Development and Study of the Structure and Properties of a Composite Textile Material with Encapsulated Heat-Preserving Components for Heat-Protective Clothing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

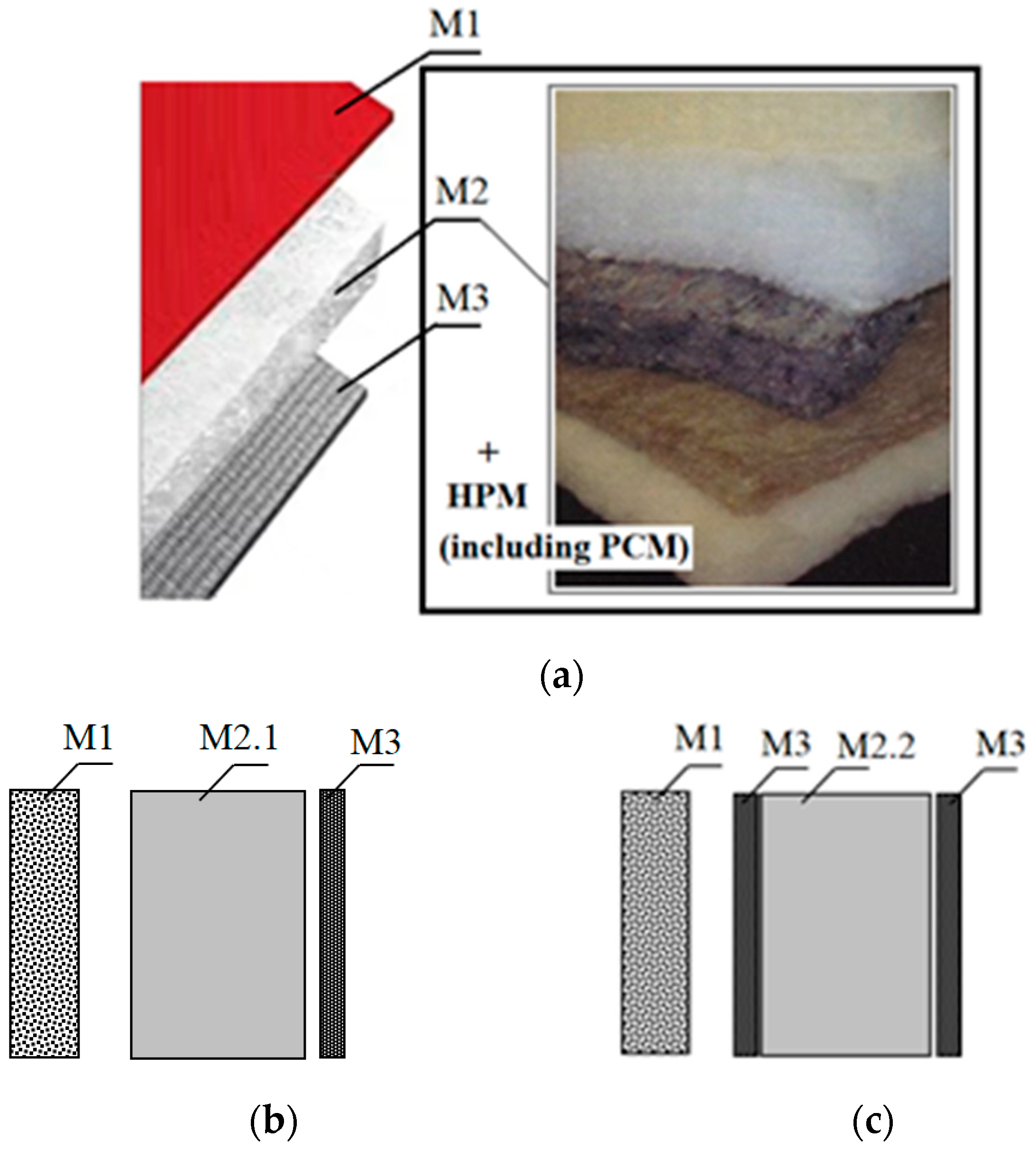

2.1.1. Materials in the Closing Shells

- M1—

- functions as the main barrier protection against harmful environmental factors (production processes and weather), preserves and maintains the clothing shape and size;

- M2—

- provides thermal insulation and thermoregulation (including heat-preservation);

- M3—

- allows for moisture exchange, thermic regulation (including heat-preservation), and surface sliding.

2.1.2. Heat-Accumulating Components

2.1.3. Materials Used in the Study

- (1)

- 100/0;

- (2)

- 70/30;

- (3)

- 50/50;

- (4)

- 0/100.

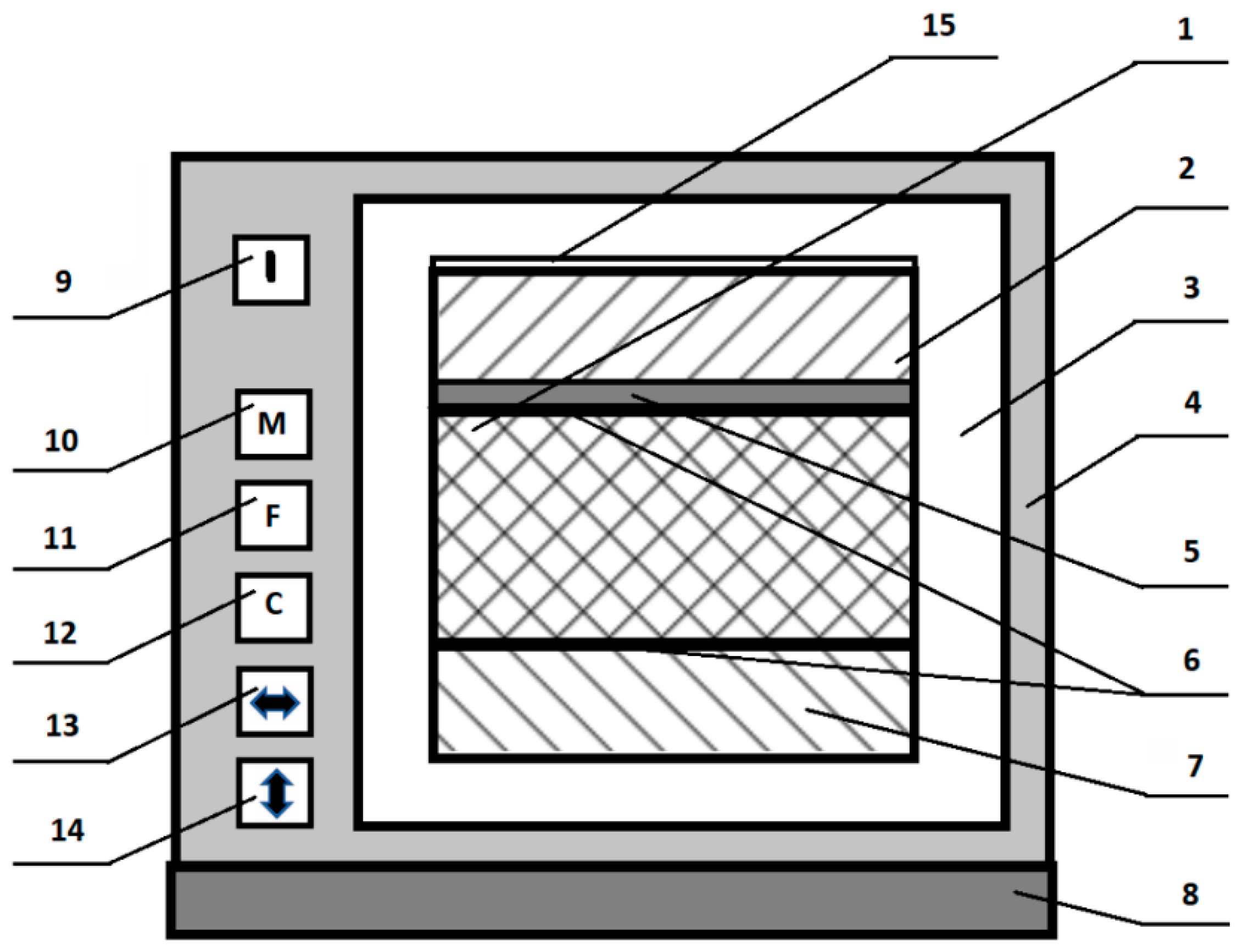

2.2. Methods

- that of temperature sensor signals: 0.5% max.;

- that of the heat flux density meter signal: 0.6% max.;

- that of the sample thickness measurements: over 0.5% (less than 0.1 mm) as the arithmetic mean of four point measurements of the sample;

- that of the pressure 0.2 kPa [34]: 1.5% max.;

- the deviation of the front faces of a hard sample specimen from parallel alignment: 0.5 mm max.;

- the loss of its mass after drying: 0.1% max.

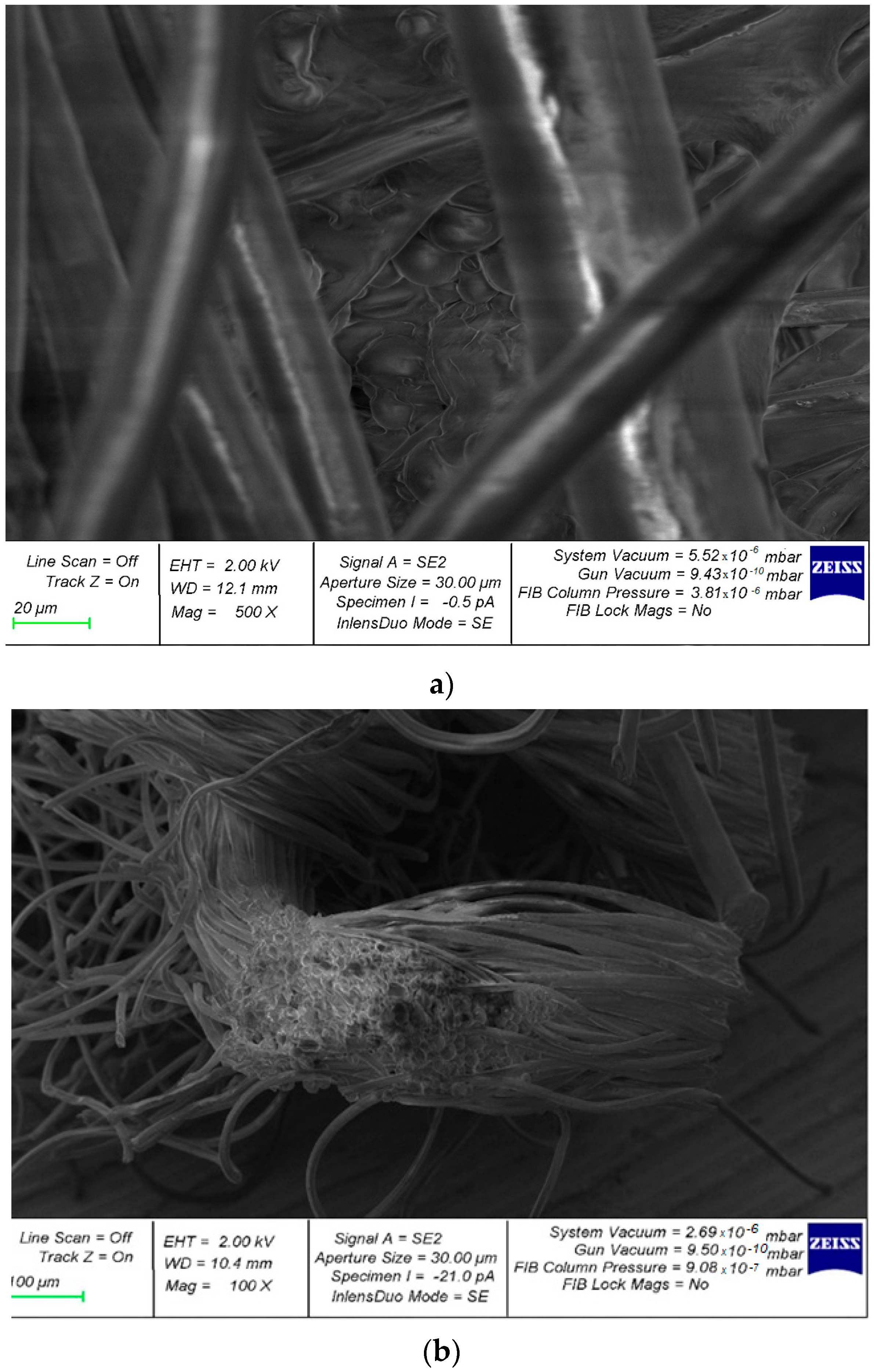

- -

- fiber diameter: 27 to 30 μm;

- -

- cavity depth: 310 to 545 μm;

- -

- average cavity diameter: 80 to 120 μm.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Angelova, R.A.; Reiners, P.; Georgieva, E.; Konova, H.P.; Pruss, B.; Kyosev, Y. Heat and mass transfer through outerwear clothing for protection from cold: Influence of geometrical, structural and mass characteristics of the textile layers. Text. Res. J. 2017, 87, 9. [Google Scholar] [CrossRef]

- Zhang, X. Heat-storage and thermo-regulated textiles and clothing. In Book Smart Fibres, Fabrics and Clothing. Fundamentals and Applications. Series in Textiles; Woodhead Publishing Limited: Cambridge, UK, 2001; pp. 34–57. [Google Scholar] [CrossRef]

- Durakovic, B. PCMs in Separate Heat Storage Modules. In Book PCM-Based Building Envelope Systems; Springer Nature: Cham, Switzerland, 2000; pp. 121–146. [Google Scholar] [CrossRef]

- Bird, J.E.; Humphries, T.D.; Paskevicius, M.; Poupin, L.; Buckley, C.E.; Kyosev, Y. Thermal properties of thermochemical heat storage materials. Phys. Chem. Chem. Phys. 2020, 22, 4617–4625. [Google Scholar] [CrossRef] [PubMed]

- Ghaib, K. Latent Heat Storage: Storage Materials, Heat Transfer, and Applications. Chem. Ing. Tech. 2017, 4, 4515–4532. [Google Scholar] [CrossRef]

- Fultz, B. Phase Transitions in Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2020; pp. 154–196. [Google Scholar] [CrossRef]

- Baranenko, A.V.; Kuznetsov, P.A.; Zakharova, V.Y.; Tsoy, A.P. Application of substances with phase transitions for thermal energy accumulation. Sci. Tech. J. Inf. Technol. Mech. Opt. 2018, 18, 990–1000. [Google Scholar] [CrossRef]

- Yinga, B.A.; Kwoka, Y.L.; Lia, Y.; Yeungb, C.Y.; Zhua, Q.Y.; Lia, F.Z. Computational Investigation of thermoregulatory effects of multi-layer PCM textile assembly. In Book Computational Textile; Springer: Berlin/Heidelberg, Germany, 2007; pp. 235–245. [Google Scholar] [CrossRef]

- Cherunova, I.V.; Kovaleva, A.A.; Nazarenko, E.V. Experimental Evaluation of Thermal Protection Properties of Volume Textile Materials. Mater. Sci. Forum 2020, 992, 916–921. [Google Scholar] [CrossRef]

- Termofiber—Properties and Applications. Available online: https://www.roshimvolokno.ru/articles/termofiber.php (accessed on 2 March 2021).

- Cherunova, I.; Kornev, N.; Jacobi, G.; Treshchun, I.; Gross, A.; Turnow, J.; Schreier, S.; Paschen, M. Application of Heat-Transfer Calculations and Computational Fluid Mechanics to the Design of Protective Clothing. J. Eng. Phys. Thermophys. 2014, 87, 855–863. [Google Scholar] [CrossRef]

- Barois, P.; Demus, D.; Goodby, J.; Gray, G.W.; Vill, V. Phase Transition: Phase Transition Theories. In Book Handbook of Liquid Crystals Set; WILEY-VCH Verlag GmbH: Weinheim, Germany, 1998. [Google Scholar] [CrossRef]

- Babaev, B.D. Principles of Heat Accumulation and Heat-Accumulating Materials in Use. High Temp. 2014, 52, 736–751. [Google Scholar] [CrossRef]

- Salih, T.W.M.; Abdulrehman, M.A.; Al-Moameri, H.H.; Al-Kamal, A.K. Energy saving in Iraq: Waxes as phase change materials for space heating. AIP Conf. Proc. 2020, 2213, 020141. [Google Scholar] [CrossRef]

- Moskvitina, A. Selection of heat accumulating materials for seasonal solar heating systems. Conf. Proc. Sci. Dev. New East. Eur. 2019. [CrossRef]

- Gasanaliev, A.M.; Gamataeva, B. Yu. Heat-Accumulating Properties of Melts. Russ. Chem. Rev. 2007, 69, 179. [Google Scholar] [CrossRef]

- Dinker, D.A.; Agarwal, M.; Agarwal, G.D. Heat storage materials, geometry and applications: A review. J. Energy Inst. 2017, 90, 1–11. [Google Scholar] [CrossRef]

- Donskoy, A.A.; Evseeva, V.A.; Merkushova, E.V.; Shashkina, M.A. Heat-Accumulating Composition. Patent RU 2239647, 10 November 2004. [Google Scholar]

- Kablov, E.N.; Minakov, V.T.; Donskoy, A.A.; Shashkina, M.A.; Evseeva, V.A. Heat-Accumulating Composition. Patent RU 2190656, 10 October 2002. [Google Scholar]

- BASF to Divest Its Micronal® PCM Business to Microtek Laboratories. Available online: https://www.maisonpassive.be/IMG/pdf/Micronal_EN.pdf (accessed on 24 March 2021).

- PureTemp. Available online: http://www.puretemp.com/how-puretemp-works (accessed on 24 March 2021).

- Hangzhou Ruhr New Material Technology Co., Ltd. (‘RuhrTech’). Available online: http://www.ruhrtech.com/#3 (accessed on 25 March 2021).

- Schoeller®-PCM. Available online: https://www.schoeller-textiles.com/en/technologies/schoeller-pcm (accessed on 24 March 2021).

- Comfortemp® Thermal Insulation. Available online: https://apparel.freudenberg-pm.com/products/Comfortemp (accessed on 26 March 2021).

- Outlast® Textiles. Available online: https://www.outlast.com/ (accessed on 23 March 2021).

- Erkan, G. Enhancing The Thermal Properties of Textiles With Phase Change Materials. Res. J. Text. Appar. 2004, 8, 57–64. [Google Scholar] [CrossRef]

- Digital Optical Microscope VHX5000 Keyence. Available online: https://sernia.ru/catalog/tsifrovye_mikroskopy_keyence/tsifrovoy_opticheskiy_mikroskop_vhx5000_keyence/ (accessed on 27 March 2021).

- GOST 7076 BuIlding Materials and Products. Method of Determination of Steady-State Thermal Conductivity and Thermal Re-sistance. 2000. Available online: http://docs.cntd.ru/document/1200005006 (accessed on 10 March 2021).

- Platinum Resistance Thermometer. Available online: https://www.sciencedirect.com/topics/engineering/platinum-resistance-thermometer (accessed on 28 March 2021).

- GOST 12997 SSI Products. General specifications. 1997. Available online: http://docs.cntd.ru/document/1200003319 (accessed on 10 March 2021).

- ISO 8301. Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. 1991. Available online: https://www.sis.se/api/document/preview/912539/ (accessed on 22 May 2021).

- ISO 11079. Ergonomics of the Thermal Environment—Determination and Interpretation of Cold Stress When Using Required Clothing Insulation (IREQ) and Local Cooling Effects. 2007. Available online: http://www.arbetsliv.eu/PPE/SS-EN_ISO_11079_2007.PDF (accessed on 22 May 2021).

- GOST 3811 Textile Materials. Textile Fabrics, Nonwonen Fabrics and Piece-Articles. Methods for Determination of Linear Dimensions Linear and Susfare Density. 2003. Available online: http://docs.cntd.ru/document/1200018455 (accessed on 15 March 2021).

- GOST R 57632 Non-Woven Textiles Heets for Protective Clothing. Warm Textiles. Technical Requirements. Methods of Testing. 2017. Available online: http://docs.cntd.ru/document/1200146752 (accessed on 16 March 2021).

- Cherunova, I.; Osipenko, L.; Stenkina, M. Influence of structure and composition of the fibrous materials on the performance characteristics of thermal protection struc-tures with combined functions. Solid State Phenom. 2018, 284, 65–70. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Kamel, S.H.; Al-Ajeely, A.N.M. Thermal Conductivity Enhancement by using Nano-material in Phase Change Material for Latent Heat Thermal Energy Storage Systems. Saussurea 2015, 5, 48–55. Available online: https://www.researchgate.net/publication/280923213 (accessed on 18 March 2021).

- Cherunova, I.; Dhone, M.; Kornev, N. Coupled thermo-aerodynamical Problems in design of protection Cloth. In Proceedings of the 6th International Conference on Coupled Problems in Science and Engineering: Coupled Problems 2015, San Servolo, Venice, Italy, 18–20 May 2015; International Center for Numerical Methods in Engineering (CIMNE): Barcelona, Spain, 2015; Volume 6, pp. 1303–1311. Available online: https://www.researchgate.net/publication/283112038_Coupled_thermo-_aerodynamical_problems_in_design_of_protection_cloth (accessed on 20 March 2021).

- GOST 12.4.303 Occupational Safety Standards System. Protective Clothing for Low Temperatures. Technical Requirements. 2019. Available online: http://docs.cntd.ru/document/1200136075/ (accessed on 20 March 2021).

| Mixture Composition | Melting Temperature, °C |

|---|---|

| Pentadecan | +9.9 |

| Dakotan | +44 |

| Heptadecan | +22 |

| Heneicosan | +40 |

| Octadecan | +26...+25.8 |

| Tetradecan | +27...+25.5 |

| Dakotan octadecan | + 31.2...+38.4 |

| Octadecan heneicosan | +35.0...+42.2 |

| Palmitic acid | +53.0…+80.0 |

| Nonadecane | +50...+55 |

| Aktekin | +48 |

| Heat-accumulating composition RU 2239647 [18] | +32.5 |

| Heat-accumulating composition RU 2190656 [19] | +33.4 |

| Sodium thiosulfate pentahydrate | +22...+36.1 |

| Sodium sulfate decahydrate (Glauber’s salt) | +58.0 |

| Sodium sulfite heptahydrate | +53.4 |

| Sodium carbonate decahydrate | +55.4 |

| Sodium acetate trihydrate | +52.6 |

| Paraffin | +25...+50 |

| Material Category * | Priority Fiber | Coupling with Heat-Accumulating Textile Components | Material for the Test Complex Test Sample |

|---|---|---|---|

| M1 | Polyester, cotton, including their combination | - | - |

| M2.1 | Polyester, Outlast | + | Termofiber + (Outlast textile) |

| M2.2 | Polyester, down | - | - |

| M3 | + | [20,21,23,24,25] |

| № of Materials | Material | Composition of Fibers and Polymer Components, % | Density, kg/m3 | Features of the Material Structure | Thickness, m |

|---|---|---|---|---|---|

| 1 | Termofiber | Polyester, 100 | 14.2 | Nonwoven fabric | 0.001...0.021 |

| 2 | Outlast textile | Outlast, 30 + Polyester, 70 | 238.0 | Outlast fleece | 0.00085 |

| Object in Accordance with Figure 3. | Average Diameter of Heat-Accumulating Capsules, μm | Fiber Diameter, µm | Length of Unencapsulated Sections, µm | Even/Uneven Distribution of the Encapsulated Layer and the Fibers in the Fabric Structure |

|---|---|---|---|---|

| (a) | 11.33 | 26...27 | 285...430 | Microcapsule fibers are grouped and oriented along the fabric length. Within 1000 µm, we can see an uneven distribution of the bonding substance over the surface area. A relative structure uniformity can be assumed for areas from 2000 µm. |

| (b) | 11.32 | 16...16.2 | 285...430 | Fibers are oriented along the fabric length. The bonding encapsulated substance is concentrated in clots along the length of the material’s inner layer. Within 1000 μm sections, we can see an uneven distribution of the bonding substance over the surface area. A relative structure uniformity can be assumed for areas from 2000 µm. |

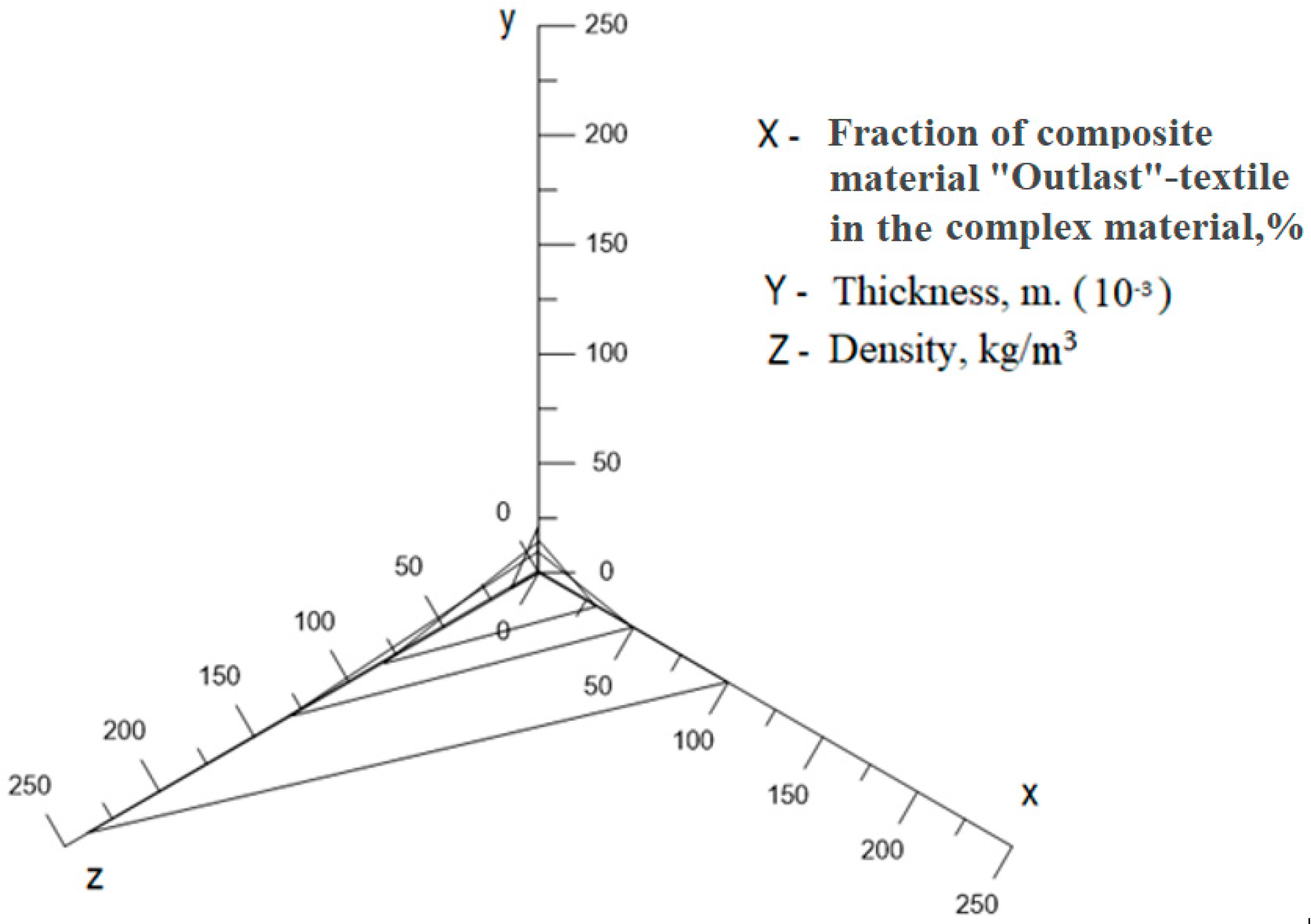

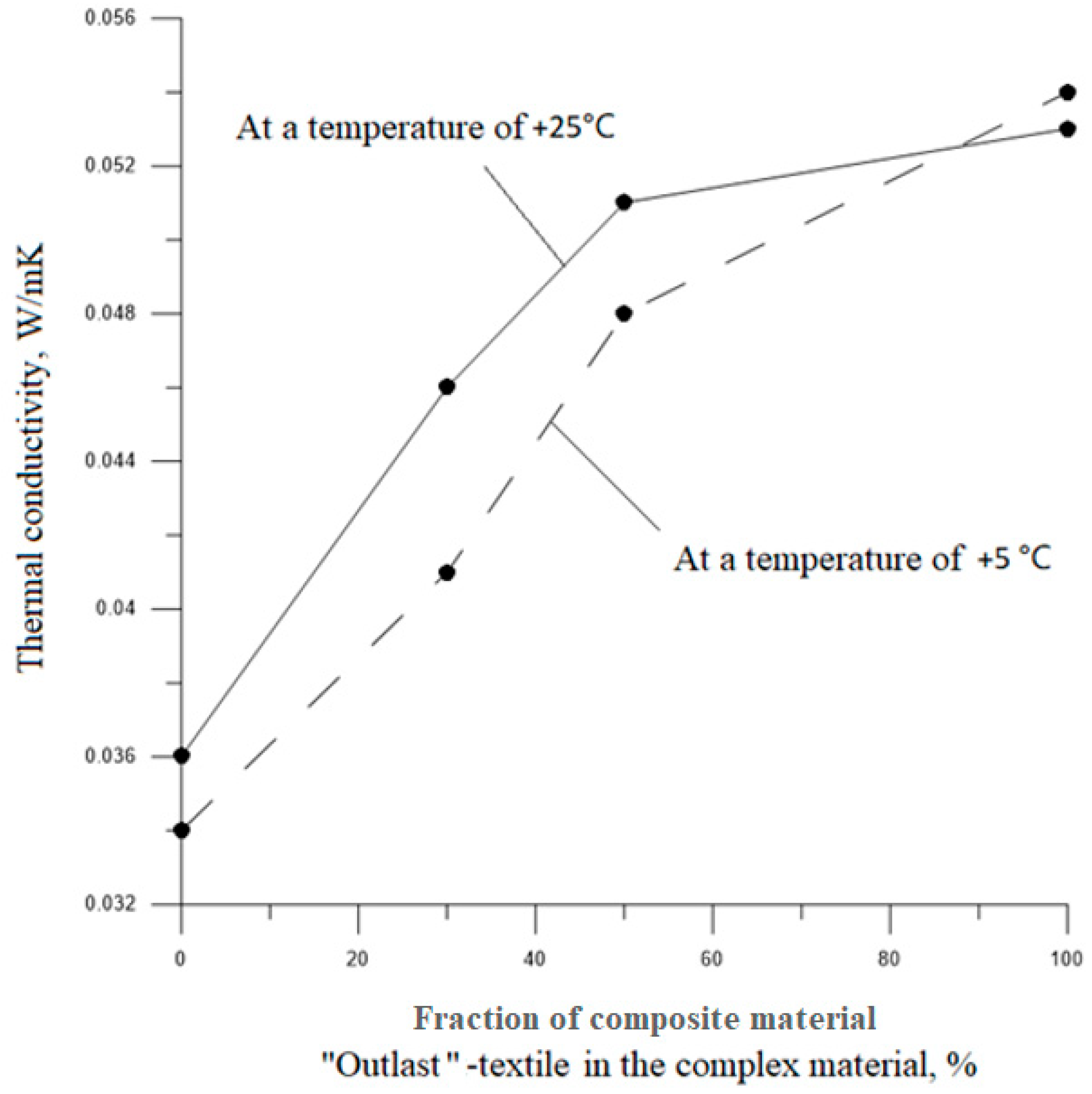

| Type of Test Samples | Fraction of Composite Material Outlast Textile in the Complex Material (Test Samples *), % | Thickness of the Component (Material №1), mm (10−3), h1 ** | Thickness of the Component (Material №2), mm (10−3), h2 **. | Number of Component Layers (Material №1), n ** | Number of Component Layers (Material №2), k ** |

|---|---|---|---|---|---|

| 1 | 0 | 21.00 | 0 | 1 | 0 |

| 2 | 30 | 2.0 | 0.85 | 5 | 5 |

| 3 | 50 | 1.0 | 0.85 | 5 | 6 |

| 4 | 100 | 0 | 0.85 | 0 | 1 |

| № of Test Samples. | Fraction of Composite Material Outlast Textile in the Complex Material, % * | Thickness of Test Samples, m (10−3). | Density, kg/m3 |

|---|---|---|---|

| 1 | 0 | 21.00 | 14.290 |

| 2 | 30 | 14.25 | 82.210 |

| 3 | 50 | 10.10 | 132.021 |

| 4 | 100 | 0.85 | 238.032 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cherunova, I.; Kornev, N.; Lukyanova, E.; Varavka, V. Development and Study of the Structure and Properties of a Composite Textile Material with Encapsulated Heat-Preserving Components for Heat-Protective Clothing. Appl. Sci. 2021, 11, 5247. https://doi.org/10.3390/app11115247

Cherunova I, Kornev N, Lukyanova E, Varavka V. Development and Study of the Structure and Properties of a Composite Textile Material with Encapsulated Heat-Preserving Components for Heat-Protective Clothing. Applied Sciences. 2021; 11(11):5247. https://doi.org/10.3390/app11115247

Chicago/Turabian StyleCherunova, Irina, Nikolai Kornev, Ekaterina Lukyanova, and Valery Varavka. 2021. "Development and Study of the Structure and Properties of a Composite Textile Material with Encapsulated Heat-Preserving Components for Heat-Protective Clothing" Applied Sciences 11, no. 11: 5247. https://doi.org/10.3390/app11115247

APA StyleCherunova, I., Kornev, N., Lukyanova, E., & Varavka, V. (2021). Development and Study of the Structure and Properties of a Composite Textile Material with Encapsulated Heat-Preserving Components for Heat-Protective Clothing. Applied Sciences, 11(11), 5247. https://doi.org/10.3390/app11115247