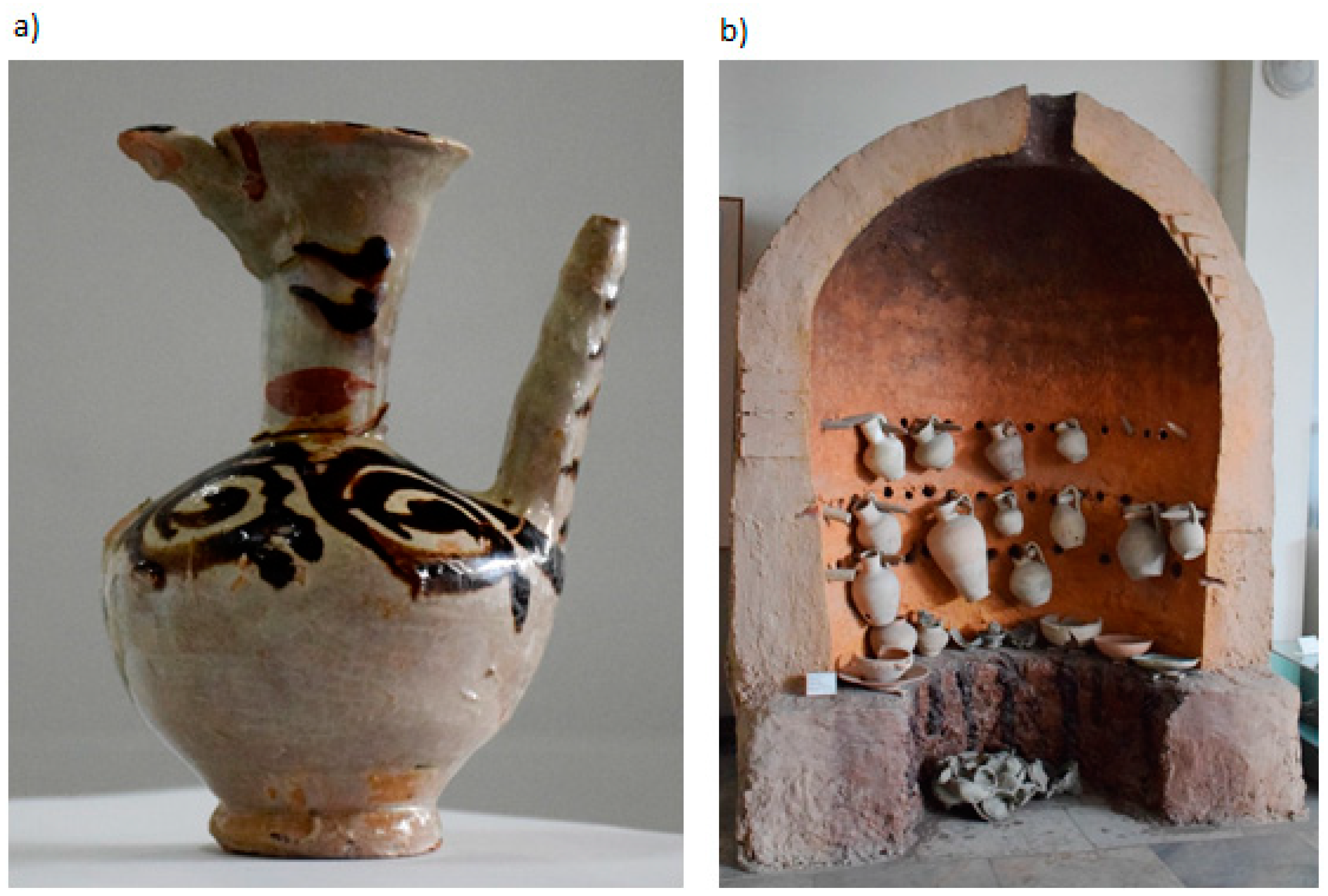

3.3. Description of the Objects of the Experiment

3.4. 3D SLS Scanning and Postprocessing of the Jug and the Oven

3.5. Structure from Motion Jug and Stove

3.6. Comparison of Data Acquisition Methods and Creating 3D Models

4. Results

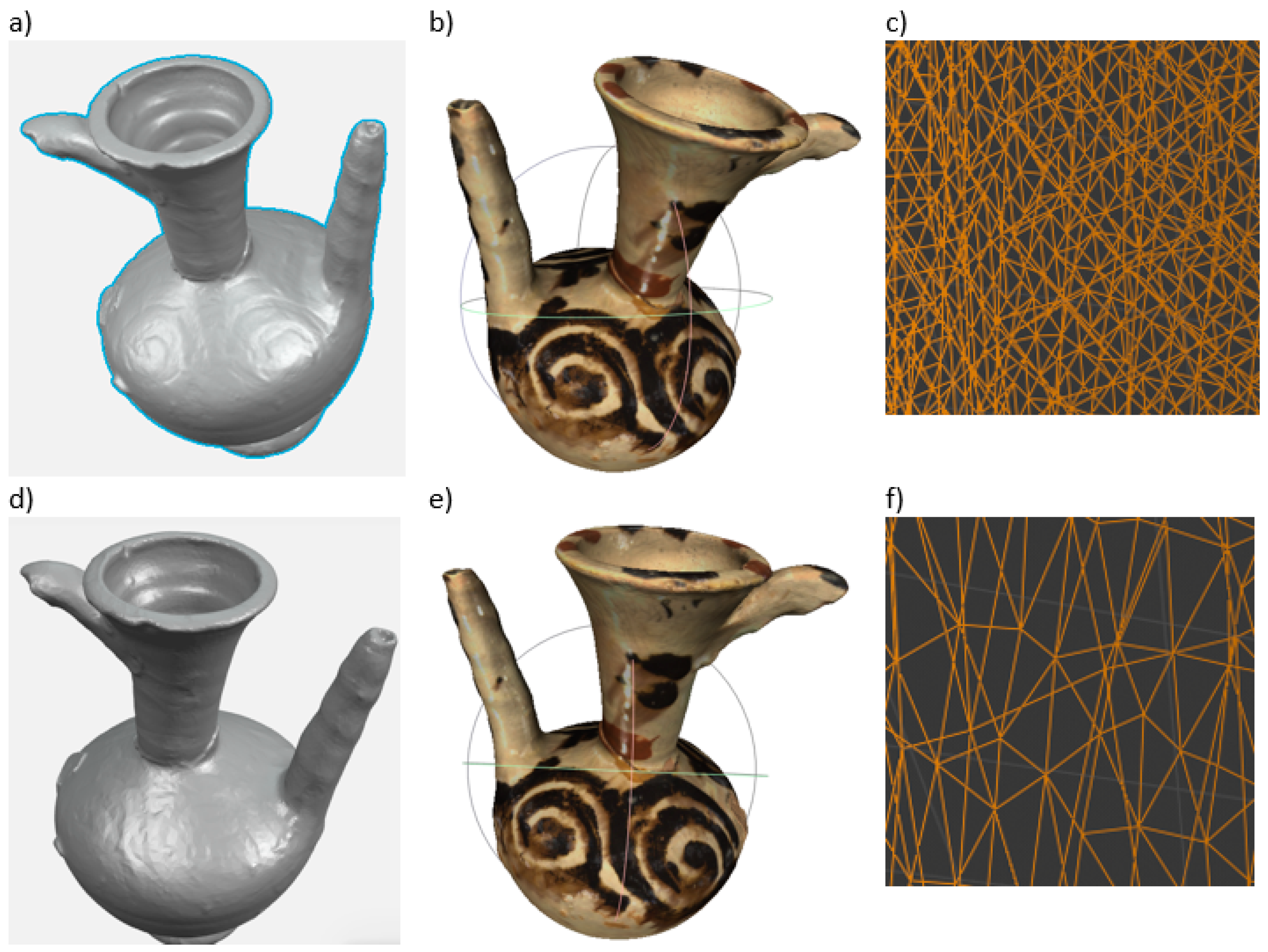

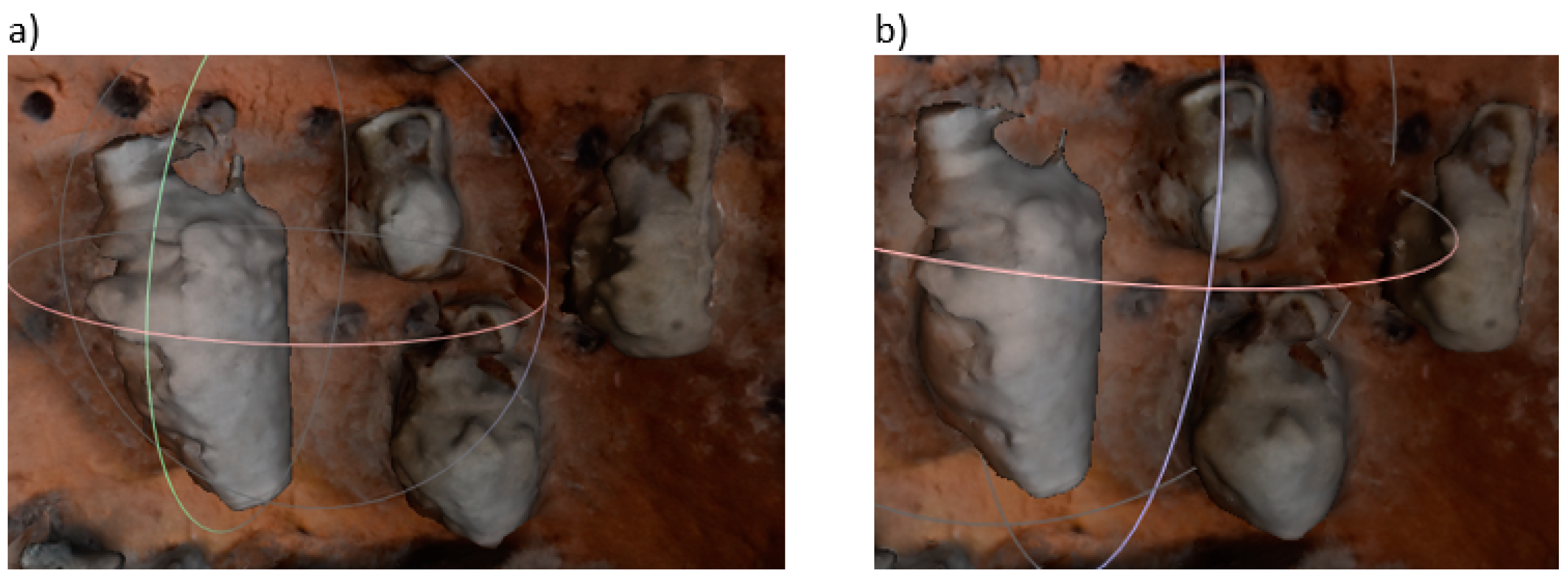

4.1. Digital 3D Models of the Jug

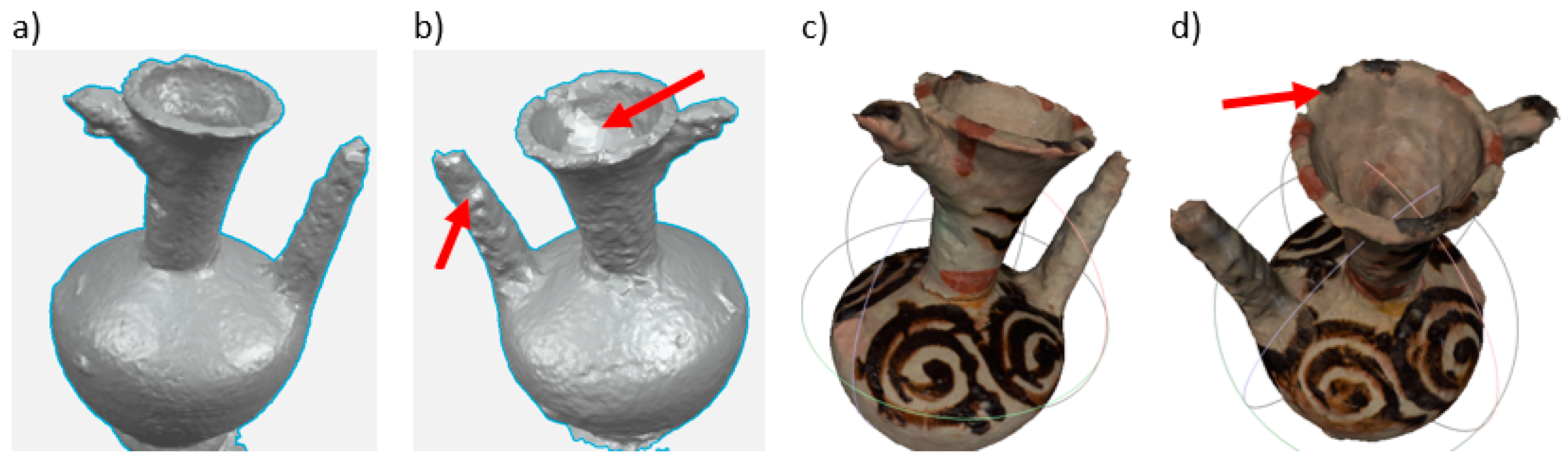

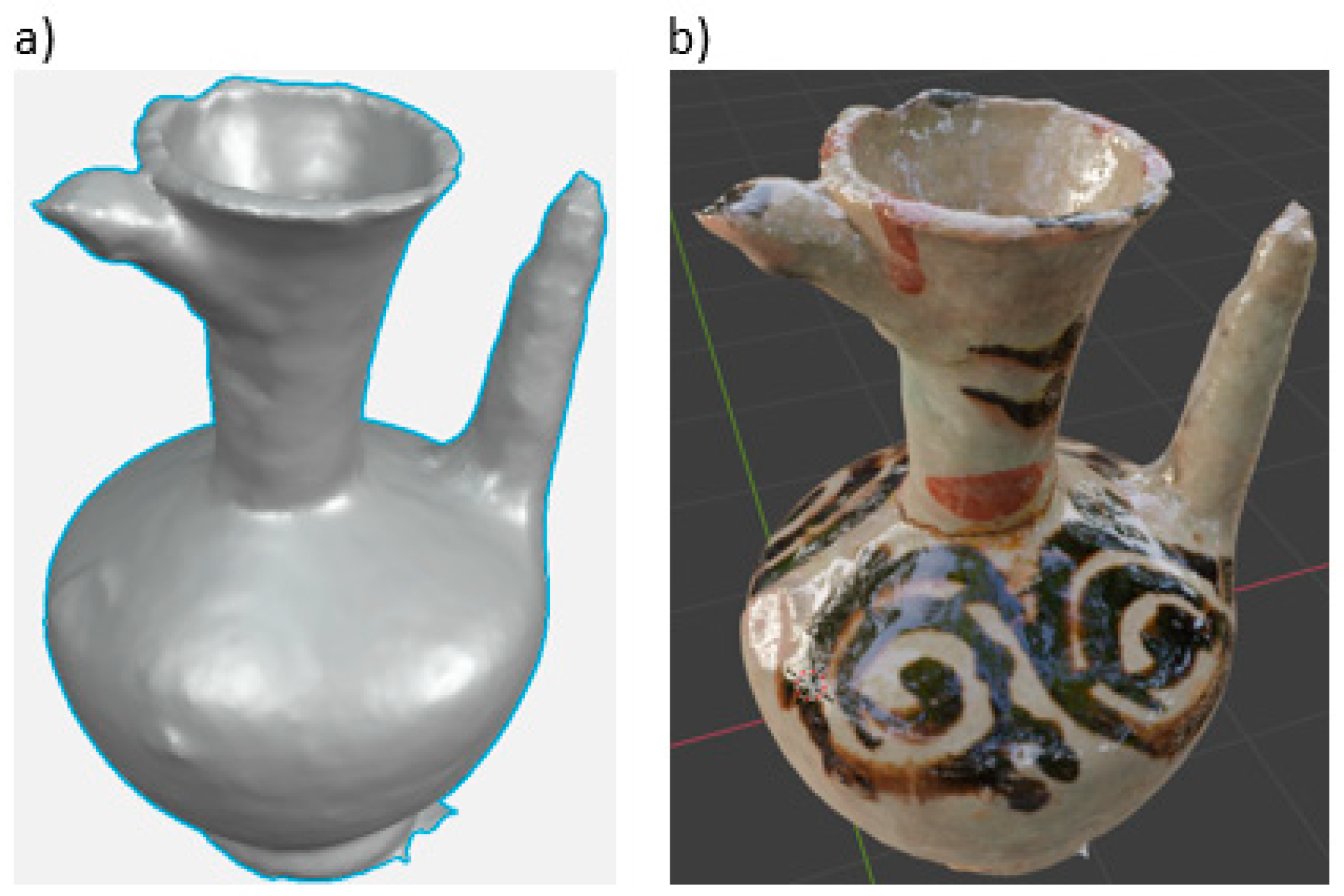

4.1.1. 3D SLS and Postprocessing

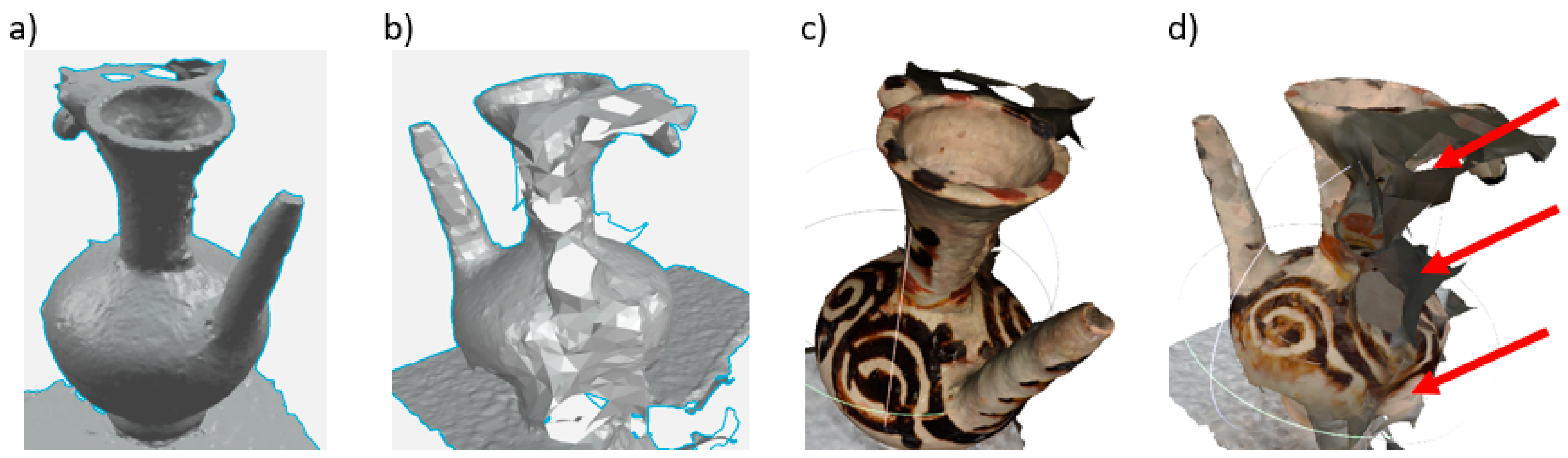

4.1.2. SfM and Postprocessing

4.1.3. Comparison of SLS and SfM Technologies

4.2. Digital Oven 3D Models

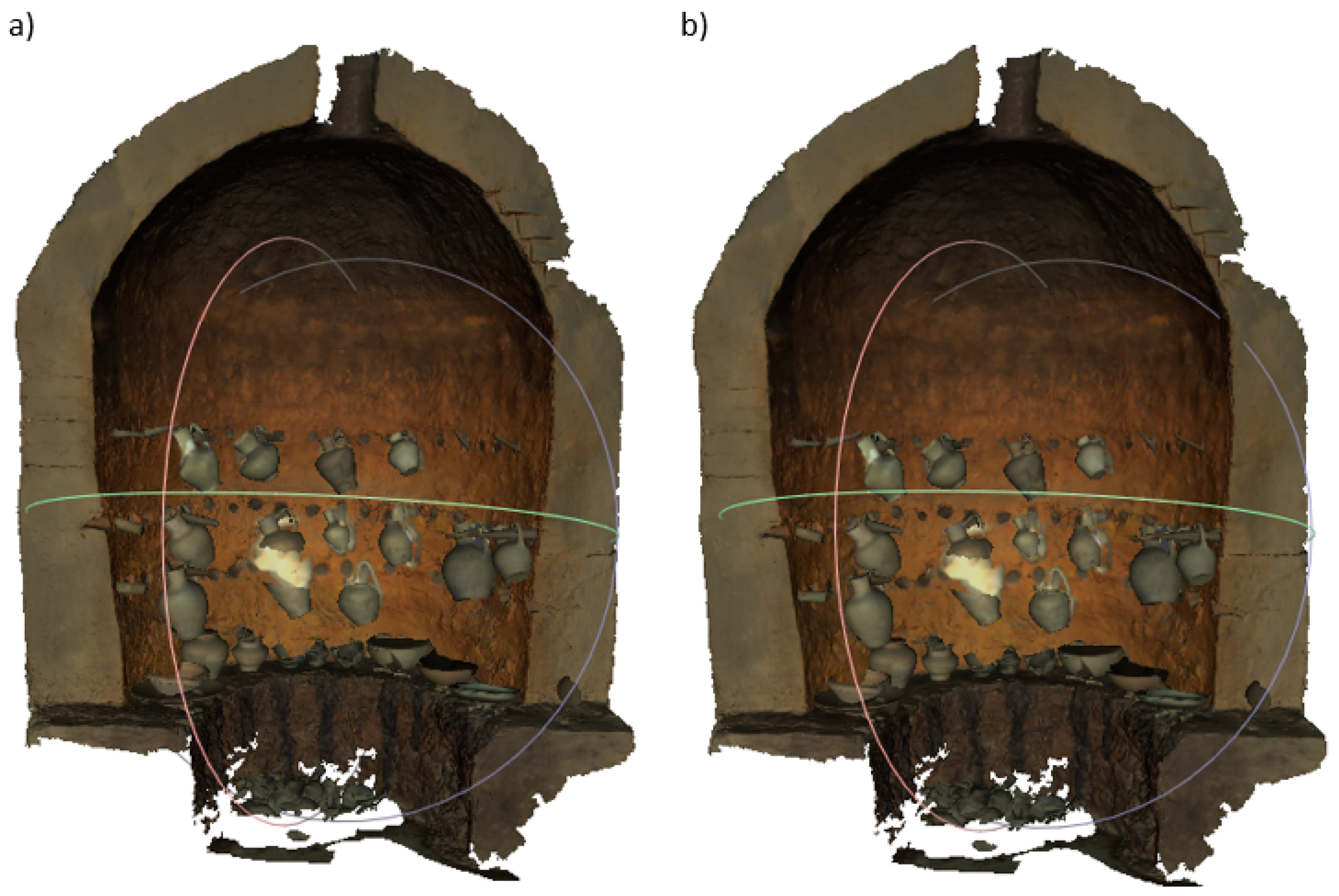

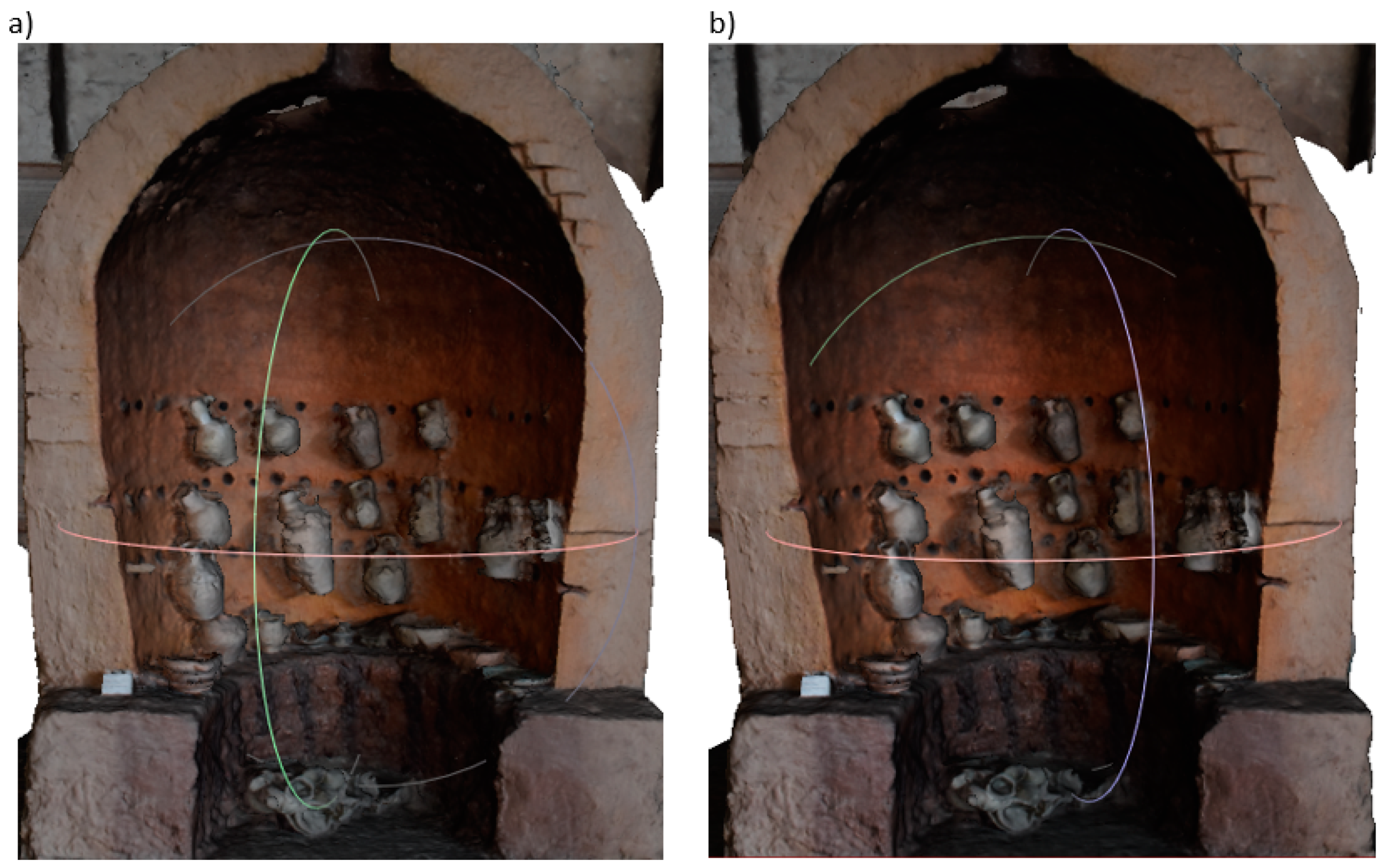

4.2.1. 3D SLS and Postprocessing

4.2.2. SfM and Postprocessing

4.2.3. Comparison of SLS and SfM Technologies

5. Conclusions and Further Work

- (1)

- Scanning with the 3D SLS method with the use of Artec Spider and Artec Eva scanners is perfect for mapping museum objects due to the lack of contact with them (the emitted light is neutral for the scanned objects, thanks to which it is possible to scan very delicate, old and valuable objects). It enables effective in situ data acquisition, which significantly simplifies the digitisation process and the necessary formalities to carry it out.

- (2)

- Performing the proper postprocessing of the data obtained in the 3D SLS scanning process allows to obtain a faithful 3D mesh model with the applied texture, which can be exported to a file in .obj format with a size many times smaller than the original data obtained.

- (3)

- Optimisation of the 3D model mesh using the 3D SLS method and reducing it by up to 10 times while reducing the texture dimension by a factor of 2 does not result in the loss of good visual quality of these objects. This remark applies to very small objects (a 14 cm high jug and a 270 cm high oven). It should be added that the total size of model and texture files is reduced by about 6 to 8 times. As a result, these models are well suited for placement on museum websites.

- (4)

- The low-cost SfM method has an unquestionable advantage (over 35 times), which can be an attractive alternative when creating digital 3D models of museum objects. The results of the comparative studies, however, show some of its shortcomings, which means that the obtained three-dimensional digital models are usually of lower visual quality. In addition, due to the improvement of their quality (e.g., surface smoothing), their size increases significantly and is about 3–5 times larger than the size of model files and texture files from the 3D SLS method after optimisation. This may mean that inserting such large model files on museum websites may discourage potential users due to the long download times.

- (5)

- The use of the SfM method to create digital 3D models of objects of medium or small size (e.g., a jug with a height of 14 cm) gives much better results when the process of cropping the photo is carried out so that the object is in the centre of the photo. The amount of noise generated in the background of the photo is reduced.

- (6)

- Although the 3D models generated by the SfM method were obtained from a small number of photos, about 30–50 (photos taken by partners from Uzbekistan), the quality of these models turned out to be quite good. This is especially true of a small jug—an object in its main axisymmetric shape. So attention should be paid to getting much more photos of the subject (from 80 to 140).

- (7)

- The time of the SfM method when applied to small objects can be reduced (more than 4 times) with careful photographing, paying attention that the object is well-framed, without unnecessary background of the surroundings.

- (8)

- The classic SfM method does not provide for placing markers next to the photographed object, so the obtained digital 3D models do not have information about their dimensions. Thus, these models are not fully suitable for the professional archiving of historical objects, but may be useful for popularising and making available tangible cultural heritage.

- (1)

- Conducting comparative studies of creating digital 3D models of museum objects using the SfM method with the use of other non-commercial and commercial programs.

- (2)

- Development of methods and algorithms for comparing the obtained 3D models, which make it possible to calculate the differences between the shape of digital artefacts obtained from both methods and to change the shape of the surface of smoothed and optimised objects in relation to the basic model obtained by the 3D SLS method.

- (3)

- Searching for better methods of post-processing 3D models from SfM to improve their visual quality while reducing their size.

- (4)

- Developing a list of good practices for the preparation of a collection of photographs of museum objects for the purposes of the SfM method for museum worker.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bendicho, V.M.L.-M.; Marchante-Ortega, Á.; Vincent, M.; Martín-Buitrago, Á.J.C.; Pintado, J.O. Uso combinado de la fotografía digital nocturna y de la fotogrametría en los procesos de documentación de petroglifos: El caso de Alcázar de San Juan (Ciudad Real, España). Virtual Archaeol. Rev. 2017, 8, 64–74. [Google Scholar] [CrossRef]

- Bianco, S.; Ciocca, G.; Marelli, D. Evaluating the Performance of Structure from Motion Pipelines. J. Imaging 2018, 4, 98. [Google Scholar] [CrossRef]

- COVID-19 and Tourism: Assessing the Economic Consequences, United Nations Conference on Trade and Development. 2020. Available online: https://unctad.org/system/files/official-document/ditcinf2020d3_en.pdf (accessed on 1 May 2021).

- Miłosz, M.; Montusiewicz, J.; Kęsik, J. 3d information technologies in cultural heritage preservation and popularization-a series 602 of seminars for museologists made by computer scientists. In Proceedings of the EDULEARN 20 Proceedings; IATED: Walencja, Spain, 2020; pp. 544–549. [Google Scholar] [CrossRef]

- Polish National Agency for Academic Exchange under Grant No. PPI/APM/2019/1/00004 Titled “3D DIGITAL SILK ROAD”. Available online: https://nawa.gov.pl/en (accessed on 5 June 2021).

- Miłosz, M.; Kęsik, J.; Montusiewicz, J. 3D Scanning and Visualization of Large Monuments of Timurid Architecture in Cen-tral Asia—A Methodical Approach. J. Comput. Cult. Herit. 2020, 14, 1–31. [Google Scholar] [CrossRef]

- Montusiewicz, J.; Barszcz, M.; Dziedzic, K. Photorealistic 3D Digital Reconstruction of a Clay Pitcher. Adv. Sci. Technol. Res. J. 2019, 13, 255–263. [Google Scholar] [CrossRef]

- Horn, C.; Ling, J.; Bertilsson, U.; Potter, R. By All Means Necessary—2.5D and 3D Recording of Surfaces in the Study of Southern Scandinavian Rock Art. Open Archaeol. 2018, 4, 81–96. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M. An Application of Integrated 3D Technologies for Replicas in Cultural Heritage. ISPRS Int. J. Geo-Inf. 2019, 8, 285. [Google Scholar] [CrossRef]

- Montusiewicz, J.; Barszcz, M.; Dziedzic, K.; Nowicki, T. The Method of Decomposition of Architectural Objects for the prep-aration of 3D Virtual Models and Replication. Adv. Sci. Technol. Res. J. 2021, 15, 247–257. [Google Scholar] [CrossRef]

- Wachowiak, M.J.; Karas, B.V. 3D Scanning and Replication for Museum and Cultural Heritage Applications. J. Am. Inst. Conserv. 2009, 48, 141–158. [Google Scholar] [CrossRef]

- Younan, S.; Treadaway, C. Digital 3D models of heritage artefacts: Towards a digital dream space. Digit. Appl. Archaeol. Cult. Herit. 2015, 2, 240–247. [Google Scholar] [CrossRef]

- Balletti, C.; Guerra, F.; Scocca, V.; Gottardi, C. 3D integrated methodologies for the documentation and the virtual recon-struction of an archaeological site. In Proceedings of the International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, 3D Virtual Reconstruction and Visualization of Complex Architectures, Avila, Spain, 25–27 February 2015; Volume XL-5/W4, pp. 215–222. [Google Scholar]

- Douglass, M.; Lin, S.; Chodoronek, M. The Application of 3D Photogrammetry for In-Field Documentation of Archaeologi-cal Features. Adv. Archaeol. Pract. 2015, 3, 136–152. [Google Scholar] [CrossRef]

- Howland, M.D.; Kuester, F.; Levy, T.E. Photogrammetry in the field: Documenting, recording, and presenting archaeology. Mediter. Archaeol. Archaeom. 2014, 4, 101–108. [Google Scholar]

- Grechi, G.; Fiorucci, M.; Marmoni, G.; Martino, S. 3D Thermal Monitoring of Jointed Rock Masses through Infrared Thermography and Photogrammetry. Remote Sens. 2021, 13, 957. [Google Scholar] [CrossRef]

- Kong, D.; Saroglou, C.; Wu, F.; Sha, P.; Li, B. Development and application of UAV-SfM photogrammetry for quantitative characterization of rock mass discontinuities. Int. J. Rock Mech. Min. Sci. 2021, 141, 1–19. [Google Scholar] [CrossRef]

- Lambers, K.; Eisenbeiss, H.; Sauerbier, M.; Kupferschmidt, D.; Gaisecker, T.; Sotoodeh, S.; Hanusch, T. Combining photo-grammetry and laser scanning for the recording and modeling of the Late Intermediate period site of Pinchango Alto, Pal-pa, Peru. J. Archaeol. Sci. 2017, 34, 1702–1712. [Google Scholar] [CrossRef]

- Bruno, F.; Bruno, S.; De Sensi, G.; Luchi, M.-L.; Mancuso, S.; Muzzupappa, M. From 3D reconstruction to virtual reality: A complete methodology for digital archaeological exhibition. J. Cult. Herit. 2010, 11, 42–49. [Google Scholar] [CrossRef]

- Lerma, J.L.; Muir, C. Evaluating the 3D documentation of an early Christian upright stone with carvings from Scotland with multiples images. J. Archaeol. Sci. 2014, 46, 311–318. [Google Scholar] [CrossRef]

- Wei, O.C.; Chin, C.S.; Majid, Z.; Setan, H. 3D documentation and preservation of historical monument using terrestrial laser scanning. Geoinf. Sci. J. 2010, 10, 73–90. [Google Scholar]

- David, A.; Kaminski, J. 3D scanning and presentation of ethnographic collections—Potentials and challenges. J. Mus. Ethnogr. 2014, 27, 78–97. [Google Scholar]

- Higueras, M.; Calero, A.I.; Collado-Montero, F.J. Digital 3D modeling using photogrammetry and 3D printing applied to the restoration of a Hispano-Roman architectural ornament. Digit. Appl. Archaeol. Cult. Herit. 2021, 20, 1–11. [Google Scholar]

- Solter, A.; Gajski, D. Project “towards the virtual museum”—Exploring tools and methods for 3D digitalization and visual-ization. Opvscvla Archaeol. 2018, 39–40, 117–124. [Google Scholar]

- Tucci, G.; Cini, D.; Nobile, A. Effective 3D digitization of archaeological artifacts for interactive virtual museum. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, XXXVIII-5, 413–420. [Google Scholar] [CrossRef]

- Neamtu, C.; Comes, R. Methodology to create digital and virtual 3d artefacts in archaeology. J. Anc. Hist. Archaeol. 2016, 3, 65–74. [Google Scholar] [CrossRef]

- Capacete-Caballero, X.; Caulfield-Sriklad, D.; McKay, F. Enhancing the display of the fashion artefact through digital mul-ti-media approaches. In Proceedings of the 1st International Conference on Digital Fashion, London, UK, 16–17 May 2013; pp. 336–345. [Google Scholar]

- Iglhaut, J.; Cabo, C.; Puliti, S.; Piermattei, L.; O’Connor, J.; Rosette, J. Structure from Motion Photogrammetry in Forestry: A Review. Curr. For. Rep. 2019, 5, 155–168. [Google Scholar] [CrossRef]

- Dappa, E.; Higashigaito, K.; Fornaro, J.; Leschka, S.; Wildermuth, S.; Alkadhi, H. Cinematic rendering—An alternative to volume rendering for 3D computed tomography imaging. Insights Imaging 2016, 7, 849–856. [Google Scholar] [CrossRef] [PubMed]

- De Moraes Jorge, A.P.; Monteiro, E.R.; Hoogenboom, B.J.; Oliveira, A.; Quintela, M.V.P. Computer photo-grammetry as a postural assessment in Schwartz-Jampel syndrome: A case report. J. Bodyw. Mov. Ther. 2021, 26, 72–76. [Google Scholar] [CrossRef] [PubMed]

- Westoby, M.J.; Brasington, J.; Glasser, N.F.; Hambrey, M.J.; Reynolds, J.M. “Structure-from-Motion” photogrammetry: A low-cost, effective tool for geoscience applications. Geomorphology 2012, 179, 300–314. [Google Scholar] [CrossRef]

- Silva-Bolíva, J.; Cataño-Ospina, A.M.; Arenas-Becerra, L.Y. Photogrammetry for the reconstruction of realistic visual landscapes that serve for the creation of scenographies in audiovisual and multimedia products. J. Phys. Conf. Ser. 2019, 1418, 23–25. [Google Scholar] [CrossRef]

- Verhoeven, G.; Doneus, M.; Briese, C.; Vermeulen, F. Mapping by matching: A computer vision-based approach to fast and accurate georeferencing of archaeological aerial photographs. J. Archaeol. Sci. 2012, 39, 2060–2070. [Google Scholar] [CrossRef]

- Caspari, G. Mapping and Damage Assessment of “Royal” Burial Mounds in the Siberian Valley of the Kings. Remote Sens. 2020, 12, 773. [Google Scholar] [CrossRef]

- Jin, D.; Li, J.; Gong, J.; Li, Y.; Zhao, Z.; Li, Y.; Li, D.; Yu, K.; Wang, S. Shipborne Mobile Photogrammetry for 3D Mapping and Landslide Detection of the Water-Level Fluctuation Zone in the Three Gorges Reservoir Area, China. Remote Sens. 2021, 13, 1007. [Google Scholar] [CrossRef]

- Fregonese, L.; Adami, A. The 3D Model of St. Mark’s Basilica in Venice. In Digital Transformation of the Design, Construction and Management Processes of the Built Environment. Research for Development; Daniotti, B., Gianinetto, M., Della Torre, S., Eds.; Springer: Cham, Switzerland, 2020; pp. 343–354. [Google Scholar]

- Bastonero, P.; Donadio, E.; Chiabrando, F.; Spano, A.T. Fusion of 3D models derived from TLS and image-based techniques for CH enhanced documentation. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2014, II-5, 73–80. [Google Scholar] [CrossRef]

- Pepe, M.; Costantino, D. UAV Photogrammetry and 3D Modelling of Complex Architecture for Maintenance Purposes: The Case Study of the Masonry Bridge on the Sele River, Italy. Period. Polytech. Civ. Eng. 2020, 65, 191–203. [Google Scholar] [CrossRef]

- Graham, C.A.; Akoglu, K.G.; Lassen, A.W.; Simon, S. Epic dimensions: A comparative analysis of 3d acquisition methods. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, XLII-2/W5, 287–293. [Google Scholar] [CrossRef]

- Kersten, T.P.; Lindstaedt, M.; Starosta, D. Comparative geometrical accuracy investigations of hand-held 3D scanning systems—An update. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, 42. [Google Scholar] [CrossRef]

- Doumit, J.; Kiselev, E. Structure from motion technology from micro scale objects cartography. Earth Sci. 2017, 42–47. [Google Scholar]

- Hellmuth, R.; Wehner, F.; Giannakidis, A. Datasets of captured images of three different devices for photogrammetry cal-culation comparison and integration into a laserscan point cloud of a built environment. Data Brief 2020, 33, 106321. [Google Scholar] [CrossRef] [PubMed]

- Aldao, E.; González-Jorge, H.; Pérez, J.A. Metrological comparison of LiDAR and photogrammetric systems for defor-mation monitoring of aerospace parts. Measurement 2021, 174, 109037. [Google Scholar] [CrossRef]

- Schonberger, J.L.; Frahm, J.-M. Structure-from-Motion Revisited. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 4104–4113. [Google Scholar]

- Wu, C. Visualsfm: A Visual Structure from Motion System. 2011. Available online: http://ccwu.me/vsfm/ (accessed on 1 May 2021).

- Fedorov-Davydov, G.A. Archaeological research in Central Asia of the Muslim period. World Archaeol. 1983, 14, 393–405. [Google Scholar] [CrossRef]

- Milosz, M.; Skulimowski, S.; Kęsik, J.; Montusiewicz, J. Virtual and interactive museum of archaeological artefacts from Afrasiyab—An ancient city on the silk road. Digit. Appl. Archaeol. Cult. Herit. 2020, 18, e00155. [Google Scholar] [CrossRef]

- 3D Digital Silk Road. Retrieved 27 January 2020. Available online: http://silkroad3d.com/ (accessed on 5 June 2021).

| Parameters | Artec Eva Scanner | Artec Spider Scanner |

|---|---|---|

| Texture capture capability | yes | yes |

| Scanning technology | structured white light | flashing light, blue light (not laser) |

| Resolution 3D, up to | 0.2 mm | 0.1 mm |

| Point precision 3D, up to | 0.1 mm | 0.05 mm |

| 3D precision at a distance, up to | 0.03%/100 cm | 0.03%/100 cm |

| Linear field of view, height × width | 214 mm × 148 mm to 536 mm × 371 mm | 90 mm × 70 mm to 180 mm × 140 mm |

| Working distance | 0.4–1 m | 0.17–0.35 m |

| Weight | 0.85 kg | 0.85 kg |

| Minimum requirements of the computer cooperating with the scanner | I5 (recommended I7), 8–12 GB RAM, NVIDIA GeForce 400 series | I5 (recommended I7), 8–12 GB RAM, NVIDIA GeForce 400 series |

| No | Features | 3D SLS | SfM | Comments |

|---|---|---|---|---|

| 1 | Device | 3D Scanner | Movie-camera/camera/smartphone | |

| 2 | Shape data acquisition | 3D scanning | Shooting | |

| 3 | Texture data acquisition | RGB information * | 2D photos | * selective uptake |

| 4 | Digitisation of transparent objects | No | Partially | |

| 5 | Data form | Point cloud | 2D photos | |

| 6 | Data size | Several GB | Several to several hundred MB * | * Camera dependent |

| 7 | Software | Specialised, device-dedicated | Device-dedicated/Open source | |

| 8 | Computer hardware | High computing power | Low computing power | |

| 9 | 3D model building method | Point cloud triangulation | Triangulation using image analysis | |

| 10 | 3D model generation | Manual, assisted | Automated | |

| 11 | Costs | High/Very High | Low | |

| 12 | Availability | Low | Widespread | |

| 13 | Time consumption | Low/Medium | Low/Medium | Object-size dependent |

| 14 | Acquisition of dimensions | Yes | No/Yes * | * Necessity to place tags |

| 15 | Model quality | Very good | Small/medium | |

| 16 | Making it photorealistic | Texture mapping | Texture mapping | |

| 17 | Possibility to export to standard formats | Yes | Yes | |

| 18 | Possibility to modify models | Yes | Yes | |

| 19 | Competence in using the equipment | Specialist/High | Common/Medium | |

| 20 | IT competences | Specialist/High | Common/Medium |

| Scan No. | Surface | Polygons | Vertices | Frame | Texture |

|---|---|---|---|---|---|

| 1 | 1060 | 23,169,773 | 13,514,745 | 1060 | 59 |

| 2 | 280 | 9,848,052 | 5,612,084 | 280 | 28 |

| 3 | 496 | 12,634,644 | 7,145,096 | 496 | 115 |

| Total | 1836 | 45,652,469 | 26,271,925 | 1836 | 202 |

| Model Mesh | Texture | |||||

|---|---|---|---|---|---|---|

| Vertices | Faces | .obj File Size [MB] | .jpg File Size [MB] | Size [Pixels] | Resolution [dpi] | |

| 3D SLS method | ||||||

| Original model | 214,870 | 429,736 | 30.1 | 7.1 MB | 4096 × 4096 | 96 × 96 |

| Processed model | 21,488 | 42,972 | 4.31 | 953 kB | 2048 × 2048 | 96 × 96 |

| SfM method | ||||||

| Without processing photos | 119,694 | 238,712 | 16.1 | 5.31 MB | 4096 × 4096 | 96 × 96 |

| After processing photos | 102,369 | 204,486 | 13.0 | 3.82 MB | 4096 × 4096 | 96 × 96 |

| After smoothing the model’s surface | 102,369 | 204,486 | 21.4 | 3.82 MB | 4096 × 4096 | 96 × 96 |

| Model Mesh | Texture | |||||

|---|---|---|---|---|---|---|

| Vertices | Faces | .obj File Size [MB] | .jpg File Size [MB] | Size [Pixels] | Resolution [dpi] | |

| 3D SLS method | ||||||

| Original model | 2,110,146 | 4,199,231 | 311 | 30.4 | 8192 × 8192 | 96 × 96 |

| After optimisation | 218,819 | 419,922 | 46.7 | 1.12 | 2048 × 2048 | 96 × 96 |

| SfM method | ||||||

| Original model | 717,745 | 1,434,925 | 98.9 | 12.5 | 4096 × 4096 | 96 × 96 |

| After smoothing the model’s surface | 717,745 | 1,434,925 | 160 | 12.5 | 4096 × 4096 | 96 × 96 |

| SfM/Meshroom Program | min | 3D SLS/Artec Studio Professional 15 Program | min | |

|---|---|---|---|---|

| Data Acquisition | 12 | 5 | ||

| Data processing | Making a 3D model from raw photos—an automated process | 20 | Converting a point cloud into a 3D mesh model—manual process | 70 |

| Photo processing | 90 | |||

| Making a 3D model from processed photos | 20 | |||

| Smoothing the model in Blender | 8 | Optimising the 3D model mesh in Blender | 10 | |

| Total | 150 | Total | 85 |

| SfM/Meshroom Program | min | 3D SLS/Artec Studio Professional 15 Program | min | |

|---|---|---|---|---|

| Data Acquisition | 3 | 55 | ||

| Data processing | Making a 3D model from raw photos—an automated process | 20 | Converting a point cloud into a 3D mesh model—manual process | 480 |

| Smoothing the model in Blender | 15 | Optimising the 3D model mesh in Blender | 15 | |

| Total | 38 | Total | 550 |

| SfM * | 3D SLS ** | |||

|---|---|---|---|---|

| Cost | € | € | ||

| Device | Nikon camera with Nikkor | 970 | Artec Spider Scanner | 19,700 |

| Artec Eva Scanner | 13,700 | |||

| Software | Meshroom | free | Artec Studio 15 Professional | 2000 |

| Blender | free | Blender | free | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barszcz, M.; Montusiewicz, J.; Paśnikowska-Łukaszuk, M.; Sałamacha, A. Comparative Analysis of Digital Models of Objects of Cultural Heritage Obtained by the “3D SLS” and “SfM” Methods. Appl. Sci. 2021, 11, 5321. https://doi.org/10.3390/app11125321

Barszcz M, Montusiewicz J, Paśnikowska-Łukaszuk M, Sałamacha A. Comparative Analysis of Digital Models of Objects of Cultural Heritage Obtained by the “3D SLS” and “SfM” Methods. Applied Sciences. 2021; 11(12):5321. https://doi.org/10.3390/app11125321

Chicago/Turabian StyleBarszcz, Marcin, Jerzy Montusiewicz, Magdalena Paśnikowska-Łukaszuk, and Anna Sałamacha. 2021. "Comparative Analysis of Digital Models of Objects of Cultural Heritage Obtained by the “3D SLS” and “SfM” Methods" Applied Sciences 11, no. 12: 5321. https://doi.org/10.3390/app11125321

APA StyleBarszcz, M., Montusiewicz, J., Paśnikowska-Łukaszuk, M., & Sałamacha, A. (2021). Comparative Analysis of Digital Models of Objects of Cultural Heritage Obtained by the “3D SLS” and “SfM” Methods. Applied Sciences, 11(12), 5321. https://doi.org/10.3390/app11125321