Banana Puree Lactic Fermentation: The Role of Ripeness, Heat Treatment, and Ascorbic Acid

Abstract

1. Introduction

2. Material and Methods

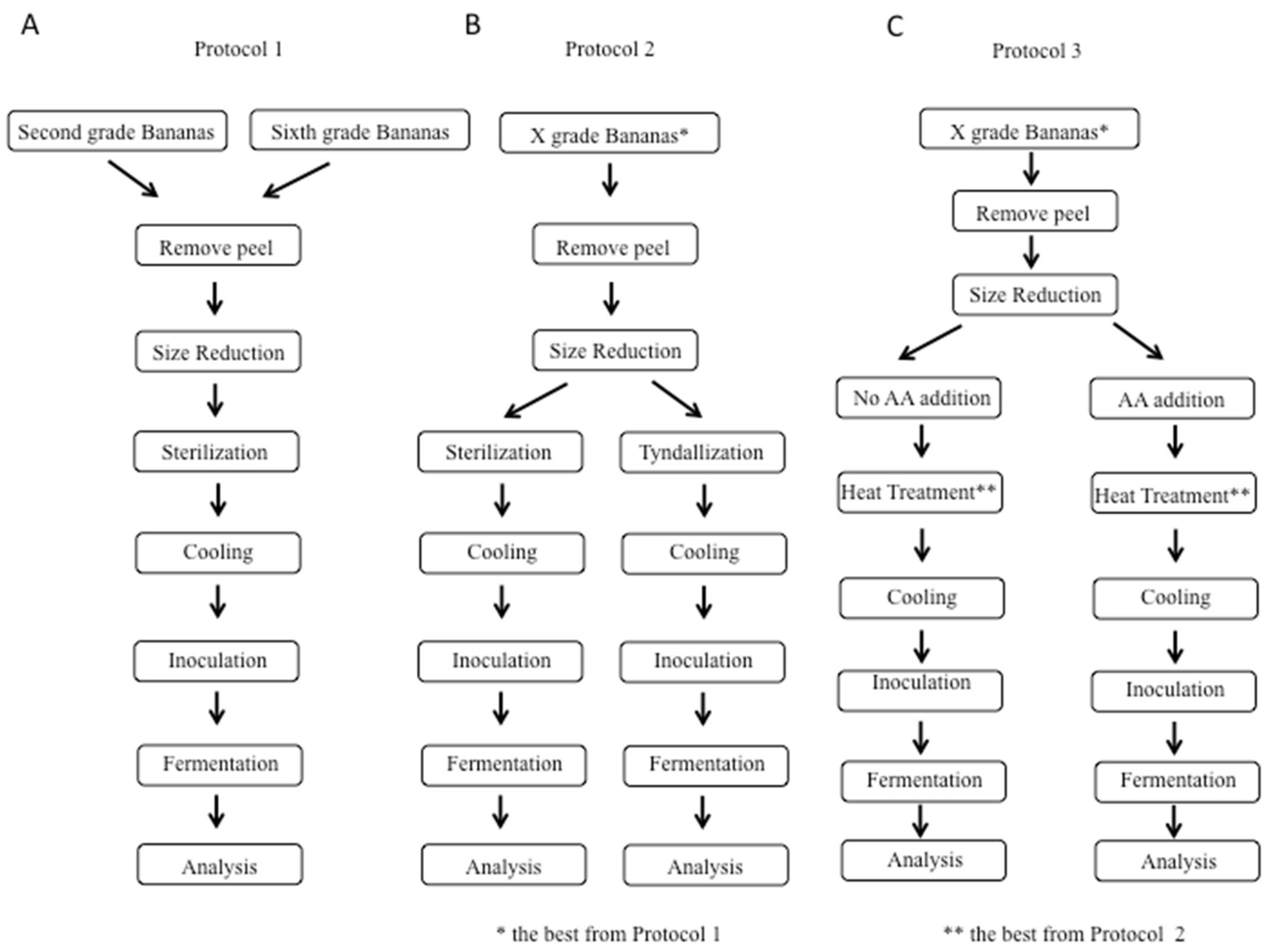

2.1. Banana Puree Pretreatment Protocols at Lab-Scale

2.1.1. Raw Material

2.1.2. Heat Treatment

2.1.3. Ascorbic Acid Addition

2.2. Lab-Scale Fermentation

2.2.1. Strain

2.2.2. Lab-Scale Fermentation Apparatus

2.2.3. Lab-Scale Fermentation Protocol

2.3. Analysis

2.4. Statistical Analysis

3. Results

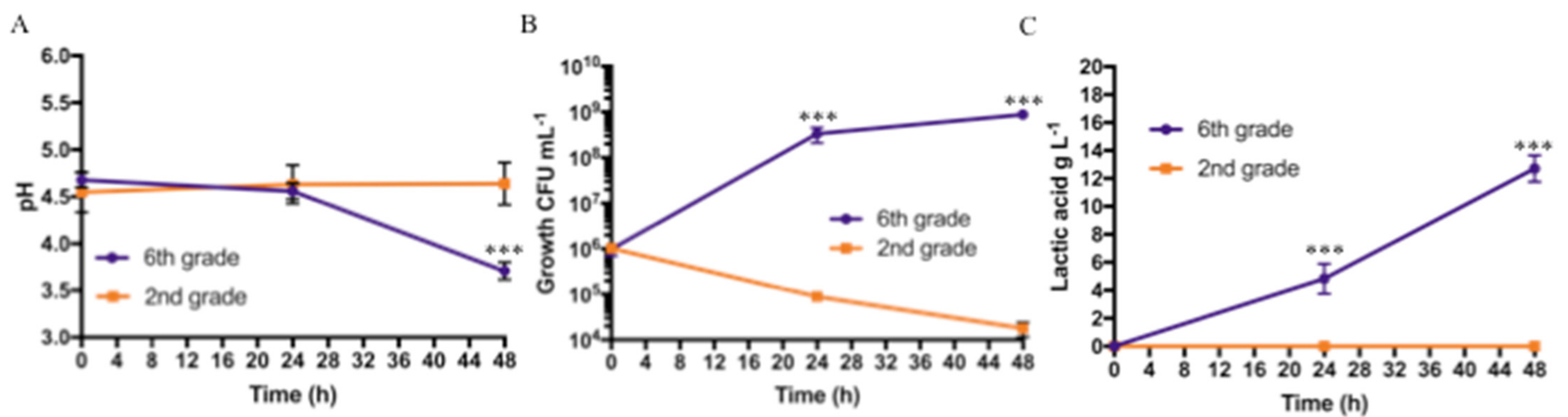

3.1. Protocol 1: Second-Grade Banana vs. Sixth-Grade Banana

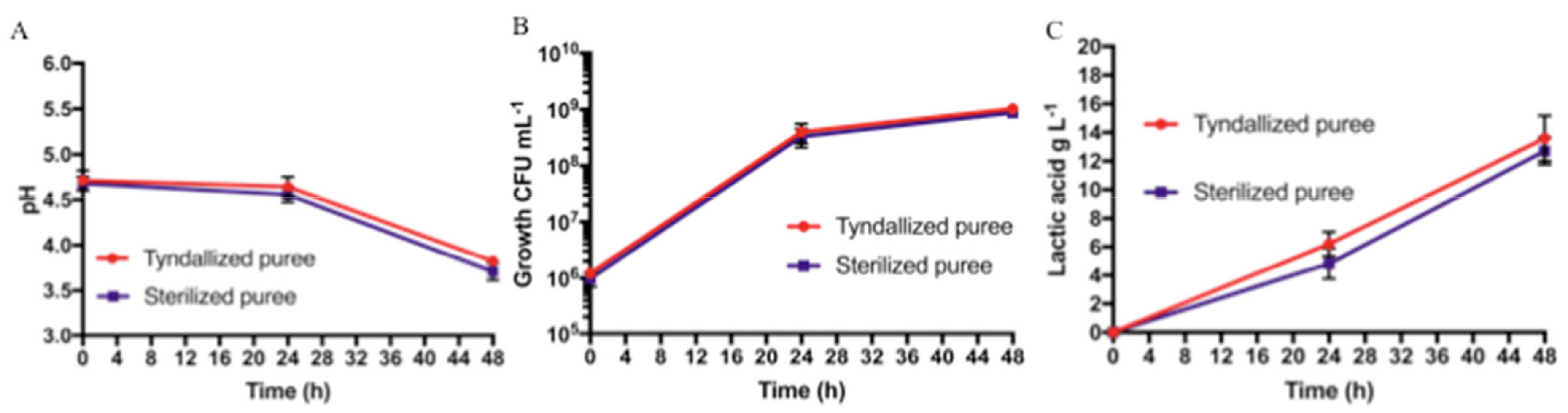

3.2. Protocol 2: Sterilization vs. Tyndallization

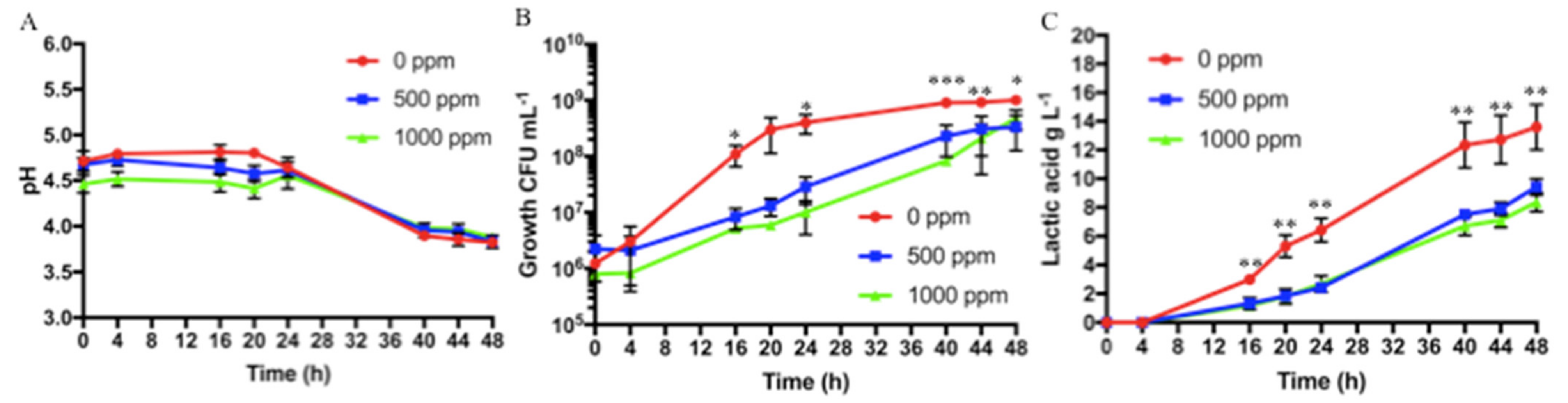

3.3. Protocol 3: Ascorbic Acid Addition

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FAO. The World Banana Economy 1985e2002. Retrieved 2011/2/20; FAO: Rome, Italy, 2003; Available online: http://www.fao.org/ (accessed on 6 January 2021).

- Pillay, M.; Tenkouano, A. Banana Breeding: Progress and Challenges; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Mohapatra, D.; Mishra, S.; Singh, C.B.; Jayas, D.S. Post-harvest Processing of Banana: Opportunities and Challenges. Food Bioprocess Technol. 2011, 4, 327–339. [Google Scholar] [CrossRef]

- Yap, M.; Fernando, W.; Brennan, C.S.; Jayasena, V.; Ranil Coorey, R. The effects of banana ripeness on quality indices for puree production. Food Sci. Technol. 2017, 80, 10–18. [Google Scholar] [CrossRef]

- Matamoros, J.J. Factibilidad Técnica de Fermentar Pulpa de Banana con L. casei y Posibilidades de Obtener un Producto Base. Master’s Thesis, Universidad de Costa Rica, San José, Costa Rica, 1981. [Google Scholar]

- De Porres, E. Minimización del tiempo requerido para reducir el pH del puré de banana mediante fermentación làctica. In Proceedings of the Segundo Congreso Latinoamericano y del Caribe de Tecnología de Alimentos, San José, Costa Rica; 1986. [Google Scholar]

- Chan-Blanco, Y.; Bonilla-Leiva, A.R.; Velμzquez, A.C. Using banana to generate lactic acid through batch process fermentation. Appl. Microbiol. Biotechnol. 2003, 63, 147–152. [Google Scholar] [CrossRef] [PubMed]

- Hidaka, H.; Eida, T.; Takizawa, T.; Tokanaga, T.; Tashiro, Y. Effects of fructooligosaccharides on intestinal flora and human health. Bifidobact. Microflora 1986, 5, 37–50. [Google Scholar] [CrossRef]

- Tomomatsu, H. Health effects of oligosaccharides. Food Technol. 1994, 48, 61–65. [Google Scholar]

- Gibson, G.R.; Roberfroid, M.B. Dietary modulation of the human colonic microbiota: Introducing the concept of prebiotics. J. Nutr. 1995, 125, 1401–1412. [Google Scholar] [CrossRef] [PubMed]

- Min, M.; Bunt, C.R.; Mason, S.L.; Hussain, M.A. Non-dairy probiotic food products: An emerging group of functional foods. Crit. Rev. Food Sci. Nutr. 2019, 59, 2626–2641. [Google Scholar] [CrossRef]

- Sims, C.A.; Bates, R.P.; Arreola, A.G. Color, polyphenoloxidase, and sensory changes in banana juice as affected by heat and ultrafiltration. J. Food Qual. 2007, 5, 371–379. [Google Scholar] [CrossRef]

- Petruzzi, L.; Campaniello, D.; Speranza, B.; Corbo, M.R.; Sinigaglia, M.; Bevilacqua, A. Thermal Treatments for Fruit and Vegetable Juices and Beverages: A Literature Overview. Compr. Rev. Food Sci. F. 2017, 16, 668–691. [Google Scholar] [CrossRef]

- Sapers, G.M.; Ziolkowski, M.A. Comparison of erythorbic and ascorbic acids as inhibitors of enzymatic browning in apple. J. Food Sci. 1987, 52, 1733–1747. [Google Scholar] [CrossRef]

- Guerrero, S.; Alzamora, S.M.; Gerschenson, L.N. Development of a Shelf-Stable Banana Puree by Combined Factors: Microbial Stability. J. Food Prot. 1994, 10, 902–907. [Google Scholar] [CrossRef]

- United Fruit Sales Corporation. Banana Ripening Manual; United Fruit Sales Corporation: Boston, MA, USA, 1964. [Google Scholar]

- Gallo, M.; Nigro, F.; Passannanti, F.; Salameh, D.; Schiattarella, P.; Budelli, A.; Nigro, R. Lactic fermentation of Cereal Flour: Feasibility Tests on Rice, Oat and Wheat. Appl. F. Biotechnol. 2019, 3. [Google Scholar] [CrossRef]

- Hill, C.; Guarner, F.; Reid, G.; Gibson, G.R.; Merenstein, D.J.; Pot, B.; Morelli, L.; Canani, R.B.; Flint, H.J.; Salminen, S.; et al. Expert consensus document. The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nat. Rev. Gastroenterol. Hepatol. 2014, 11, 506–514. [Google Scholar] [CrossRef]

- Salminen, S.; Collado, M.C.; Endo, A.; Hill, C.; Lebeer, S.; Quigley, E.M.M.; Sanders, M.E.; Shamir, R.; Swann, J.R.; Szajewska, H.; et al. The International Scientific Association of Probiotics and Prebiotics (ISAPP) consensus statement on the definition and scope of postbiotics. Nat. Rev. Gastroenterol. Hepatol. 2021, 1–19. [Google Scholar] [CrossRef]

- Shahnawaz, U.K. Probiotics in dairy foods: A review. Nutr. Food Sci. 2014, 1, 71–88. [Google Scholar] [CrossRef]

- Civardi, E.; Garofoli, F.; Longo, S.; Mongini, M.E.; Grenci, B.; Mazzucchelli, I.; Angelini, M.; Castellazzi, A.; Fasano, F.; Grinzato, A.; et al. Safety, growth, and support to healthy gut microbiota by an infant formula enriched with functional compounds. Clin. Nutr. 2017, 36, 238–245. [Google Scholar] [CrossRef]

- Mahmoudi, R.; Fakhri, O.; Farhoodi, A.; Kaboudari, A.; Pir-Mahalleh, S.F.R.; Tahapour, K.; Khayyati, M.; Chegin, R. A Review on Probiotic Dairy Products as Functional Foods Reported from Iran. Int. J. Food Nutr. Saf. 2015, 6, 1–12. [Google Scholar]

- Gallo, M.; Nigro, F.; Passannanti, F.; Salameh, D.; Budelli, A.; Marzocchella, A.; Nigro, R. Rice Fermentation by Lactobacillus paracasei CBAL74. Int. J. Rice Res. 2018, IJRR-103. [Google Scholar] [CrossRef]

- Gallo, M.; Passannanti, F.; Colucci Cante, R.; Nigro, F.; Salameh, D.; Schiattarella, P.; Schioppa, C.; Budelli, A.; Nigro, R. Effects of the Glucose Addition during Lactic Fermentation of Rice, Oat; Wheat Flours. Appl. Food Biotechnol. 2019, 1, 21–30. [Google Scholar] [CrossRef]

- Salameh, D.; Nigro, F.; Colucci Cante, R.; Passannanti, F.; Gallo, M.; Budelli, A.; Marzocchella, A.; Nigro, R. Fermentation of Rice Flour Supernatant Using Lactobacillus Paracasei Cba L74. Chem. Eng. Trans. 2019, 75, 289–294. [Google Scholar] [CrossRef]

- Colucci Cante, R.; Gallo, M.; Nigro, F.; Passannanti, F.; Salameh, D.; Budelli, A.; Nigro, R. Lactic Fermentation of cooked navy beans by Lactobacillus paracasei CBA L74 aimed at a potential production of functional legume-based foods. Can. J. Chem. Eng. 2020, 98. [Google Scholar] [CrossRef]

- Gallo, M.; Passannanti, F.; Cante, R.; Nigro, F.; Schiattarella, P.; Zappulla, S.; Budelli, A.; Nigro, R. Lactic fermentation of cereals aqueous mixture of oat and rice flours with and without glucose addition. Heliyon 2020, 6. [Google Scholar] [CrossRef]

- Gallo, M.; Passannanti, F.; Schioppa, C.; Montella, S.; Cante, R.; Nigro, F.; Budelli, A.; Nigro, R. Enzymatic pre-treatment and lactic fermentation of wheat flour suspension at high solid content. J. Food Process. Preserv. 2020, 45, e15299. [Google Scholar] [CrossRef]

- Cante, R.; Gallo, M.; Nigro, F.; Passannanti, F.; Budelli, A.; Nigro, R. Mathematical modeling of Lactobacillus paracasei CBA L74 growth during rice flour fermentation performed with and without pH control. Appl. Sci. 2021, 11, 2921. [Google Scholar] [CrossRef]

- Nocerino, R.; Paparo, L.; Terrin, G.; Pezzella, V.; Amoroso, A.; Cosenza, L.; Cecere, G.; De Marco, G.; Micillo, M.; Albano, F.; et al. Cow’s milk and rice fermented with Lactobacillus paracasei CBA L74 prevent infectious diseases in children: A randomized controlled trial. Clin. Nutr. 2017, 1, 118–125. [Google Scholar] [CrossRef]

- Sarno, M.; Lania, G.; Cuomo, M.; Nigro, F.; Passannanti, F.; Budelli, A.; Fasano, F.; Troncone, R.; Auricchio, S.; Barone, M.V.; et al. Lactobacillus paracasei CBA L74 interferes with gliadin peptides entrance in Caco-2 cells. Int. J. Food Sci. Nutr. 2014, 65. [Google Scholar] [CrossRef]

- Labruna, G.; Nanayakkara, M.; Pagliuca, C.; Nunziato, M.; Iaffaldano, L.; D’Argenio, V.; Colicchio, R.; Budelli, A.L.; Nigro, R.; Salvatore, P.; et al. Celiac disease-associated Neisseria flavescens decreases mitochondrial respiration in CaCo-2 epithelial cells: Impact of Lactobacillus paracasei CBA L74 on bacterial-induced cellular imbalance. Cell Microbiol. 2019, 21. [Google Scholar] [CrossRef] [PubMed]

- Gallo, M.; Nigro, F.; Passannanti, F.; Nanayakkara, M.; Lania, L.; Parisi, F.; Salameh, D.; Budelli, A.; Barone, M.V.; Nigro, R. Effect of pH control during rice fermentation in preventing a gliadin P31-43 entrance in epithelial cells. Int. J. Food Sci. Nutr. 2019, 70. [Google Scholar] [CrossRef] [PubMed]

- Aegerter, P.; Dunlap, C. Culture of Five Commonly Used Acid-Producing Bacteria on Banana Pulp. Appl. Environ. Microbiol. 1980, 5, 937–942. [Google Scholar] [CrossRef] [PubMed]

- De Porres, E.; de Arriola, M.C.; Garcia, R.; Rolz, C. Lactic acid fermentation of banana puree. Lebensm. Wiss. Technol. 1985, 18, 379–382. [Google Scholar]

- Emaga, T.; Andrianaivo, R.H.; Wathelet, B.; Tchango, J.; Paquot, M. Effects of the stage of maturation and varieties on the chemical composition of banana and plantain peels. Food Chem. 2007, 103, 590–600. [Google Scholar] [CrossRef]

- Prabha, T.N.; Bhagyalakshmi, N. Carbohydrate metabolism in ripening banana fruit. Phytochemistry 1998, 6, 915–919. [Google Scholar] [CrossRef]

- Duan, X.; Cheng, G.; Yang, E.; Yi, C.; Ruenroengklin, N.; Lu, W.; Luo, Y.; Jiang, Y. Modification of pectin polysaccharides during ripening of postharvest banana fruit. Food Chem. 2008, 1, 144–149. [Google Scholar] [CrossRef]

- Shalini, R.; Antony, U. Fructan distribution in banana cultivars and effect of ripening and processing on Nendran banana. J. Food Sci. Technol. 2015, 12, 8244–8251. [Google Scholar] [CrossRef][Green Version]

- Shalini, R.; Abinaya, G.; Saranya, P.; Antony, U. Growth of selected probiotic bacterial strains with fructans from Nendran banana and garlic. Food Sci. Technol. 2017, 83, 68–78. [Google Scholar] [CrossRef]

- Tajkarimi, M.; Ibrahim, S.A. Antimicrobial activity of ascorbic acid alone or in combination with lactic acid on Escherichia coli O157:H7 in laboratory medium and carrot juice. Food Control 2011, 6, 801–804. [Google Scholar] [CrossRef]

- International Dairy Federation. Standards for Fermented Milks; International Dairy Federation: Brussels, Belgium, 1997; D-Doc. 316. [Google Scholar]

- Tsen, J.H.; Lin, Y.P.; King, V. Banana puree fermentation by Lactobacillus acidophilus immobilized in Ca-alginate. J. Gen. Appl. Microbiol. 2003, 49, 357–361. [Google Scholar] [CrossRef][Green Version]

- Tsen, J.H.; Lin, Y.P.; King, V. Fermentation of banana media by using kappa-carrageenan immobilized Lactobacillus acidophilus. Int. J. Food Microbiol. 2004, 91, 215–220. [Google Scholar] [CrossRef]

| Addition of 500 ppm | Addition of 1000 ppm | |

|---|---|---|

| Before tyndallization | 516 | 1054 |

| After tyndallization | 293 | 534 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallo, M.; Passannanti, F.; Schiattarella, P.; Esposito, A.; Colucci Cante, R.; Nigro, F.; Budelli, A.; Nigro, R. Banana Puree Lactic Fermentation: The Role of Ripeness, Heat Treatment, and Ascorbic Acid. Appl. Sci. 2021, 11, 5153. https://doi.org/10.3390/app11115153

Gallo M, Passannanti F, Schiattarella P, Esposito A, Colucci Cante R, Nigro F, Budelli A, Nigro R. Banana Puree Lactic Fermentation: The Role of Ripeness, Heat Treatment, and Ascorbic Acid. Applied Sciences. 2021; 11(11):5153. https://doi.org/10.3390/app11115153

Chicago/Turabian StyleGallo, Marianna, Francesca Passannanti, Paola Schiattarella, Angela Esposito, Rosa Colucci Cante, Federica Nigro, Andrea Budelli, and Roberto Nigro. 2021. "Banana Puree Lactic Fermentation: The Role of Ripeness, Heat Treatment, and Ascorbic Acid" Applied Sciences 11, no. 11: 5153. https://doi.org/10.3390/app11115153

APA StyleGallo, M., Passannanti, F., Schiattarella, P., Esposito, A., Colucci Cante, R., Nigro, F., Budelli, A., & Nigro, R. (2021). Banana Puree Lactic Fermentation: The Role of Ripeness, Heat Treatment, and Ascorbic Acid. Applied Sciences, 11(11), 5153. https://doi.org/10.3390/app11115153