Study on the Performance of Optical Lenses under High Fluxes of Solar Radiation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tested Lenses

2.2. Irradiation Tests

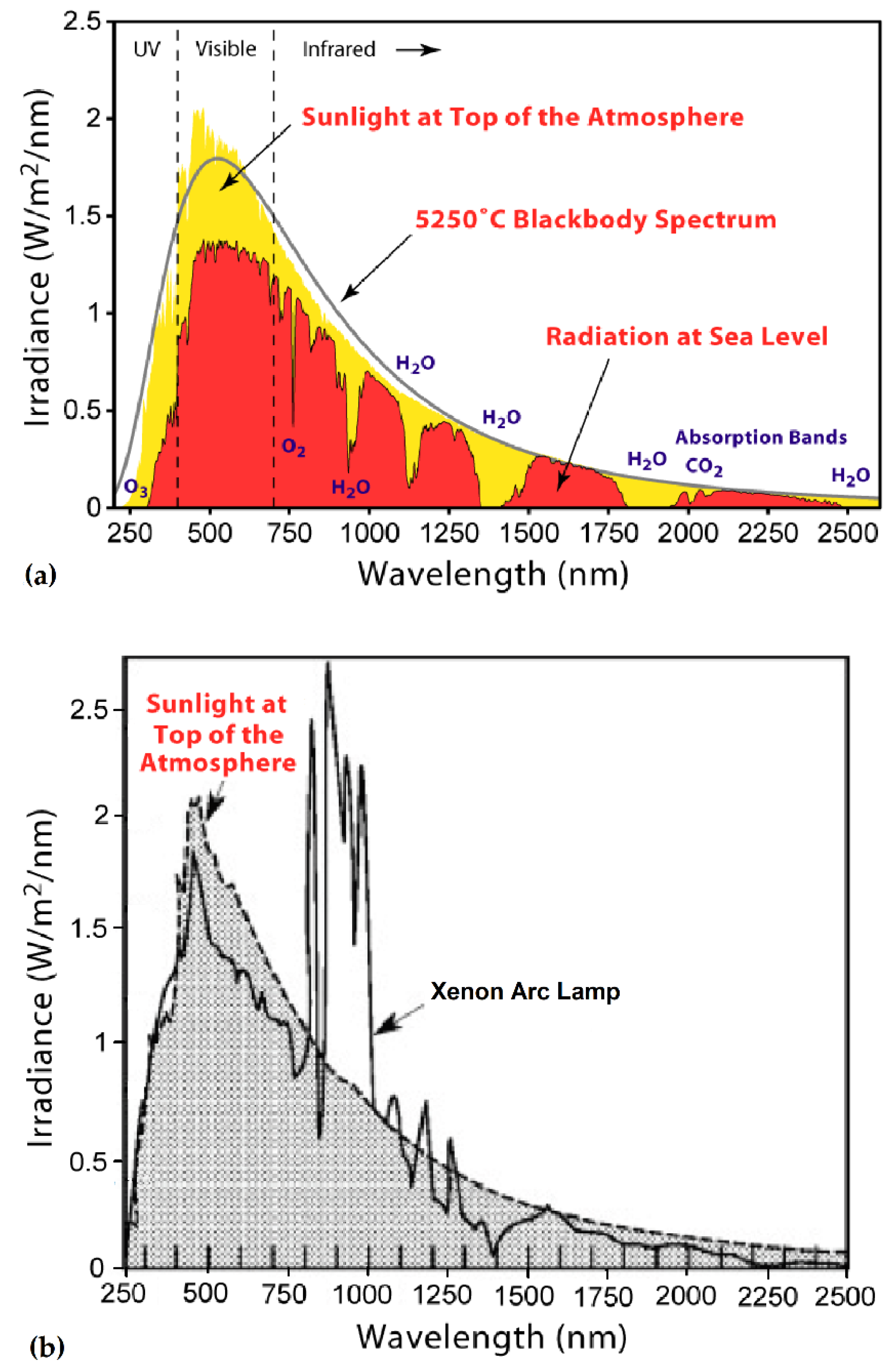

2.2.1. Irradiation with a Solar Simulator Using Xenon Arc Lamp

2.2.2. Irradiation with Concentrated Natural Sunlight

2.3. Vibrational Spectral Analyses of Lenses

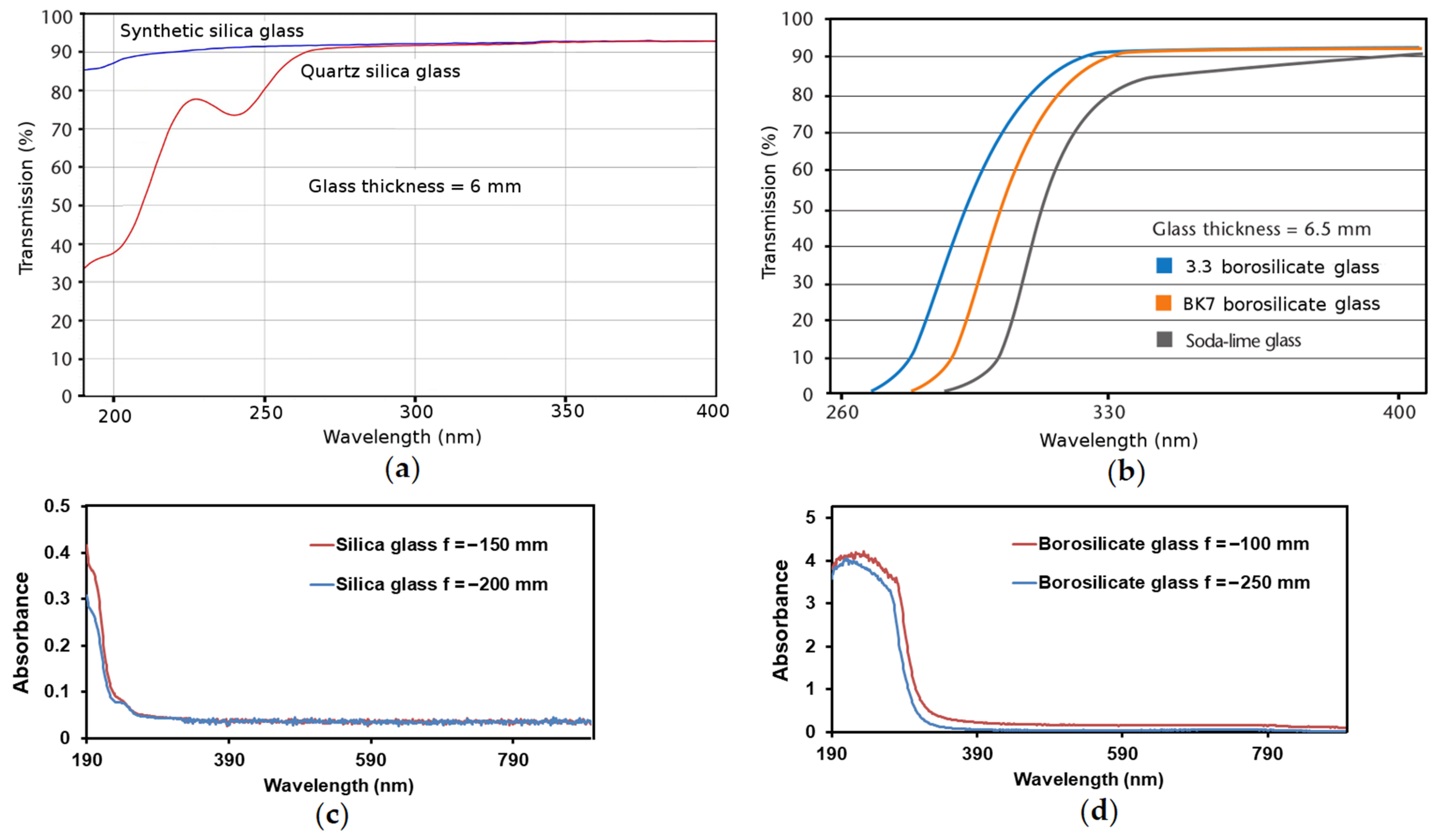

2.3.1. Ultraviolet (UV)–Visible Spectral Analysis

2.3.2. Raman Spectral Analysis

3. Results and Discussion

3.1. Results from Tests with Xenon Arc Lamp

3.2. Results from Tests with Concentrated Natural Sunlight

3.3. Results from Vibrational Spectral Analyses of Lenses

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Himalaya, M.A.G. Improved Apparatus for Making Industrial Use of the Heat of the Sun and Obtaining High Temperatures. Patent GB190116181, 26 October 1901. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=19011026&DB=EPODOC&locale=en_EP&CC=GB&NR=190116181A&KC=A&ND=2 (accessed on 16 April 2021).

- Himalaya, M.A.G. Solar Apparatus for Producing High Temperatures. U.S. Patent 797,891, 22 August 1905. Available online: https://patents.google.com/patent/US797891 (accessed on 16 April 2021).

- Levêque, G.; Bader, R.; Lipinski, W.; Haussener, S. High-flux optical systems for solar thermochemistry. Sol. Energy 2017, 156, 133–148. [Google Scholar] [CrossRef] [Green Version]

- Fernández-González, D.; Ruiz-Bustinza, I.; González-Gasca, C.; Piñuela-Noval, J.; Mochón-Csataños, J.; Sancho-Gorostiaga, J.; Verdeja, L.F. Concentrated solar energy applications in materials science and metallurgy. Sol. Energy 2018, 170, 520–540. [Google Scholar] [CrossRef]

- Bushra, N.; Hartmann, T. A review of state-of-the-art reflective two-stage solar concentrators: Technology categorization and research trends. Renew. Sustain. Energ. Rev. 2019, 114, 109307. [Google Scholar] [CrossRef]

- Rosa, L.G. Solar Heat for Materials Processing: A Review on Recent Achievements and a Prospect on Future Trends. ChemEngineering 2019, 3, 83. [Google Scholar] [CrossRef] [Green Version]

- Sonawane, P.D.; Raja, V.K.B. Concentrated solar energy in materials processing. Int. J. Ambient Energy 2020, 41, 1201–1207. [Google Scholar] [CrossRef]

- Kumar, K.R.; Chaitanya, N.V.V.K.; Natarajan, S.K. Solar thermal energy technologies and its applications for process heating and power generation—A review. J. Clean. Prod. 2021, 282, 125296. [Google Scholar] [CrossRef]

- Almeida, J. Advances in Solar-Pumped Laser Efficiency and Brightness. Ph.D. Thesis, Faculty of Sciences and Technology, NOVA University of Lisbon, Caparica, Portugal, September 2017. Available online: https://run.unl.pt/bitstream/10362/28836/3/Almeida_2017.pdf (accessed on 1 June 2021).

- Costa, H.; Almeida, J.; Liang, D.W.; Garcia, D.; Catela, M.; Tiburcio, B.D.; Vistas, C.R. Design of a multibeam solar laser station for a megawatt solar furnace. Opt. Eng. 2020, 59, 086103. [Google Scholar] [CrossRef]

- Abanades, S.; Tescari, S.; Rodat, S.; Flamant, G. Natural gas pyrolysis in double-walled reactor tubes using thermal plasma or concentrated solar radiation as external heating source. J. Nat. Gas Chem. 2009, 18, 1–8. [Google Scholar] [CrossRef]

- Ugwuishiwu, B.O.; Owoh, I.P.; Udom, I.J. Solar energy application in waste treatment—A review. Niger. J. Technol. 2016, 35, 432–440. [Google Scholar] [CrossRef] [Green Version]

- Padilla, I.; Romero, M.; Robla, J.I.; López-Delgado, A. Waste and Solar Energy: An Eco-Friendly Way for Glass Melting. ChemEngineering 2021, 5, 16. [Google Scholar] [CrossRef]

- Gonzalez, A.; Gonzalez-Aguilar, J.; Romero, M. Preliminary analysis of a 100-kWth mini-tower solar field with an integrated optical waveguide receiver for solar chemistry. In Proceedings of the ASME 2010 4th International Conference on Energy Sustainability, Phoenix, AZ, USA, 17–22 May 2010; Volume 2, pp. 543–552. [Google Scholar] [CrossRef]

- De Almeida, G. Proposta: Estrutura de Suporte do Concentrador e Dispositivos de Fixação e Regulação dos Seus Elementos Ópticos; do Autor: Lisboa, Portugal, 2019. [Google Scholar]

- Luque, S.; Santiago, S.; Gómez-García, F.; Romero, M.; González-Aguilar, J. A new calorimetric facility to investigate radiative-convective heat exchangers for concentrated solar power applications. Int. J. Energy Res. 2018, 42, 966–976. [Google Scholar] [CrossRef]

- Fundamentals of Xenon Arc Lamps. Xenon Arc Lamp Construction. Available online: http://zeiss-campus.magnet.fsu.edu/articles/lightsources/xenonarc.html (accessed on 5 May 2021).

- Romero, M.; González-Aguilar, J.; Luque, S. Ultra-modular 500m2 heliostat field for high flux/high temperature solar-driven processes. AIP Conf. Proc. 2017, 1850, 030044. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Hernández, A.; Gonzalo, I.B.; Romero, M.; González-Aguilar, J. Drift analysis in tilt-roll heliostats. Sol. Energy 2020, 211, 1170–1183. [Google Scholar] [CrossRef]

- Paschotta, R. Thermal Lensing. Available online: https://www.rp-photonics.com/thermal_lensing.html (accessed on 28 May 2021).

- Spectrum of Solar Radiation (Earth). Available online: https://en.wikipedia.org/wiki/Solar_irradiance#/media/File:Solar_spectrum_en.svg (accessed on 5 May 2021).

- Finlayson-Pitts, B.J.; Pitts, J.N., Jr. Applications of Atmospheric Chemistry. In Chemistry of the Upper and Lower Atmosphere; Academic Press: Cambridge, MA, USA, 2000; pp. 871–942. [Google Scholar] [CrossRef]

- Crystran—Silica Glass, SiO2. Available online: https://www.crystran.co.uk/userfiles/images/silica-glass-uv-transmission.jpg (accessed on 7 May 2021).

- BOROFLOAT® 33—Optical Properties Datasheet. Available online: https://www.schott.com/en-us/products/borofloat/downloads (accessed on 7 May 2021).

- Scholze, H. Glass: Nature, Structure, and Properties, 1st ed.; Springer: New York, NY, USA, 1991. [Google Scholar] [CrossRef]

- Fernández Navarro, J.M. El Vidrio; Tercera Edición; Consejo Superior de Investigaciones Científicas: Madrid, Spain, 2003; Available online: https://editorial.csic.es/publicaciones/libros/10909/978-84-00-08158-4/el-vidrio-constitucion-fabricacion-propiedades.html (accessed on 1 June 2021).

- Tuschel, D. Selecting an Excitation Wavelength for Raman Spectroscopy. In Molecular Spectroscopy Workbench: The 2016 Collection; Spectroscopy E-Books 2016; Volume e4, Issue 2; Available online: https://cdn.sanity.io/files/0vv8moc6/spectroscopy/6d3eda3f1fa42c509c63a2c0f1ea1f265df62902.pdf (accessed on 1 June 2021).

- Manghnani, M.H.; Hushur, A.; Sekine, T.; Wu, J.; Stebbins, J.F.; Williams, Q. Raman, Brillouin, and nuclear magnetic resonance spectroscopic studies on shocked borosilicate glass. J. Appl. Phys. 2011, 109, 113509. [Google Scholar] [CrossRef] [Green Version]

- McMillan, P.F.; Wolf, G.H.; Poe, B.T. Vibrational spectroscopy of silicate liquids and glasses. Chem. Geol. 1992, 96, 351–366. [Google Scholar] [CrossRef]

- Smith, C.F. The vibrational analysis of boron in vitreous silica. In Borate Glasses: Structure, Properties, Applications; Pye, L.D., Fréchette, V.D., Kreidl, N.J., Eds.; Springer US: New York, NY, USA; Philadelphia, PA, USA, 1978; pp. 307–319. Available online: https://www.springer.com/gp/book/9781468433593#aboutBook (accessed on 1 June 2021).

- Konijnendijk, W.L.; Stevels, J.M. Raman scattering measurements of silicate glasses and compounds. J. Non-Cryst. Solids 1976, 21, 447–453. [Google Scholar] [CrossRef]

- Manara, D.; Grandjean, A.; Neuville, D.R. Advances in understanding the structure of borosilicate glasses: A Raman spectroscopy study. Am. Miner. 2009, 94, 777–784. [Google Scholar] [CrossRef]

- Gautam, C.R.; Yadav, A.K. Synthesis and optical investigations on (Ba,Sr)TiO3 borosilicate glasses doped with La2O3. Opt. Photonics J. 2013, 3, 1–7. [Google Scholar] [CrossRef]

| Designation | Material | Diameter (mm) | Thickness | Focal Length (mm) | |

|---|---|---|---|---|---|

| Board (mm) | Center (mm) | ||||

| DB100 | Borosilicate glass | 50.8 | 9.0 | 2.0 | −100 1 |

| DB150 | Borosilicate glass | 50.8 | 7.7 | 3.5 | −150 2 |

| DB200 | Borosilicate glass | 50.8 | 6.7 | 3.5 | −200 2 |

| DB250 | Borosilicate glass | 50.8 | 5.0 | 2.0 | −250 1 |

| DS151 | Silica glass | 50.8 | 8.4 | 3.5 | −150 2 |

| DS201 | Silica glass | 50.8 | 7.1 | 3.5 | −200 2 |

| Designation | Material | Diameter (mm) | Thickness | Focal Length (mm) | BFL 2 (mm) | |

|---|---|---|---|---|---|---|

| Board (mm) | Center (mm) | |||||

| CB100 | Borosilicate glass | 76.2 | 2.5 | 19.3 | 100 1 | 87.2 1 |

| CS100 | Silica glass | 76.2 | 2.4 | 22.9 | 100 1 | 84.2 1 |

| Attenuator | Radiation-Flux in the Focal Zone (W cm−2) | Attenuation Factor |

|---|---|---|

| Without attenuator | 316 | 1 |

| Attenuator no. 1 | 249 | 0.788 |

| Attenuator no. 2 | 221 | 0.699 |

| Attenuator no. 3 | 193 | 0.611 |

| Attenuator no. 4 | 162 | 0.513 |

| Attenuator no. 5 | 130 | 0.411 |

| Lens Type | Type of Support and Mask | Irradiation Power (W) | Irradiation Time (min) | Maximum Temperature 1 (°C) | Comment |

|---|---|---|---|---|---|

| DB150 | M, 1 inch | 180 | ≈10 | ≈100 | Fractured after ≈10 min |

| DB200 | M, no mask | 311 | ≈3 | ≈84 | Fractured after ≈3 min |

| DS151 | A, 1 inch | 180 | 60 | ≈205 | No changes observed in the lens |

| DS151 | M, 1 inch | 180 | 60 | ≈127 | No changes observed in the lens |

| DS151 | A, 1 inch | 350 | 60 | ≈189 | No changes observed in the lens |

| DS151 | A, 1 inch | 852 | 60 | ≈342 | No changes observed in the lens |

| DS201 | M, 1 inch | 180 | 60 | ≈126 | No changes observed in the lens |

| DS201 | M, 1 inch | 350 | 60 | ≈191 | No changes observed in the lens |

| DS201 | M, 1 inch | 852 | 60 | ≈340 | No changes observed in the lens |

| CB100 | A, no mask | 311 | 60 | ≈182 | No changes observed in the lens |

| CB100 | A, no mask | 607 | ≈10 | ≈262 | Fractured after ≈10 min |

| CS100 | A, no mask | 311 | 60 | ≈148 | No changes observed in the lens |

| CS100 | A, no mask | 607 | 60 | ≈213 | No changes observed in the lens |

| Lens Type | Type of Support and Mask | Irradiation Power (W) | Irradiation Time (min) | Maximum Temperature 1 (°C) | Comment |

|---|---|---|---|---|---|

| DB100 | A, 1 inch | 200 | 60 | ≈507 | No changes observed in the lens |

| DB250 | A, 1 inch | 253 | 60 | ≈577 | No changes observed in the lens |

| DS151 | A, 1 inch | 202 | 60 | ≈537 | No changes observed in the lens |

| CB100 | A, 2 inch | 314 | 60 | ≈241 | No changes observed in the lens |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosa, L.G.; Pereira, J.C.G.; Rahmani, K.; Almeida, G.D.; Santos, L.F. Study on the Performance of Optical Lenses under High Fluxes of Solar Radiation. Appl. Sci. 2021, 11, 5174. https://doi.org/10.3390/app11115174

Rosa LG, Pereira JCG, Rahmani K, Almeida GD, Santos LF. Study on the Performance of Optical Lenses under High Fluxes of Solar Radiation. Applied Sciences. 2021; 11(11):5174. https://doi.org/10.3390/app11115174

Chicago/Turabian StyleRosa, Luís Guerra, José Carlos Garcia Pereira, Kaveh Rahmani, Guilherme De Almeida, and Luís F. Santos. 2021. "Study on the Performance of Optical Lenses under High Fluxes of Solar Radiation" Applied Sciences 11, no. 11: 5174. https://doi.org/10.3390/app11115174

APA StyleRosa, L. G., Pereira, J. C. G., Rahmani, K., Almeida, G. D., & Santos, L. F. (2021). Study on the Performance of Optical Lenses under High Fluxes of Solar Radiation. Applied Sciences, 11(11), 5174. https://doi.org/10.3390/app11115174