1. Introduction

In recent years, space remote sensing technology has played an increasingly im-portant role in military and civil high-tech fields, and more and more precision support structures are required for the new generation of space remote sensors. However, when the remote sensing camera moves around the earth, due to the influence of external heat flux, such as solar radiation, the earth’s reflection of sunlight and infrared radiation, the camera experiences complex periodic temperature changes. The thermal deformation of the remote sensing camera structure reduces the position accuracy of the optical elements and causes them to deviate from the ideal position. In order to reduce the influence of the thermal load on the imaging quality of the remote sensing camera, the thermal dimen-sional stability of the structure should be fully considered in the design of the camera support structures [

1,

2,

3,

4].

Reflective space remote sensors, including coaxial and off-axis remote sensors, are commonly used due to their large aperture, high resolution and lightweight design. A concentric remote sensor structure is centrally symmetrical with respect to the optical axis. In the thermal stability design of a coaxial remote camera, only the spacing changes of optical components along the optical axis caused by thermal deformation need to be considered due to the system’s symmetry [

5,

6]. The off-axis reflective optical system is widely used in space remote sensing camera because of its advantages of a larger field of view and the lack of central occlusion [

7,

8]. However, the off-axis remote sensing camera has an obvious asymmetrical structure, and its reflector exhibits a relative displacement in many directions when it is subjected to a temperature load. Therefore, the thermal stabil-ity design of off-axis cameras needs to reduce the thermal deformation in multiple direc-tions at the same time, which makes the design more difficult [

9].

Carbon-fiber-reinforced plastics (CFRPs) have excellent mechanical properties, such as high stiffness, high strength and low coefficient of thermal expansion (CTE), and are considered to be the next generation of aerospace application materials [

10,

11,

12,

13]. In recent years, structural thermal stability has increasingly been accomplished through the use of carbon-fiber-reinforced composites. Jen Chueh Kuo made a low expansion truss support structure with carbon-fiber-reinforced materials for FORMOSAT-5 remote sensing [

14]; Yuan Qian copied a prototype carbon-fiber-reinforced plastics (CFRP) panel for a 5-m Dome A Terahertz Explorer antenna using resin-rich layer technology [

15]. Yoshinori Suematsu used cyanate ester carbon fiber composite to construct the supporting structure of a solar telescope [

16]. In addition, researchers have paid attention to thermal character-istics in the design of carbon fiber materials. By adjusting the angle and sequence of the carbon fiber layer, the coefficient of thermal expansion of the CFRP structure can be ad-justed, even close to zero thermal expansion [

17]. Shun Tanaka researched the effect of the angle error of carbon fiber ply on the coefficient of thermal expansion [

18]. Zhengchun Du manufactured carbon fiber truss bars with an extremely low coefficient of axial thermal expansion through the adjustment of the carbon fiber ply angle [

19]. Lin Yang quantita-tively studied the axial thermal expansion coefficient of the carbon fiber rod through the CTE function, and demonstrated passive thermal compensation for an off-axis space cam-era in the optical axis direction [

20]. However, in these studies, the thermal stability design was only committed to ensuring the position accuracy of the structure along a certain main direction under the thermal load, which is scarcely sufficient to meet the thermal stability requirements of the asymmetric support structure in an off-axis remote sensing camera.

In this sutdy, we solved the problem of how to use carbon-fiber-reinforced compo-sites to reduce the thermal deformation of an asymmetric structure in an off-axis remote sensing camera. By adjusting the angle of the carbon-fiber-reinforced polymer (CFRP) laminate, we were able to design a type of composite laminate with extremely low thermal expansion, which was applied to the support structure design of an off-axis space remote sensing camera, and the thermal stability of the support structure in the asymmetric di-rection was thus realized. Finally, the effectiveness of the thermal stability design for an off-axis camera was verified using finite element thermal deformation analysis and optical analysis.

2. Low Thermal Deformation Optical Mechanical Structure

2.1. The Remote Sensing Camera

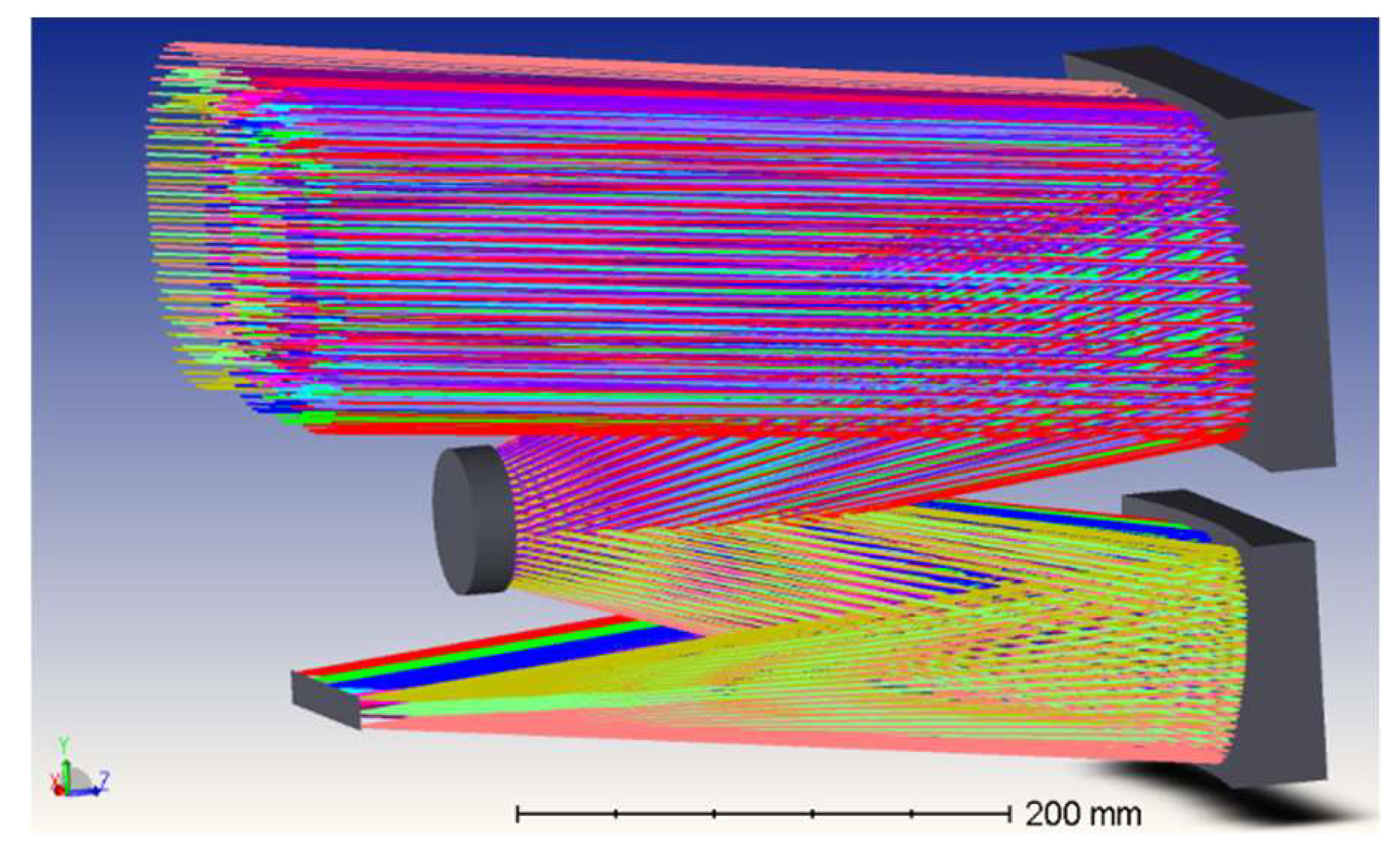

A typical off-axis three-mirror optical system is used in the remote sensing camera. The optical system consists of three mirrors. The primary mirror and third mirror are as-pherical mirrors, and the secondary mirror is a spherical mirror. The distance between the primary mirror and the secondary mirror is 297 mm. The optical system diagram of the space camera is shown in

Figure 1.

For our purposes, the basic structure of the remote sensing camera system can be simply divided into the main support structure and optical components, as shown in

Figure 2. The main support structure is composed of frames and the bearing cylinder made of CFRP. The optical component comprises the reflectors, metal plates and the metal con-nectors between the plate and the frame.

In the working process of the remote sensing camera in orbit, the periodic change of temperature inevitably causes serious deformation of the mirror. The deformation not only comes from the expansion deformation caused by the thermal load, but also from the thermal stress between the support structure and the body of the mirrors. Therefore, the final thermal deformation control of the mirror should be realized in two aspects:

The surface deformation of reflectors caused by thermal stress: Thermal stress will inevitably occur when different materials are joined together, which ultimately re-duces the accuracy of the mirror surface. In this case, it is important to ensure that the reflector body matches the thermal expansion coefficient of the mounted back-plate. Studies have shown that the combination of a Zerodure reflector and an Invar backplate is effective, enabling remote sensing cameras to maintain good surface ac-curacy in periodically changing temperatures [

21,

22,

23].

Rigid body displacement of the reflectors: This means that appropriate technology should be used to minimize the thermal expansion of the support structure. There-fore, the components with zero or near-zero CTE are preferable, in order to achieve low thermal deformation, for example, in the supporting frame and central bearing cylinder. It is difficult to reduce the actual thermal deformation to zero in every di-rection, and the thermal expansion deformation is smaller in the direction with good symmetry, so we need to strictly control the thermal deformation in the asymmetric direction. This method can reduce the actual rigid body displacement of the optical module and obtain the optimal thermal stability of the structure in the periodic tem-perature environment.

In the following sections, we will discuss how to use CFRP materials to design a support structure with low CTE, so as to realize the extremely low thermal deformation of the optomechanical structure for the off-axis remote sensing camera.

2.2. Design Theory of Zero-Thermal-Expansion Material

The support structure of a remote sensing camera is traditionally made of aluminum alloy or titanium alloy. However, the requirements in this field are to significantly reduce the weight of the camera, improve its stiffness and enhance its environmental adaptability. The technology of using carbon-fiber-reinforced plastics (CFRP) has been developed and successfully applied in various remote sensing camera structures, because it has excellent specific stiffness, specific strength and low CTE. We choose CFRP to construct a support structure with near zero thermal expansion, so as to realize the low thermal expansion support structure design of the remote sensing camera. The basic design theory of the single- and multi-layer thermal expansion of various composite components is introduced in [

24].

For the single-layer composite, the stress–strain relationship caused by temperature is as follows:

where {

σ} is temperature-induced stress, [

Q] is the stiffness matrix describing the relation-ship between stress and strain, {

ε} is the strain of the composite, {

α} is the coefficient of thermal expansion and Δ

t is the temperature change.

According to the classical theory of composite laminates, the stress–strain relation-ship can be expressed as:

where [

A], [

B] and [

D] are the tension compression stiffness matrix, coupling stiffness matrix and bending stiffness matrix, respectively and {

Nt} and {

Mt} are the internal stress matrix and internal bending moment matrix caused by temperature load, respectively.

In engineering applications, laminated composites are usually designed with sym-metrical folding to avoid torsion due to temperature changes [

25]. For multi-layer compo-site structures with symmetrical layers, the coupling stiffness matrix is zero, and the ma-terial thermal deformation can be expressed as:

For multilayer symmetrical laminates, the coefficient of thermal expansion along the center layer can be expressed as:

Carbon-fiber-reinforced plastics (CFRP) not only have a very low linear thermal ex-pansion coefficient, but also have a negative axial linear thermal expansion coefficient. Therefore, composites with a thermal expansion coefficient of zero can be obtained by utilizing these characteristics.

2.3. Design of Zero-Expansion Laminated Plates

The support structure consists of frames and a bearing cylinder, and its basic struc-ture is a CFRP laminated plane. Therefore, the thermal stability of the support structure is closely related to the CTE of the CFRP laminates. The CFRP laminates are made of car-bon fiber and adhesive resin in a certain proportion. The CTE of CFRP laminates is deter-mined by the properties and proportions of the carbon fiber and adhesive resin [

13]. Cy-anate esters are widely used in CFRP design due to their low coefficient of thermal expan-sion [

26]. In this paper, M40/cyanate ester unidirectional prepreg is used as the basic ma-terial of the support structure, and the basic properties of the material are shown in

Table 1.

Considering the formability of the material and the design principle of composite laminates, three layering methods are chosen for this kind of material in order to achieve zero expansion:

±θ/0°/90°;

±θ/0°/∓θ;

±θ/90°/∓θ.

The definition of the fold angle for the laminated plate is shown in

Figure 3.

For the three different types of laying angles presented above, the relationship be-tween the thermal expansion coefficient and the laying angle can be calculated. When us-ing ±θ/0°/90° in the laying scheme, the relationship between the thermal expansion coef-ficient and the folding angle of multi-layer composites was calculated. The calculation results are shown in

Figure 4a. Similarly, the thermal expansion coefficients of the com-posite laminates at the other two folding angles were calculated, and are shown in

Figure 4b,c.

It can be easily observed in

Figure 4 and

Table 2 that the theoretical CTE in the 0° direction is 0.383 × 10

−6/°C when the laying angle is ±20°/0°/90°. When the laying angle is ±50°/0°/∓50°, the theoretical CTE in the 0° direction is 0.168 × 10

−6/°C. Both of the two plies can meet the requirements of low thermal expansion coefficients.

In the practical application of the off-axis remote sensor considered in this paper, the elastic modulus is also an important parameter, which must be carefully considered in the practical application of composite materials. The elastic moduli corresponding to the above two plies are shown in

Table 3. Considering the elastic modulus requirements, we chose ±20°/0°/90° as the best practical winding angle for the CFRP plane structure. In this case, the maximum stiffness of the laminate can be obtained while meeting the CTE re-quirements.

3. Design of Support Structure with Low Expansion Coefficient

CFRP is widely used in the design of space camera structure because of its good per-formance, such as its light weight, high rigidity and low thermal expansion [

13,

18,

22]. Based on the above calculations and discussion, a support structure made of M40 carbon fiber composite for the remote sensing camera was designed and developed. The support-ing structure consists of front frame, rear frame and central bearing cylinder, as shown in

Figure 5.

The camera support structure needs to have high stiffness, strength and low weight to ensure that the remote sensing camera has good mechanical properties. By optimizing the mechanical properties of the whole structure of the camera, the optimal size of the supporting structure of each part can be obtained. After optimization, the thickness of front and rear frames is 4 mm and the thickness of center bearing cylinder is 1.5 mm.

For this kind of structure, the common design method is to use isotropic ply to ensure the consistency of the structure in all directions. However, the thermal stability of the sup-port structure of the remote sensor is not considered in the isotropic stacking mode, and the thermal deformation in the direction of structural asymmetry will especially affect the imaging quality. According to the existing optical element layout and form of the support structure, the remote sensor structure has good symmetry in the X direction, so we need to strictly control the thermal expansion deformation of the structure in the Y and Z asym-metric directions.

3.1. Design of The Support Frames

The front and rear frames in the support structure are directly in contact with the reflector assembly. According to the layout of the optical elements and the supporting structure, the thermal expansion of the frame structure has a decisive effect on the thermal displacement of the mirror assembly in the Y direction. Therefore, we need to design the ply angle to minimize the thermal expansion coefficient of the front and rear frames in the Y direction.

In

Section 2.3, we have already obtained the zero-expansion paving scheme. Based on the calculation in

Table 2, we selected ±20°/0°/90° laying method, winding the front and rear frames, where 0° is in the same direction as that of +Y, as shown in

Figure 6.

3.2. Design of Bearing Cylinder

As the structure connecting the front and rear frames, the composite bearing cylinder has a great influence on the distance change of the optical elements in the Z direction. Therefore, it is necessary to minimize the thermal expansion coefficient of the bearing cyl-inder in the Z direction through the design of the ply angle.

We chose the ±20°/0°/90° laying method in the winding of the bearing cylinder, where the 0° direction is the same as that of +Z, as shown in

Figure 7. The designed bearing cylinder can reduce the change in the distance between the secondary mirror and other mirrors when the temperature changes.

So far, we have completed the thermal stability design of the off-axis camera support structure through the selection of composite layers. The obtained support structure has very low CTE in the Y and Z directions.

4. Finite Element Analysis of the Support Structure

We obtained the low-CTE design of the off-axis remote sensing camera structure in the asymmetric direction by adjusting the CFRP ply angle. In order to verify the thermal stability of the designed support structure, we take the whole space remote sensing cam-era as the analysis object to calculate the thermal deformation of the support structure.

4.1. The Establishment of Finite Element Model

We established the finite element model of the camera as shown in

Figure 8. In order to reduce the joint stress between different materials caused by thermal load, the optical components of the camera in this model were composed of Zerodure mirrors and Invar backplanes.

4.2. Thermal Deformation Analysis

The temperature conditions of the camera during on-rail operation are 20 °C ± 5 °C, so we analyzed the thermal deformation of the camera when the temperature increased by 5 °C. In addition, we also analyzed a support structure composed of M40 material with isotropic ply as a contrast.

Figure 9 shows the thermal deformation clouds of the isotropic laminated support structure and the asymmetric zero-expansion support structure, re-spectively. The influence of temperature load on the rigid body displacement of the mir-rors is shown in

Table 4.

Considering the particularity of the off-axis TMA space camera structure, when the structure is thermally deformed, the thermal deformation can be offset due to the sym-metry of the structure in the X direction, so the displacement of the optical elements in the X direction is small in the macro view; however, in the Y and Z directions with significant asymmetry, the thermal displacement of the optical elements is obvious [

18,

27].

It can be seen from the thermal deformation clouds that the thermal deformation of the camera support structure is obvious when the support structure is designed with iso-tropic layers. The maximum thermal deformation occurs in the front frame. However, the thermal deformation of the whole structure tends to be uniform when the support struc-ture is designed with an asymmetric zero-expansion layer.

Based on the actual displacement of the reflectors under the two support structures, the reflector displacement caused by the thermal load is not obvious due to the good struc-tural symmetry in the X direction. However, in the Y and Z directions, where the struc-tural asymmetry is obvious, the displacement of the mirror in the zero-expansion design is obviously smaller than that of the isotropic laminate, which proves that the zero-expan-sion design in the asymmetric direction in the off-axis remote sensing camera has an ob-vious effect on reducing the rigid body displacement of the thermal deformation of the camera reflectors.

In order to further determine the effect of the zero-expansion support structure in improving the thermal stability of the camera, we input the displacement data of the mir-rors in

Table 3 into Zmax to analyze the influence of the thermal deformation of the struc-ture on the optical transfer function. The results of this analysis are shown in

Figure 10.

The analysis shows that when isotropic layers are used in the support structure, the MTF of the optical system decreases from 0.422 to 0.378 at a rise of 5 °C, and the decrease percentage is 10.43%. When the zero-expansion layers are used in the support structure, the MTF of the optical system decreases from 0.422 to 0.411 at a rise of 5 °C, and the de-crease percentage is 2.61%. The influence of the thermal deformation on the MTF of the optical transmission is greatly reduced. These results prove that the application of the zero-expansion design in the support structure of the off-axis remote sensing camera can improve the imaging performance stability under the conditions of periodic temperature changes. It has a significant effect on the thermal stability design of the support structure of a space off-axis remote sensing camera.

5. Conclusions

In this paper, a thermal stability design method based on CFRP is proposed for the asymmetric support structure of an off-axis TMA space camera. A complete example of thermal stability design is presented in the detailed design of the CFRP support structure for the camera.

The relationship between CTE and the ply angle of multi-layer composites is demonstrated through the theoretical analysis of the composites. By adjusting the laying angle of the carbon fiber composite, the expansion of the camera support structure can be re-duced almost to zero in the asymmetric direction. Finite element thermal analysis and optical analysis show that the proposed support structure with low CTE greatly reduces the displacement of the optical elements under temperature load conditions compared with a support structure with isotropic layers, and the influence of a temperature rise of 5 °C on the MTF of the optical system decreases from 10.41% to 2.67%.

This proves that it is necessary to fully consider the thermal stability design method in relation to structural asymmetry, a method which has great potential in the thermal stability design of off-axis space cameras and will attract more attention with the improve-ment of the precision of off-axis space cameras.

Author Contributions

Conceptualization, W.S. and P.X.; methodology, W.S. and P.X.; software, W.S., S.L. and Y.X.; validation, W.S. and P.X.; writing—original draft preparation, W.S.; writing—review and editing, W.S. and P.X.; supervision, W.S.; project administration, P.X.; funding acquisition, P.X. All authors have read and agreed to the published version of the manuscript.

Funding

This paper was supported by the National Key Research and Development Program of China (Grant No. 2016YFB0501200).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, Y.F.; Tong, Y.L.; Sun, T.F.; Yu, L. Thermal design to meet stringent temperature gradient/stability requirements of space camera’s tube. In Signal and Information Processing, Networking and Computers; Sun, S., Fu, M., Xu, L., Eds.; Lecture Notes in Electrical Engineering; Springer Singapore Pte Ltd.: Singapore, 2019; pp. 164–172. [Google Scholar]

- Wang, X.; Guo, C.; Liu, Y.; Chen, J.; Wang, Y.; Hu, Y. Design and manufacture of 1.3 m large caliber light-weighted space optical components. In International Conference on Space Optics—Icso, Chania, Greece, 9–12 October 2018; Sodnick, Z., Karafolas, N., Cugny, B., Eds.; SPIE: Bellingham, WA, USA, 2018; Volume 11180. [Google Scholar]

- Yang, H.B.; Shen, F.; Zhang, Z.T.; Chen, L.H.; Wu, Q.W. Thermal design and verification of the large-temperature-difference space optical system. In Proceedings of the 2017 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 6–9 August 2017; IEEE: New York, NY, USA, 2017; pp. 740–745. [Google Scholar]

- Lin, S.M.; Wang, H.; Liu, Y.; Xue, Y.K.; Xiang, B.B.; Liu, J.; Xie, Y.J.; Liu, M.Y.; Wu, L.Q. Athermalization for the supporting structure of space camera primary and secondary mirrors. In Proceedings of the Third International Conference on Photonics and Optical Engineering, Xi’an, China, 5–8 December 2018; Tian, A., Ed.; SPIE: Bellingham, WA, USA, 2019; Volume 11052. [Google Scholar]

- Da Deppo, V.; Focardi, M.; Morgante, G.; Middleton, K.; Pace, E.; Claudi, R.; Micela, G.; Team, A. The optical configuration of the telescope for the ARIEL ESA mission. In Space Telescopes and Instrumentation 2018: Optical, Infrared, and Millimeter Wave; Lystrup, M., MacEwen, H.A., Fazio, G.G., Eds.; SPIE: Bellingham, WA, USA, 2018; Volume 10698. [Google Scholar]

- Yoon, J.-S.; Park, G.; Han, J.-H. Effects of dimensional stability for space telescope composite structures. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- He, C.W.; Huang, P.; He, Y.W.; Dong, X.C.; Fan, B. Simplified unobscured optics design for a diffractive telescope. Appl. Opt. 2020, 59, 1660–1666. [Google Scholar] [CrossRef] [PubMed]

- Ji, H.; Zhu, Z.; Tan, H.; Shan, Y.; Tan, W.; Ma, D. Design of a high-throughput telescope based on scanning an off-axis three-mirror anastigmat system. Appl. Opt. 2021, 60, 2817–2823. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Luo, J.; Wang, J.; Zhang, X.; Liu, Y. Improvement of a computer-aided alignment algorithm for the nonsymmetric off-axis reflective telescope. Appl. Opt. 2021, 60, 2127–2140. [Google Scholar] [CrossRef] [PubMed]

- Pradeep, T.; Soni, S.K.; Thomas, B. Design manufacture and testing of a composite support structure for spacecraft application. Mater. Today Proc. 2020, 22, 1374–1379. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, L.; Gong, X.X. Design and optimization of the CFRP mirror components. Photonic Sens. 2017, 7, 270–277. [Google Scholar] [CrossRef] [Green Version]

- Wei, L.; Zhang, L.; Gong, X.; Ma, D.-M. Design and optimization for main support structure of a large-area off-axis three-mirror space camera. Appl. Opt. 2017, 56, 1094–1100. [Google Scholar] [CrossRef] [PubMed]

- Pati, S.; Manomaisantiphap, S.; Goto, T.; Takahashi, T.; Yokozeki, T. Development of CFRP with Polyaniline-based Resin using curable dopants employing storage stable prepregs. Appl. Compos. Mater. 2021, 28, 381–394. [Google Scholar] [CrossRef]

- Kuo, J.-C.; Hung, H.-C.; Yang, M.-Y.; Chen, C.-R.; Lin, J. Composite materials application on FORMOSAT-5 remote sensing instrument structure. Terr. Atmos. Ocean. Sci. 2017, 28, 157–165. [Google Scholar] [CrossRef] [Green Version]

- Qian, Y.; Hao, X.; Shi, Y.; Cai, D.a.; Wu, N.; Lou, Z.; Zuo, Y. Deformation behavior of high accuracy carbon fiber-reinforced plastics sandwiched panels at low temperature. J. Astron. Telesc. Instrum. Syst. 2019, 5. [Google Scholar] [CrossRef]

- Suematsu, Y.; Hara, H.; Katsukawa, Y.; Kano, R.; Shimizu, T.; Ichimoto, K. Design of all-reflective space-borne 1-m aperture solar optical telescope. In Proceedings of the International Conference on Space Optics—Icso, Chania, Greece, 9–12 October 2018; Sodnick, Z., Karafolas, N., Cugny, B., Eds.; SPIE: Bellingham, WA, USA, 2018; Volume 11180. [Google Scholar]

- Pathak, A.K.; Garg, H.; Subhedar, K.M.; Dhakate, S.R. Significance of carbon fiber orientation on thermomechanical properties of carbon fiber reinforced epoxy composite. Fibers Polym. 2020, 11. [Google Scholar] [CrossRef]

- Tanaka, S.; Ikeda, T.; Senba, A. Sensitivity analysis of thermal deformation of CFRP laminate reflector due to fiber orientation error. J. Mech. Sci. Technol. 2016, 30, 4423–4426. [Google Scholar] [CrossRef]

- Du, Z.; Zhu, M.; Wang, Z.; Yang, J. Design and application of composite platform with extreme low thermal deformation for satellite. Compos. Struct. 2016, 152, 693–703. [Google Scholar] [CrossRef]

- Yang, L.; Wei, L.; Zhang, L. Thermal compensation design of truss structure for large-scale off-axis three-mirror space telescope. Opt. Eng. 2019, 58. [Google Scholar] [CrossRef]

- Li, F.; Cai, W.; Zhang, F.; Li, N.; Fan, J. Optomechanical stability design of space optical mapping camera. In Proceedings of the 2017 International Conference on Optical Instruments and Technology: Optical Systems and Modern Optoelectronic Instruments, Beijing, China, 28–30 October 2017; Wang, Y., Jia, B., Tatsuno, K., Eds.; SPIE: Bellingham, WA, USA, 2017; Volume 10616. [Google Scholar]

- Ford, V.; Parks, R.; Coleman, M. Passive thermal compensation of the optical bench of the galaxy evolution explorer. In Space Systems Engineering and Optical Alignment Mechanisms; Peterson, L.D., Guyer, R.C., Eds.; SPIE: Bellingham, WA, USA, 2004; Volume 5528, pp. 171–180. [Google Scholar]

- Li, Z.; Chen, B.; Song, K.; Wang, X.; Liu, S.; Yang, L.; Hu, Q.; Qiao, K.; Zhang, L.; Wu, G.; et al. Opto-mechanisms design of extreme-ultraviolet camera onboard Chang E lunar lander. Opt. Express 2014, 22, 15932–15940. [Google Scholar] [CrossRef] [PubMed]

- Zeng, C.; Yu, X.; Guo, P. Active deformation and engineering analysis of CFRP mirror of various lay-up sequences within quasi-isotropic laminates. In Proceedings of the 7th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Advanced Optical Manufacturing Technologies, Harbin, China, 26–29 April 2014; Yang, L., Ruch, E., Li, S., Eds.; SPIE: Bellingham, WA, USA, 2014; Volume 9281. [Google Scholar]

- Zenkour, A.M. Hygrothermal effects on the bending of angle-ply composite plates using a sinusoidal theory. Compos. Struct. 2012, 94, 3685–3696. [Google Scholar] [CrossRef]

- la Pierre des Ammbrois, S.D.; Corazzari, I.; Damiano, O.; Cornillon, L.; Terenzi, A.; Casalegno, V.; Ferraris, M. Adhesive joining of Zerodur-CFRP-Zerodur sandwich structures for aerospace applications. Macromol. Mat. Eng. 2020, 305. [Google Scholar] [CrossRef]

- Fan, Y.; Wu, X.F. Three mirrors aberrations optical transform function with the thermal elastic deformation. In Electrical Information and Mechatronics and Applications, Pts 1 and 2; Wang, X.D., Xu, B.Y., Zhong, S.B., Eds.; Applied Mechanics and Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012; Volume 143–144, pp. 181–184. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).