A Binocular Vision-Based 3D Sampling Moiré Method for Complex Shape Measurement

Abstract

:1. Introduction

2. Principles

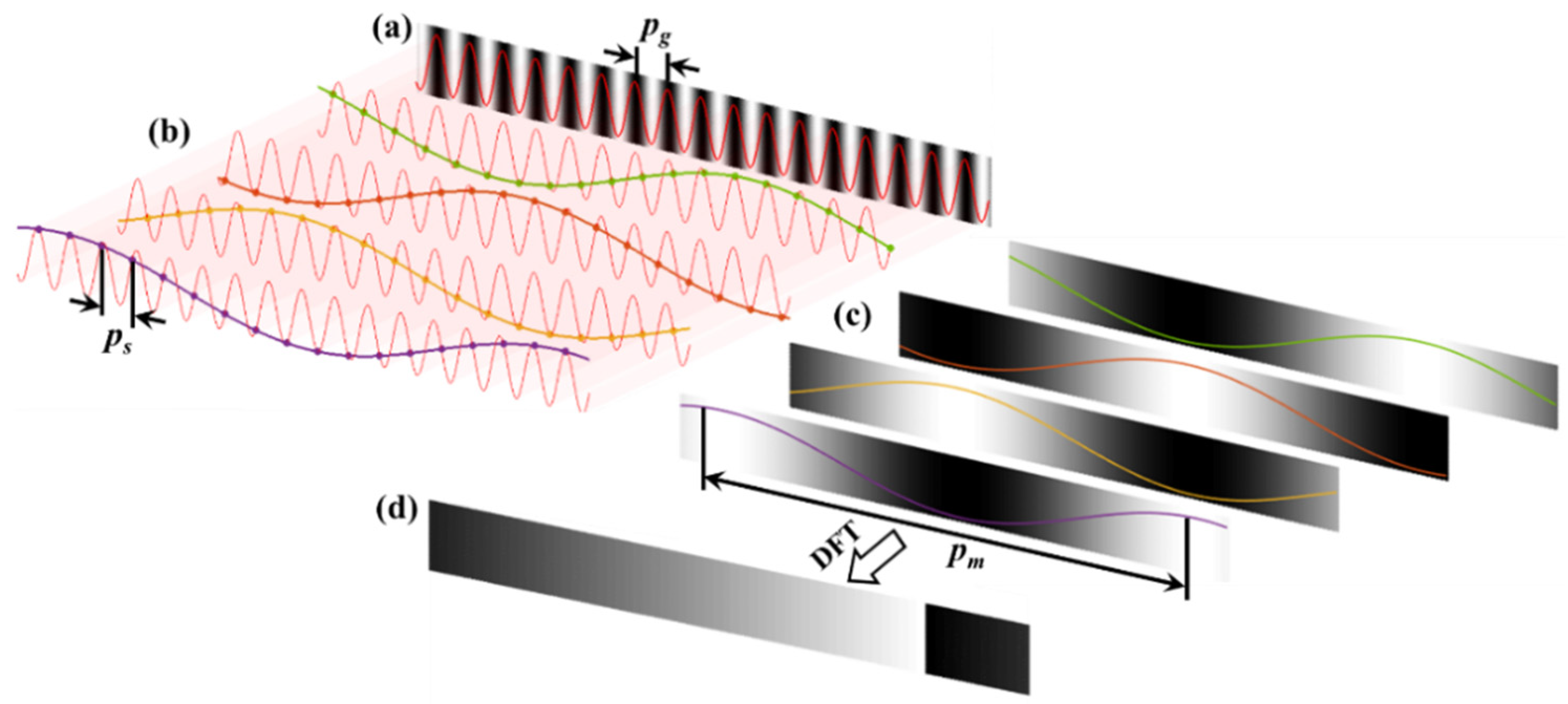

2.1. Principles of the Sample Moiré Method

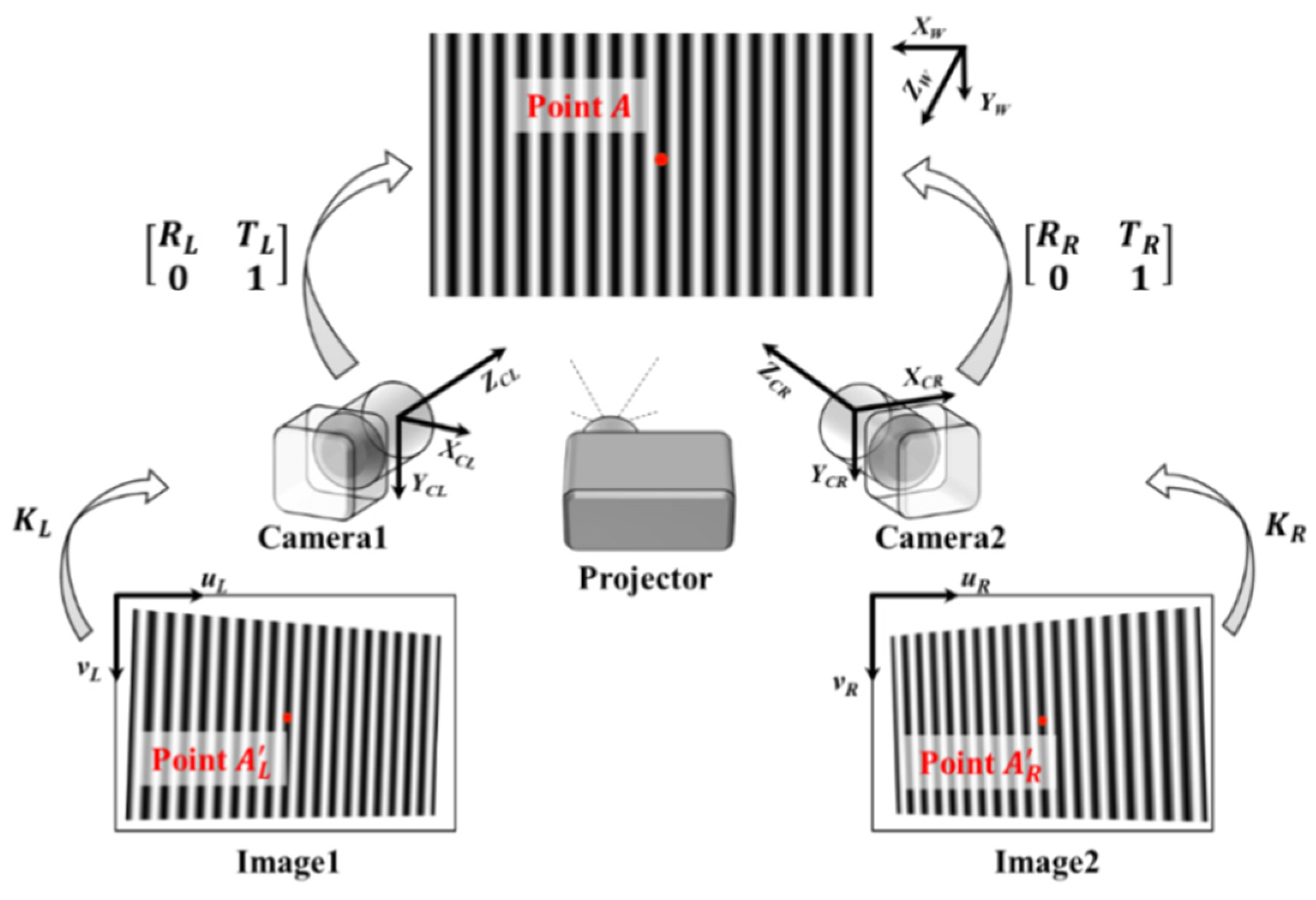

2.2. Three-Dimensional Shape Measurement Method with Binocular Vision

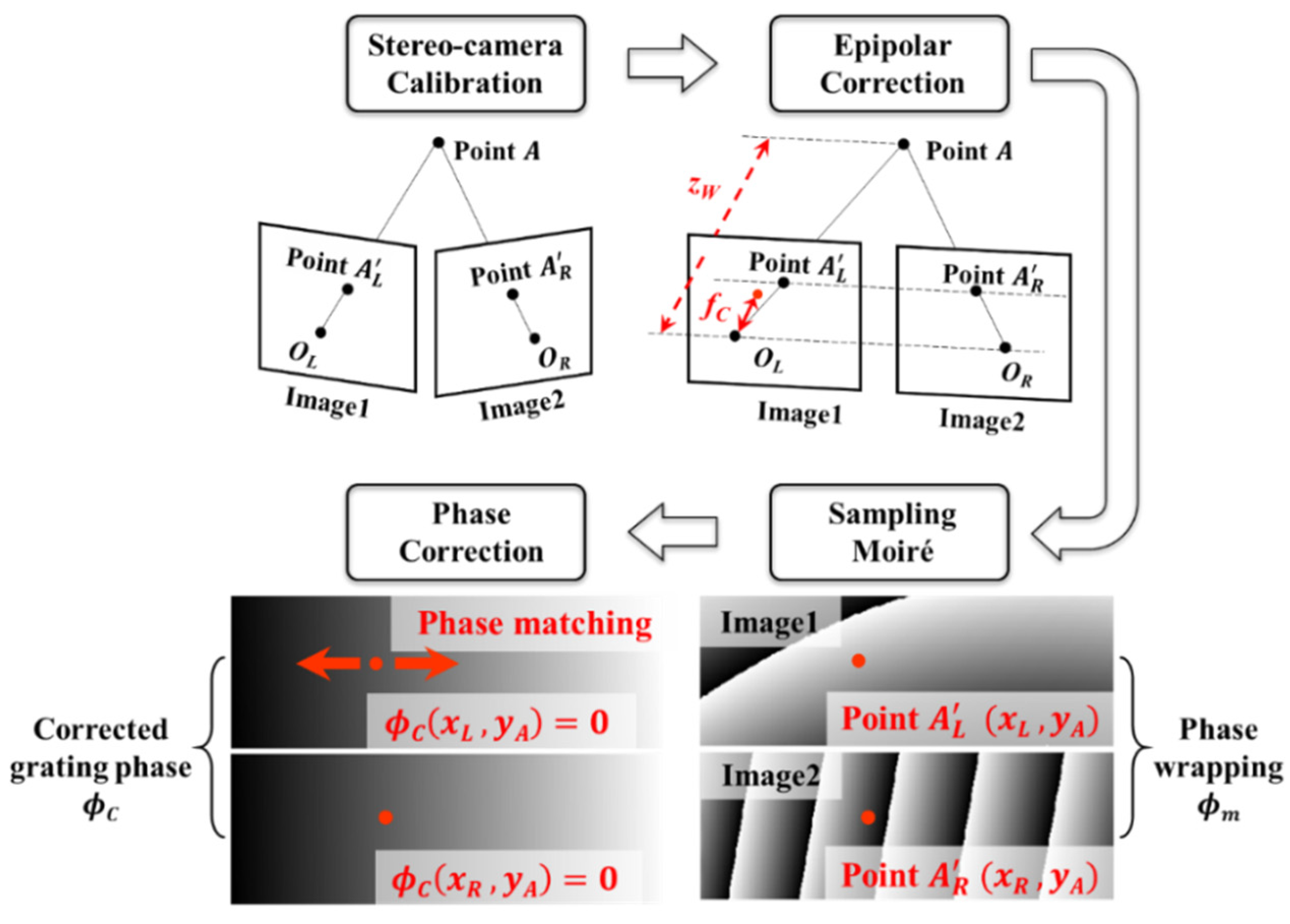

2.3. Phase Correction

3. Digital Simulation Experiment and Discussions

3.1. Precision of 3D Shape Measurement

3.2. Anti-Noise Ability

3.3. Effect of Sampling Pitch

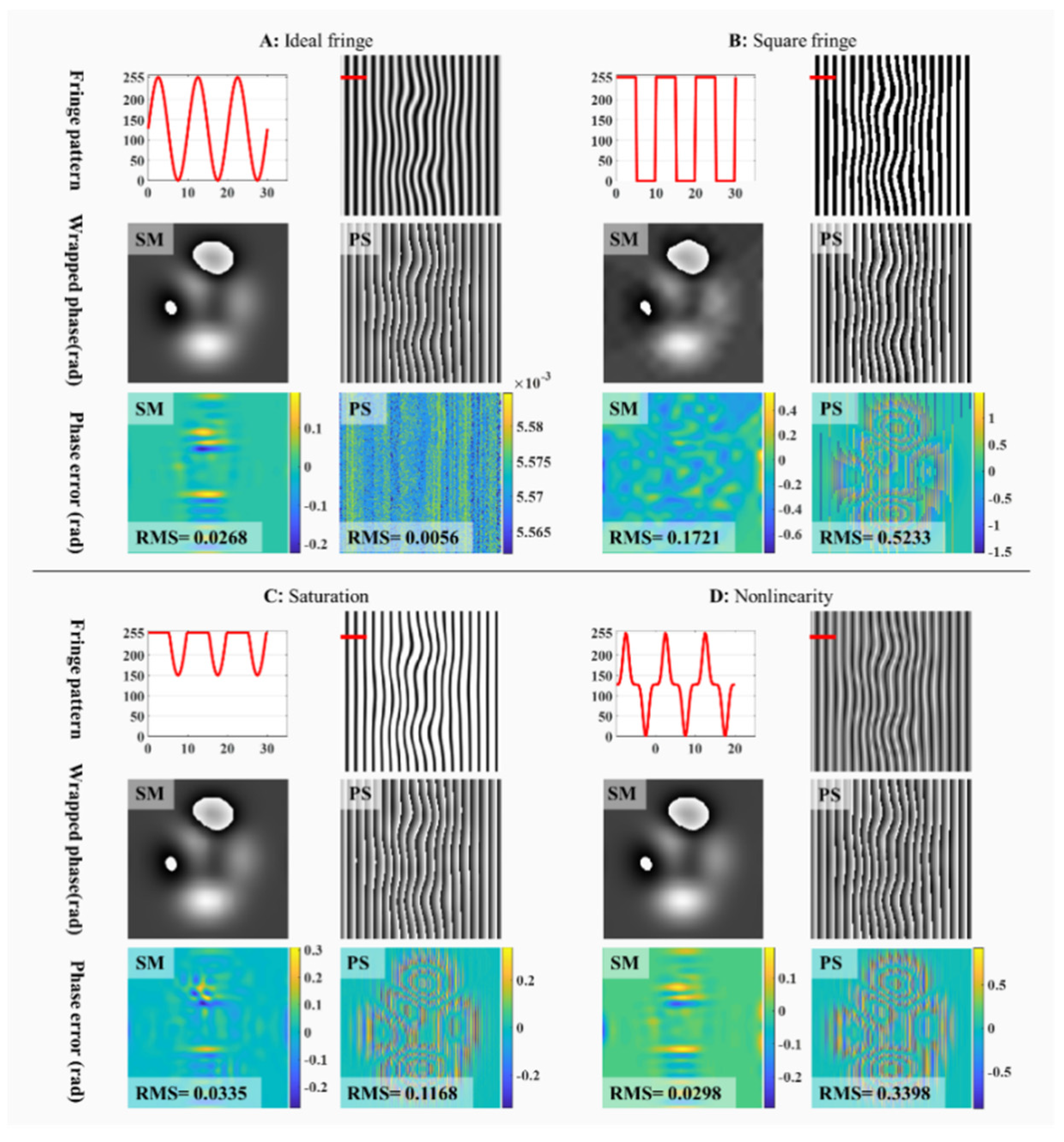

3.4. Effect of the Fringe Pattern

4. Experimental Verification and Application

4.1. Experimental Verification

4.2. Experimental Application

5. Conclusions

- (1)

- Based on the binocular vision model, the y direction parallax in the left and right images can be eliminated through epipolar rectification. On that basis, a phase correction method for sampling moiré was developed to solve the phase match problem of sampling moiré at different visual angles, and accurate measurement of 3D shapes by sampling moiré was achieved.

- (2)

- Through numerical simulation, 3D sampling moiré and 3D-DIC were compared in terms of measurement accuracy and anti-noise capability, and the influence of sampling pitch and fringe patterns on the measurement accuracy was analyzed. The results showed that the 3D sampling moiré method has the same level of measurement accuracy as 3D-DIC, but its anti-noise capability is much better than that of DIC. In the experiment, a sampling pitch close to the fringe pitch was selected, effectively reducing the measurement error. Compared with the traditional phase shifting method, sampling moiré is insensitive to the distortion of fringe patterns, so it is more effective for deformation measurement in a complex environment.

- (3)

- A three-point bending loading configuration was used for experimental verification of the measurement accuracy of 3D sampling moiré. The measurement results of 3D sampling moiré were compared with the linear displacement of the high-precision stepping motor, indicating that the average measurement error of the out-of-plane displacement was 31 μm. Three-dimensional sampling moiré has the same level of measurement accuracy as the phase shifting method, but has higher measurement efficiency because only one image is necessary for phase analysis.

- (4)

- The cantilever configuration was designed and DED carried out to print a cladding layer on the beam surface. The deflection deformation caused by the residual stress with different printing parameters was experimentally characterized based on the 3D sampling moiré method. The effective experimental results showed that this method is applicable to the deflection measurement, which has the potential for the analysis of residual deformation and stress arising in additive manufacturing processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- van der Jeught, S.; Dirckx, J.J.J. Real-time structured light profilometry: A review. Opt. Lasers Eng. 2016, 87, 18–31. [Google Scholar] [CrossRef]

- Feng, S.; Zhang, L.; Zuo, C.; Tao, T.; Chen, Q.; Gu, G. High dynamic range 3D measurements with fringe projection profilometry: A review. Meas. Sci. Technol. 2018, 29, 122001. [Google Scholar] [CrossRef]

- Mohammadi, F.; Kofman, J. Multi-Wavelength Digital-Phase-Shifting Moiré Based on Moiré Wavelength. Appl. Sci. 2019, 9, 1917. [Google Scholar] [CrossRef] [Green Version]

- Zuo, C.; Feng, S.; Huang, L.; Tao, T.; Yin, W.; Chen, Q. Phase shifting algorithms for fringe projection profilometry: A review. Opt. Lasers Eng. 2018, 109, 23–59. [Google Scholar] [CrossRef]

- González, A.L.; Meneses, J.E. Fourier Spectral Analysis to Reduce the Gamma Effect in Fringe Projection Profilometry. In Digital Holography and Three-Dimensional Imaging; Optical Society of America: Washington, DC, USA, 2019; p. Th3A.31. [Google Scholar]

- Morimoto, Y.; Fujigaki, M. Accuracy of sampling moiré method. In Proceedings of the ICEM 2008: International Conference on Experimental Mechanics, Nanjing, China, 8–11 November 2008; Volume 7375, p. 737526. [Google Scholar]

- Ri, S.; Agarwal, N.; Wang, Q.; Kemao, Q. Comparative study of sampling moiré and windowed Fourier transform techniques for demodulation of a single-fringe pattern. Appl. Opt. 2018, 57, 10402–10411. [Google Scholar] [CrossRef] [PubMed]

- Ri, S.; Saka, M.; Nanbara, K.; Kobayashi, D. Dynamic Thermal Deformation Measurement of Large-Scale, High-Temperature Piping in Thermal Power Plants Utilizing the Sampling Moiré Method and Grating Magnets. Exp. Mech. 2013, 53, 1635–1646. [Google Scholar] [CrossRef]

- Ri, S.; Muramatsu, T.; Saka, M.; Nanbara, K.; Kobayashi, D. Accuracy of the Sampling Moiré Method and its Application to Deflection Measurements of Large-Scale Structures. Exp. Mech. 2011, 52, 331–340. [Google Scholar] [CrossRef]

- Hara, T.; Nakabo, M.; Fujigaki, M. Dynamic deformation measurement of real bridge using sampling moire camera. In IEEE Conference Anthology; IEEE: New York, NY, USA, 2013; pp. 1–6. [Google Scholar]

- Ri, S.; Wang, Q.; Tsuda, H.; Shirasaki, H.; Kuribayashi, K. Optical Phase-Based Method for Dynamic Deflection Measurement of Railroad Bridge. In Mechanical Engineering and Materials; Springer: Cham, Switzerland, 2019; pp. 21–25. [Google Scholar]

- Wang, Q.; Ri, S.; Enomoto, T. Residual Thermal Strain Distribution Measurement of Underfills in Flip Chip Electronic Packages by an Inverse Approach Based on the Sampling Moiré Method. Exp. Mech. 2020, 60, 611–626. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Ri, S.; Tsuda, H.; Takashita, Y.; Kitamura, R.; Ogihara, S. Interlaminar Shear Behavior of Laminated Carbon Fiber Reinforced Plastic from Microscale Strain Distributions Measured by Sampling Moiré Technique. Materials 2018, 11, 1684. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.H.; Ri, S.; Tsuda, H.; Kodera, M.; Suguro, K.; Miyashita, N. Visualization and automatic detection of defect distribution in GaN atomic structure from sampling Moiré phase. Nanotechnol 2017, 28, 455704. [Google Scholar] [CrossRef] [Green Version]

- Xia, P.; Wang, Q.; Ri, S.; Tsuda, H. Calibrated Phase-Shifting Digital Holographic Microscope Using a Sampling Moiré Technique. Appl. Sci. 2018, 8, 706. [Google Scholar] [CrossRef] [Green Version]

- Morimoto, Y.; Masaya, A.; Ueki, M. High-speed 3D shape measurement by one pitch phase analysis method using brightness values in small square area of single-shot image. Opt. Lasers Eng. 2019, 113, 38–46. [Google Scholar] [CrossRef]

- Ri, S.; Wang, Q.; Xia, P.; Tsuda, H. Spatiotemporal phase-shifting method for accurate phase analysis of fringe pattern. J. Opt. 2019, 21, 095702. [Google Scholar] [CrossRef]

- Lei, Z.K.; Wang, Z.L. Vibration Testing Parameters Measured by Sampling Moiré Method. Appl. Mech. Mater. 2012, 226–228, 1975–1980. [Google Scholar] [CrossRef]

- Cheng, X.; Liu, X.; Li, Z.; Zhong, K.; Han, L.; He, W.; Gan, W.; Xi, G.; Wang, C.; Shi, Y. High-Accuracy Globally Consistent Surface Reconstruction Using Fringe Projection Profilometry. Sensors 2019, 19, 668. [Google Scholar] [CrossRef] [Green Version]

- Marinello, F.; Bariani, P.; Pasquini, A.; De Chiffre, L.; Bossard, M.; Picotto, G.B. Increase of maximum detectable slope with optical profilers, through controlled tilting and image processing. Meas. Sci. Technol. 2007, 18, 384–389. [Google Scholar] [CrossRef]

- Tomita, D.; Murata, Y.; Fujigaki, M. 3D Displacement Distribution Measurement Using Sampling Moire Method with Multiple Cameras. In Emerging Challenges for Experimental Mechanics in Energy and Environmental Applications, Proceedings of the 5th International Symposium on Experimental Mechanics and 9th Symposium on Optics in Industry (ISEM-SOI); Conference Proceedings of the Society for Experimental Mechanics Series; Martínez-García, A., Furlong, C., Barrientos, B., Pryputniewicz, R., Eds.; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Shimo, K.; Fujigaki, M.; Masaya, A.; Morimoto, Y. Dynamic shape and strain measurements of rotating tire using a sampling moiré method. Opt. Eng. 2011, 50. [Google Scholar] [CrossRef]

- Zhang, Z. A Flexible New Technique for Camera Calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Xie, H. Determination of the moiré spacing in sampling moiré method based on the generation mechanism of sampling moiré. In Proceedings of the Sixth International Conference on Optical and Photonic Engineering (icOPEN 2018), Shanghai, China, 24 July 2018; Volume 10827, p. 082724. [Google Scholar]

- Sonka, M.; Hlavac, V.; Boyle, R. Image Processing, Analysis, and Machine Vision; Cengage Learning: Boston, MA, USA, 2014. [Google Scholar]

- Hu, Z.; Xie, H.; Lu, J.; Wang, H.; Zhu, J. Error evaluation technique for three-dimensional digital image correlation. Appl. Opt. 2011, 50, 6239–6247. [Google Scholar] [CrossRef] [PubMed]

- Fusiello, A.; Trucco, E.; Verri, A. A compact algorithm for rectification of stereo pairs. Mach. Vis. Appl. 2000, 12, 16–22. [Google Scholar] [CrossRef]

- Pan, B.; Wu, D.; Yu, L. Optimization of a three-dimensional digital image correlation system for deformation measurements in extreme environments. Appl. Opt. 2012, 51, 4409–4419. [Google Scholar] [CrossRef] [PubMed]

- Sutton, M.; Yan, J.; Tiwari, V.; Schreier, H.; Orteu, J. The effect of out-of-plane motion on 2D and 3D digital image correlation measurements. Opt. Lasers Eng. 2008, 46, 746–757. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S. Absolute phase retrieval methods for digital fringe projection profilometry: A review. Opt. Lasers Eng. 2018, 107, 28–37. [Google Scholar] [CrossRef]

- Fujigaki, M.; Tomita, D.; Murata, Y. Surface Orientation Measurement Using Sampling Moire Method; Advancement of Optical Methods in Experimental Mechanics, Volume 3; Springer: New York, NY, USA, 2017; pp. 49–54. [Google Scholar]

- He, W.; Zhong, K.; Li, Z.; Meng, X.; Cheng, X.; Liu, X.; Shi, Y. Accurate calibration method for blade 3D shape metrology system integrated by fringe projection profilometry and conoscopic holography. Opt. Lasers Eng. 2018, 110, 253–261. [Google Scholar] [CrossRef]

- Zhong, K.; Li, Z.; Li, R.; Shi, Y.; Wang, C. Pre-calibration-free 3D shape measurement method based on fringe projection. Opt. Express 2016, 24, 14196–14207. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, T.; Zuback, J.; Zhang, W.; DebRoy, T. Residual stresses and distortion in additively manufactured compositionally graded and dissimilar joints. Comput. Mater. Sci. 2018, 143, 325–337. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Heigel, J.C.; Michaleris, P.; Palmer, T. Effect of inter-layer dwell time on distortion and residual stress in additive manufacturing of titanium and nickel alloys. J. Mater. Process. Technol. 2015, 215, 123–131. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Zhang, Q.; Xie, H.; He, W. A Binocular Vision-Based 3D Sampling Moiré Method for Complex Shape Measurement. Appl. Sci. 2021, 11, 5175. https://doi.org/10.3390/app11115175

Shi W, Zhang Q, Xie H, He W. A Binocular Vision-Based 3D Sampling Moiré Method for Complex Shape Measurement. Applied Sciences. 2021; 11(11):5175. https://doi.org/10.3390/app11115175

Chicago/Turabian StyleShi, Wenxiong, Qi Zhang, Huimin Xie, and Wei He. 2021. "A Binocular Vision-Based 3D Sampling Moiré Method for Complex Shape Measurement" Applied Sciences 11, no. 11: 5175. https://doi.org/10.3390/app11115175

APA StyleShi, W., Zhang, Q., Xie, H., & He, W. (2021). A Binocular Vision-Based 3D Sampling Moiré Method for Complex Shape Measurement. Applied Sciences, 11(11), 5175. https://doi.org/10.3390/app11115175